Patents

Literature

33results about How to "Accurate Overlay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

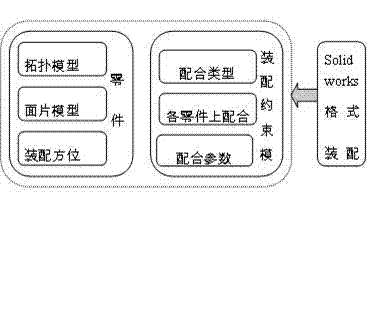

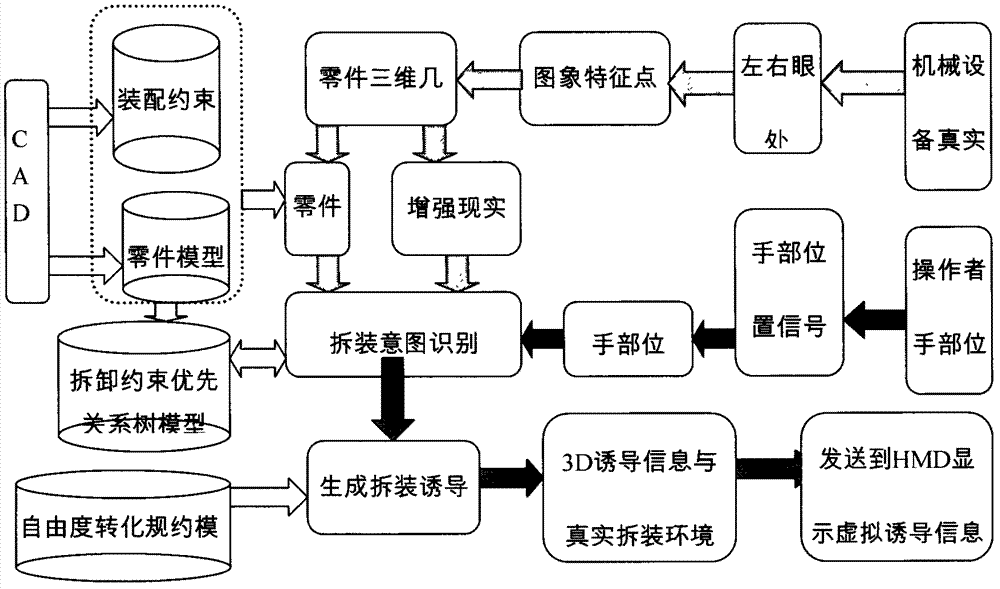

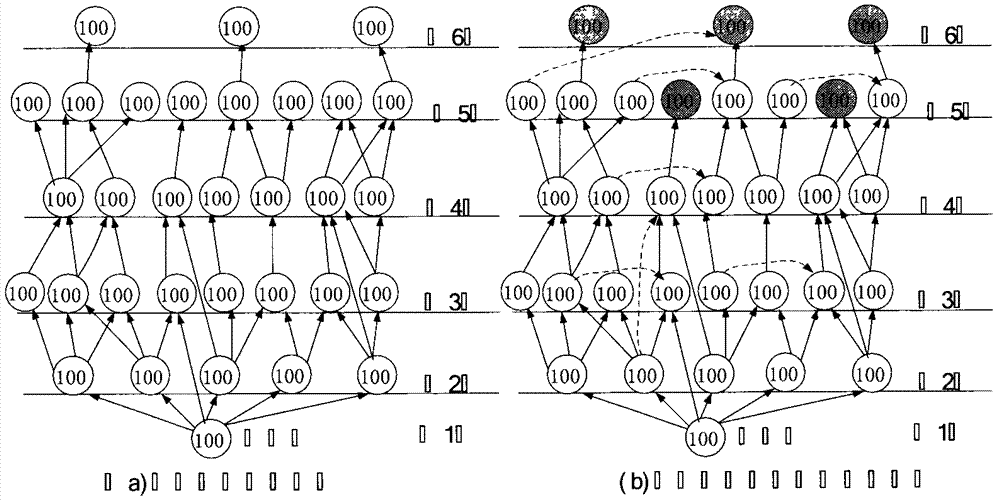

Induction method of three-dimensional (3D) online induction system for mechanical equipment dismounting

InactiveCN102789514AAugmented reality inductionImprove high universalityInput/output for user-computer interactionGraph readingInduction motor3d design

The invention discloses an induction method of a three-dimensional (3D) online induction system for mechanical equipment dismounting. The induction system comprise an eyeglass-type augmented reality helmet, a hand position tracking device and a computer, wherein the augmented reality helmet is provided with two display screens and two cameras; and wireless communication can be realized among the augmented reality helmet, the hand position tracking device and the computer. An induction method for realizing the three-dimensional online induction system for mechanical equipment dismounting comprises the following steps of: 1, transforming a virtual assembly model; 2, initializing the induction system; 3, recognizing the dismounting purpose; 4, generating induction information; 5, overlapping the induction information; and 6, repeating the steps 3-5 until the online product induction is finished. The method disclosed by the invention has the characteristics of accurate induction information, strong universal capability and convenience in carrying, and can be used for realizing the 3D online induction driven by requirements of operators, current situations of tasks and dismounting history and realizing the integration of product 3D design and dismounting induction.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

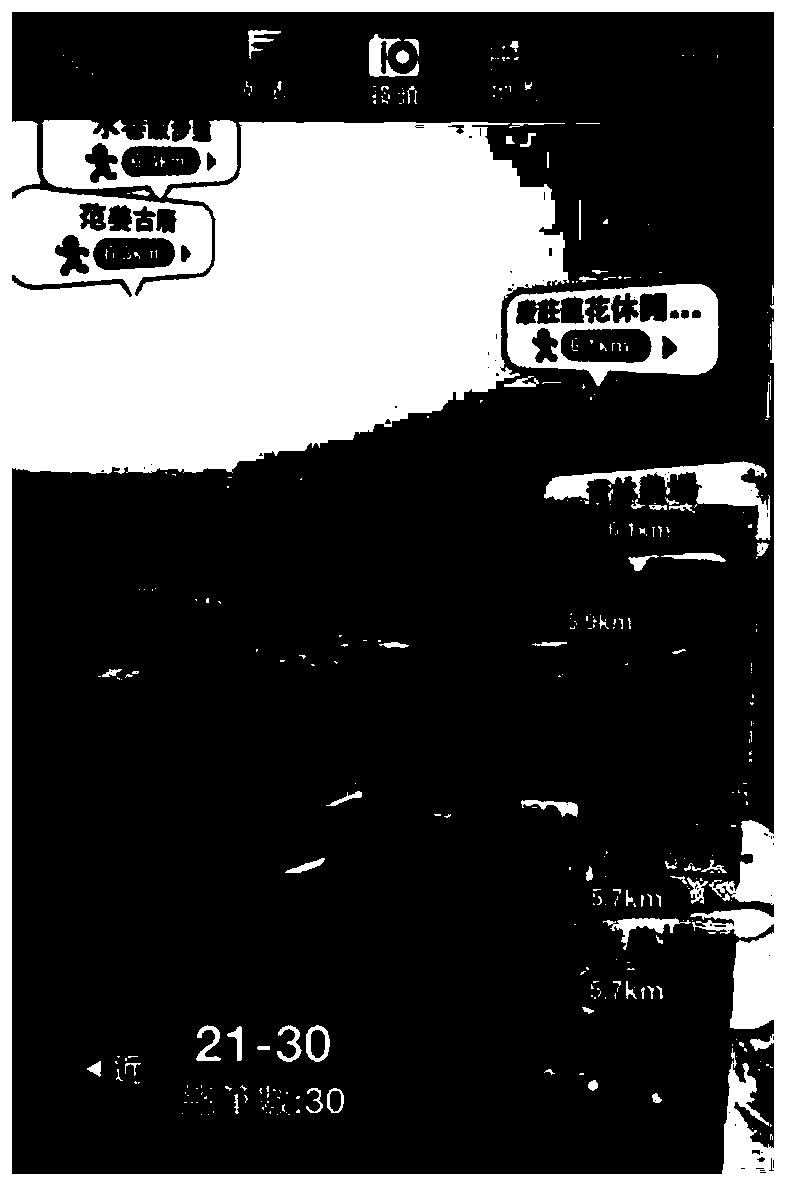

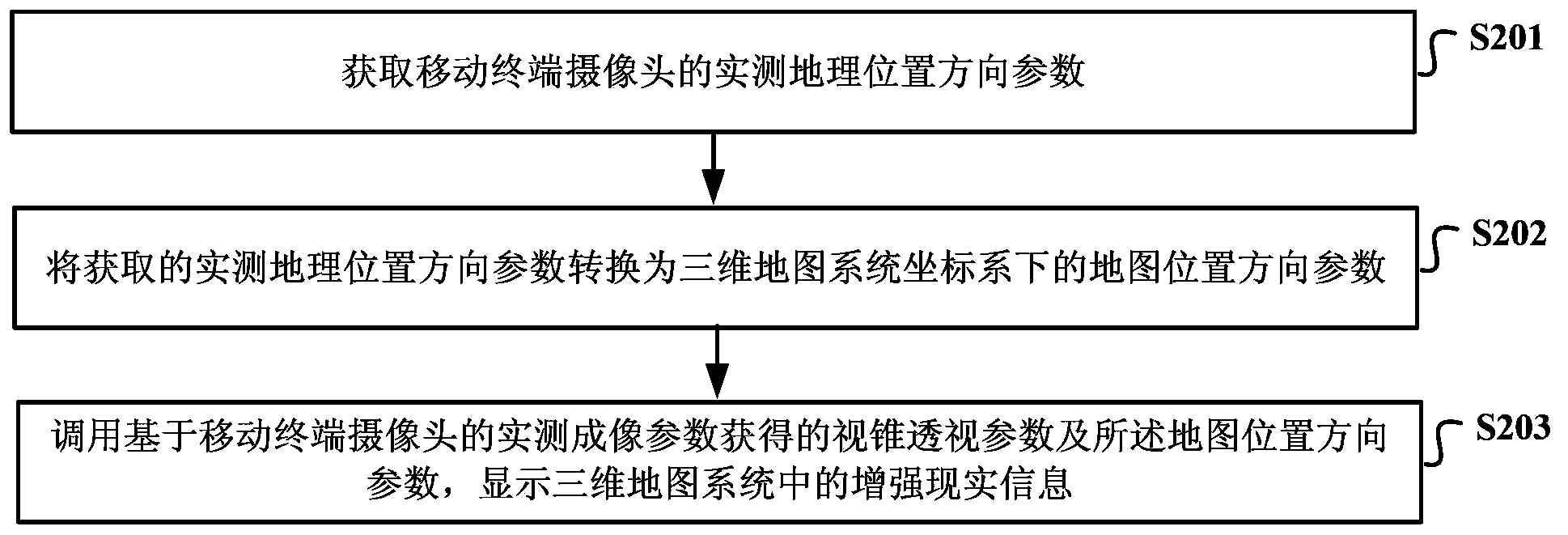

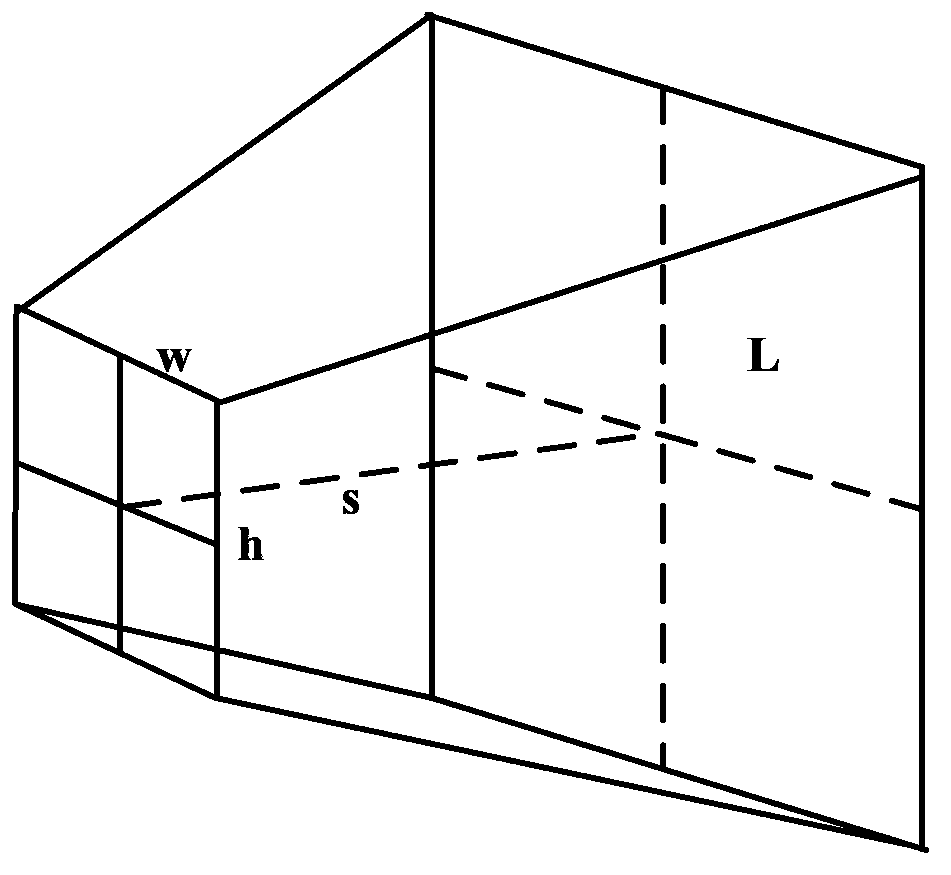

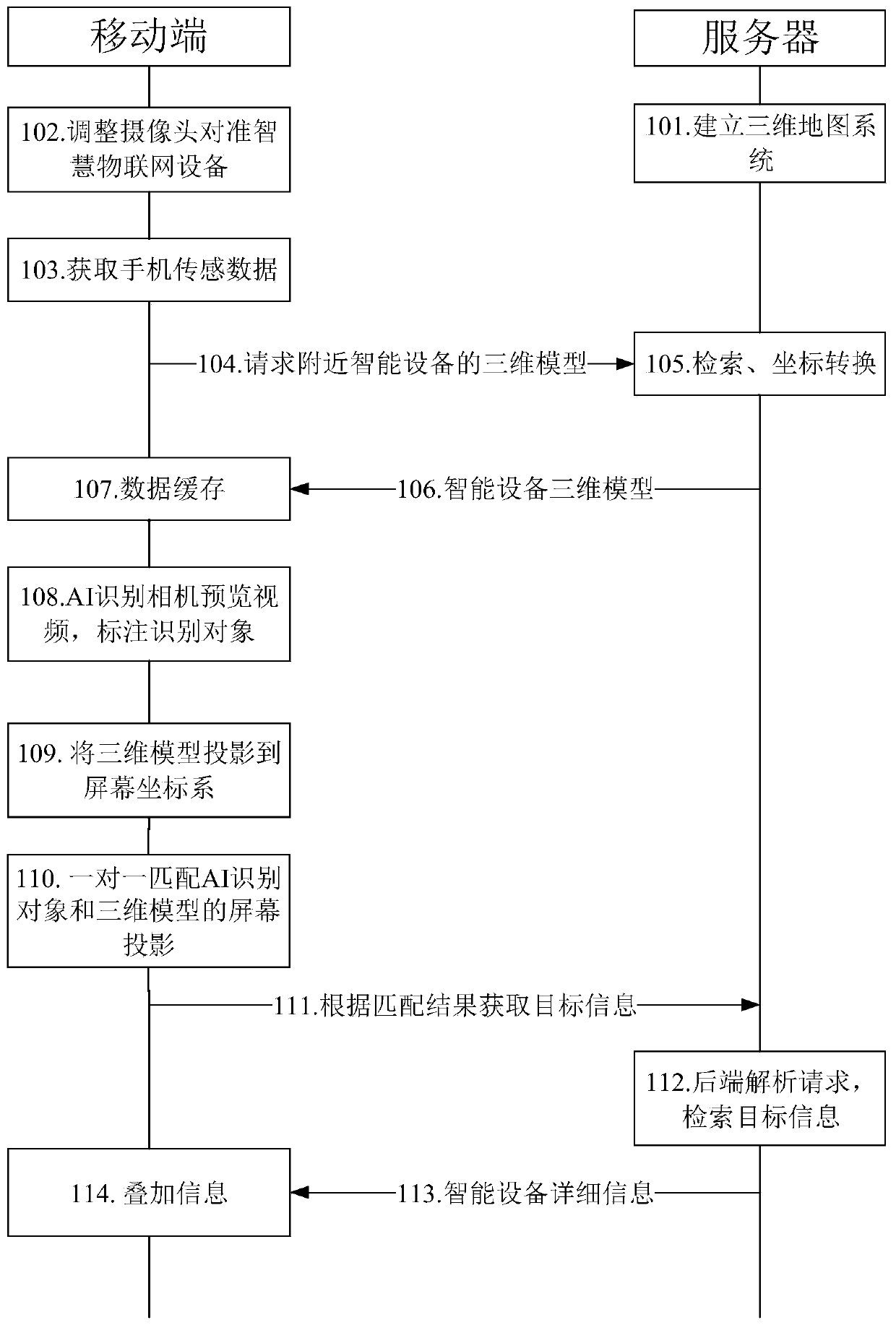

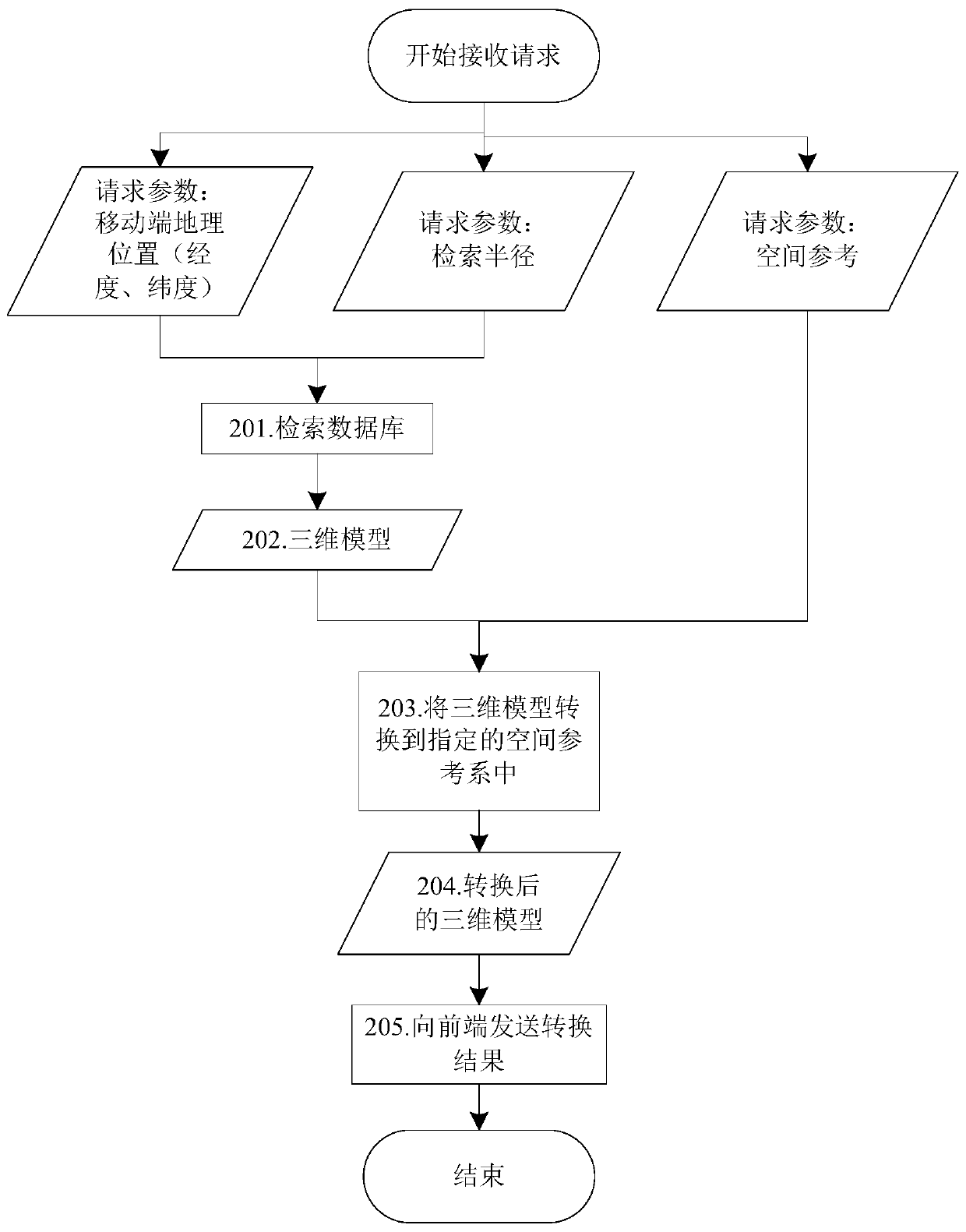

Method and device for achieving augmented reality based on three-dimensional map system

InactiveCN103578141AAccurate overlayImprove experienceImage data processingGeographic siteGeolocation

The invention discloses a method and device for achieving augmented reality based on a three-dimensional map system. The accuracy of the overlapping position of the information of the three-dimensional map system and existence in a reality scene is improved. The method for achieving the augmented reality based on the three-dimensional map system comprises the steps of acquiring the direction parameter of the actually-measured geographic position of a mobile terminal camera, converting the direction parameter of the actually-measured geographic position into the geographic position direction parameter under the coordinate system of the three-dimensional map system, calling a vision cone perspective parameter obtained based on the actually-measured imaging parameter of the mobile terminal camera and the geographic position direction parameter, and displaying augmented reality information in the three-dimensional map system.

Owner:北京图盟科技有限公司

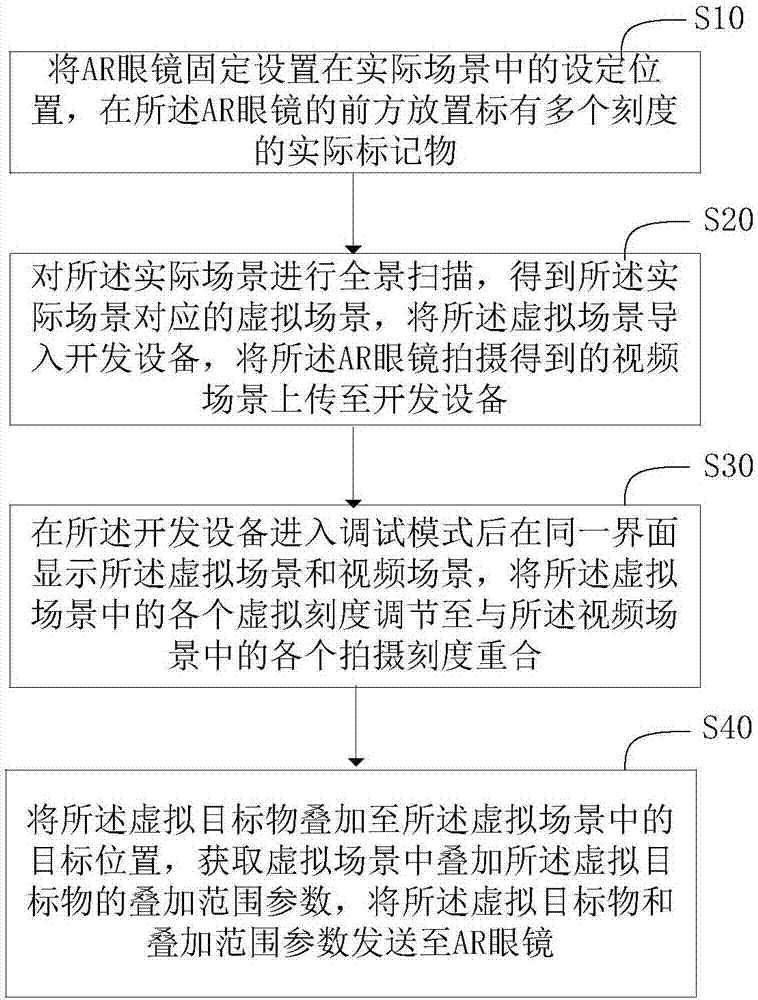

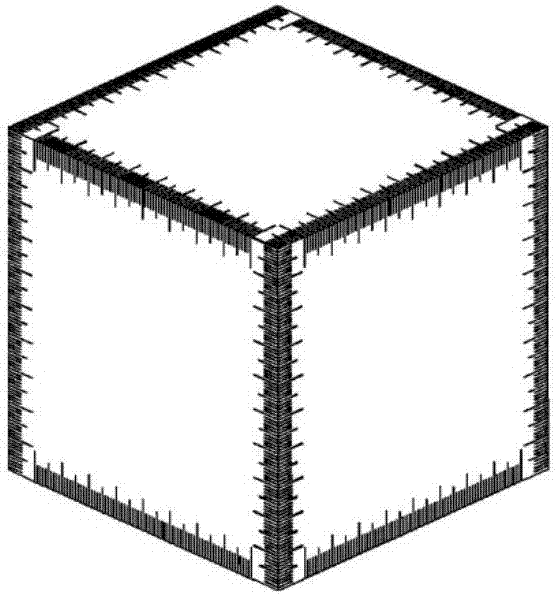

Overlapped method for virtual object in AR glasses

ActiveCN106875493AReduce resource overheadReduce the risk of overheatingImage data processingVirtual targetComputer graphics (images)

Owner:广东电网有限责任公司培训与评价中心

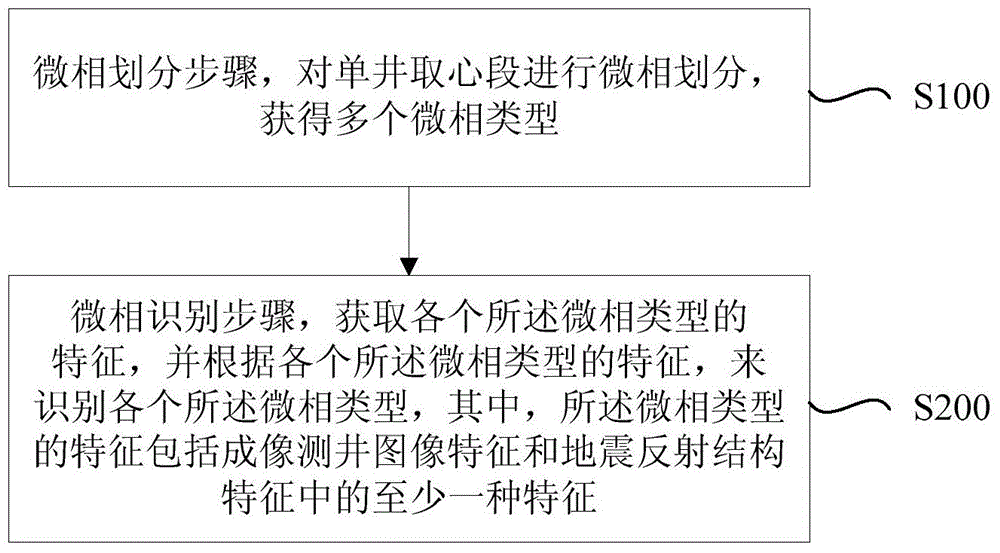

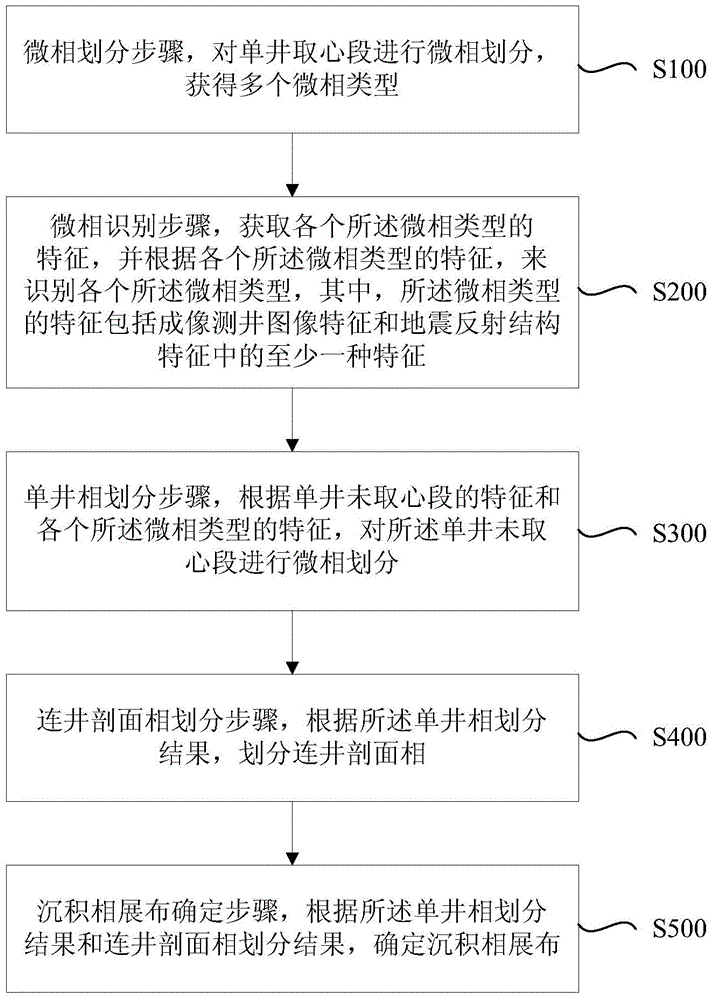

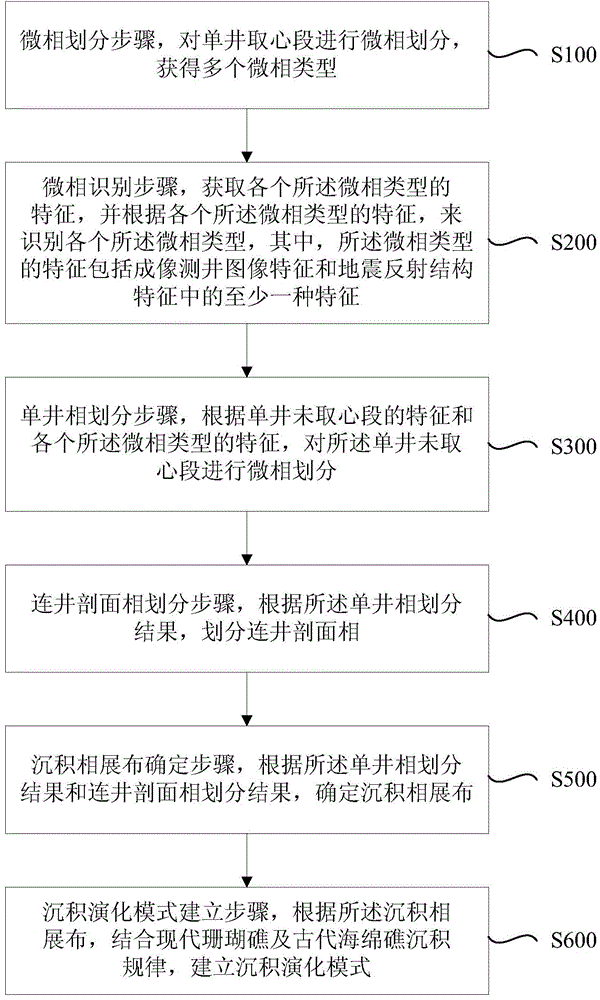

Carbonate rock microfacies type identification method and sedimentary facies description method thereof

InactiveCN104975850AAccurate identificationIncrease the accuracy of recognitionBorehole/well accessoriesImaging FeatureBiology

The invention provides a carbonate rock microfacies type identification method and a sedimentary facies description method thereof; the microfacies type identification method comprises the following steps: a microfacies classifying step: carrying out microfacies classification for a single well coring segment so as to obtain a plurality of microfacies types; a microfacies identification step: obtaining features of the microfacies types, and identifying each microfacies type according to the features of the microfacies types, wherein the microfacies type features comprise at least one of the following features: imaging logging image feature and earthquake reflection composition feature. In a microfacies types identifying process, the method combines the imaging logging image feature with the earthquake reflection composition feature, thus more accurately identifying microfacies of the carbonate rocks.

