Patents

Literature

35results about How to "Reduce the risk of overheating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

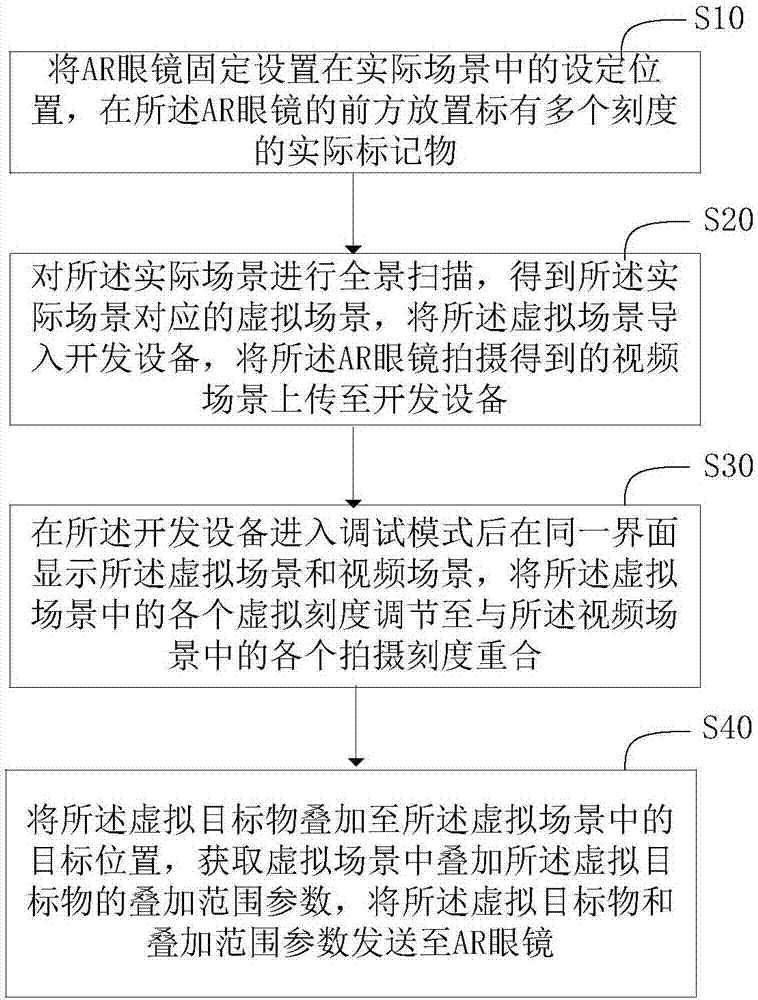

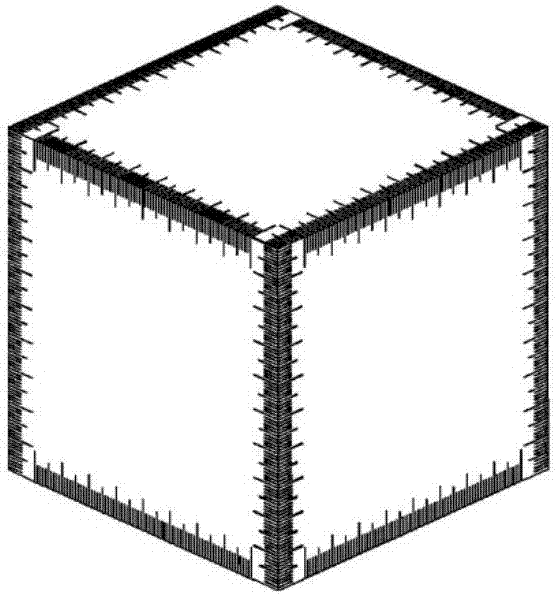

Overlapped method for virtual object in AR glasses

ActiveCN106875493AReduce resource overheadReduce the risk of overheatingImage data processingVirtual targetComputer graphics (images)

Owner:广东电网有限责任公司培训与评价中心

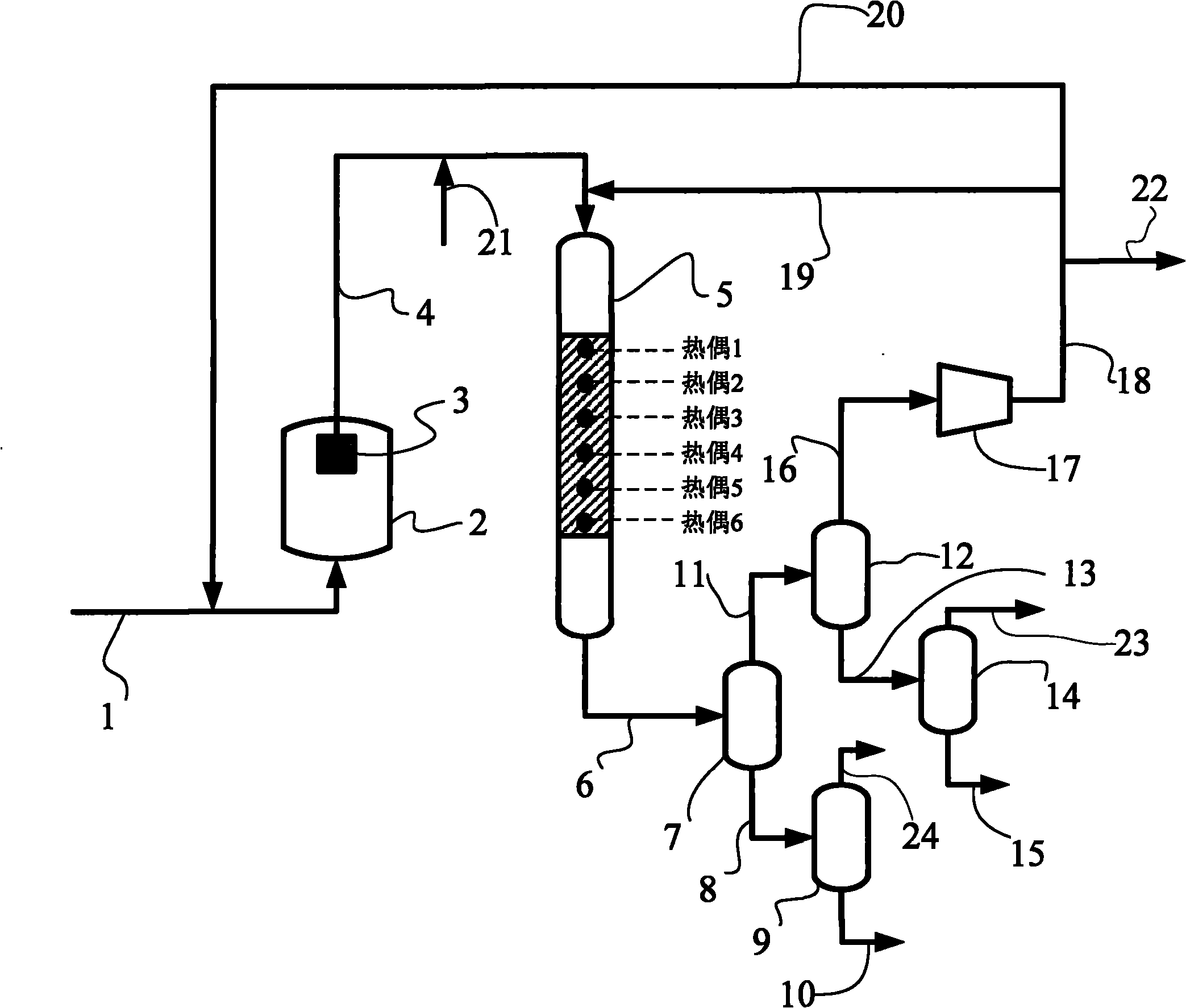

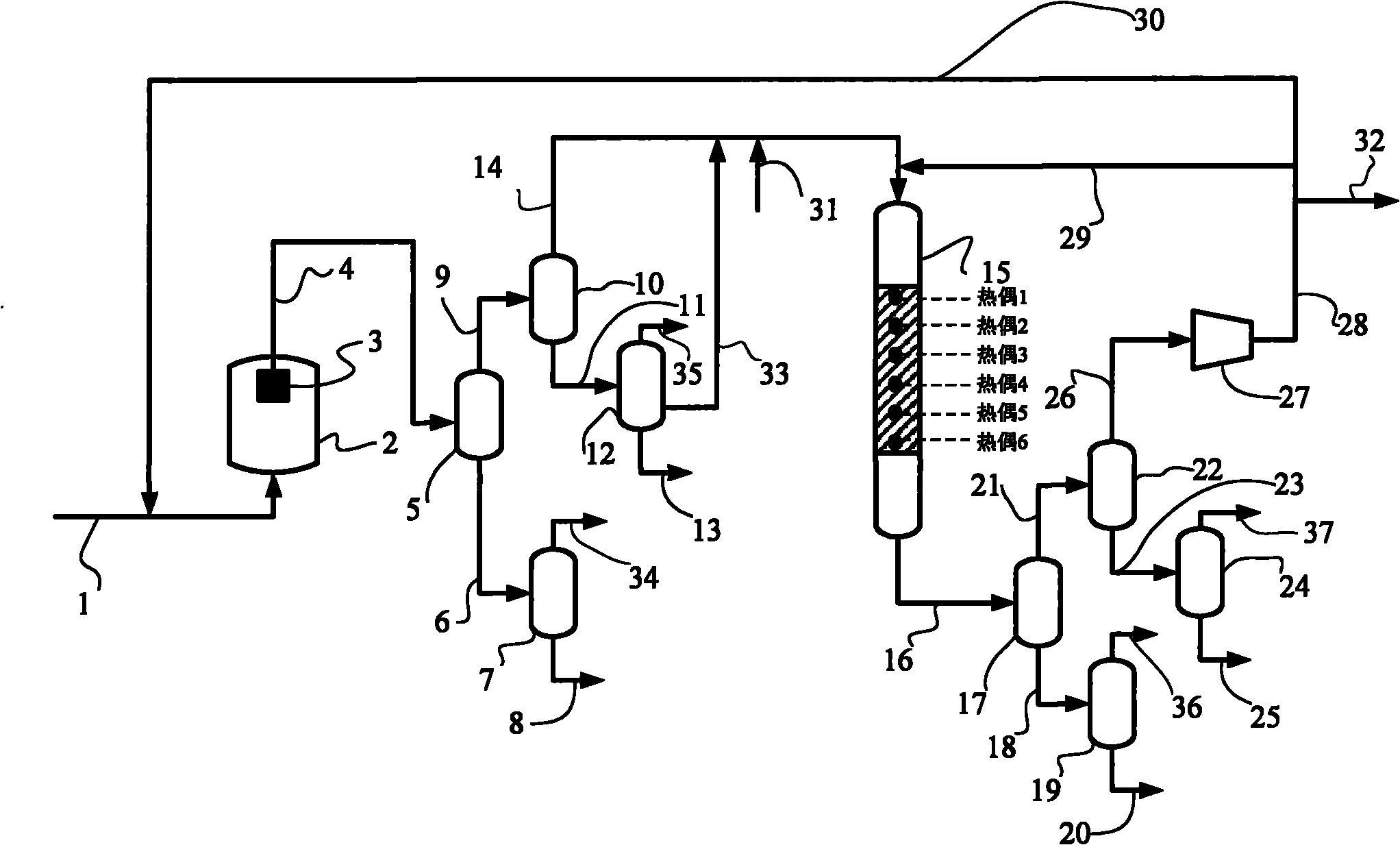

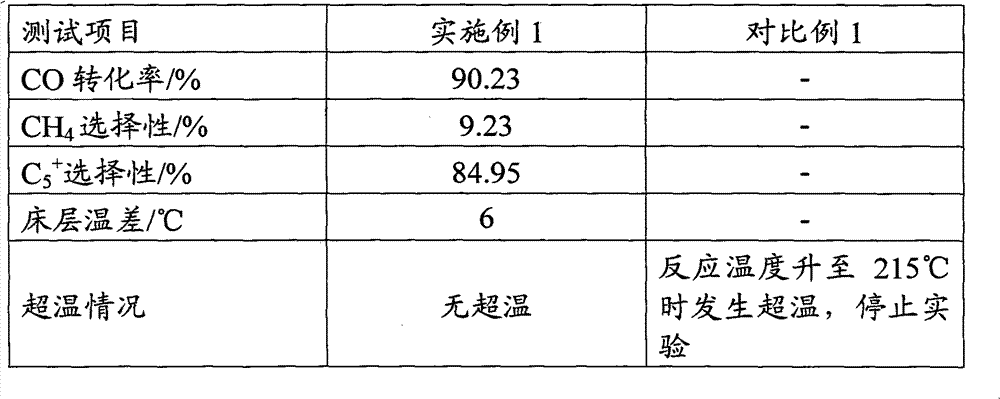

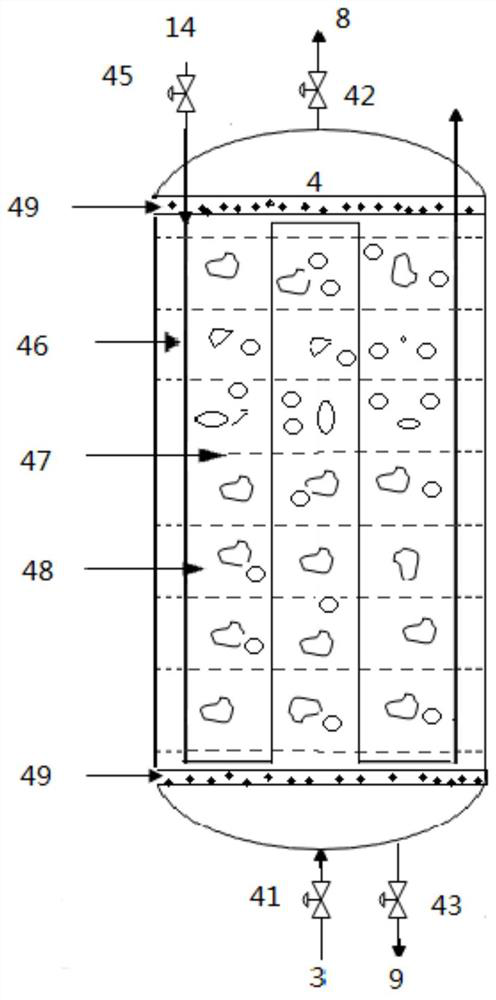

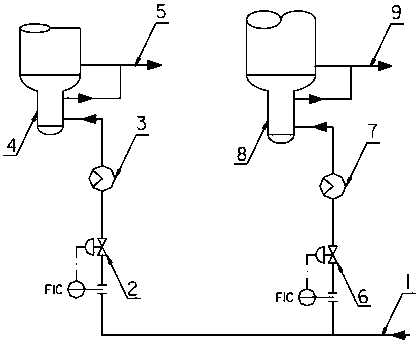

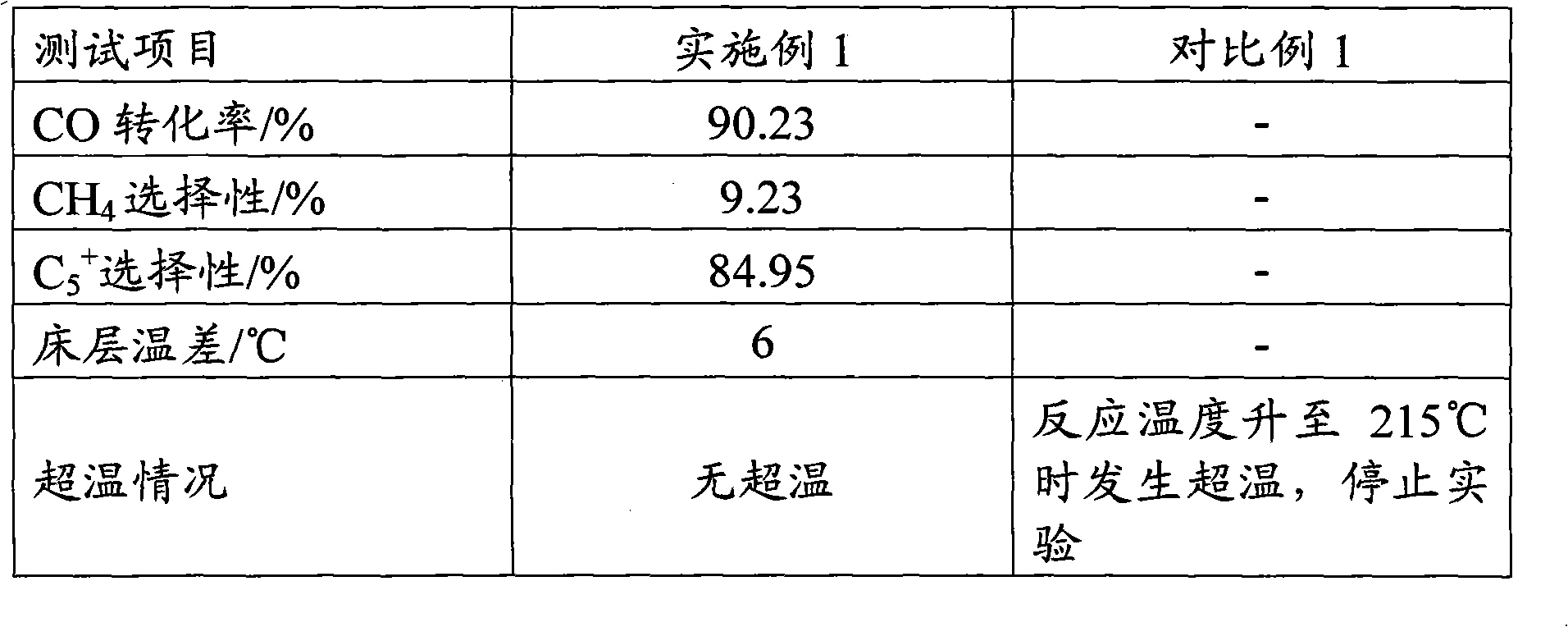

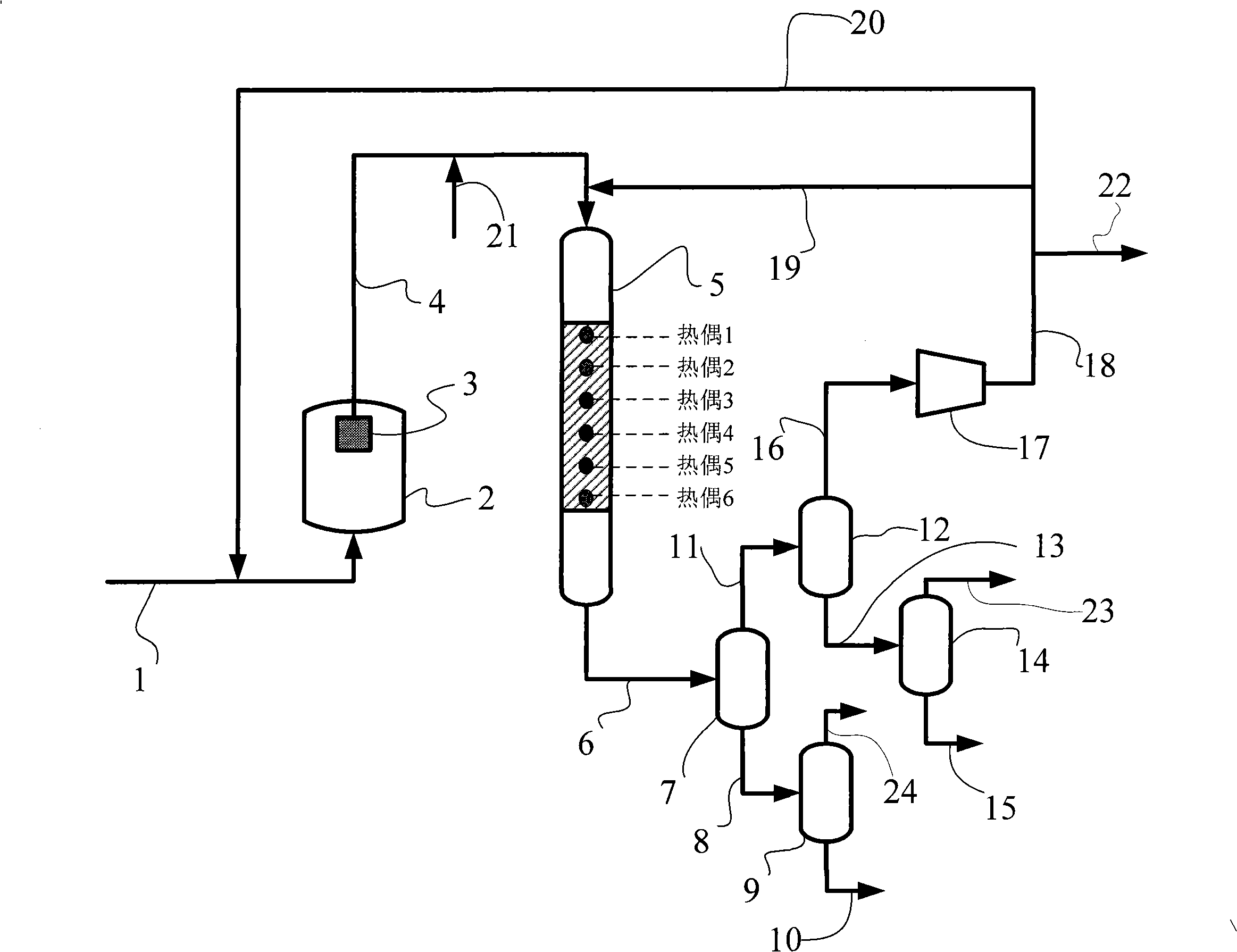

Fischer-Tropsch synthesis method

ActiveCN101863728AEasy to operateReduce the risk of overheatingHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionParaffin waxSynthesis methods

