Patents

Literature

132results about How to "Ensure continuous and efficient operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Efficient heterogeneous catalytic oxidation ferric-carbon micro-electrolysis packing and preparation method thereof

ActiveCN104761024ANo compactionHyperactive stateWater/sewage treatmentHigh current densityElectrolysis

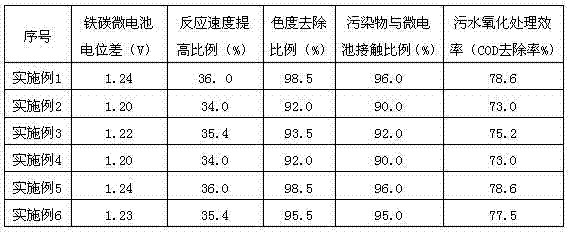

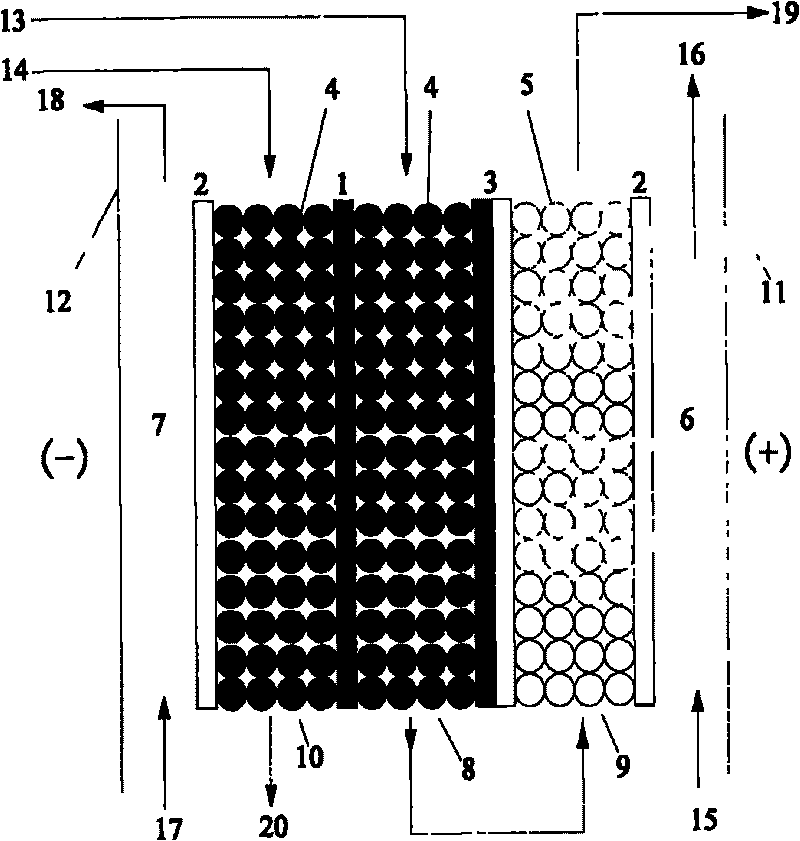

The invention discloses efficient heterogeneous catalytic oxidation ferric-carbon micro-electrolysis packing and a preparation method thereof. The packing is prepared from the following raw materials in parts by weight: 45-65 parts of pure iron powder, 10-25 parts of cast iron powder, 2-8 parts of graphite powder, 5-15 parts of active carbon powder, 2-10 parts of copper powder, 2-10 parts of manganese powder, 2-10 parts of aluminum powder, 2-10 parts of fine wood bits, 1-6 parts of sodium silicate, 1-6 parts of sodium borate, 2-6 parts of pyrite dust and 5-15 parts of an adhesive. The efficient heterogeneous catalytic oxidation ferric-carbon micro-electrolysis packing disclosed by the invention is prepared by taking heterogeneous metal alloy with high potential difference as a catalyst and using a high-temperature micropore roasting technology and has the characteristics of heterogeneous metal and ferric-carbon integration, micropore framework type alloy structure, large specific surface area, low density, strong activity, high current density and the like; organic wastewater is treated so that COD, ammonia nitrogen and total phosphorus can be efficiently removed, the chroma can be reduced, the biodegradability can be improved, the treatment effect is extremely stable, and the phenomena of packing passivating, hardening and the like caused in the operation process can be avoided.

