Shellfish slicer

A processing device and slicing technology, used in bivalve processing, food preservation, meat/fish preservation, etc., can solve problems such as heating and affecting the quality of dried scallops, improve drying efficiency, reduce stacking thickness, and ensure drying effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

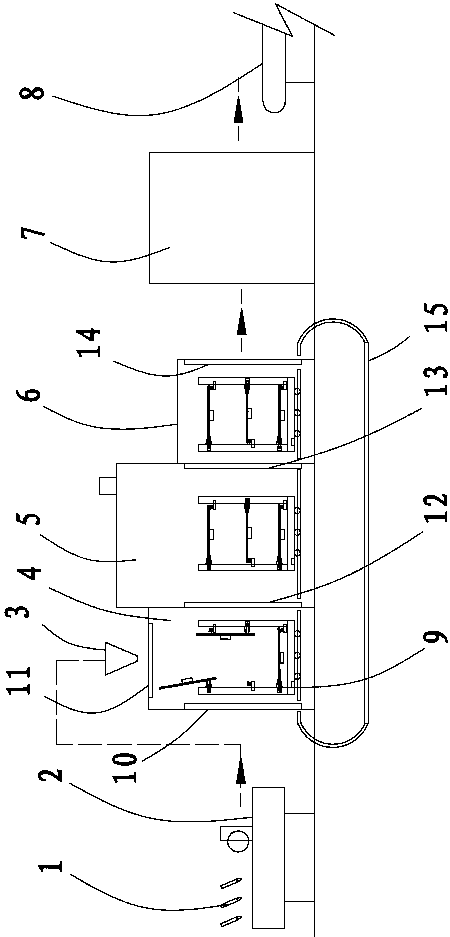

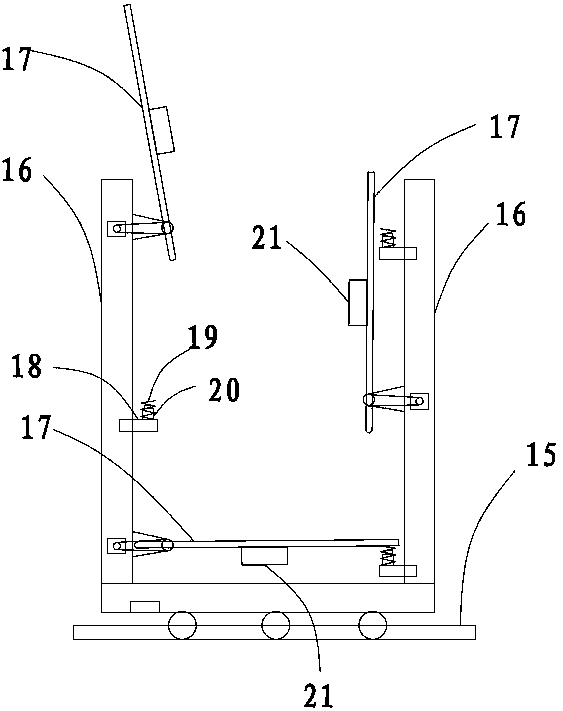

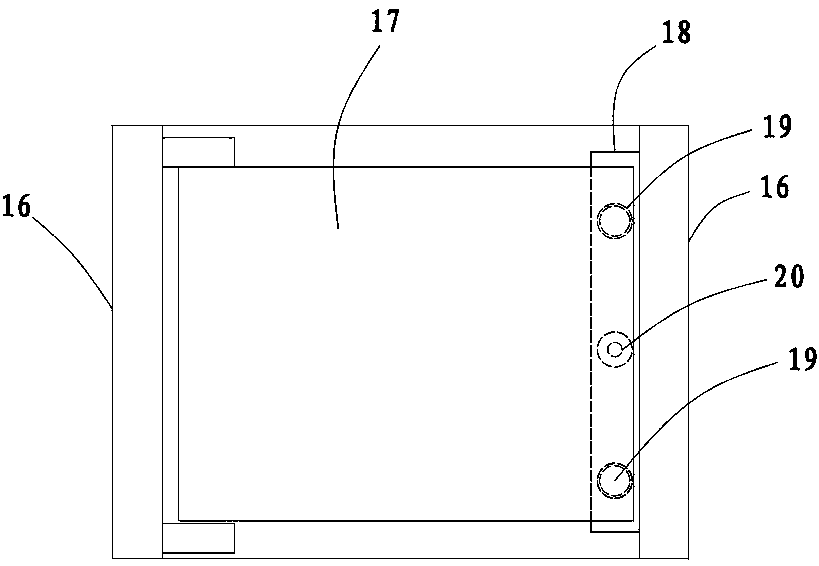

[0021] Embodiment: a shellfish slice processing device, such as figure 1 shown. After the shellfish of the device is separated from the shell, the cleaned shellfish sequentially passes through the slicer 2, the vacuum freeze-drying chamber 5, the returning greenhouse 7, and the packaging machine 8, and then packs after completing low-temperature slicing and drying. The slicer uses a conveyor belt to transport the shellfish. A low-temperature air nozzle 1 is installed above the conveying channel before the blade of the slicer 2. The low-temperature air nozzle sprays low-temperature gas at -45 to 0°C to the shellfish to reduce the temperature of the shellfish and avoid the slicing process. If the temperature of the shellfish meat is too high, the quality will be affected. The vacuum freeze-drying chamber is a low-pressure vacuum environment with a temperature of -45 to -35°C. The return room adopts natural return temperature, and nitrogen, argon or other types of rare gases ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com