A Large Capacity Circulating Fluidized Bed Hot Water Boiler with Forced Water Circulation

A circulating fluidized bed and hot water boiler technology, applied in fluidized bed combustion equipment, water heaters, fluid heaters, etc., can solve the problems of unsafe water circulation system, excessive resistance of water system, complex water circulation system, etc. It achieves the effects of preventing furnace shutdown caused by the blockage of returning material, stable long-term operation, and reducing the failure rate of returning material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

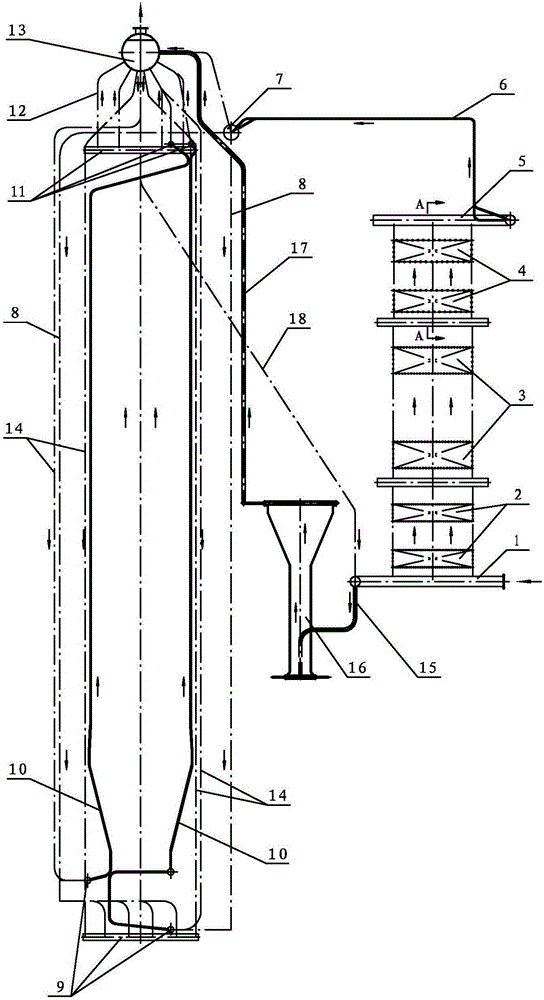

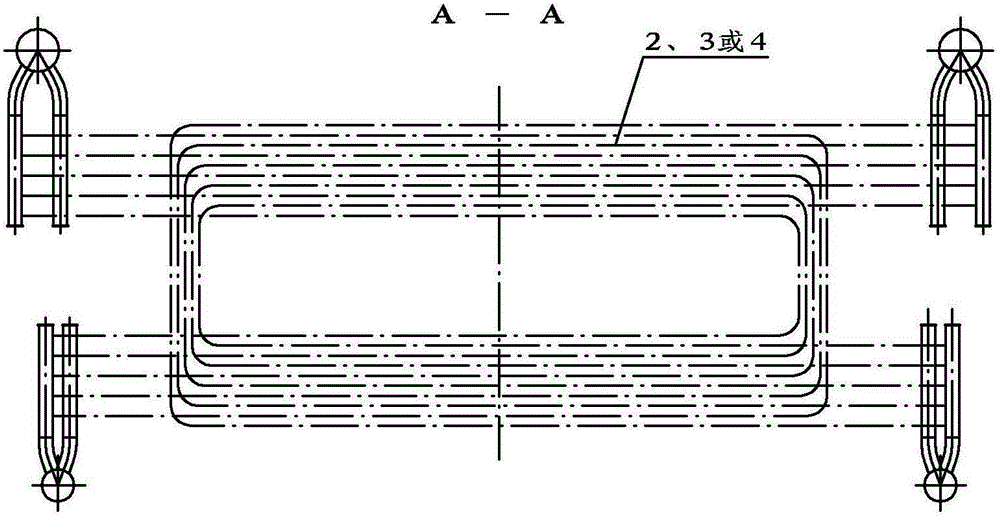

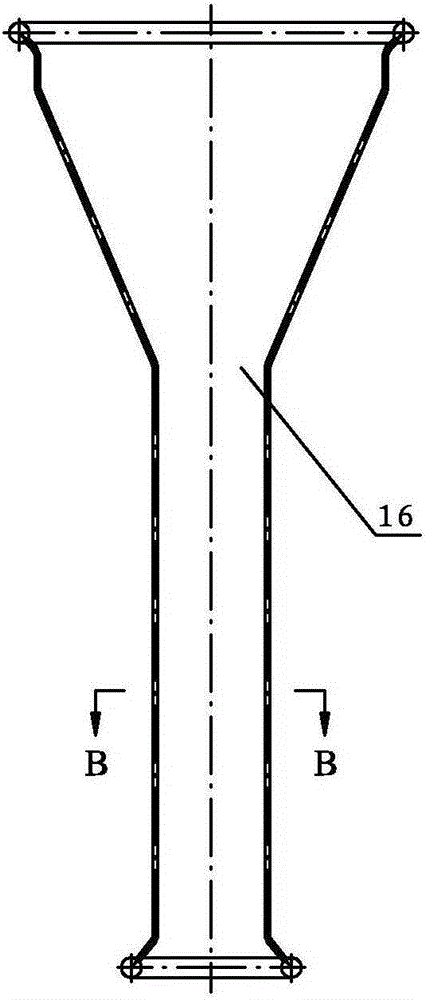

[0012] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, this embodiment includes water supply distribution header 1, lower economizer 2, middle economizer 3, upper economizer 4, economizer upper header 5, economizer coating pipe 6, collection Water bag 7, downpipe 8, water wall lower header 9, furnace water wall 10, water wall upper header 11, outlet pipe 12, drum 13, connecting pipe 14, water cooling jacket water inlet pipe 15, separator water cooling jacket 16 , water cooling jacket outlet pipe 17, power failure water supply pipe 18, one water outlet end of the water distribution header 1 is connected to the lower economizer 2, the lower economizer 2 is connected to the middle economizer 3, and the middle economizer 3 is connected to the upper economizer The economizer 4 is connected, the water outlet end of the upper economizer 4 is connected with the economizer upper header 5, and the economizer upper header 5 is connected with the ...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination figure 1 To illustrate this embodiment, valves are installed on the downcomer 8 , the water inlet pipe 15 of the water cooling jacket, the outlet pipe 17 of the water cooling jacket and the power failure water supply pipe 18 of this embodiment. The power failure protection function is realized by closing and opening the valve. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 1 This embodiment will be described. The lower economizer 2 , the middle economizer 3 and the upper economizer 4 in this embodiment have variable cross-section structures. After the cross-section is changed, the functions of equal smoke velocity and no ash accumulation are realized, which avoids the problems of increased resistance and increased exhaust gas temperature caused by the ash accumulation of the economizer, and completely solves the problems of ash accumulation, wear and corrosion of the economizer tube. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com