Dry ore dressing apparatus and its magnetic separating unit

A beneficiation equipment and magnetic separation technology are applied in the recovery of various minerals from tailings deposits, in the field of dry electromagnetic beneficiation equipment and its working unit structure, which can solve the problem of insufficient single mineral beneficiation of mineral processing equipment, difficult industrial promotion, and low beneficiation efficiency. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

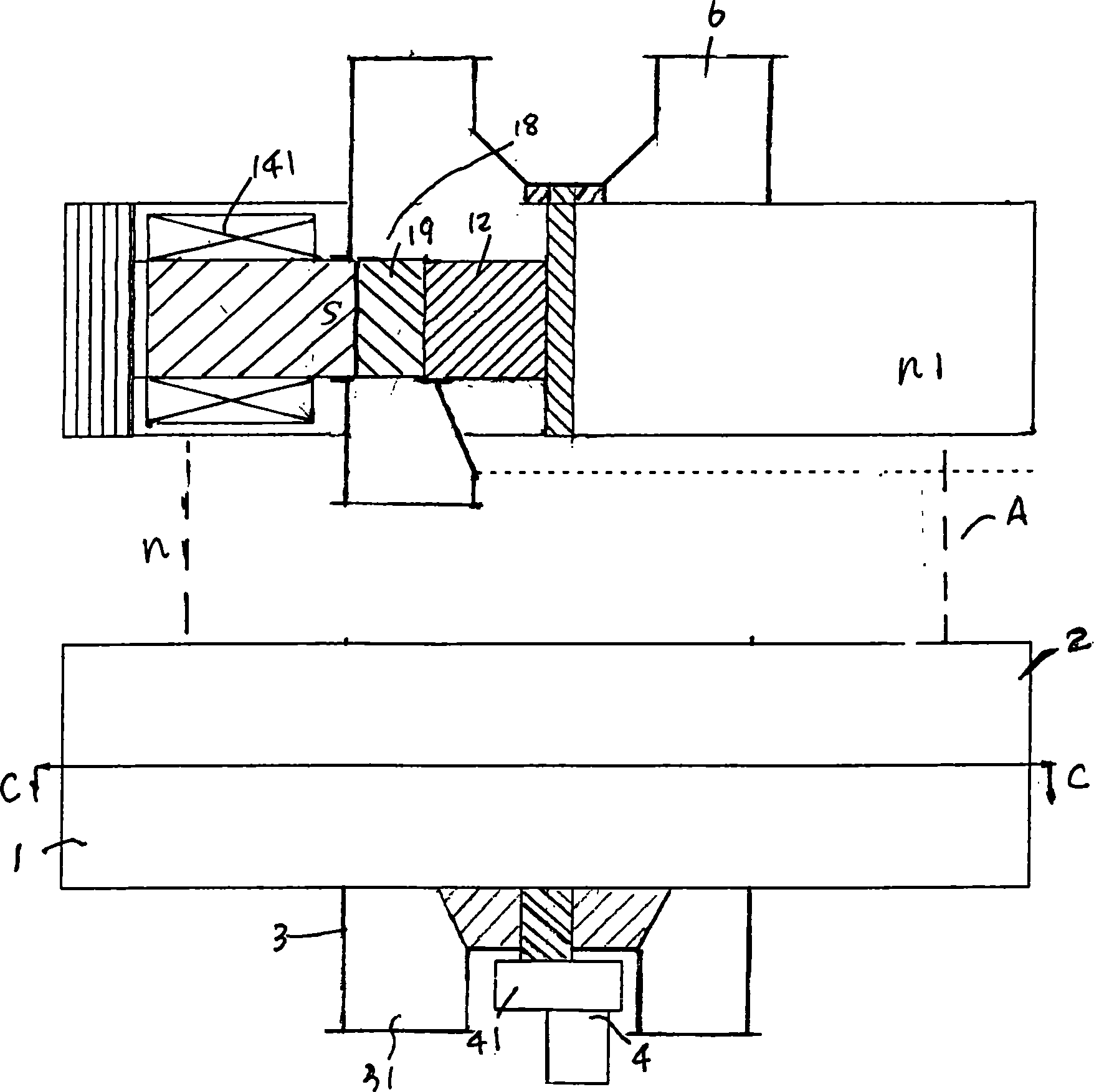

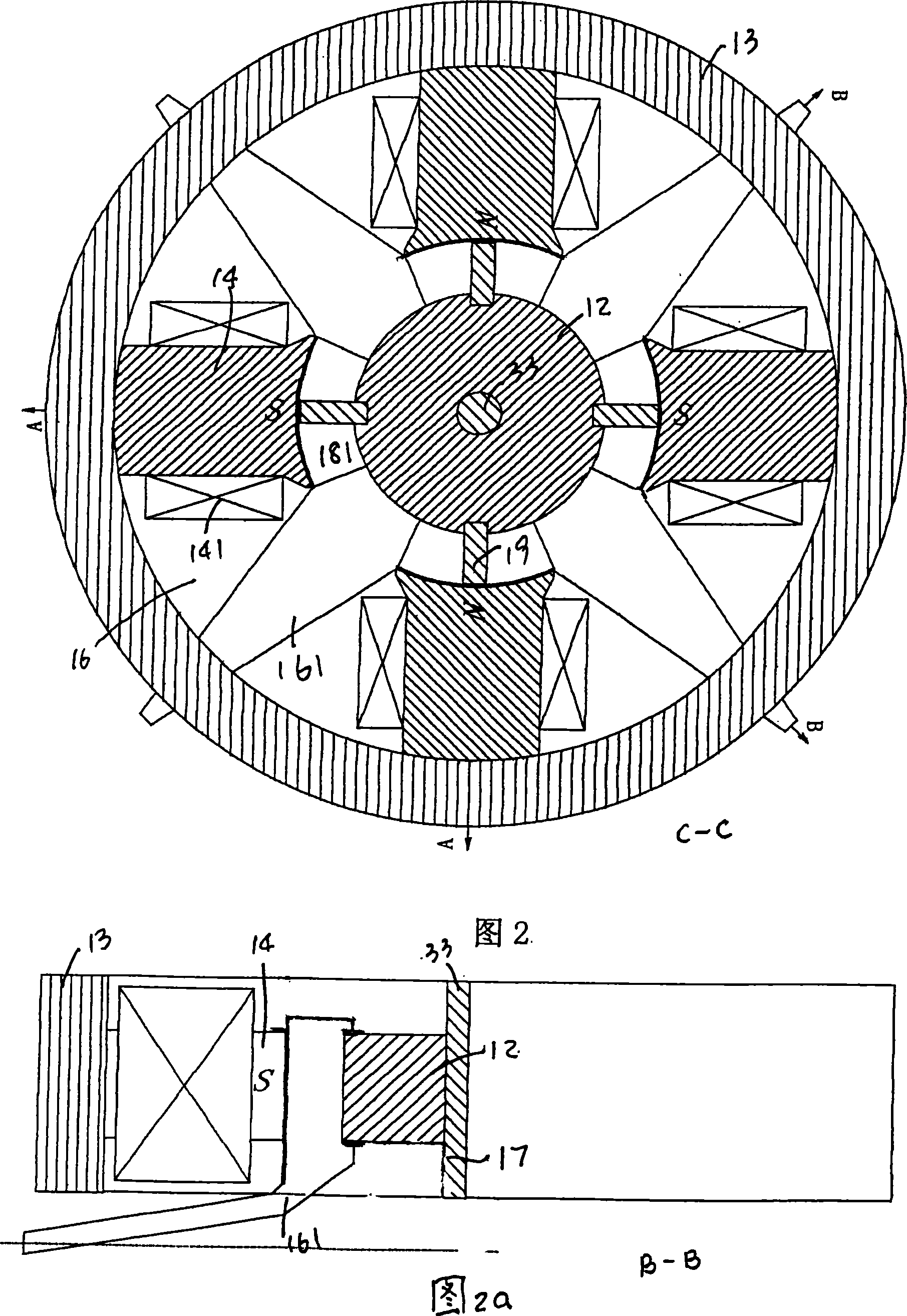

[0029] Such as figure 1 As shown in -2, a dry-type mineral separation equipment A includes a feeding device 3, wherein several magnetic separation units are connected in series by means of connectors 2, and each magnetic separation unit is driven by its own deceleration power mechanism 4. The power mechanism has a deceleration device 41, and the described feeding device 3 is a mechanism that sends the wind into the magnetic separation unit after being mixed with the selected material. It has a feeding port 31 communicated with the material channel 18 of the magnetic separation unit 1, each The material passage area of the magnetic separation unit together forms a material passage through up and down; the feeding device is made of non-magnetic material; the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com