The invention provides a Fischer-Tropsch synthesis method. The invention adopts two Fischer-Tropsch synthesis reaction vessels in serial connection, wherein the first Fischer-Tropsch synthesis reaction vessel is a slurry bed reaction vessel, and the second Fischer-Tropsch synthesis reaction vessel is a fixed bed reaction vessel. Outflow materials of the first Fischer-Tropsch synthesis reaction vessel fully or partially enter the second Fischer-Tropsch synthesis reaction vessel for carrying out synthesis reaction, and H2 and / or CO is injected between the two Fischer-Tropsch synthesis reaction vessels for regulating the molar ratio of H / C at an inlet of the second Fischer-Tropsch synthesis reaction vessel. The method provided by the invention overcomes the defects of great axial temperaturedifference, obvious heat point and difficult control of the reaction temperature of the fixed bed Fischer-Tropsch synthesis reaction vessel, and simultaneously ensures that the proportion of paraffinproducts in the products can not be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

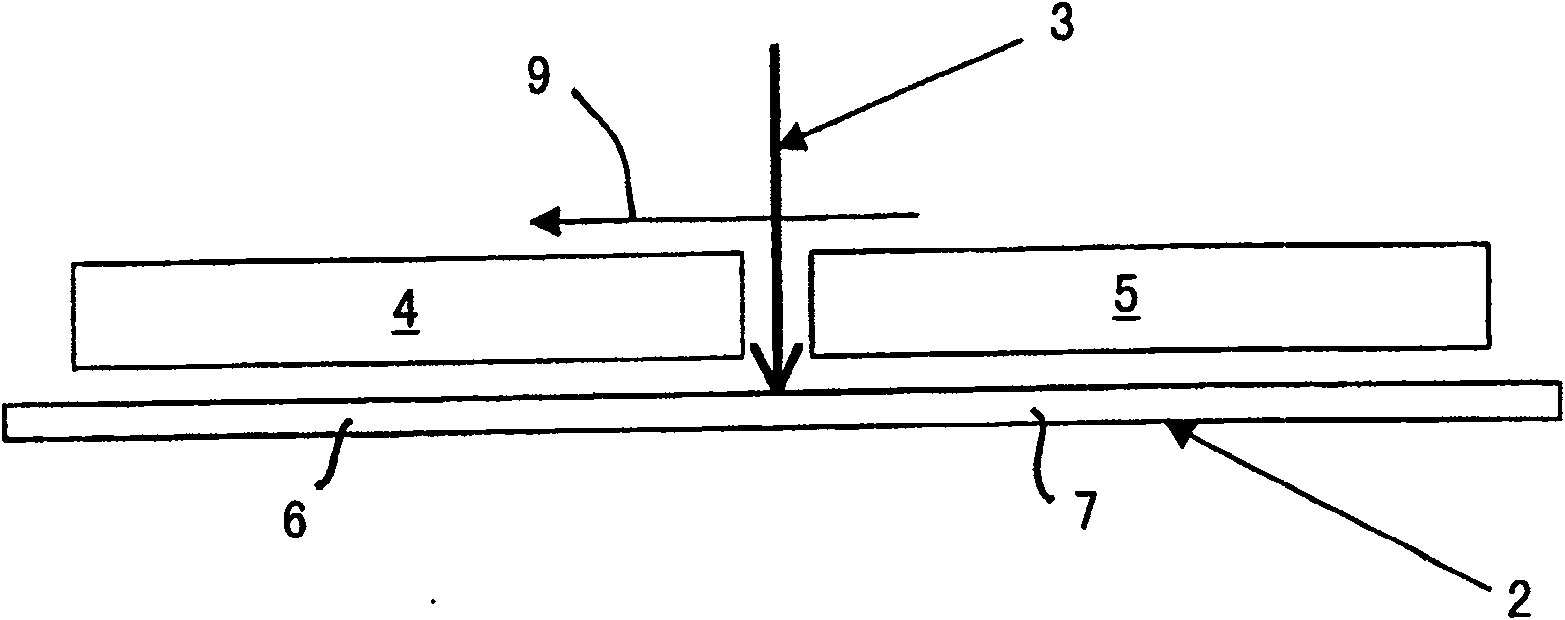

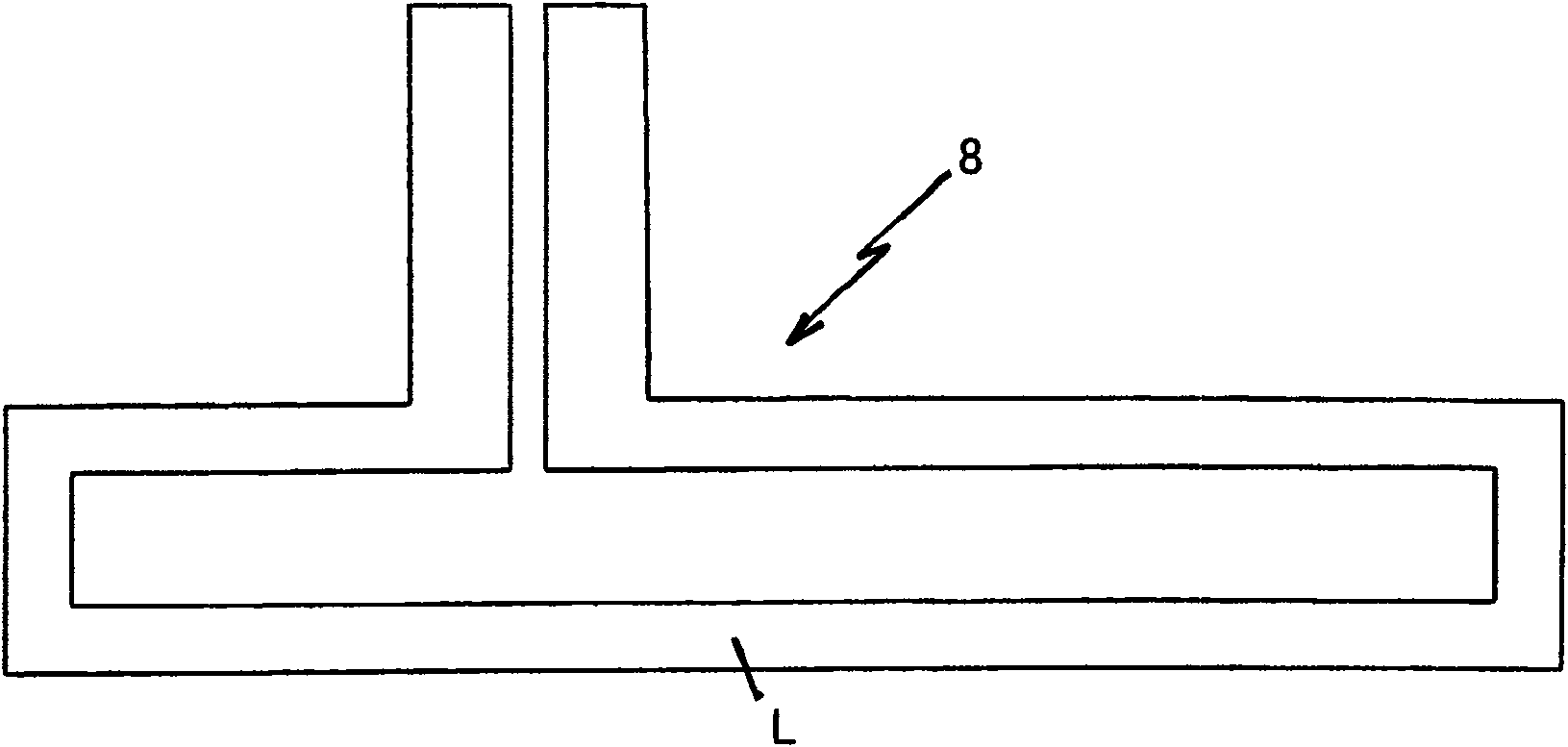

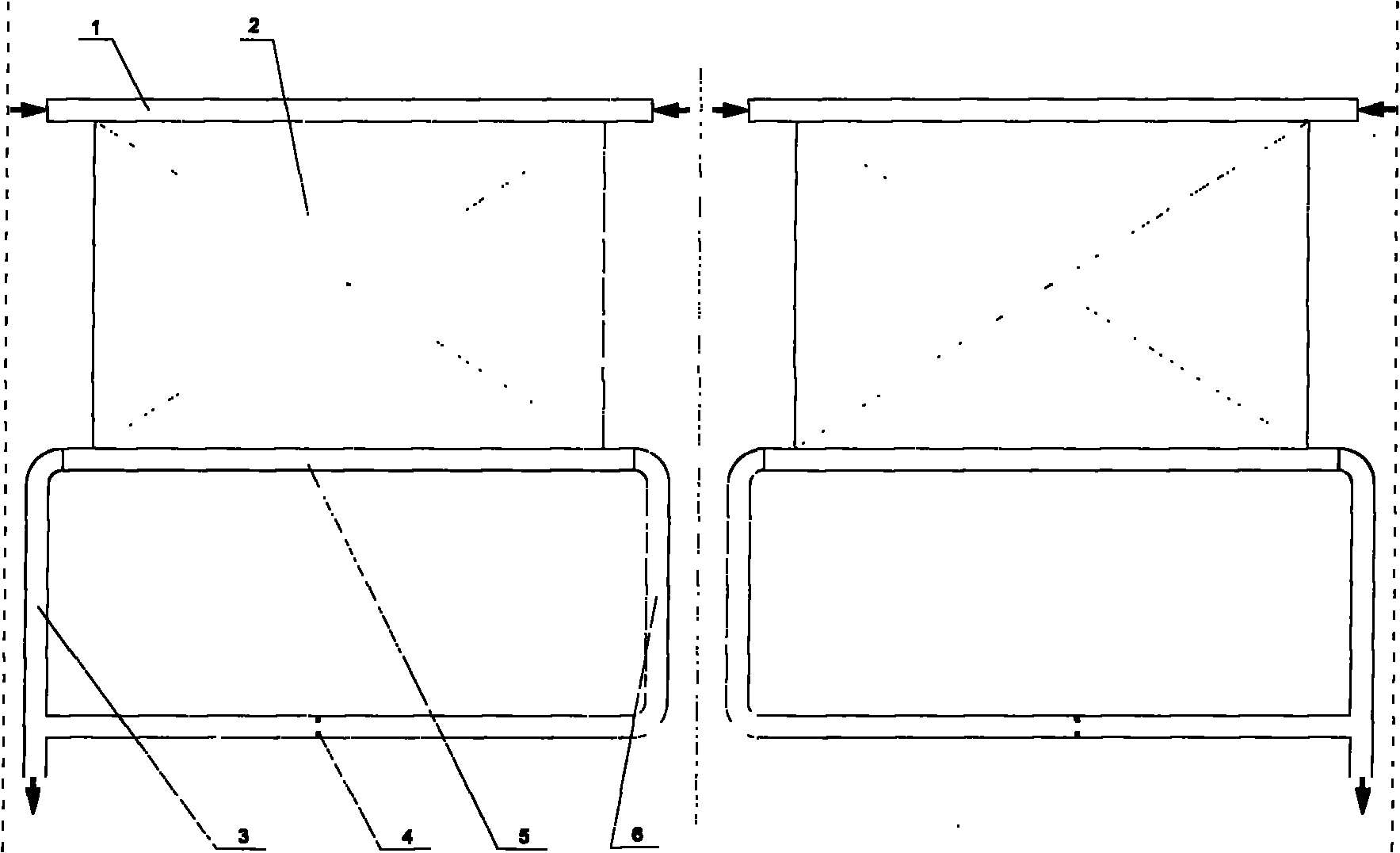

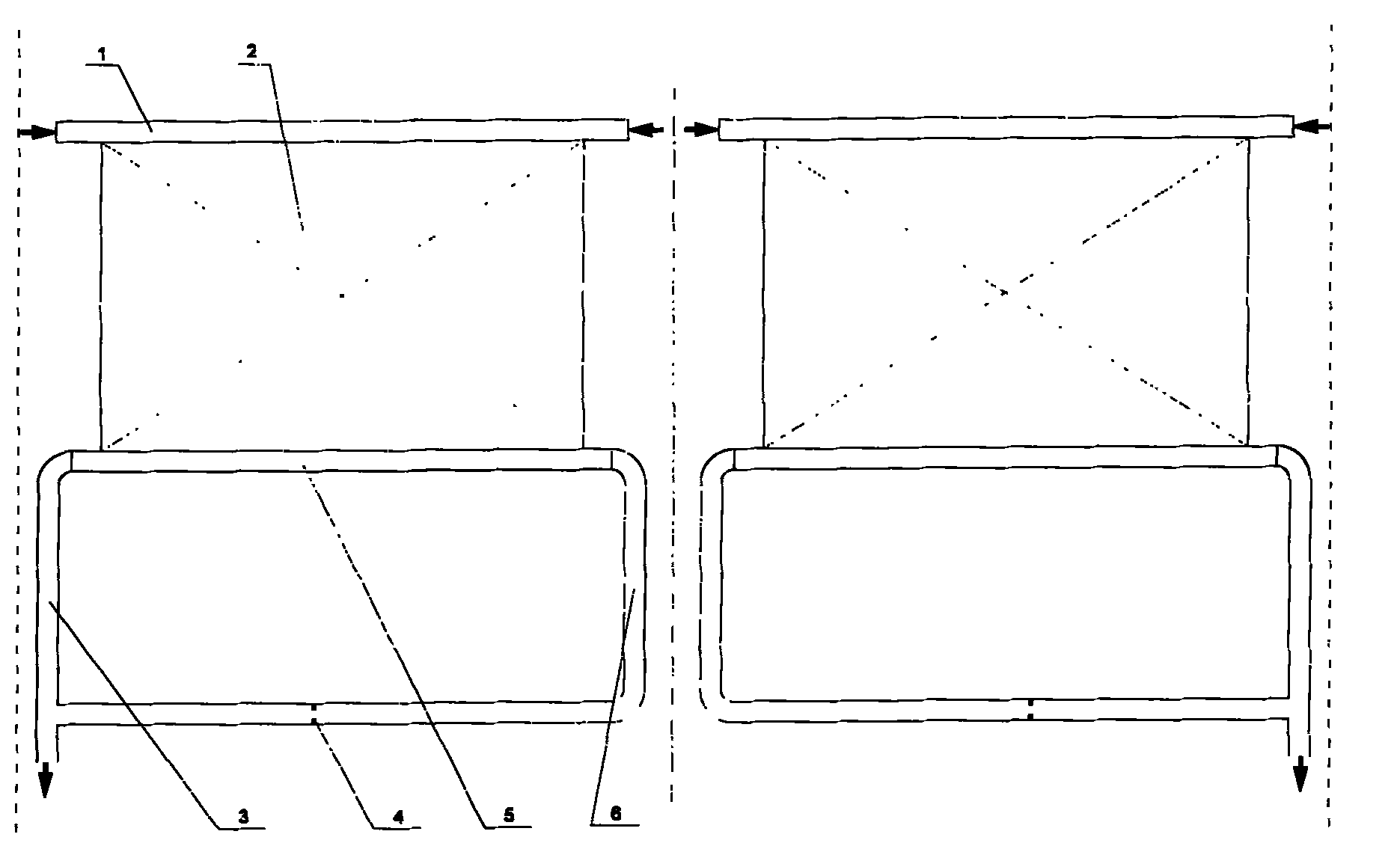

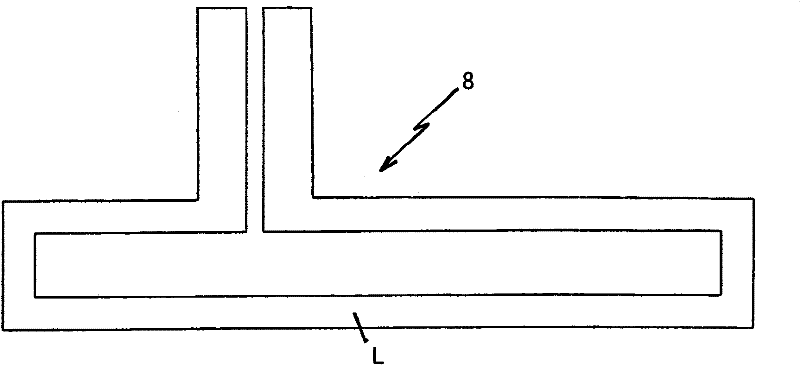

Method and apparatus for the heat treatment of welds

InactiveCN101578379AReduce temperature gradientReduce the risk of overheatingInduction heatingIncreasing energy efficiencyLoop lengthEngineering

The present invention relates to a method and a device for the heat treatment of welds. To improve and further develop the heat treatment of the weld and the joining weld regions (6, 7) before and behind the actual welding by means of a laser, which is carried out during welding of steel sheets (2) to minimize the risk of crack formation or alteration of the microstructure in the region of the weld, it is proposed according to the invention that the heating of the region of the weld (6, 7) be carried out by means of a multiply stepped line inductor (4, 5) which can be set in a defined way and has zones of different power densities and is configured with a multiple division of its conductor loop lengths and / or with different plating of the conductor loops and / or with a plurality of spacing steps from the steel strip (2). Here, a steeper temperature rise occurs in the first heating stage than in the subsequent heating stage.