Owner:HUBEI QUANSHENG ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

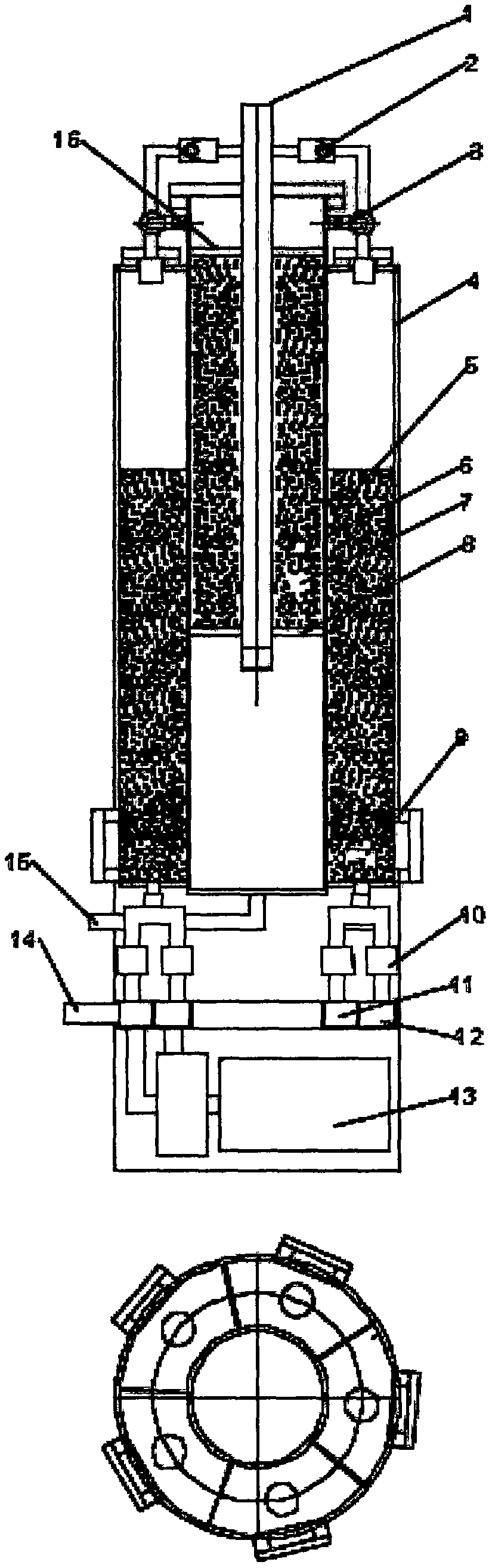

Electro-deionization method and device for synchronously concentrating and purifying heavy metal wastewater

InactiveCN101200325ALow flow resistanceImproved hydrodynamic propertiesDispersed particle separationWater/sewage treatment by ion-exchangeStrong acidsPollution

