Patents

Literature

60results about How to "Brought out in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

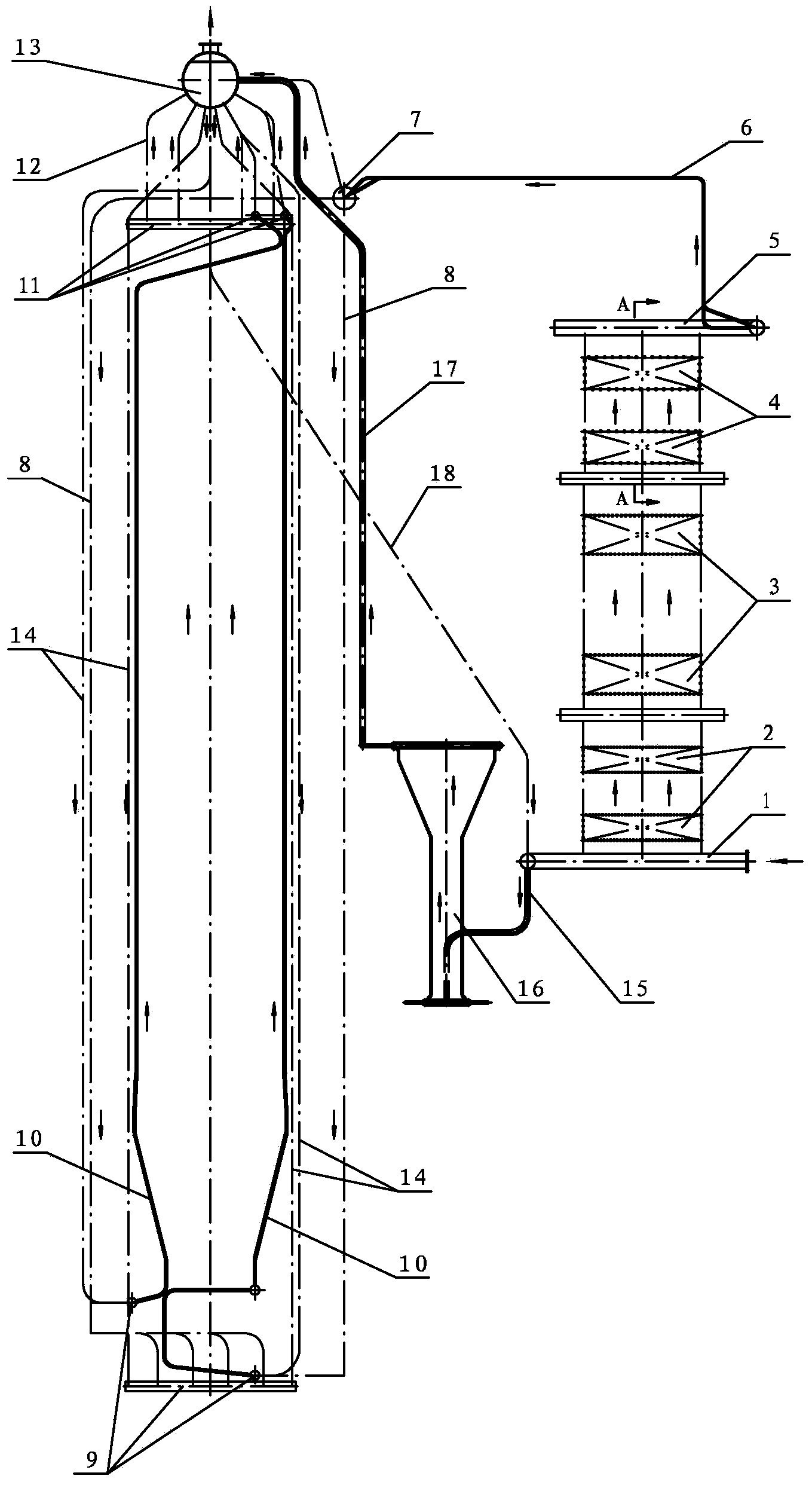

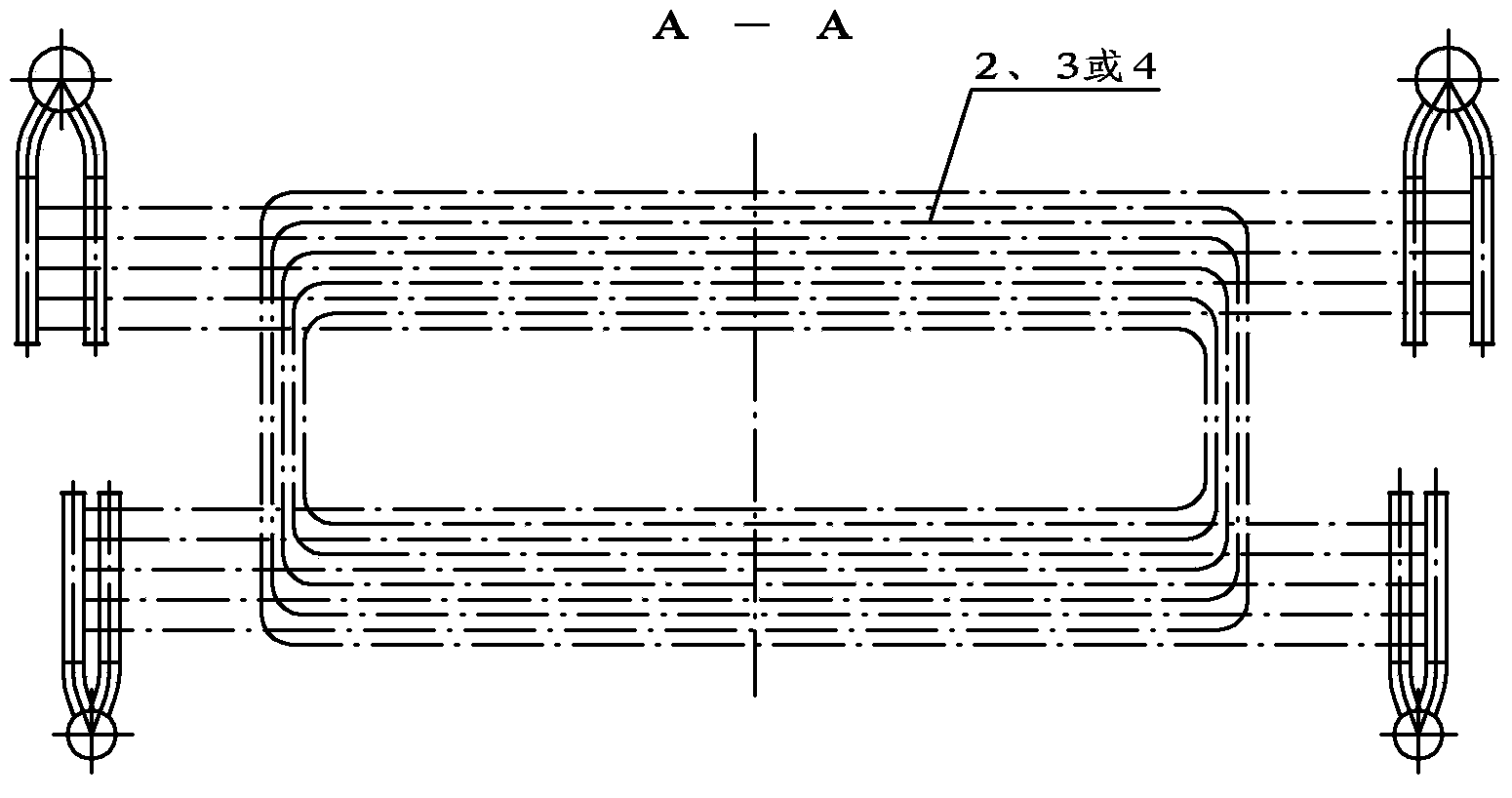

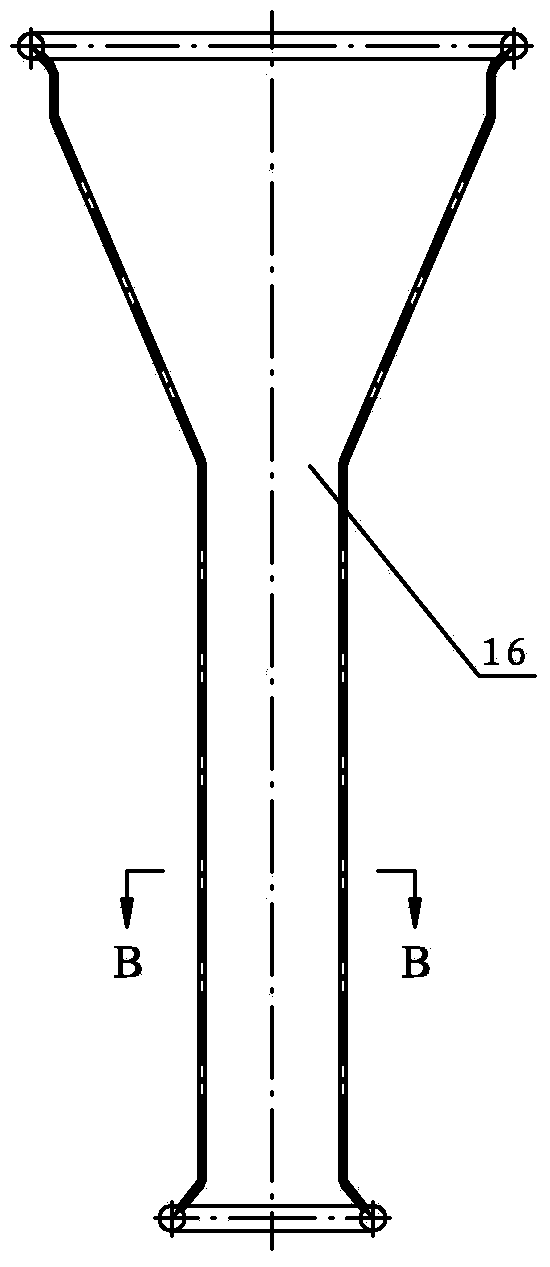

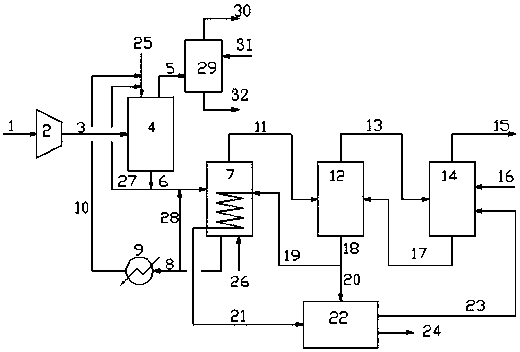

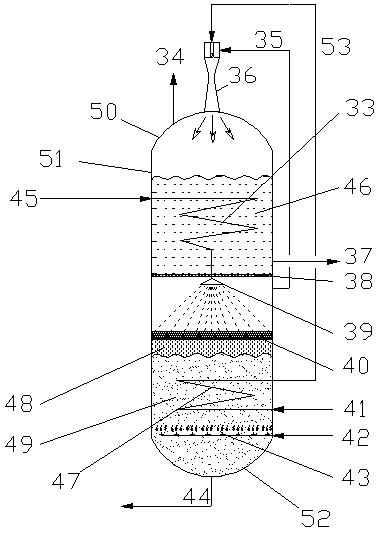

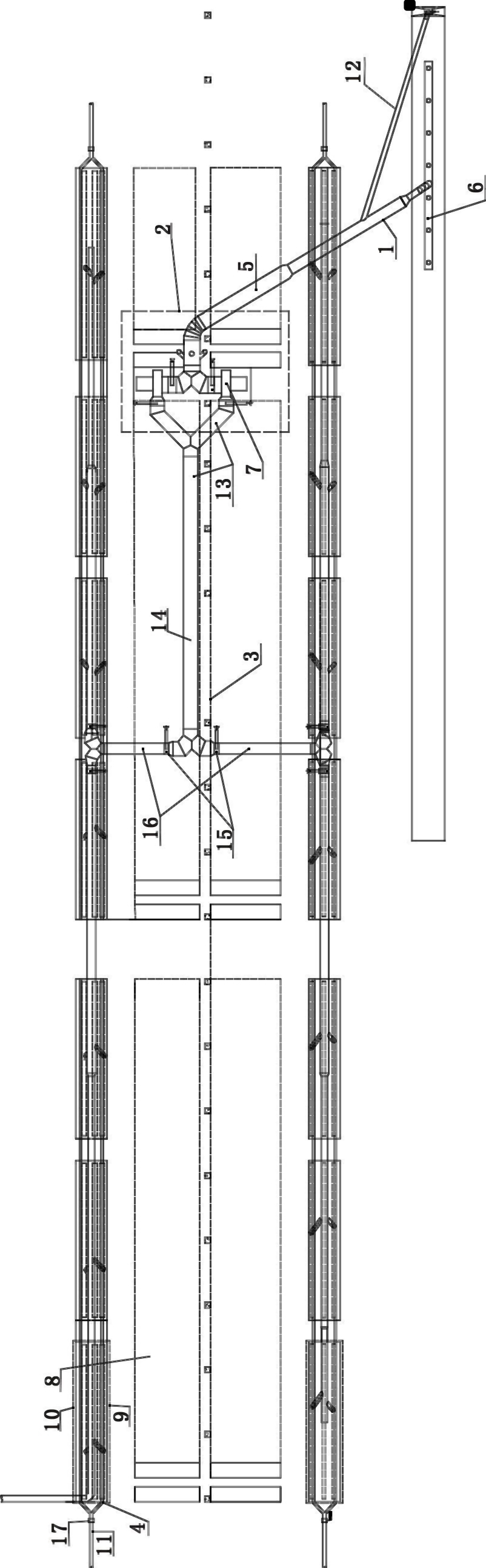

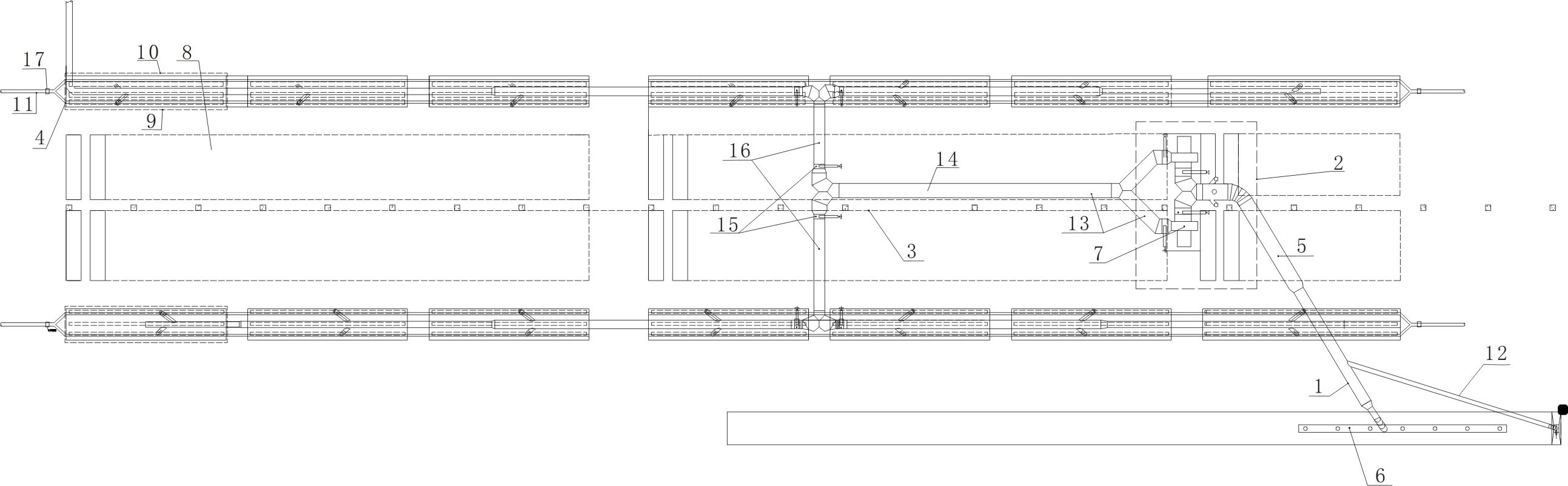

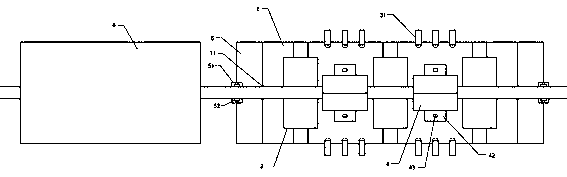

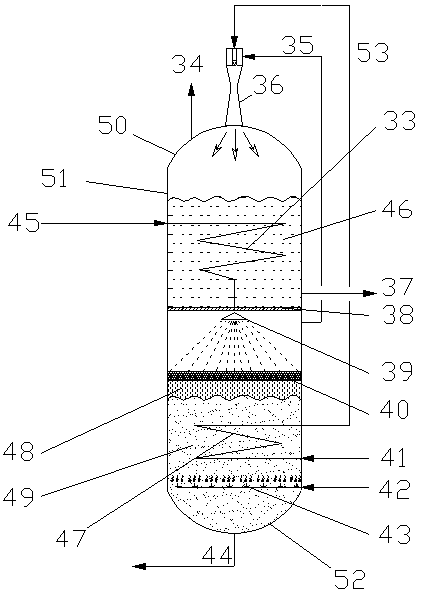

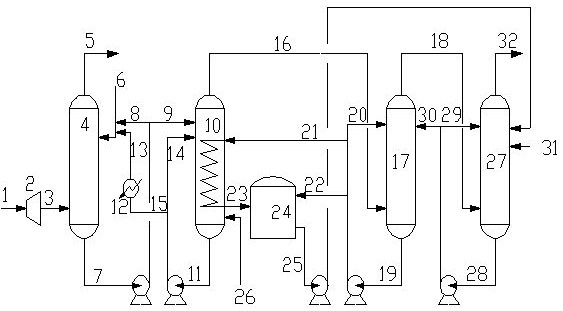

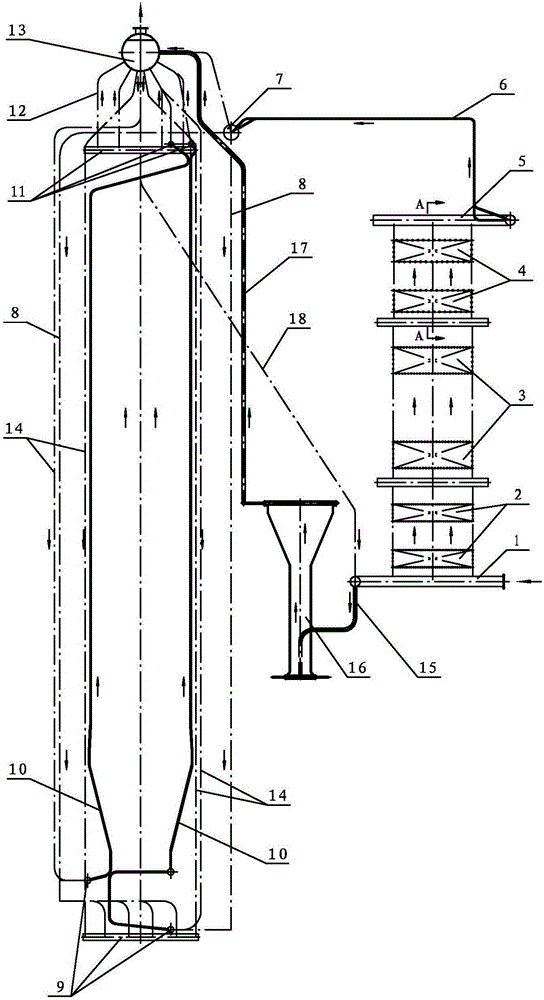

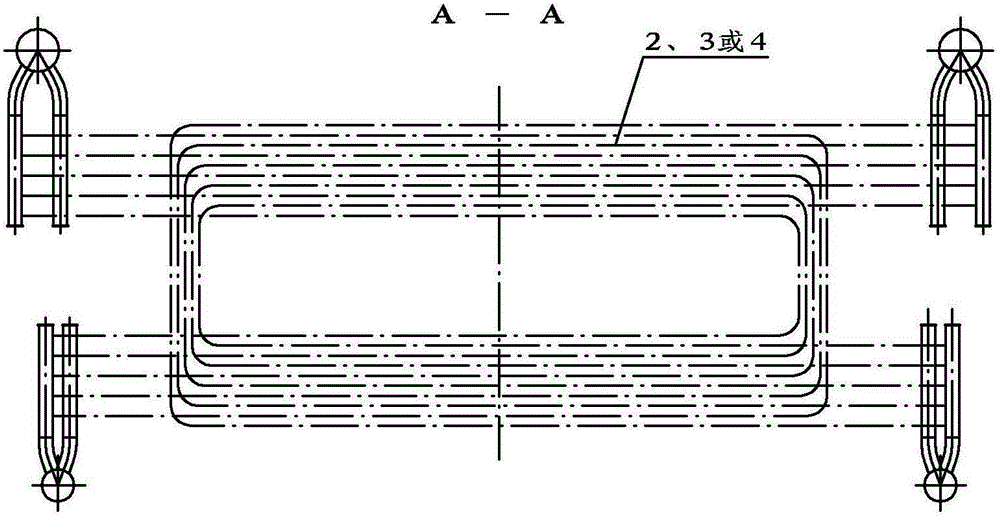

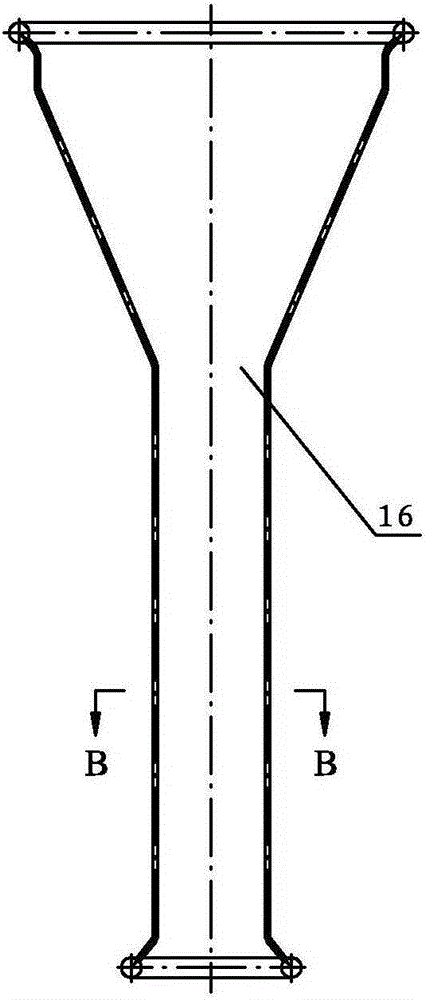

Forced water circulation high-capacity hot water boiler of circulating fluidized bed

ActiveCN103644648AImplement security requirementsAvoid damageFluidized bed combustionWater heatersWater circulationHearth