Owner:SMS DEMAG AG

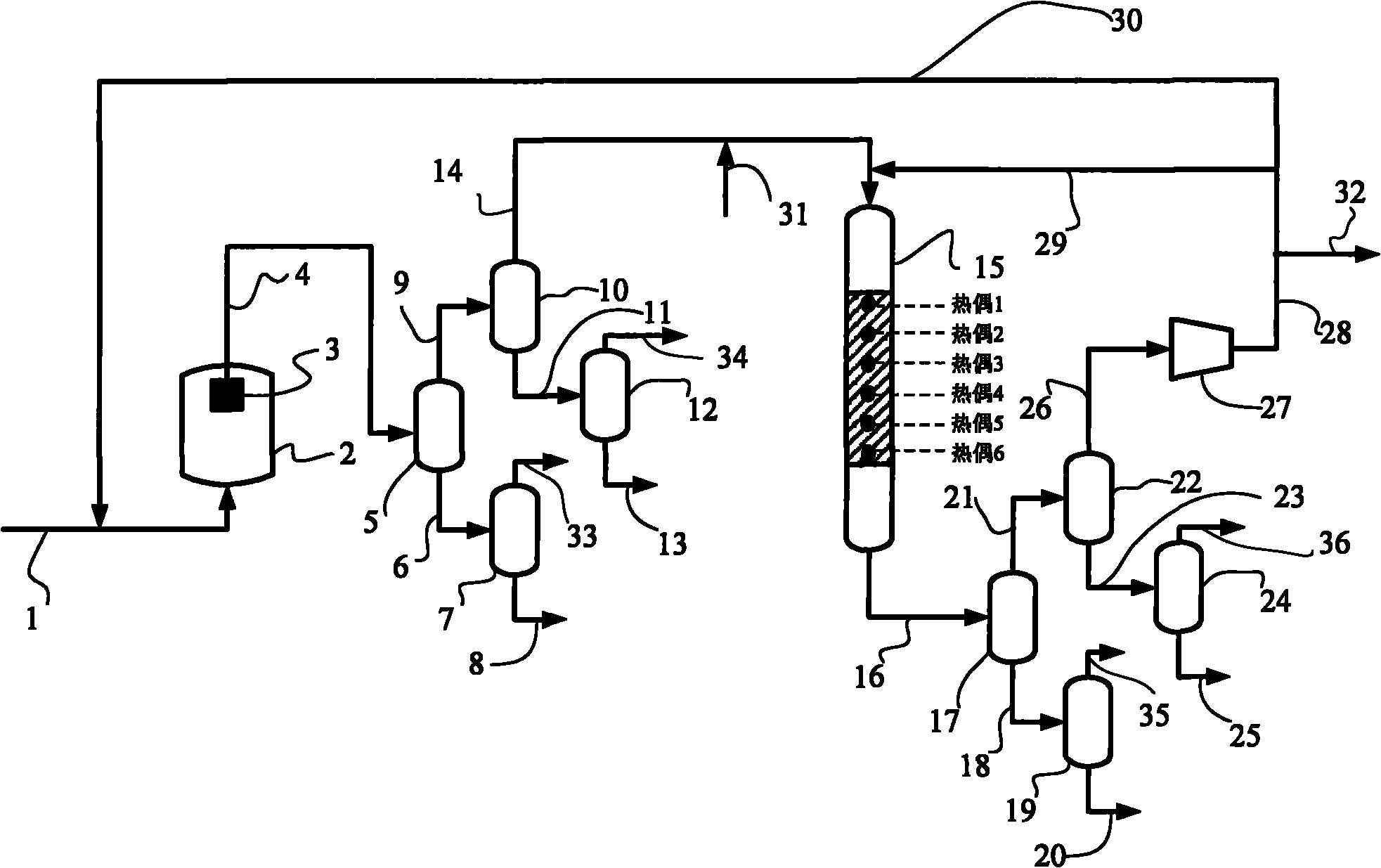

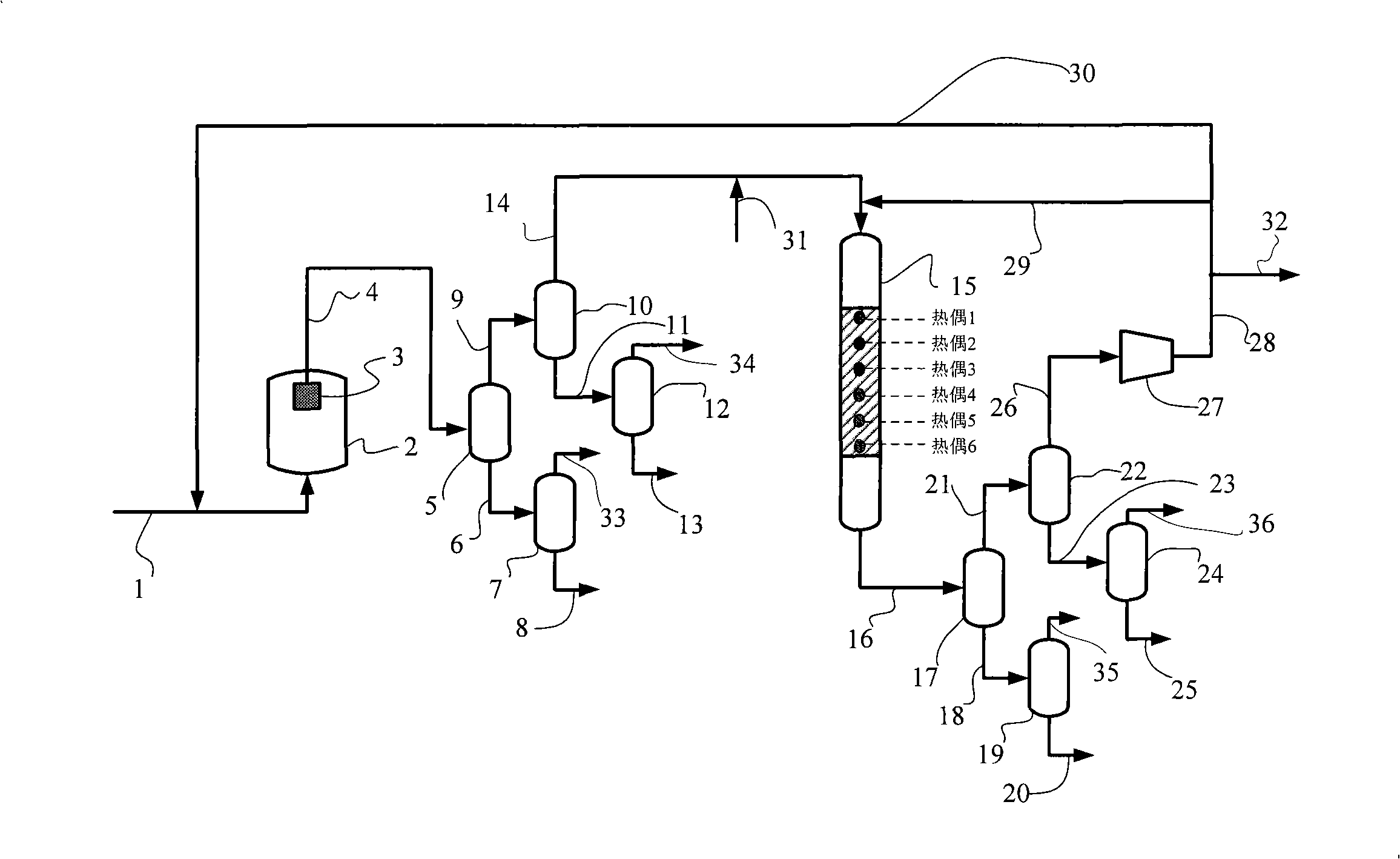

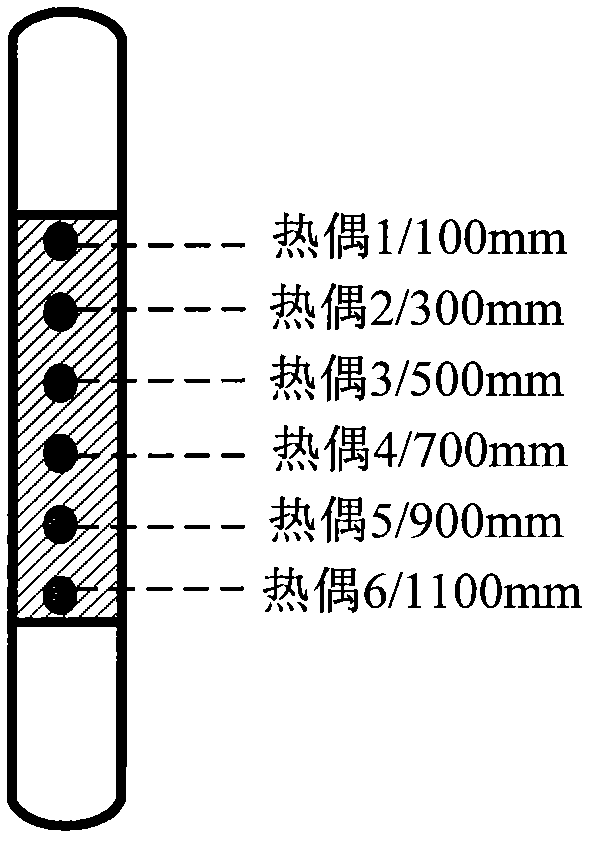

Method for making Fischer-Tropsch synthetic reaction stable

ActiveCN102952563AReduce the risk of overheatingSmall temperature differenceLiquid hydrocarbon mixture productionHydrogenSteady state

A method for making a Fischer-Tropsch synthetic reaction stable. A catalyst for Fischer-Tropsch synthesis is activated and enters an initial phase of a Fischer-Tropsch synthetic reaction; at the reaction initial phase, an inert medium is introduced into synthesis gas so as to allow a mixture flow containing hydrogen, carbon monoxide and the inert medium to contact with the Fischer-Tropsch synthesis catalyst bed layer for reaction; with the activity of the Fischer-Tropsch synthesis catalyst being in a steady state, the amount of the inert medium in the reactant flow is decreased gradually till the Fischer-Tropsch synthetic reaction is in a steady-state phase, wherein at the reaction initial phase, the reaction condition is the same as the reaction condition at the steady-state phase. With the method, the risk of overtemperature at the reaction initial phase is reduced; hot spot areas are reduced; the Fischer-Tropsch synthetic reaction can go into a steady-state phase stably; and guarantee for the long-period running of Fischer-Tropsch synthesis equipment is provided.

Owner:CHINA PETROLEUM & CHEM CORP +1

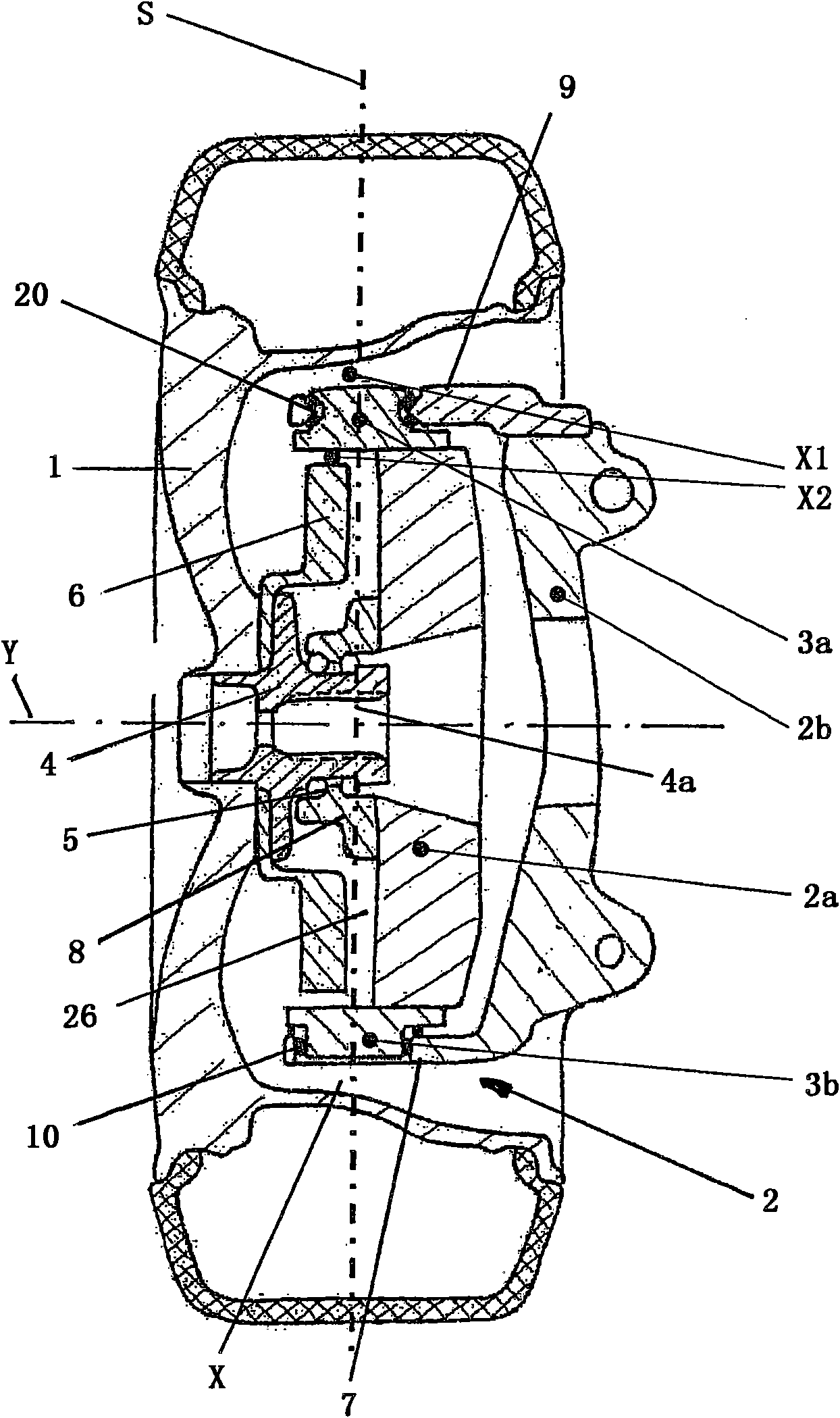

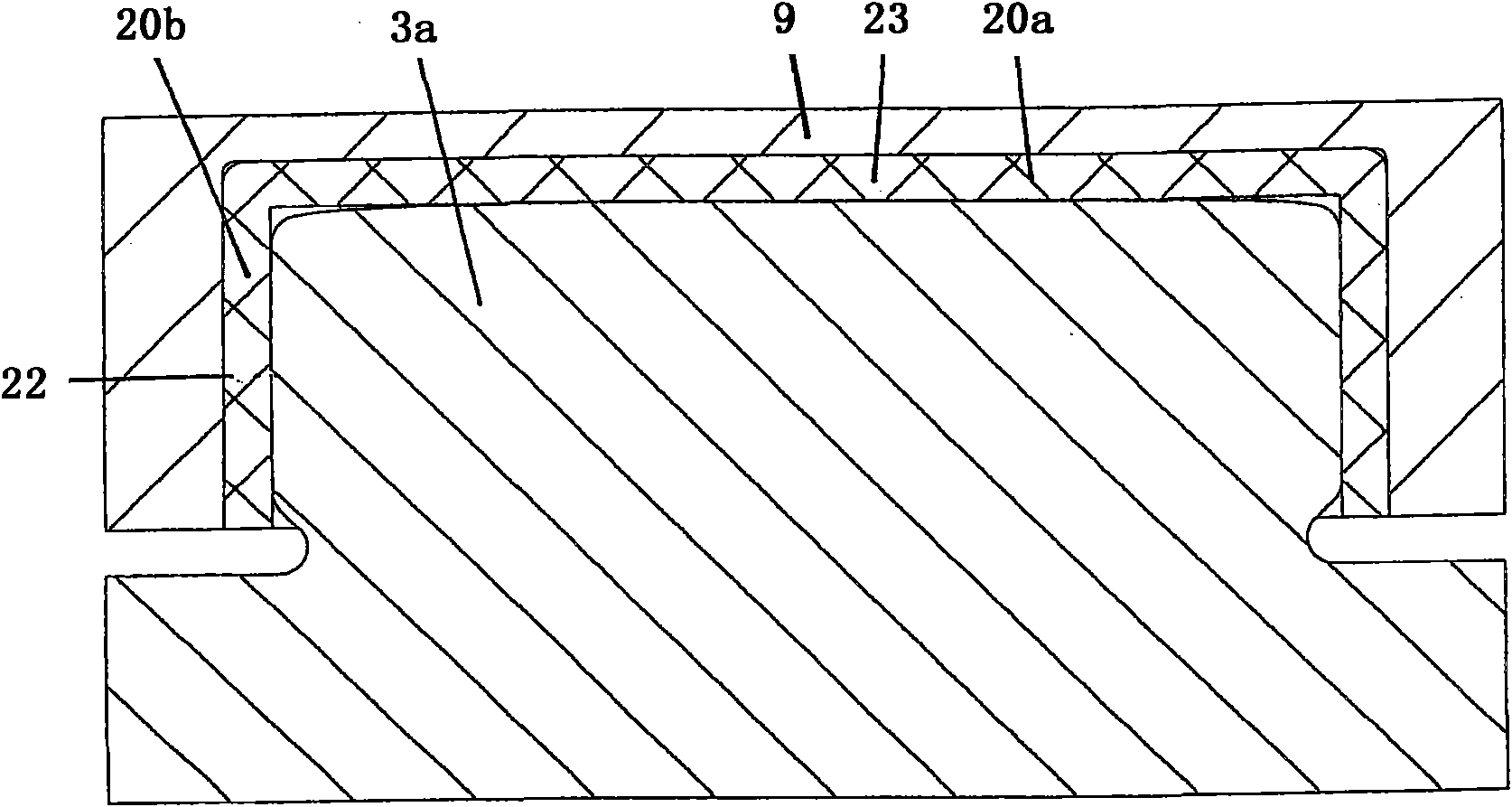

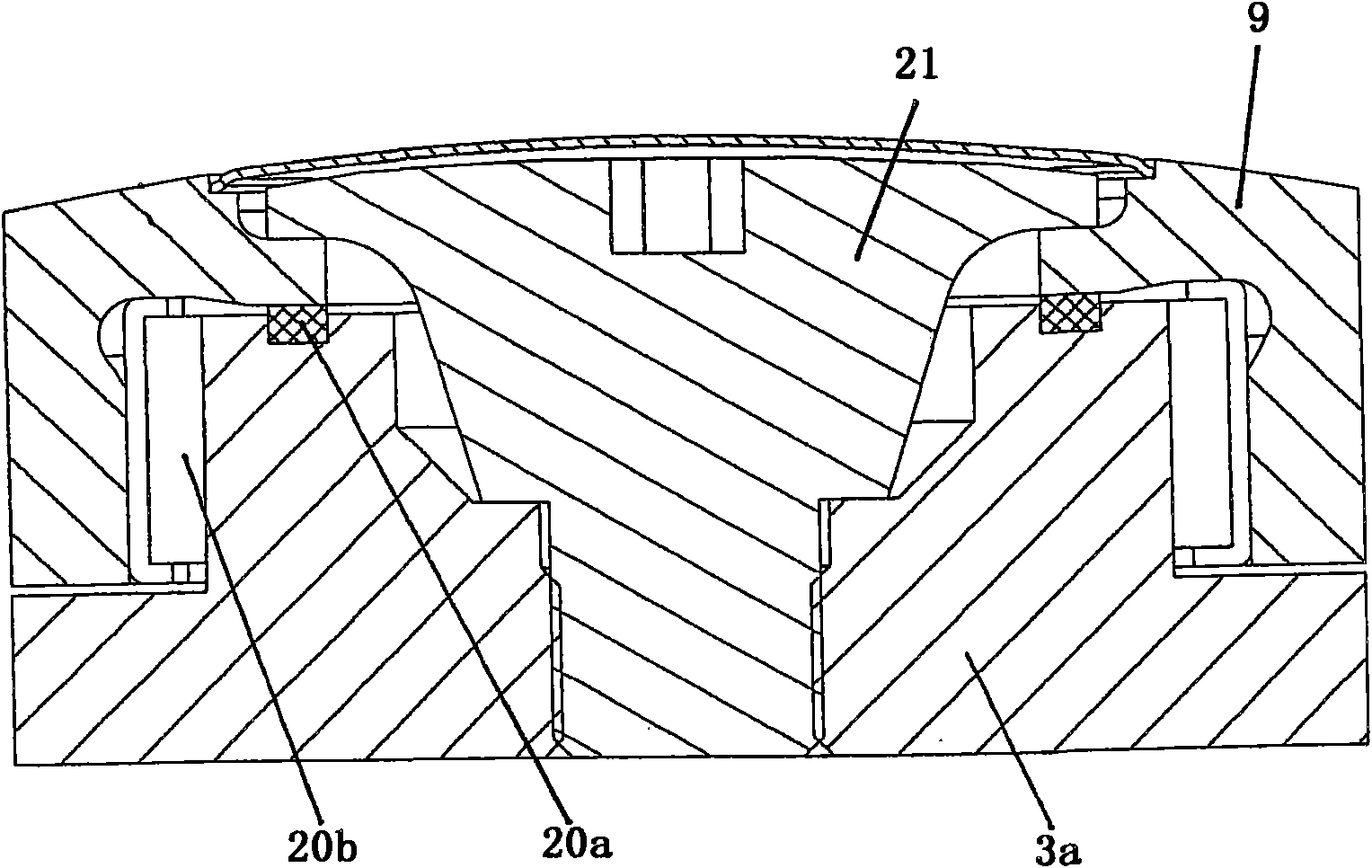

Motor vehicle wheel suspension with a suspension carrier unit pivotable around steering axis

InactiveCN101920629AImprove stabilityReduce the risk of overheatingBraking element arrangementsHubsMechanical engineeringEngineering

