Superheated liquid overpressure relief experimental device

An experimental device and liquid technology, applied in the field of superheated liquid overpressure release experimental device, can solve the problems of in-service container leakage, BLEVE, and ineffective prevention of in-service pressure vessel BLEVE accidents, etc., to achieve accurate data collection, increase The effect of cooling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

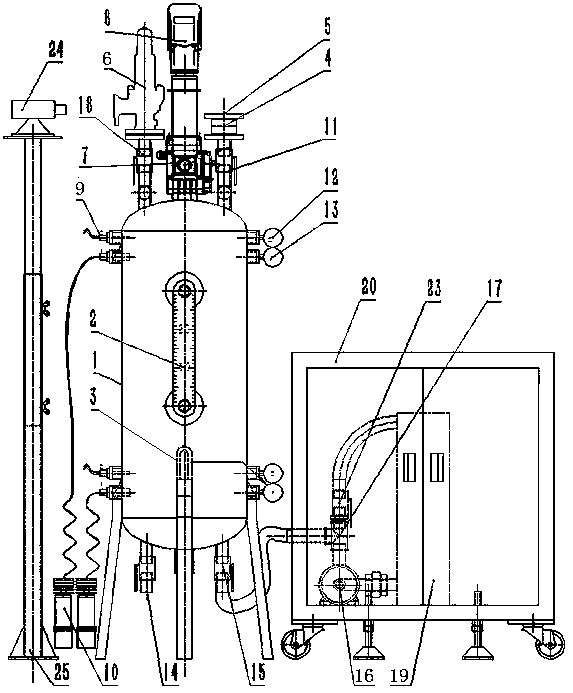

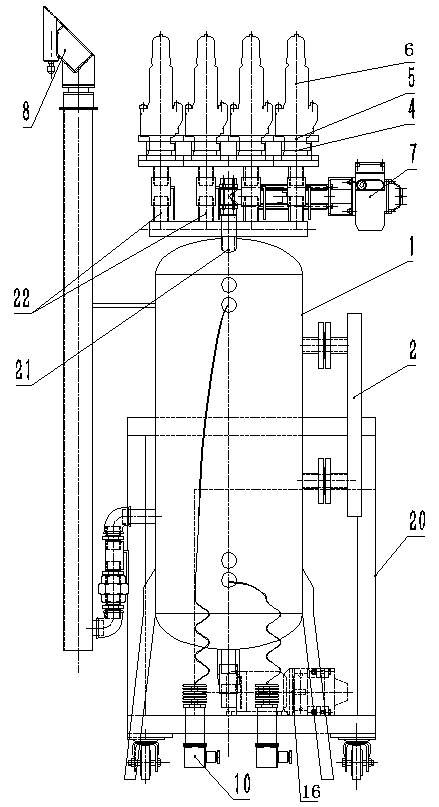

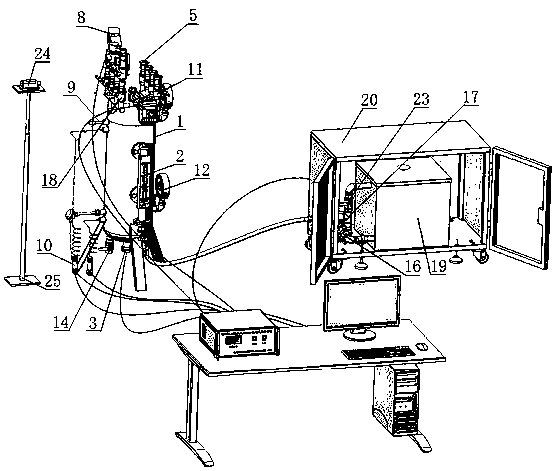

[0060] Below in conjunction with accompanying drawing, the present invention will be further described:

[0061] combine figure 1 , figure 2 , image 3 , Figure 4 As shown, this superheated liquid overpressure relief experimental device includes a pressure vessel 1, an operating table 20, a data acquisition system, and a computer control system. The connecting pipe 21 at the center of the lower head of the pressure vessel 1 is equipped with a heating electrode 3, and the heating electrode 3 is connected to Yudian instrument AI-518 / 518P temperature controller, the lower head of the pressure vessel 1 is connected to the injection ball valve 15 and the vent ball valve 14 through the other two connecting pipes, that is: the central connecting pipe is connected to the heater, and the side connecting pipe is connected to the venting ball valve 14. The connecting pipe on the other side is connected with the injection ball valve 15; the connecting pipes of the ultrasonic liquid l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com