Owner:CHINA PETROLEUM & CHEM CORP +1

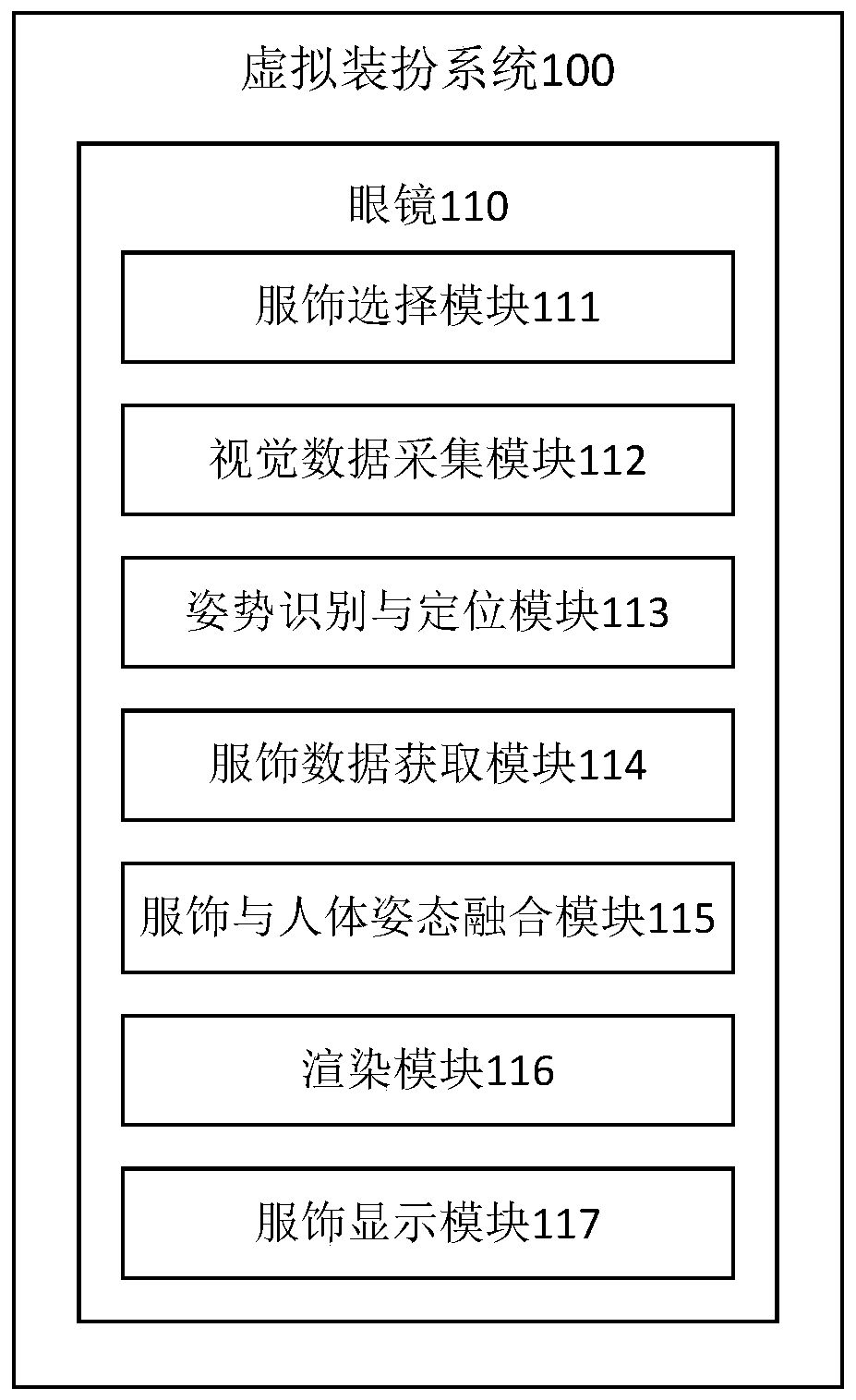

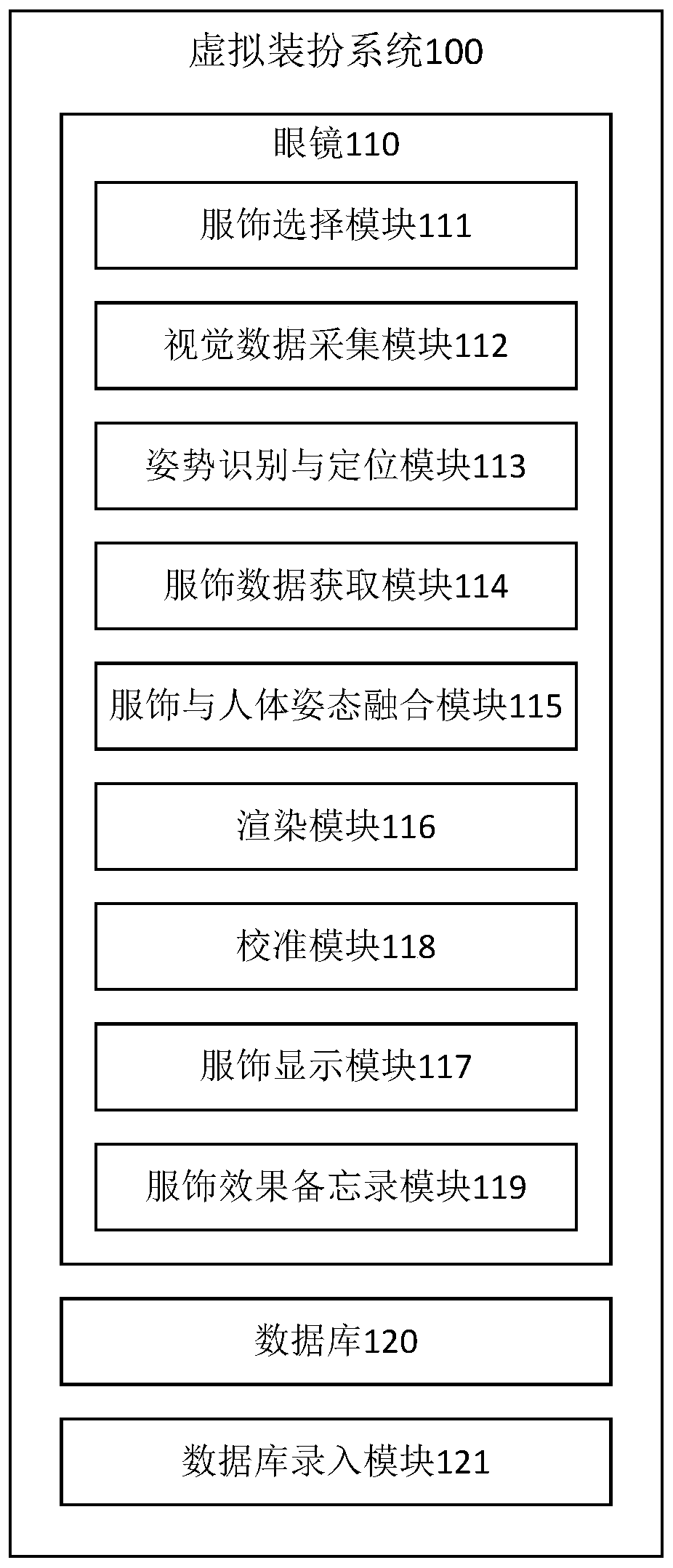

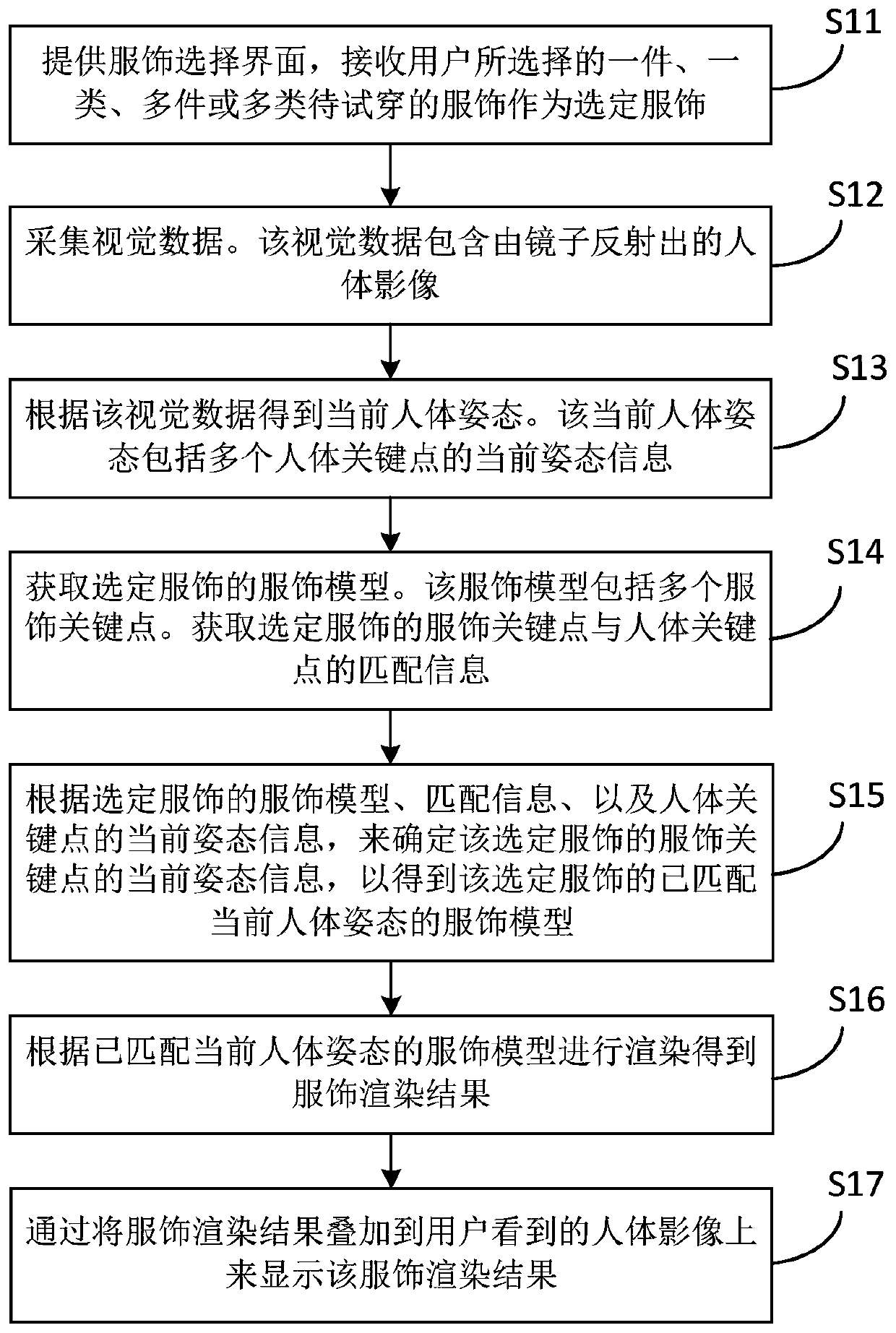

Virtual dress-up system, method, device and medium

ActiveCN110363867AImprove experienceEliminate distractionsBiometric pattern recognition3D modellingHuman bodyEyewear

The present invention relates to a virtual dress-up system, a virtual dress-up method, a virtual dress-up device and a medium. The system comprises a pair of glasses comprising a memory and a processor, for: providing a dress selection interface, receiving a selected dress selected by a user; collecting visual data including a human body image reflected by the mirror; obtaining a current human body posture according to the visual data; obtaining a clothing model of the selected clothing, and obtaining matching information of clothing key points of the selected clothing and human body key points; obtaining a clothes model of the selected clothes matched with the current human body posture according to the current human body posture, the clothes model of the selected clothes and the matchinginformation; rendering according to the clothing model matched with the current human body posture to obtain a clothing rendering result; displaying apparel rendering results. By means of the virtualdress-up system, method and device and the medium, a user can achieve virtual dress-up experience only by wearing augmented reality glasses and using any common mirror around the user, and the virtual dress-up system, method and device are flexible, convenient to use and good in user experience.

Owner:YUTOU TECH HANGZHOU

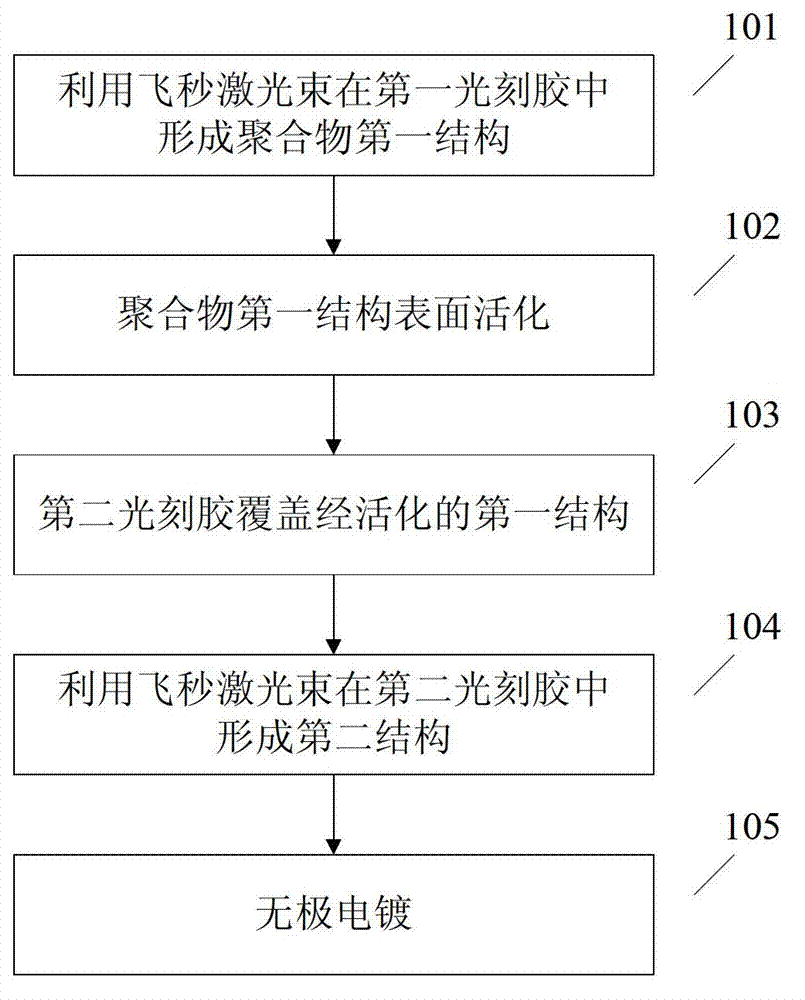

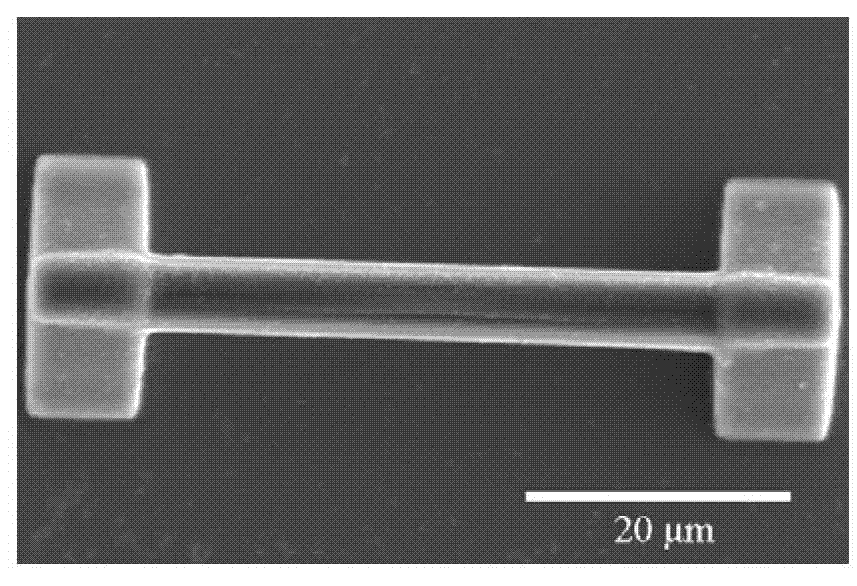

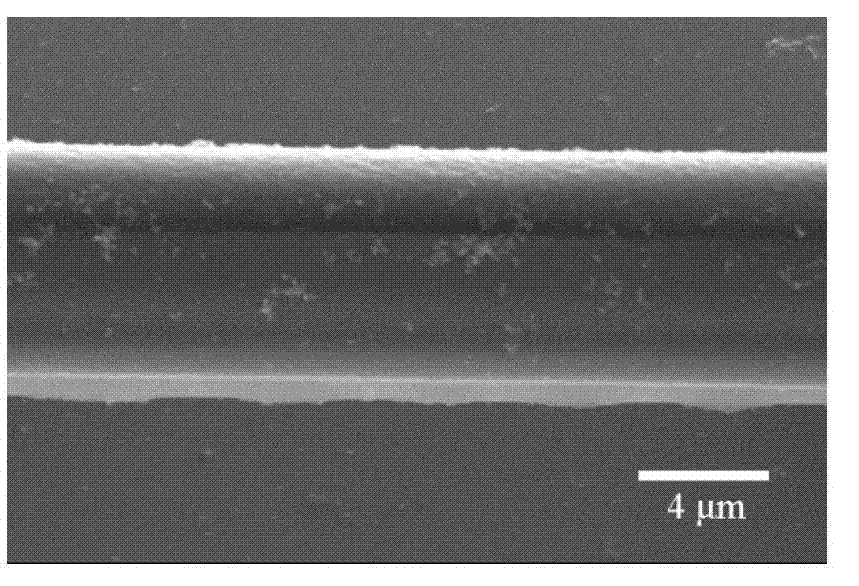

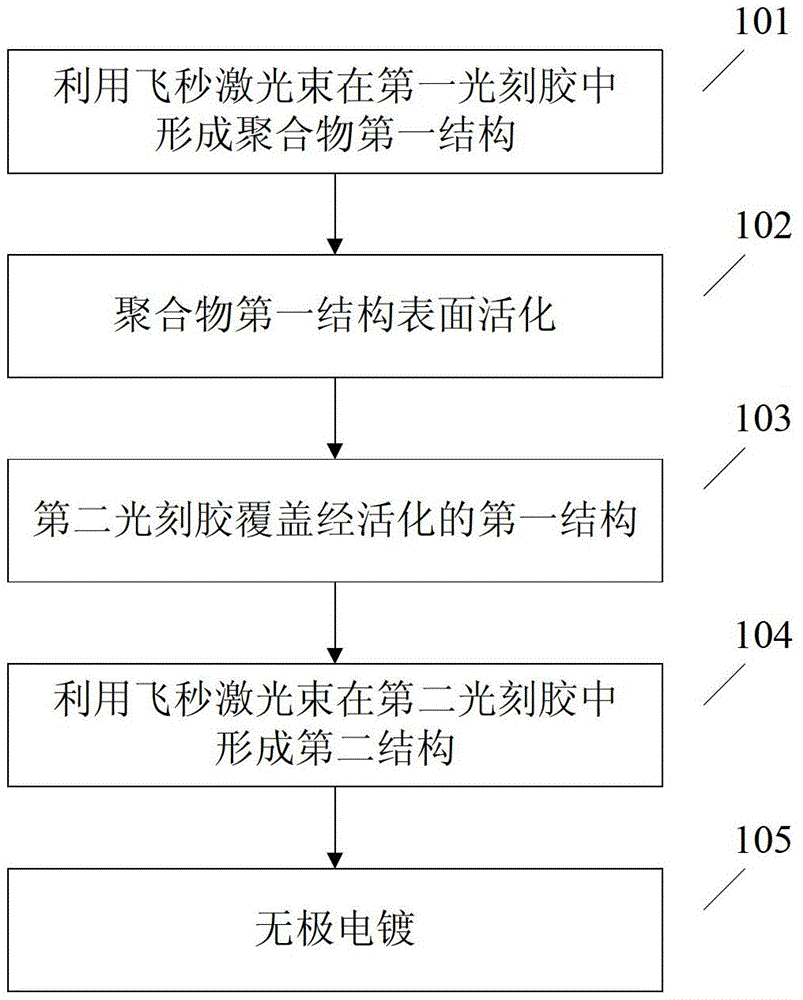

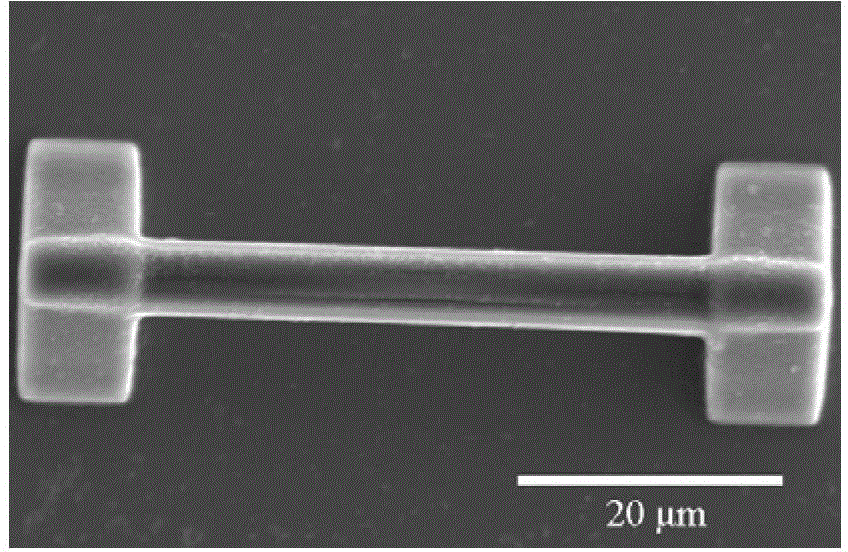

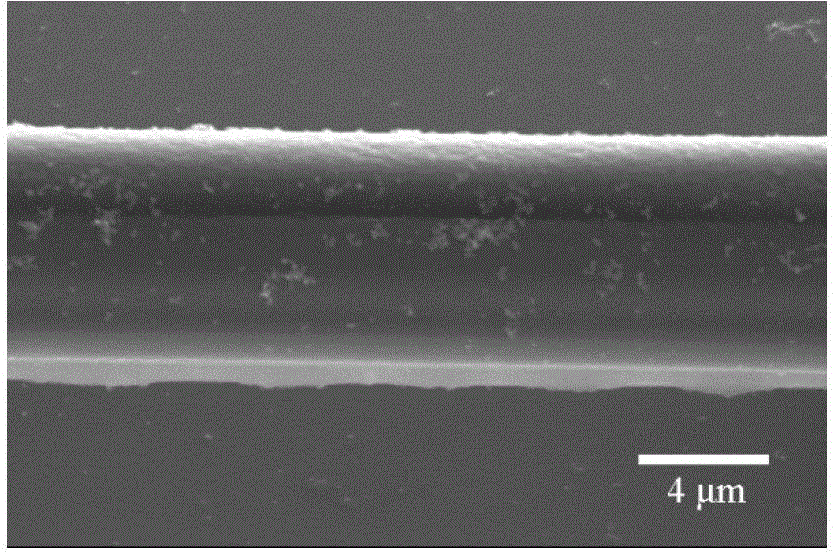

Preparation method for three-dimensional metal micro-nanometer device

ActiveCN102951604ALow costReduce process stepsDecorative surface effectsChemical vapor deposition coatingThin membraneNanometre

The invention relates to a preparation method for a three-dimensional metal micro-nanometer device. The method comprises the steps: forming a first structure of a polymer in a first photoresist by utilizing femtosecond laser beam; activating the surface of the first structure of the polymer; covering the activated first structure of the polymer by a second photoresist; forming a second structure partially contacted with the first structure in the second photoresist by utilizing femtosecond laser beam to obtain a complex of the partially exposed and activated surface of the first structure; and carrying out electrodeless plating to the complex in electroplate solution, and forming a metal thin membrane on the exposed surface of the first structure to obtain the three-dimensional metal micro-nanometer device. The first structure and the second structure are respectively machined so as to accurately align on three dimensions, selective electroplating of micro-nanometer structure can be realized by combining electrodeless electroplating technique, and the three-dimensional metal micro-nanometer device with any three-dimensional metal micro-nanometer structure can be obtained.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

