Cable extrusion production line

A cable extrusion and processing line technology, used in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of unsatisfactory cooling effect and poor product quality, and achieve the effect of excellent cooling effect, improved quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention will be further described by specific embodiment:

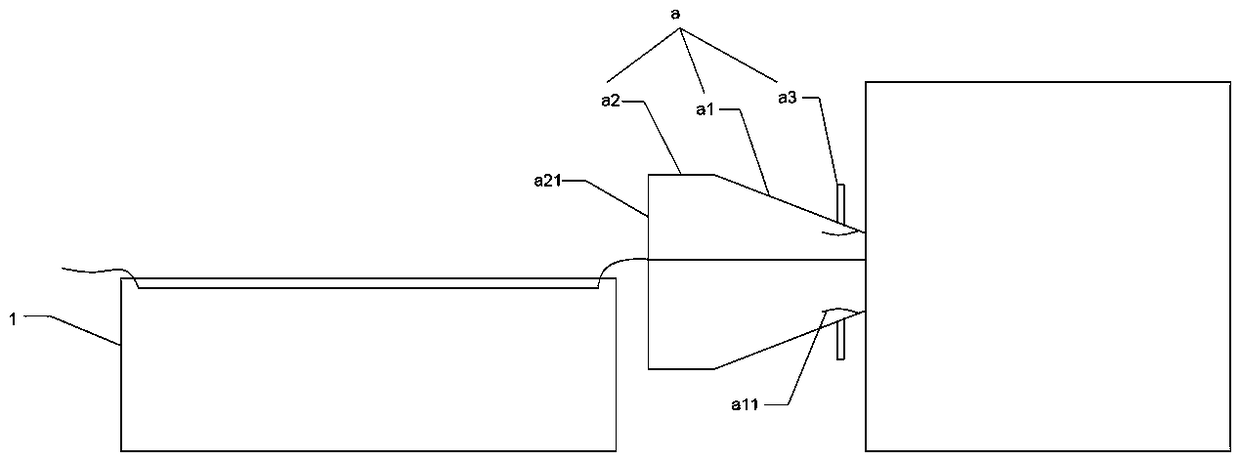

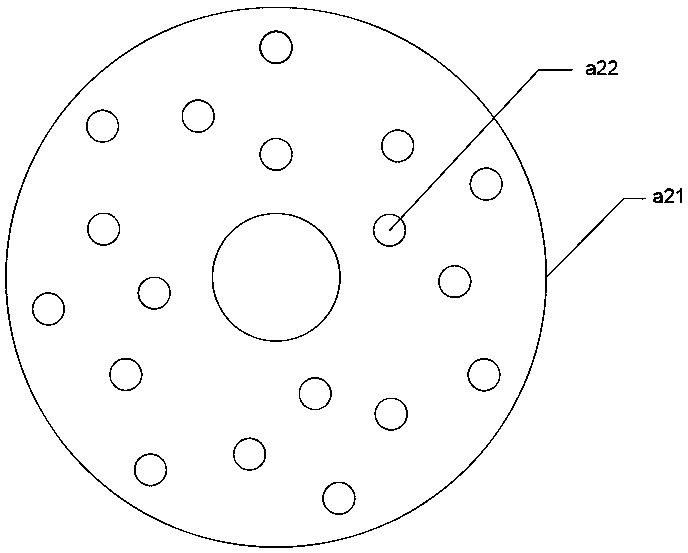

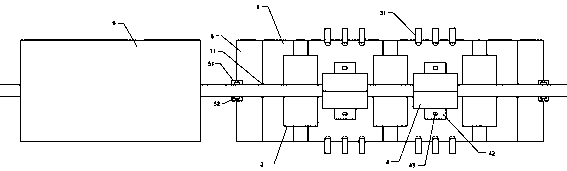

[0025] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , cable extrusion processing line, including extruder, heater and cooling line, cooling line includes buffer chamber a, cooling water tank 1, circulating water mechanism, degassing mechanism and air cooler; buffer chamber a includes connection to extruder And cover the flared barrel section a1 of the extrusion port of the extruder, the straight barrel section a2 connected to the flared barrel section a1 and then docked with the cooling water tank 1, and the flared barrel section a1 and the straight barrel section a2. For the air duct a3 of the hot air, the cross-sectional area of the flaring barrel section a1 increases as the distance between the section and the extruder increases, and the end of the flaring barrel section a1 near the extruder side is set There is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com