Temperature sensing milk bottle

A feeding bottle and temperature range technology, applied to feeding bottles, etc., can solve the problems of easy falling off of heat-sensitive discoloration materials, increased thickness and weight of feeding bottles, and increased manufacturing costs, to achieve accurate and rapid response to temperature changes in the bottle, convenient disinfection, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

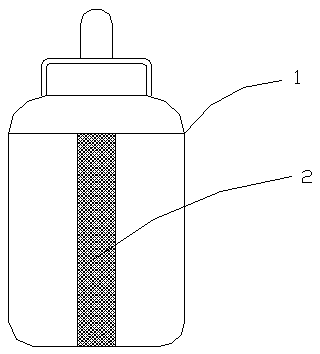

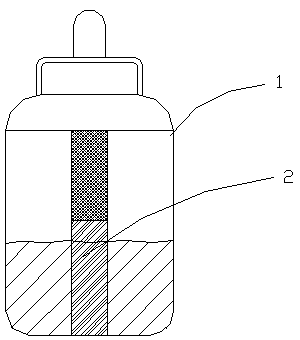

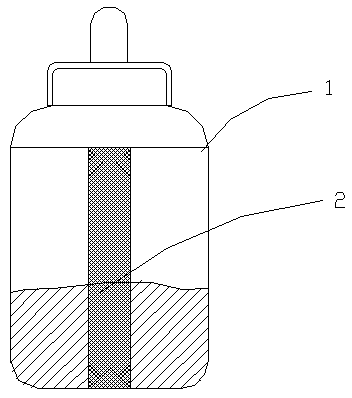

[0032] A temperature sensing feeding bottle according to the present invention, such as Figure 1 to Figure 3 As shown, the side of the bottle body of the feeding bottle 1 includes a temperature-sensitive color-developing area 2, and the temperature-sensitive color-developing area fuses with the surrounding area to form a single thin-layer bottle body; the temperature-sensitive color-developing area 2 is modulated as : The first color appears in the first temperature range, and the second color appears when the temperature rises to the second temperature range. Such as figure 1 As shown, when no milk is filled, the thermosensitive discoloration area of the empty bottle shows the first color. Such as figure 2 As shown, when hot water is put into the feeding bottle to dissolve the milk powder, the temperature-sensitive discoloration area changes to a second color, indicating that the temperature of the liquid exceeds a predetermined temperature. Such as image 3 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com