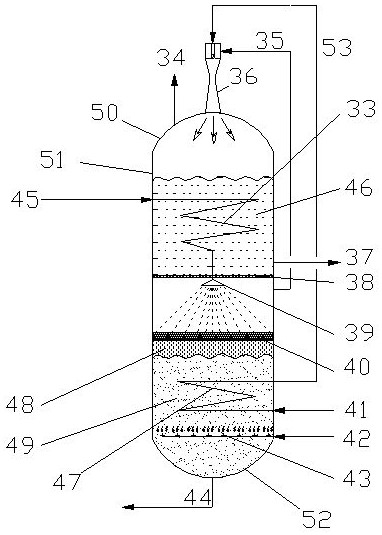

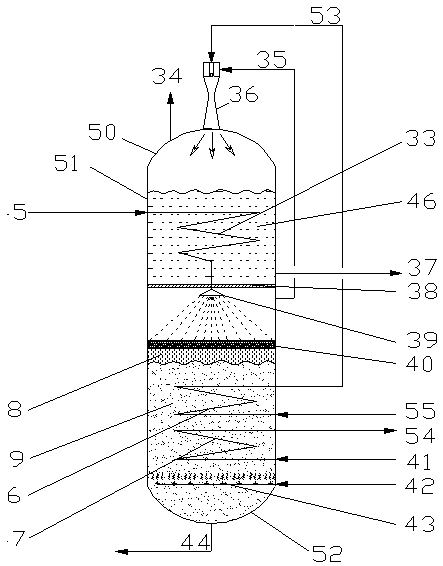

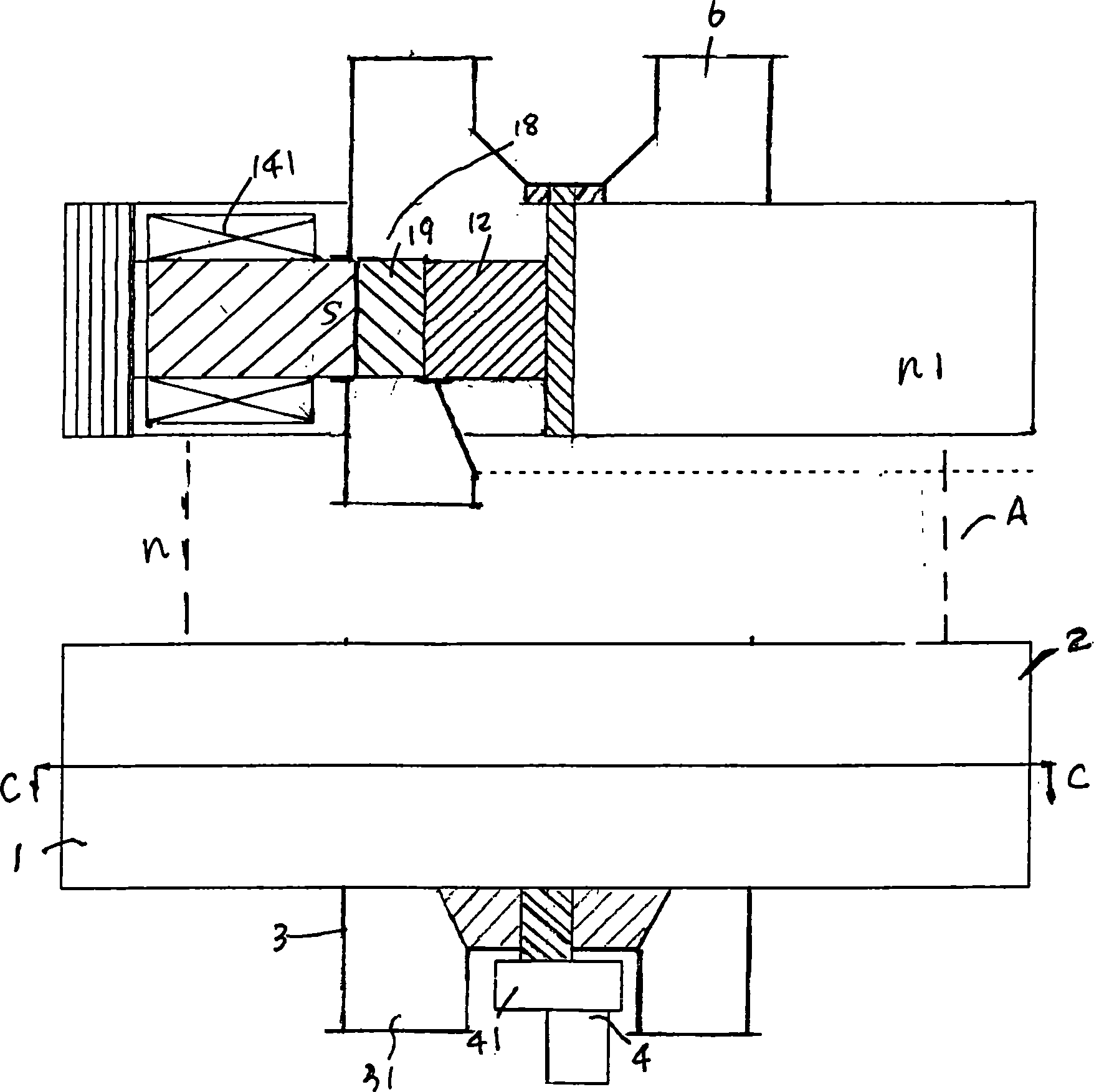

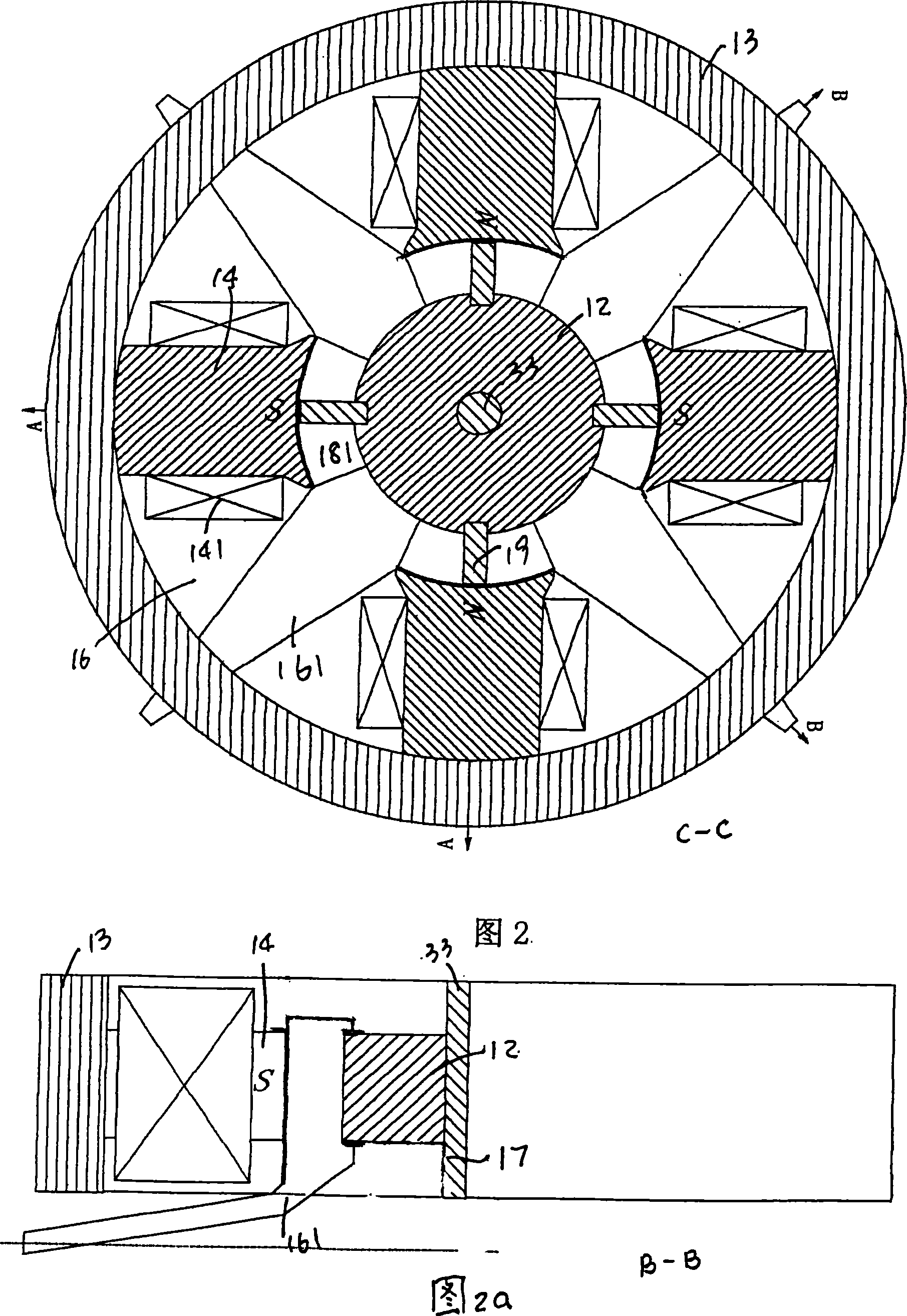

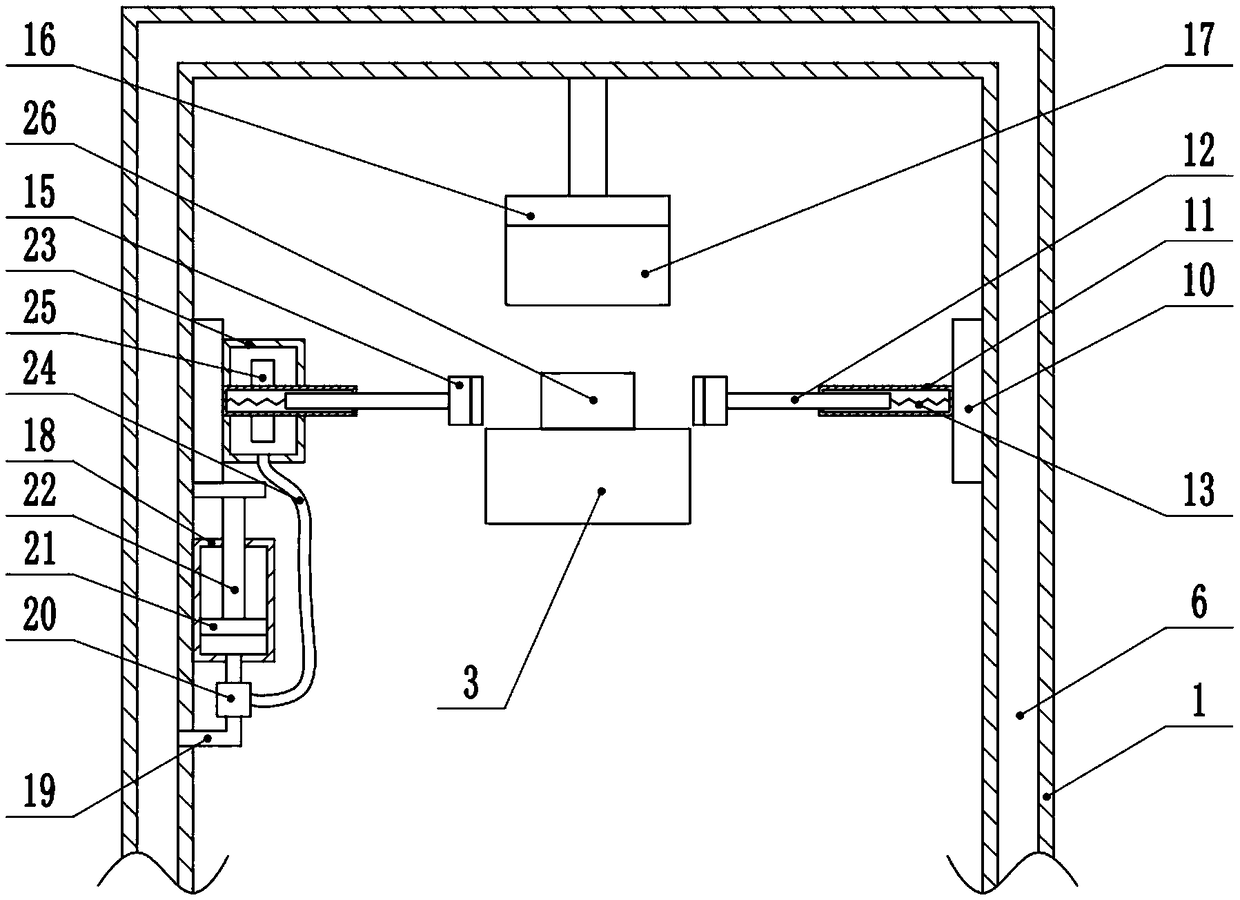

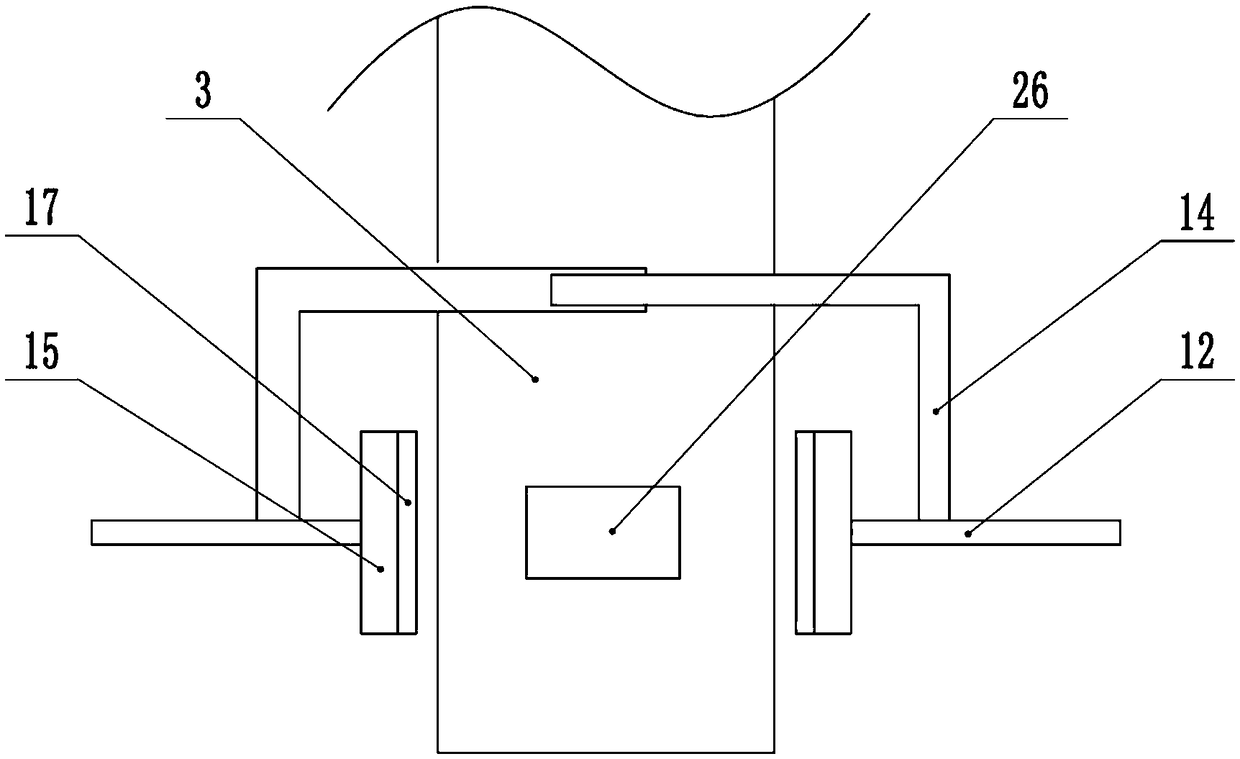

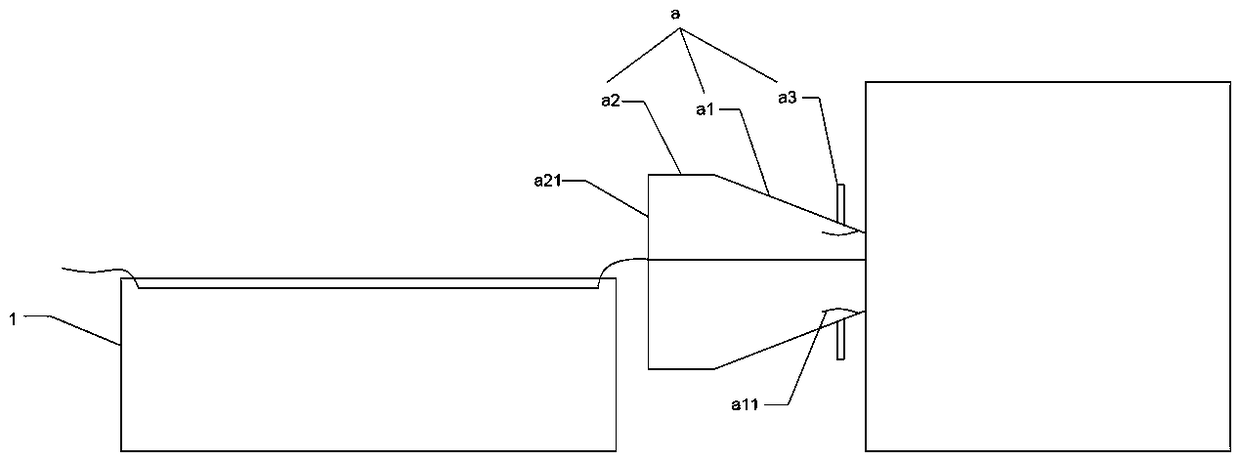

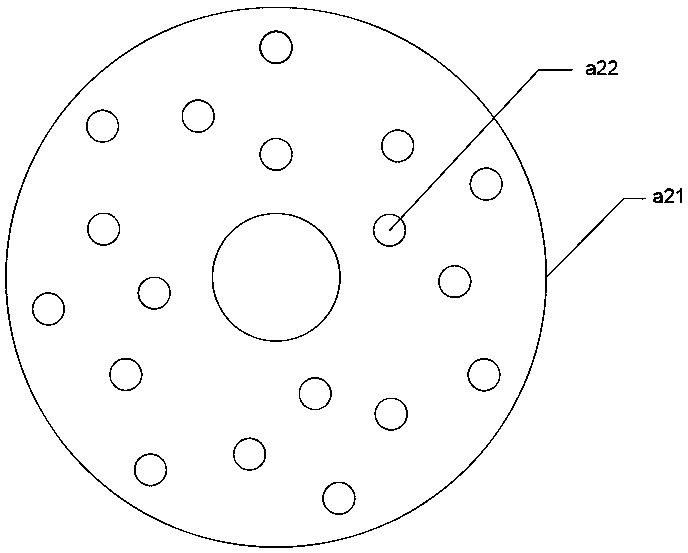

The invention discloses a forced water circulation high-capacity hot water boiler of a circulating fluidized bed, which relates to a hot water boiler of a fluidized bed, and aims to ensure water circulation safety and power failure protection of a high-capacity hot water boiler of a circulating fluidized bed. A water supply distribution header is connected with lower coal economizers; the lower coal economizers, middle coal economizers and upper coal economizers are sequentially connected with one another; the upper coal economizers are connected with a coal economizer upper header; the coal economizer upper header is connected with a collection water bag by a coal economizer coating pipe; the collection water bag is connected with water cooling wall lower headers by a descending pipe; the water cooling wall lower headers are connected with a hearth water cooling wall; the hearth water cooling wall is connected with water cooling wall upper headers; the water cooling wall upper headers are connected with a boiler cylinder by extraction pipes; the water supply distribution header is connected with a separator water cooling sleeve by a water cooling sleeve water intake pipe; the separator water cooling sleeve is connected with the boiler cylinder by a water cooling sleeve water outlet pipe; the boiler cylinder is connected with the water cooling wall lower headers by communicating pipes, and is connected with the water supply distribution header by a power failure water supply pipe. The forced water circulation high-capacity hot water boiler provided by the invention is applied to large concentrated heat supply and warming.

Owner:哈尔滨红光锅炉总厂有限责任公司

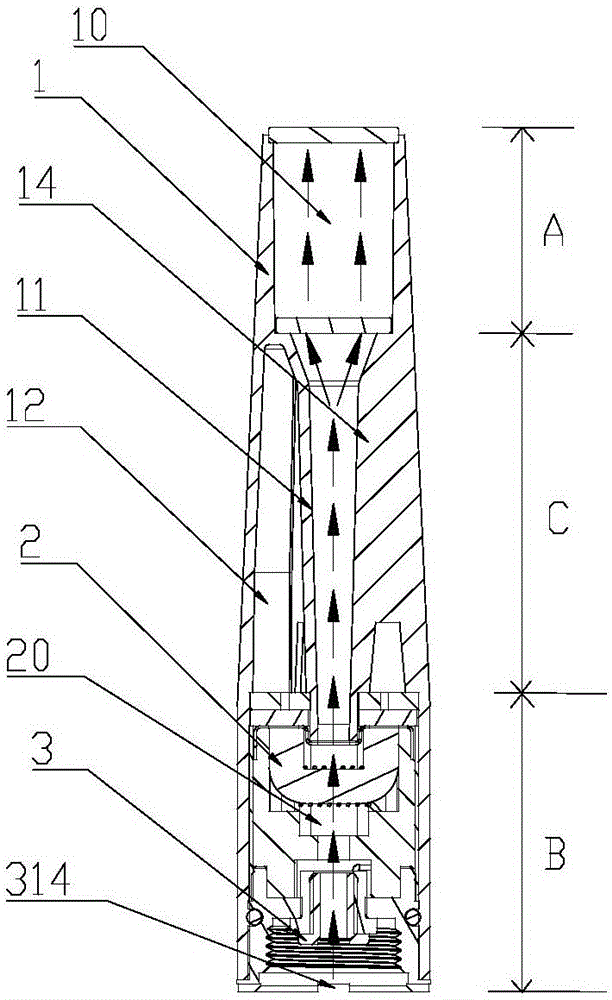

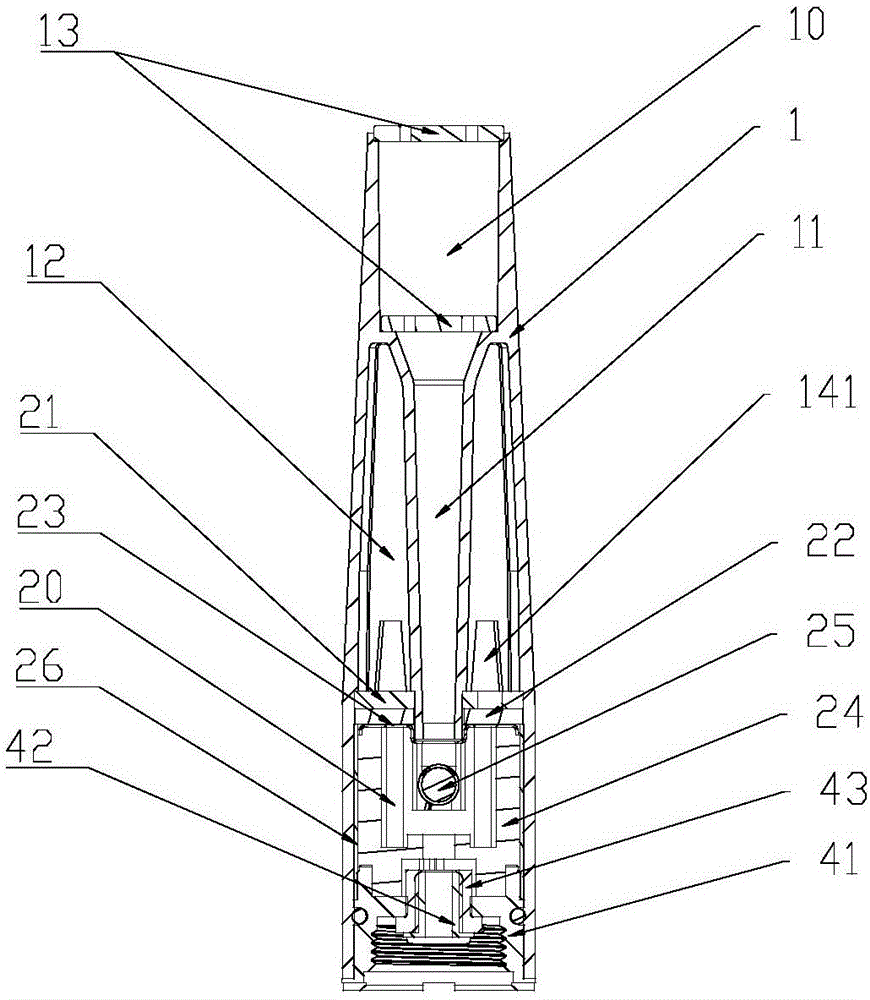

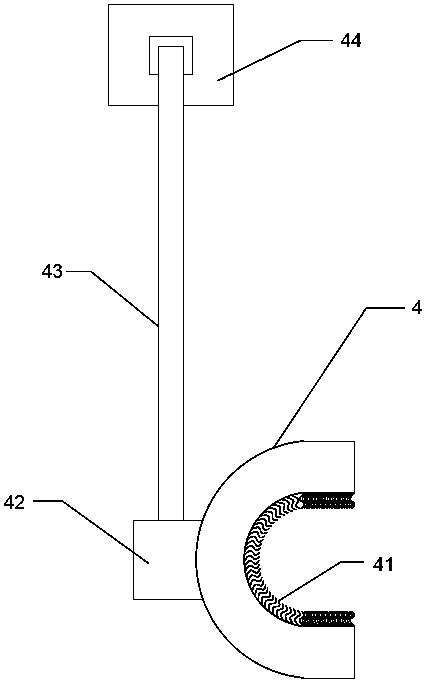

Electronic cigarette atomizer with divergent smoke outlet pipe

The invention discloses an electronic cigarette atomizer with a divergent smoke outlet pipe. The electronic cigarette atomizer comprises an atomizer pipe, an atomization device and a connecting part; one end of the atomizer pipe is provided with a suction nozzle segment, the other end of the atomizer pipe is provided with an atomization connecting segment, the middle of the atomizer pipe is provided with a liquid storage segment, a suction nozzle containing cavity which has the large section and can contain additives is formed in the suction nozzle segment, the smoke outlet pipe which is integrally formed with the atomizer pipe is arranged at the central axis inside the liquid storage segment, the two ends of the smoke outlet pipe are communicated with an atomization cavity and the suction nozzle containing cavity respectively, and the inner diameter of the smoke outlet pipe is gradually increased from one end of the atomization cavity to one end of the suction nozzle containing cavity; a liquid storage cavity used for storing cigarette liquid is formed between the smoke outlet pipe and the atomizer pipe; the atomization device is connected with the liquid storage cavity and the smoke outlet pipe, so that the cigarette liquid in the liquid storage cavity is atomized and then exhausted through the smoke outlet pipe. The electronic cigarette atomizer has the advantages that the volume of smoke sucked from a suction nozzle is increased, the smoke flow rate of the end, located in the atomization cavity, of the smoke outlet pipe is increased, therefore, it is guaranteed that air in the atomization cavity fully flows and quickly brings the smoke out, and the atomization efficiency is improved.