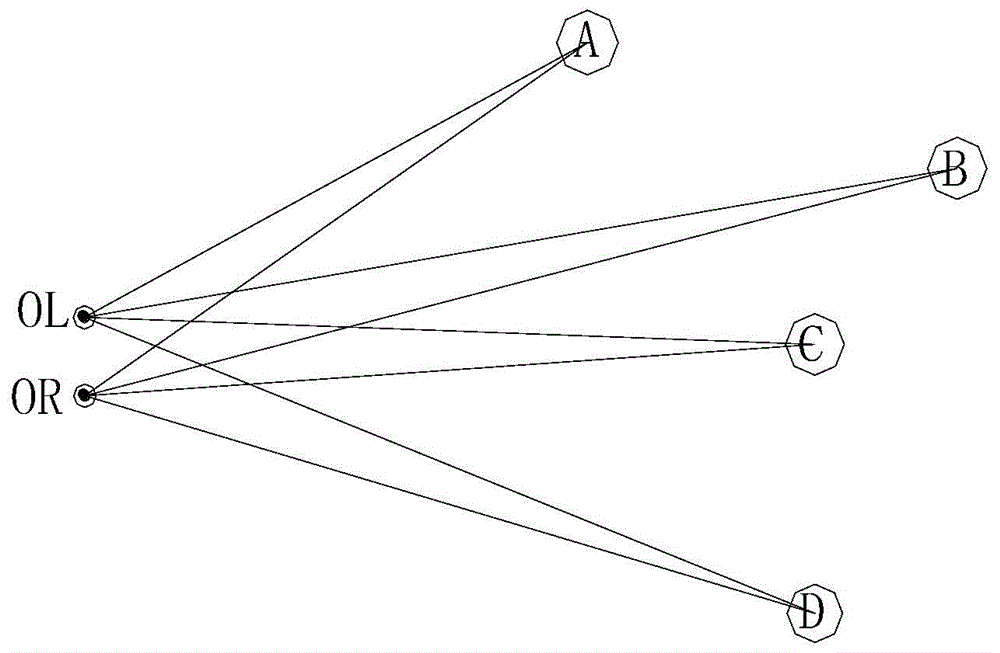

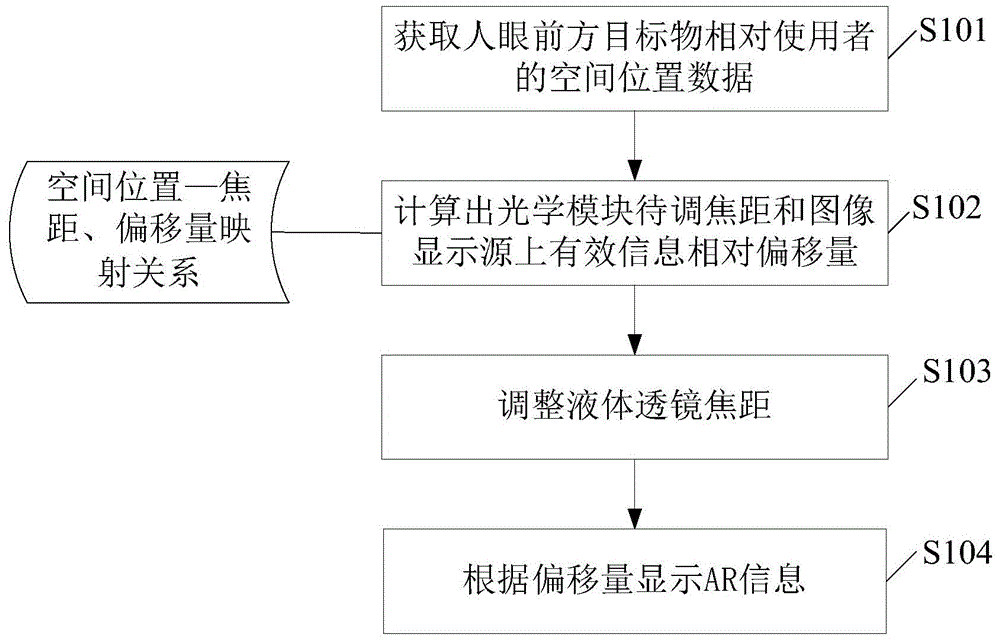

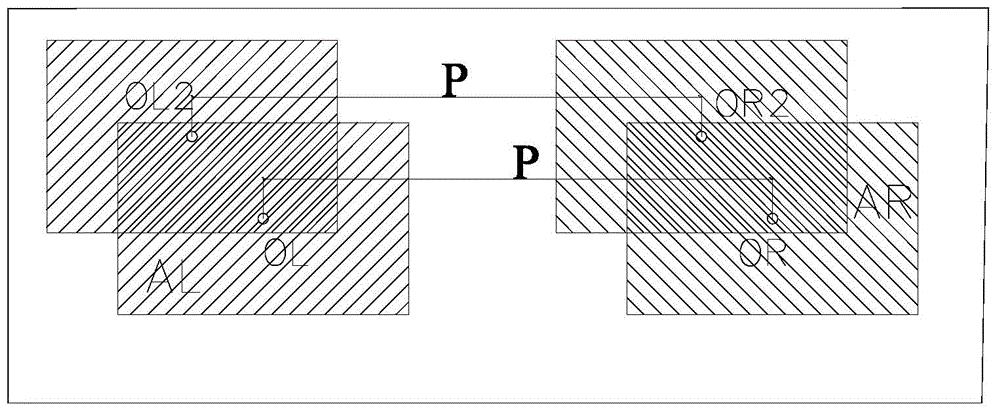

Binocular AR (Augmented Reality) head-mounted display device and information display method thereof

InactiveCN105872527AFusion wellVarious measurement methodsSteroscopic systemsComputer graphics (images)Display device

The invention discloses a binocular AR head-mounted display device and an information display method thereof. The adjustment of the projection distance is realized by zooming a liquid lens, and the adjustment of the projection angle is realized by calculating the relative offset of effective display information on an image display source. Finally, the virtual information can be accurately superimposed on the spatial position of the target object, so that the virtual information can be highly integrated with the environment, and the real augmented virtual reality can be realized. The scheme of the present invention is simple. On the premise that the distance mapping relationship η is preset in the head-mounted display device, it is only necessary to obtain the spatial position data of the target object relative to the user, and the spatial position data can be measured in various ways. distance, depth of field camera, etc., with mature hardware technology, high reliability and low cost.

Owner:CHENGDU IDEALSEE TECH

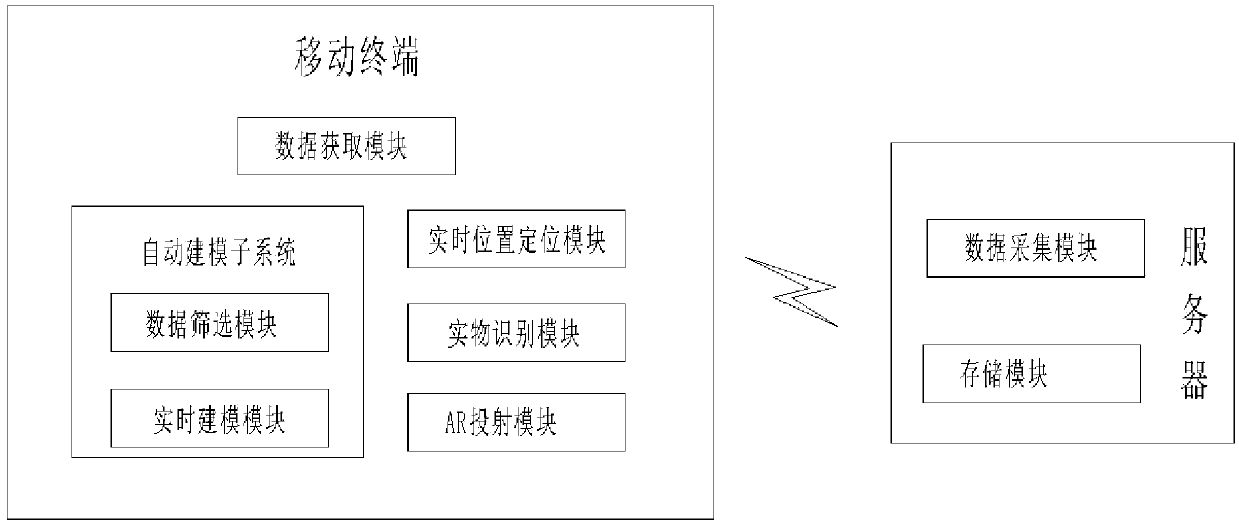

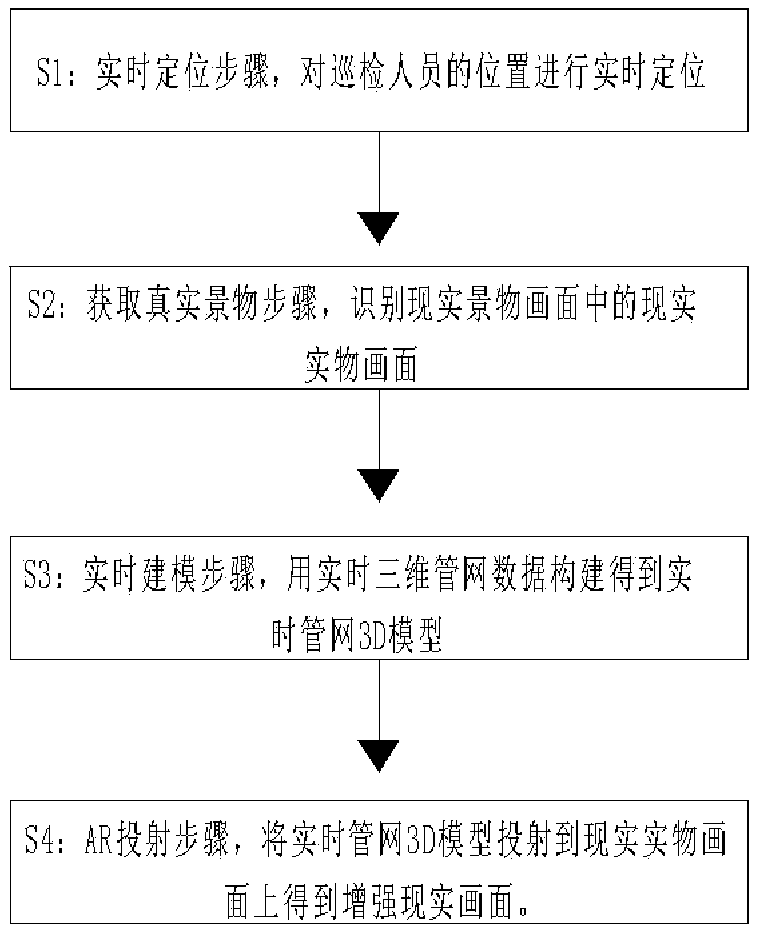

AR-based pipe network visualization system

ActiveCN109615708AImprove visualizationReduce memory requirementsData processing applicationsClimate change adaptationNetwork dataComputer science

The invention relates to the technical field of augmented reality, in particular to an AR-based pipe network visualization system which comprises a real object recognition module used for collecting areal scene picture, obtaining the real-time position of an inspector and recognizing the real scene picture from the real scene picture according to the real-time position; the data screening moduleis used for acquiring the pipe network big data and the real-time position of the inspection personnel, and screening the pipe network big data according to the real-time position to obtain real-timepipe network data; the real-time modeling module is used for acquiring real-time pipe network data, generating real-time three-dimensional pipe network data from the real-time pipe network data and constructing the real-time three-dimensional pipe network data into a real-time pipe network 3D model; and the AR projection module is used for acquiring the real-time pipe network 3D model and the real-time object picture and projecting the real-time pipe network 3D model to the real-time object picture to obtain an augmented reality picture. According to the invention, the problems of serious memory capacity waste and low inspection efficiency caused by pre-construction of a 3D model in the existing AR visualization system can be solved.

Owner:重庆予胜远升网络科技有限公司 +1

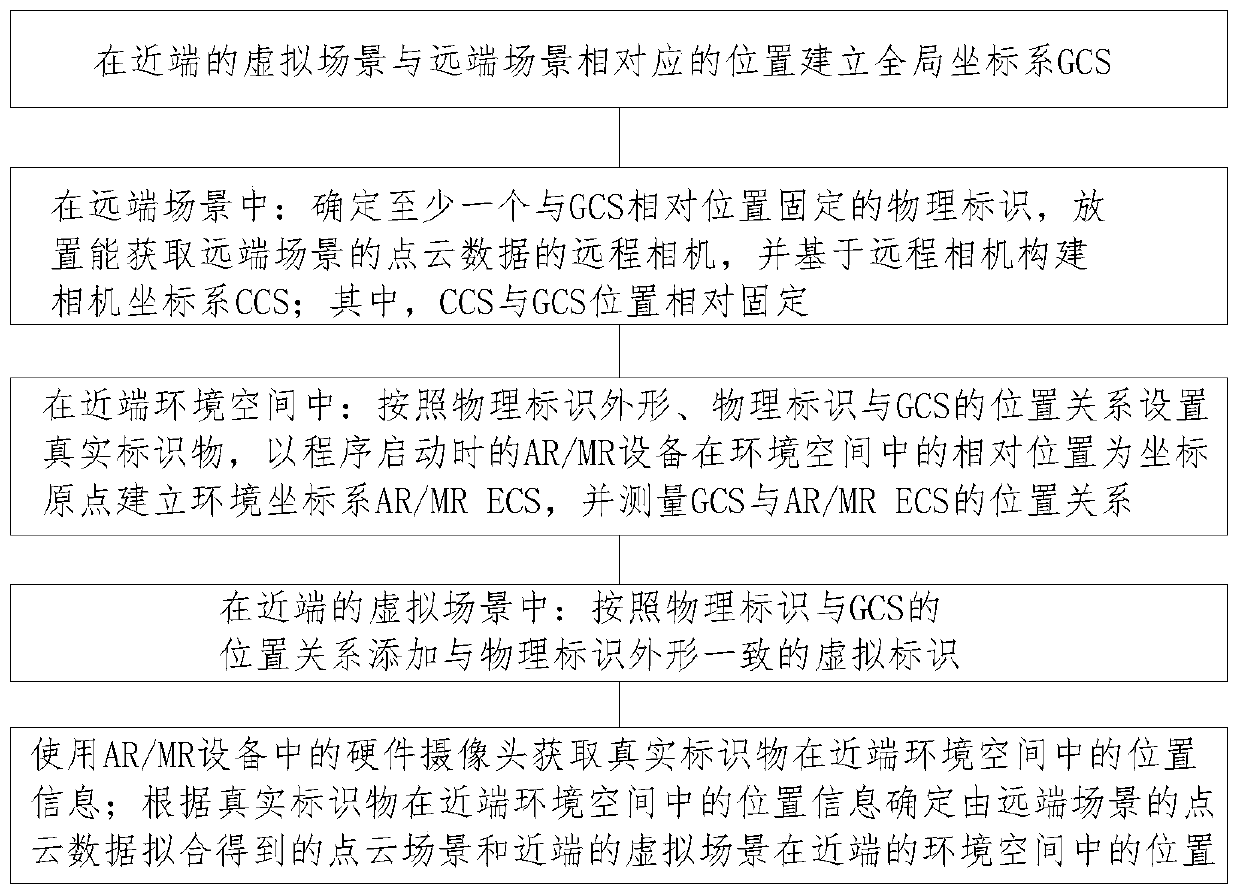

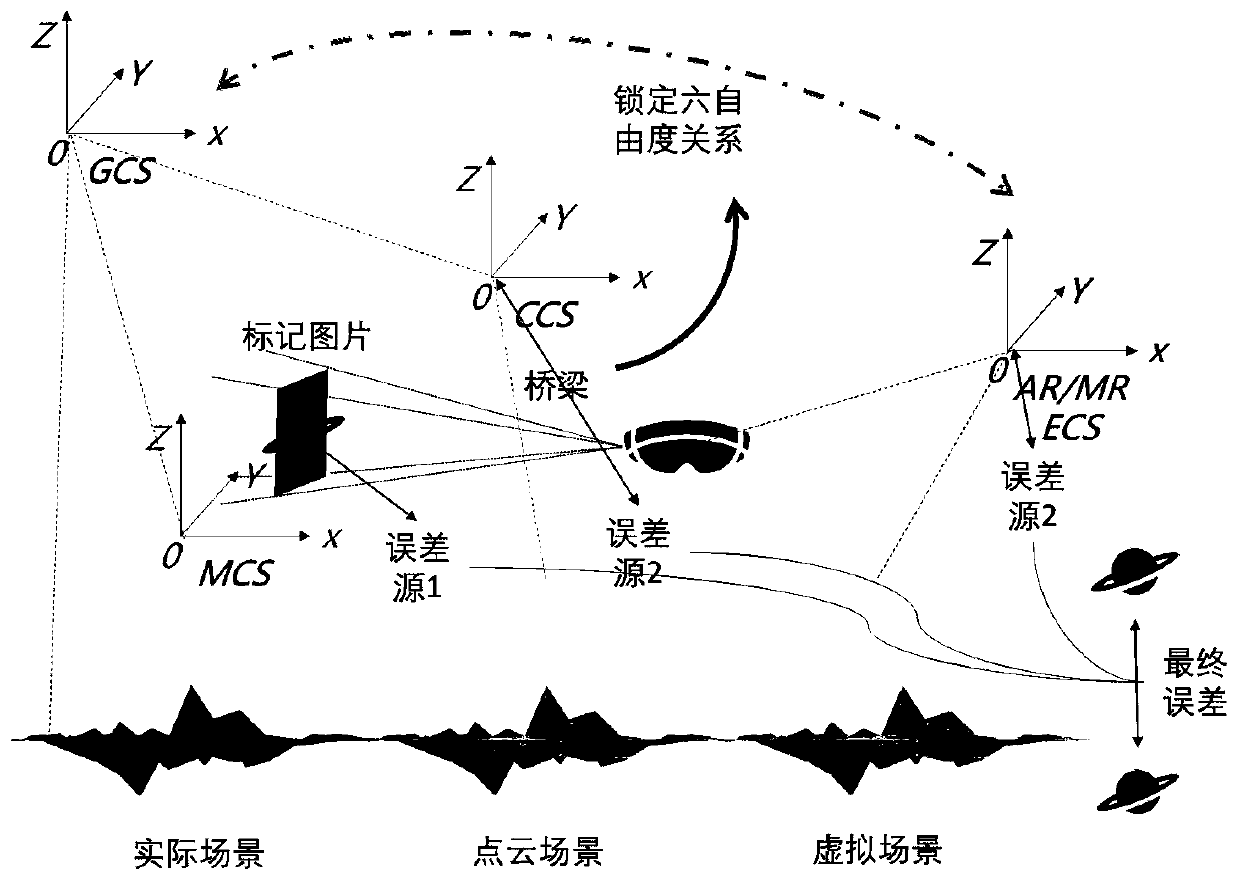

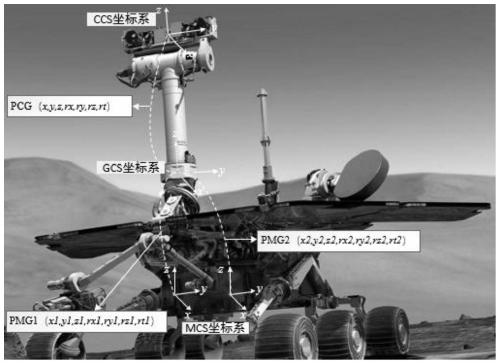

Remote virtual-real high-precision matching and positioning method for augmented reality and mixed reality

The invention provides a remote virtual-real high-precision matching and positioning method for augmented reality and mixed reality, and relates to the technical field of mixed reality and augmented reality. By constructing multiple coordinate systems and determining the position relation between the coordinate systems, the real markers are used for determining the positions of the point cloud scene of the remote scene and the near-end virtual scene in the near-end environment space, and oriented remote virtual-real high-precision matching positioning is achieved. Method according to the invention, according to the method, the position of the virtual object in the mixed and augmented reality environment can be adaptively and accurately positioned on the basis of marking the position of theobject in the real space and crossing the space obstacle, and the scene in the virtual space is accurately superposed into the near-end environment space, so that interactive operations such as remote training demonstration and auxiliary guidance under virtual-real comparison are conveniently realized.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

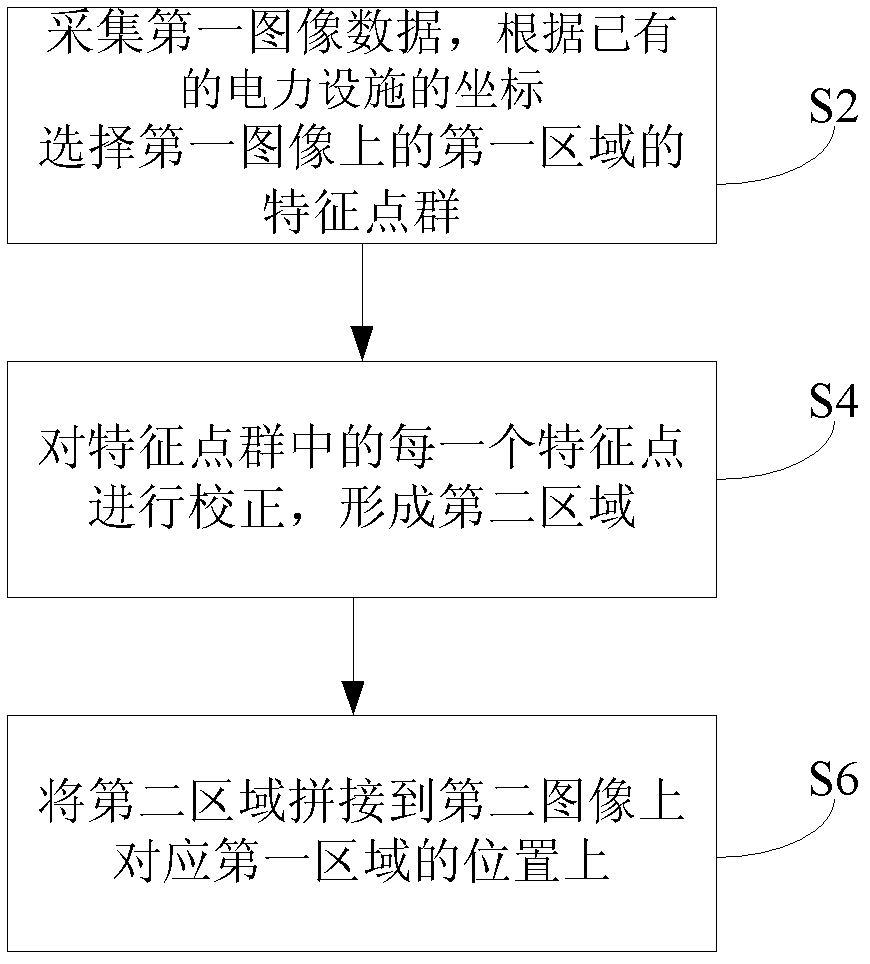

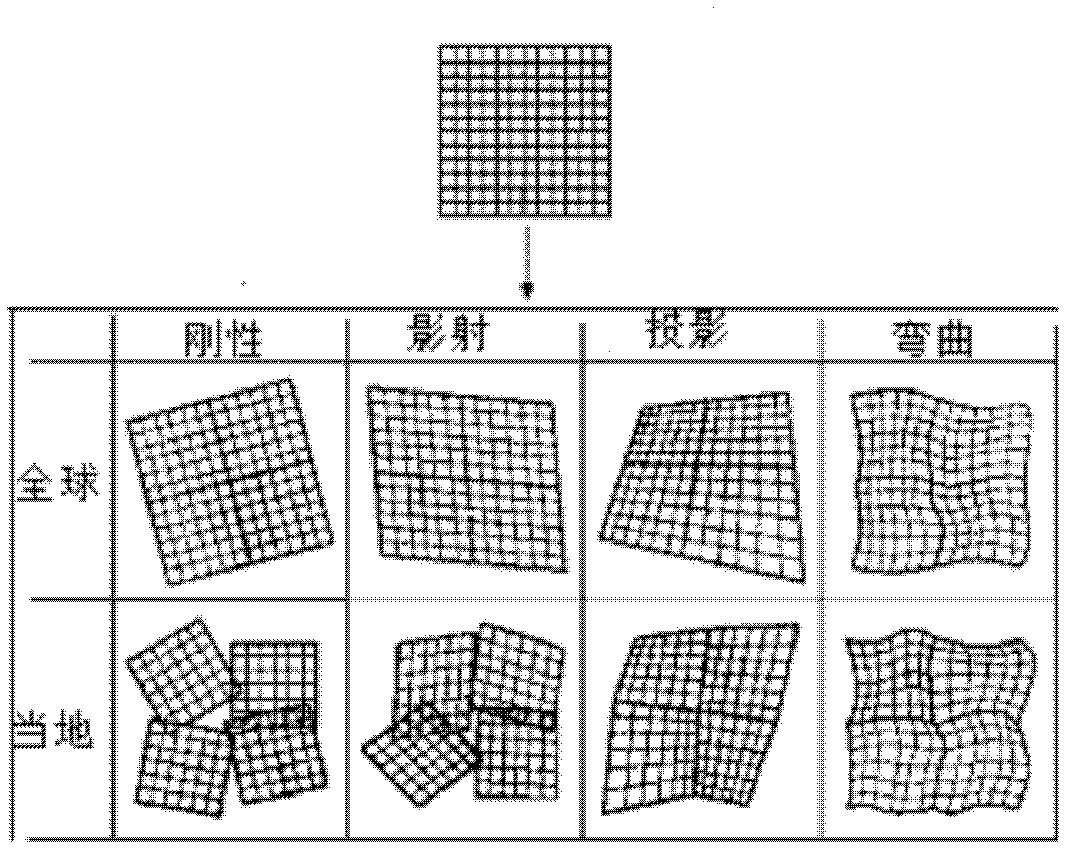

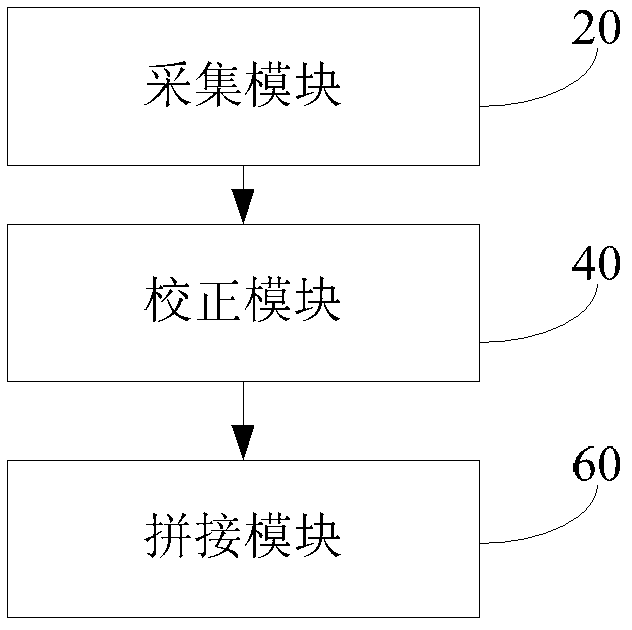

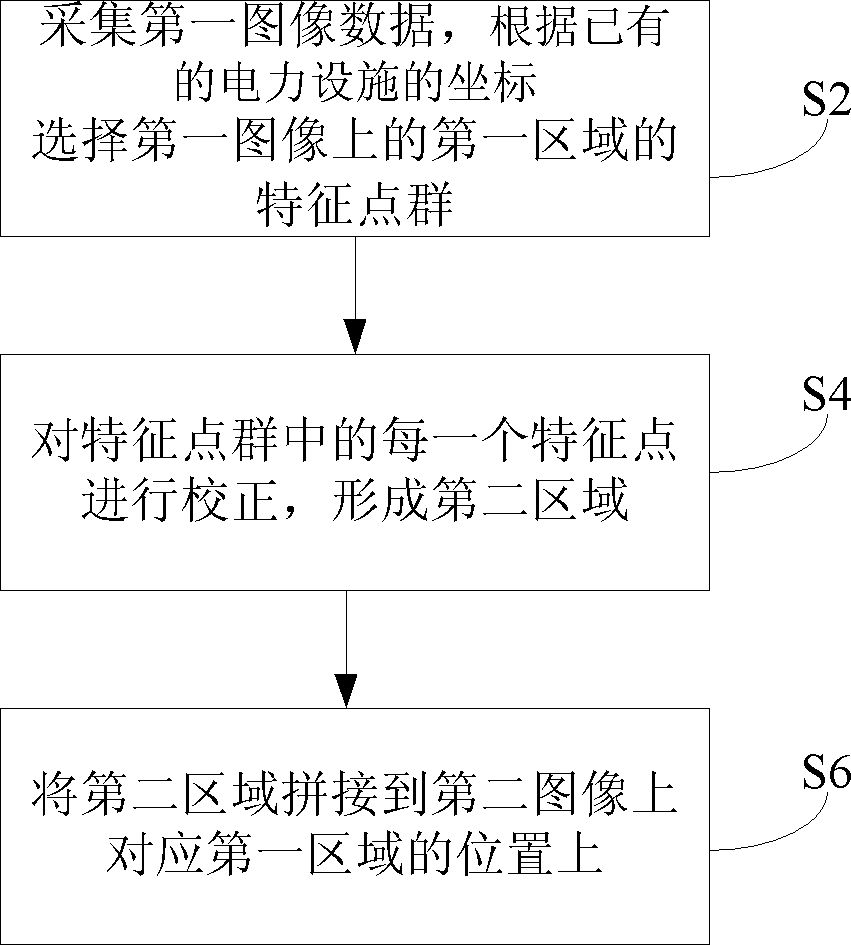

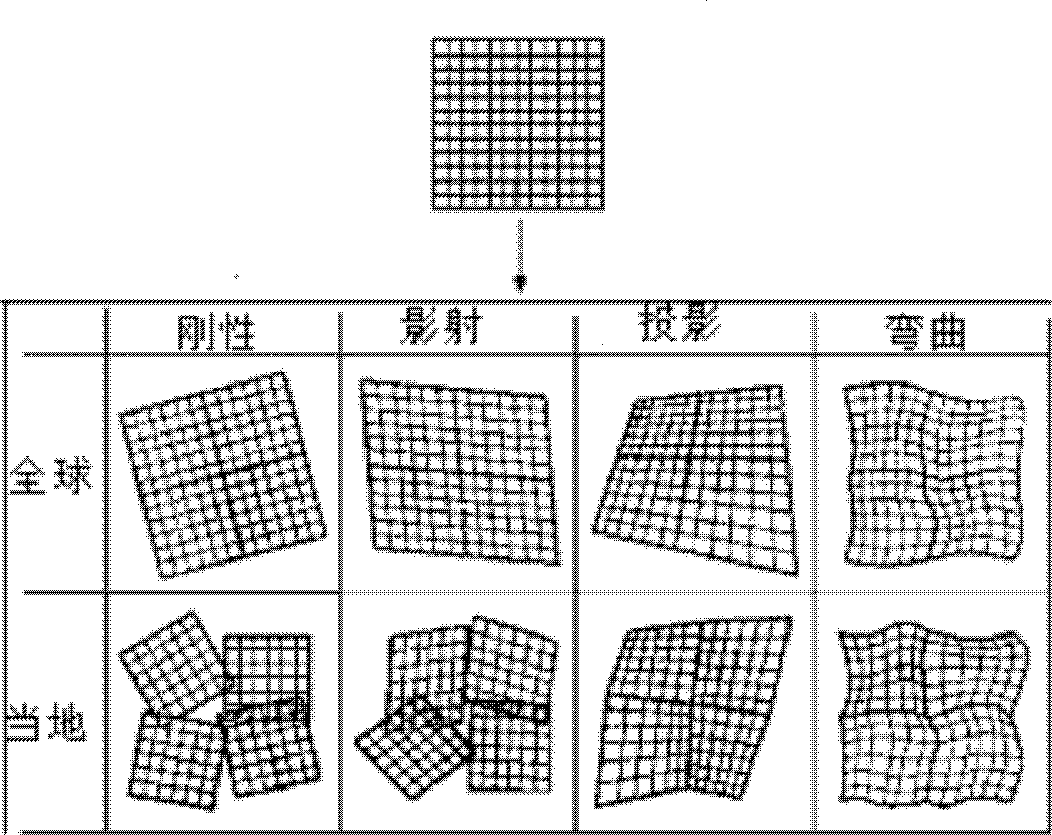

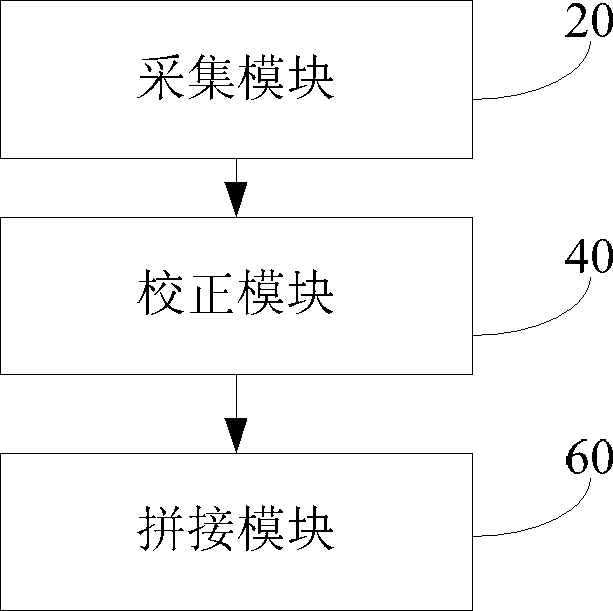

Method and device for splicing characteristic point correction partitions

ActiveCN102324096AAddressing Digital ConvergenceMeet the use requirementsImage analysisEditing/combining figures or textImaging dataGeologic map