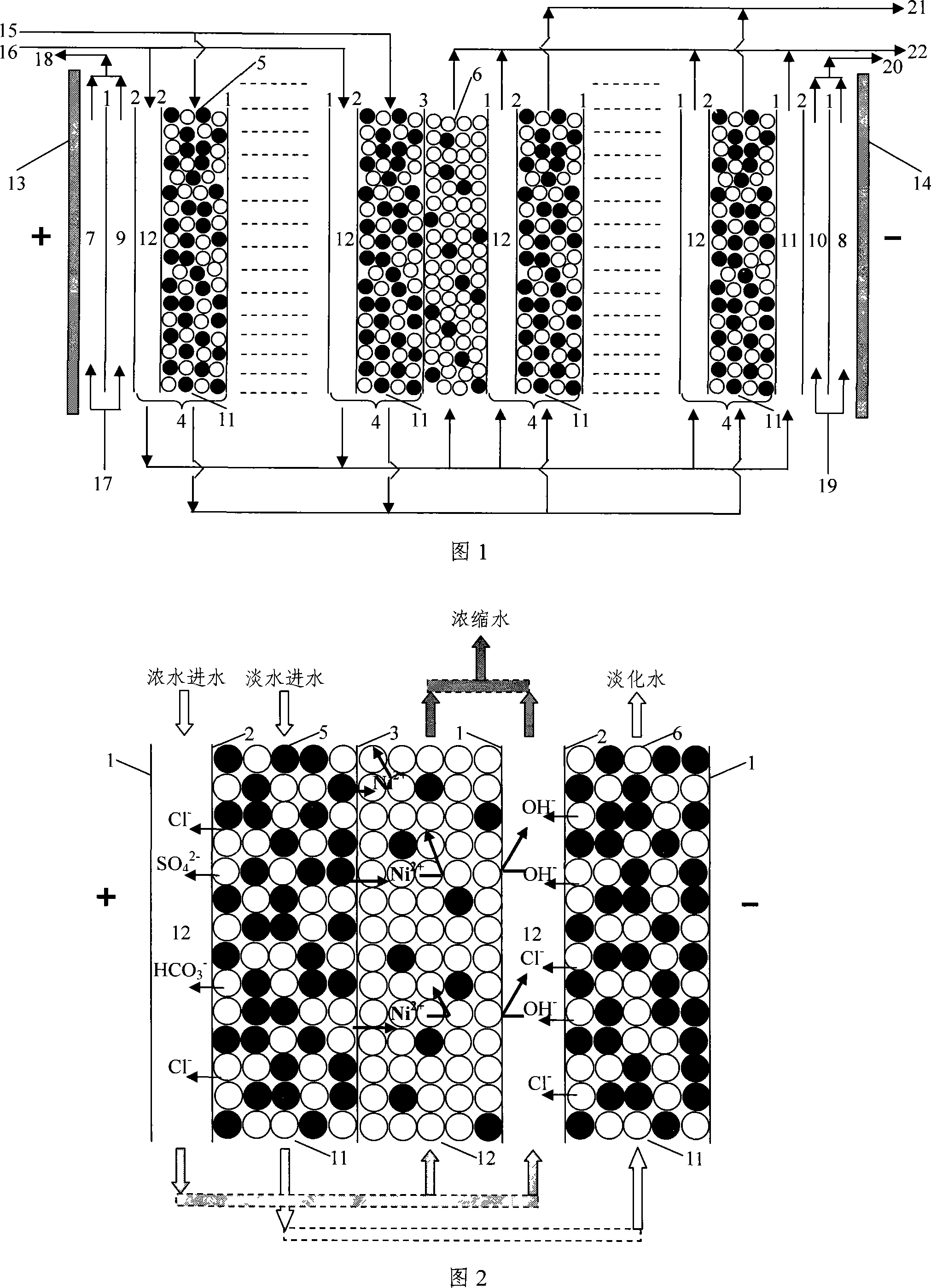

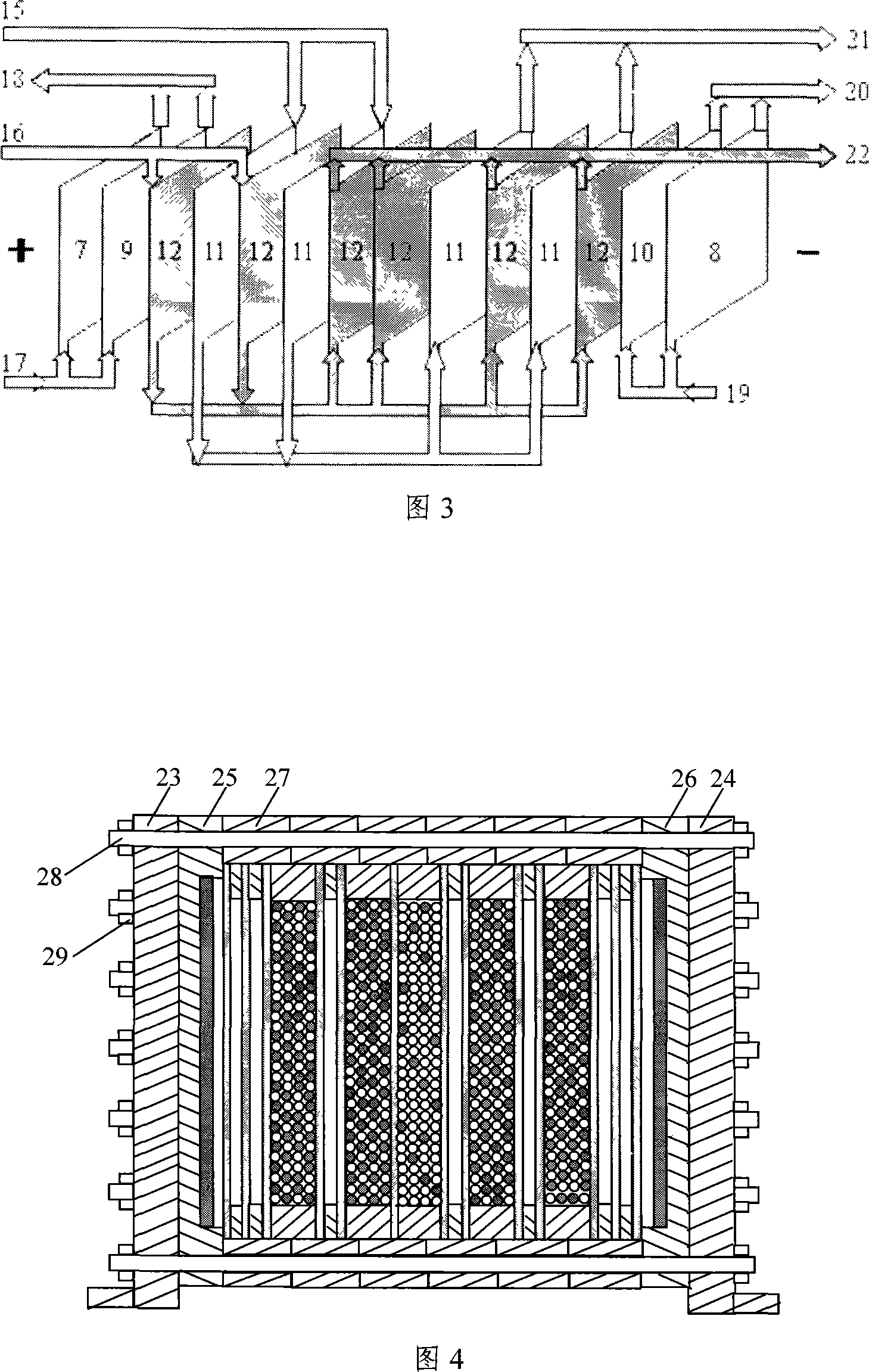

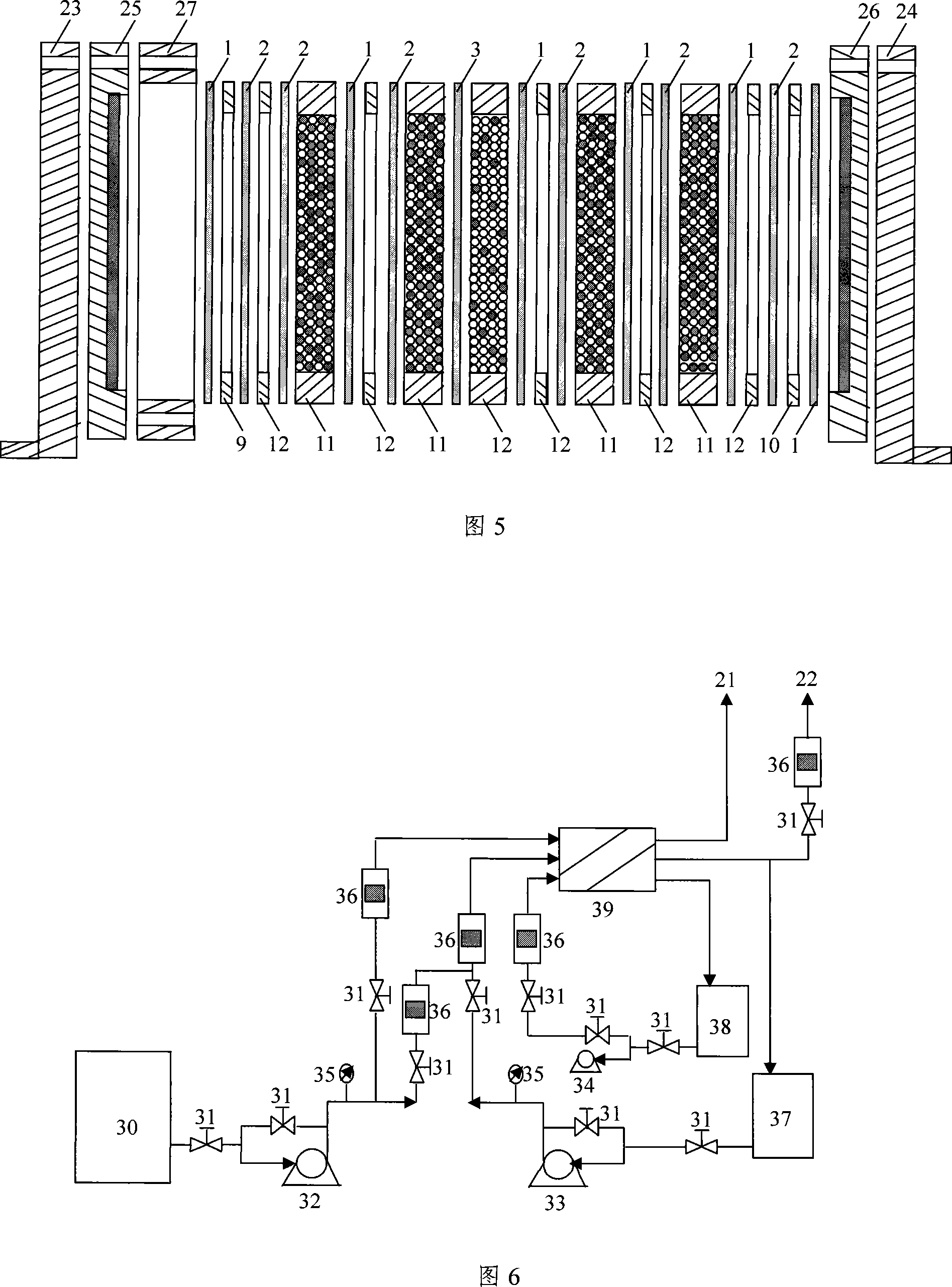

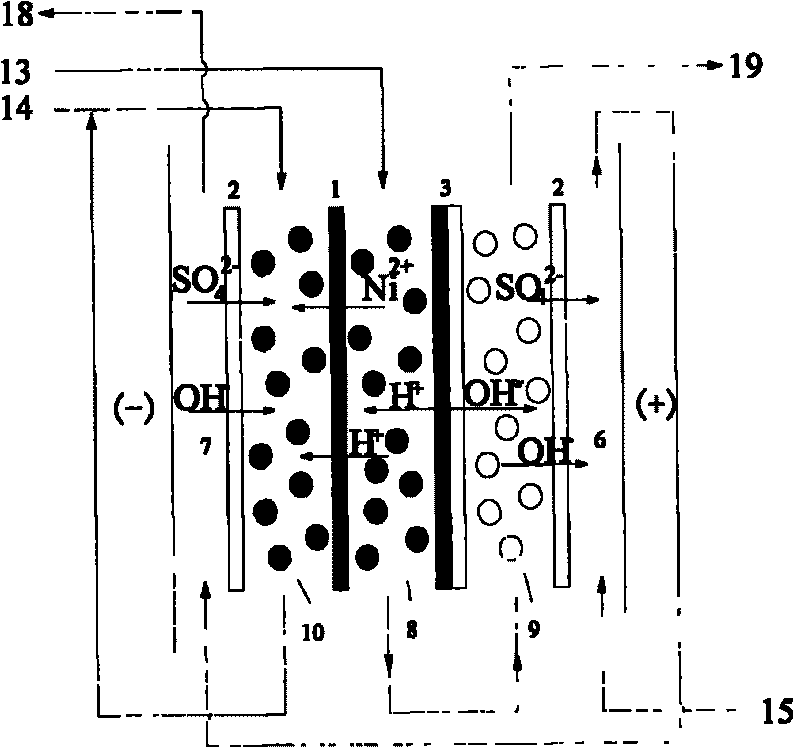

The invention relates to an electro-deionization method and device for concentrating and purifying heavy metal wastewater synchronously, belonging to a wastewater treatment technique, which adopts first-stage two-section or first-stage multi-section electro-deionization device, wherein the inner sides of the positive and negative poles are arranged with corresponding pole protection chambers, the desalting chamber is filled with large-hole strong-acid strong-base mixed bed resin with narrow particles distributed; cation exchange film is adopted as the direction-turning film, after direction-turning, two adjacent concentration chambers are arranged continuously, both are separated by cation exchange film, simultaneously after direction-turning, the first concentration chamber is filled with large-hole mixed bed resin with the volume of cathode resin more than 50 percent, the heavy metal wastewater to be treated enters the desalting chamber and the concentration chamber in two paths, the heavy metal ion and cathode in the desalted water flow are transferred into the concentration chamber so as to obtain the desalted water, the concentrated water flow is partially circulated or closely circulated so as to obtain the concentrated liquid of metal wastewater, thereby recycling valence metals and pure water resources synchronously and realizing zero emission and resource treatment of wastewater. Compared with the prior art, the wastewater treatment process has higher separation efficiency, more reliable operation, more convenient operation, continuous process operation and no secondary pollution.