Owner:林光榕

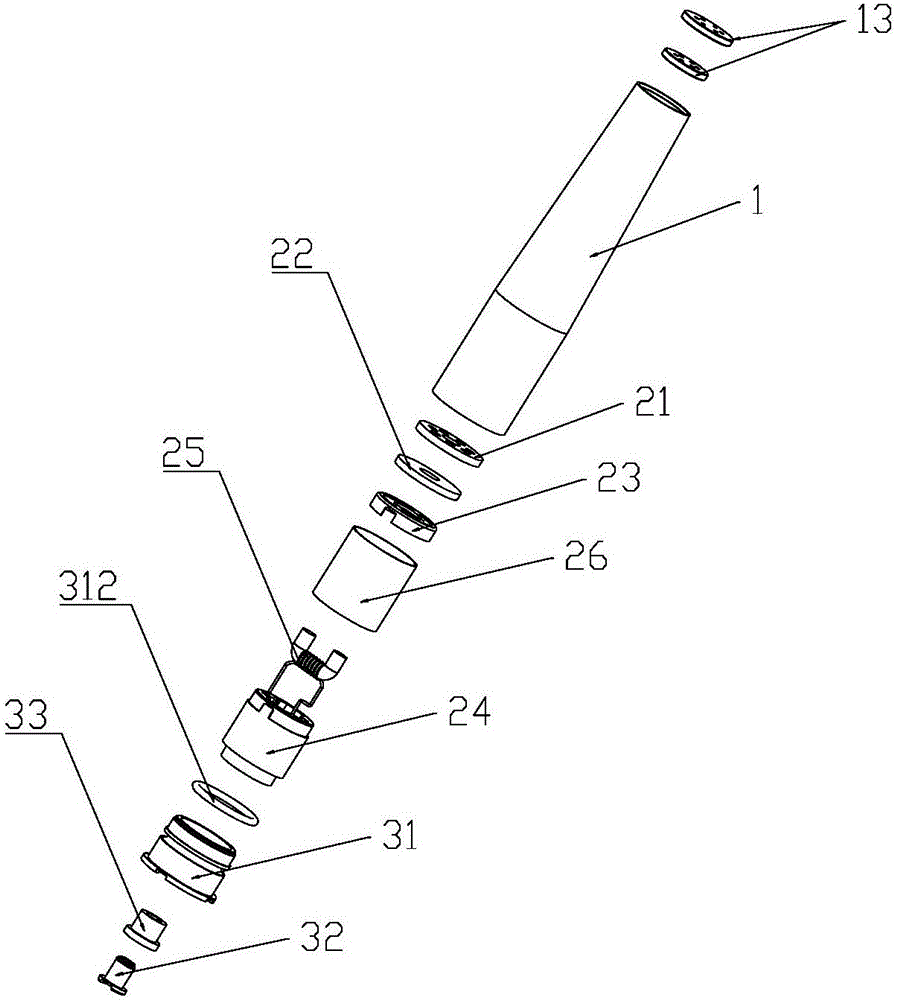

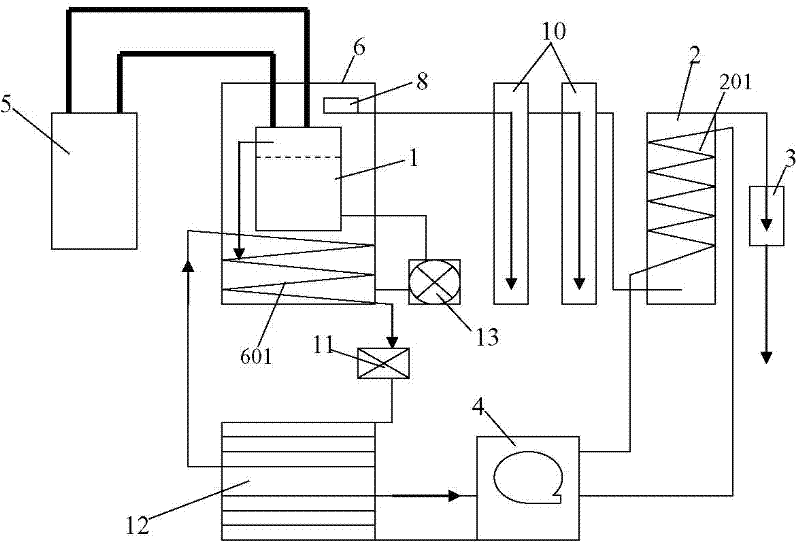

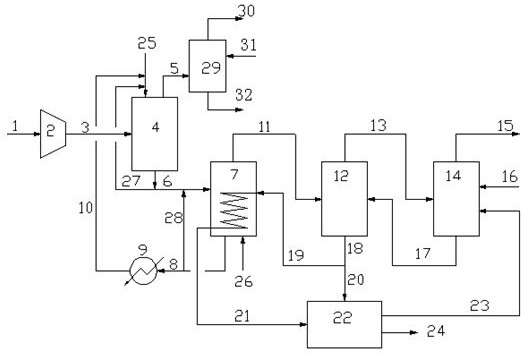

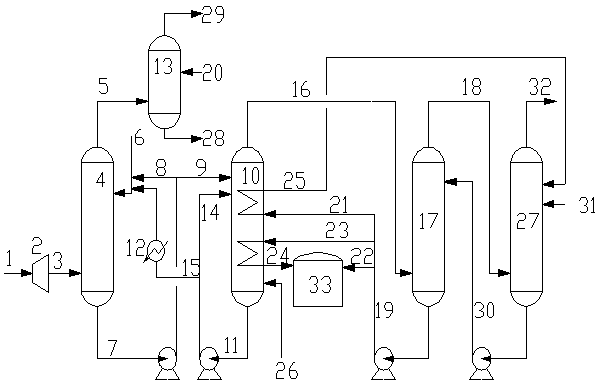

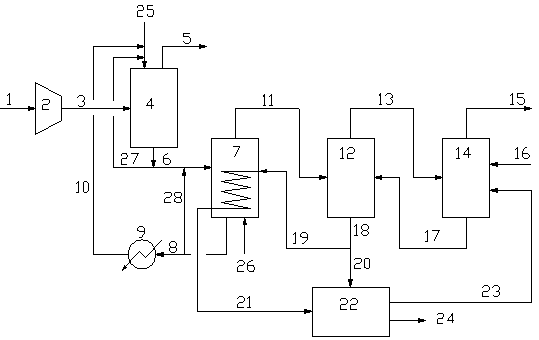

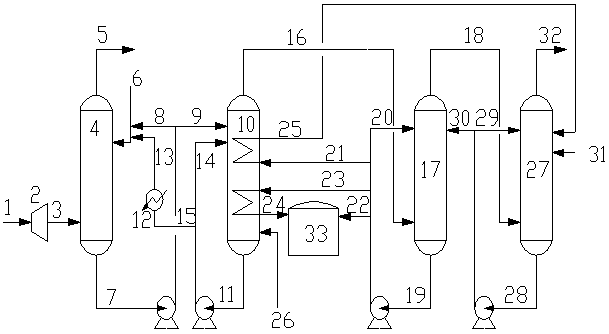

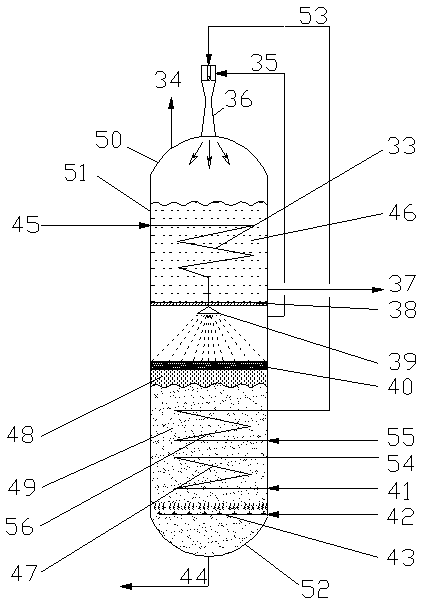

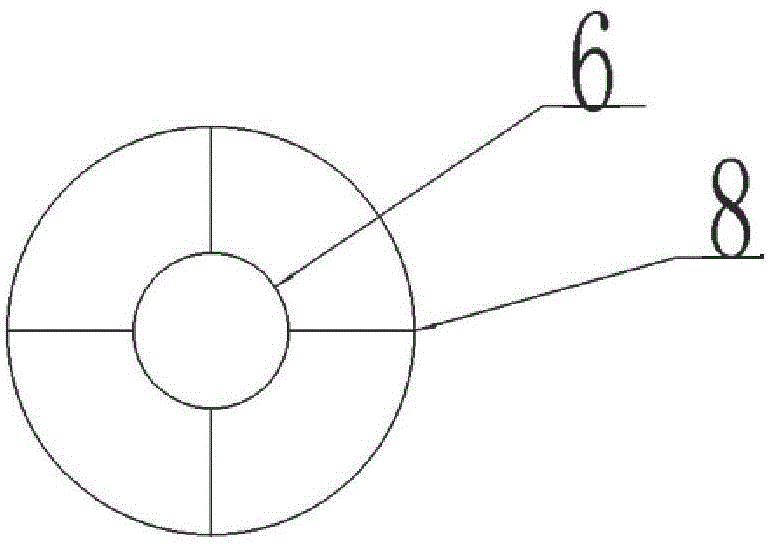

Treating method and device for carbon dioxide and hydrogen sulfide containing gas

ActiveCN108722148AReasonable useReduce energy consumptionGas treatmentDispersed particle separationProduct gasChemical products

The invention discloses a treating method and device for carbon dioxide and hydrogen sulfide containing gas. The device comprises a hydration reactor, a hydrate decomposing device, an exhaust gas treating device, a first-stage absorbing reactor, a second-stage absorbing reactor and a product tank. The invention further provides a method for treating the carbon dioxide and hydrogen sulfide containing gas through the abovementioned device. With the adoption of the device and the method, NaHS products meeting national quality standard can be produced while acidic gas standardized discharging is realized; the environment treatment and the production process of chemical products are integrated. Compared with the prior art, the method has the advantages that the carbon dioxide and hydrogen sulfide containing gas can be economically and efficiently pretreated; the energy in the technical process can be reasonably utilized, so that the energy consumption is extremely decreased; the whole treatment process is environmentally friendly, reliable, and free of three wastes.

Owner:CHINA PETROLEUM & CHEM CORP +1

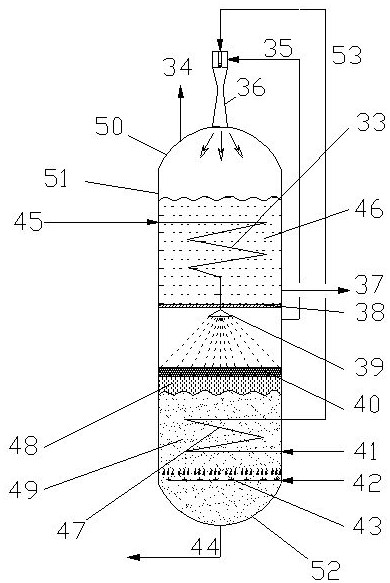

Electrolytic type oxy-hydrogen generation device

InactiveCN101956205BReduce manufacturing costReduce design difficultyCellsChemical industryHydrogenPower flow

Owner:归建明 +1

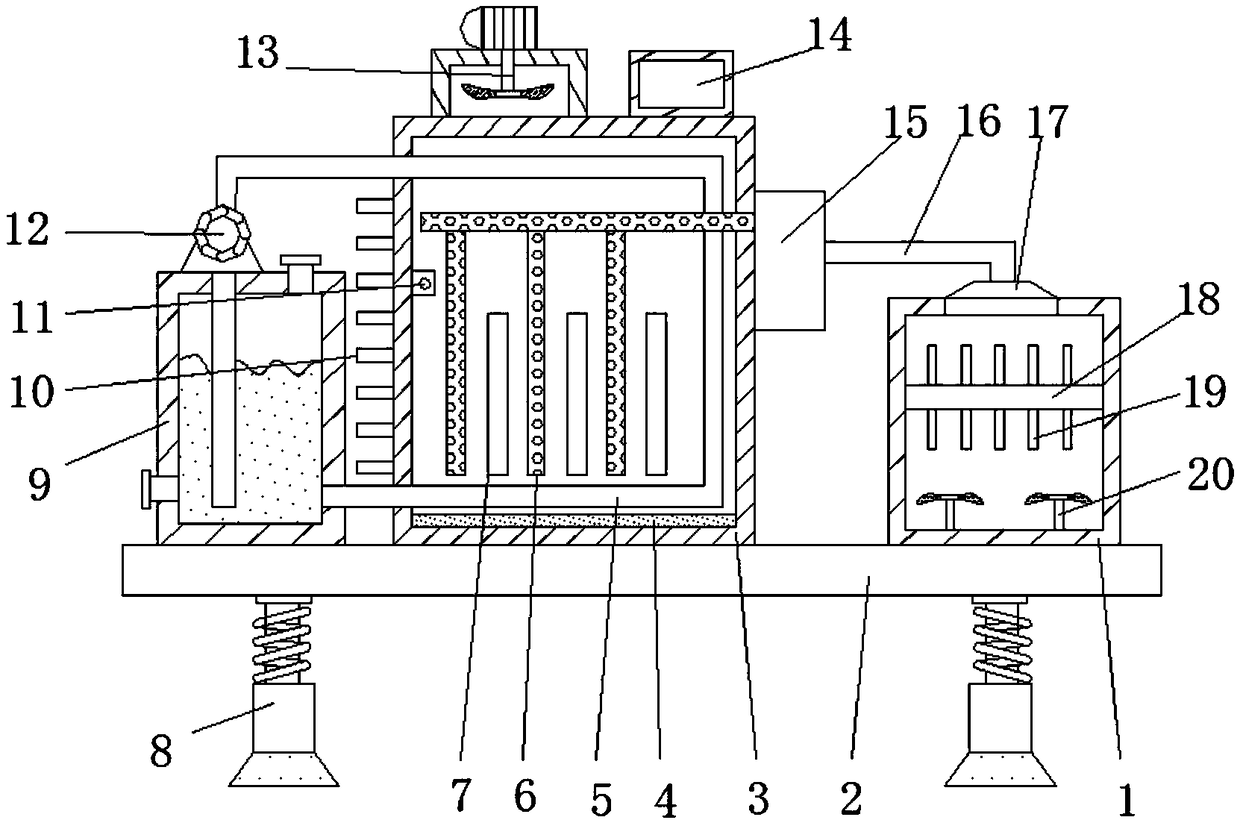

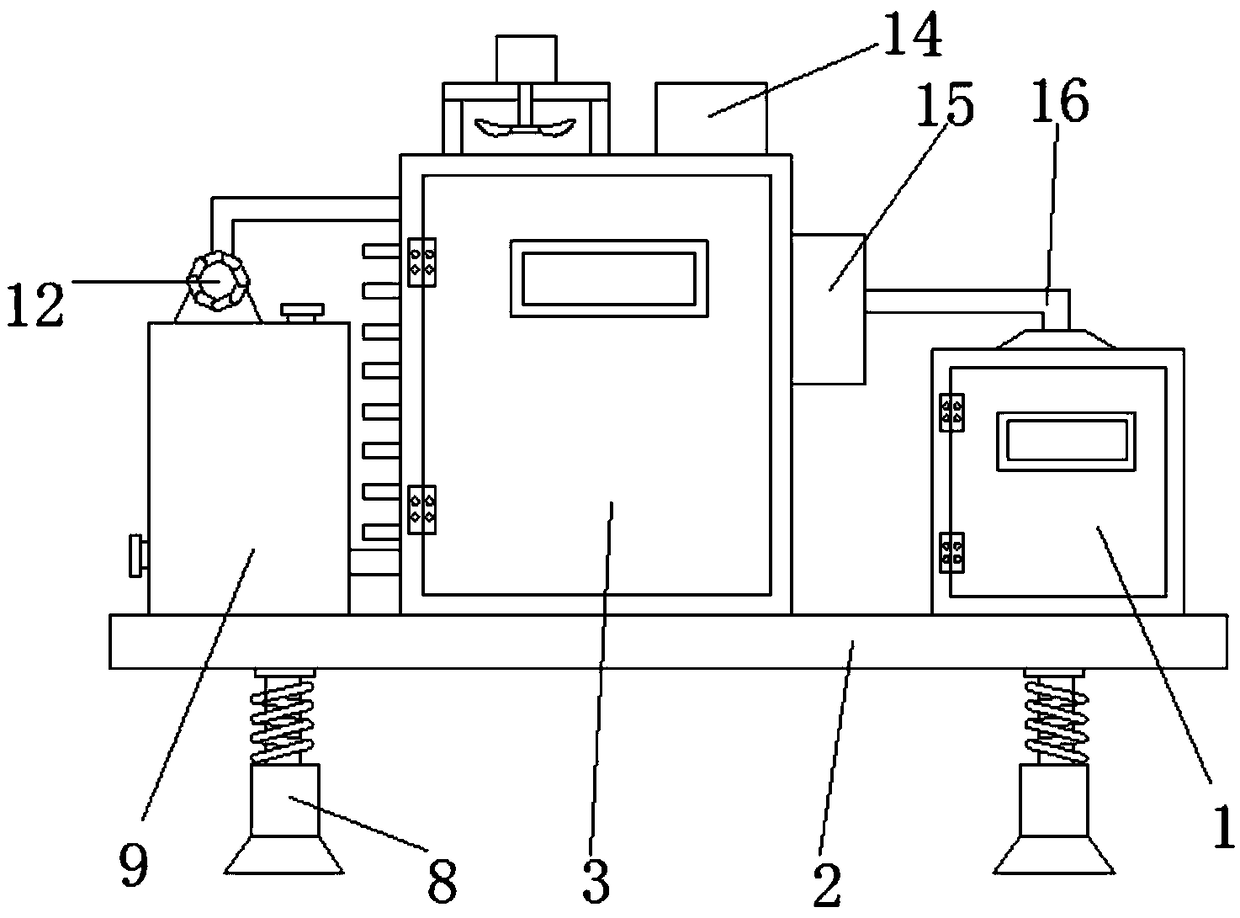

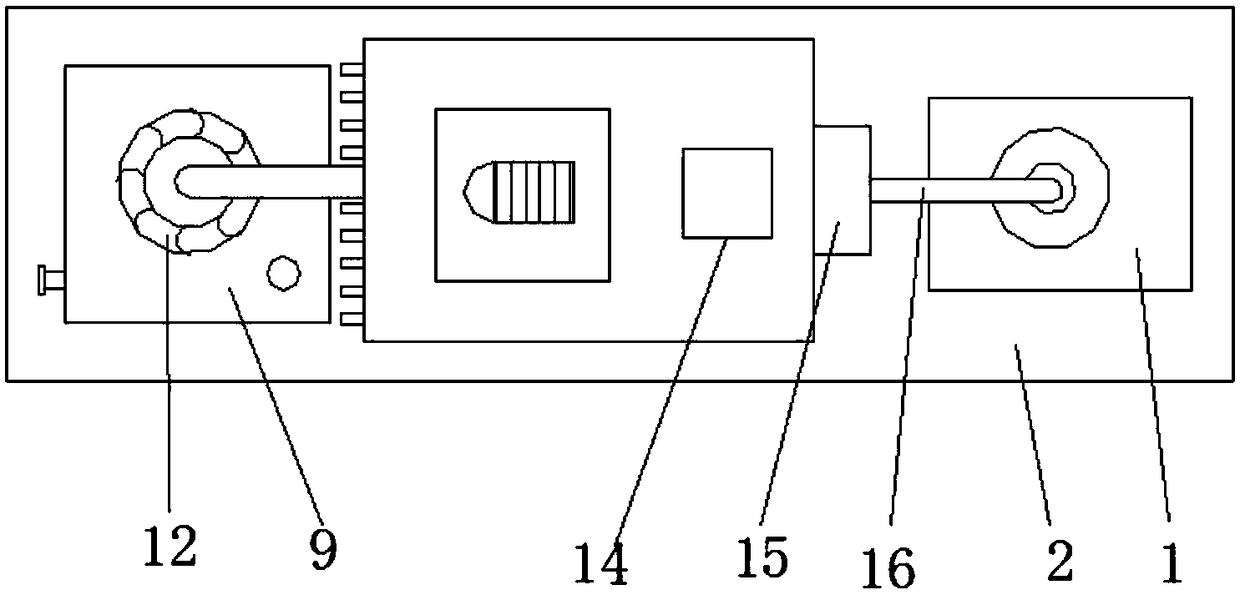

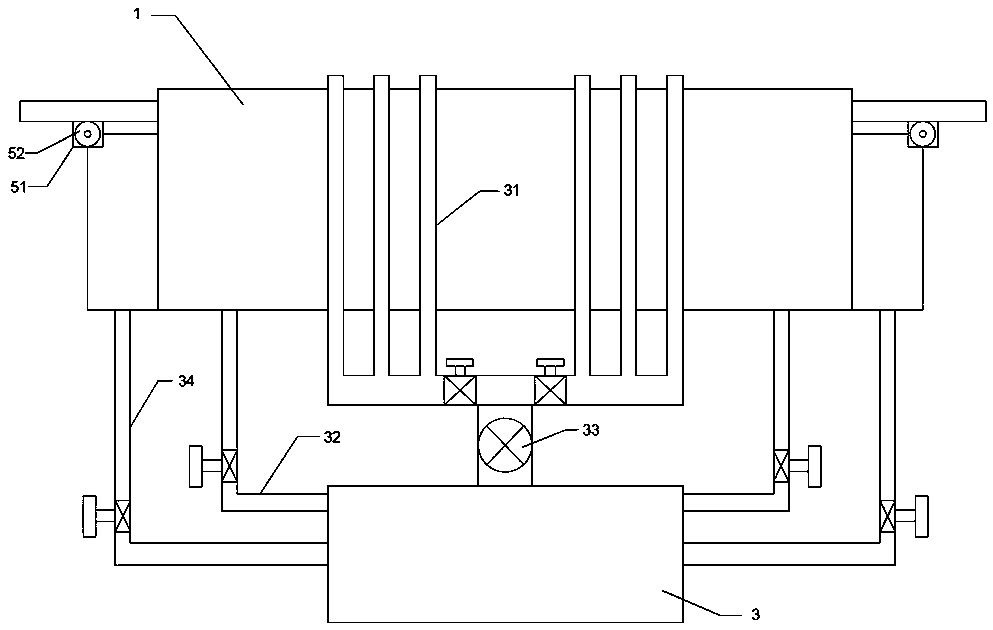

Lead-extrapolation transformer with good cooling effect

InactiveCN109326417ABrought out in timeReduce the temperatureTransformers/inductances coolingTransformers/inductances casingsCold airTransformer

The invention discloses a lead-extrapolation transformer with the good cooling effect. The lead-extrapolation transformer comprises a bottom plate, a transformer body, a cool air box and a water tankare fixed to the outer wall of the top of the bottom plate through bolts, an air fan support is welded to the outer wall of the top of the transformer body, a first air fan is fixed to the outer wallof the bottom of the air fan support, a processor is fixedly connected to the outer wall of the top of the transformer body through bolts, radiating fins distributed at equal distance are fixedly connected to the outer wall of one side of the transformer body through bolts, and a temperature sensor is fixedly connected to the inner wall of the middle of one side of the transformer body through a bolt. By means of the lead-extrapolation transformer with the good cooling effect, heat of the side wall of the transformer can be brought out in time, the temperature of the transformer is thus reduced, and the temperature of the transformer can be monitored in real time; through cooling, the transformer is in the constant-temperature state, the top of the transformer can be effectively cooled, circulation of water can be achieved, heat inside the transformer is thus taken away, the transformer can be subjected to cold air cooling, and cooling is convenient and rapid.

Owner:BENGBU ZHIDA TECH CONSULTING CO LTD

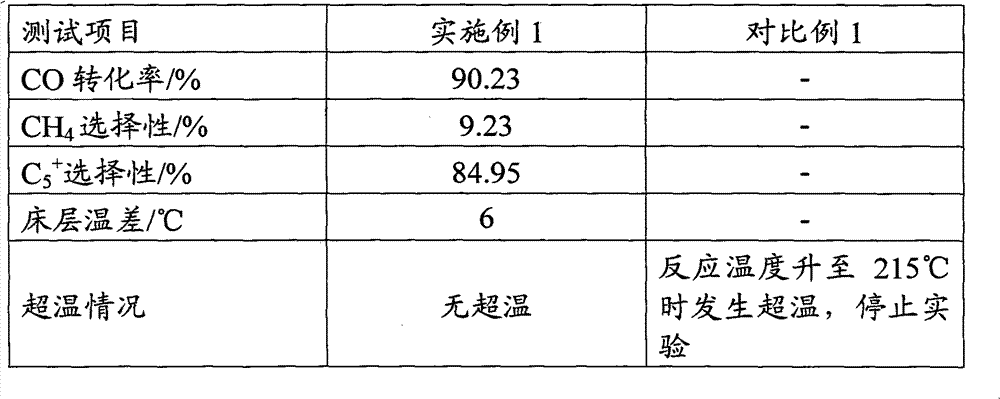

Method for making Fischer-Tropsch synthetic reaction stable

ActiveCN102952563AReduce the risk of overheatingSmall temperature differenceLiquid hydrocarbon mixture productionHydrogenSteady state

A method for making a Fischer-Tropsch synthetic reaction stable. A catalyst for Fischer-Tropsch synthesis is activated and enters an initial phase of a Fischer-Tropsch synthetic reaction; at the reaction initial phase, an inert medium is introduced into synthesis gas so as to allow a mixture flow containing hydrogen, carbon monoxide and the inert medium to contact with the Fischer-Tropsch synthesis catalyst bed layer for reaction; with the activity of the Fischer-Tropsch synthesis catalyst being in a steady state, the amount of the inert medium in the reactant flow is decreased gradually till the Fischer-Tropsch synthetic reaction is in a steady-state phase, wherein at the reaction initial phase, the reaction condition is the same as the reaction condition at the steady-state phase. With the method, the risk of overtemperature at the reaction initial phase is reduced; hot spot areas are reduced; the Fischer-Tropsch synthetic reaction can go into a steady-state phase stably; and guarantee for the long-period running of Fischer-Tropsch synthesis equipment is provided.