Owner:SCHAEFFLER TECH AG & CO KG

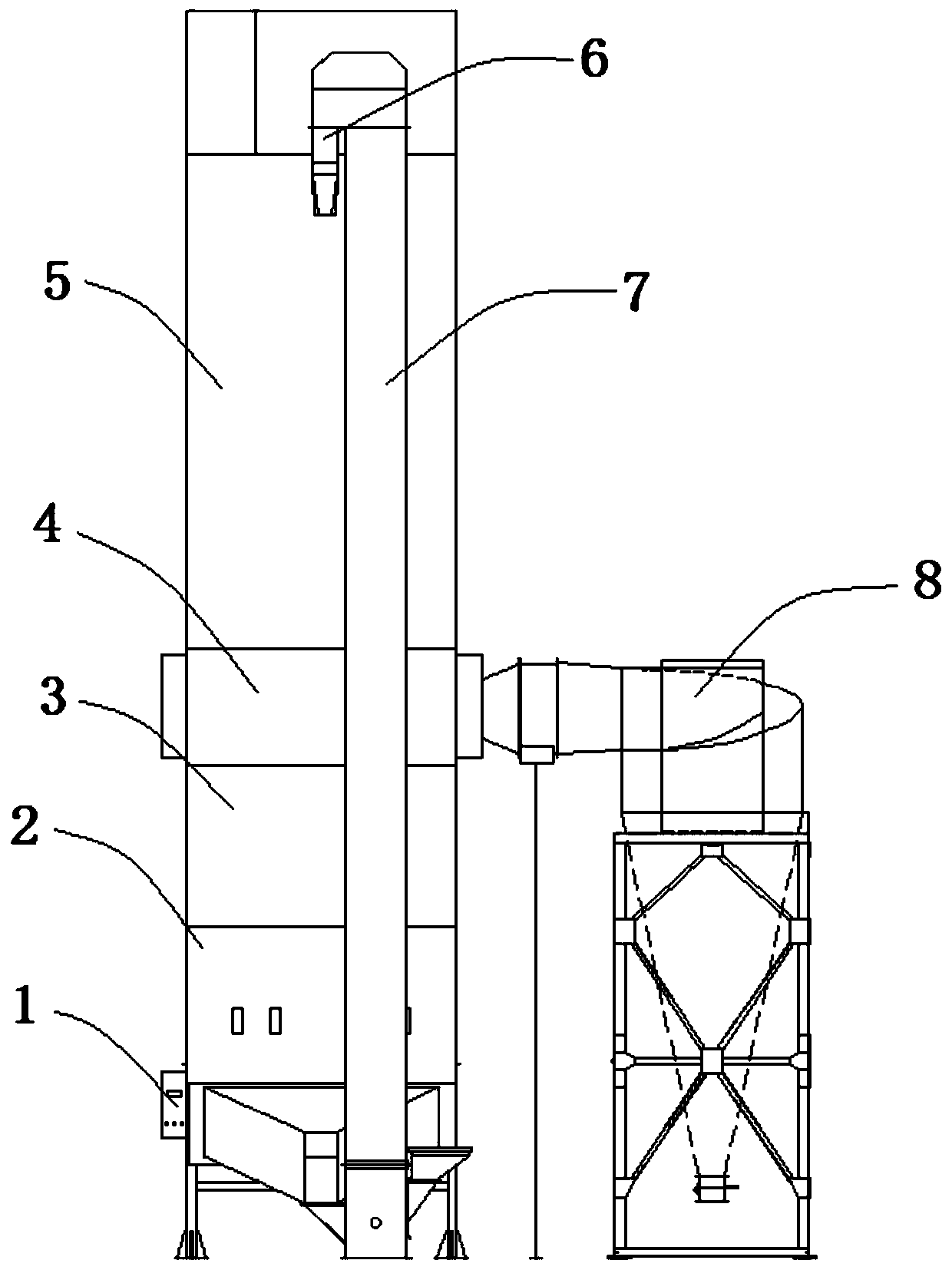

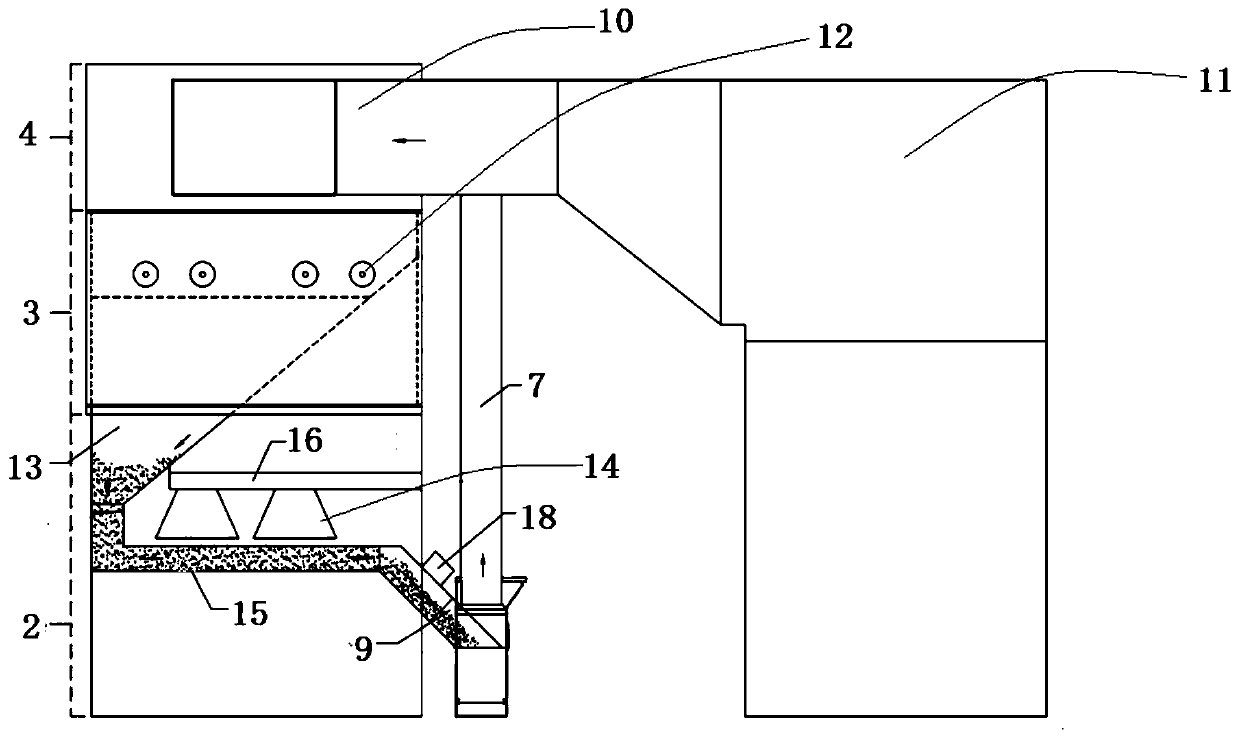

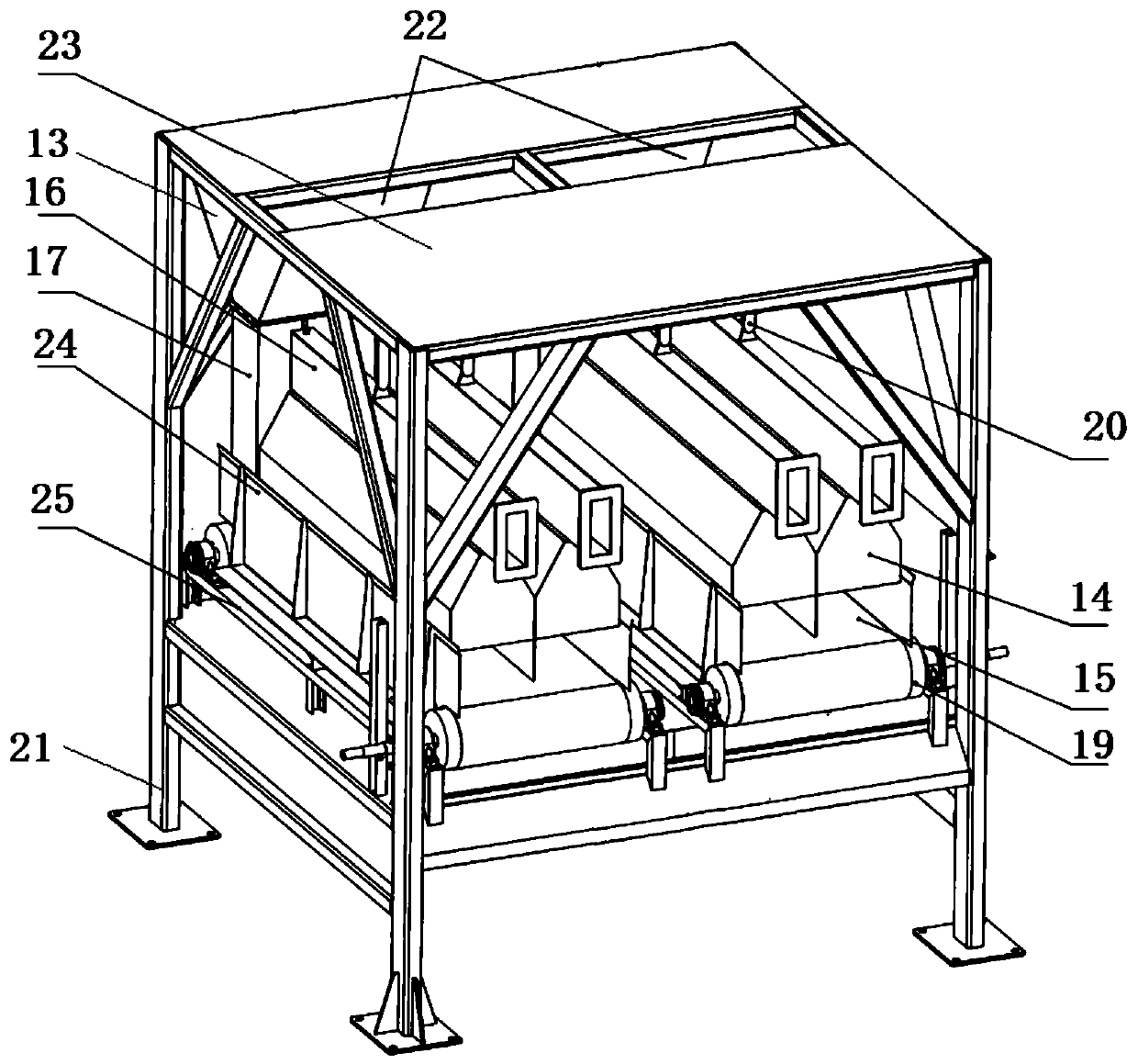

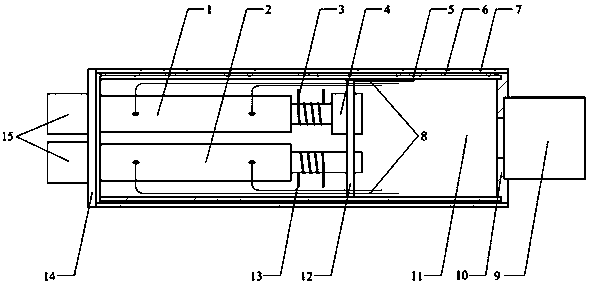

Batch type microwave grain dryer and drying method

PendingCN110094944AReduce waist burst rateReduce moisture gradientDrying solid materials with heatDrying gas arrangementsMicrowaveGrain elevator

The invention relates to a batch type microwave grain dryer and a drying method. The batch type microwave grain dryer is provided with a grain elevator, and a tempering bin, a drying chamber, a collecting chamber and a microwave heating device which are connected with each other are sequentially arranged from top to bottom, wherein the drying chamber is used for drying and dehumidifying grains, and the microwave heating device is used for microwave heating of grains; a discharging port at the upper end of the grain elevator is connected with the tempering bin, and a discharging port of the microwave heating device is connected with a feeding port at the lower end of the grain elevator. According to the batch type microwave grain dryer, the grain discharging speed, the microwave heating radiation frequency and the temperature and humidity of the drying chamber hot air are controlled according to grain temperature and grain moisture, so that variable temperature and variable frequency drying are realized, and the drying efficiency of the grain is effectively improved.

Owner:ZOOMLION HEAVY MASCH CO LTD

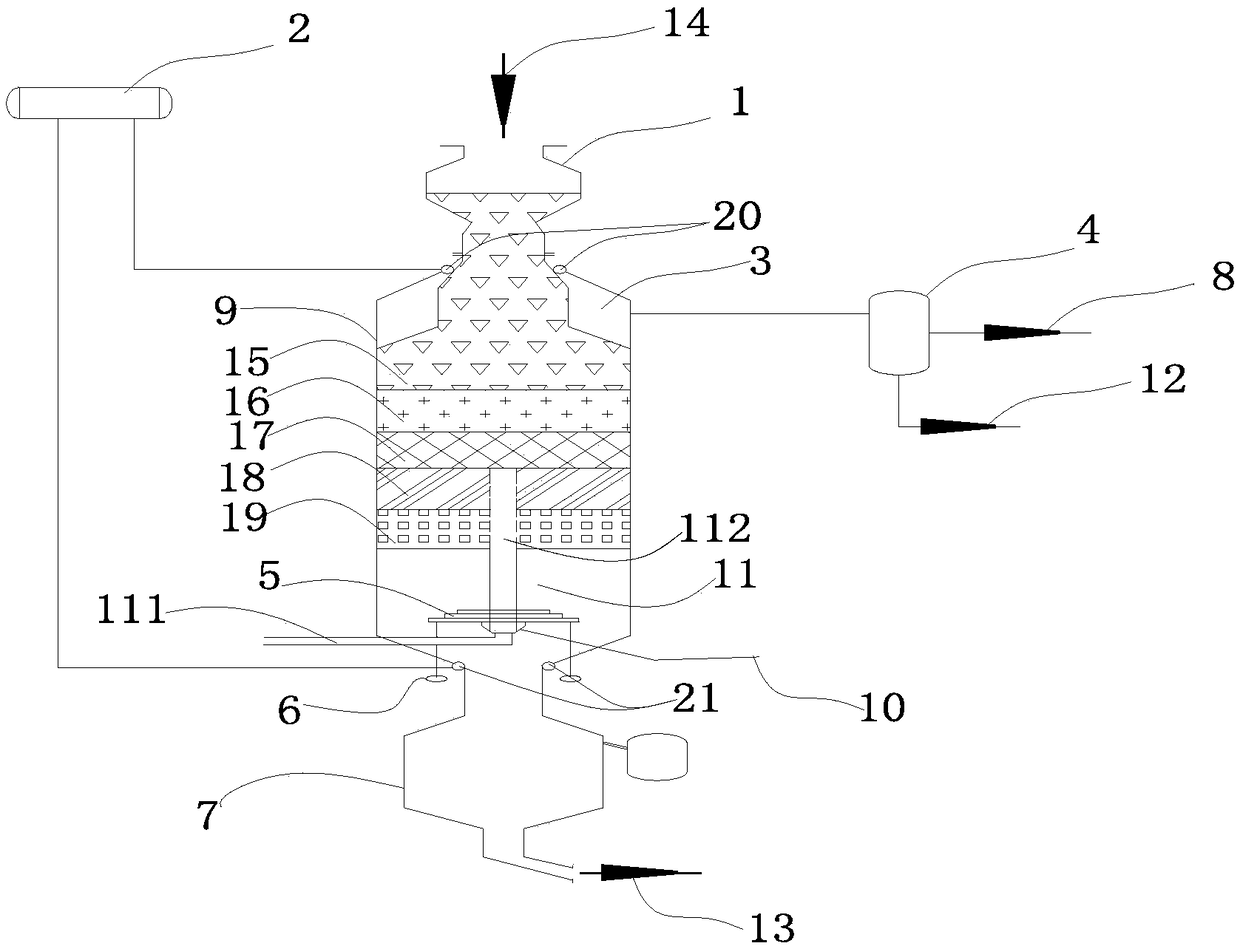

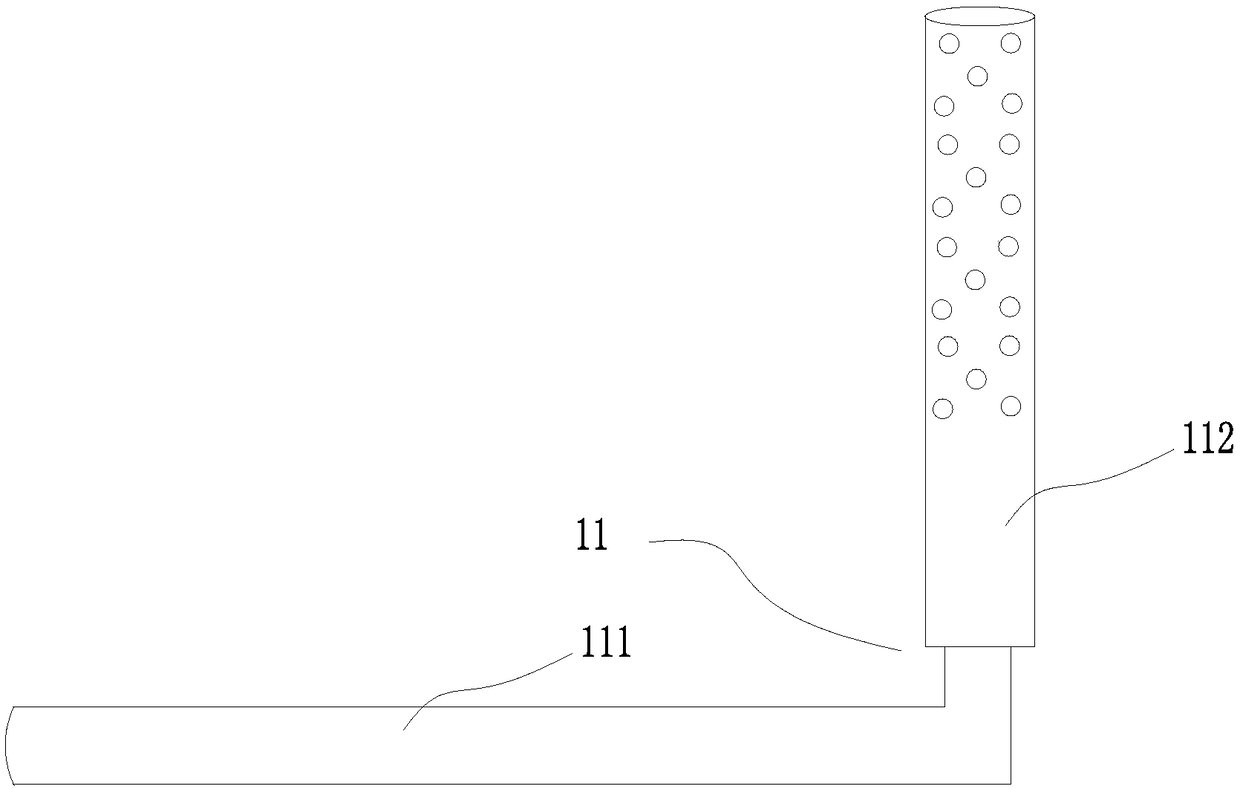

Water cooled wall type fixed bed gasifier capable of supplying oxygen in grading way

PendingCN108130132AIncrease heightEasy maintenanceGasifier feeding meansCombustible gas productionReaction layerCombustion chamber

The invention relates to a water cooled wall type fixed bed gasifier capable of supplying oxygen in a grading way. The gasifier comprises a water cooled wall outer shell, a gas liquid separator, a furnace grate system, a coal lock, an ash lock and a graded oxygen supply device. An upper opening and a lower opening are respectively formed in the top and the bottom of the water cooled wall outer shell; the gas liquid separator is communicated with the water cooled wall outer shell through a pipeline; the furnace grate system comprises a furnace grate and a transmission device; the coal lock is installed on the upper opening of the water cooled wall outer shell; the ash lock is installed on the lower opening of the water cooled wall outer shell; the graded oxygen supply device comprises a gasifying agent pipeline and a graded oxygen pipeline. The gasifier limits a gasification combustion chamber through the water cooled wall outer shell, the water cooled wall outer shell takes away the heat released by the high-temperature high-pressure coal gas, the outer shell avoids the damage caused by superhigh temperature, and the water cooled wall outer shell is more convenient to overhaul whenbeing compared with the water cooled sleeve type outer shell. By supplying the oxygen in a grading way, the height of a bed layer of a reaction layer is increased, the side reaction is reduced, the environment pollution is reduced, and the risk that the temperature of the furnace grate exceeds is reduced.

