A method for arranging steel bars in building construction

A technology for steel bar layout and building, which is applied in the direction of buildings, building components, building reinforcements, etc., can solve the problems of house stability and firmness danger, foundation load, etc., to improve firmness and stability, reduce construction costs, reduce input effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

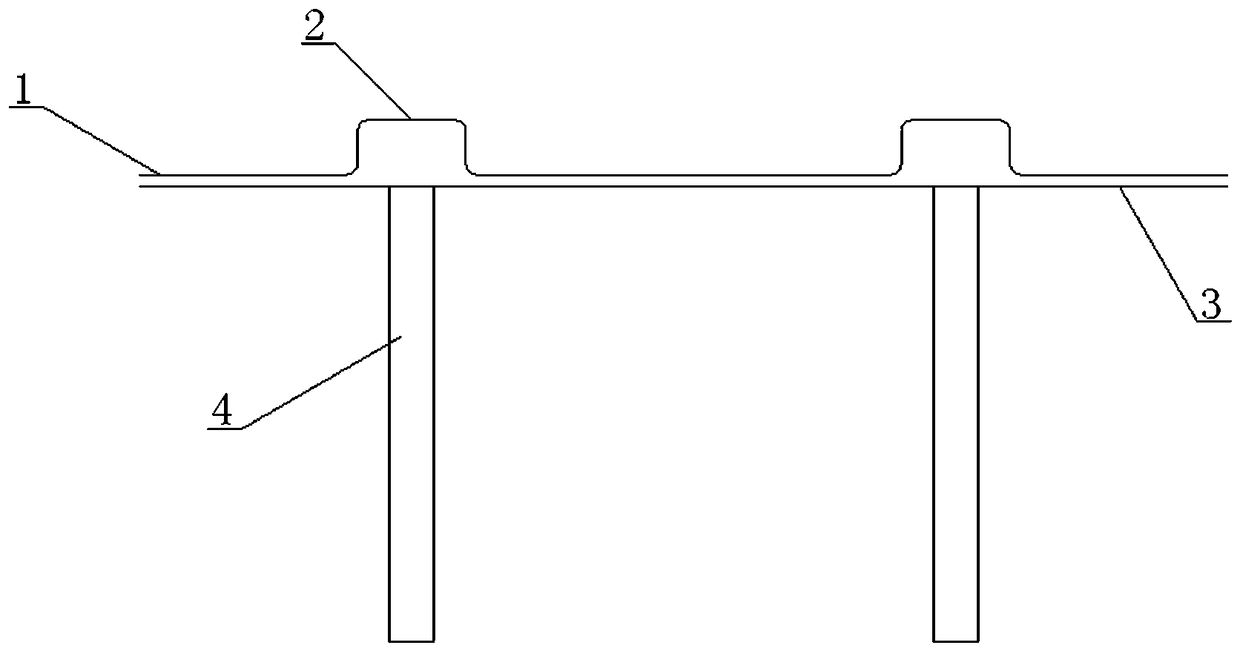

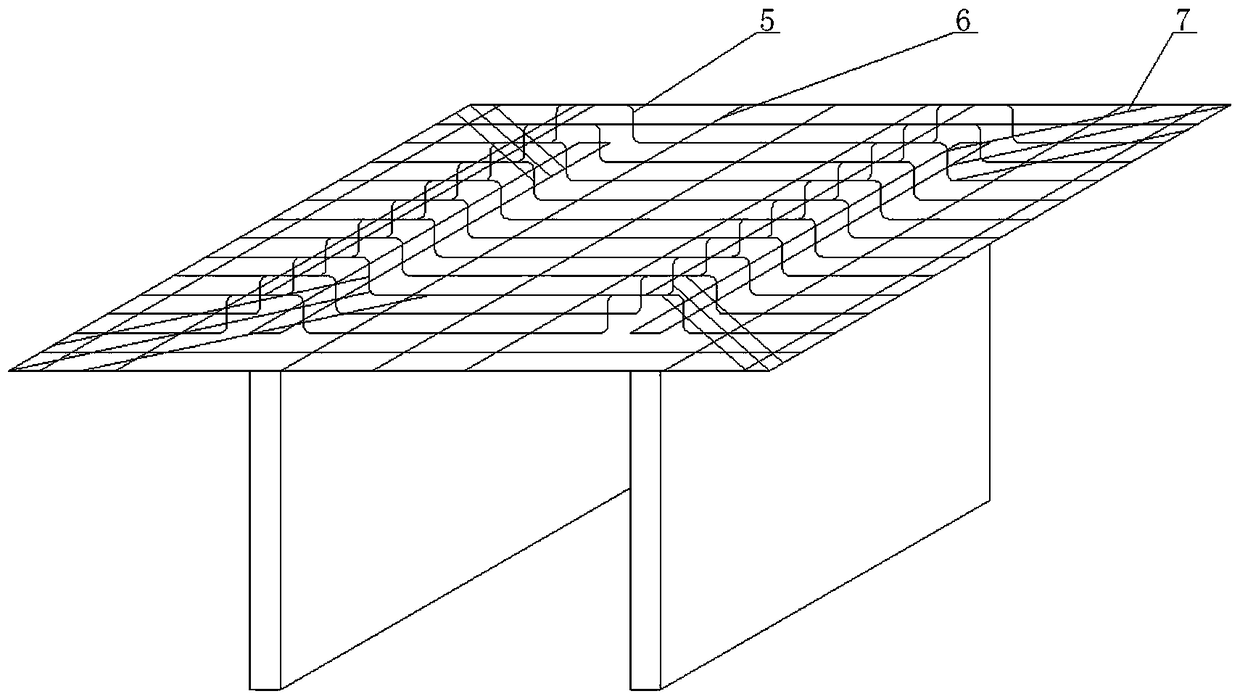

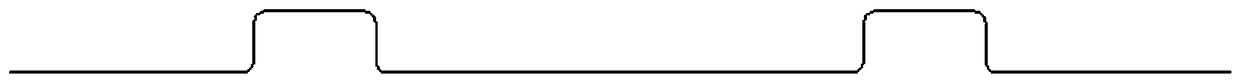

[0030] see Figures 1 to 2 Shown, a kind of reinforcing bar arrangement method of building construction adopts the mode of bow-shaped arrangement of reinforcing bars, and described method comprises the following steps:

[0031] (1) Build the pouring formwork 3, the top surface of the formwork 3 is flush with the top surface of the load-bearing member 4;

[0032] (2) Arrangement of steel bars, pre-place several positioning ribs 6 on the top surface of the load-bearing member, where the number of positioning ribs 6 is determined according to the distance between the two load-bearing members 4; On the pre-placed positioning ribs 6, the positioning ribs 6 are fixed on the main force ribs 5, and the distance between the main force ribs 5 is 8cm; the positioning ribs 6 are arranged, and the positioning ribs 6 are placed on the main force ribs 5. When the load-bearing member is 4, the arrangement is omitted, and the positioning ribs 6 are connected and fixed to the main ribs 5, and ...

Embodiment 2

[0040] see Figures 1 to 2 Shown, a kind of reinforcing bar arrangement method of building construction adopts the mode of bow-shaped arrangement of reinforcing bars, and described method comprises the following steps:

[0041] (1) Build the pouring formwork 3, the top surface of the formwork 3 is flush with the top surface of the load-bearing member 4;

[0042] (2) Arrangement of steel bars, pre-place several positioning ribs 6 on the top surface of the load-bearing member, where the number of positioning ribs 6 is determined according to the distance between the two load-bearing members 4; On the pre-placed positioning ribs 6, the positioning ribs 6 are fixed on the main force ribs 5, and the distance between the main force ribs 5 is 10cm; the positioning ribs 6 are arranged, and the positioning ribs 6 are placed on the main force ribs 5. When the load-bearing member is 4, the layout is omitted, and the positioning rib 6 is connected to the fixed main rib 5, and the distanc...

Embodiment 3

[0050] see Figures 1 to 2 Shown, a kind of reinforcing bar arrangement method of building construction adopts the mode of bow-shaped arrangement of reinforcing bars, and described method comprises the following steps:

[0051] (1) Build the pouring formwork 3, the top surface of the formwork 3 is flush with the top surface of the load-bearing member 4;

[0052] (2) Arrangement of steel bars, pre-place several positioning ribs 6 on the top surface of the load-bearing member, where the number of positioning ribs 6 is determined according to the distance between the two load-bearing members 4; On the pre-placed positioning ribs 6, the positioning ribs 6 are fixed on the main force ribs 5, and the distance between the main force ribs 5 is 12cm; the positioning ribs 6 are arranged, and the positioning ribs 6 are placed on the main force ribs 5. When the load-bearing member is 4, the arrangement is omitted, and the positioning ribs 6 are connected to the fixed main ribs 5, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com