Owner:CHINA PETROLEUM & CHEM CORP +1

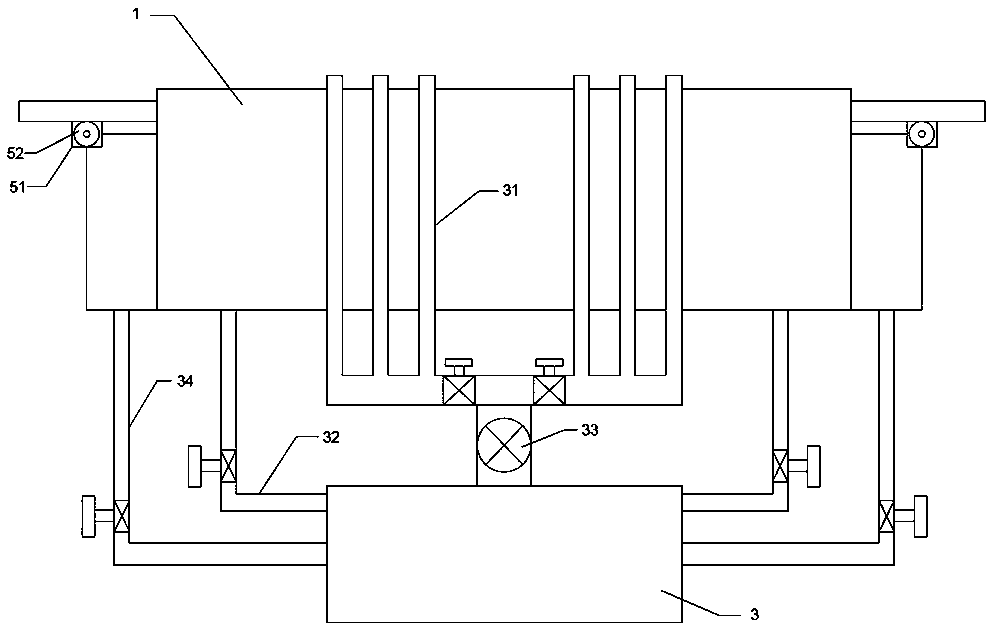

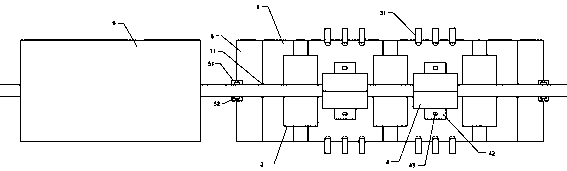

Cooling assembly for cable extrusion production line

PendingCN108454061ASimple structureEasy to useCleaning using toolsInsulating conductors/cablesProduction lineBristle

A cooling assembly for a cable extrusion production line comprises a cooling water tank, a circulating water mechanism and a bubble removing mechanism; a plurality of conveying carrier rollers are arranged in the cooling water tank at intervals in the cable conveying direction, cable through holes are formed in the two ends of the cooling water tank in the cable conveying direction, and the two ends are connected with guide conveying parts respectively; the circulating water mechanism comprises a water inlet pipe, a water outlet pipe, a water storage tank and a water pump; the bubble removingmechanism comprises base blocks and flexible bristles, the base blocks are located in the cooling water tank and between every two conveying carrier rollers, the flexible bristles are arranged on thebase blocks and used for horizontally rubbing with a cable back and forth, and the base blocks are connected with connecting blocks which are connected with connecting rods; each base block is connected with a horizontal reciprocating air cylinder through the corresponding connecting rod or at least two base blocks are connected with one horizontal reciprocating air cylinder through the corresponding connecting rods. The cooling assembly is simple in structure, convenient to use and good in overall cooling effect, the surface of an obtained product is smooth, and the quality is greatly improved.

Owner:FUJIAN TONGYU CABLES

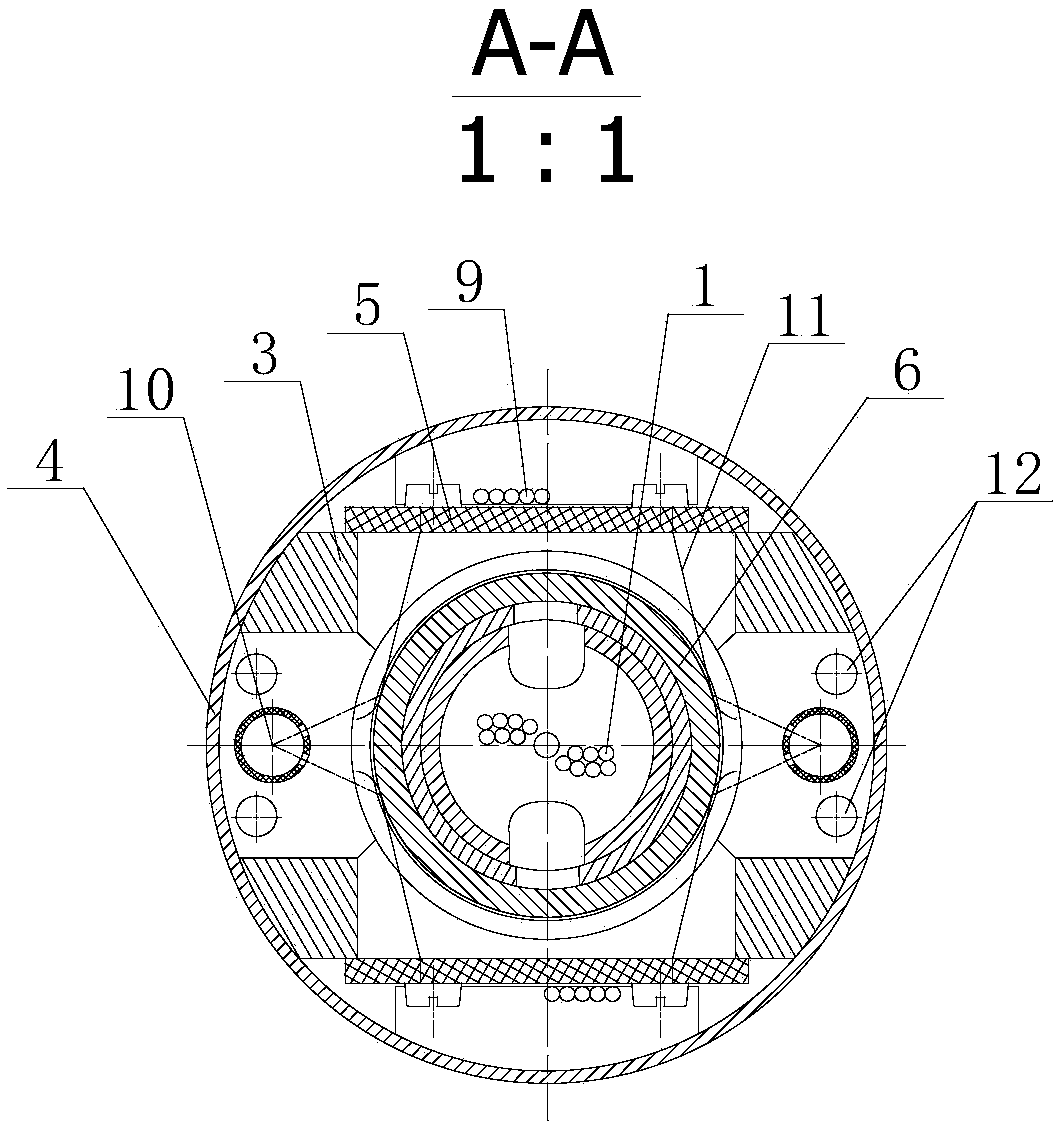

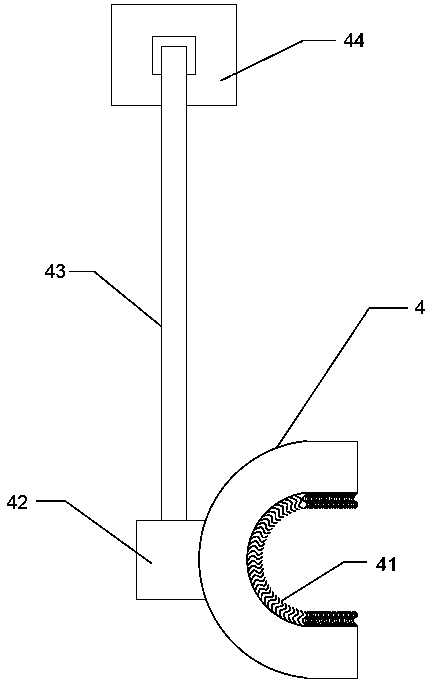

High-efficiency cooling structure for high-speed conductive slip ring

InactiveCN109659785AImprove heat transfer efficiencyAvoid destructionRotary current collectorModifications using gaseous coolantsEngineeringSlip ring

The invention discloses a high-efficiency cooling structure for a high-speed conductive slip ring. The structure comprises a ring outgoing line, a shifting fork, a bracket, an outer cover, a brush carrier plate, a ring piece, a core shaft, an air pipe, an air inlet hole, an air pipe joint, a brush outgoing line, an air inlet hole, a brush wire, an air outlet hole, a plug and a movable sealing ring. The core shaft, the ring piece fixed on the core shaft, the shifting fork and the ring outgoing line form a rotor part; the brush wire is fixed on the brush carrier plate, the brush carrier plate isfixed on the bracket through a bolt, and the outer cover and the bracket are assembled to form a stator part; the air inlet hole and the air outlet hole are formed in the same end of the bracket, andone ends of the two air pipes are connected with the symmetrical air inlet holes in the sliding ring, and the other ends are plugged by plugs and extend into the sliding ring; and outside the slip ring, the air pipe joint is connected with the air inlet, and the rotor part and the stator part rotate relatively through a bearing. The structure can greatly improve the cooling efficiency, and solvesthe problem that the heat exchange efficiency of a cooling medium and a temperature rise point is low when a slip ring insulation sheet is too high or a friction point is deep.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

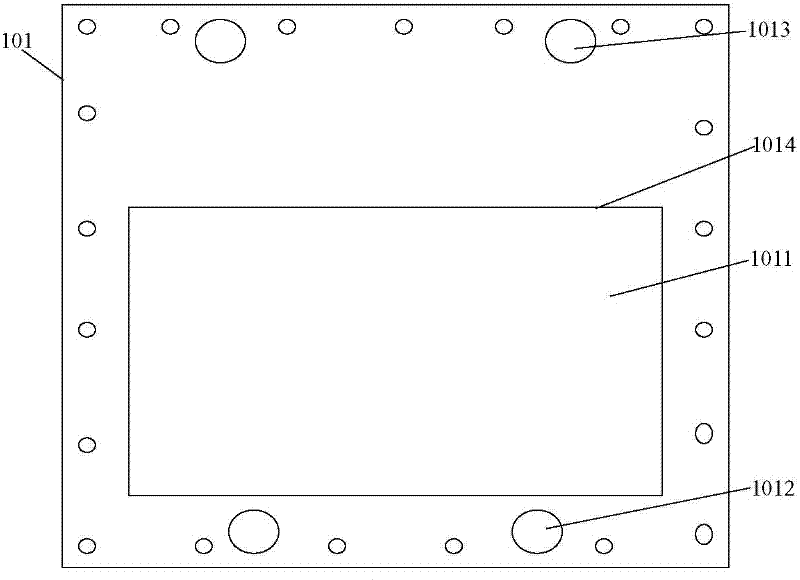

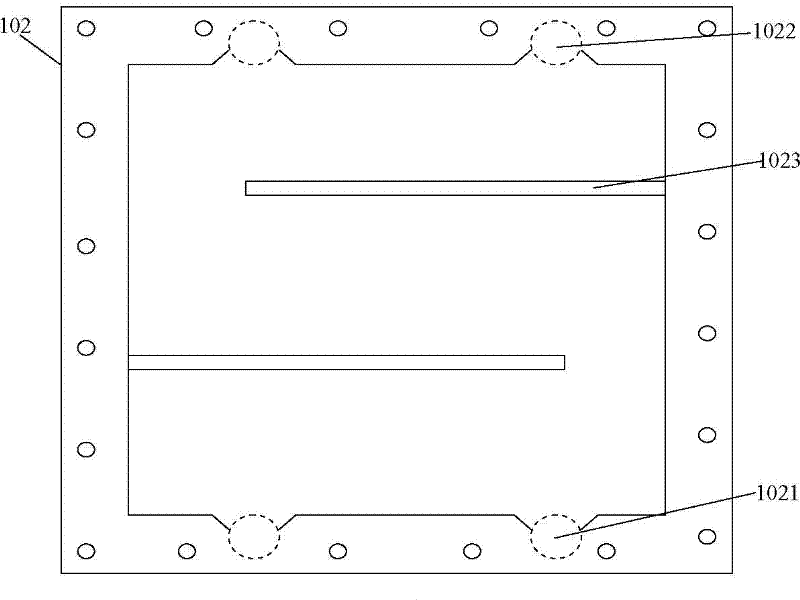

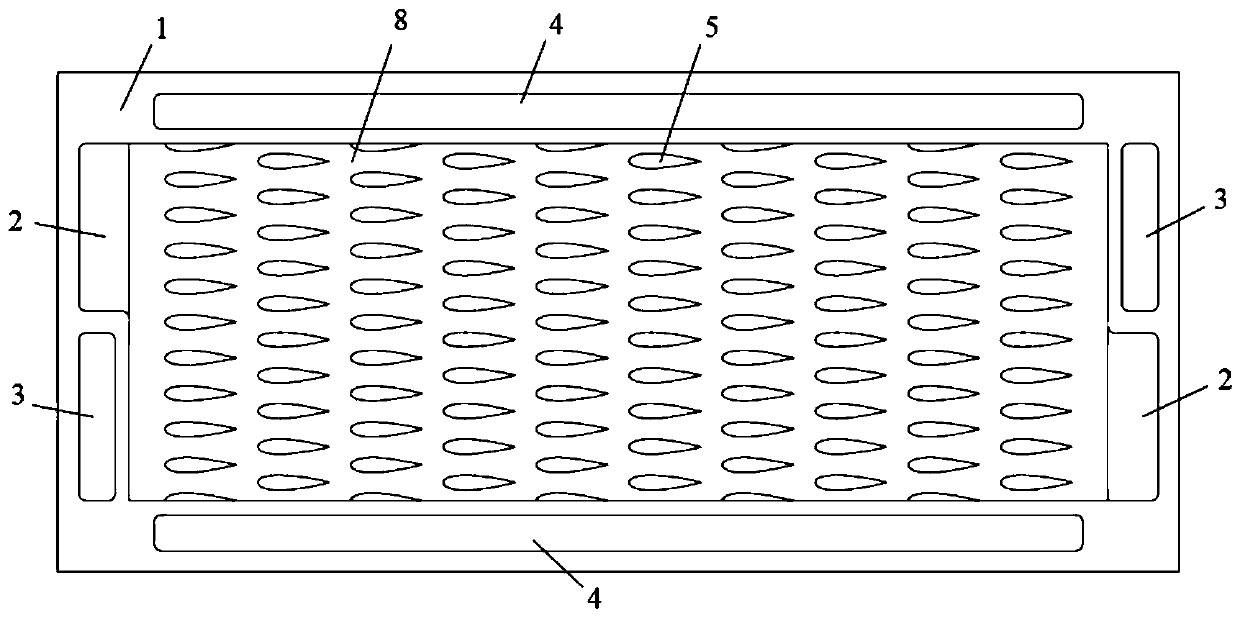

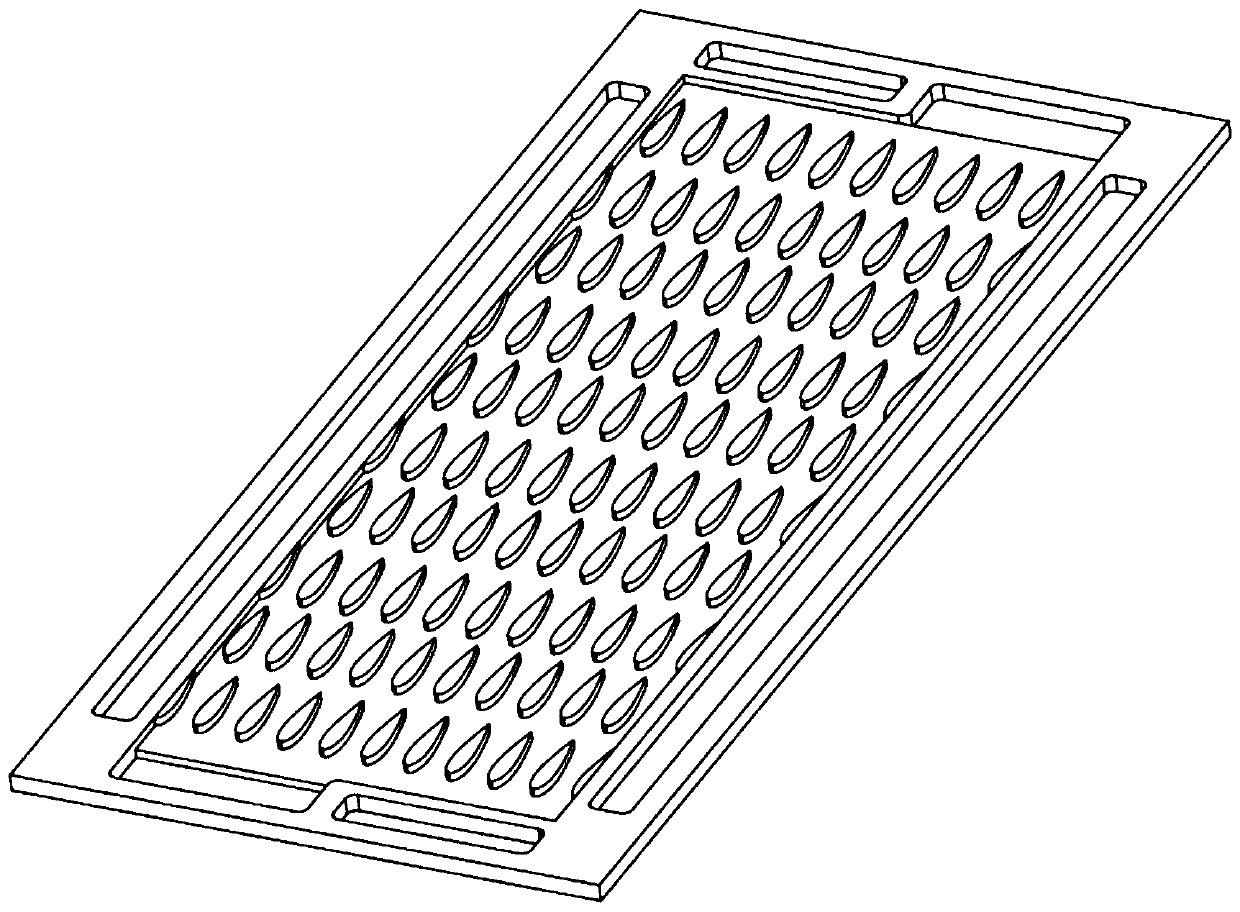

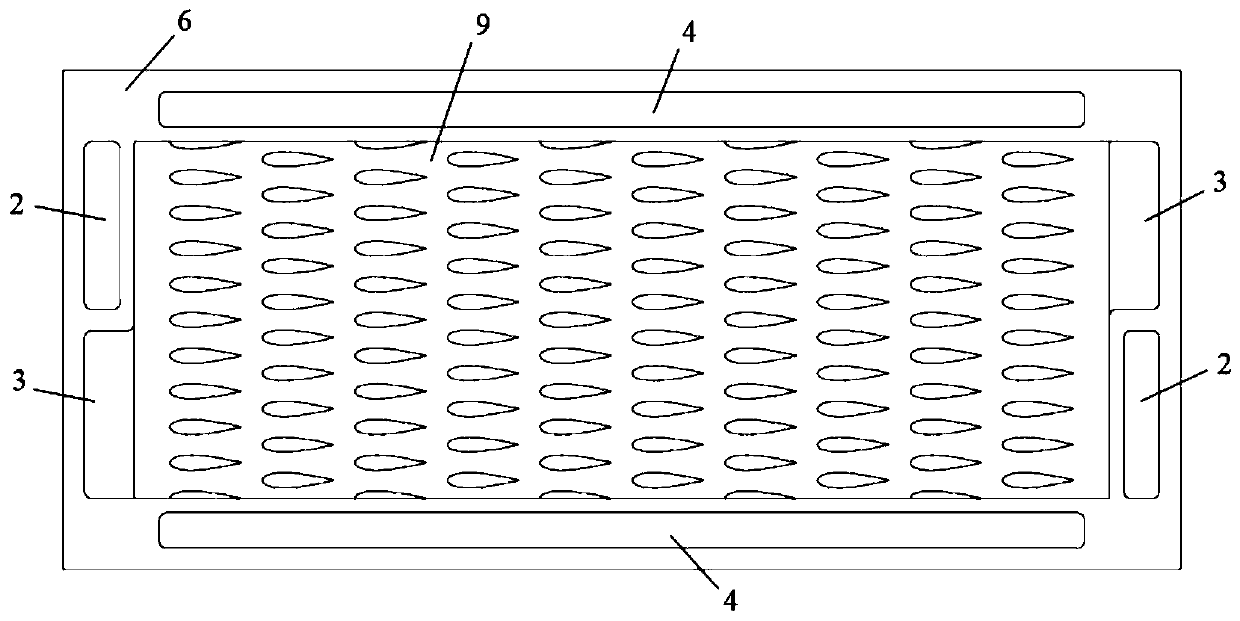

Fuel cell bipolar plate

PendingCN110085887AAvoid uneven distribution of reactantsAvoid adverse effectsFuel cellsMembrane configurationEngineering

The invention discloses a fuel cell bipolar plate, which comprises an anode plate, a cathode plate and two cooling plates, wherein the anode plate is sequentially superimposed, covered and connected with one cooling plate from bottom to top, the cathode plate is sequentially superimposed, covered and connected with the other cooling plate from top to bottom, the anode plate and the cathode plate constitute a fuel cell unit with a membrane electrode clamped between the anode plate and the cathode plate, the upper surface of the anode plate is provided with a hydrogen horizontal flow channel, the upper surface of the cathode plate is provided with an air horizontal flow channel, and the upper surface of each cooling plate is provided with a cooling liquid horizontal flow channel; and the anode plate, the cathode plate and the cooling plates are respectively provided with a plurality of hydrogen vertical flow channels, air vertical flow channels and cooling liquid vertical flow channels.The bipolar plate is small in flow resistance and can enable the temperature field inside the cell to be uniform in distribution.