Owner:北京阳华科技有限公司

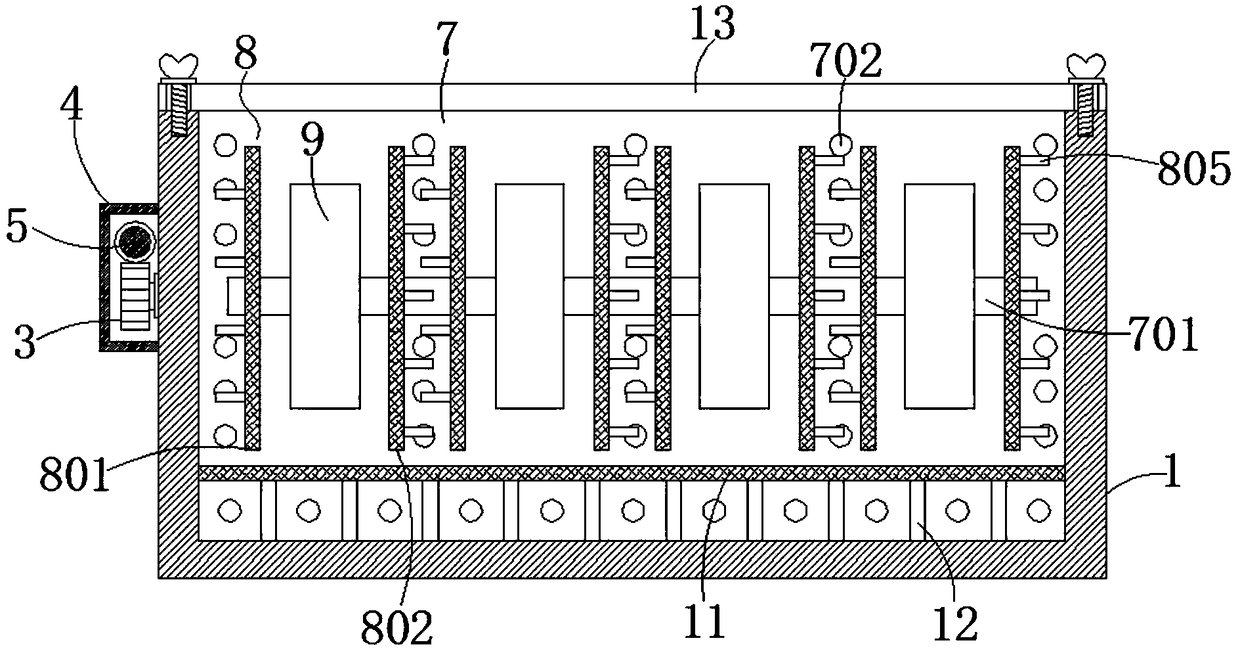

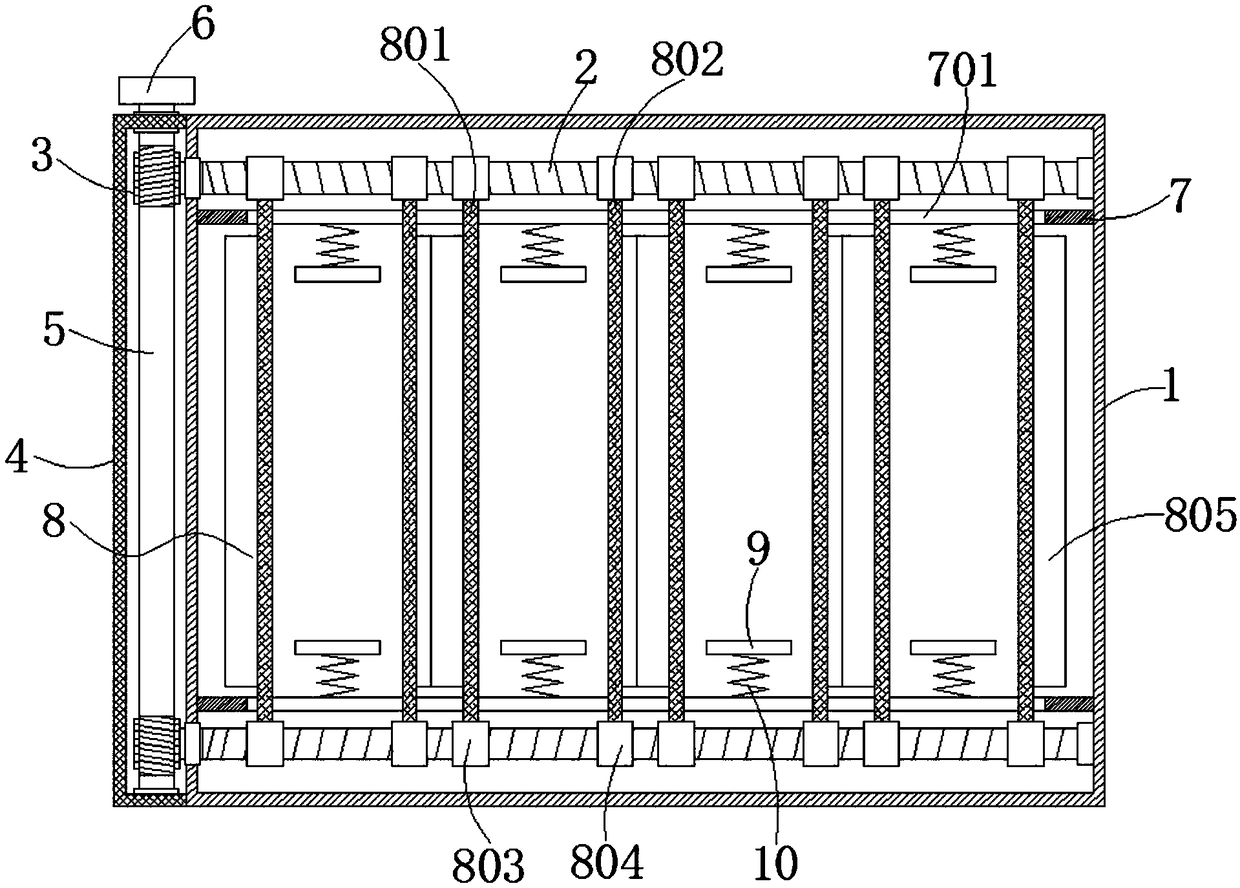

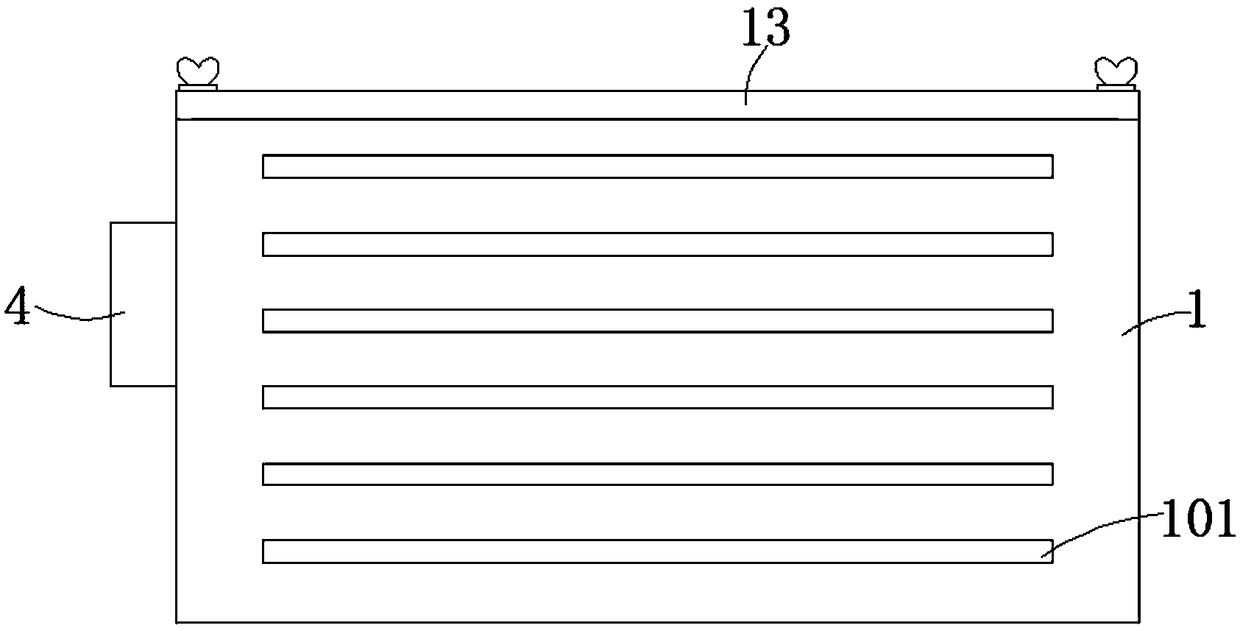

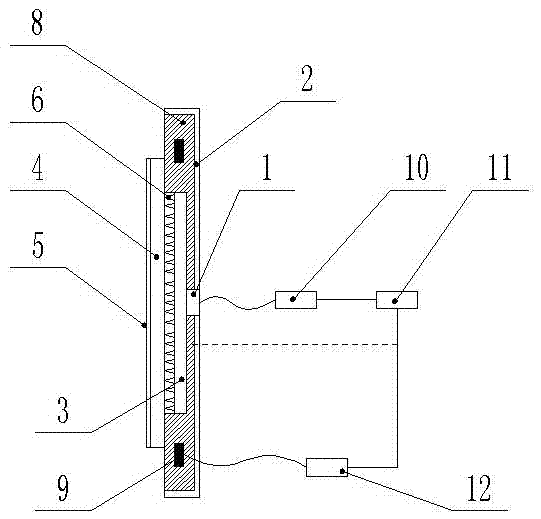

A lithium battery energy storage system battery box

InactiveCN109216615AEasy to disassembleEasy to installSecondary cellsCell component detailsEngineeringHeat sink

A lithium battery energy storage system battery box includes a box, threaded shank, Fixed frame, worm, rotary handle, fixing plate, cooling clamping mechanism, splint, spring, aluminium base plate, first fin, Cover, fan and fan switch, the front side wall of the box body is evenly provided with a ventilation groove, the front and rear sides of the box body are respectively provided with threaded rods, the right end of the threaded rod is rotatably connected with the right side wall of the box body, the left end of the threaded rod penetrates the left side wall of the box body, the left end ofthe threaded rod is provided with a worm wheel, The left side of the worm wheel is provided with a fixing frame, the fixing frame is fixed on the left side wall of the box body, a worm is arranged above the worm wheel, and the worm is meshed with the worm wheel. The invention is convenient to disassemble and assemble. The battery box can fix and efficiently radiate lithium batteries with differentsizes, effectively reduces the risk of excessively high temperature of the energy storage system, and has strong applicability.

Owner:浙江亚鼎科技有限公司

Medical electrode sheet

InactiveCN106924873AGuaranteed StrengthAvoid stimulationDiagnostic recording/measuringSensorsEngineeringElectrically conductive adhesive

The invention discloses a medical electrode sheet, which comprises a lead buckle, a backing sticker, a conductive electrode, a conductive adhesive and a release film, wherein the conductive electrode is arranged at the left side of the backing sticker; the conductive adhesive is arranged at the left side of the backing sticker; the conductive electrode and the conductive adhesive are both located in a groove of the backing sticker; the conductive electrode is located between the backing sticker and the conductive adhesive; the release film covers the surface of the conductive adhesive; one face, facing the conductive adhesive, of the conductive electrode is provided with projections distributed at uniform intervals; the projections are distributed on the conductive electrode according to a concentric circle form; the areas of cross sections, parallel with the conductive adhesive, of the projections are gradually reduced in a direction from the conductive electrode to the conductive adhesive, and a conical cylinder or tetrahedron structure form is formed; and the tail end of each projection is a plane or a spherical surface. processing and manufacturing are facilitated; contact with the skin is more uniform; stimulation on the skin of the human body is avoided; the temperature is monitored and controlled; and no hidden safety dangers in the case of use exist.

Owner:杨配媛

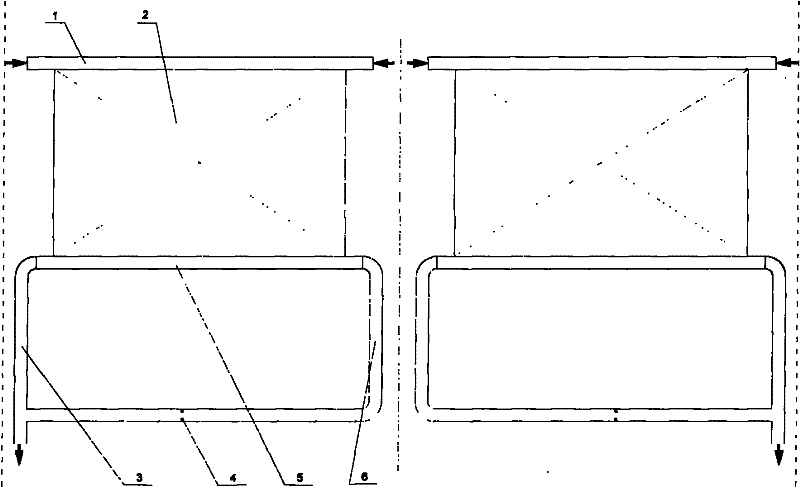

Arrangement method of tower-type boiler high-temperature reheater container system

The invention relates to an arrangement method of a tower-type boiler high-temperature reheater container system, which can reduce the thermal deflection among the screens of reheater effectively according to the operation characteristic of the tower-type boilers. The arrangement method comprises: arranging a resistance device in a lead-out steam guide pipe, close to the center of the boiler, of the tower-type boiler reheater outlet container, the distribution of inter-screen flow is changed by changing the difference between the lead-out flows on two sides of the reheater system outlet container so as to be matched with the distribution of inter-screen heat release difference on a smoke side to reduce inter-screen thermal deflection.

Owner:SHANGHAI WANGTE ENERGY RESOURCE SICENCE & TECH

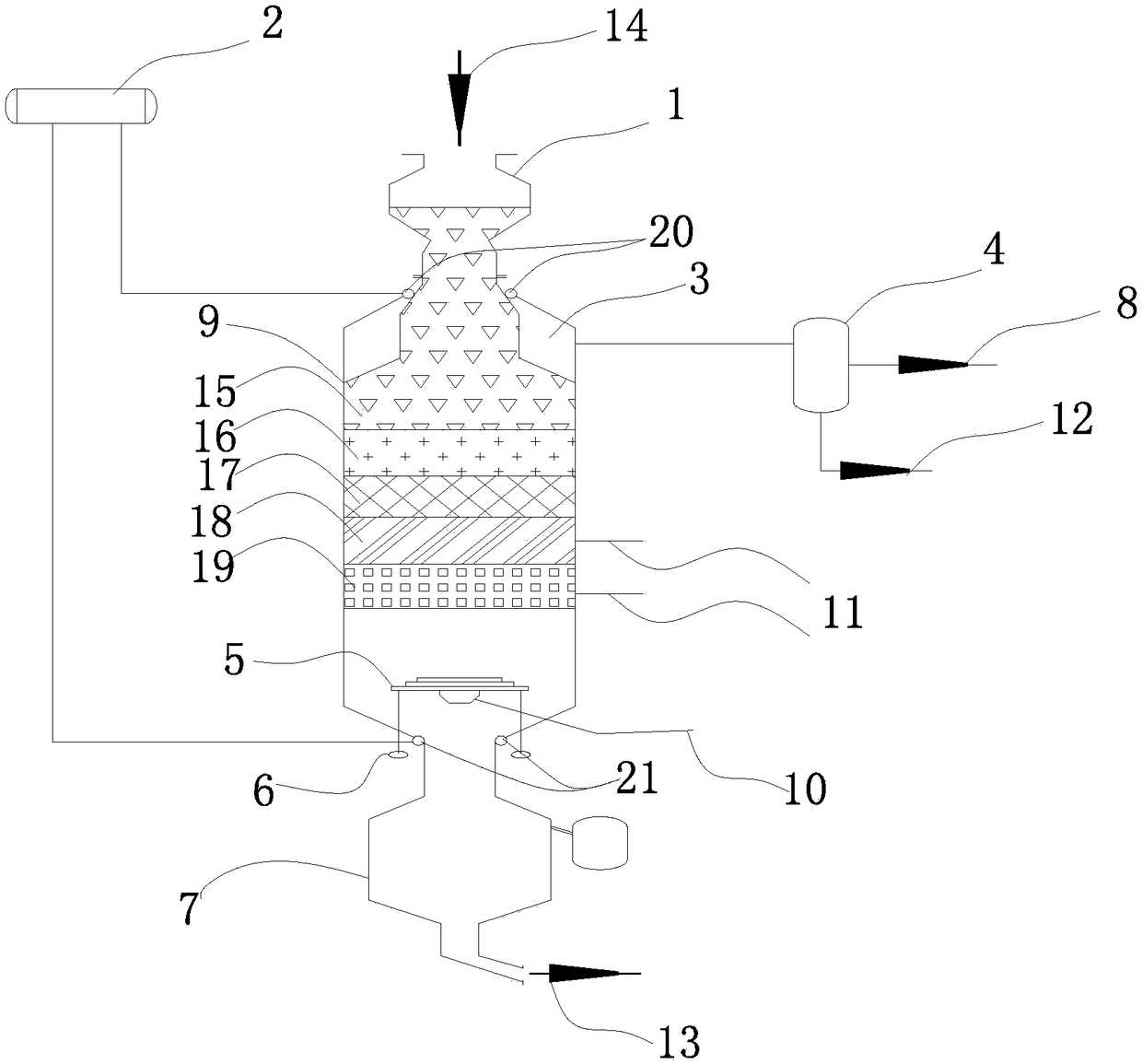

Central oxygen supply water-cooled wall type fixed bed gasifier

PendingCN108085066AIncrease heightEasy maintenanceGasification processes detailsCombustible gas productionReaction layerCombustion chamber

The invention relates to a central oxygen supply water-cooled wall type fixed bed gasifier. The gasifier comprises a water-cooled wall shell, a gas-liquid separator, a grate system, a coal lock, an ash lock and a stage-by-stage oxygen supplier, wherein the top and bottom of the water-cooled wall shell are respectively provided with an upper end opening and a lower end opening; the gas-liquid separator communicates with the water-cooled wall shell through a pipeline; the grate system comprises a grate and an actuator; the coal lock is mounted at the upper end opening of the water-cooled wall shell; the ash lock is mounted at the lower end opening of the water-cooled wall shell; and the stage-by-stage oxygen supplier comprises a gasifying agent pipeline and a central oxygen supply pipe. Thegasifier disclosed by the invention defines a gasifying combustion chamber by means of the water-cooled wall shell, and brings away heat released by high-temperature and high-pressure coal gas by means of the water-cooled wall shell, preventing the shell from being damaged by ultrahigh temperature, and compared with a water-cooled jacket type shell, the water-cooled wall shell is more convenient to overhaul. By stage-by-stage oxygen supply, the height of a bed layer of a reaction layer can be increased, the proceeding of side reaction is reduced, environmental pollution is reduced, and the risk that a grate overheats is decreased.

Owner:北京阳华科技有限公司

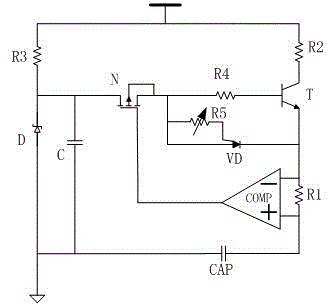

Intelligent lamp charger of intelligent traffic system

InactiveCN105140997AReduce switching frequencyReduce the risk of overheatingBatteries circuit arrangementsElectric powerSwitching frequencyComparator

The invention relates to an intelligent lamp charger of an intelligent traffic system. The intelligent lamp charger includes a charging triode and a comparator, an emitting electrode of the charging triode is connected with a charging output end through a current detection resistor, two ends of the current detection resistor are connected with two input ends of the comparator, the intelligent lamp charger also includes a compensating pipe and a base voltage generation circuit, a control end of the compensating pipe is connected with an output end of the comparator, an input end and an output end of the compensating pipe are connected with an output end of the base voltage generation circuit and a base electrode of the charging triode, the base voltage generation circuit is formed by a divider resistor and a voltage stabilizing diode which are connected in series, and a temperature protection circuit is connected in parallel between the base electrode and the emitting electrode of the charging triode. The intelligent lamp charger of the intelligent traffic system does not control the triode directly, and lowers switching frequency of the charger tube, thereby reducing switching loss, and the intelligent lamp charger has a temperature regulation function, thereby reducing risks caused by overheating of a device.