Owner:NANKAI UNIV

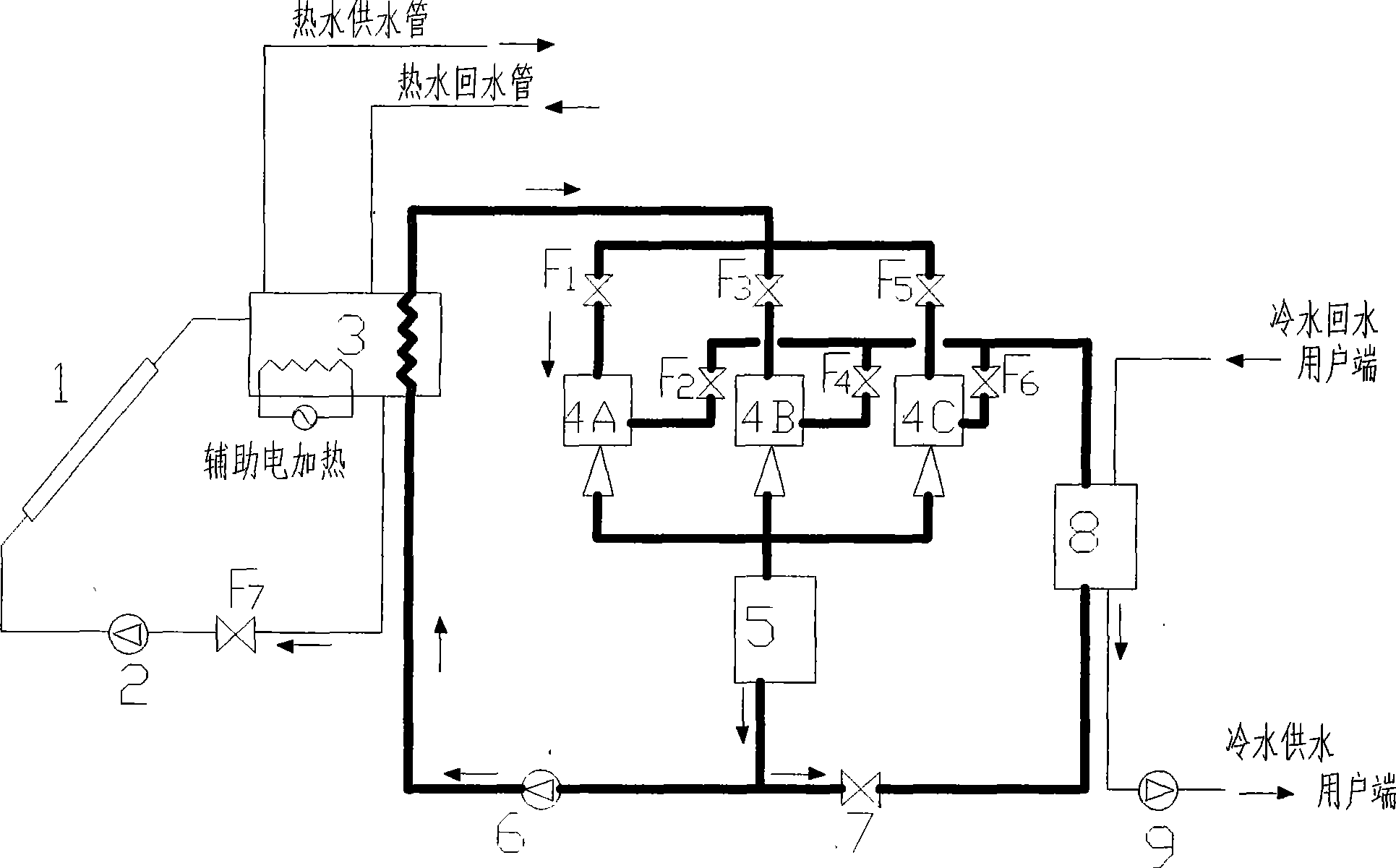

Multi-injector parallel connection type solar injection cooling device

InactiveCN101387457AWide temperature rangeMeet supplySolar heat devicesMachines using refrigerant evaporationCold airConnection type

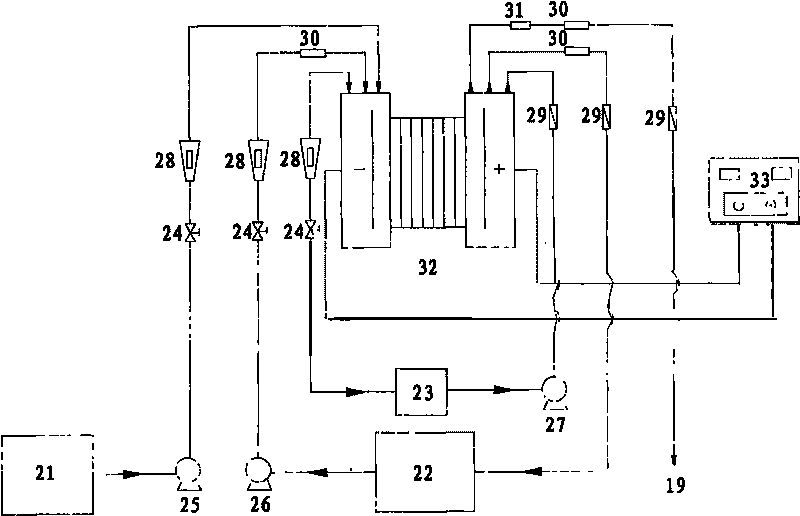

The invention relates to a multi-ejector parallel type solar ejecting refrigeration unit which utilizes solar energy to supply cold air, which comprises a solar hot-water loop, an ejecting refrigerant loop and an air conditioner water loop. The unit solves the problems that the prior ejecting refrigeration system is only provided with an ejector, the structural dimension of the ejector is fixed and the efficiency of an ejector system is drastically declined directly because operation condition is derivated from design condition. The unit is arranged between a generator and a condenser, and is provided with two or more than two ejectors with different structural dimensions in parallel. The multiple ejectors can meet high-efficiency operation of variable working conditions; and the unit can automatically or manually switch to a proper ejector for working according to solar radiation or weather changing conditions, further ensure that the system operates in refrigeration season with high efficiency, can improve the operation efficiency of the solar ejector system, and realize the aim of supplying the cold air with high efficiency and reasonability, thereby improving the utilization rate of solar energy, saving energy, relieving the pressure of electricity grid at the peak time, and improving the light-heat utilization efficiency.