Owner:XIAN THERMAL POWER RES INST CO LTD

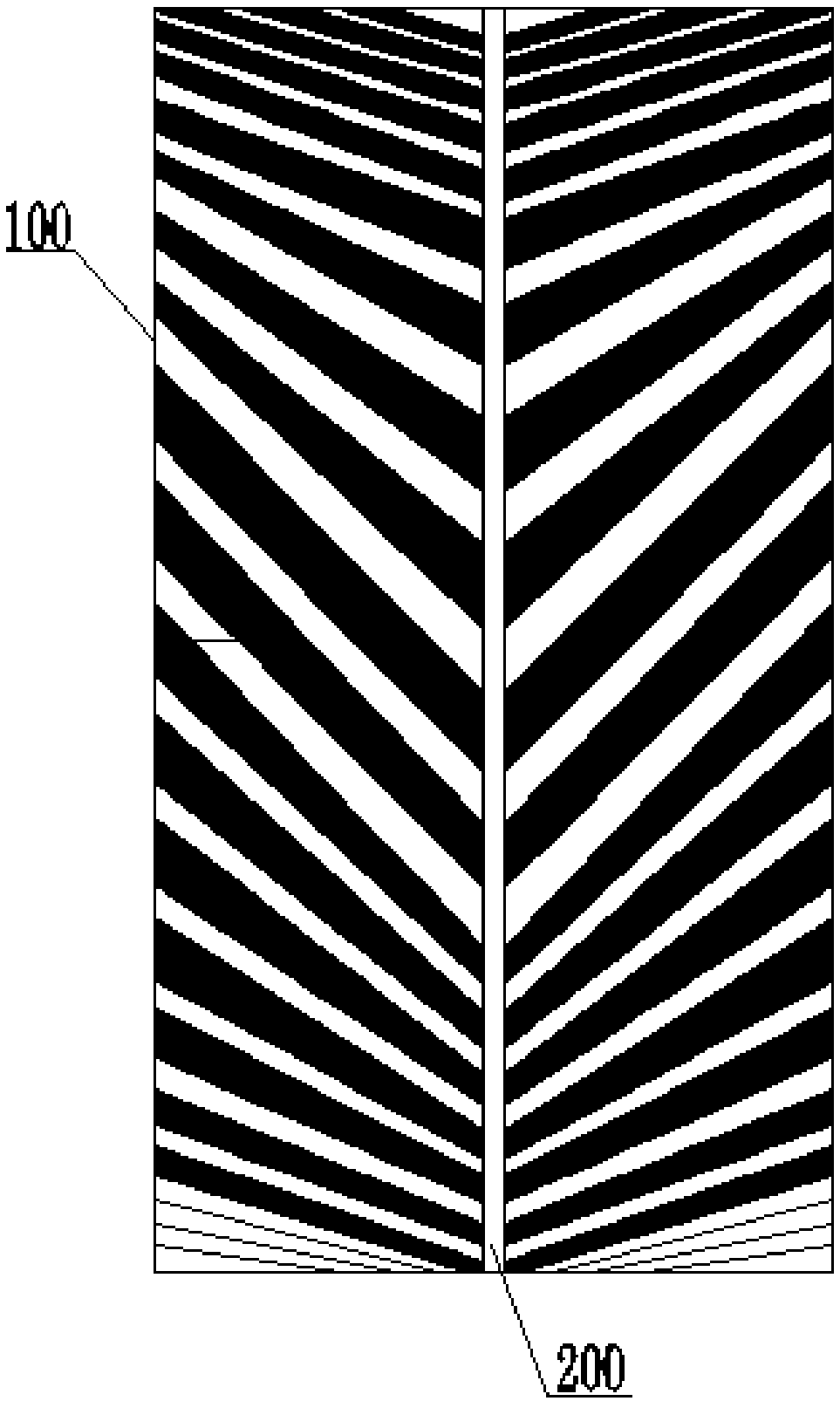

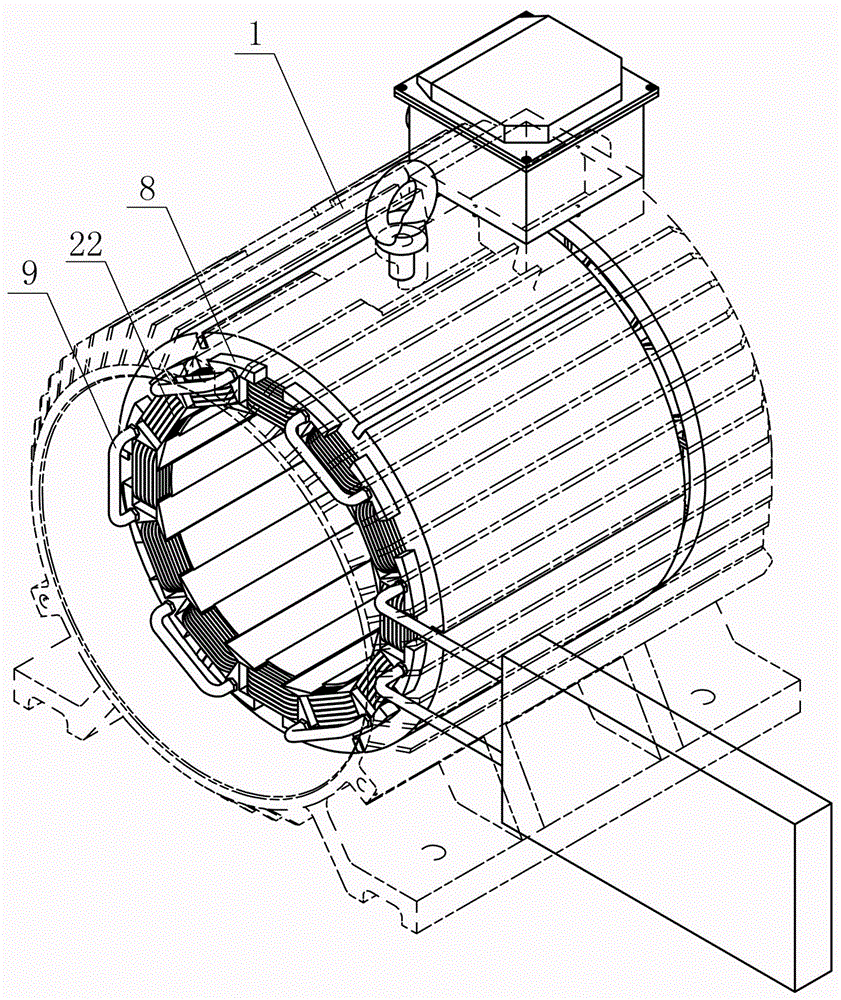

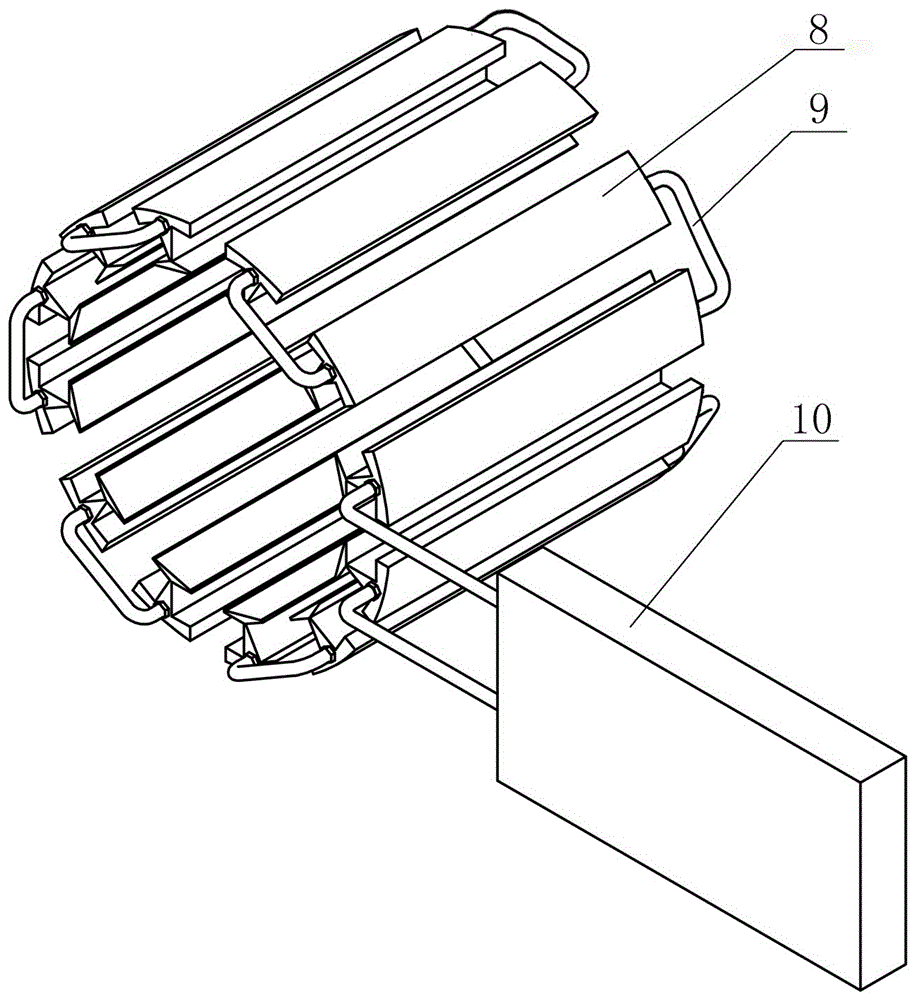

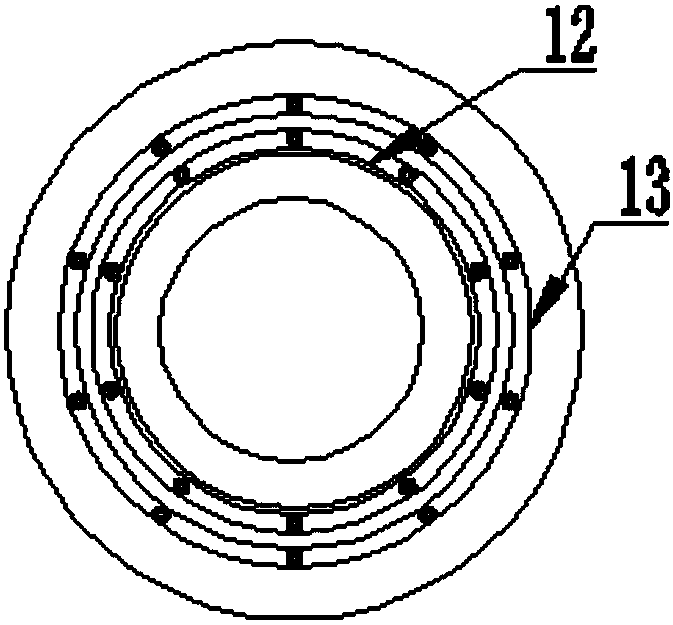

Stator core and motor

PendingCN108110914AReduce temperature riseImprove performanceMagnetic circuit stationary partsElectric machinesPunchingElectric machinery

The invention relates to the technical field of motors, and particularly relates to a stator core and a motor. The stator core includes multiple sets of stator punching sheets, and the multiple sets of stator punching sheets are sequentially in stacked arrangement; multiple outer diameter grooves are arranged on the stator punching sheets, the adjacent sets of stator punching sheets perform rotation, and the multiple outer diameter grooves form a spiral groove; and the motor includes the above stator core. According to the scheme of the invention, the technical problem that the temperature rise of the stator core of the motor in the prior art cannot be effectively controlled can be alleviated.

Owner:博远机电(嘉兴)有限公司

Kiln waste heat utilization system

InactiveCN102486352AIncrease productionEfficient use ofDrying gas arrangementsIncreasing energy efficiencyThermal energyCold air

The invention relates to a kiln waste heat utilization system, which comprises a remote heat collection system, a mixing system, a conveying system and a dehumidification system. One end of an air pipe in the remote heat collection system is connected with a kiln waste heat collection air pipe, the other end of the air pipe is communicated with a mixing chamber of the mixing system, the mixing chamber is communicated with an induced draft fan of a boiler, an air pipe of the mixing chamber is provided with a cold air gate, the outlet pipe of the induced draft fan of the boiler is communicated with a plurality of drying chambers through a conveying pipe of the conveying system, and the drying chambers are divided into a mold drying chamber close to a grouting area and a blank drying chamber outside the mold drying chamber and are communicated with a dehumidification pipe of the dehumidification system. By adopting the kiln waste heat utilization system, heat in hot air produced by a kiln can be reused for drying blanks and molds produced with the kiln, the waste heat can be effectively utilized, the energy can be saved, and the production yield of the kiln can be improved.

Owner:枝江市玖源包装制品有限公司

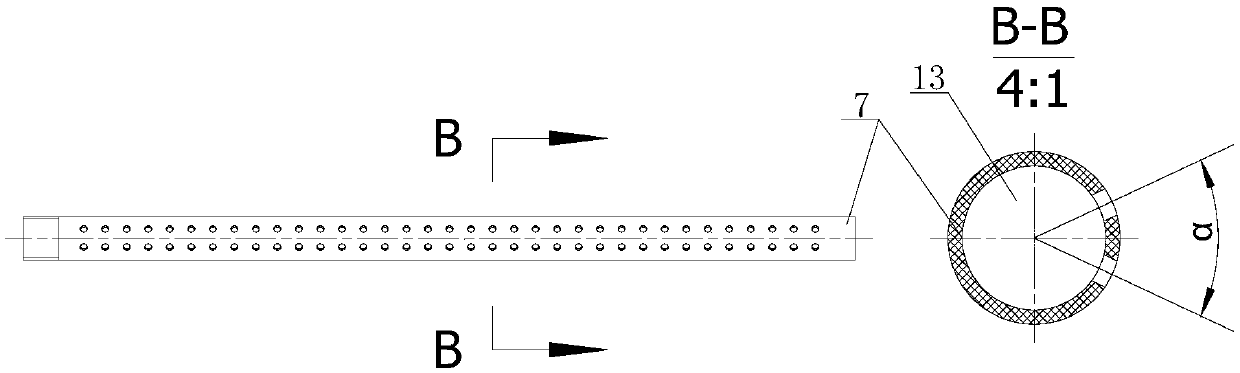

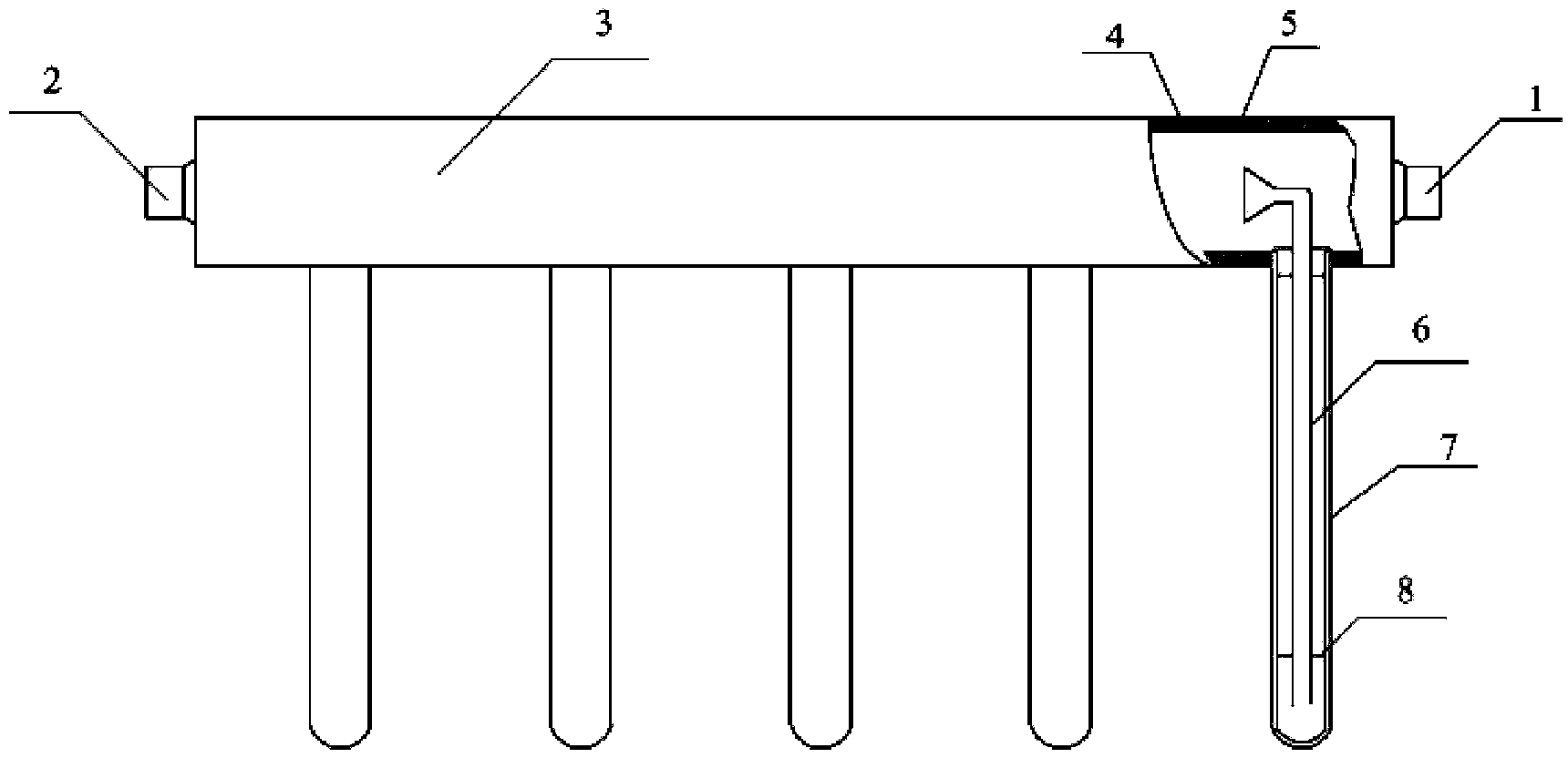

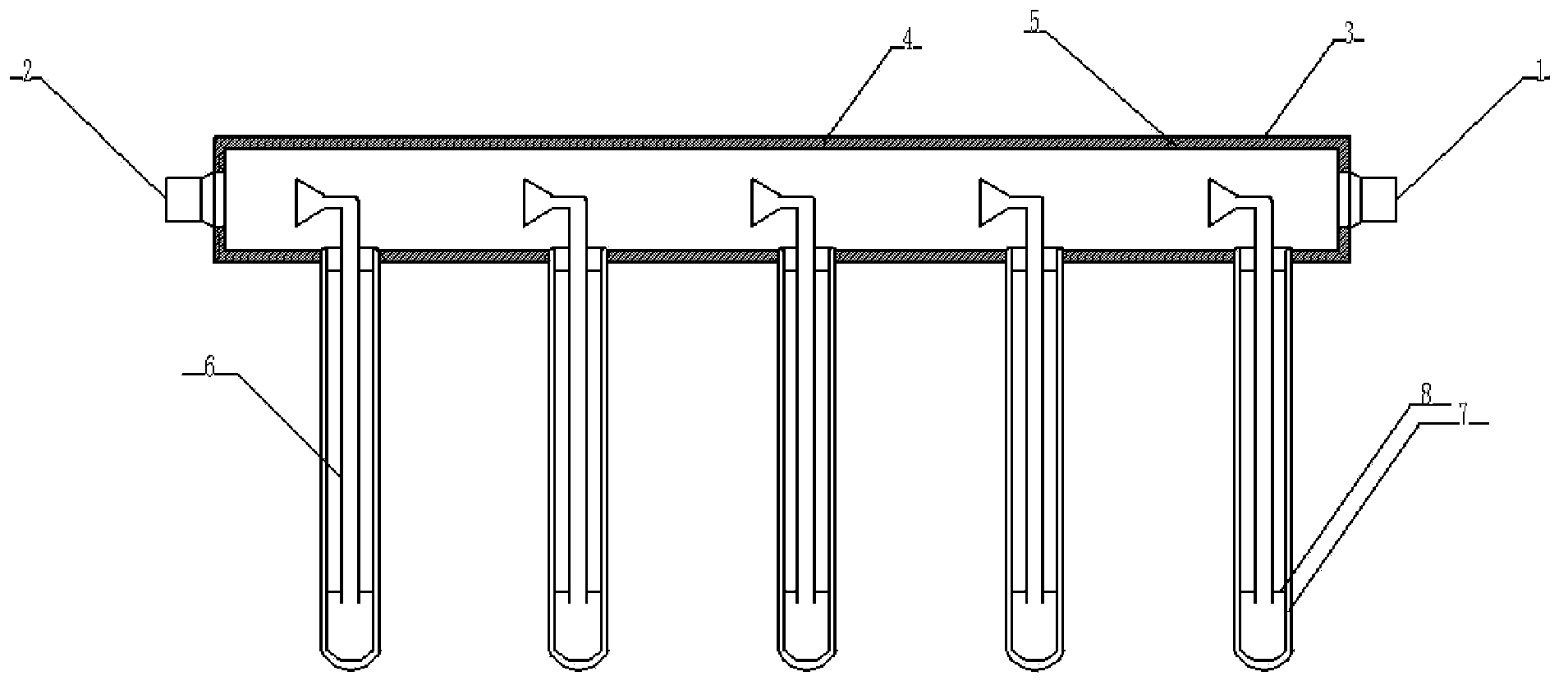

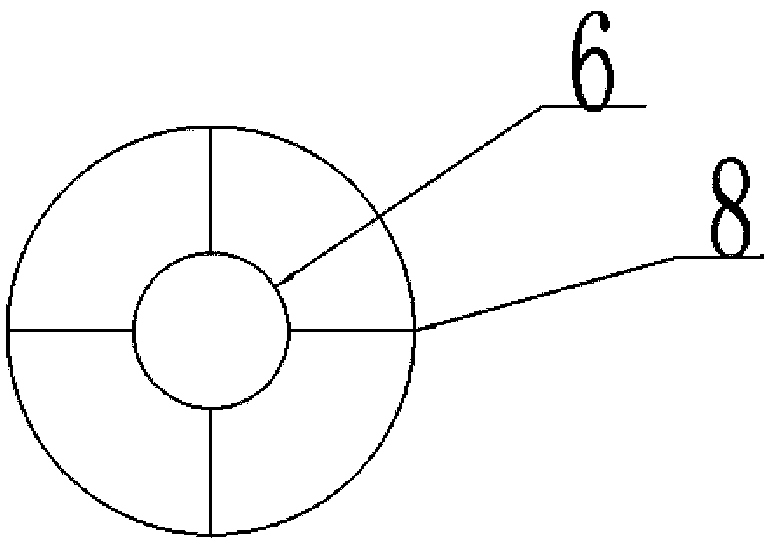

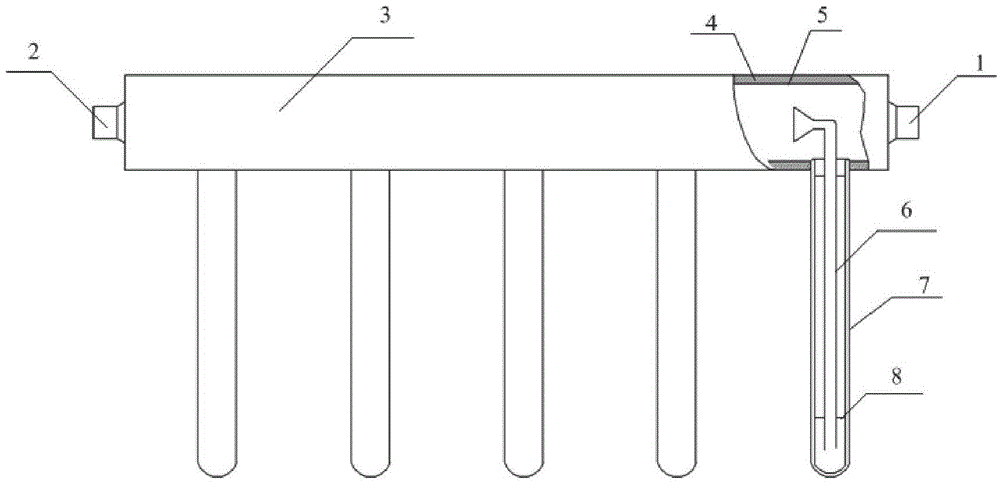

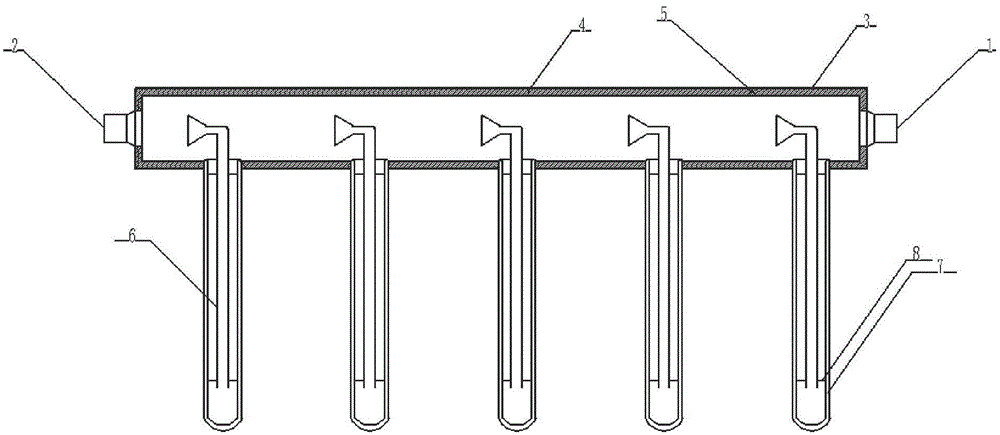

Vacuum tube type solar energy air collector

ActiveCN103411320ALow costSimple structureSolar heating energySolar heat devicesStraight tubeHeating system

The invention discloses a vacuum tube type solar energy air collector which comprises a box body, wherein an air inlet is formed in one end of the box body, an air outlet is formed in the other end of the box body, the box body is provided with a vacuum tube connecting opening and a vacuum tube, the vacuum tube is communicated with the box body through the vacuum tube connecting opening in an airtight mode, an inner tube of the vacuum tube is coated by a selective absorbing coating and provided with an expansion opening inserting tube, the expansion opening inserting tube is of an L shape and comprises an expansion opening section and a straight tube section, the straight tube section is vertical to the expansion opening section, and the expansion opening section is provided with a funnel-shaped opening; the straight tube section is fixed inside the vacuum tube; the expansion opening section stretches into the box body, and the funnel-shaped opening of the expansion opening section backs on to the air inlet in the one end of the box body. According to the negative pressure suction type vacuum tube type solar energy air collector, a heat tube is not used, manufacturing cost is low, the structure is simple, installation is convenient to achieve, heat collection efficiency is high, resistance is little, and the vacuum tube type solar energy air collector is suitable for series-parallel connection of various heat collectors and is applied to a large-scale air drying system and a heating system.