The invention provides a method for splicing characteristic point correction partitions and is used for solving the problem of digital convergence of historical precious drawings in the prior art. The method comprises the following steps of: 2, acquiring first image data, and selecting a characteristic point group of a first area on a first image according to a preset coordinate; 4, correcting each characteristic point in the characteristic point group, and thus forming a second area; and 6, splicing the second area at a position, corresponding to the first area, on a second image. By adoption of the technical scheme of the invention, the problem of the digital convergence of various kinds of paper drawings which are accumulated over the years and include paper geologic maps with different time, different dryness and humidity and different scales can be effectively solved, the paper drawings can be accurately superposed and converged with geologic, geographic and grid vector data, and use requirements of stages such as scanning, designing, construction, running and maintenance on geologic information are met.

Owner:STATE GRID CORP OF CHINA +1

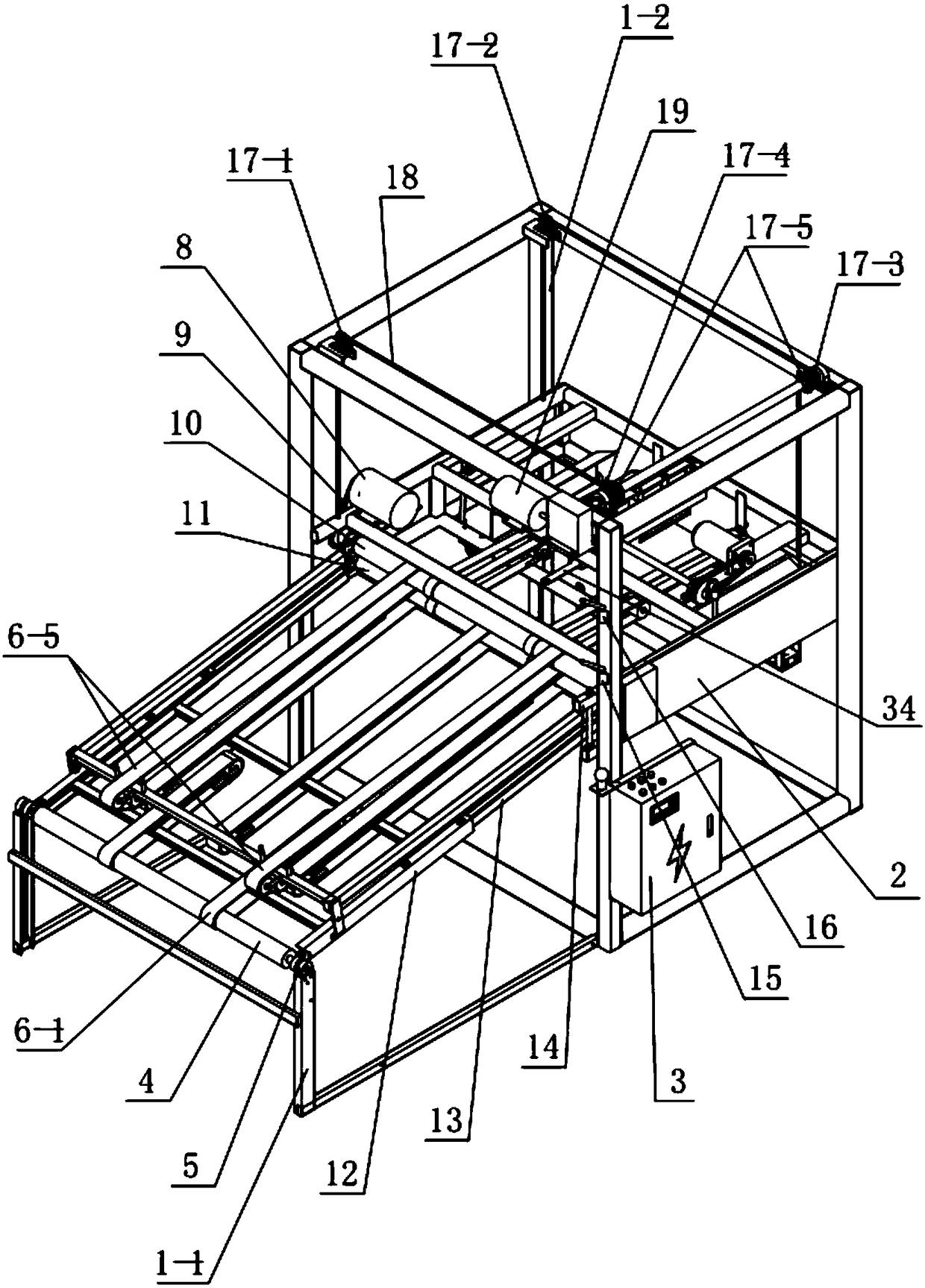

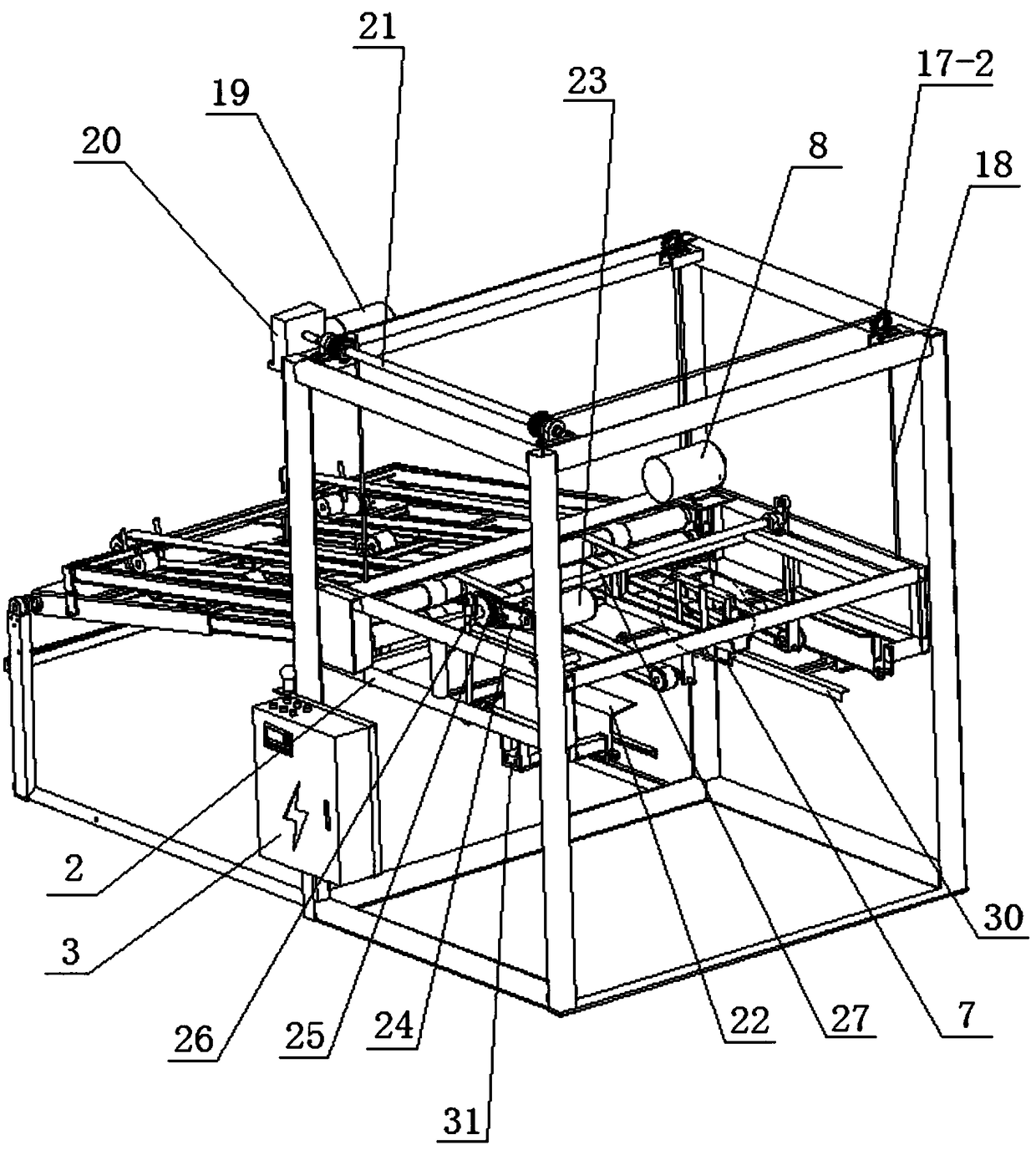

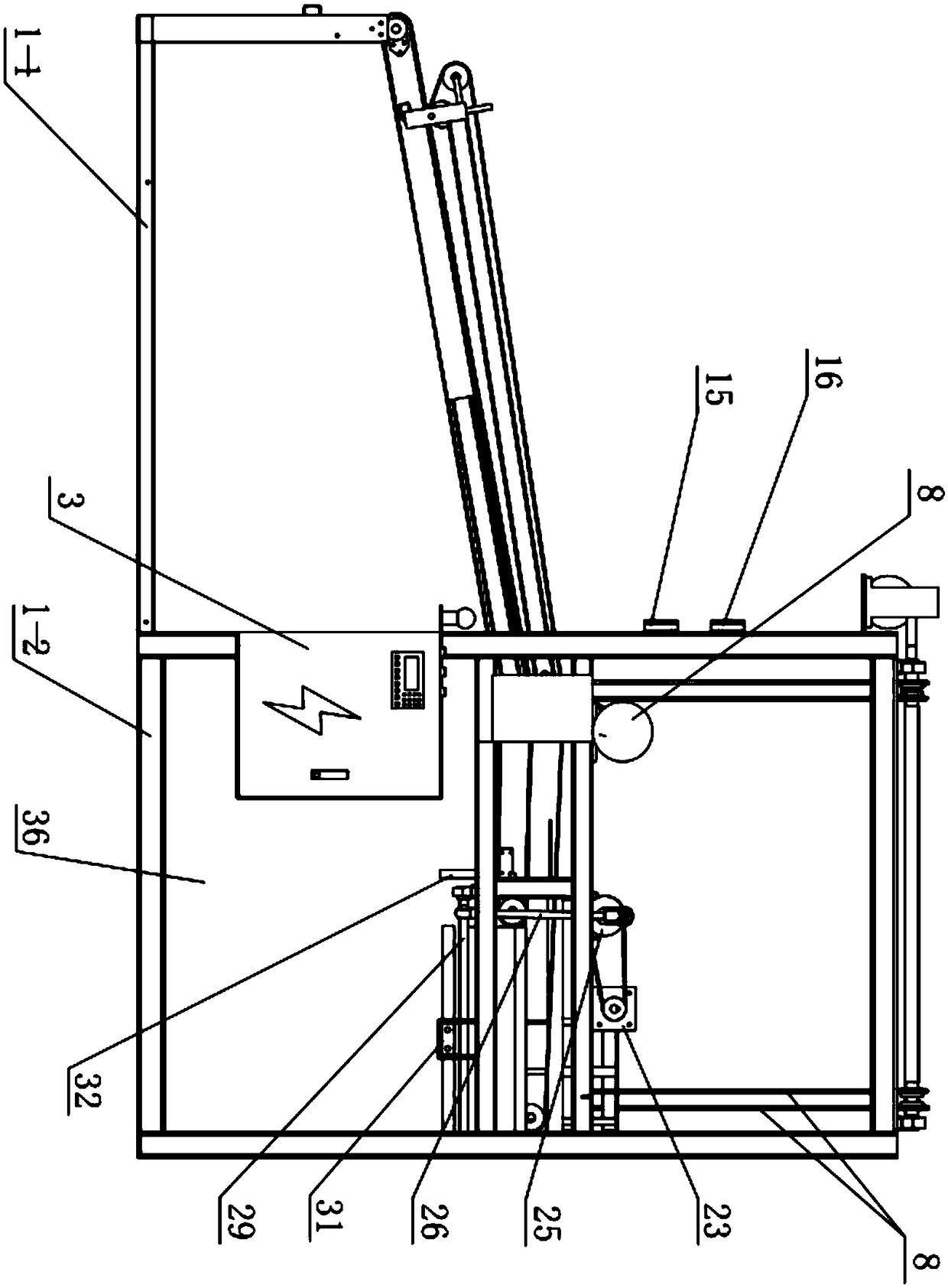

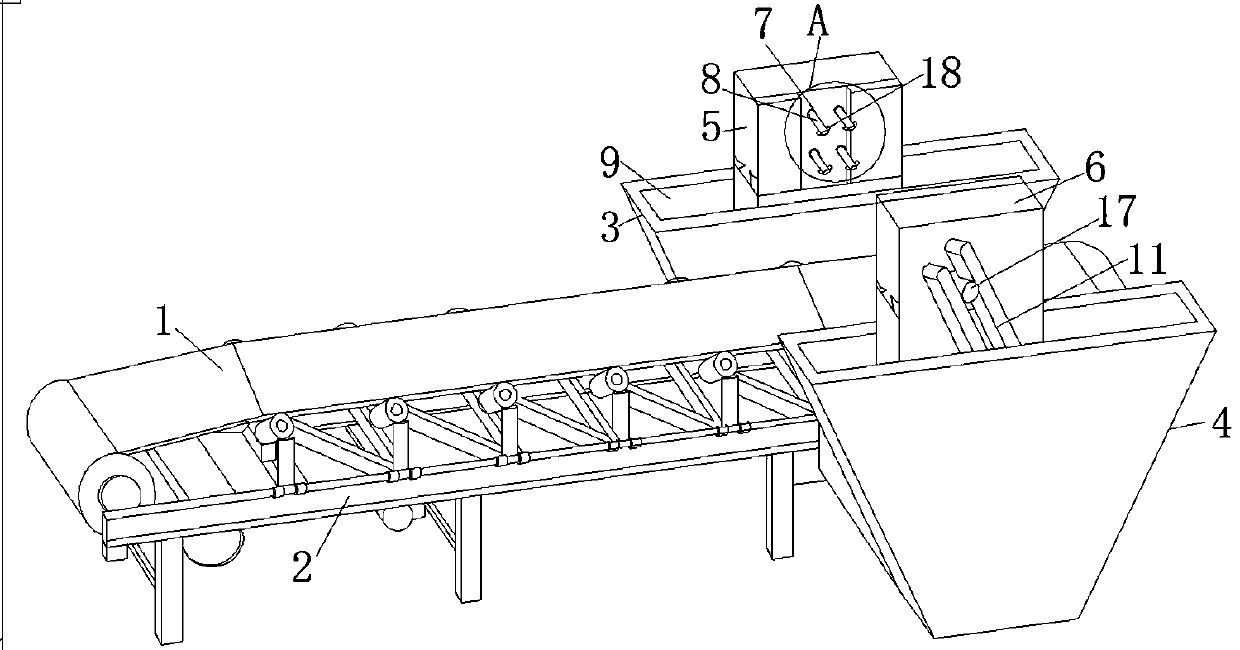

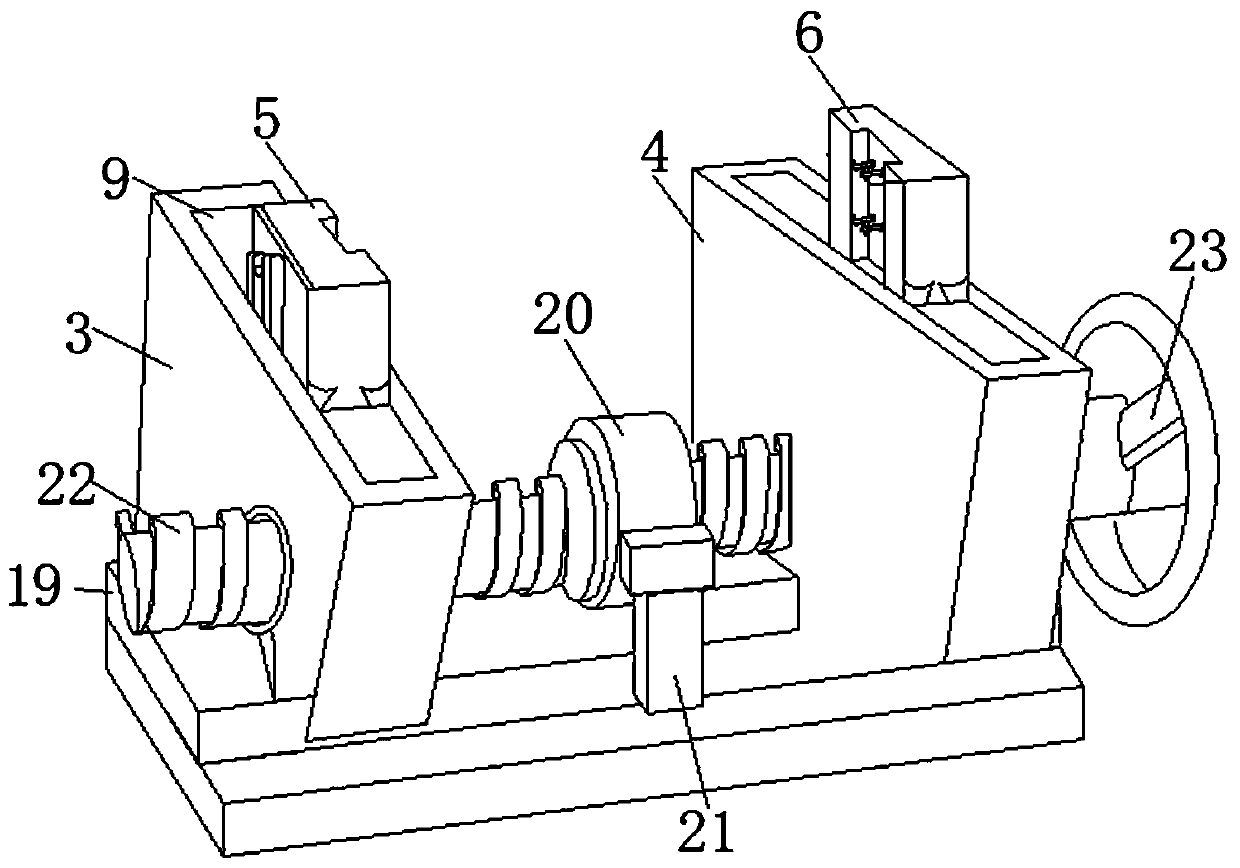

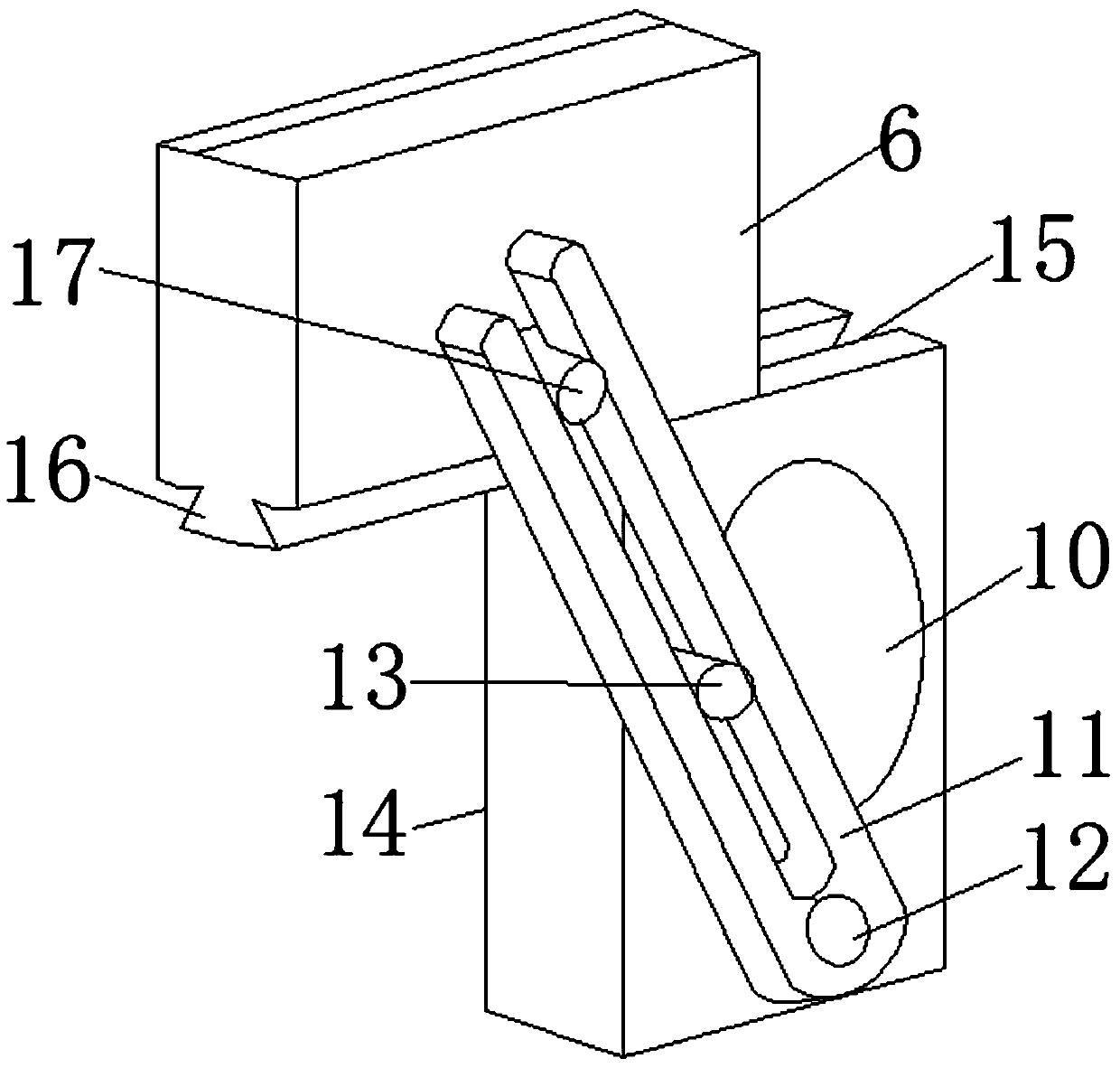

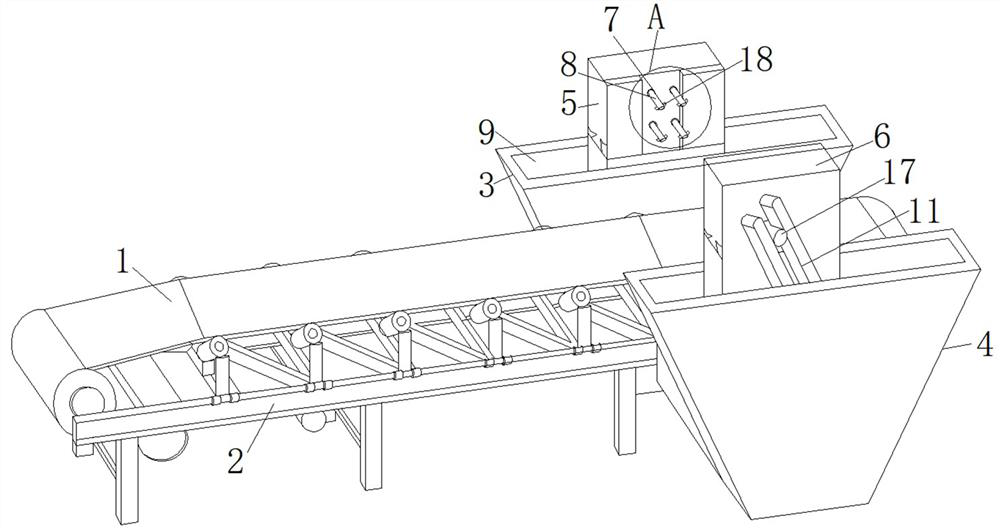

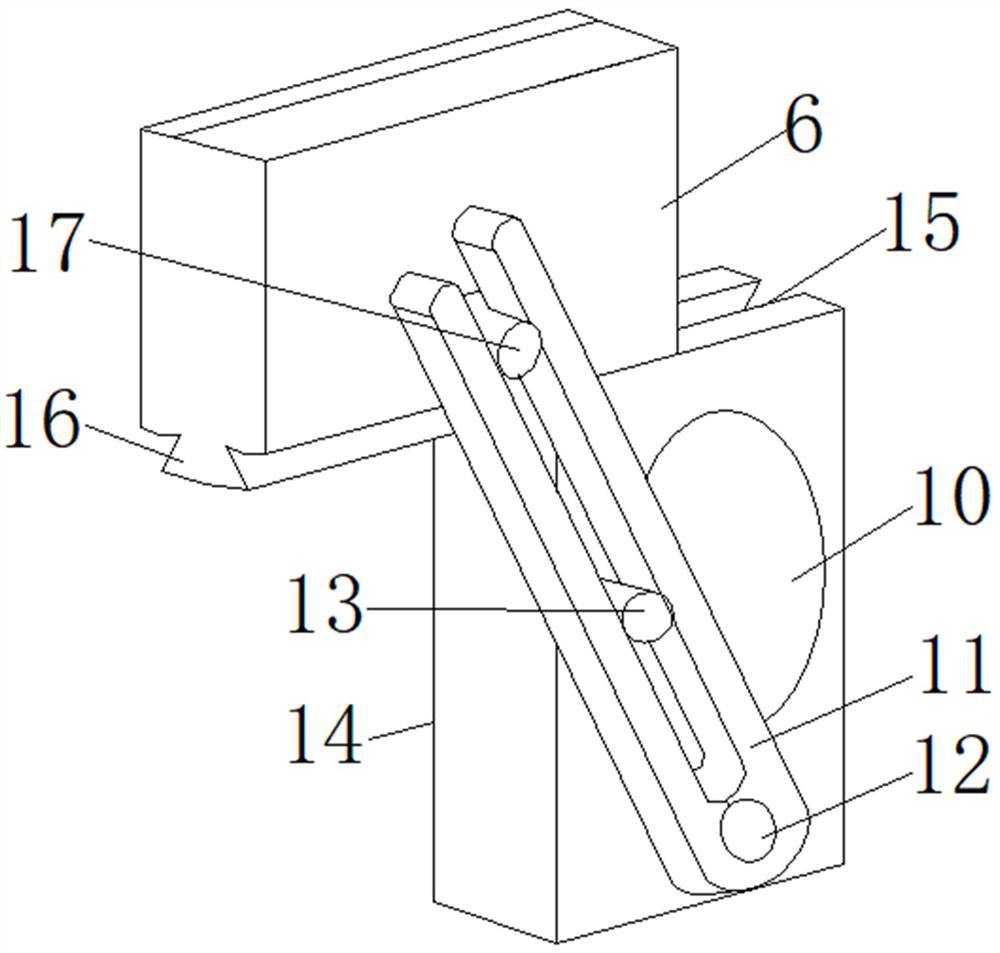

Automatic palletizing machine

PendingCN109095191AAccurate OverlayAccurately undertakeConveyorsStacking articlesDrive shaftEngineering

The invention discloses an automatic palletizing machine. The automatic palletizing machine is provided with a board receiving mechanism mainly composed of a board receiving device, a downward pressing device and temporary board receiving devices symmetrically arranged on two sides of the output end of a conveying mechanism. When the machine is in work, a transmission shaft is driven to rotate bya third driving device, so that a crank connection rod component connected with a rotation shaft drives clamping boards to do reciprocating actions of opening or closing, and thus a board can be accurately clamped, meanwhile the arranged downwards pressing device presses downwards, the board is effectively pressed down and palletized, and the board is prevented from blocking the machine. Therefore, the board receiving mechanism adopted by the invention can accurately carry and effectively level the boards, automatically and orderly palletize the boards, and also can solve the technical problems that the boards cannot be palletized due to the fact that the surfaces of the boards are uneven, and the boards deviates during a conveying process; and palletizing of the boards adopts a way of receiving the boards from the bottom up, so that the machine has the advantages of being good in palletizing effect, prevented from being blocked, not easy to wear and high in security performance.

