Induction method of three-dimensional (3D) online induction system for mechanical equipment dismounting

A mechanical equipment, 3D technology, applied in the direction of mechanical mode conversion, user/computer interaction input/output, computer parts, etc. Human-computer interaction, large changes in disassembly and assembly scenarios, etc., to achieve the effect of improving high universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

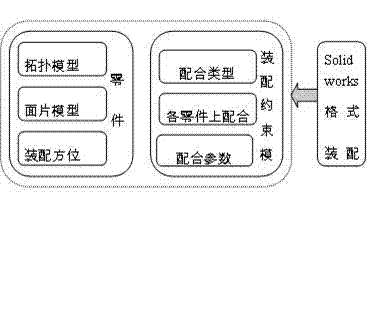

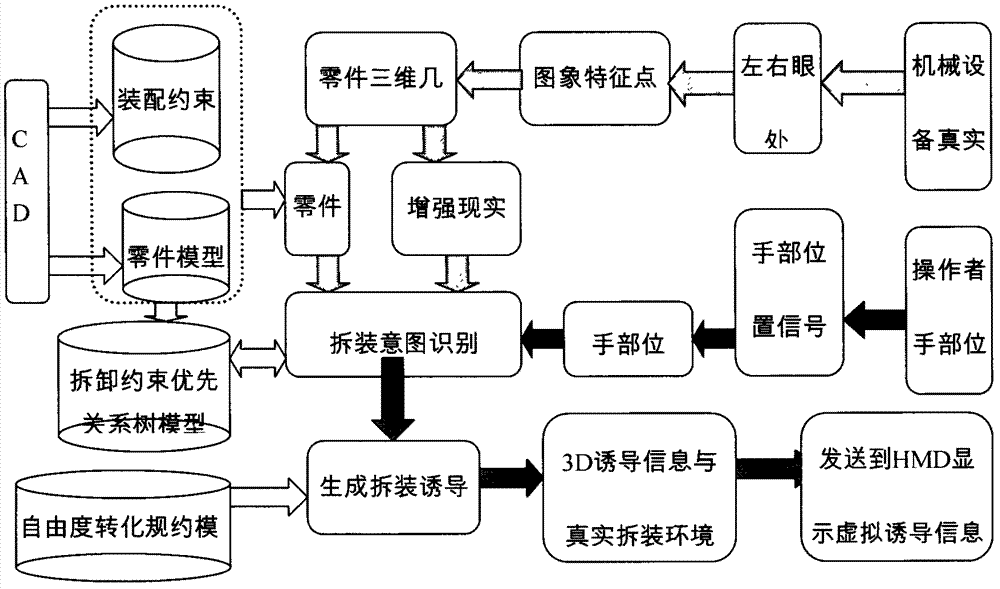

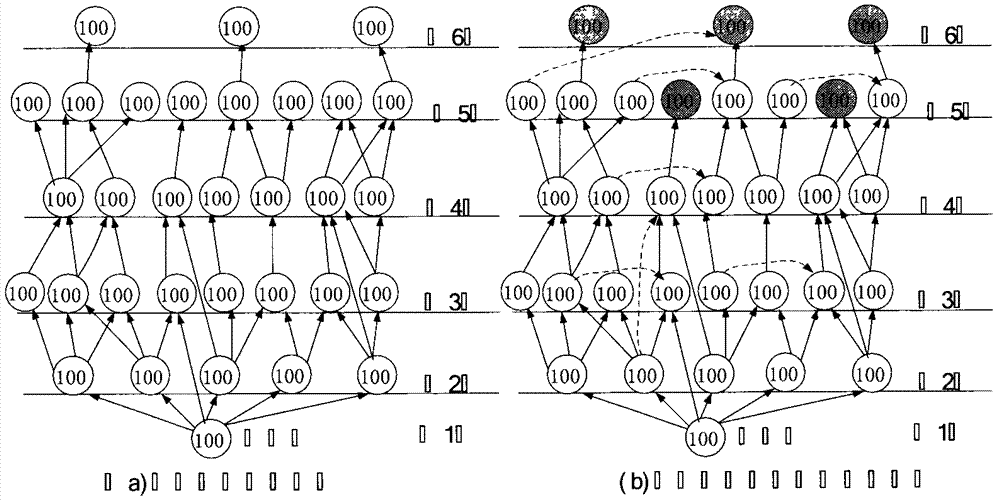

[0040] Such as figure 1 As shown, a 3D online guidance system for mechanical equipment disassembly and assembly includes a portable computer, an augmented reality head-mounted display (HMD) (which contains 2 CCDs), 2 hand position trackers, and a gap between the computer and the HMD and hand position trackers. Wireless communication is possible. The steps of the induction method of the system of the present invention include virtual assembly model conversion; initialization of the induction system; identification of disassembly intention; generation of induction i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com