Owner:山东亿家能太阳能有限公司

Combinational cooling apparatus of cable extrusion molding line

Disclosed is a combinational cooling apparatus of a cable extrusion molding line. The combinational cooling apparatus comprises a cooling water channel, a circulation water mechanism, a bubble removing mechanism and an air cooling mechanism; multiple conveying support rollers are arranged in the cooling water channel in the cable conveying direction at intervals; cable connecting ports are formedin the two ends, in the cable conveying direction, of the cooling water channel, and the two ends are also connected with guiding and conveying parts respectively; the circulation water mechanism comprises a water inlet pipe, a water outlet pipe, a water storage tank and a water pump; the bubble removing mechanism comprises base blocks positioned in the cooling water channel and between adjacent two conveying support rollers, and flexible brush bristles arranged on the base blocks and used for wiping cables horizontally in a reciprocating manner; the base blocks are connected with connecting blocks; the connecting blocks are connected with connecting rods; each base block is connected with a horizontal reciprocating air cylinder through the corresponding connecting rod, or at least two base blocks are jointly connected with one horizontal reciprocating air cylinder through the corresponding connecting rods; and the air cooling mechanism comprises a cylinder with a hollow body interiorand a fan. The combinational cooling apparatus is simple in structure, convenient to use and excellent in overall cooling effect, the obtained product is bright and clean in surface, and the quality is highly improved.

Owner:FUJIAN TONGYU CABLES

Method and device for treating gas containing carbon dioxide and hydrogen sulfide

ActiveCN108722148BGreat operating flexibilityMild operating conditionsGas treatmentDispersed particle separationHydration reactionChemical products

The invention discloses a treatment method and device for gas containing carbon dioxide and hydrogen sulfide. The device includes a hydration reactor, a hydrate decomposer, a gas exhaust processor, a primary absorption reactor, a secondary absorption reactor and a product tank . Also provided is a method for treating gas containing carbon dioxide and hydrogen sulfide by using the above device. It can produce NaHS products that meet the national quality standards while achieving acid gas discharge standards, and organically combine environmental governance with the production process of chemical products into an integrated process. Compared with the prior art, the method of the present invention can economically and efficiently pretreat the gas containing carbon dioxide and hydrogen sulfide, rationally utilize the energy in the process, and greatly reduce energy consumption; the whole process is environmentally friendly, reliable, No "three wastes" are generated.

Owner:CHINA PETROLEUM & CHEM CORP +1

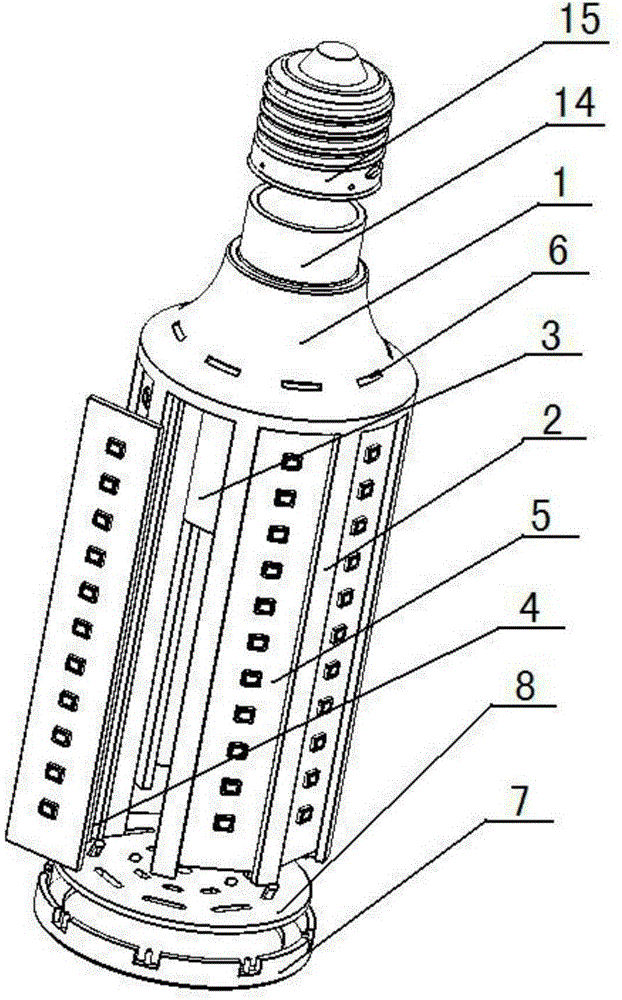

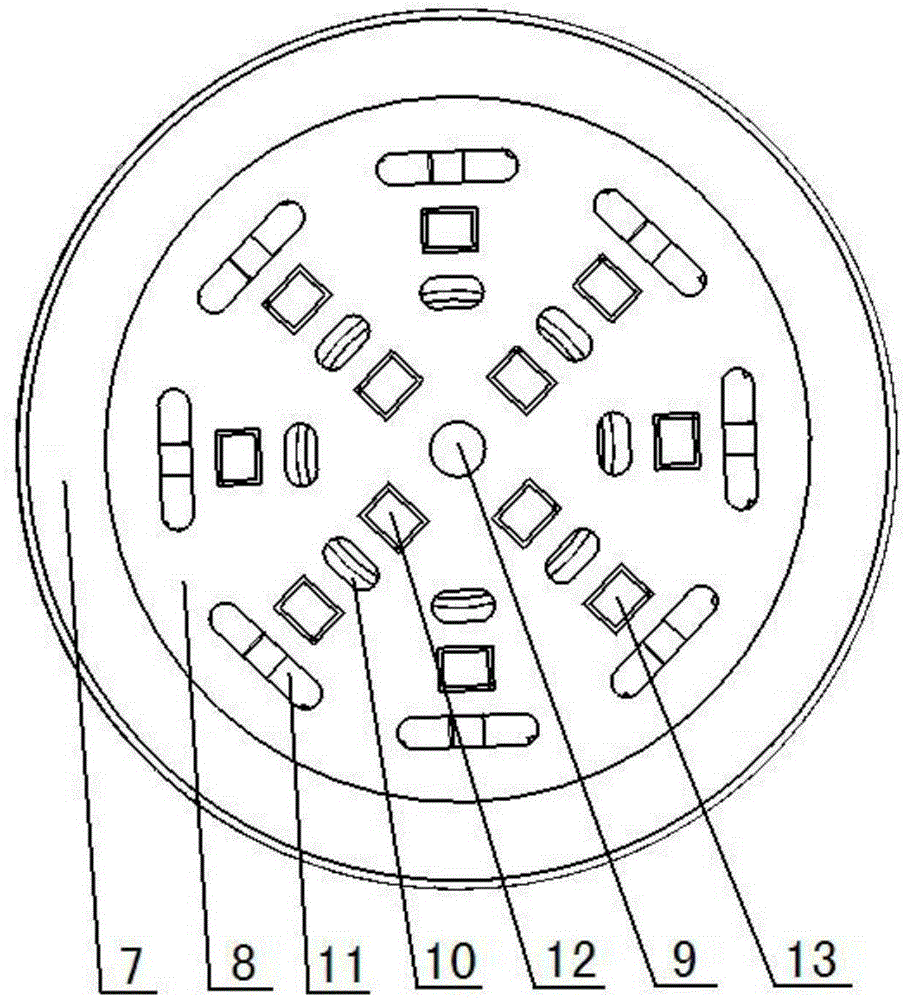

Heat dissipation structure based on LED corn lamp

InactiveCN105387433AIncreased light decay timeGood cooling effectElectric circuit arrangementsLighting heating/cooling arrangementsLamp shellEngineering

The invention discloses a heat dissipation structure based on an LED corn lamp. The heat dissipation structure comprises a base, a plurality of fixing ribs integrally arranged on the edge of the lower end surface of the base and an annular driving power bin formed in the middle of the lower end surface of the base. Slots are formed in the left side wall and the right side wall of each fixing rib, and a strip-shaped lamp panel is fixed between every two adjacent fixing ribs through the slots. The base is provided with a plurality of upper ventilation holes, and a round lamp panel is fixed under the fixing ribs through an end cover and is provided with a plurality of lower ventilation holes. According to the heat dissipation structure, the base is provided with the upper ventilation holes, the round lamp panel is provided with the lower ventilation holes, and therefore convection of heated air inside an LED corn lamp shell can be realized, hot air generated by exchanging heat with the lamp panels can be discharged from the LED shell faster, the heat dissipation requirement can be completely met through the heat dissipation structure for the LED corn lamp, the LED corn lamp is good in heat dissipation effect, and the manufacturing cost of the LED corn lamp is lowered.

Owner:CHONGQING SANGNAIMEI PHOTOELECTRIC TECH

Combined treatment process and system for acid gas

ActiveCN108722135AGreat operating flexibilityMild operating conditionsGas treatmentDispersed particle separationProduct gasChemical products

The invention discloses a combined treatment process and a system for acid gas. According to the combined treatment process and the system, NaHS products meeting national quality standards can be produced while up-to-standard discharge of the acid gas is realized; environmental improvement is organically combined with the production process of a chemical product. Compared with the prior art, the process and the system disclosed by the invention have the advantages that the acid gases containing CO2 and hydrogen sulfide can be economically and efficiently pretreated, energy in the technologicalprocess is reasonably utilized and energy consumption is greatly reduced; the whole treatment process is environmentally friendly and reliable and no three wastes are produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

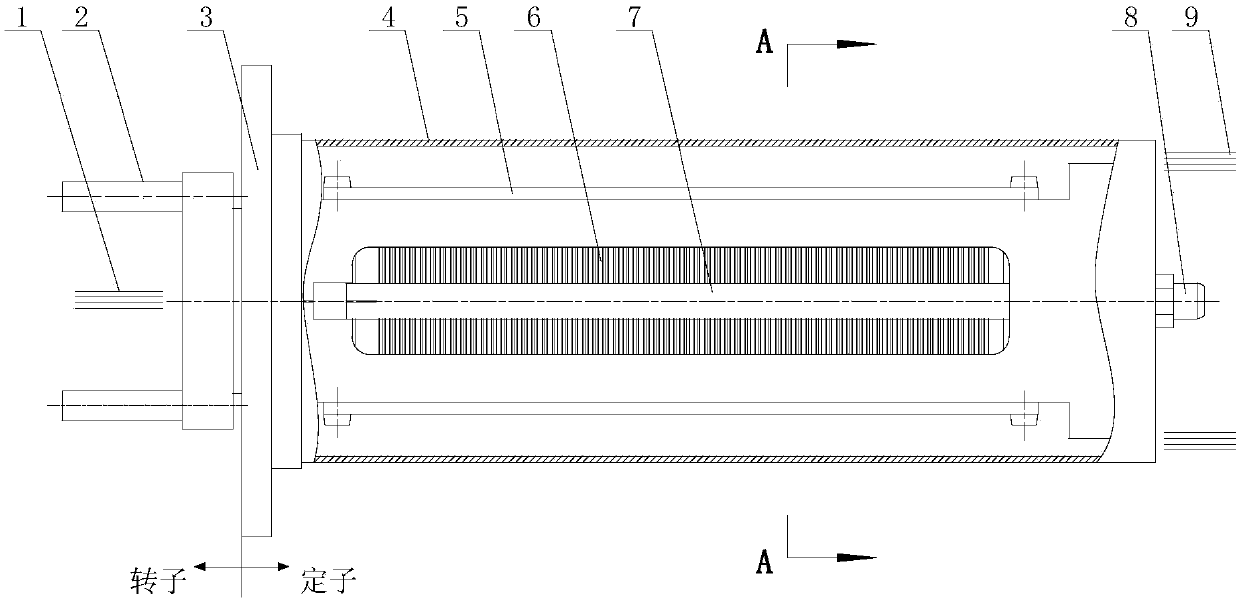

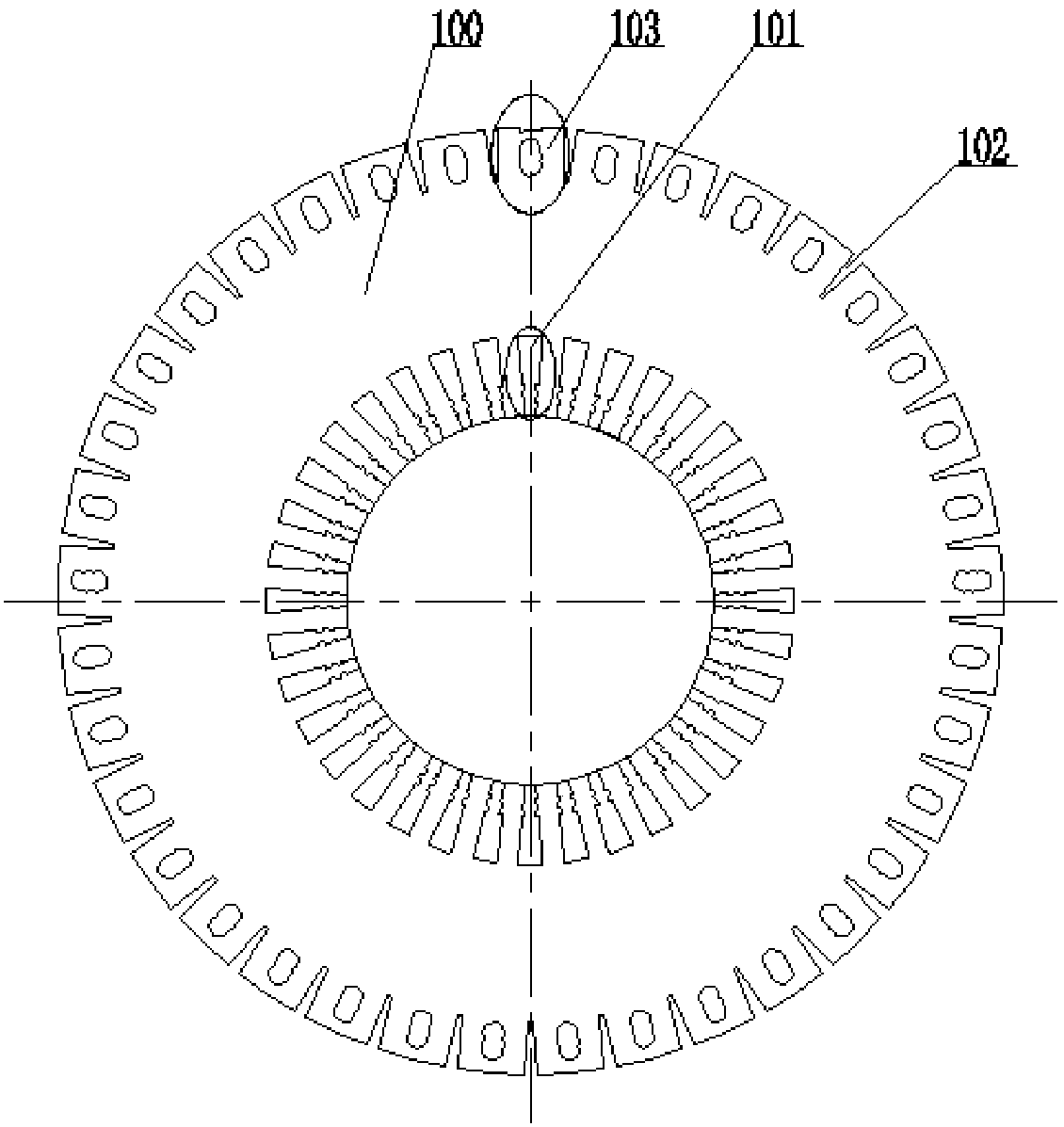

Efficient-heat radiation and low-pulsation switched reluctance motor

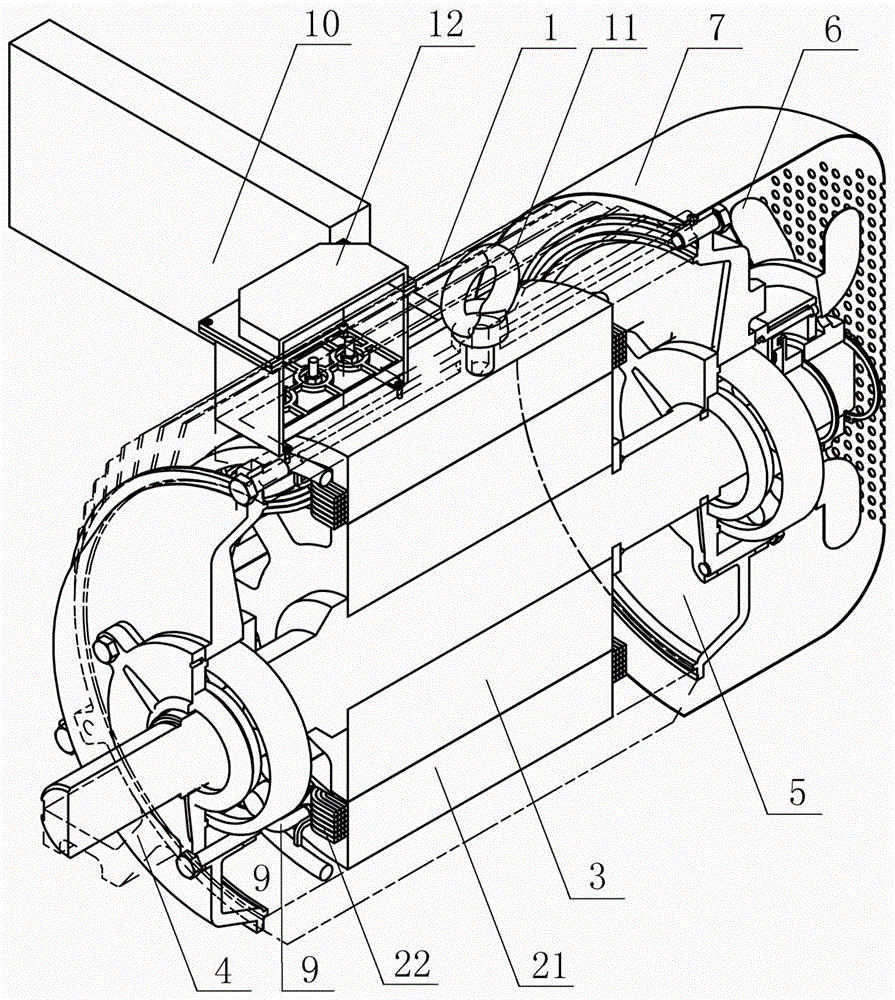

InactiveCN105680626AReduce vibrationReduce pulsationCooling/ventillation arrangementWindings conductor shape/form/constructionStator coilEngineering

The invention discloses an efficient-heat radiation and low-pulsation switched reluctance motor, which comprises a frame housing, a stator, a rotor, a front end cover and a rear end cover, wherein the rear part of the rear end cover is provided with a fan; a fan housing is arranged outside the fan; the stator comprises a stator iron core and a plurality of stator windings, an aluminum profile insulation sheet is embedded between adjacent two stator windings, and two ends of each aluminum profile insulation sheet are respectively connected onto the frame housing; a coolant flow hole from one end to the other end is arranged in each aluminum profile insulation sheet, the coolant flow holes in all aluminum profile insulation sheets are communicated via flow guide pipelines arranged at two ends, and the flow guide pipelines are also communicated with a heat radiation device outside the frame housing. The aluminum profile insulation sheet plays a role of reinforcing the winding coil, the stator coil and the stator can be combined more tightly, the heat radiation effects are better, the pulsation and the noise of the motor are reduced, and as the flow guide pipelines are also communicated with the heat radiation device outside the frame housing, heat inside the motor can be timely taken out.

Owner:ZHENGZHOU DAYUE ENERGY SAVING TECH CO LTD

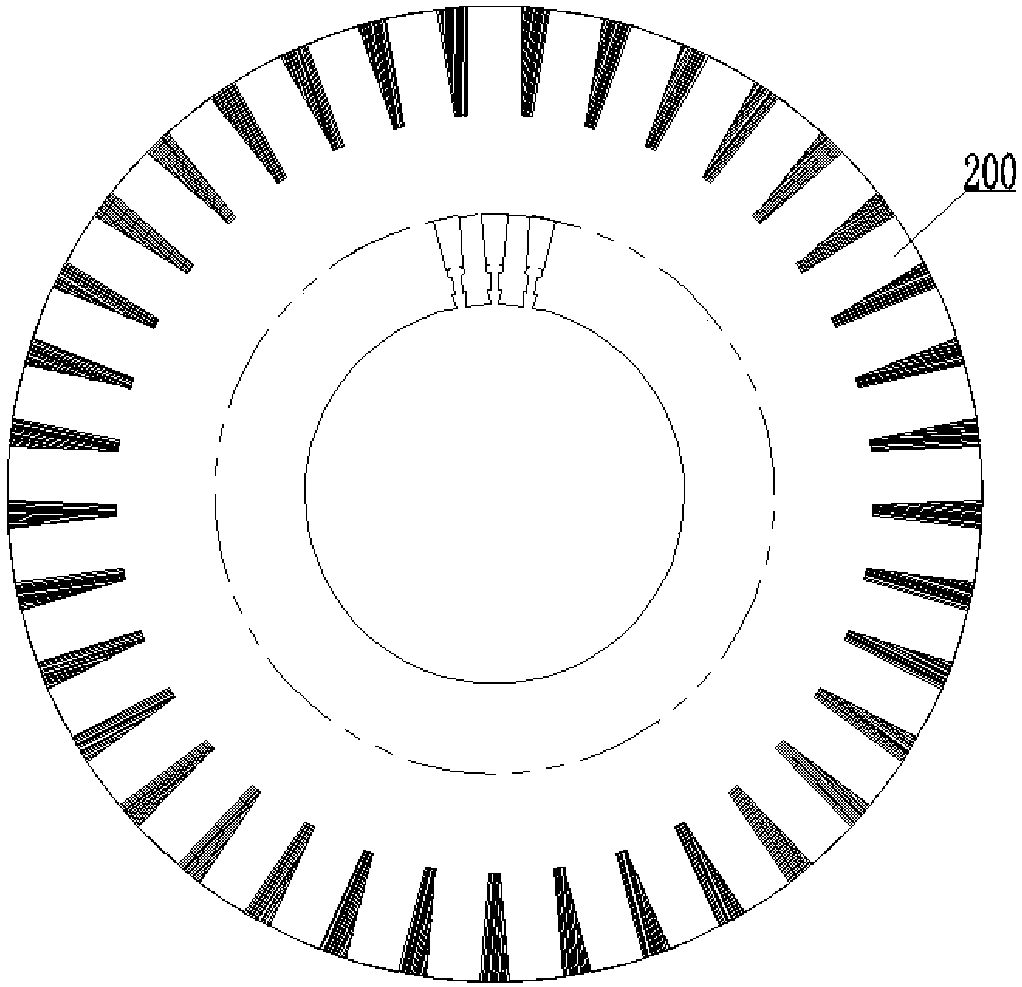

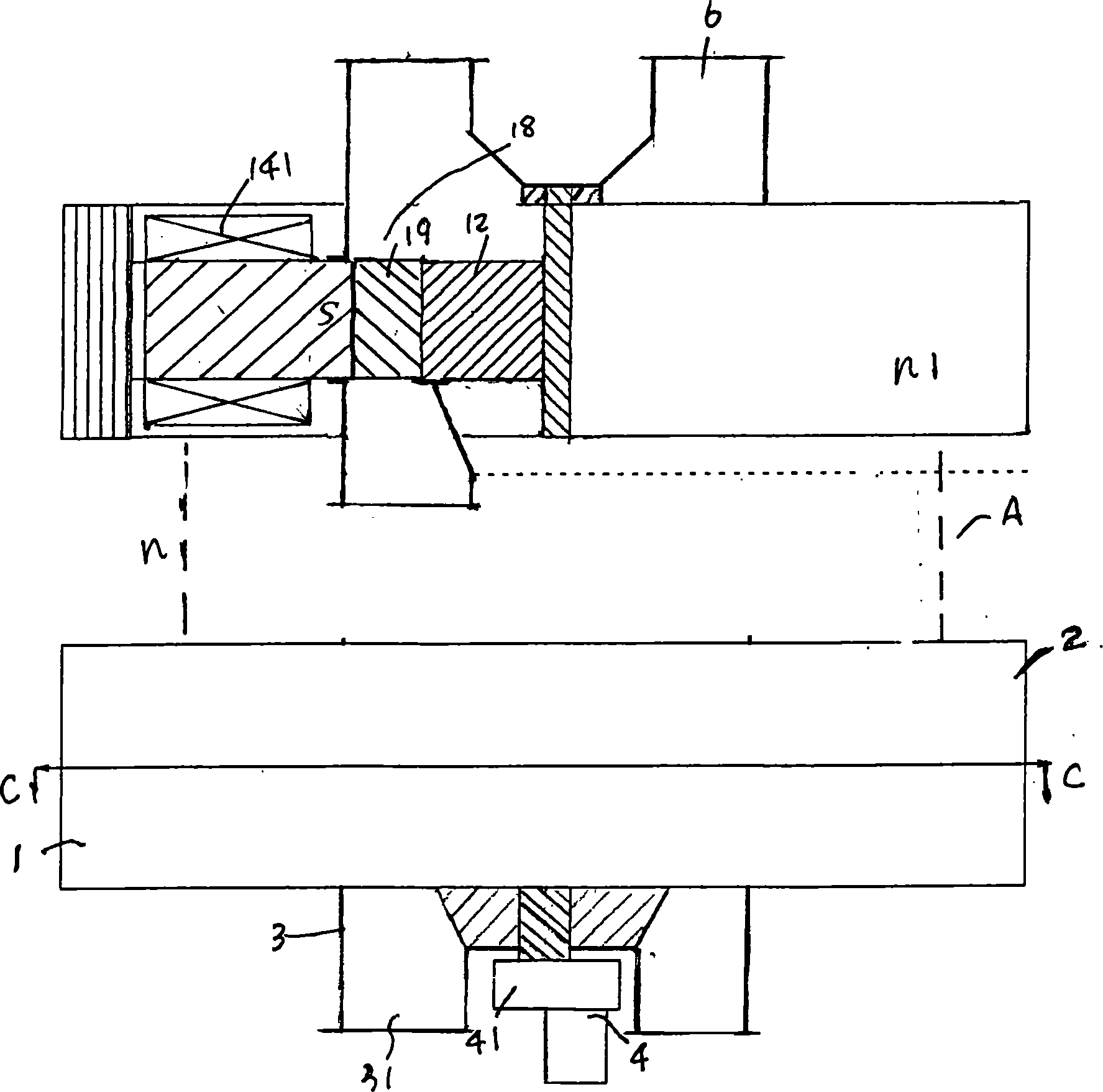

Dry ore dressing apparatus and its magnetic separating unit

InactiveCN1887430AOptimize structural configurationStrong noveltyMagnetic separationArray data structureDrive shaft