Owner:广西腾森自动化设备有限公司

Identity card copy anti-counterfeiting method and special template

InactiveCN102189862AWith anti-counterfeiting functionPrevent handlingDuplicating/marking methodsSpecial ornamental structuresFixed positionOperating system

The invention discloses an identity card copy anti-counterfeiting method and a special template. The special template consists of special copy paper which is specially printed with patterns and words and of which the frame is provided with small holes and a transparent film, wherein a window is formed at a relatively fixed position of the transparent film. The method comprises the following steps of: placing an identity card in the window when the template is used; copying by using the special copy paper, wherein the patterns, the words and the frame small holes on the special copy paper are staggered and superposed with text information on the identity card; and finally acquiring an anti-counterfeit identity card copy. By the anti-counterfeiting method, the identity card copy cannot be separated from the copied special copy paper, so that the identity card copy can be prevented from counterfeiting.

Owner:赵利军

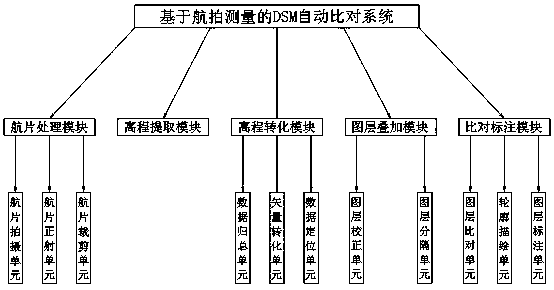

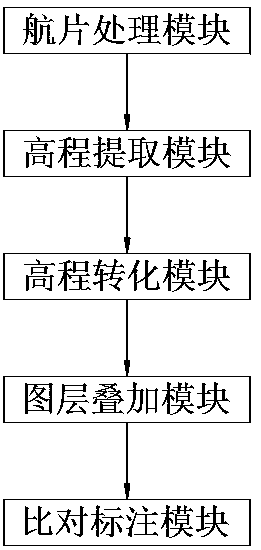

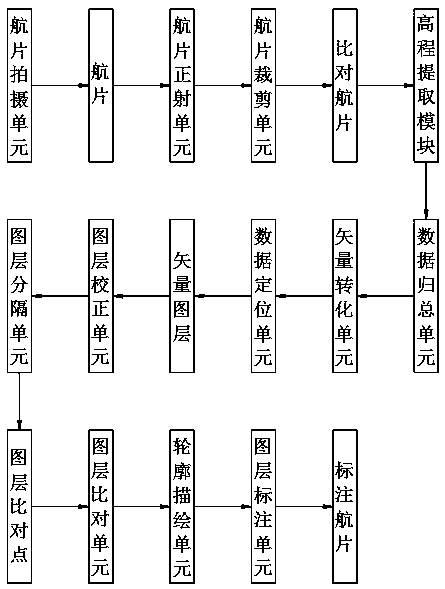

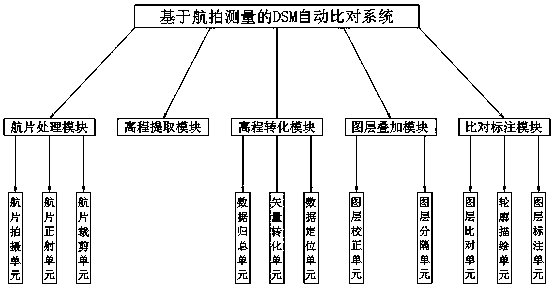

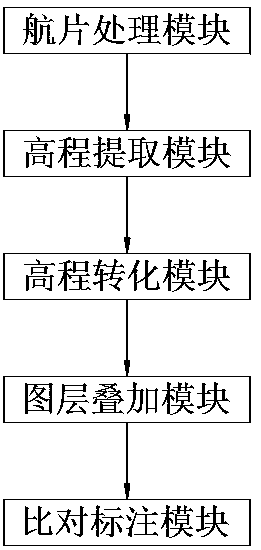

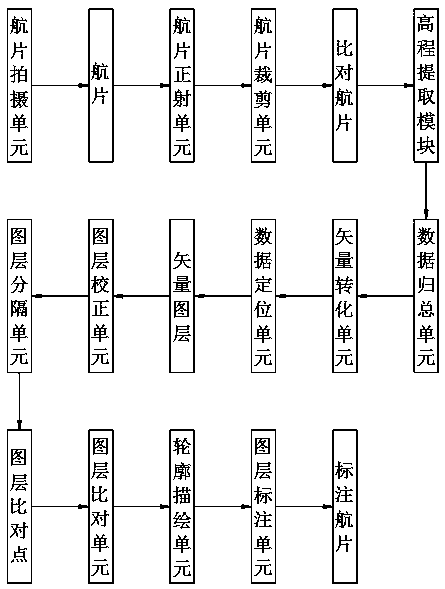

DSM automatic comparison system based on aerial photography measurement

ActiveCN111401345AImprove comparison efficiencyShorten the timeImage enhancementImage analysisEngineeringAerial photography

The invention discloses a DSM automatic comparison system based on aerial photography measurement, and belongs to the technical field of aerial photography measurement. The system comprises an elevation extraction module, an elevation conversion module, a layer superposition module and a comparison labeling module; the elevation extraction module is used for extracting elevation data of the two stages of aerial photos processed by the aerial photo processing module; the elevation conversion module is used for converting the elevation data of the two-stage aerial photo extracted by the elevation extraction module into a vector layer; the layer superposition module is used for performing superposition processing on vector layers of the two stages of aerial photos; the comparison labeling module is used for labeling areas with changes in the two-stage aerial photo vector layers. According to the invention, the method is scientific and reasonable, is suitable for large-scale aerial photo inspection and comparison, greatly shortens the inspection and comparison time, greatly reduces the manpower investment, can more accurately discover the existence of illegal buildings, is higher in comparison pertinence, and can achieve the effect of screening buildings with different areas through the adjustment of various numerical values.

Owner:常州市新翼空间信息科技有限公司

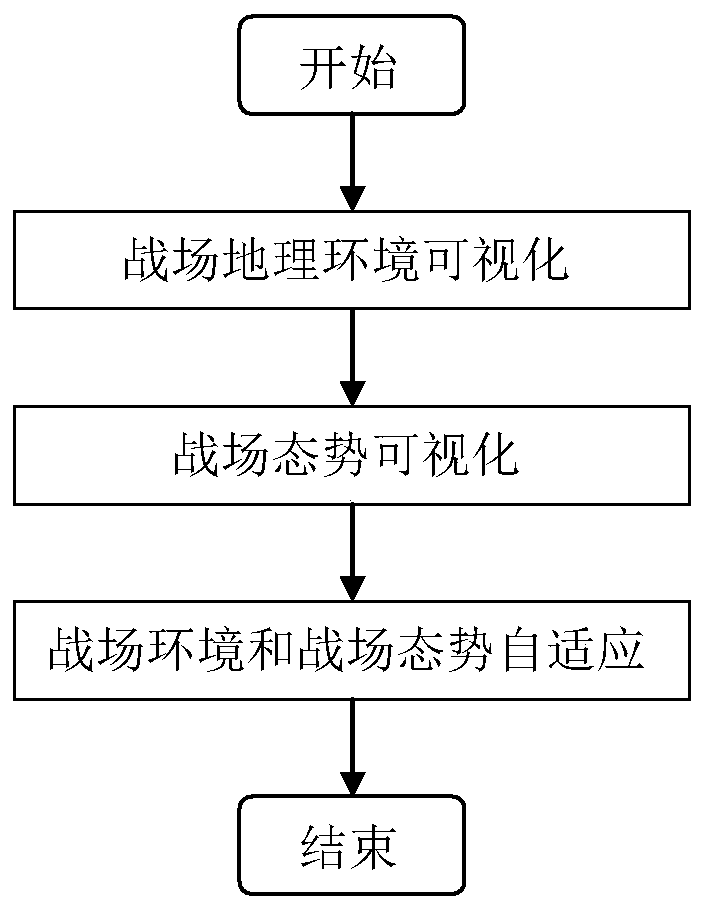

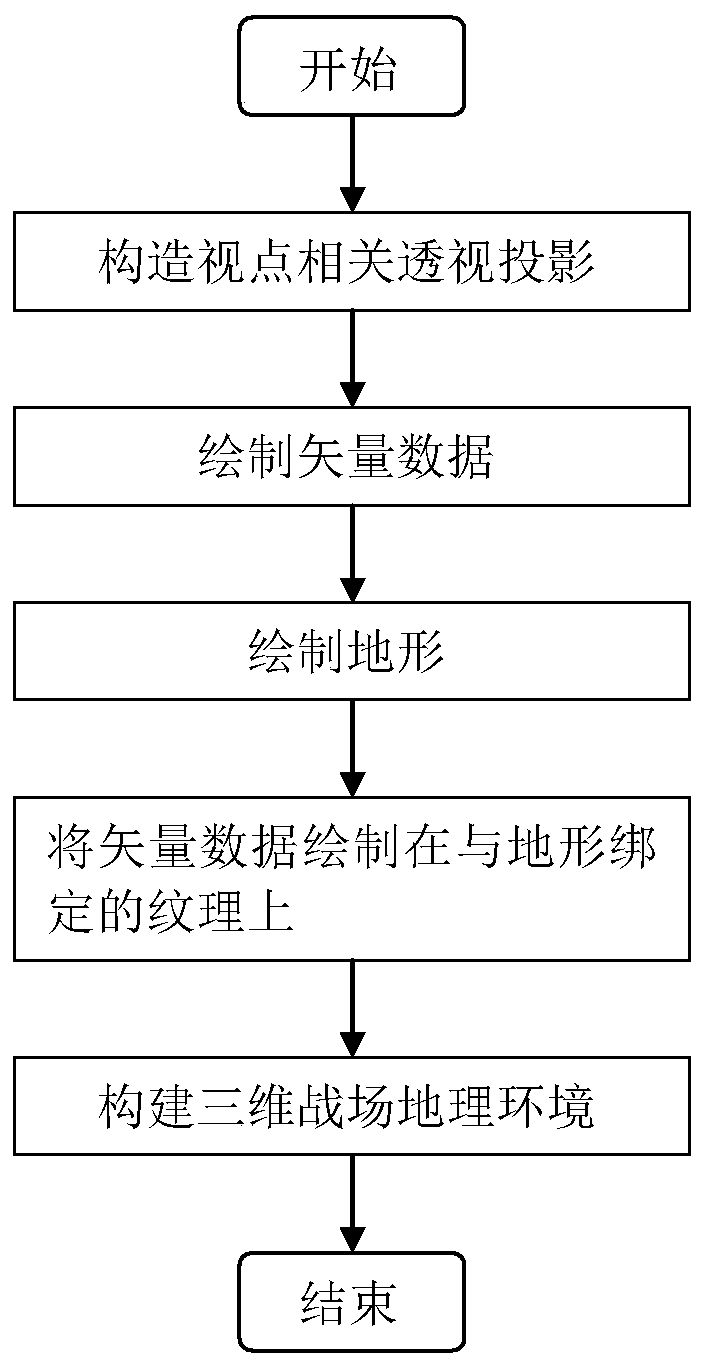

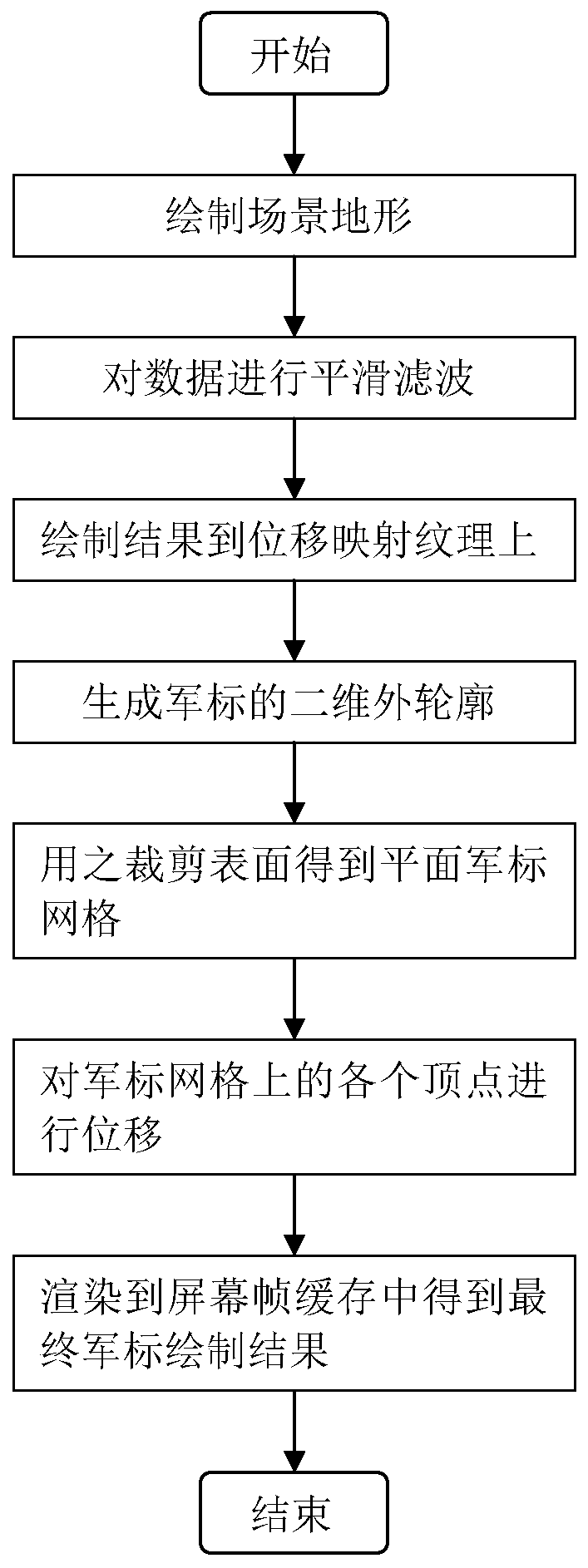

Visual generation method of self-adaptive combat scene

PendingCN111145348ARealize visualizationAchieve followCharacter and pattern recognitionImage generationInteractive editingEngineering

The invention provides a visual generation method of a self-adaptive combat scene. The method comprises steps of obtaining perspective projection of a current terrain visual range through a scene viewpoint; drawing the two-dimensional vector data of the current terrain on the texture bound with the terrain in real time through perspective projection so that a three-dimensional battlefield geographical environment is formed; carrying out displacement on vertexes on military mark grids according to textures bound with terrains, and rendering the vertexes into a screen frame cache to obtain a final military mark drawing result, so that visualization of battlefield situations is achieved, and self-adaptation is conducted on the battlefield environment and the battlefield situations. Accordingto the invention, visualization of battlefield situation is realized, three-dimensional terrain following of the irregular military standard can be realized, the operation efficiency is high, and thereal-time requirements of interactive editing and dynamic deduction can be met.

Owner:扬州船用电子仪器研究所

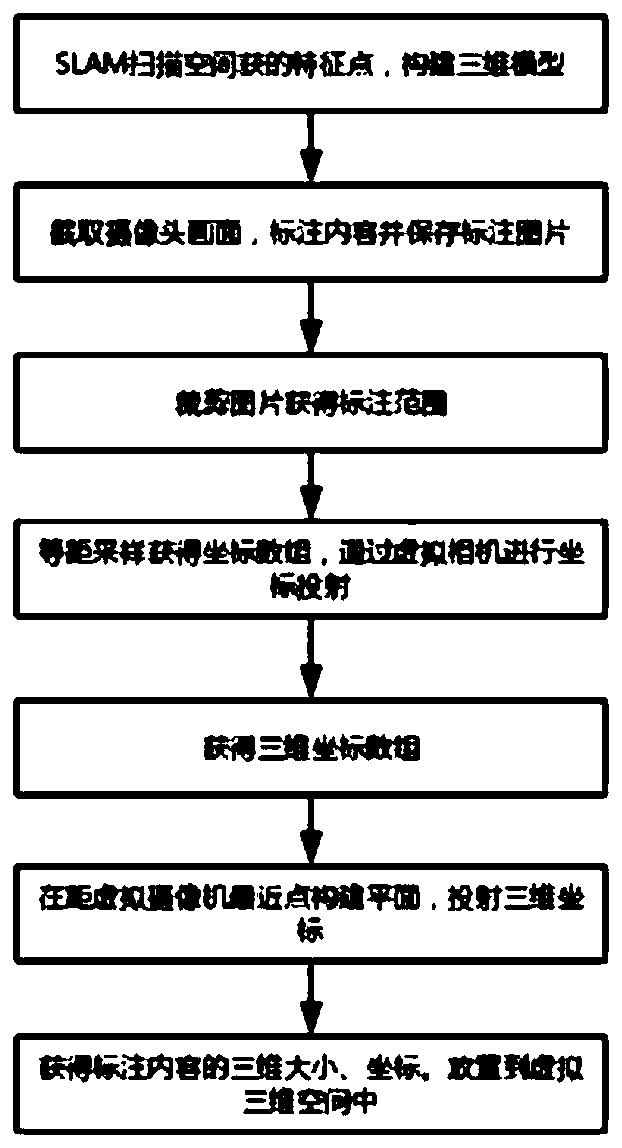

Spatial labeling method based on SLAM

The invention discloses a space labeling method based on SLAM. The method comprises the steps of performing two-dimensional mapping on a two-dimensional map subjected to remote labeling; carrying outspace conversion based on an SLAM technology; accurately placing the two-dimensional plane content marked by an expert at the position of the three-dimensional virtual space corresponding to the expert; and finally, rendering the three-dimensional virtual space through glasses equipment. The imaging effect of the human eyes is overlapped with the real scene through the glasses, and finally the effect seen by a user is completely consistent with the position marked by the expert. The change along with the position change of the user is avoided. According to the spatial labeling method based onthe SLAM, the labeling content is converted into a three-dimensional space placement map from a two-dimensional plane labeling map; the three-dimensional space placement map is accurately superposedin a real three-dimensional space, and a labeling target is followed in real time; labeling positions and information can be visually seen; and text or language expressions are omitted.

Owner:上海世长信息科技有限公司

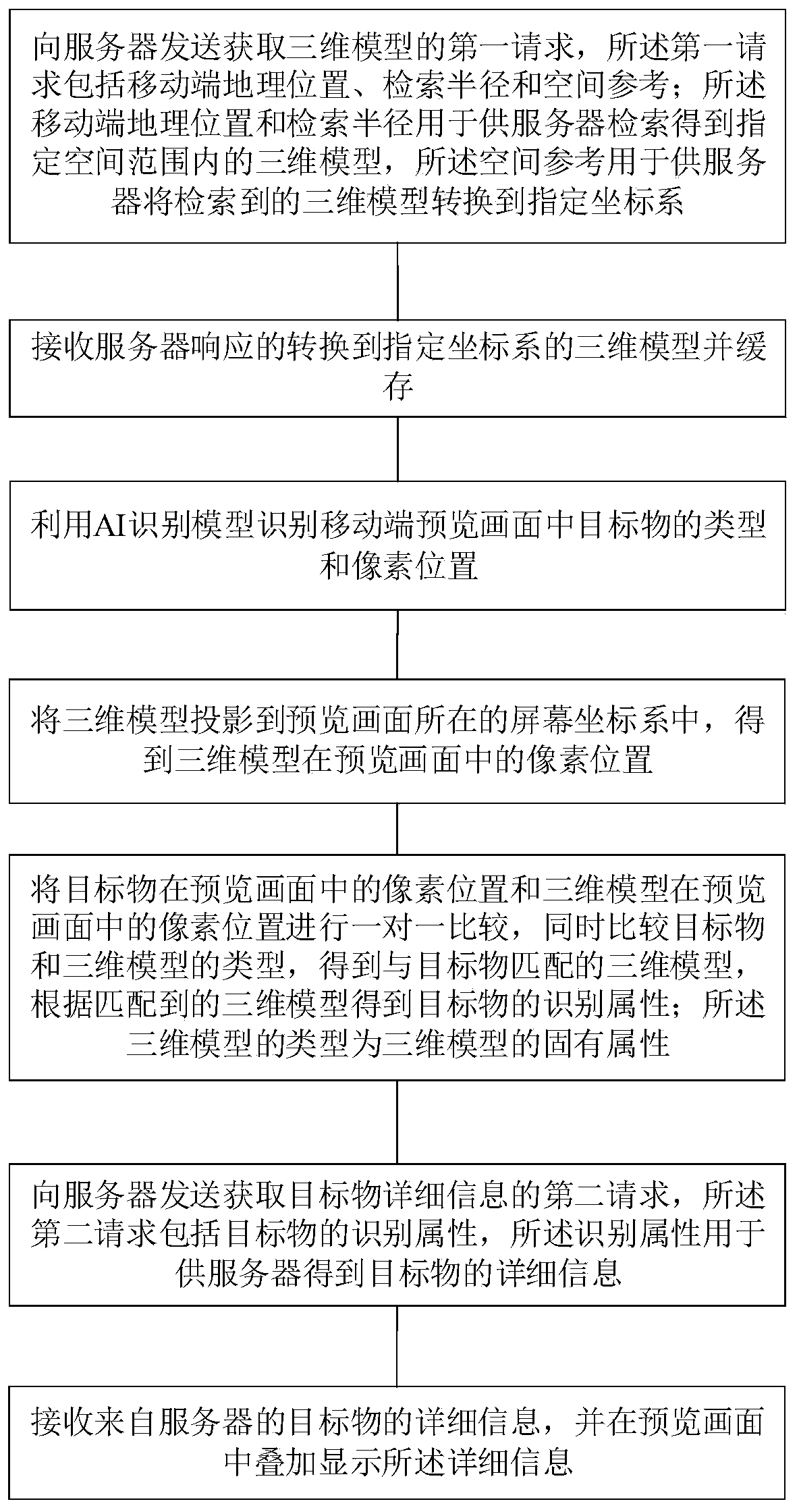

Mobile terminal augmented reality method and system based on target detection and spatial projection

ActiveCN110196638AReduce productionReduce storageInput/output for user-computer interactionImage data processingTerminal equipmentSimulation

The invention discloses a mobile terminal augmented reality method and system based on target detection and spatial projection. The system comprises a mobile terminal and a server. According to the system, the machine learning is utilized to identify a target ground object needing to be displayed in an enhanced manner, then the space calculation is used for matching the target ground object and the three-dimensional model of the target ground object, and finally the other information of the target ground object is retrieved according to the three-dimensional model, so that the virtual information is accurately superposed into a shot picture to realize an augmented reality effect, and the three-dimensional model uses a simplified model to reduce the model manufacturing, storage and processing costs. The method and the system can be completed by using a single mobile terminal device without using the additional auxiliary devices, so that the use difficulty is reduced.