Owner:CHENGDU CHUANRUI TECH

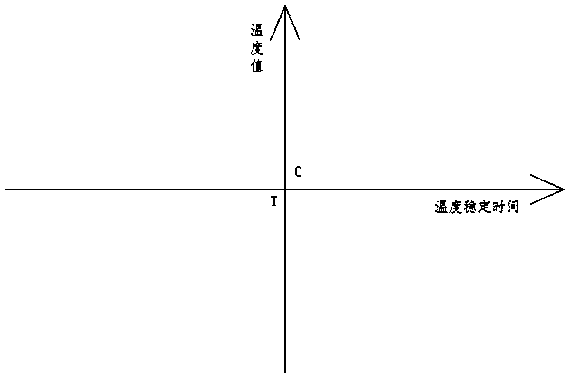

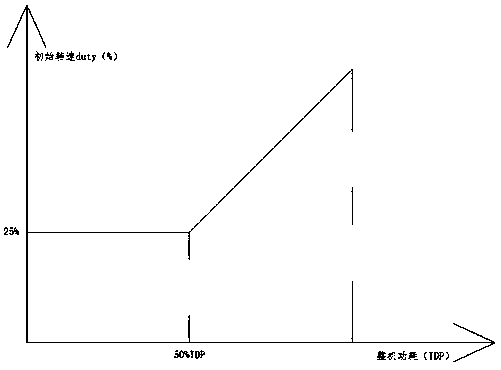

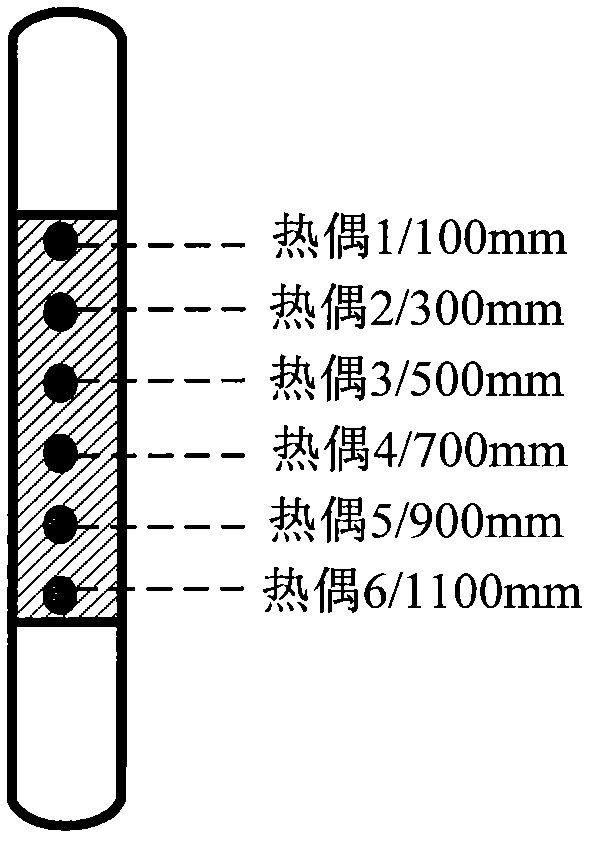

Fan regulation and control method based on overall power consumption

InactiveCN107893773AGive full play to the role of regulationReduce power consumptionPump controlNon-positive displacement fluid enginesEngineeringPower consumption

The invention relates to a fan regulation and control method based on overall power consumption. The fan regulation and control method is characterized by comprising the following steps: S1: collecting temperature values of electronic elements and devices, and setting a boundary point C of the temperature values of the electronic elements and devices; S2: determining temperature stable time of theelectronic elements and devices, and setting a boundary point T of the temperature stable time of the electronic elements and devices; S3: collecting the power consumption value of a fan; S4: regulating and controlling a PID parameter according to the boundary point C of the temperature values of the electronic elements and devices and boundary point T of the temperature stable time of the electronic elements and devices, to realize increase or reduction of a rotary speed of the fan; and S5: regulating and controlling an initial rotary speed value of the fan according to the collected fan power consumption value.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

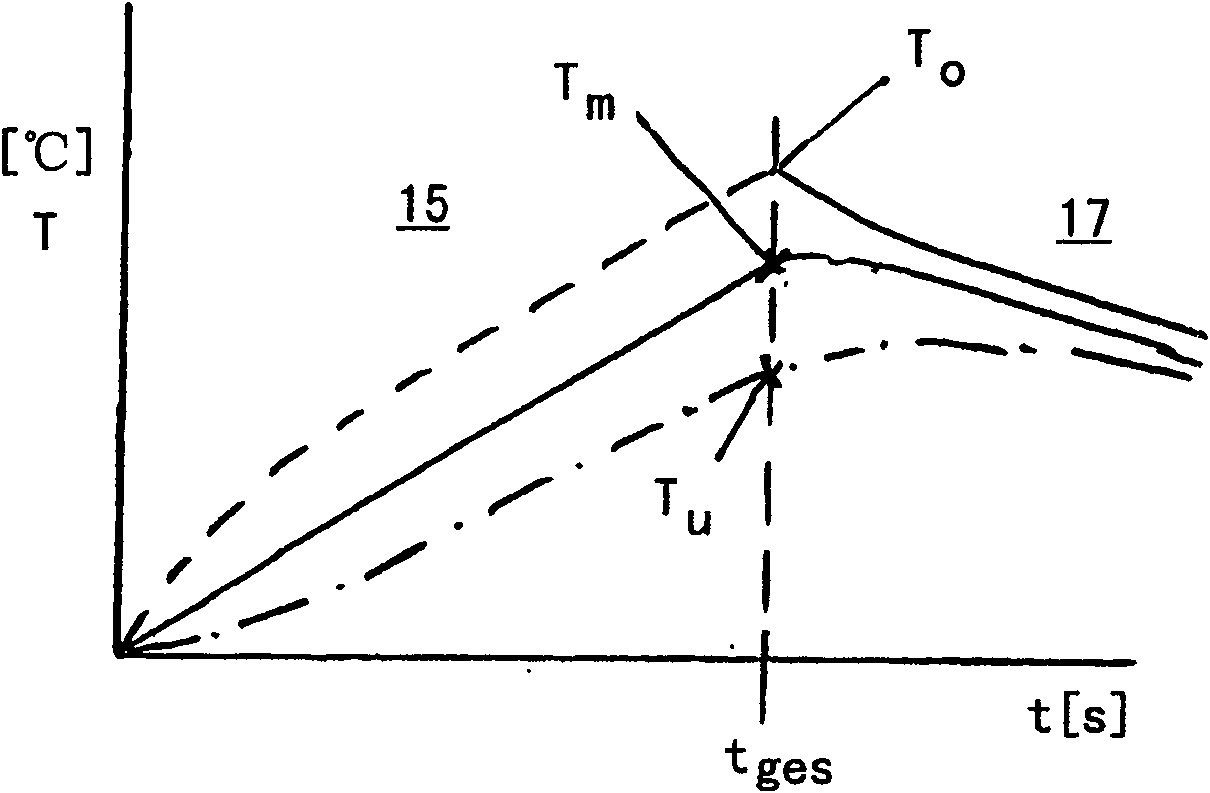

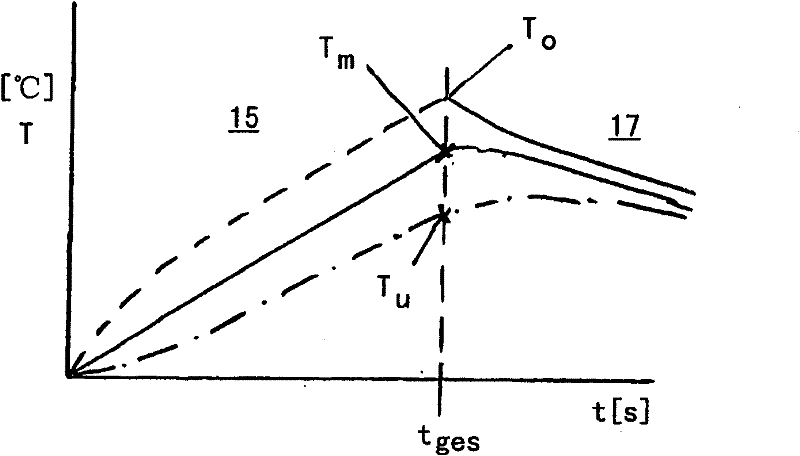

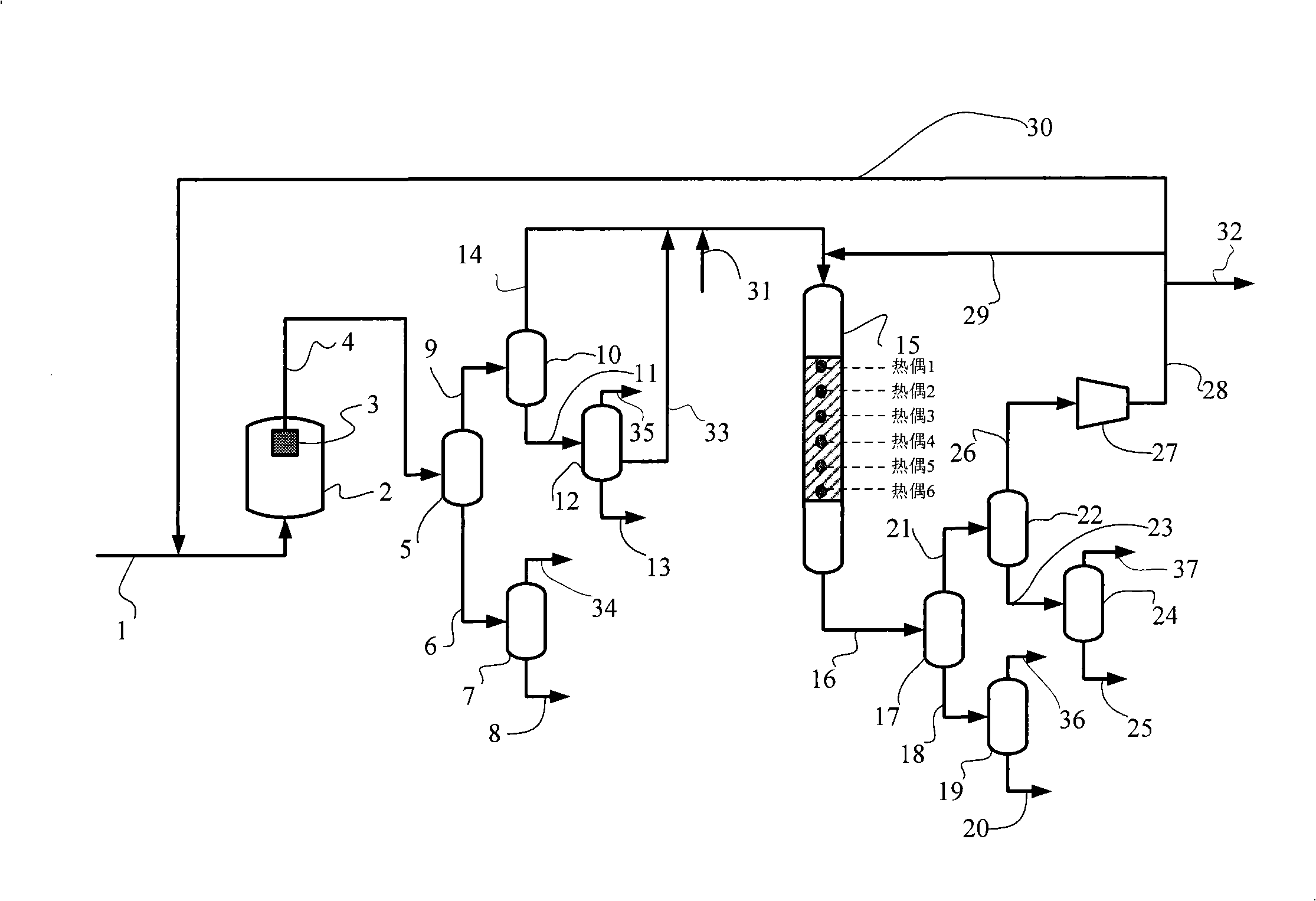

Fischer-Tropsch synthesis device starting method

ActiveCN103007835AReduce the risk of overheatingSmooth startChemical/physical processesLiquid hydrocarbonsTemperature difference

The invention discloses a Fischer-Tropsch synthesis device starting method. The Fischer-Tropsch synthesis device starting method comprises the following step that 1, a Fischer-Tropsch synthesis catalyst is reduced by reduction gas at a temperature of 300 to 600 DEG C; 2, a Fischer-Tropsch synthesis reaction process is carried out under the condition of an axial temperature difference delta T1 of a catalyst bed; 3, a Fischer-Tropsch synthesis reaction process is carried out under the condition of an axial temperature difference delta T2 of the catalyst bed; and 4, a Fischer-Tropsch synthesis reaction process is carried out under the condition of an axial temperature difference delta T3 of the catalyst bed so that a liquid hydrocarbon is produced, wherein the axial temperature difference delta T1 is more than 0DEG C and less than 1 / 2 of the axial temperature difference delta T2; and the axial temperature difference delta T2 is more than 1 / 3 the axial temperature difference delta T3 and less than 2 / 3 of the axial temperature difference delta T3. The Fischer-Tropsch synthesis device starting method can solve the problem that in Fischer-Tropsch synthesis device starting, a temperature is over the standard temperature easily, and can improve starting smoothness.

Owner:CHINA PETROLEUM & CHEM CORP +1

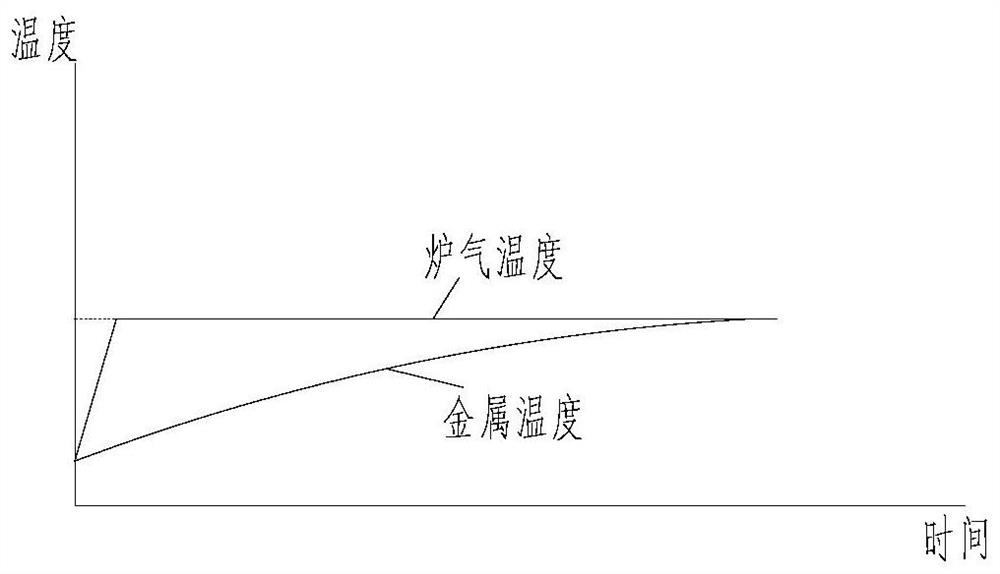

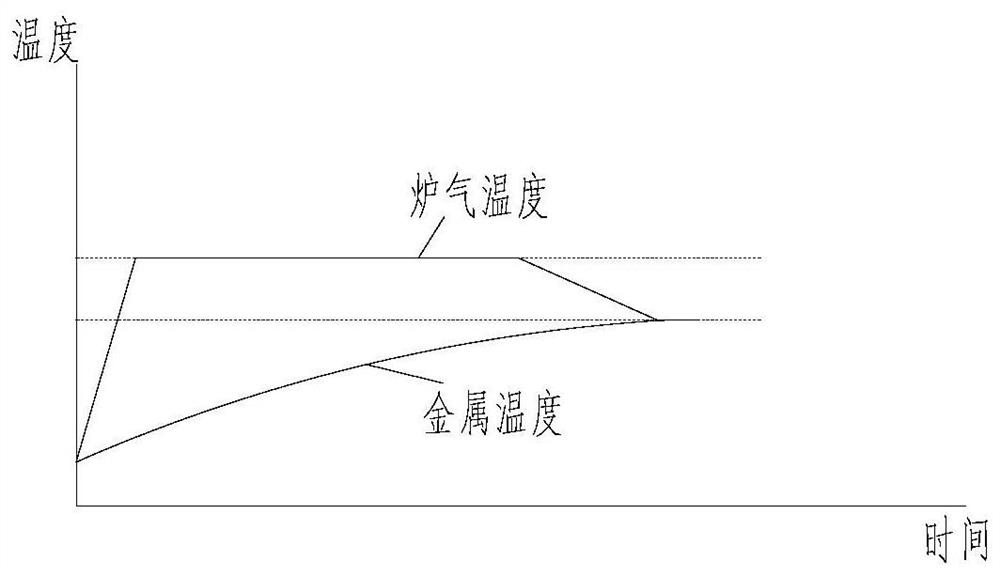

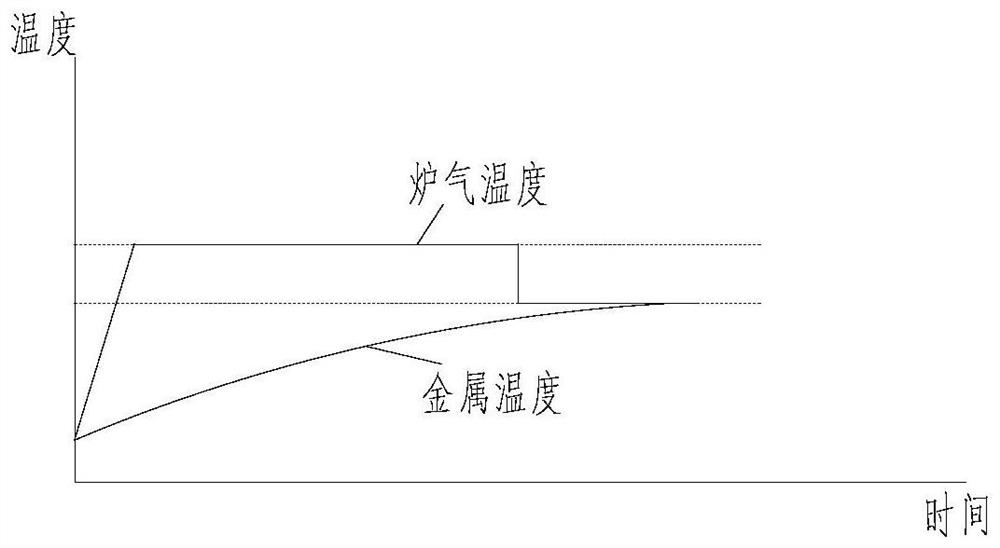

Proportional cooling control method used for differential temperature heating technology heat treatment furnace

PendingCN113481361AShorten the production cycleReduce the risk of metal overheatingHeat treatment process controlAutomatic controlProcess engineering

The invention belongs to the technical field of heat treatment, and particularly relates to a proportional cooling control method used for a differential temperature heating technology heat treatment furnace. At present, an excessively-small slope of slope cooling is prone to metal overtemperature, and the production cycle can be prolonged due to an excessively-large slope; and the production period of jump cooling is long. According to the proportional cooling control method used for the differential temperature heating technology heat treatment furnace, the metal temperature participates in furnace gas temperature control, and the metal temperature and an original PID temperature control algorithm of a control system are combined, so that the production period is greatly shortened, and meanwhile, the risk of metal overtemperature is avoided; and an effect of automatically controlling a differential temperature cooling process is achieved, the production period is shortened, and the purpose of reducing the risk of metal overtemperature is achieved.