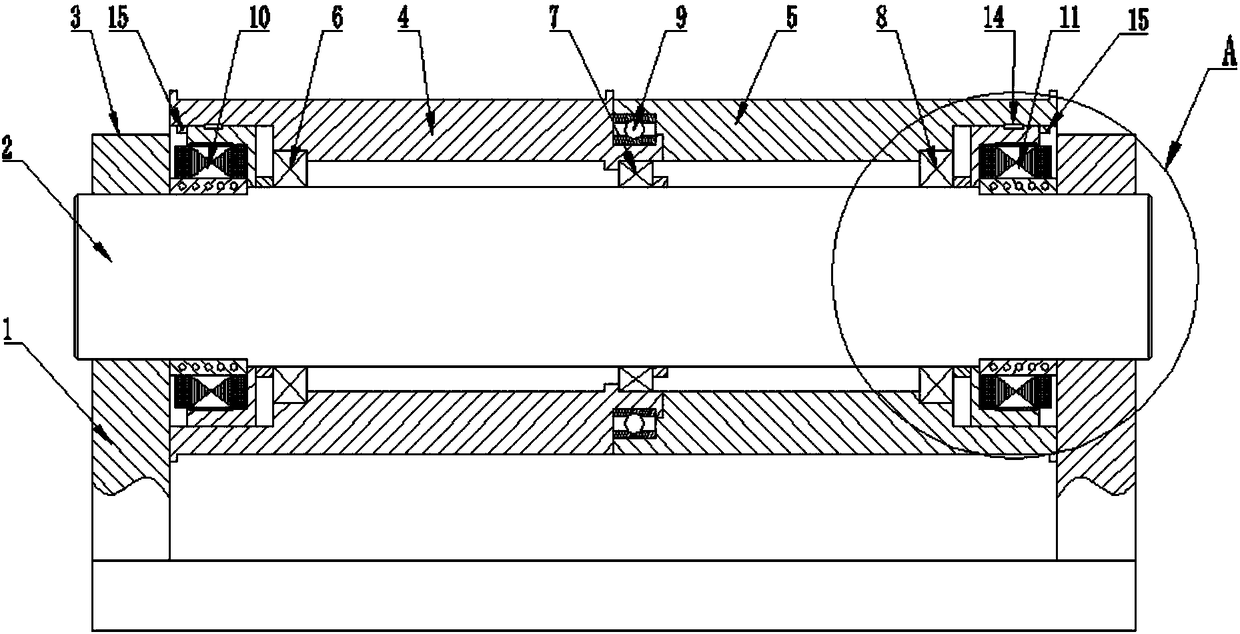

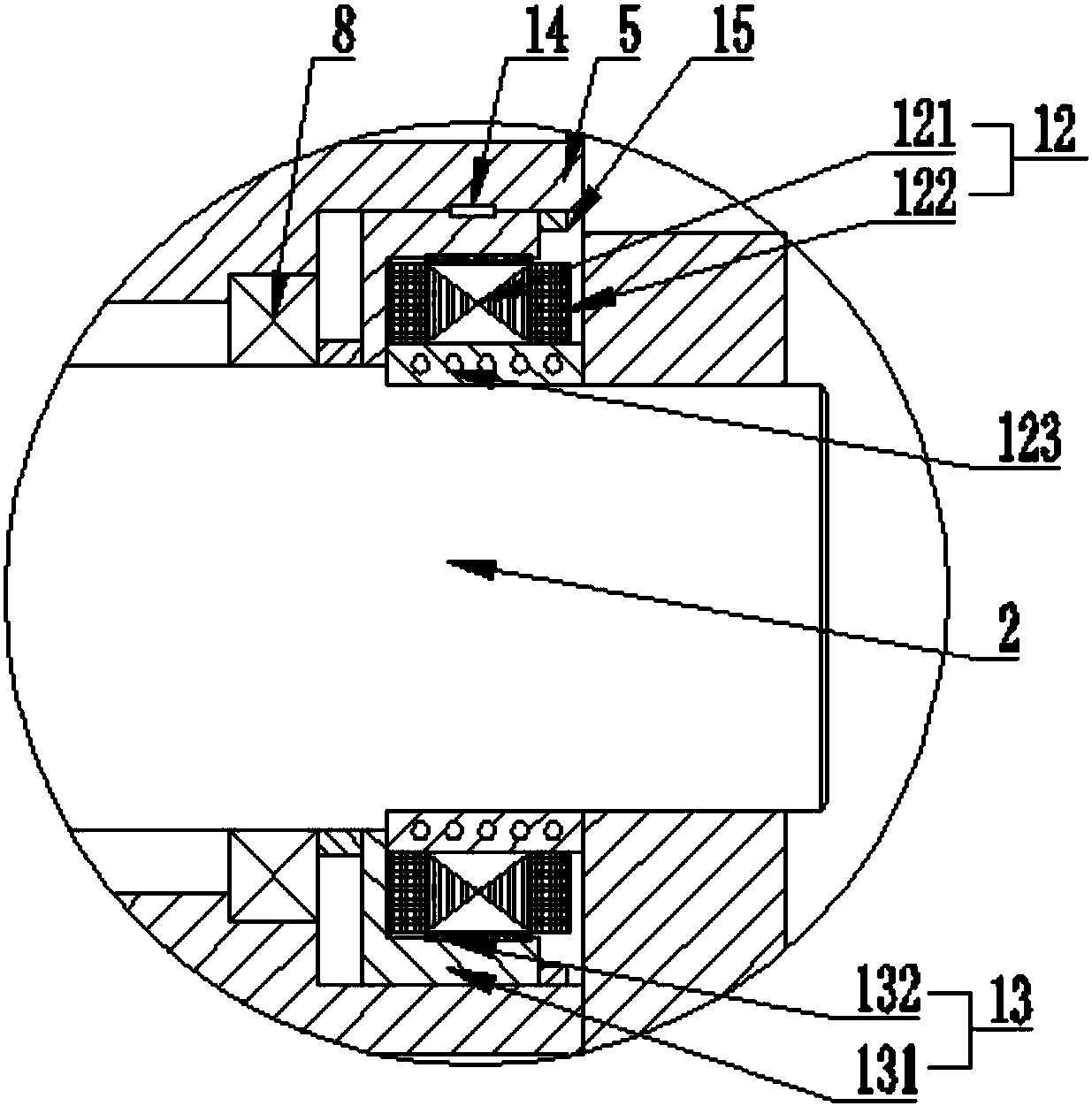

The magnetic separating unit includes one power mechanism with speed reducer, one rotating magnetic yoke inside the casing with scrapers, several static magnetic yokes around the rotating magnetic yoke and on the casing. The dry ore dressing apparatus with the magnetic separating unit has the oppositely configured like magnetic poles, discharge passage set in the zero-magnetism area between magnetic poles, ring interval around the driving shaft and between the static magnetic yokes and the rotating magnetic yoke, and exciting winding connected to the controllable power source on the static magnetic yokes.

Owner:宝丽恒通(天津)科技股份有限公司

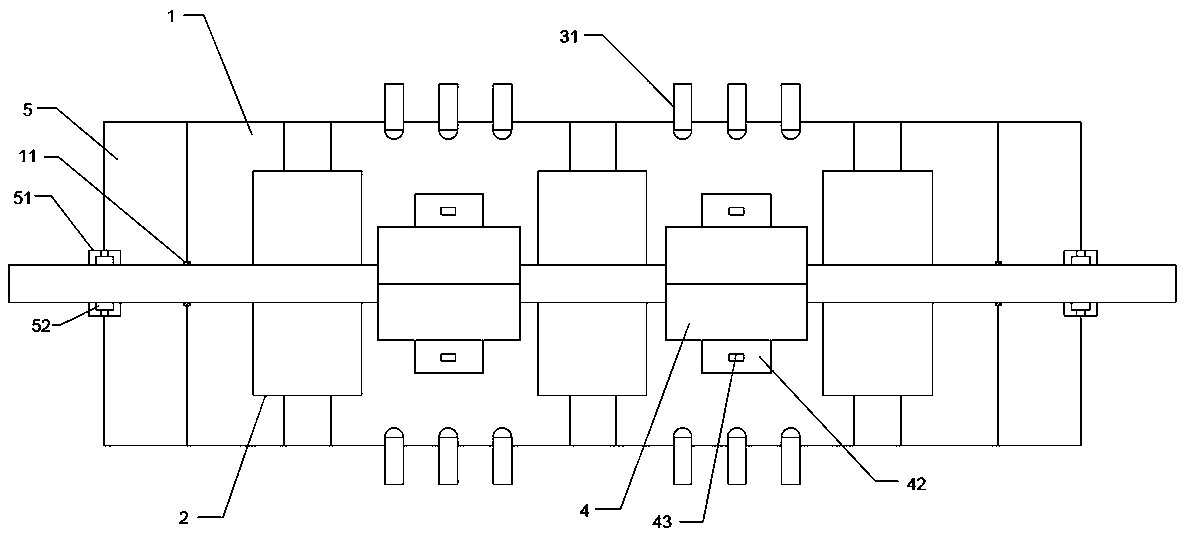

Winch roller device directly driven by frameless combined type permanent magnet synchronous linear motors

PendingCN108217490AQuick responseHigh control precisionMechanical energy handlingWinding mechanismsPermanent magnet synchronous motorLinear motor

The invention discloses a winch roller device directly driven by frameless combined type permanent magnet synchronous linear motors. The winch roller device directly driven by the frameless combined type permanent magnet synchronous linear motors comprises a base. A fixed shaft is arranged on the base and fixed through a shaft pressing cover. The fixed shaft is sleeved with a first roller and a second roller. A fourth bearing is arranged between the first roller and the second roller. The part, at the tail end of the first roller, of the fixed shaft is provided with one synchronous linear motor. The part, at the tail end of the second roller, of the fixed shaft is provided with the other synchronous linear motor. Each synchronous linear motor comprises a stator assembly and a rotor assembly, wherein the stator assembly is composed of a plurality of stator units of fan-shaped structures, each stator unit is an independent controlling mechanism and comprises a stator iron core and a stator winding wound around the stator iron core, the stator assembly is fixedly installed on the fixed shaft, and the rotor assembly is fixedly connected with the inner walls of the tail ends of the first roller and the second roller. The two rollers are installed on the fixed shaft integrally, the space is saved, and meanwhile energy loss is lowered.

Owner:HUBEI HUANYEE ELECTROMAGNETIC EQUIP ENG TECH CO LTD

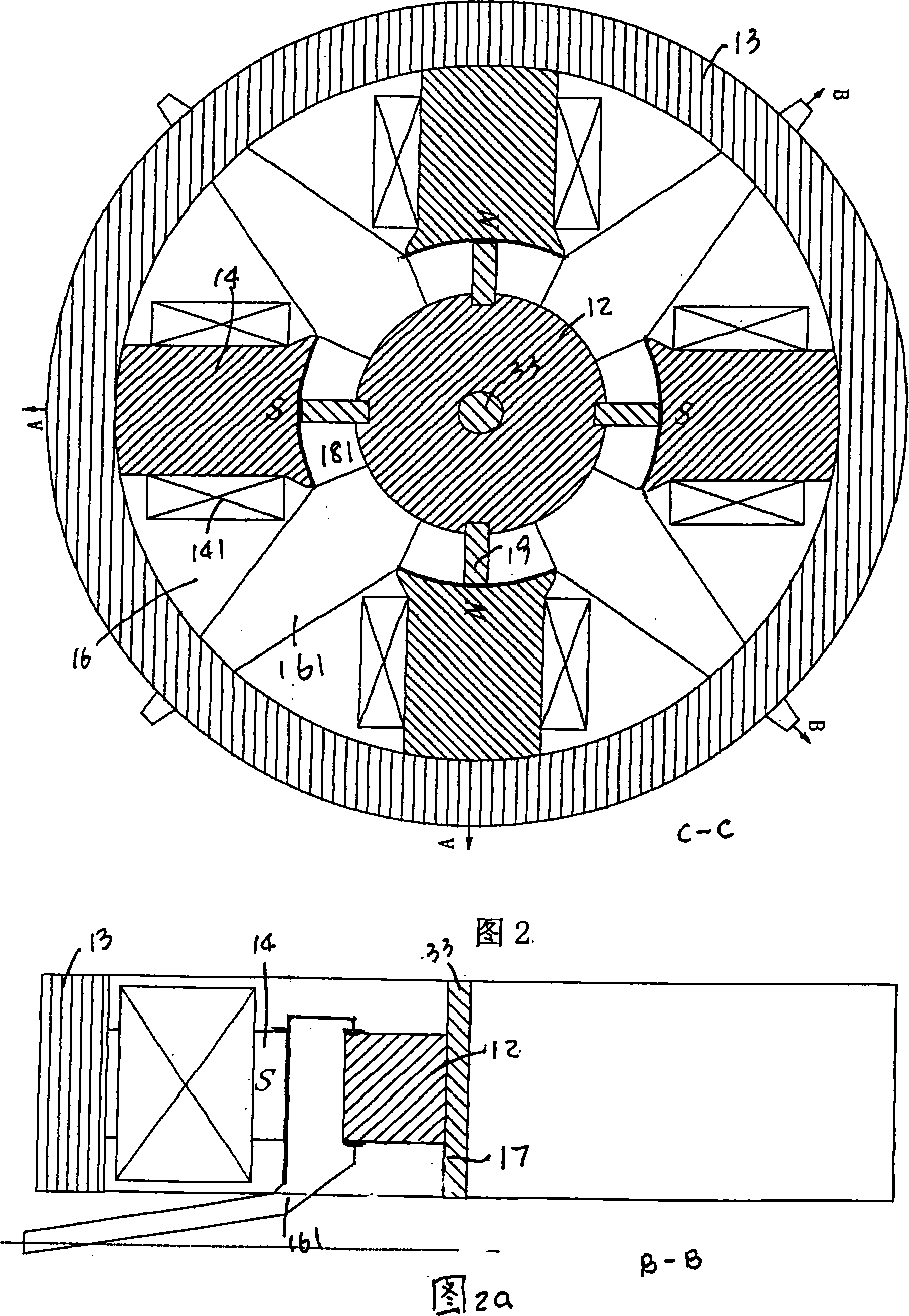

Dry tail ore dressing apparatus

InactiveCN1887431AStrong noveltyCreativeMagnetic separationElectrical and Electronics engineeringTailings

The dry tail ore dressing apparatus includes one feeder and features its magnetic dressing units connected serially through connectors and driven with one speed reducing power mechanism. The feeder to feed wind and dressed material into the magnetic dressing units possesses feeding port communicated to the material channels of the magnetic dressing units, and all the material channels form one common vertically communicated material passage.

Owner:天津市新源电气科技有限公司

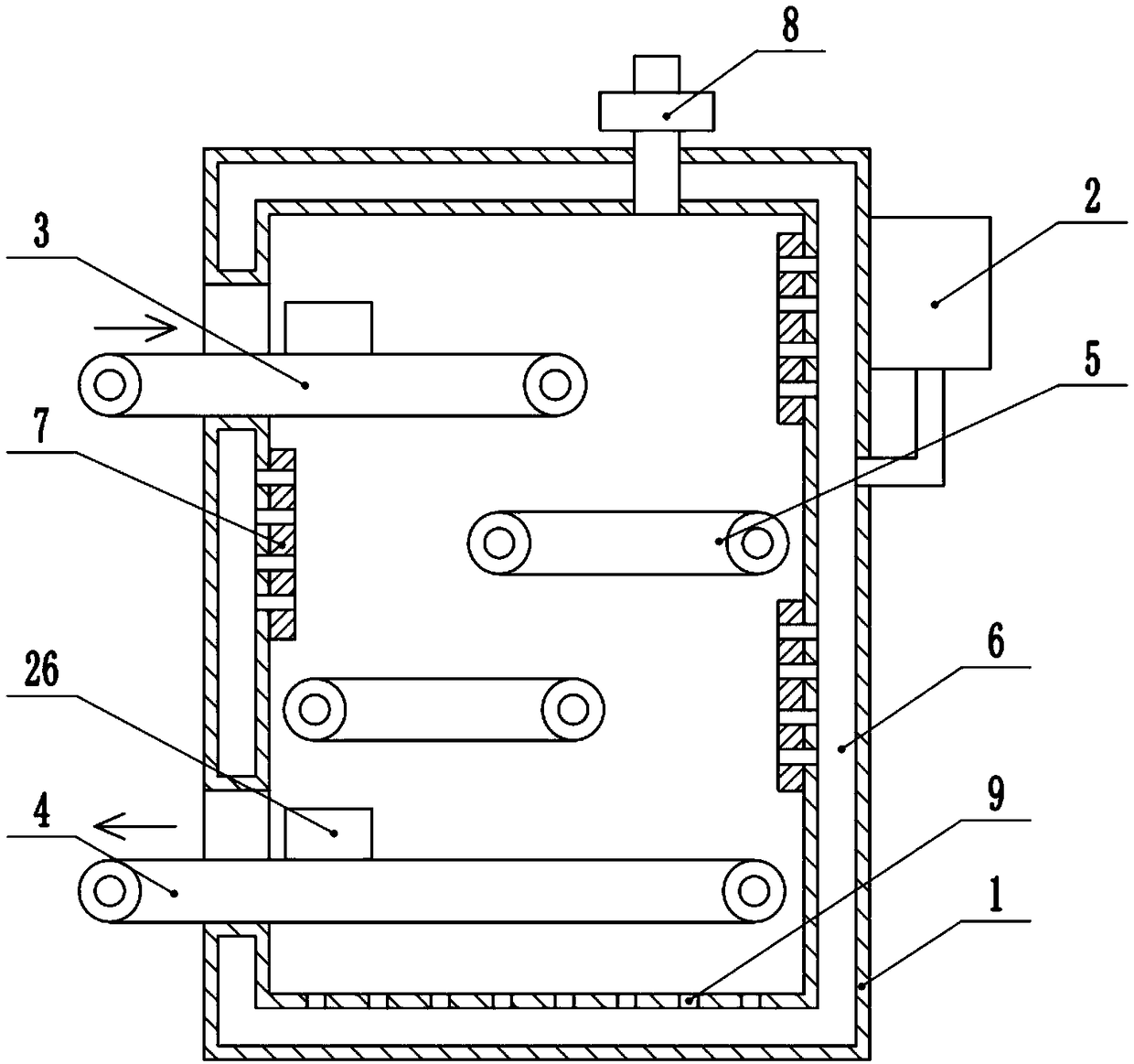

Automobile part drying device

PendingCN108645186AAvoid unsatisfactory cleanlinessAvoid preprocessing effect dropDrying gas arrangementsDrying machines with progressive movementsSlide plateEngineering

The invention relates to the technical field of automobile part machining and discloses an automobile part drying device. The automobile part drying device comprises a rack. A drying box and an air supply box are arranged on the rack. The driving box is provided with a feed conveying mechanism and a discharge conveying mechanism. An intermediate conveying mechanism is arranged in the drying box. The drying box is provided with a cavity. Air collection plates are arranged in the drying box. A pretreatment mechanism is arranged in the drying box. The pretreatment mechanism comprises sliding plates oppositely arranged on the two sides of the feed conveying mechanism. An outer sleeve rod is rotatably connected to each sliding plate. An inner sleeve rod is in spline connection with each outer sleeve rod. A spring is connected between each inner sleeve rod and the corresponding outer sleeve rod. One end of each inner sleeve rod is fixedly connected with an electromagnet. The two electromagnets are attracted magnetically and are each provided with a water absorption part. A top plate is fixedly connected to the interior of the drying box. The top plate is located above the electromagnets.The side, facing automobile parts, of the top plate is provided with a water absorption part. Through the automobile part drying device, the problem that automobile parts are heated unevenly and dried non-uniformly in the drying process in the prior art is solved.

Owner:重庆旺豹商贸有限公司

Cable extrusion production line

The invention discloses a cable extrusion production line. The cable extrusion production line comprises an extruding machine, a heater and a cooling line; the cooling line comprises a buffer room, acooling water bath, a circulating water mechanism, a bubble-removing mechanism and an air-cooling mechanism; the buffer room comprises a flared barrel section, a straight barrel section and an air duct; multiple conveyor rollers are arranged in the cooling water bath along a cable conveying direction at intervals; the circulating water mechanism comprises a water inlet pipe, a water outlet pipe, awater storage tank and a water pump; the bubble-removing mechanism comprises base blocks and flexible brush; the base block is connected with a connecting block, the connecting block is connected with a connecting rod, each base block is connected with a horizontal reciprocating cylinder, or at least two base blocks are commonly connected with a horizontal reciprocating cylinder; the air coolingmechanism comprises a barrel body with a hollow internal and a fan. The cable extrusion production line disclosed by the invention is simple in structure, convenient for use, and excellent in overallcooling effect; the obtained product is bright and clean in surface, and the quality is greatly improved.