Owner:CETHIK GRP

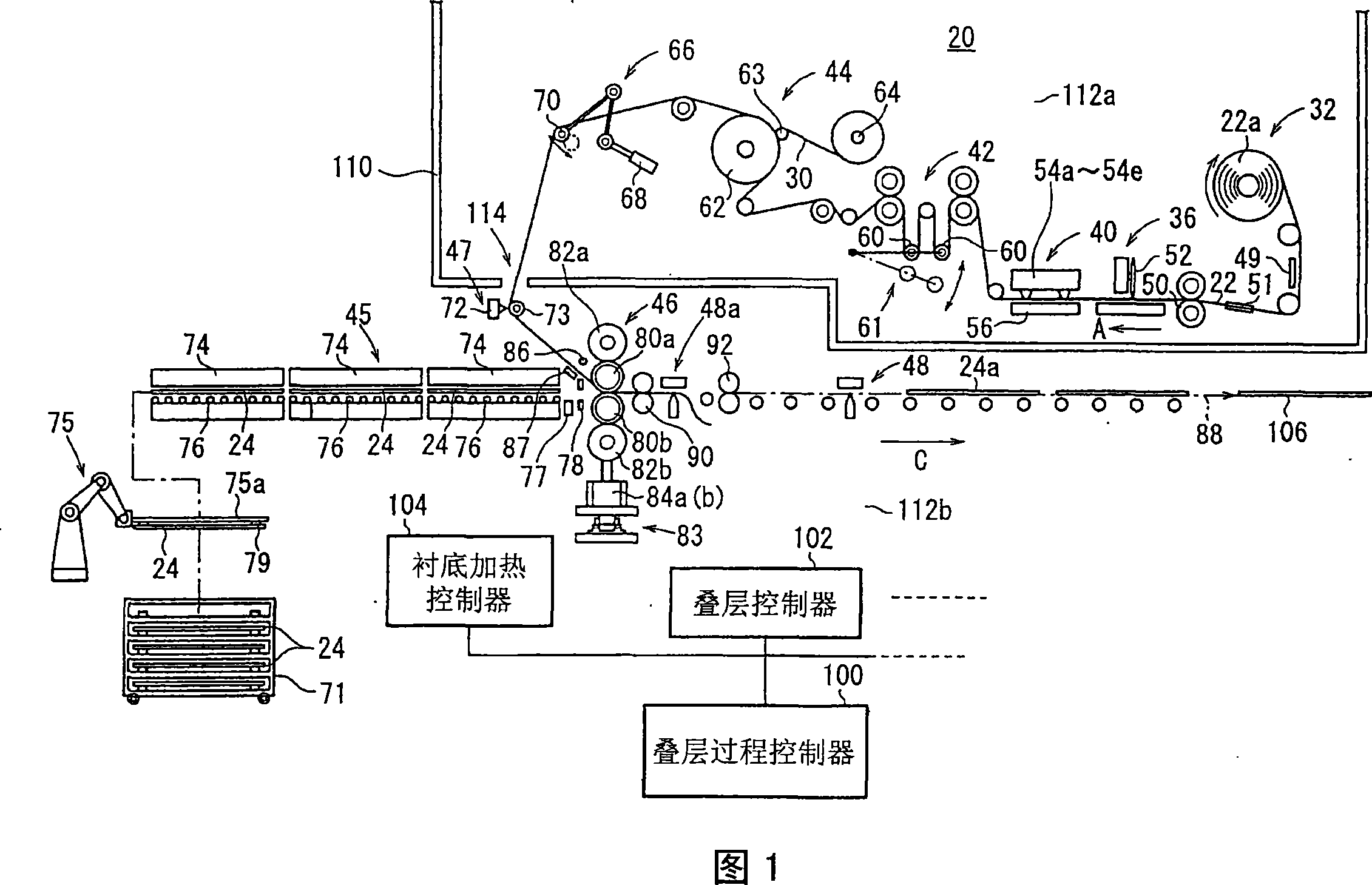

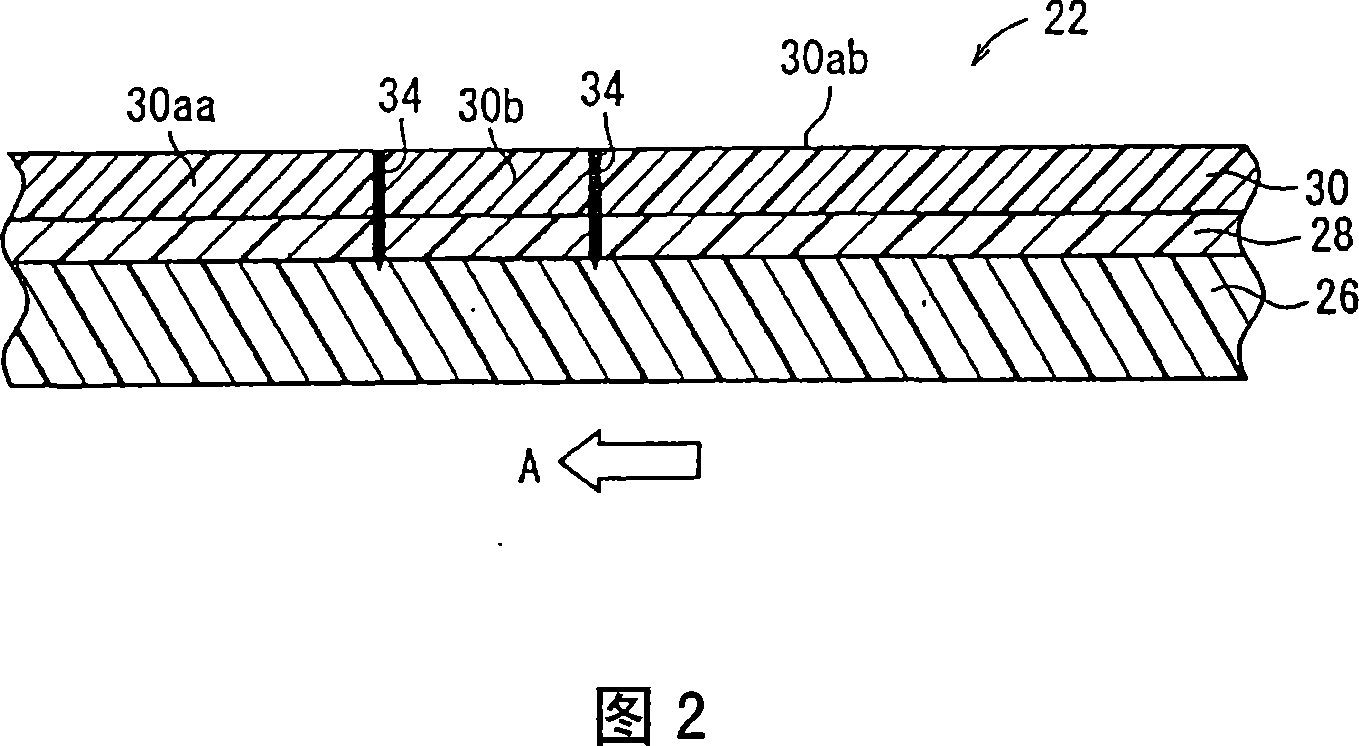

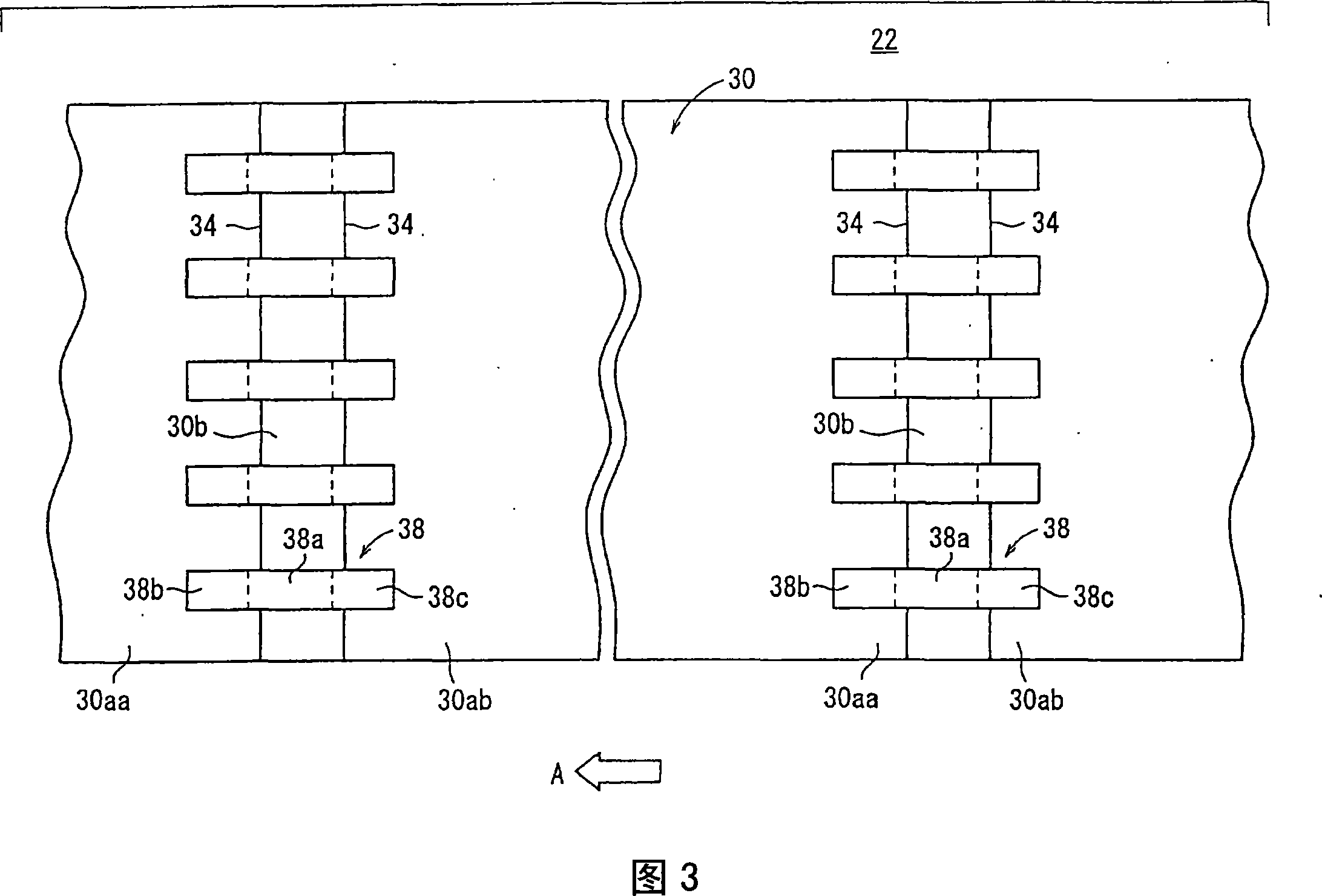

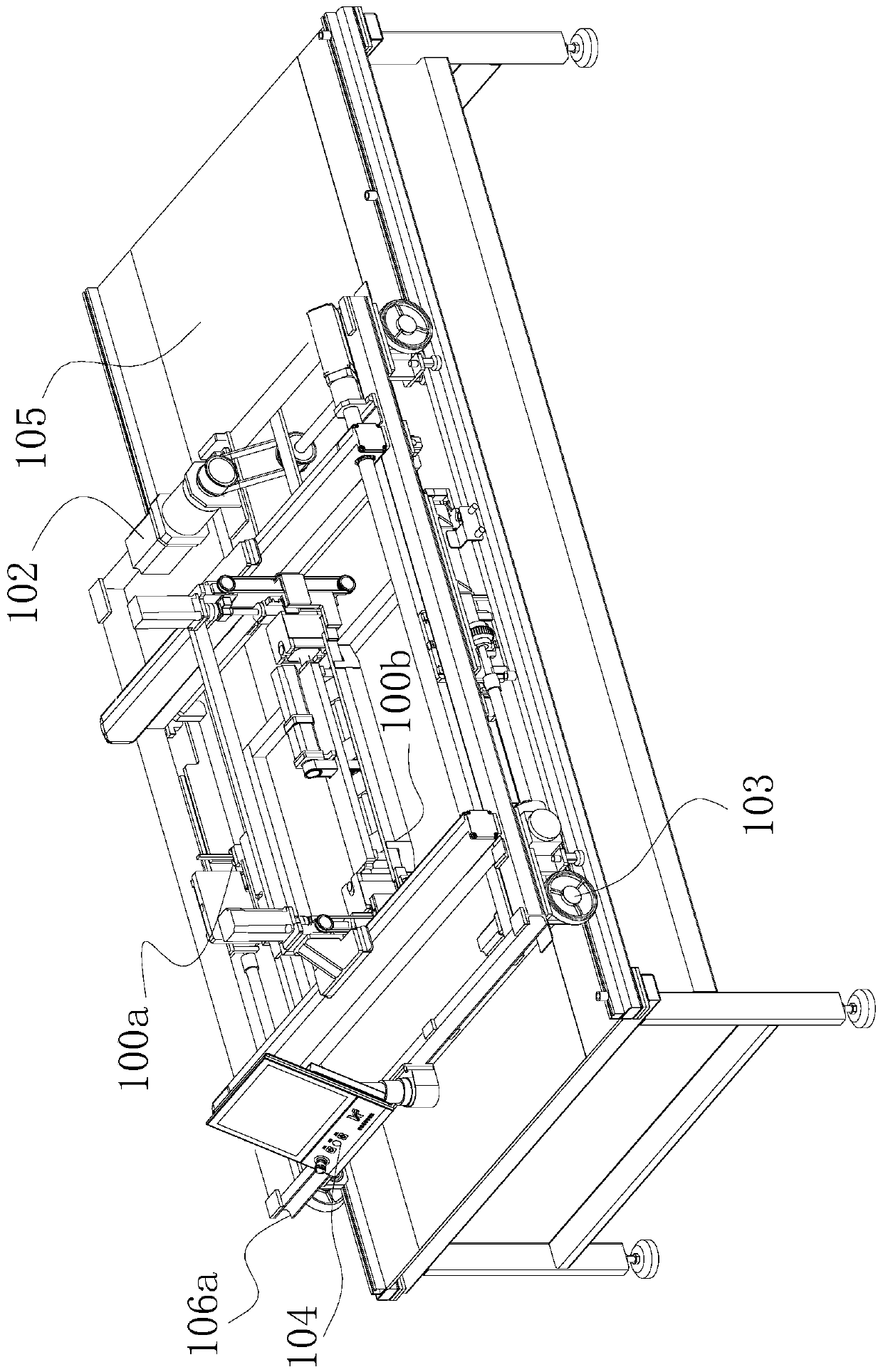

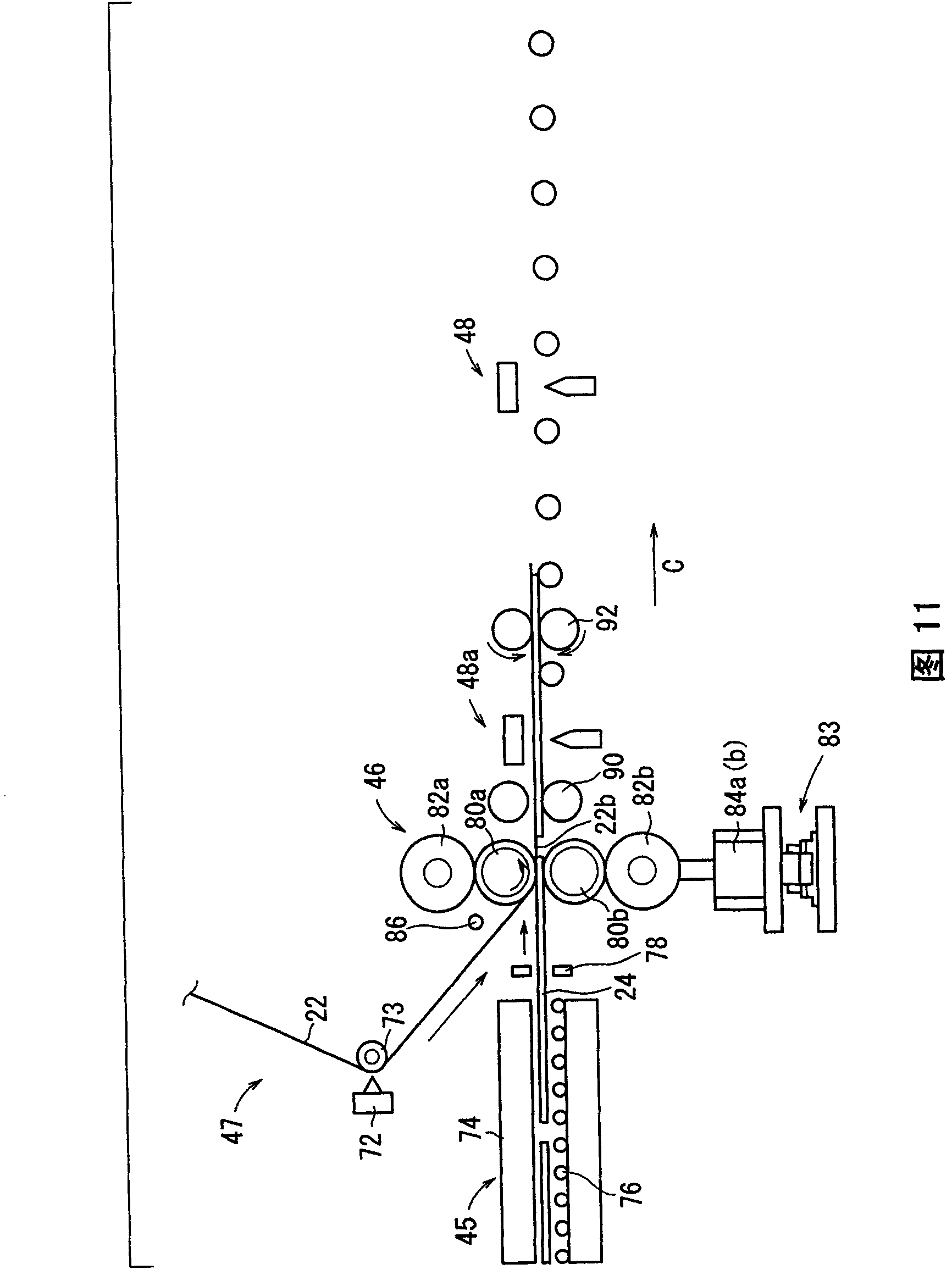

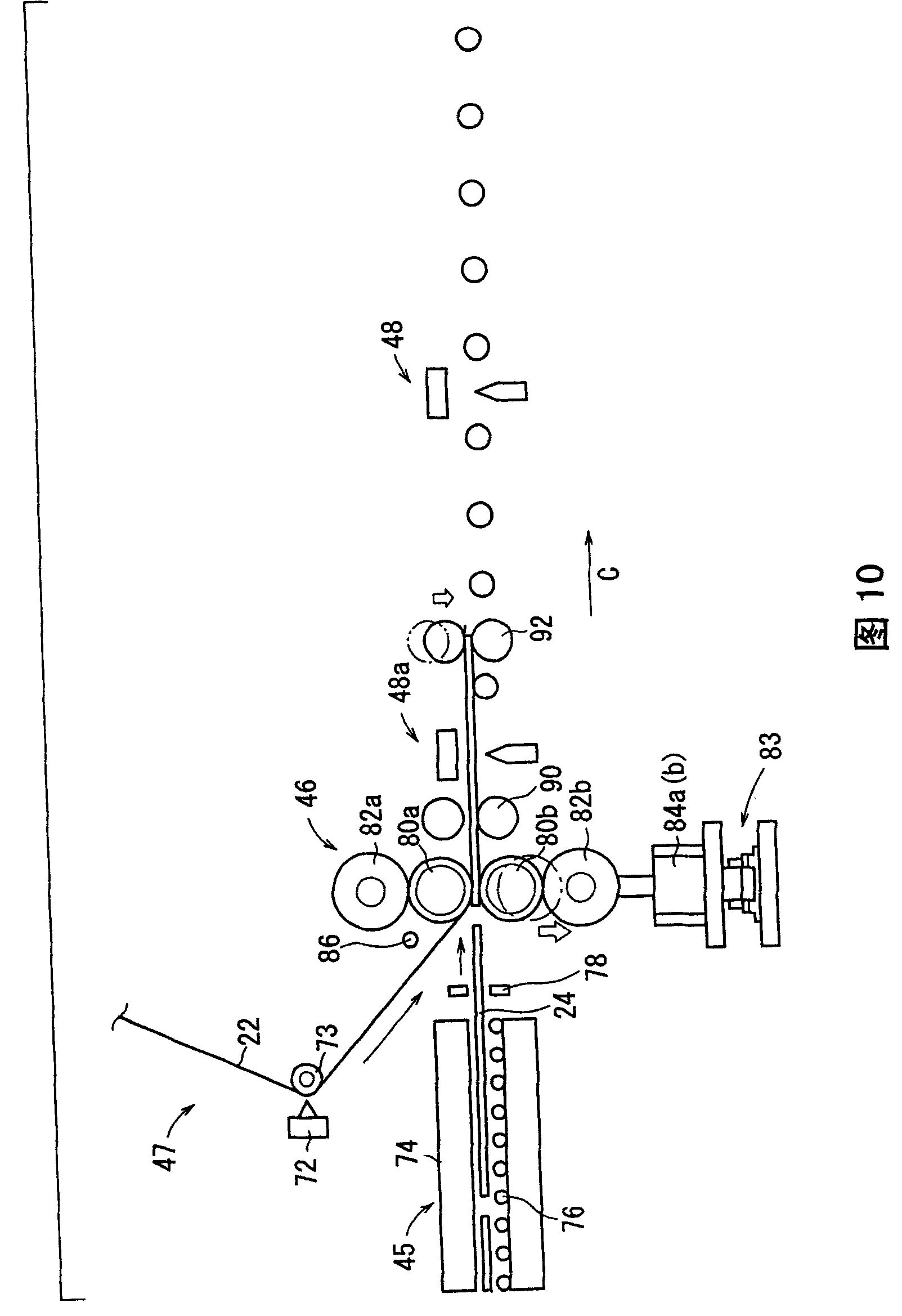

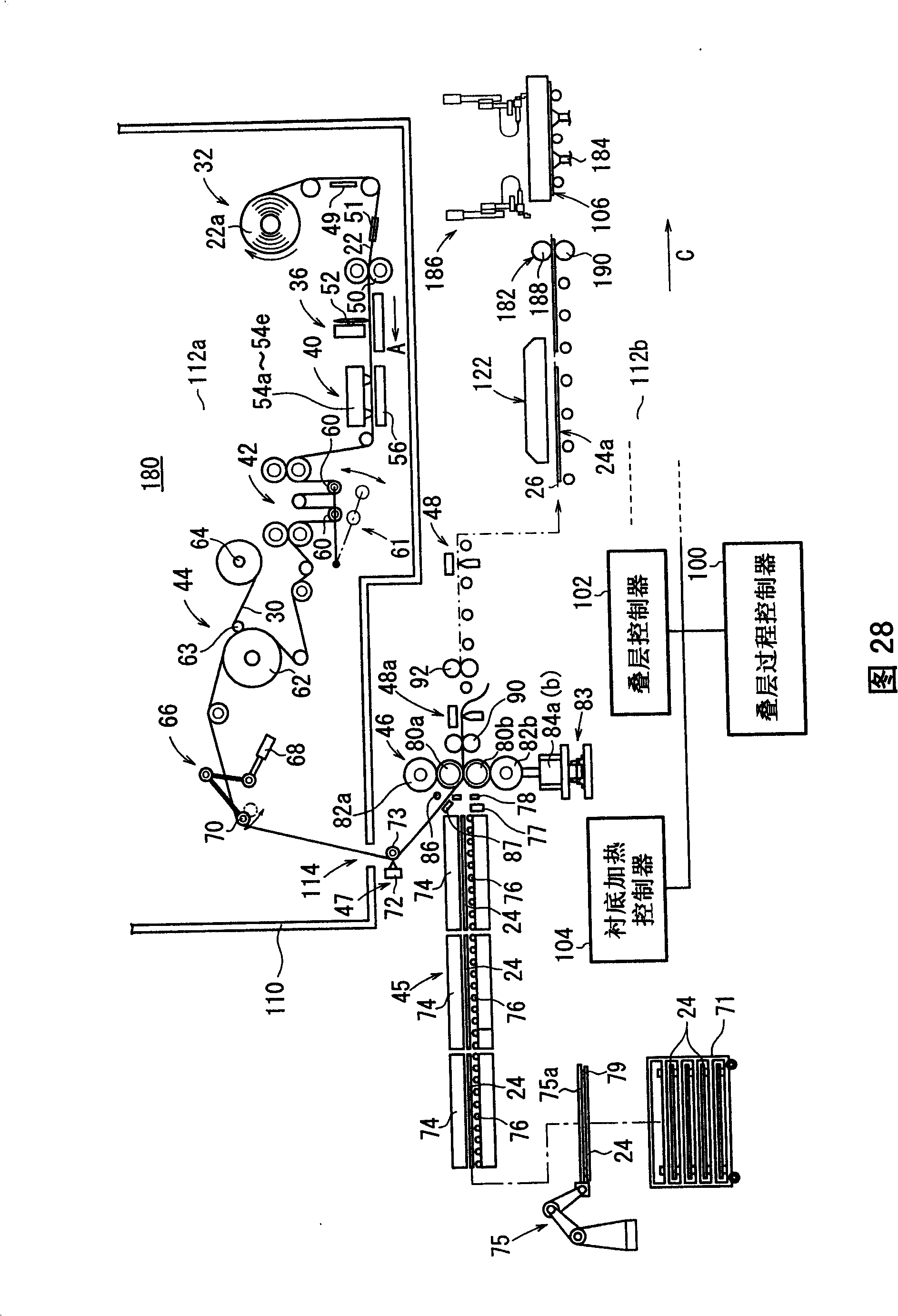

Apparatus and method for manufacturing photosensitive laminate

InactiveCN101146681AAccurate OverlayQuality improvementLamination ancillary operationsLaminationManufactured apparatusGlass transition

A manufacturing device (20), comprising a discharge mechanism (32), a processing mechanism (36), a label bonding mechanism (40), a storage mechanism (42), a peeling mechanism (44), a substrate feeding mechanism (45), a stacking mechanism (46) and substrate stripping mechanism (186). The cooling mechanism (122) is arranged between the stacking mechanism (46) and the substrate peeling mechanism (186), and is used for cooling the stacked substrate (24a), which is made of the glass substrate (24) and stacked thereon Consists of a photosensitive sheet (22), a protective film (30) peeled from the overlay substrate (24a), and a heating mechanism (182) for heating a resin layer such as a backing layer (27) to a predetermined temperature range, the resin The layers are inside the cooled superimposed substrate (24a), in the temperature range of the glass transition temperature or a temperature below the glass transition temperature.