Owner:BEIJING AVIATION FEIFANG MACHINERY EQUIP FACTORY

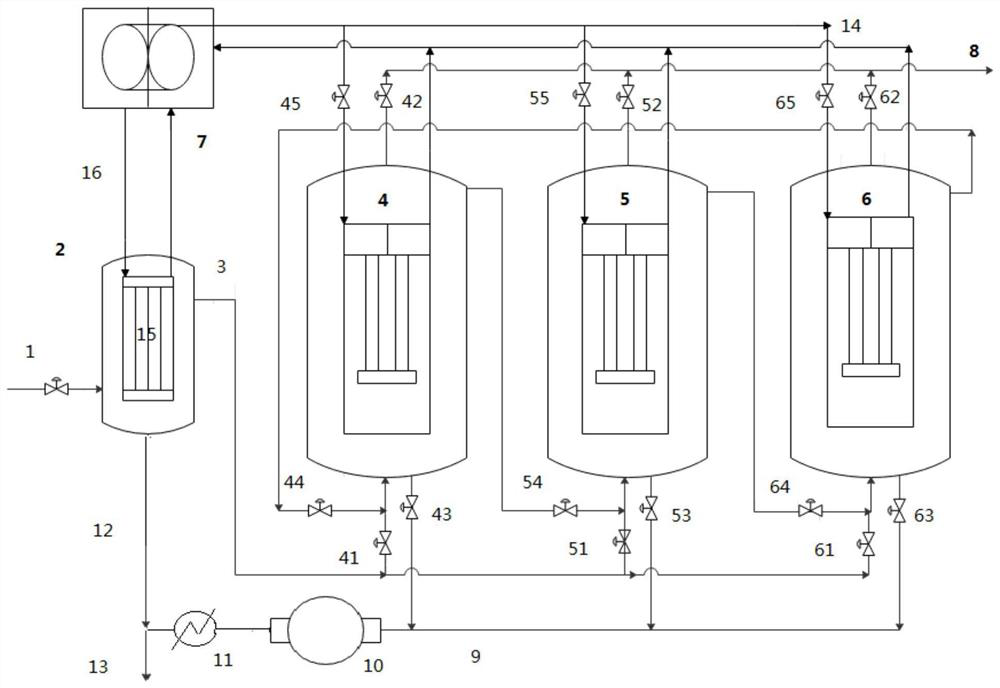

Low-temperature adsorption and high-temperature desorption efficient oil gas recovery method

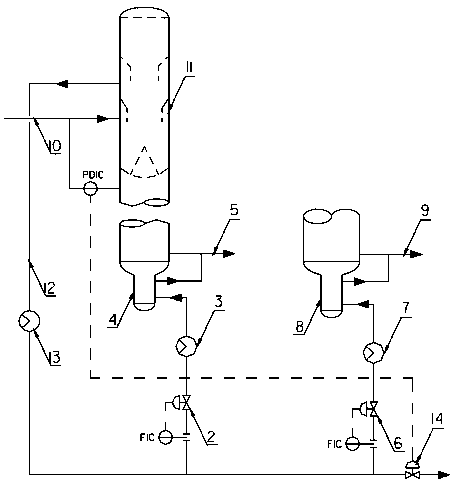

PendingCN113041771AEnsure stable operationAchieve efficient utilizationGas treatmentDispersed particle separationRefrigerantEvaporator

The invention discloses a low-temperature adsorption and high-temperature desorption efficient oil gas recovery method, and relates to an oil gas recovery method. Raw material oil gas is introduced into a primary cooling tower, a refrigerant in a heat pump system is used for evaporating and refrigerating in an evaporator in the tower to cool the raw material oil gas, part of heavy components and water vapor in the oil gas are condensed and separated, condensate generated by cooling enters an absorption system, and cooled low-temperature oil gas enters an adsorption unit. The adsorption unit is provided with at least three towers, two towers are connected in series for adsorption, the other tower is used for desorption and regeneration, and the three towers are alternately switched through valve control in the adsorption and desorption processes to circularly treat oil gas. The gas reaching the emission standard after adsorption is discharged. Saturated oil gas is adsorbed by the adsorption tower, heat obtained in the primary cooling tower enters a heat exchange facility in the adsorption tower by the heat pump system through refrigerant circulation of the heat pump system to heat an adsorption bed layer, vacuum desorption is carried out, and desorbed oil gas is introduced into the absorption system. Low-temperature adsorption and high-temperature desorption are realized, the oil gas recovery rate is high, the adsorbent regeneration efficiency is high, and the operation cost is low.

Owner:周静怡

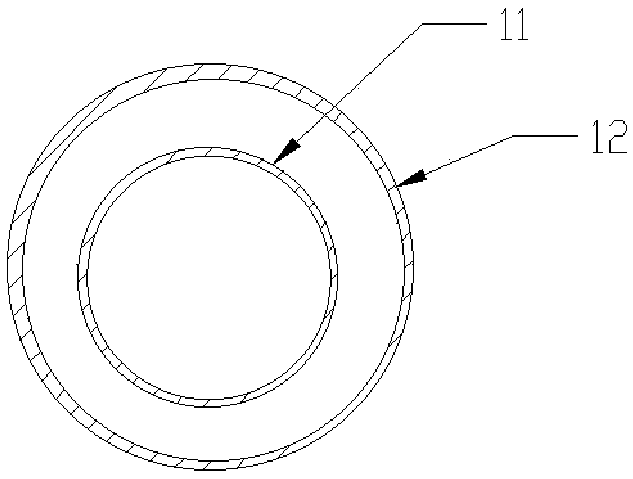

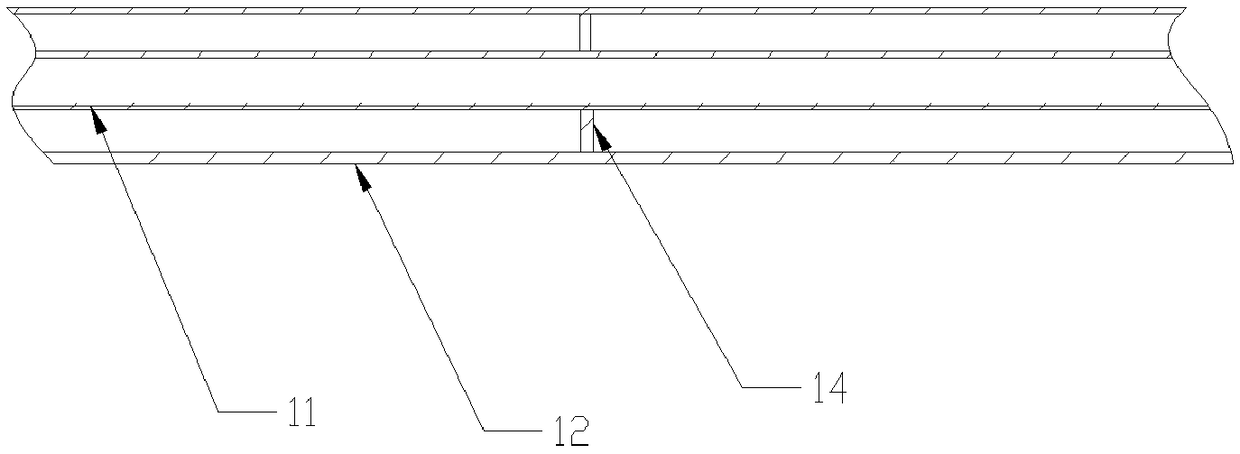

Refrigerating device and refrigeration and transportation box provided with same

PendingCN109264202AStable and accurate temperatureAvoid low temperaturesContainers preventing decayShock-sensitive articlesTemperature controlEngineering

The invention provides a refrigerating device and a refrigeration and transportation box provided with the same and relates to the field of refrigeration device. The technical problem is solved that arefrigeration unit existing the prior art possibly causes inaccurate temperature control of a refrigeration chamber in the refrigeration process. The refrigeration device comprises a refrigeration unit and a cold energy transmission portion, wherein the cold energy transmission portion comprises a communicating pipe for containing a refrigerant and an energy storing device coating the outer surface of the communicating pipe, the refrigerant can flow in the refrigeration unit and the communicating pipe, the energy storing device comprises a sleeve arranged on the outer surface of the communicating pipe, an airtight space is formed between the inner surface of the sleeve and the outer surface of the communicating pipe and is filled with energy storage liquid, and the energy storing device can absorb and store the cold energy released by the refrigerant. By utilizing the refrigerating device, an appropriate refrigerating environment can be provided for a refrigerator or a refrigeration box more accurately.

Owner:北京优冷供应链管理有限公司

Warm feeling enhancing fabric and preparation method thereof

ActiveCN112609467AEfficient thermal managementRelieve drynessTextiles and paperHeat managementThermal insulation

The invention provides a warm feeling enhancing fabric and a preparation method thereof. The warm feeling enhancing fabric comprises a heating layer, a heat conduction and heat storage layer and a thermal insulation layer. The heating layer is a fabric finished by a warm feeling and moisture retention composite finishing agent, the heat conduction and heat storage layer is a high heat conduction phase change microcapsule coating, and the thermal insulation layer is an aerogel foaming coating. According to the preparation method, efficient heat management of the fabric can be realized through cooperation of heating, heat conduction, heat storage and heat insulation effects among all layers, so that the warm feeling effect is remarkably enhanced; and meanwhile, moisturizing factors are added into the fabric, so that dryness and discomfort of the skin are relieved in winter, and the skin can be kept moist.

Owner:武汉中科先进材料科技有限公司

Bearing cavity sealing system of aero-engine and control method of bearing cavity sealing system

PendingCN114776402AReduce sealing pressure differenceHigh trafficLeakage preventionMachines/enginesEngineeringAir compressor

The invention discloses a bearing cavity sealing system of an aero-engine and a control method of the bearing cavity sealing system. The bearing cavity sealing system of the aero-engine comprises an air guide flow path and at least two exhaust flow paths, the air guide flow path is used for guiding sealing air into a middle bearing cavity and a rear bearing cavity from an air compressor, and the exhaust back pressures of the at least two exhaust flow paths are different. The air guide flow path is selectively communicated with at least one exhaust flow path in the at least two exhaust flow paths. According to the bearing cavity sealing system of the aero-engine, the exhaust flow paths with different exhaust back pressures are arranged, so that the exhaust back pressures of the air guide flow paths can be controlled according to the running state of the aero-engine, and then the flow of sealing air is adjusted. When the aero-engine is in a high Mach number pneumatic parameter state, the exhaust back pressure is reduced to further reduce the horizontal distribution of the on-way pressure of an air guide flow path, so that the sealing pressure difference of a bearing cavity is effectively reduced, and the lubricating oil consumption is reduced.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Method and apparatus for the heat treatment of welds

InactiveCN101578379BReduce temperature gradientReduce the risk of overheatingInduction heatingFurnace typesLoop lengthEngineering

Owner:SMS DEMAG AG

A method and calorimeter for measuring the heat release rate of materials in a reactor

ActiveCN105913886BQuick exportReduce precisionNuclear energy generationNuclear monitoringTest sampleTemperature difference

The invention discloses a technique for measuring the heat release rate of materials in a reactor. The thermal compensation method is used to measure the heat release rate of the material based on the equivalent heat equivalent principle of temperature difference. The calorimeter designed by this technology is mainly composed of two measurement bridges and a comparison bridge with the same shape and material. The sample material is fixed on the measurement bridge, and controllable electric power is input on the comparison bridge to make the temperature difference between the measurement points on the comparison bridge The temperature difference between the measuring points corresponding to the measuring bridge is equal, and the input controllable electric power divided by the sample mass is the heat release rate of the sample to be tested. In order to allow the calorimeter to be placed in a static coolant and to increase its safety, the calorimeter has a cold junction with enhanced heat transfer capability. In order to weaken the influence of gas heat conduction and radiation heat transfer on the measurement results, the calorimeter adopts a double cladding design with a gap between the two claddings. This technology effectively overcomes the influence of material properties on the measurement results due to changes in environmental parameters and reduces the impact on The correction of the experimental results realizes the direct measurement of the heat release rate of the material.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Method for improving process of displacement gas of reactor of continuous reformer

InactiveCN108018073AImprove healthReduce the risk of overheatingNaphtha treatmentHydrogenEthyl Chloride

The invention discloses a method for improving a process of a displacement gas of a reactor of a continuous reformer. The displacement gas is changed from circulating hydrogen to gas-source hydrogen containing less hydrocarbon substances so as to solve the technical problems that lifting and transportation are influenced by a catalyst with oil caused by poor purging effects of the circulating hydrogen due to many hydrocarbon substances in the circulating hydrogen; and non-methane hydrocarbons in a regenerated vent gas exceed the standards because a chlorine absorption section or a chlorine absorption tank of the spent catalyst tend to deterioration in operating conditions and has the hydrocarbon substances.

Owner:SINOPEC GUANGZHOU ENG +1

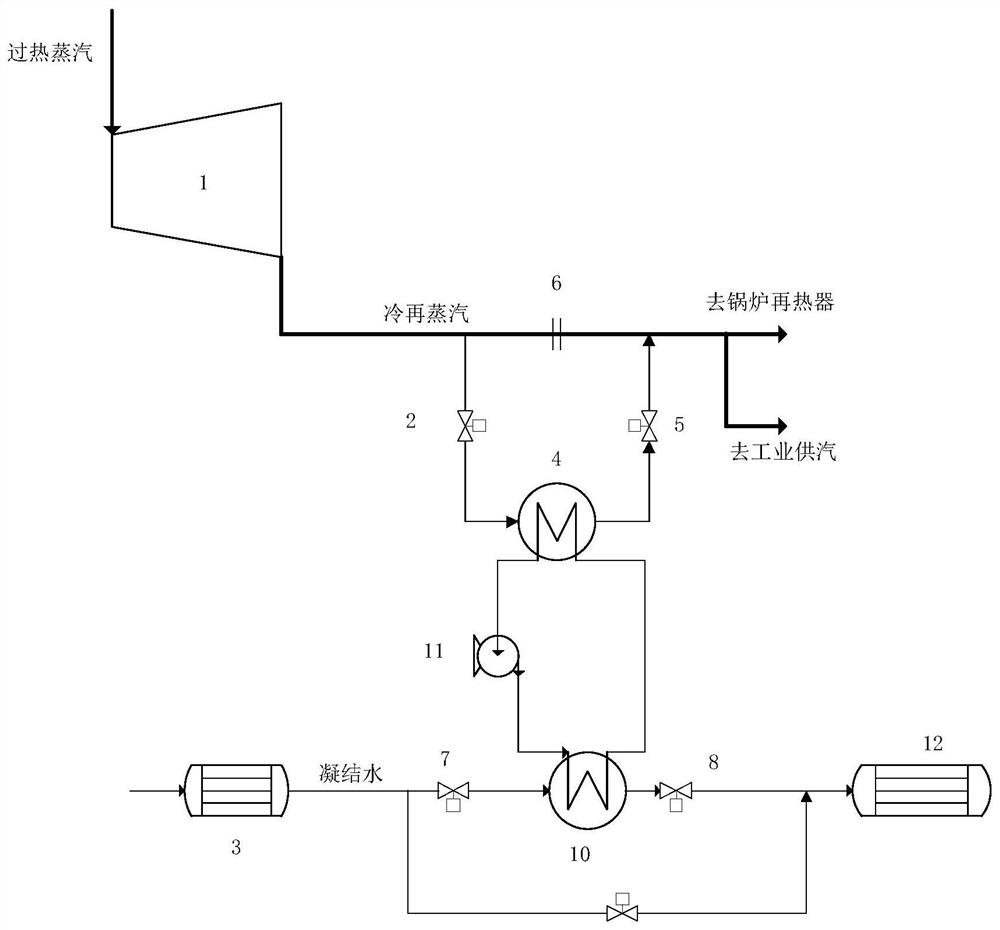

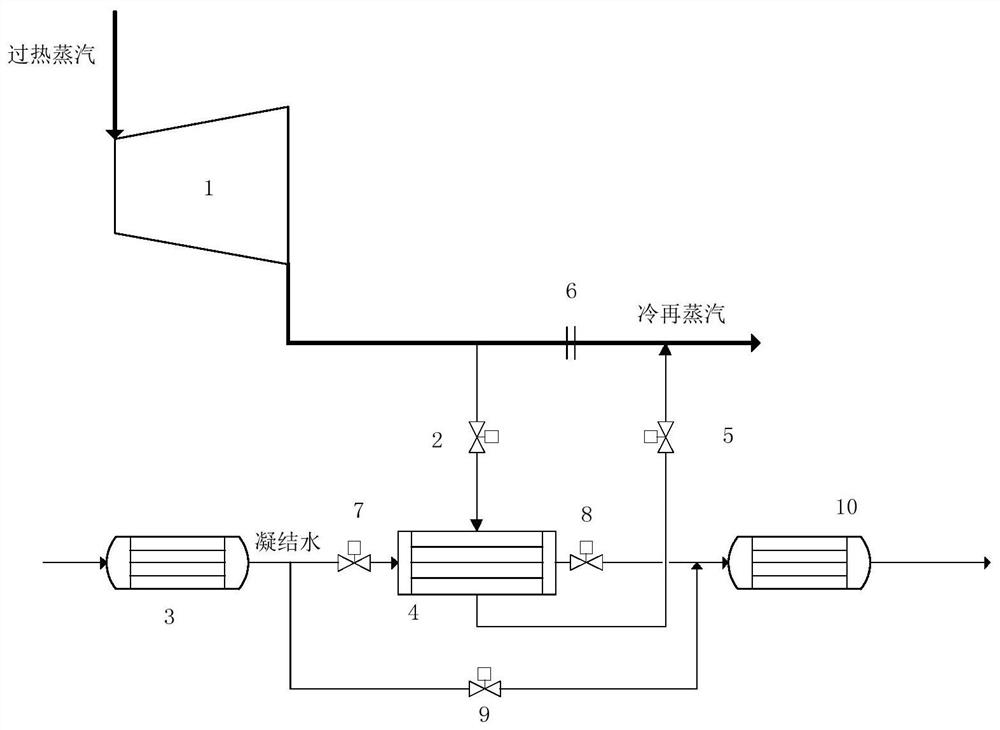

Condensed water combined cycle system and method for improving cold reheat steam supply capacity of boiler

PendingCN111927587AImprove economyReduce the risk of overheatingSteam useCondensed waterProcess engineering

The invention discloses a condensed water combined cycle system and method for improving the cold reheat steam supply capacity of a boiler. The system comprises steam pipeline isolation valves, a heatrecycling heat exchanger, a flow adjusting pore plate, a water inlet isolation valve, a water outlet isolation valve, a bypass isolation valve, a water-water heat exchanger and a circulating pump. Cold reheat steam enters the heat recycling heat exchanger through a steam pipeline, the cold reheat steam is mixed with original steam through a steam return pipeline after being subjected to heat exchange and cooling, the flow adjusting pore plate is newly arranged on the cold reheat steam pipeline for balancing the steam flow, and closed circulating water absorbs heat in the heat recycling deviceand is conveyed into the water-water heat exchanger through the circulating pump. Condensed water at an outlet of a shaft seal heater enters the water-water heat exchanger after passing through the water inlet isolation valve, by means of the system, the cold reheat industrial steam supply capacity of the boiler can be effectively improved, the overtemperature risk of a boiler reheater can be reduced, meanwhile, online operation and shutdown can be realized, in addition, the cold reheat steam supply flow of a unit can be effectively promoted, and therefore, the economical efficiency of the unit is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

Arrangement method of tower-type boiler high-temperature reheater container system

The invention relates to an arrangement method of a tower-type boiler high-temperature reheater container system, which can reduce the thermal deflection among the screens of reheater effectively according to the operation characteristic of the tower-type boilers. The arrangement method comprises: arranging a resistance device in a lead-out steam guide pipe, close to the center of the boiler, of the tower-type boiler reheater outlet container, the distribution of inter-screen flow is changed by changing the difference between the lead-out flows on two sides of the reheater system outlet container so as to be matched with the distribution of inter-screen heat release difference on a smoke side to reduce inter-screen thermal deflection.