Owner:FUJIAN TONGYU CABLES

Treatment method and device for acid gas

ActiveCN108722149AReasonable useReduce energy consumptionDispersed particle separationSulfur compoundsChemistryPre treatment

The invention discloses a treatment method and a device for acid gas. The device comprises a hydration reactor, a hydrate neutralizing device, a first-stage absorption reactor, a second-stage absorption reactor and a product tank. The invention also provides a method for treating the acid gas by adopting the device. According to the treatment method and the device, NaHS products meeting national quality standards can be produced while up-to-standard discharge of the acid gas is realized; environmental improvement is organically combined with the production process of a chemical product. Compared with the prior art, the method disclosed by the invention has the advantages that the acid gases containing CO2 and hydrogen sulfide can be economically and efficiently pretreated, energy in the technological process is reasonably utilized and energy consumption is greatly reduced; the whole treatment process is environmentally friendly and reliable and no three wastes are produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

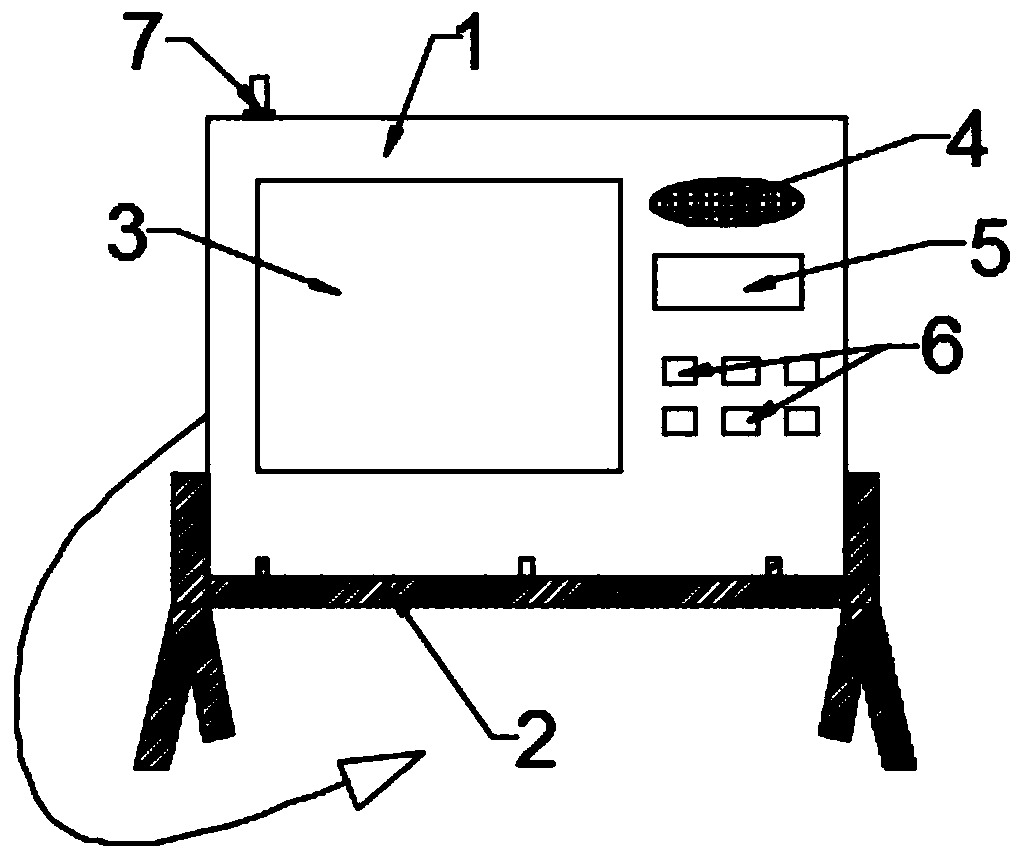

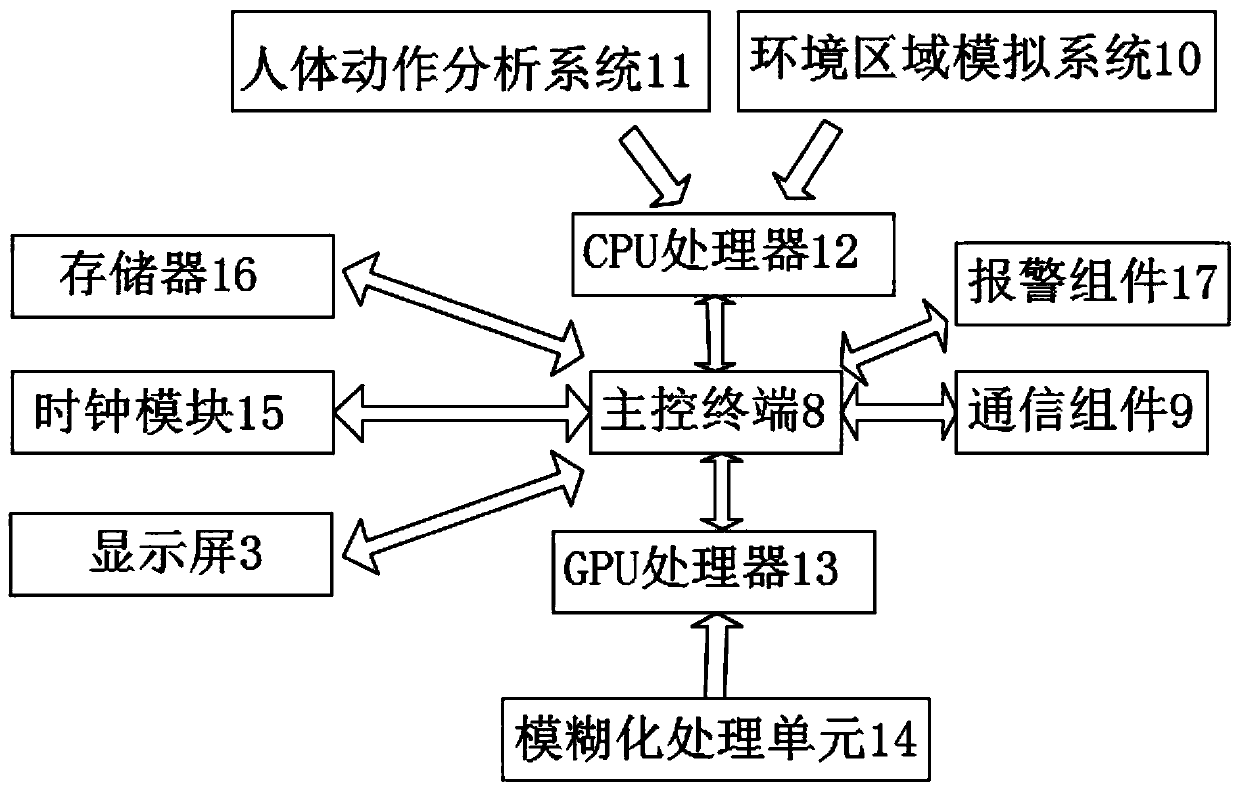

Regional retention alarm device

The invention discloses a regional retention alarm device. The regional retention alarm device comprises a shell and a display screen. The shell is arranged on a bracket, one side of the shell is provided with a display screen, one side of the display screen is provided with a sound outlet, a clock display screen and a plurality of keys from top to bottom, and the top end of the shell is providedwith an antenna. The regional retention alarm device can perform simulation for the environment in the region to obtain retained action characteristics and compare the detected human body action characteristics with the retained action characteristics so as to determine whether a monitored person is retained or not and send alarm signals to avoid accidents, and the safety is high; the regional retention alarm device can perform fuzzy processing for the monitored image so that privacy of the monitored person can be prevented from being exposed in a specific region environment with high privacy,and privacy exposure can be avoided; and moreover, the motion characteristics of the human body in the monitoring image can be displayed on the display screen, so that a guardian can know the actionof the person under guardianship in time, and dangers are avoided.

Owner:安徽泛米科技有限公司

Treating technology and system for hydrogen sulfide and dioxide carbon containing acidic gas

ActiveCN108722138ACost-effective pretreatmentReasonable useDispersed particle separationEnvironmental resistanceChemical products

The invention discloses a treating technology and system for hydrogen sulfide and dioxide carbon containing acidic gas. With the adoption of the technology and the system, NaHS products meeting national quality standard can be produced while acidic gas standardized discharging is realized; the environment treatment and the production process of chemical products are integrated. Compared with the prior art, the CO2 gas and hydrogen sulfide containing acidic gas can be economically and efficiently pretreated; the energy in the technical process can be reasonably utilized, so that the energy consumption is extremely decreased; the whole treatment process is environmentally friendly, reliable, and free of three wastes.

Owner:CHINA PETROLEUM & CHEM CORP +1

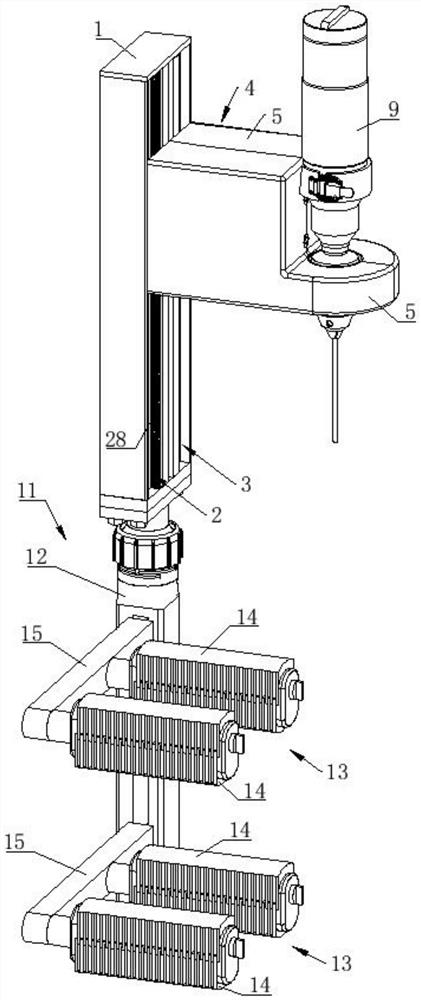

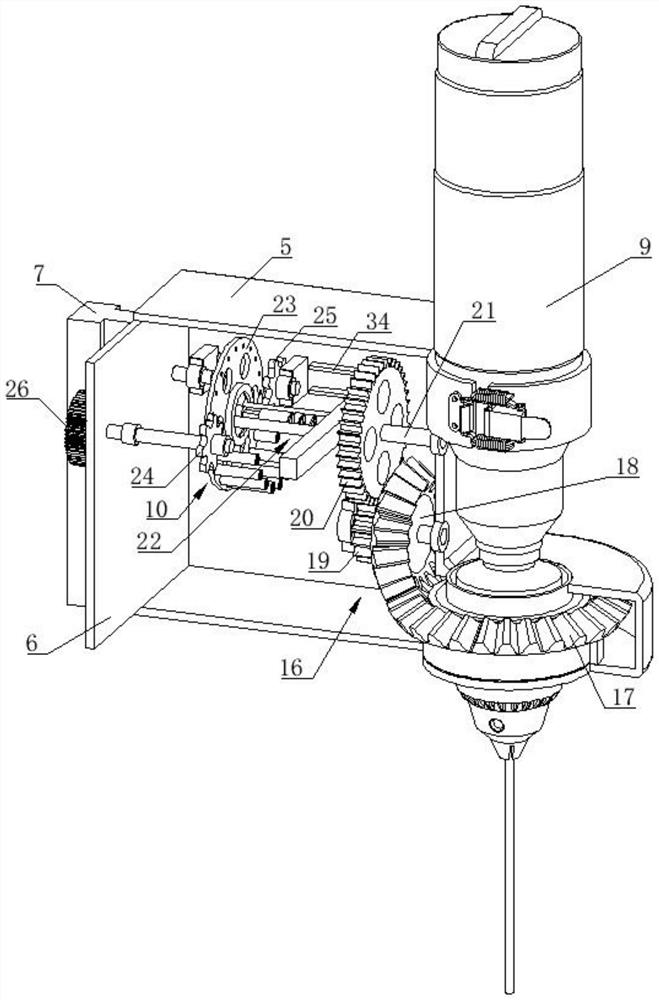

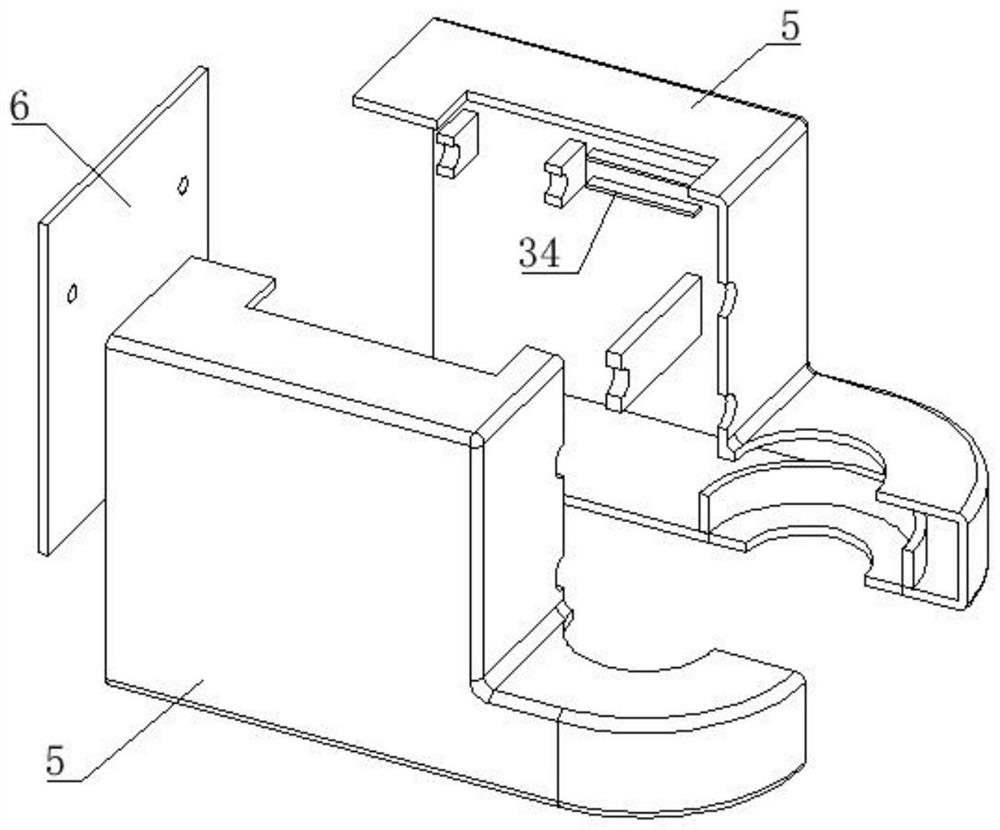

Electric bone drill

The invention discloses an electric bone drill which comprises a mounting frame, a mounting shell, a speed reduction assembly, a displacement assembly and a bone drill body, the speed reduction assembly is arranged in the mounting shell, the bone drill body is detachably mounted on the mounting shell, the speed reduction assembly is used for reducing the rotating speed of a drill bit clamp of the bone drill body, and the displacement assembly is in transmission connection with the speed reduction assembly. The displacement assembly drives the installation shell and the bone drill body to move in a reciprocating mode, the moving feeding amount of the bone drill body is always larger than the backward displacement amount of the bone drill body, the feeding amount of the bone drill body is reduced after each reciprocating movement, the installation shell is installed on the installation frame in a sliding mode, and the installation frame is fixed to an operating table or an affected part of a patient. The problems that in the prior art, when a doctor holds a bone drill by hand to conduct orthopedic drilling, the drilling feeding amount cannot be controlled, drilling cannot be conducted at a constant speed, the drilling depth cannot be effectively controlled, and the slipping phenomenon occurs are solved.

Owner:彭强

Vacuum tube type solar energy air collector

ActiveCN103411320BReduce resistanceEnhanced convectionSolar heating energySolar heat devicesStraight tubeCollector device

The invention discloses a vacuum tube type solar energy air collector which comprises a box body, wherein an air inlet is formed in one end of the box body, an air outlet is formed in the other end of the box body, the box body is provided with a vacuum tube connecting opening and a vacuum tube, the vacuum tube is communicated with the box body through the vacuum tube connecting opening in an airtight mode, an inner tube of the vacuum tube is coated by a selective absorbing coating and provided with an expansion opening inserting tube, the expansion opening inserting tube is of an L shape and comprises an expansion opening section and a straight tube section, the straight tube section is vertical to the expansion opening section, and the expansion opening section is provided with a funnel-shaped opening; the straight tube section is fixed inside the vacuum tube; the expansion opening section stretches into the box body, and the funnel-shaped opening of the expansion opening section backs on to the air inlet in the one end of the box body. According to the negative pressure suction type vacuum tube type solar energy air collector, a heat tube is not used, manufacturing cost is low, the structure is simple, installation is convenient to achieve, heat collection efficiency is high, resistance is little, and the vacuum tube type solar energy air collector is suitable for series-parallel connection of various heat collectors and is applied to a large-scale air drying system and a heating system.

Owner:HIMIN SOLAR

A method and device for treating acid gas

ActiveCN108722139BGreat operating flexibilityMild operating conditionsGas treatmentDispersed particle separationChemical productsProcess engineering

The invention provides a method and device for treating acid gas. The device can produce NaHS products meeting national quality standards while realizing up-to-standard discharge of the acid gas, andorganically integrates environmental governance and the production process of chemical products into an integrated process. Compared with the prior art, the method has the advantages that the acid containing CO2 gas and hydrogen sulfide gas can be economically and efficiently pretreated, energy during a technical process is reasonably utilized, energy consumption is greatly reduced, and the wholetreatment process is environmentally friendly, reliable, and free from production of three wastes.

Owner:CHINA PETROLEUM & CHEM CORP +1

A Large Capacity Circulating Fluidized Bed Hot Water Boiler with Forced Water Circulation

ActiveCN103644648BImplement security requirementsAvoid damageFluidized bed combustionWater heatersWater circulationHearth

The invention discloses a forced water circulation high-capacity hot water boiler of a circulating fluidized bed, which relates to a hot water boiler of a fluidized bed, and aims to ensure water circulation safety and power failure protection of a high-capacity hot water boiler of a circulating fluidized bed. A water supply distribution header is connected with lower coal economizers; the lower coal economizers, middle coal economizers and upper coal economizers are sequentially connected with one another; the upper coal economizers are connected with a coal economizer upper header; the coal economizer upper header is connected with a collection water bag by a coal economizer coating pipe; the collection water bag is connected with water cooling wall lower headers by a descending pipe; the water cooling wall lower headers are connected with a hearth water cooling wall; the hearth water cooling wall is connected with water cooling wall upper headers; the water cooling wall upper headers are connected with a boiler cylinder by extraction pipes; the water supply distribution header is connected with a separator water cooling sleeve by a water cooling sleeve water intake pipe; the separator water cooling sleeve is connected with the boiler cylinder by a water cooling sleeve water outlet pipe; the boiler cylinder is connected with the water cooling wall lower headers by communicating pipes, and is connected with the water supply distribution header by a power failure water supply pipe. The forced water circulation high-capacity hot water boiler provided by the invention is applied to large concentrated heat supply and warming.

Owner:哈尔滨红光锅炉总厂有限责任公司

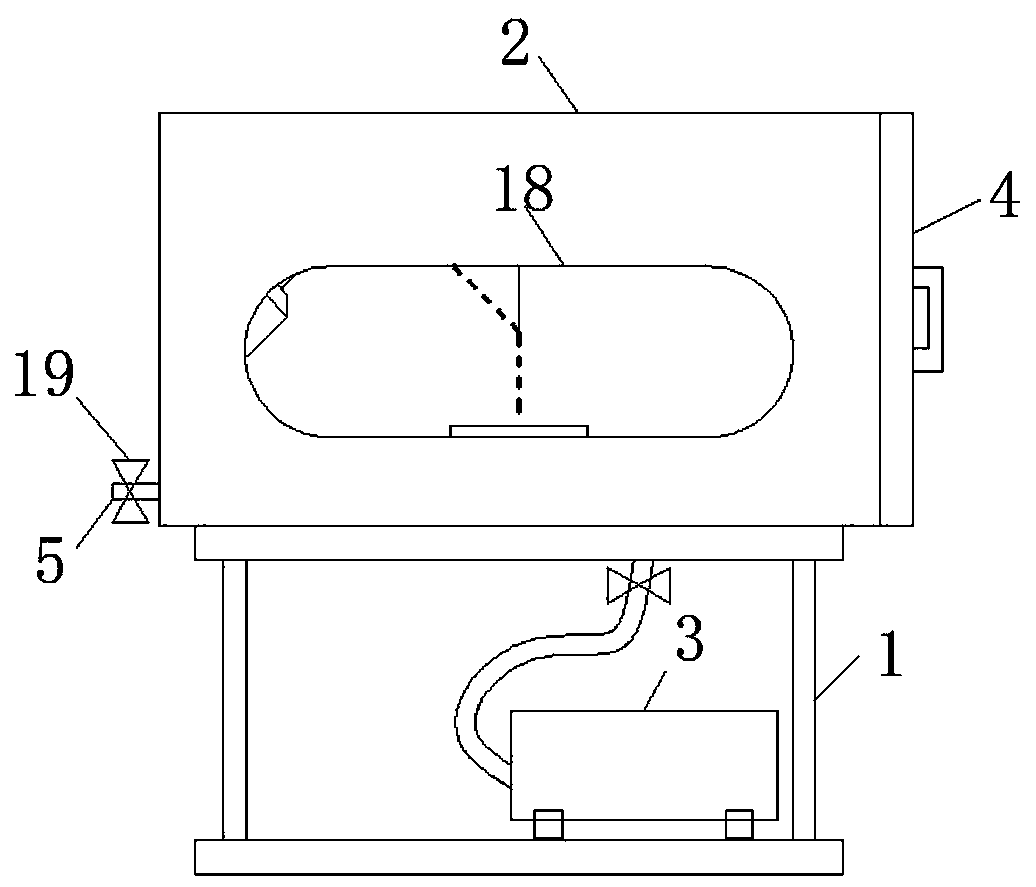

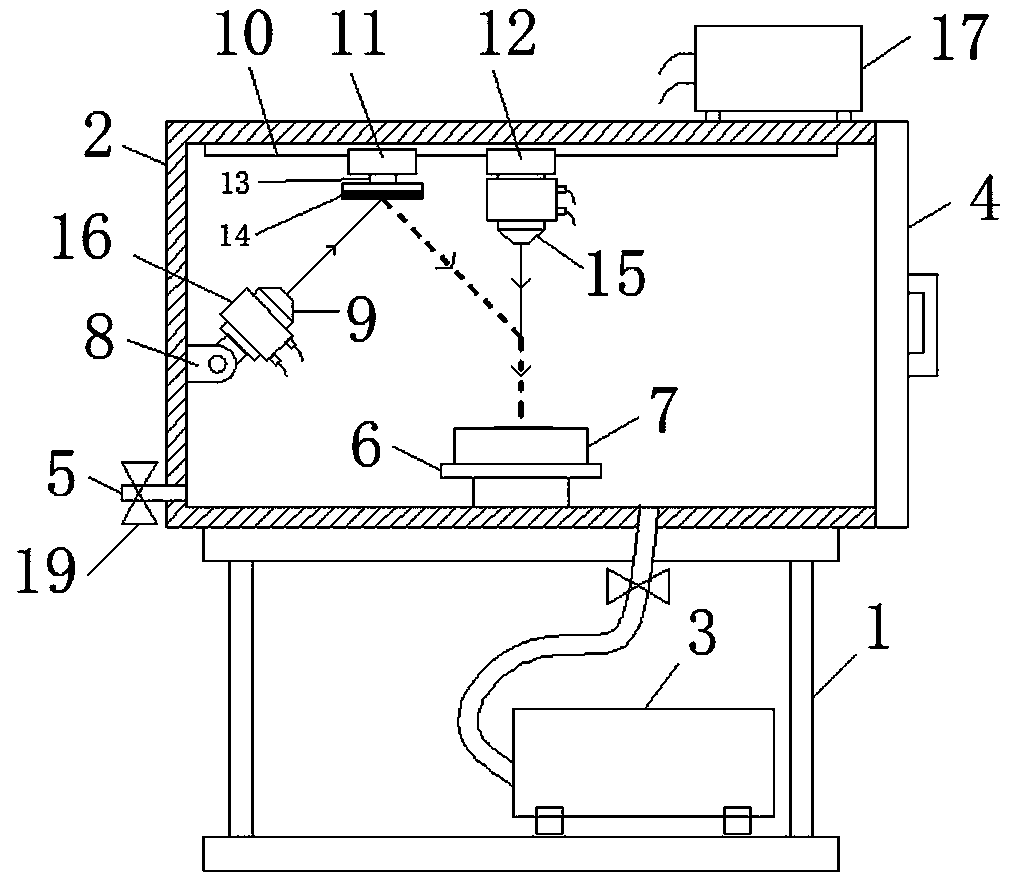

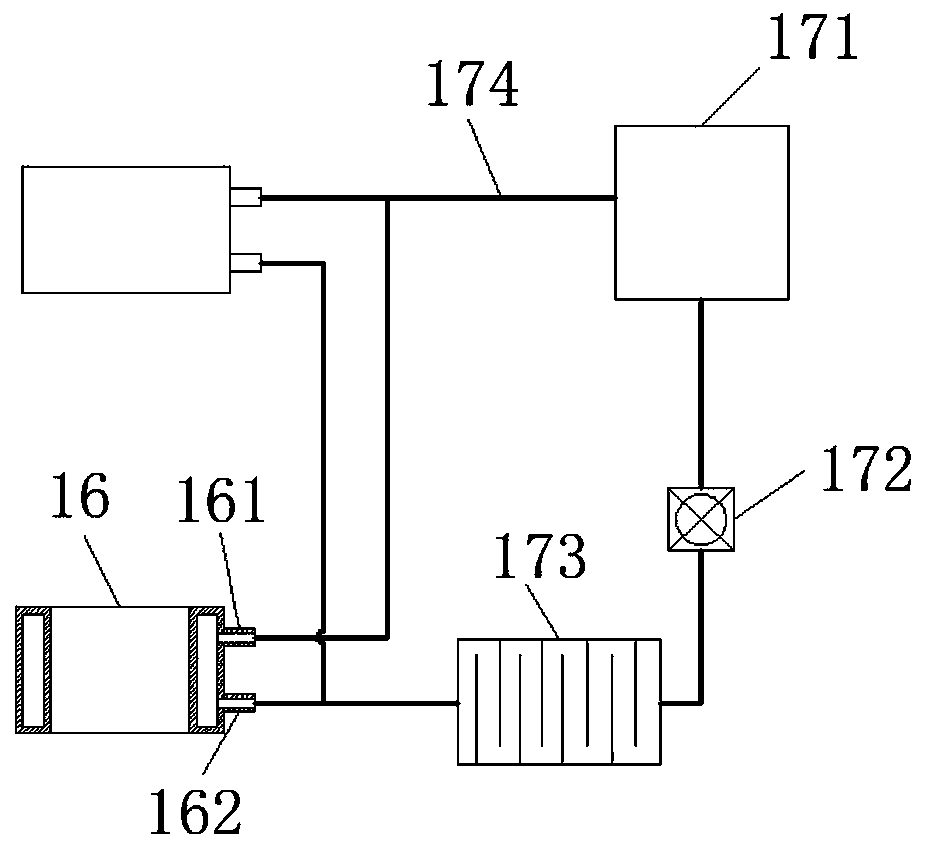

A dual ion beam metal coating automation equipment

ActiveCN108531872BHigh bonding strengthReasonable structureVacuum evaporation coatingSputtering coatingMetal coatingIon beam

The invention relates to double-ion-beam metal coating automation equipment. A vacuum coating chamber is arranged at the top of an equipment rack; a main ion source is arranged in the middle of the left side wall of an inner cavity of the vacuum coating chamber; a target material sliding block and an auxiliary source sliding block are arranged at the top of the inner cavity of the vacuum coating chamber separately, the target material sliding block is always located on the left side of the auxiliary source sliding block, the target material sliding block and the auxiliary source sliding blockcan move back and forth along the same horizontal line, a target material is arranged on the target material sliding block, and an auxiliary ion source is fixedly installed at the bottom of the auxiliary source sliding block; cooling wrapping layers are arranged on the outer walls of the main ion source and the auxiliary ion source respectively. The double-ion-beam metal coating automation equipment has the advantages that through heat dissipation protection, the service life of the equipment can be prolonged, and the use effect of the equipment can be improved; besides, the equipment can adapt to coating with various forms and sizes through various adjustment modes.

Owner:广东英冠薄膜科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com