Owner:FUJIFILM CORP

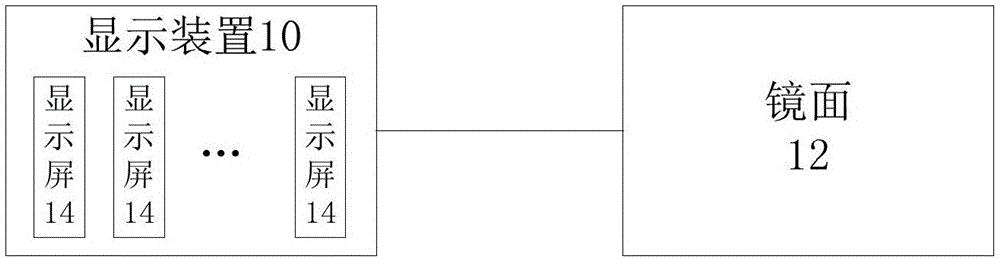

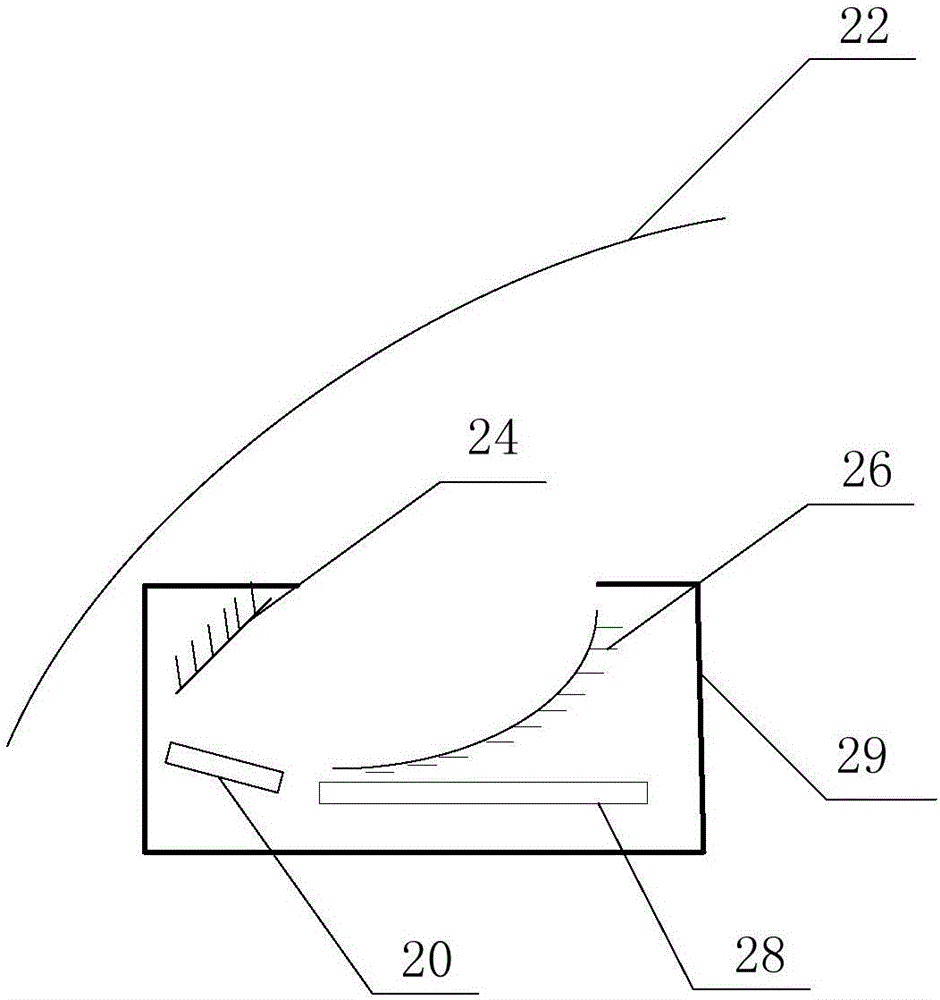

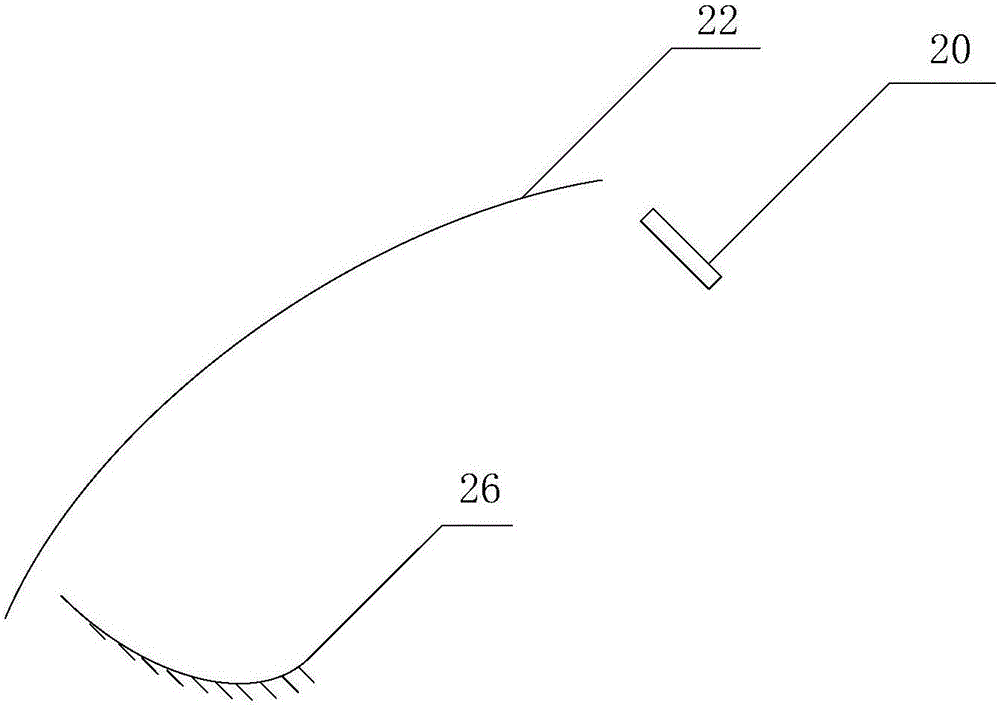

Vehicle-mounted head up display device, system and augmented reality method

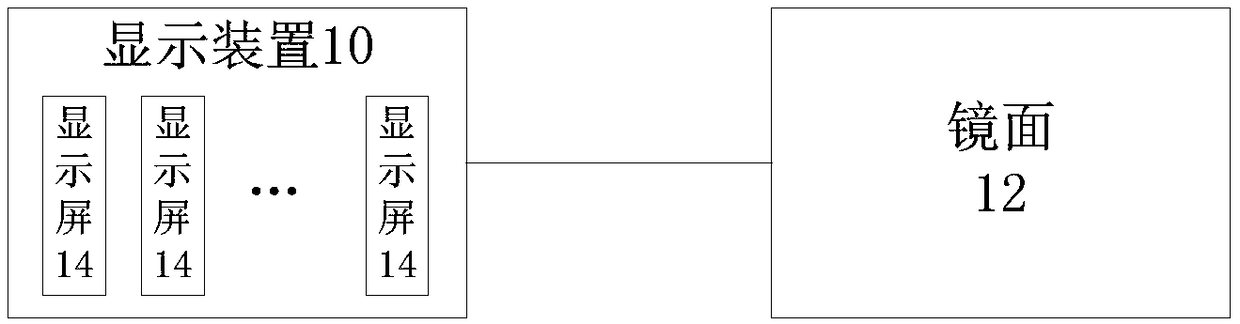

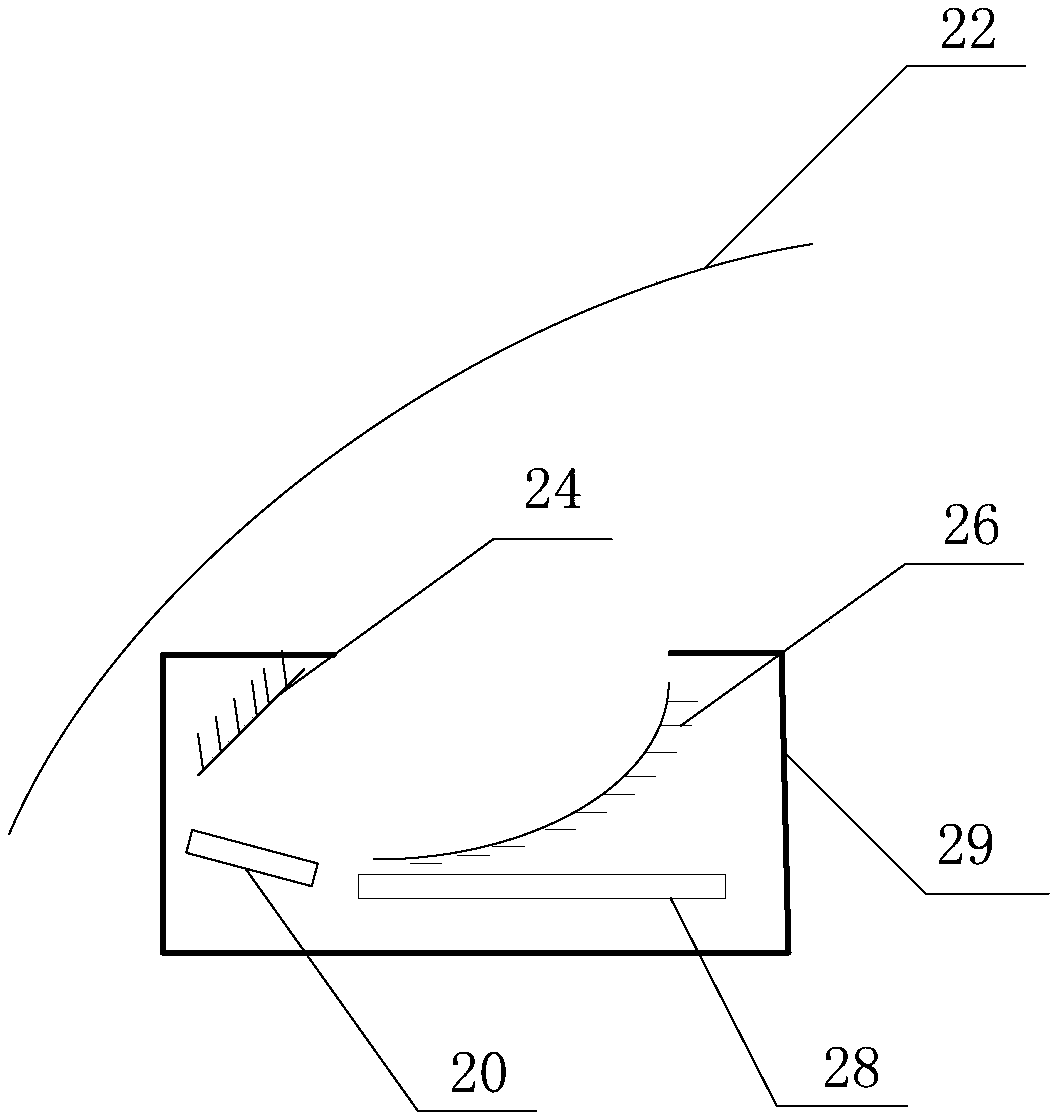

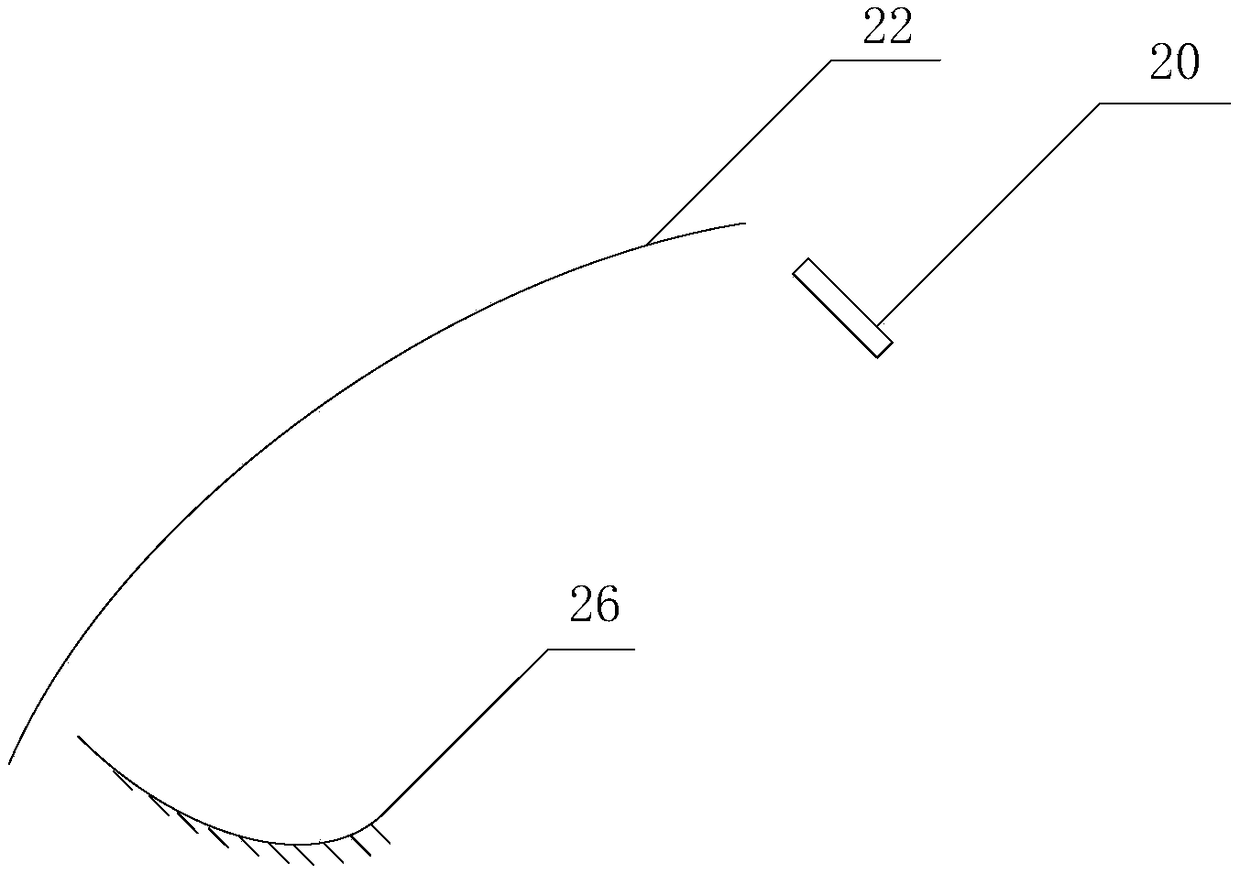

The invention provides a vehicle-mounted head up display device, system and augmented reality method thereof. The vehicle-mounted head up display device comprises a display device and a mirror plane, and is characterized in that the display device comprises a set of display screens arranged in an array mode, and the set of display screens comprises multiple display screens; each display screen is connected with a vehicle-mounted imaging processing device and used for receiving driving identification signals outputted by the vehicle-mounted imaging processing device, wherein the driving identification signals received by the display screens are combined into a complete driving identifier; and the driving identification signals received by each display screen are reflected by the mirror plane for one time or multiple times to vehicle wind screen glass so as to display the complete driving identifier. The embodiment of the invention enables an image projected by an HUD (head up display) on the wind screen glass to be large and long in distance.

Owner:MINGSHANG TECH CO LTD

Vehicle-mounted head-up display device, system and method for augmenting reality thereof

The invention provides a vehicle-mounted head up display device, system and augmented reality method thereof. The vehicle-mounted head up display device comprises a display device and a mirror plane, and is characterized in that the display device comprises a set of display screens arranged in an array mode, and the set of display screens comprises multiple display screens; each display screen is connected with a vehicle-mounted imaging processing device and used for receiving driving identification signals outputted by the vehicle-mounted imaging processing device, wherein the driving identification signals received by the display screens are combined into a complete driving identifier; and the driving identification signals received by each display screen are reflected by the mirror plane for one time or multiple times to vehicle wind screen glass so as to display the complete driving identifier. The embodiment of the invention enables an image projected by an HUD (head up display) on the wind screen glass to be large and long in distance.

Owner:MINGSHANG TECH CO LTD

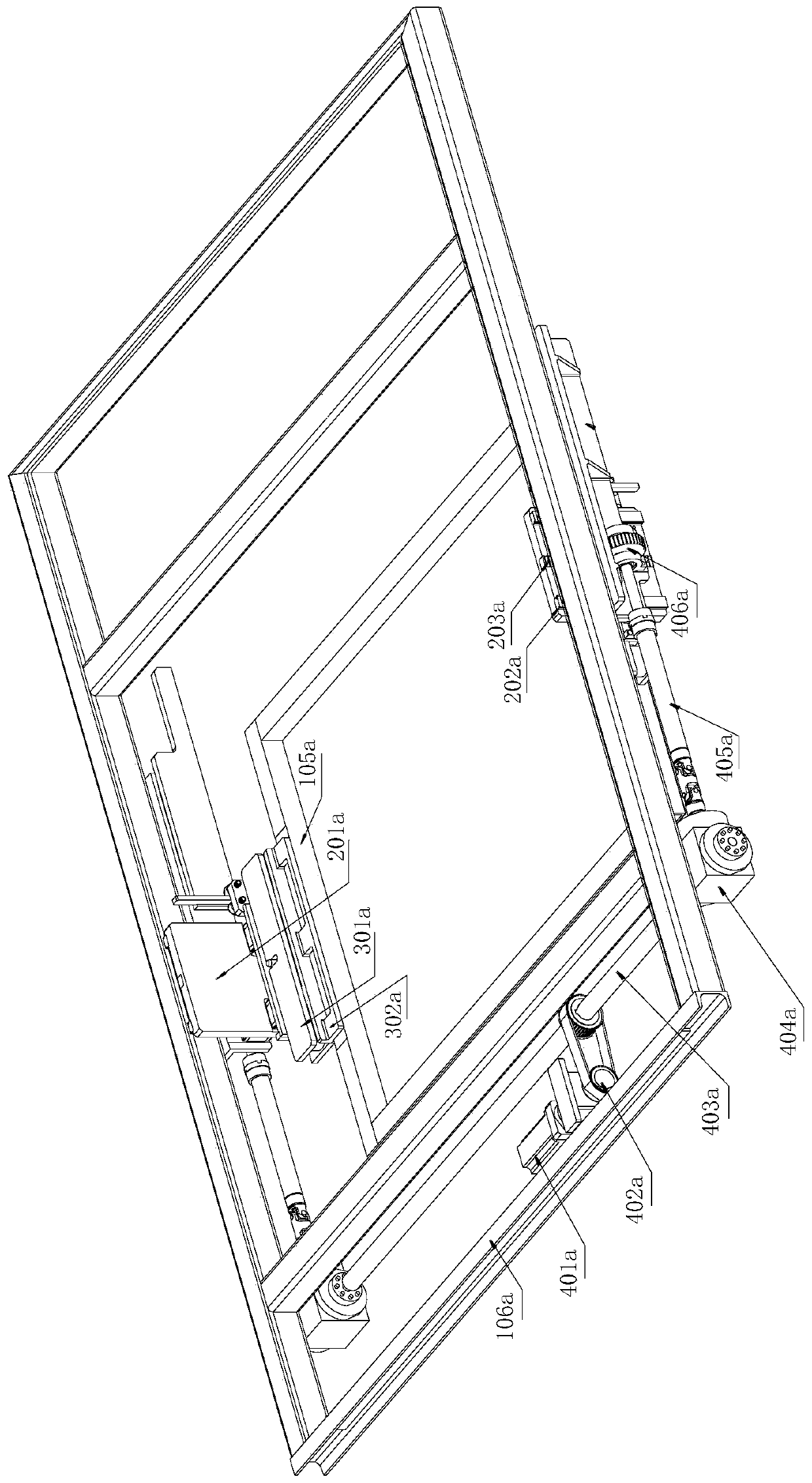

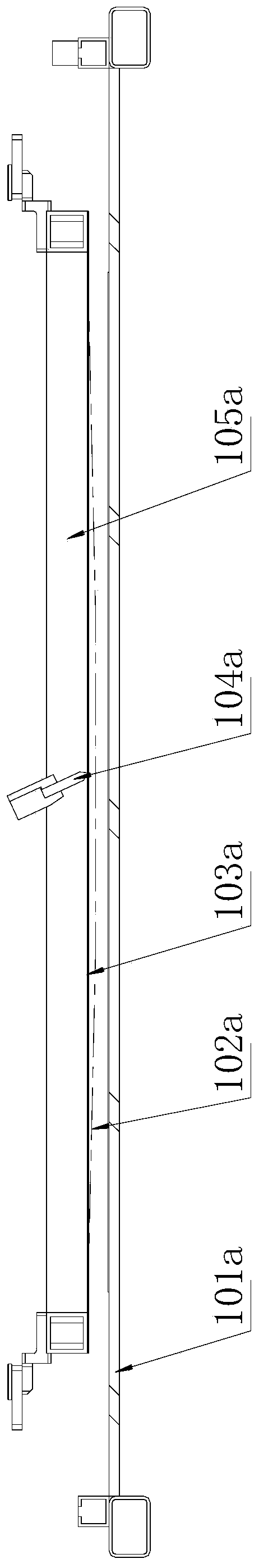

A 3D additive printing machine

The invention discloses a 3D material additive printing machine. A power device, a traveling device, a printing device and a screen frame device are disposed on a machine frame. Power of the traveling device is provided through the power device, and the machine frame is driven to move; the printing device comprises a scraper and a printing support; the screen frame device comprises a screen frame and a screen frame lifting device, and the screen frame is fixed to the machine frame through the screen frame lifting device; the printing support is disposed in the position, above the screen frame device, of the machine frame, and the scraper is arranged on the printing support; a printing control system comprises a distance judging device, a scraping force sensor, a processor and a position adjusting device; the processor receives a distance signal judged by the distance judging device and a scraper scraping force signal sensed by the scraping force sensor and instructs the position adjusting device to make adjustment, so that preset distance between screen cloth and a layer printing surface and the preset scraping force of the scraper are maintained; and accordingly, printing ink can uniformly permeate a silk screen and can be uniformly distributed on a to-be-printed target, repeated accurate overlaying is achieved, and the thickness of material additive manufacturing is reached.

Owner:福建屹立智能化科技有限公司

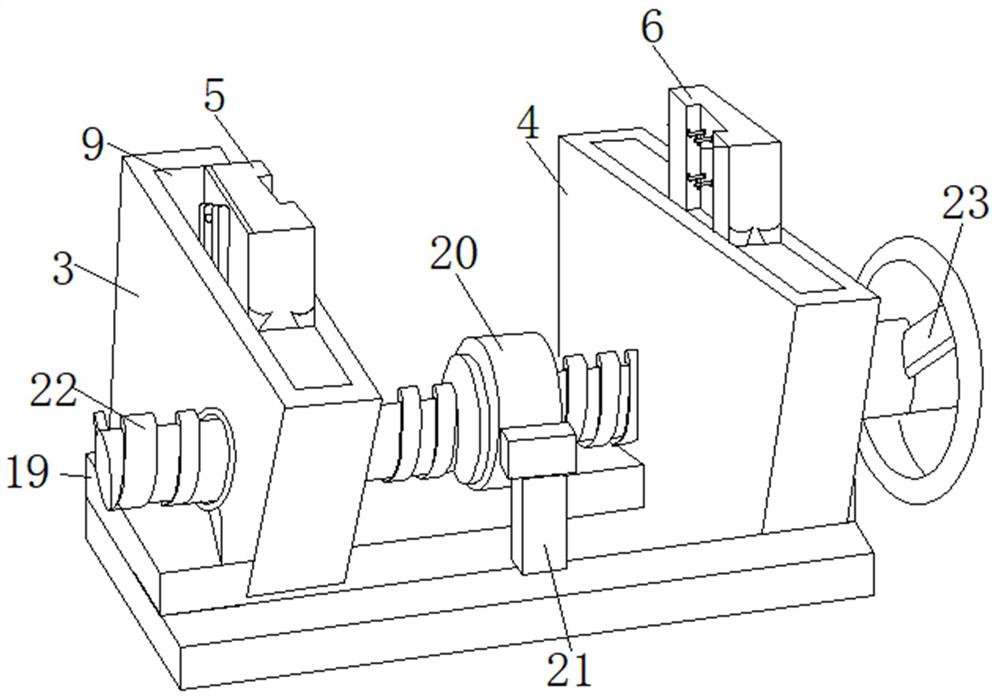

Propelling device for positioning adjustment of rock wool production line

ActiveCN111116035APrecise positioningAvoid inaccurate whereaboutsGlass making apparatusElectric machineEngineering

The invention discloses a propelling device for positioning adjustment of a rock wool production line. The propelling device includes a transfer structure; a base is arranged at the lower end of the conveying structure; a reciprocating structure is connected to the base in a sliding manner; the reciprocating structure is located at the two ends of the conveying structure. The reciprocating structure comprises a first reciprocating frame and a second reciprocating frame. Through grooves are formed in the upper end of the first reciprocating frame and the upper end of the second reciprocating frame, square columns are fixedly connected into the first reciprocating frame and the second reciprocating frame, rotating motors are arranged in the square columns, a rotating wheel is arranged at oneend of each rotating motor, and one fixed column is arranged at one end of each rotating wheel. According to the propelling device for positioning adjustment of the rock wool production line, cottonfelt can be accurately thrown, later-period uniform pressurization is facilitated, enough limiting force can be guaranteed when the cotton felt falls down, the falling position and the folding angle of the cotton felt can be accurately positioned, returning is rapid, and the forming work efficiency of the cotton felt is improved.

Owner:宁夏领航岩棉科技有限公司

A propulsion device for positioning adjustment of rock wool production line

ActiveCN111116035BPrecise positioningPrecise clampingGlass making apparatusElectric machineControl engineering

The invention discloses a propulsion device for positioning adjustment of a rock wool production line, which includes a transmission structure, a base is provided at the lower end of the transmission structure, and a reciprocating structure is slidably connected to the base, and the reciprocating structure is located at both ends of the transmission structure. The reciprocating structure includes No. 1 reciprocating frame and No. 2 reciprocating frame. The upper ends of the No. 1 reciprocating frame and No. 2 reciprocating frame are provided with through grooves. The inside of the No. 1 reciprocating frame and No. 2 reciprocating frame are fixedly connected with A square column, a rotating motor is arranged inside the square column, a running wheel is arranged at one end of the rotating motor, and a fixed cylinder is arranged at one end of the rotating wheel. The propulsion device for positioning adjustment of a rock wool production line described in the present invention can accurately place the cotton felt, which is beneficial to the uniform pressure in the later stage, and can ensure sufficient limit force when the cotton felt falls. And the folding angle has precise positioning, and the retraction is rapid, which improves the working efficiency of cotton felt forming.

Owner:宁夏领航岩棉科技有限公司

A dsm automatic comparison system based on aerial photography measurement

ActiveCN111401345BImprove comparison efficiencyShorten the timeImage enhancementImage analysisAlgorithmEngineering

The invention discloses a DSM automatic comparison system based on aerial photography measurement, which belongs to the technical field of aerial photography measurement. The elevation data of the two-phase aerial photos processed by the image processing module is extracted, the elevation conversion module is used to convert the elevation data of the two-phase aerial photos extracted by the elevation extraction module into a vector layer, and the layer overlay module is used for the two-phase aerial photos The vector layer of the photo is superimposed, and the comparison and labeling module is used to mark the area that has changed in the vector layer of the two-phase aerial photo. The time and manpower input for the comparison can more accurately detect the existence of illegal buildings. The comparison is more pertinent, and the effect of buildings with different areas can be screened by adjusting the value of each value.

Owner:常州市新翼空间信息科技有限公司

Method and device for splicing characteristic point correction partitions

ActiveCN102324096BAddressing Digital ConvergenceMeet the use requirementsImage analysisEditing/combining figures or textImaging dataGeologic map

Owner:STATE GRID CORP OF CHINA +1

Apparatus and method for manufacturing photosensitive laminate

InactiveCN101146681BAccurate OverlayQuality improvementLamination ancillary operationsLaminationManufactured apparatusGlass transition

A manufacturing apparatus (20) has a reel-out mechanism (32), a processing mechanism (36), a label bonding mechanism (40), a reservoir mechanism (42), a peeling mechanism (44), a substrate feed mechanism (45), an attachment mechanism (46), and a base peeling mechanism (186). A cooling mechanism (122) is disposed between the attachment mechanism (46) and the base peeling mechanism (186), for cooling an attached substrate (24a), the attached substrate (24a) being made up of a glass substrate (24) and a photosensitive web (22) attached thereto, from which a protective film (30) has been peeled off, together with a heating mechanism (182) for heating a resin layer, for example a cushion layer (27), inside the cooled attached substrate (24a) to within a predetermined temperature range, which is at or below the glass transition temperature.

Owner:FUJIFILM CORP

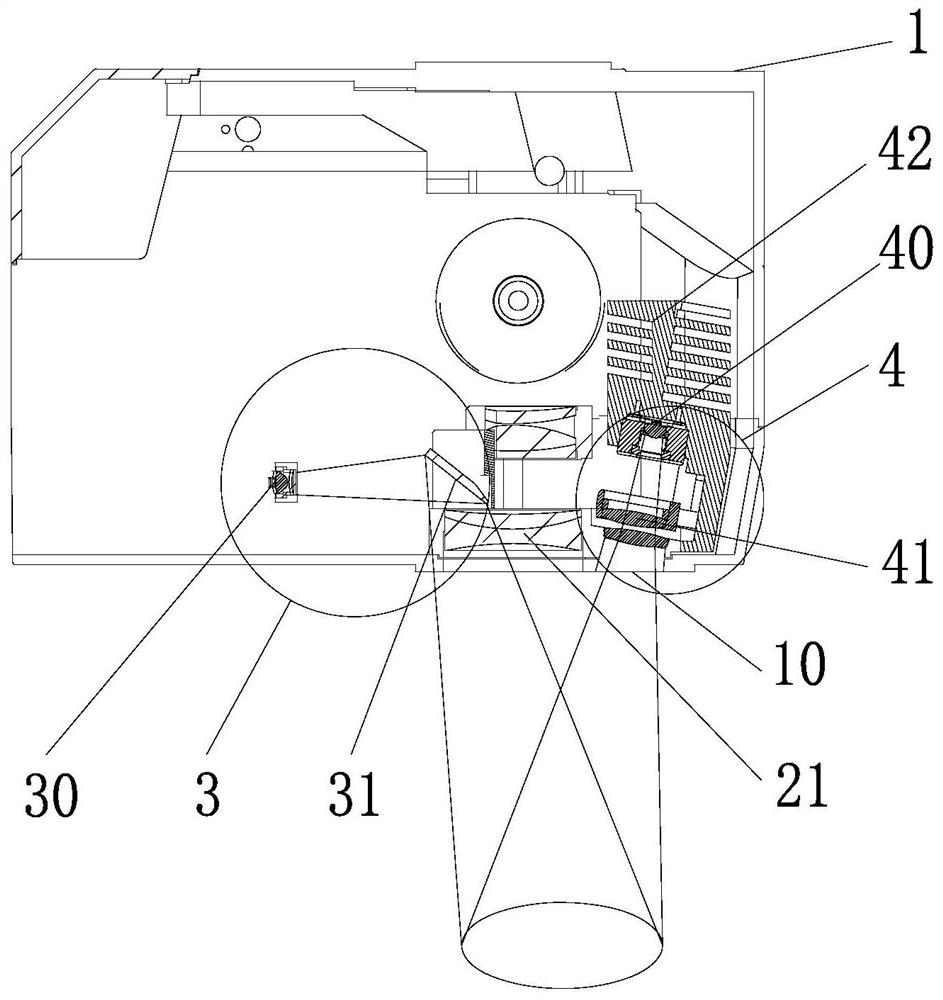

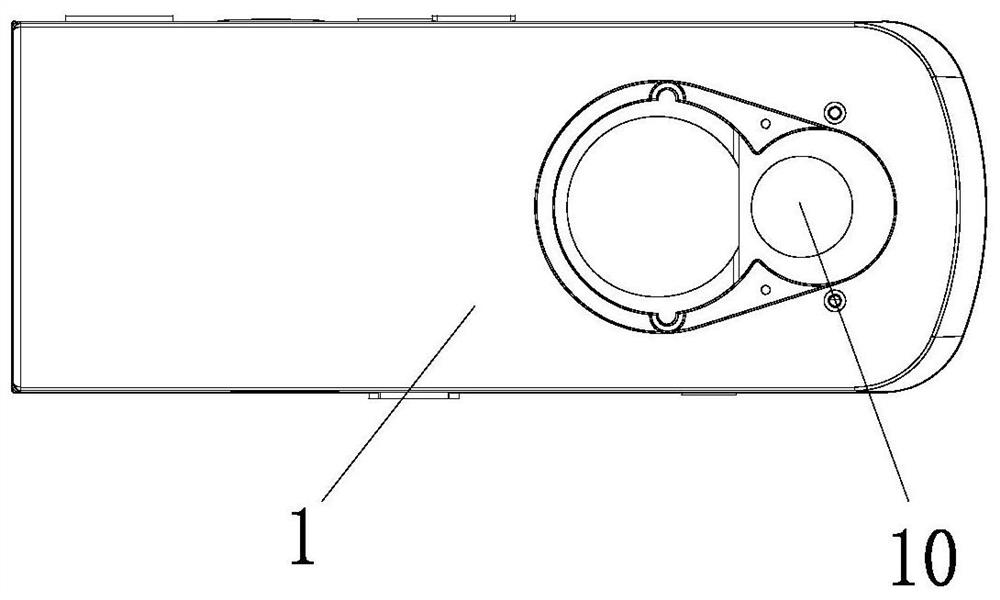

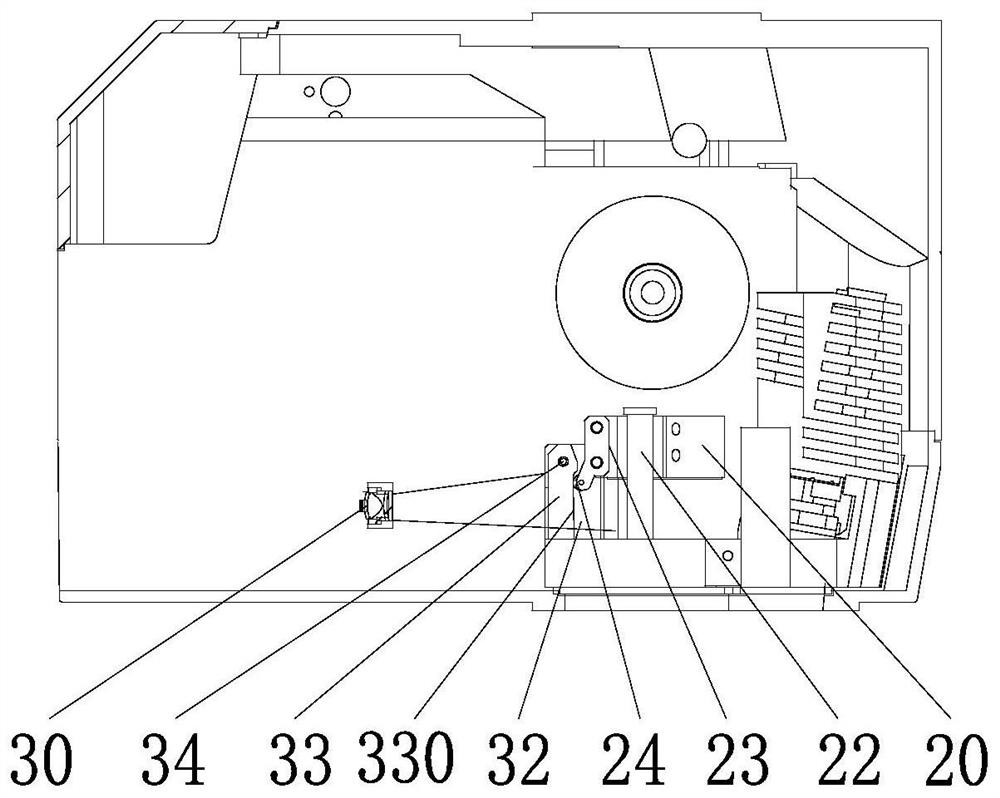

Medical microscope

The invention relates to a medical microscope, which comprises a shell, an observation unit and an illumination unit, wherein the observation unit comprises a large objective lens arranged on an observation light path; the illumination unit comprises a first illumination unit and a second illumination unit, the first illumination unit comprises a first light source, the second illumination unit comprises a second light source, and the first illumination unit and the second illumination unit are arranged in the shell and located on the two sides of the large objective lens respectively; and the first lighting unit further comprises a first adjusting assembly used for adjusting the angle of light emitted by the first light source, and / or the second lighting unit further comprises a second adjusting assembly used for adjusting the angle of light emitted by the second light source. The medical microscope can provide sufficient illumination, and is low in cost, long in service life and low in power consumption; the built-in device is small, light and compact in structure; the internal mechanism is simple, the light path is not complicated, and the internal space is small; and the brightness adjustment is diversified, and the superposition is accurate.