Owner:SHANGHAI WANGTE ENERGY RESOURCE SICENCE & TECH

Method for making Fischer-Tropsch synthetic reaction stable

ActiveCN102952563BReduce the risk of overheatingSmall temperature differenceLiquid hydrocarbon mixture productionHydrogenSteady state

A method for making a Fischer-Tropsch synthetic reaction stable. A catalyst for Fischer-Tropsch synthesis is activated and enters an initial phase of a Fischer-Tropsch synthetic reaction; at the reaction initial phase, an inert medium is introduced into synthesis gas so as to allow a mixture flow containing hydrogen, carbon monoxide and the inert medium to contact with the Fischer-Tropsch synthesis catalyst bed layer for reaction; with the activity of the Fischer-Tropsch synthesis catalyst being in a steady state, the amount of the inert medium in the reactant flow is decreased gradually till the Fischer-Tropsch synthetic reaction is in a steady-state phase, wherein at the reaction initial phase, the reaction condition is the same as the reaction condition at the steady-state phase. With the method, the risk of overtemperature at the reaction initial phase is reduced; hot spot areas are reduced; the Fischer-Tropsch synthetic reaction can go into a steady-state phase stably; and guarantee for the long-period running of Fischer-Tropsch synthesis equipment is provided.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fischer-Tropsch synthesis method

ActiveCN101863728BEasy to operateReduce the risk of overheatingHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionParaffin waxSynthesis methods

The invention provides a Fischer-Tropsch synthesis method. The invention adopts two Fischer-Tropsch synthesis reaction vessels in serial connection, wherein the first Fischer-Tropsch synthesis reaction vessel is a slurry bed reaction vessel, and the second Fischer-Tropsch synthesis reaction vessel is a fixed bed reaction vessel. Outflow materials of the first Fischer-Tropsch synthesis reaction vessel fully or partially enter the second Fischer-Tropsch synthesis reaction vessel for carrying out synthesis reaction, and H2 and / or CO is injected between the two Fischer-Tropsch synthesis reaction vessels for regulating the molar ratio of H / C at an inlet of the second Fischer-Tropsch synthesis reaction vessel. The method provided by the invention overcomes the defects of great axial temperaturedifference, obvious heat point and difficult control of the reaction temperature of the fixed bed Fischer-Tropsch synthesis reaction vessel, and simultaneously ensures that the proportion of paraffinproducts in the products can not be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fischer-Tropsch synthesis device starting method

ActiveCN103007835BReduce the risk of overheatingSmooth startChemical/physical processesLiquid hydrocarbonsTemperature difference

Owner:CHINA PETROLEUM & CHEM CORP +1

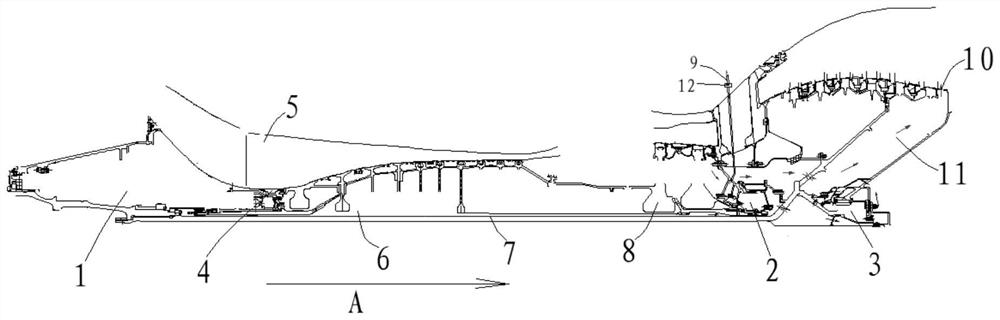

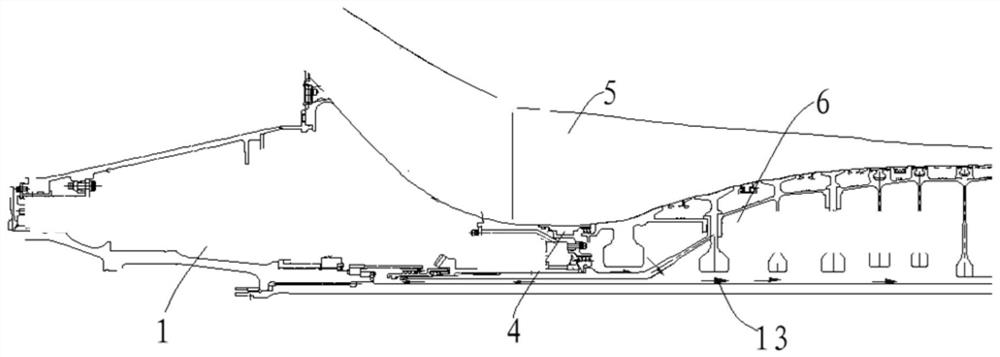

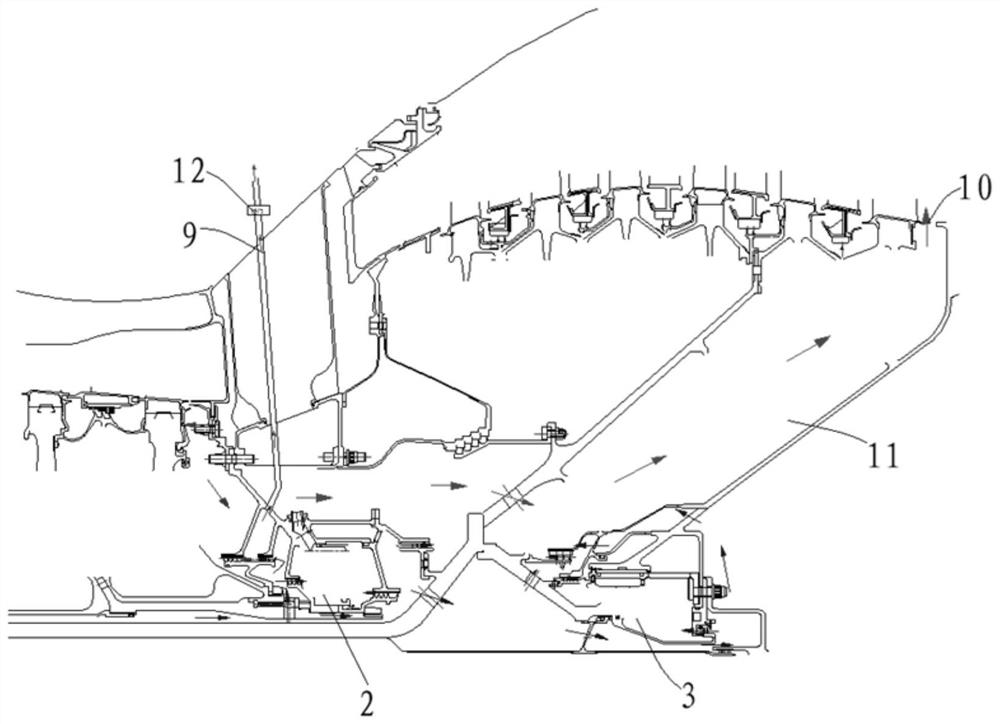

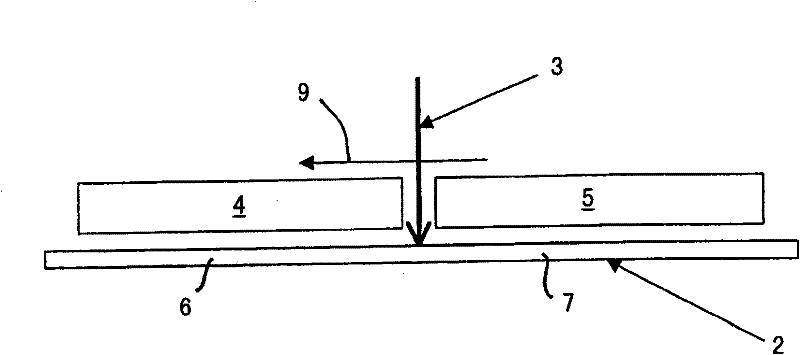

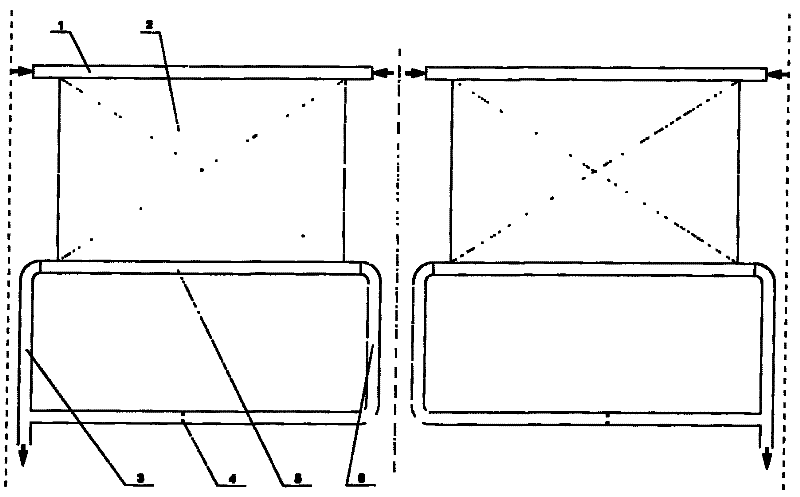

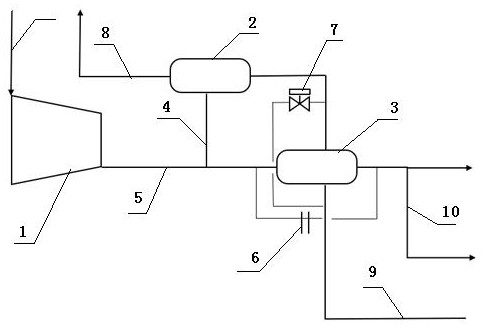

Cold section steam multi-stage utilization system for enhancing industrial steam supply capacity of once-through boiler

PendingCN113530623AReduce the temperatureReduce the risk of overheatingSteam engine plantsIsolation valveProcess engineering

The invention relates to a cold section steam multi-stage utilization system for enhancing the industrial steam supply capacity of a once-through boiler. At present, more once-through boilers use cold resteam as steam sources, but if much cold resteam is extracted, a boiler reheater is likely to have an over-temperature risk. The cold section steam multi-stage utilization system for enhancing the industrial steam supply capacity of the once-through boiler comprises a steam turbine high-pressure cylinder (1), a high-pressure heater (2) and a stepped heat exchanger (3), and the steam turbine high-pressure cylinder is connected with the high-pressure heater through a high-pressure heater steam extraction pipeline (4) and connected with the stepped heat exchanger through a steam pipeline (5). A flow adjusting pore plate (6) is installed on the steam pipeline, the stepped heat exchanger is connected to the flow adjusting pore plate in parallel, and feed water of an outlet of the high-pressure heater enters the stepped heat exchanger after passing through a bypass isolating valve (7). The cold section steam multi-stage utilization system is applied to the field of energy gradient utilization.

Owner:HUANENG YIMIN COAL POWER CO LTD

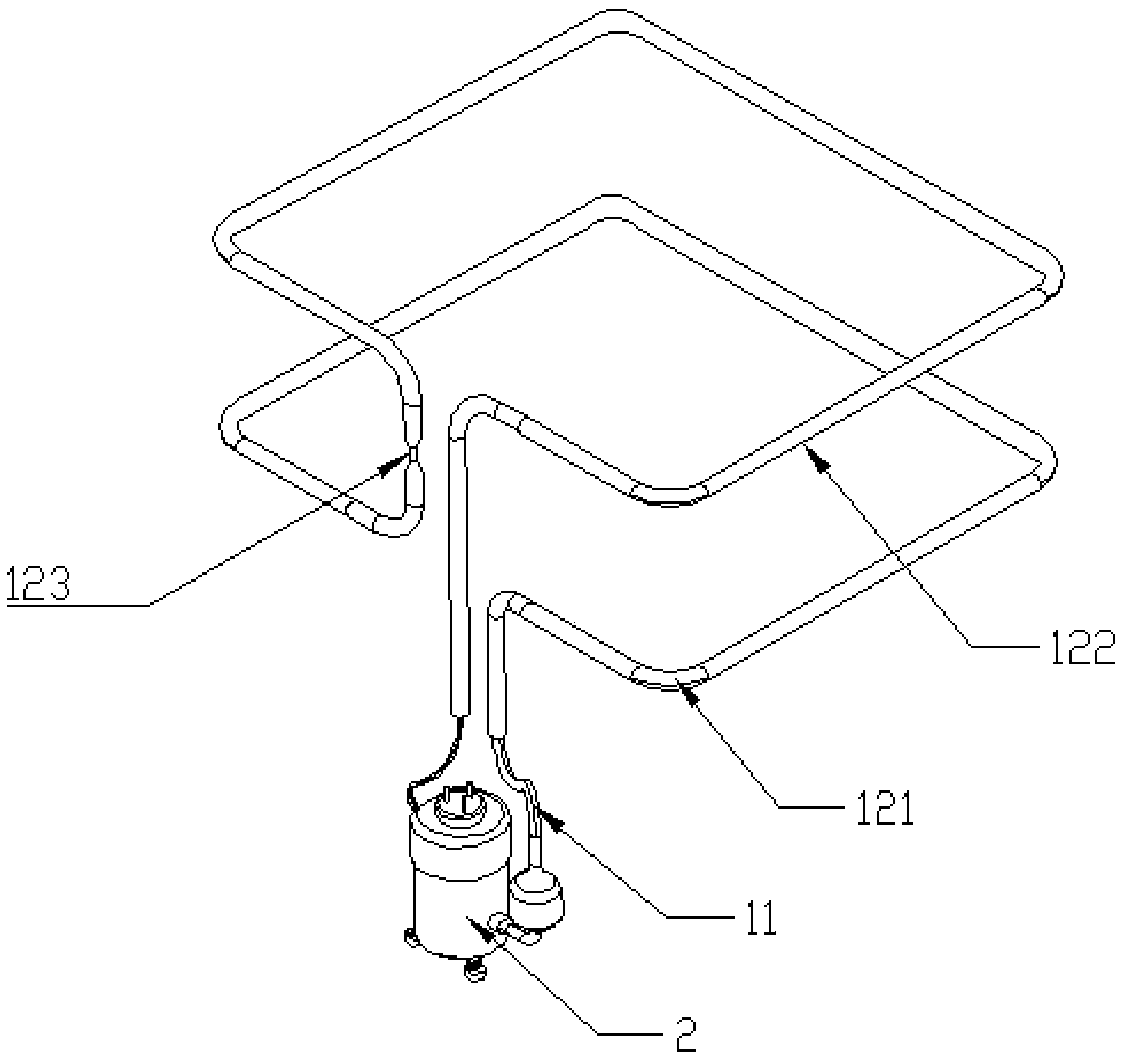

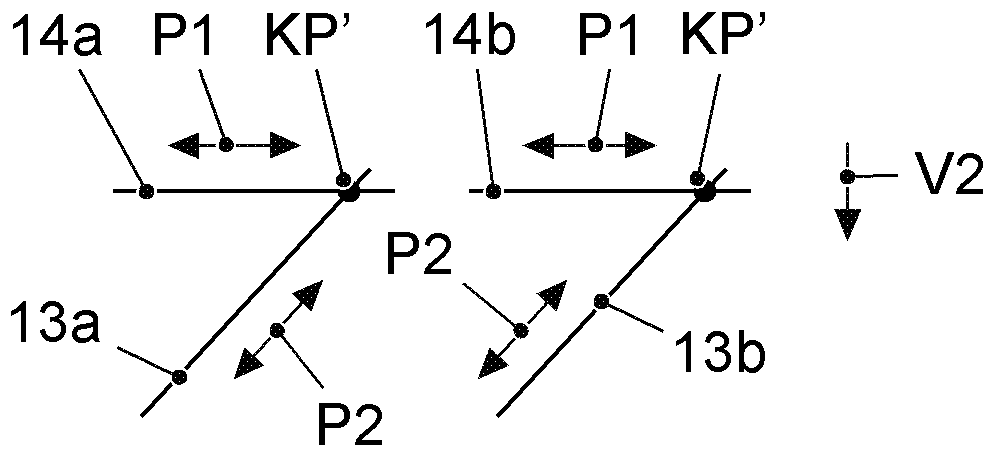

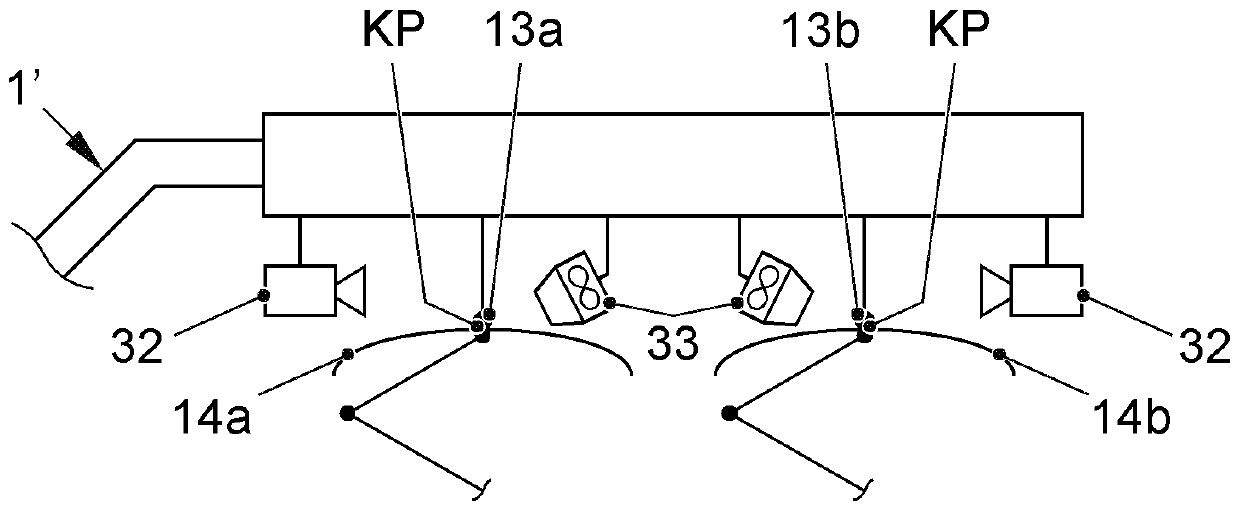

Method for charging electrically operated vehicle at standstill

ActiveCN110126681AImprove distributionReduce the risk of overheatingCharging stationsElectric vehicle charging technologyElectrical conductorCharging station

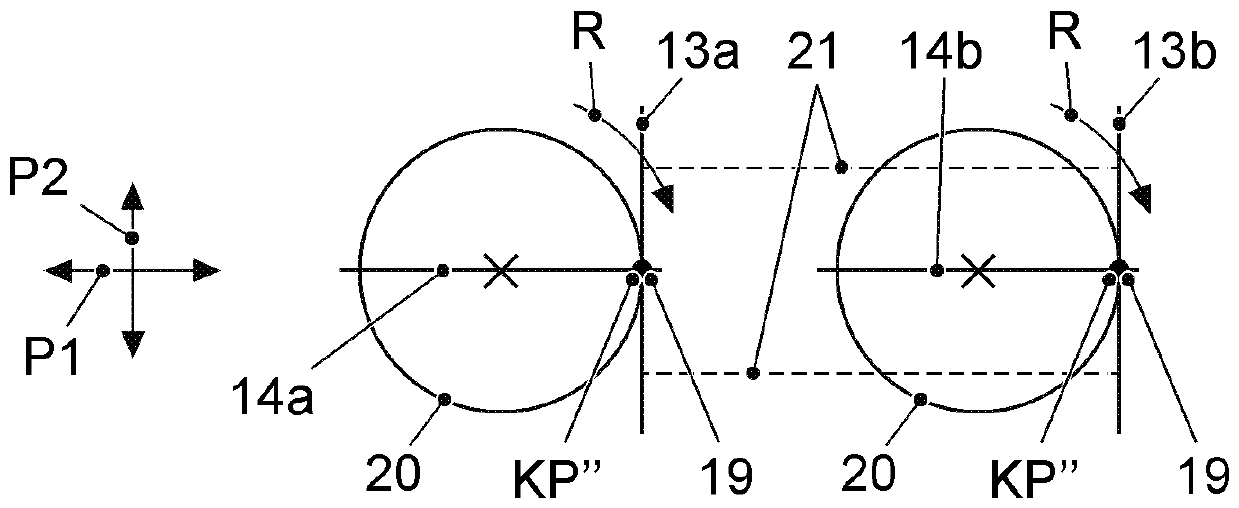

The invention relates to a method for charging an electrically operable vehicle (K) while the vehicle is parked. In the method, at least one current collector (14a, 14b) on the roof side of the vehicle (K) is brought into contact with at least one conductor (13a, 13b) of the charging station (1), said conductor being arranged above the vehicle (K). Several possibilities are proposed in order to avoid overheating of the contact area during charging and thus to achieve a high transfer power. It is therefore proposed to move the conductors (13a, 13b) in order to form locally varying contact points between the conductors (13a, 13b) and the current collectors (14a, 14b). It is alternatively proposed to cool the contact points present between the conductor and the current collector or to form linear contact regions between the conductor and the current collector.

Owner:VOLKSWAGEN AG

Condensed water co-utilization system improving cold reheat cold reheat steam supply ability of boiler and method

PendingCN111894691AReduce the temperatureLower the temperature by more than 30°CSteam regenerationSteam useIsolation valveProcess engineering

The invention discloses a condensed water co-utilization system improving cold reheat steam supply ability of a boiler and a method. The system comprises a steam pipeline isolating valve, a heat recovery heat exchanger, a flow regulating pore plate, a water inlet isolating valve, a water outlet isolating valve, and a bypass isolating valve; cold reheat steam enters the heat recovery heat exchangerthrough a steam pipeline; after heat exchanging and cooling, the cold reheat steam is mixed with original steam via a steam return pipeline; the flow regulating pore plate is newly arranged on a coldreheat steam pipeline and is used for balancing steam flow; and condensed water at an opening of a shaft seal heater passes the water inlet isolating vale and enters the heat recovery heat exchanger.The system can effectively improve the cold reheat industrial steam supply ability of the boiler, lower the risk of over temperature of a reheater of the boiler, and realize online operation and shutdown. The system can effectively improve the flow of cold reheat steam supply of a unit, and further improve the economic benefits of the unit.

Owner:XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com