Owner:ZUMAX MEDICAL

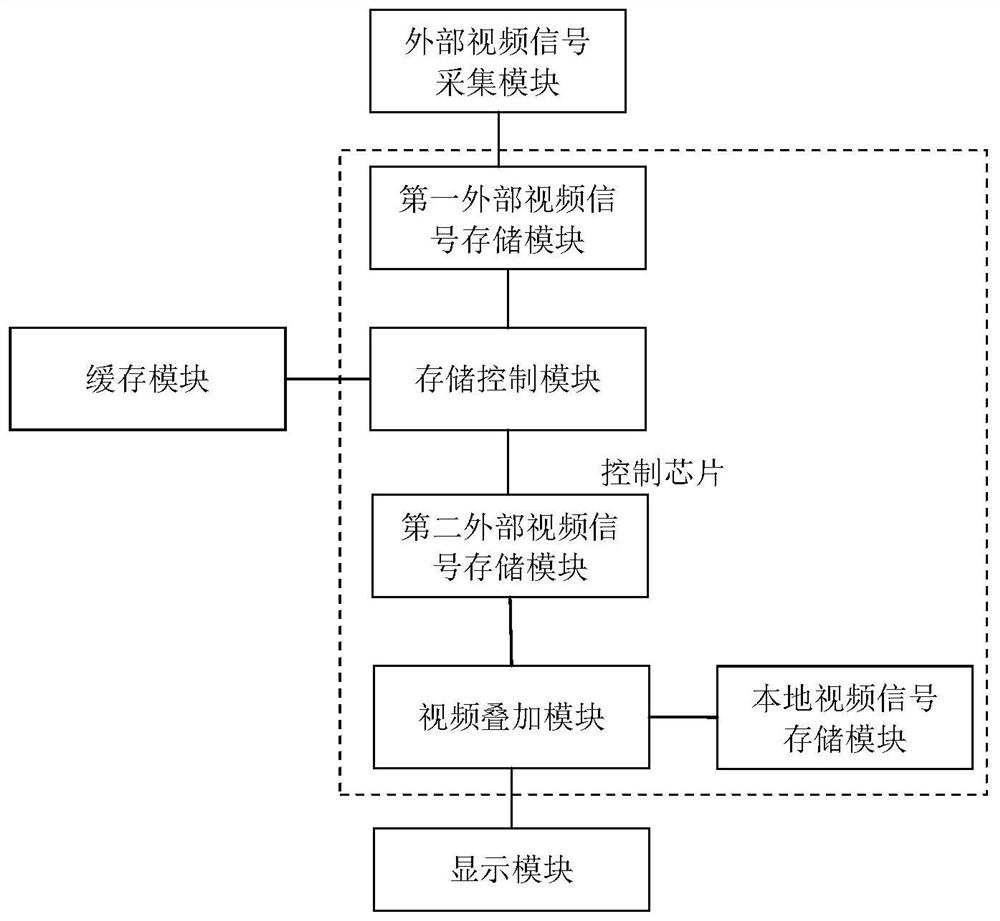

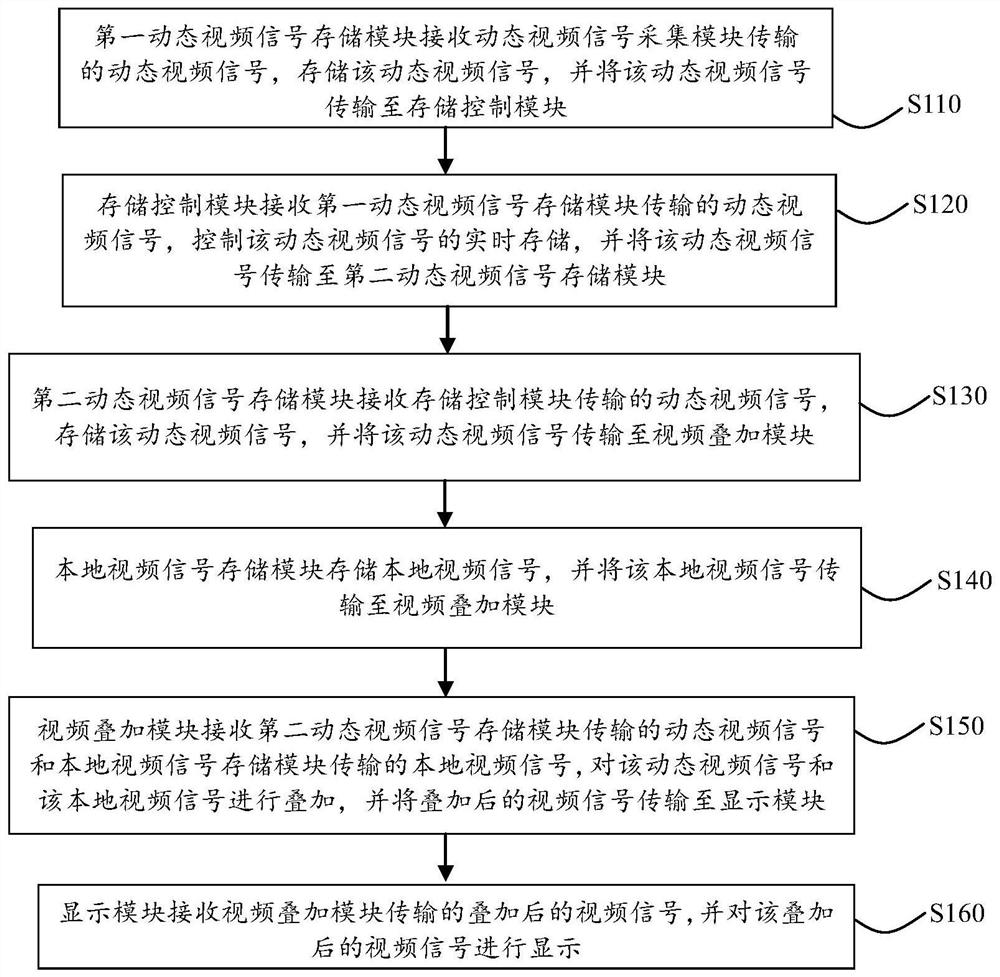

A video overlay device and method

ActiveCN107454348BEliminate transmission delaysAccurate overlay in real timeTelevision system detailsColor television detailsComputer hardwareVideo overlay

The invention relates to a video overlay device and method. The video overlay device includes a first dynamic video signal storage module for storing a dynamic video signal and transmitting the dynamic video signal to a storage control module; the storage control module for controlling the real-time storage of the dynamic video signal and transmitting the dynamic video signal to a second dynamic video signal storage module; the second dynamic video signal storage module for storing the dynamic video signal and transmitting the dynamic video signal to a video overlay module; a local video signal storage module for storing a local video signal and transmitting the local video signal to a video overlay module; the video overlay module for overlaying the dynamic video signal and the local video signal and transmitting the overlaid video signal to a display module; and the display module for receiving the overlaid video signal transmitted by the video overlay module and displaying the overlaid video signal.

Owner:深圳市亿威尔信息技术股份有限公司

Preparation method for three-dimensional metal micro-nanometer device

ActiveCN102951604BReduce high costReduce process stepsDecorative surface effectsChemical vapor deposition coatingCrystallographyThin membrane

The invention relates to a preparation method for a three-dimensional metal micro-nanometer device. The method comprises the steps: forming a first structure of a polymer in a first photoresist by utilizing femtosecond laser beam; activating the surface of the first structure of the polymer; covering the activated first structure of the polymer by a second photoresist; forming a second structure partially contacted with the first structure in the second photoresist by utilizing femtosecond laser beam to obtain a complex of the partially exposed and activated surface of the first structure; and carrying out electrodeless plating to the complex in electroplate solution, and forming a metal thin membrane on the exposed surface of the first structure to obtain the three-dimensional metal micro-nanometer device. The first structure and the second structure are respectively machined so as to accurately align on three dimensions, selective electroplating of micro-nanometer structure can be realized by combining electrodeless electroplating technique, and the three-dimensional metal micro-nanometer device with any three-dimensional metal micro-nanometer structure can be obtained.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

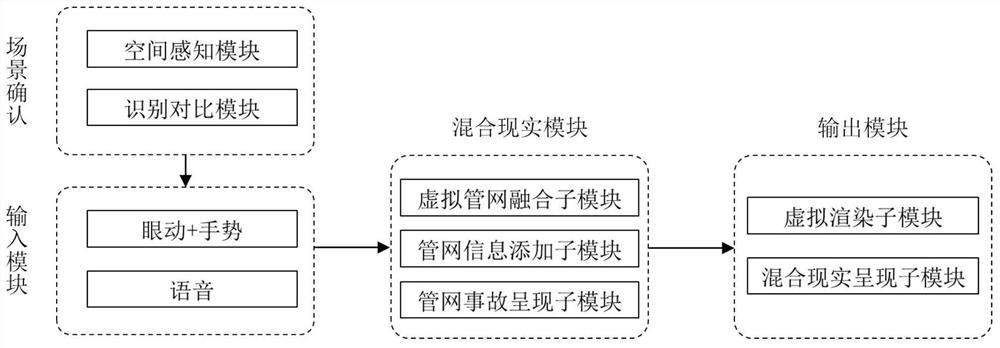

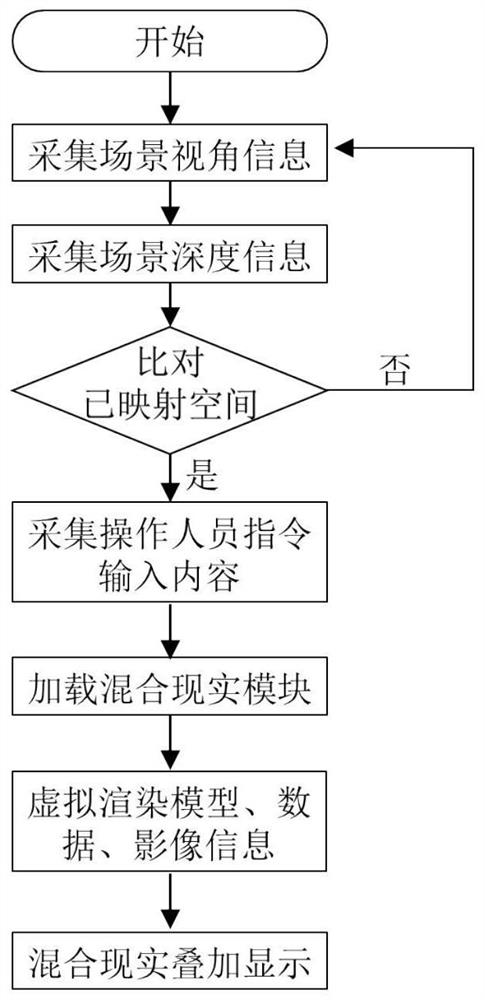

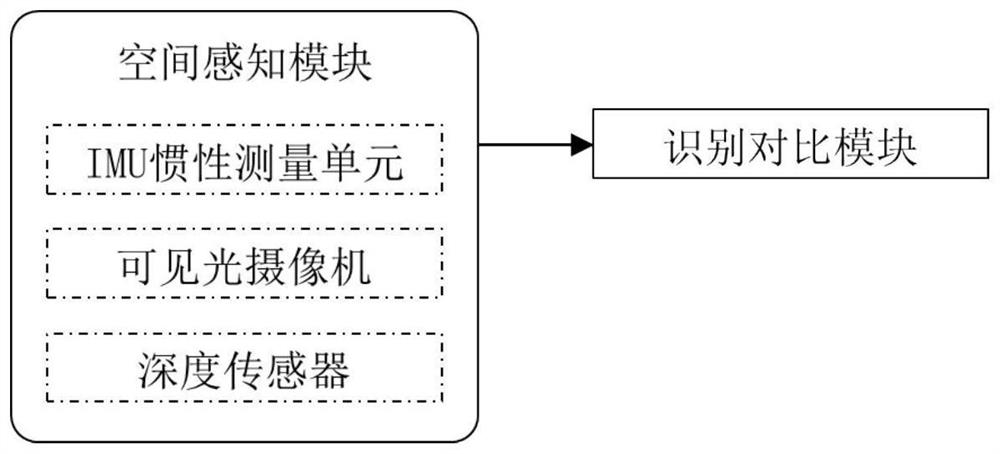

Underground pipe network teaching auxiliary system and method based on MR glasses

PendingCN112183223AAccurate overlayInput/output for user-computer interactionChecking time patrolsMixed realityEngineering

The invention discloses an underground pipe network teaching auxiliary system and method based on MR glasses. The system comprises a space perception module, an identification comparison module, an input module, a mixed reality module and an output module. The method comprises the steps: acquiring three-dimensional scene information, judging whether a current area is a mapped space or not, acquiring an interaction instruction in real time, generating auxiliary enhancement information to be rendered and performing virtual rendering to form enhanced image information. According to the underground pipe network information enhancement teaching auxiliary system and method, underground pipe network detection training teaching and information enhancement of the inspection process are achieved, anunderground pipe network can be visually and vividly recognized without excavation, and the teaching effect and the inspection efficiency are improved.

Owner:BEIJING VOCATIONAL COLLEGE OF LABOUR & SOCIAL SECURITY

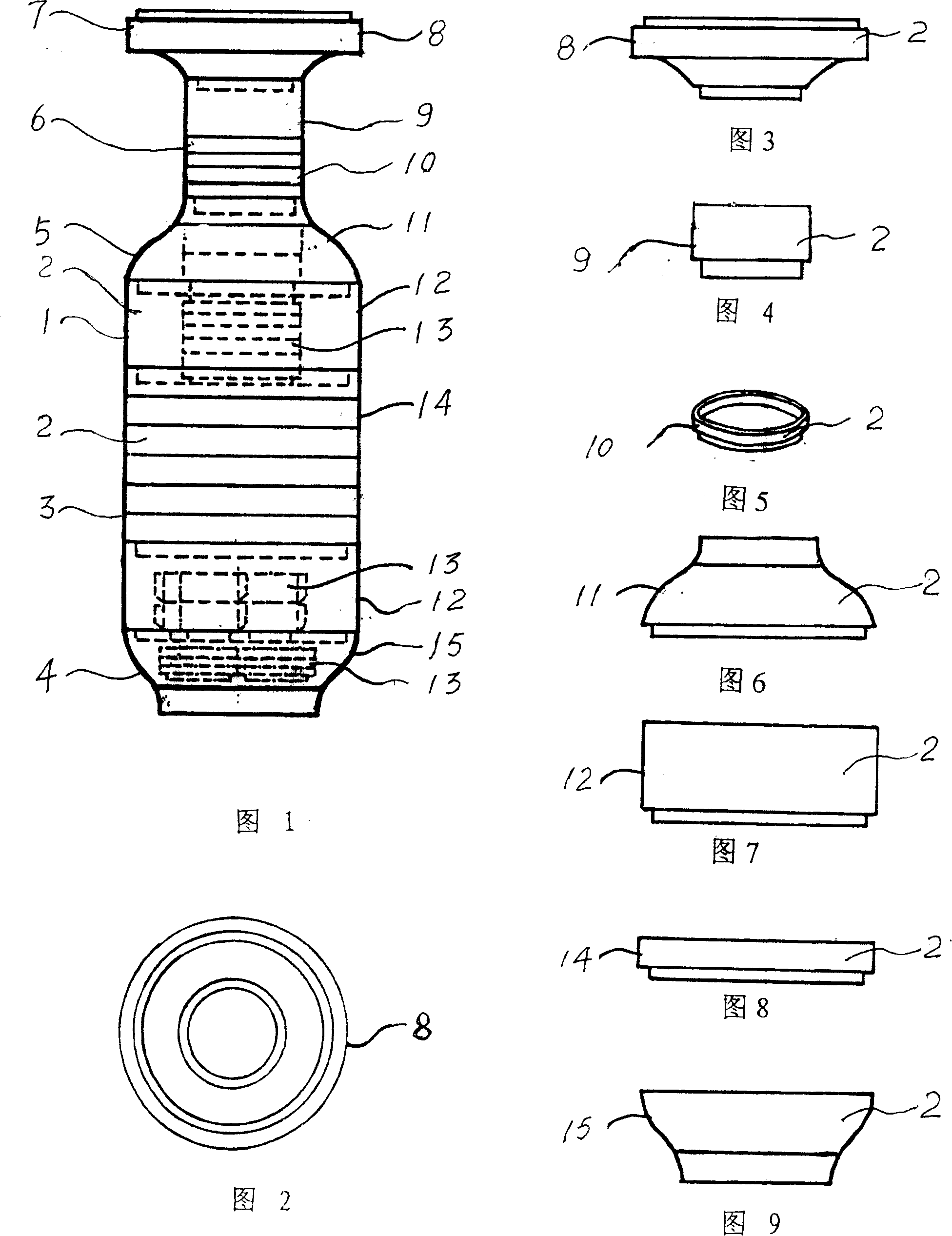

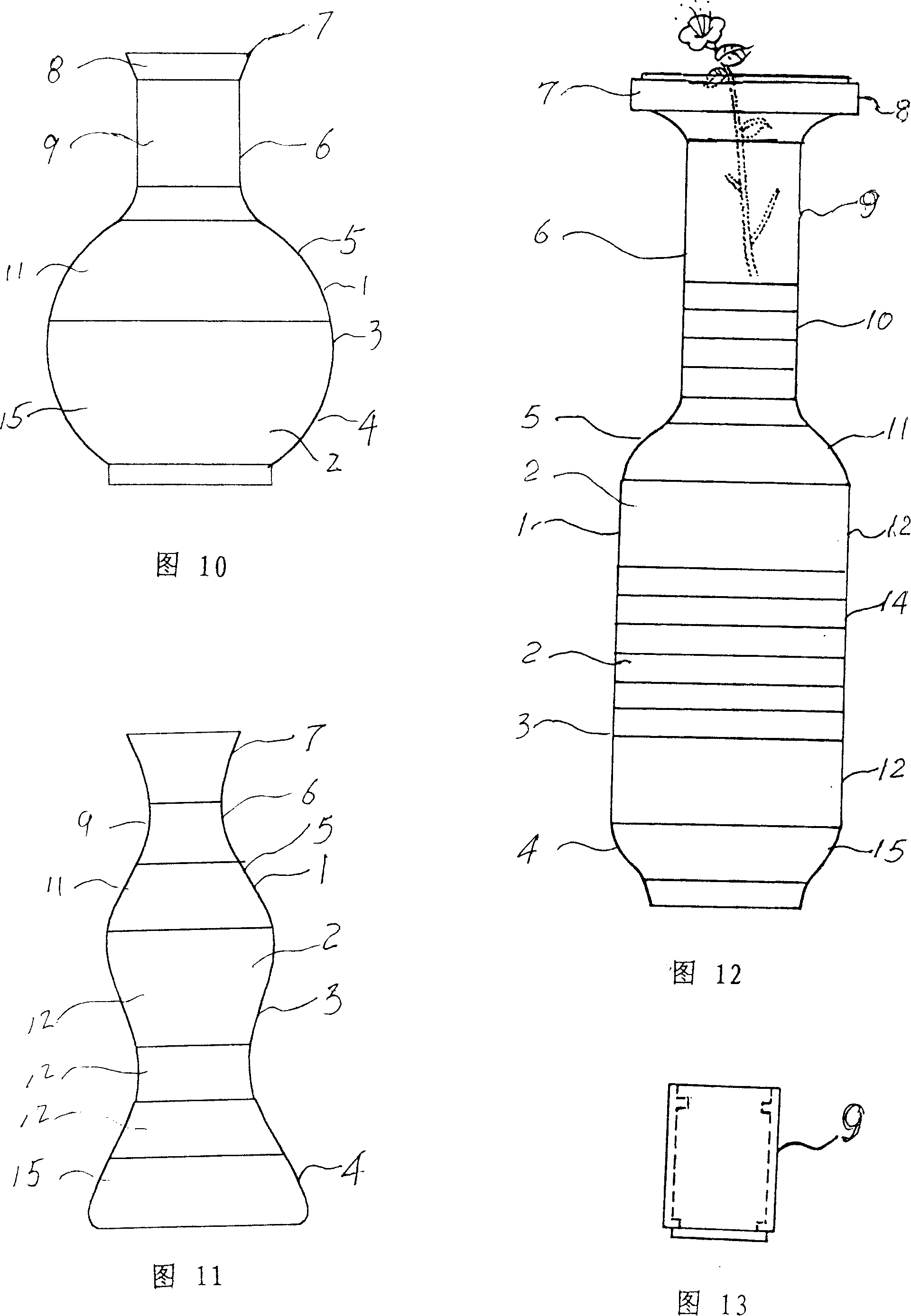

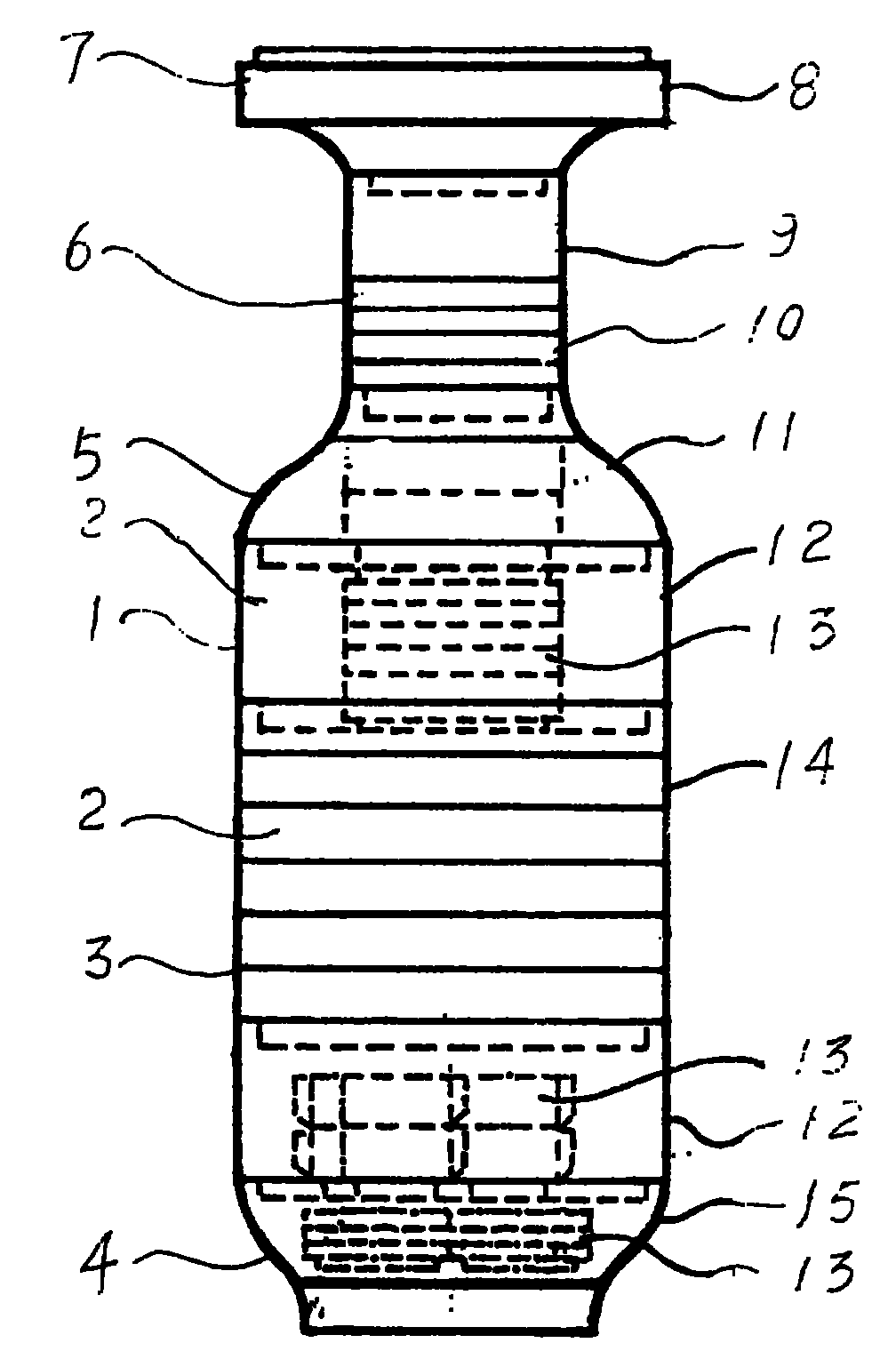

Whole set dinnerware capable of being superposed into flower vase when stored and its making method

This invention is about a set of tableware that can be stacked into a vase when put away, and it mainly includes bowls and dishes. The tableware are put upper or lower to form a stereo vase. Each tableware will contribute to the outside wall of the external contour of the vase. The methods to make a set of tableware contain the procedure of determining the external contour of the vase, the sorts and quantity and outside walls of tableware, the positioning mode of stacking and formed tableware etc. One advantage of producing such set of tableware is that the tableware can be stacked into a complete vase which is really like a vase-a garniture in a household. Each tableware can be independently used, easily taken away or replaced. The make method is simple and precise.

Owner:余祖胜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com