Owner:ZHONGYUAN ENGINEERING COLLEGE

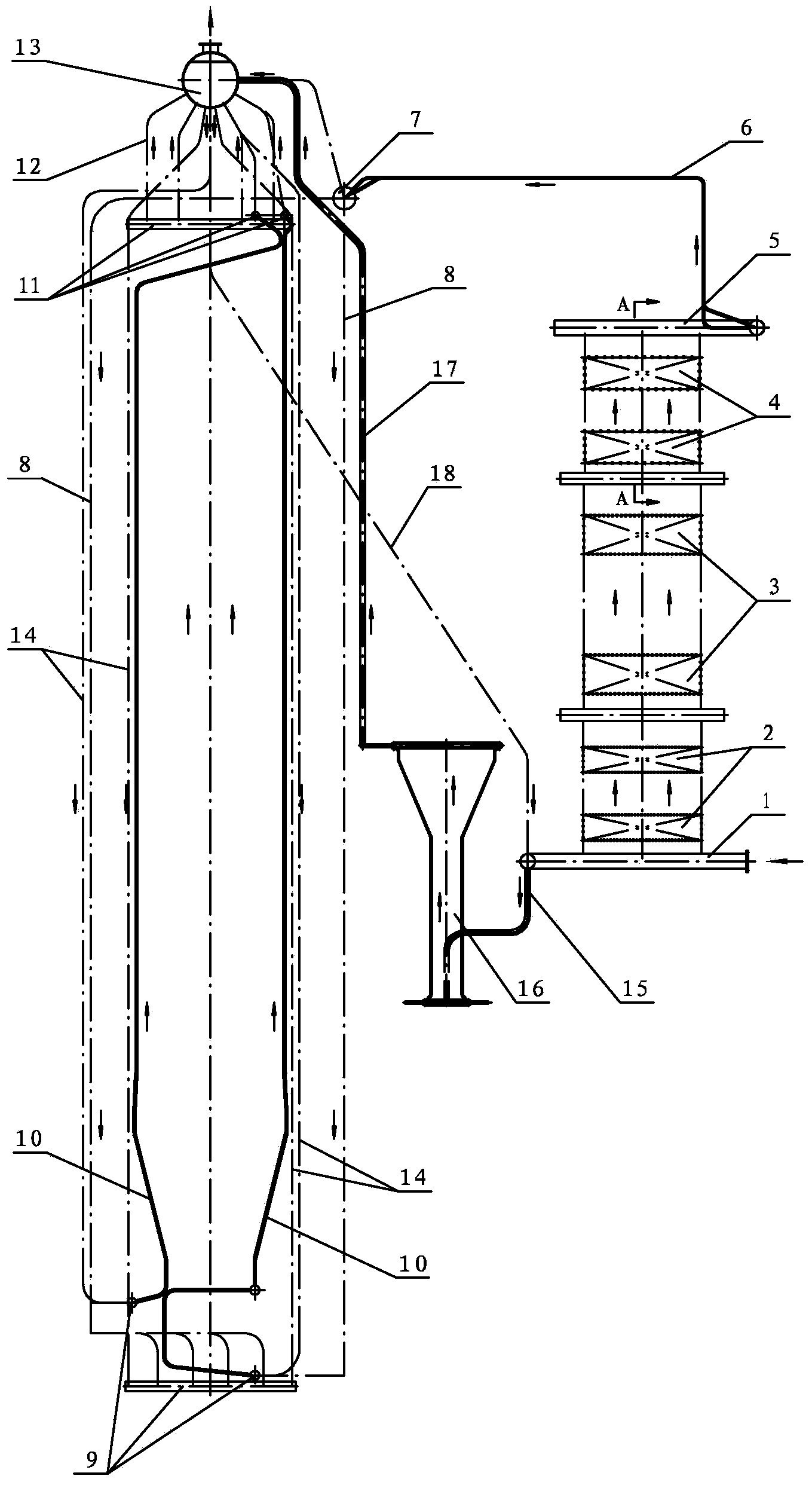

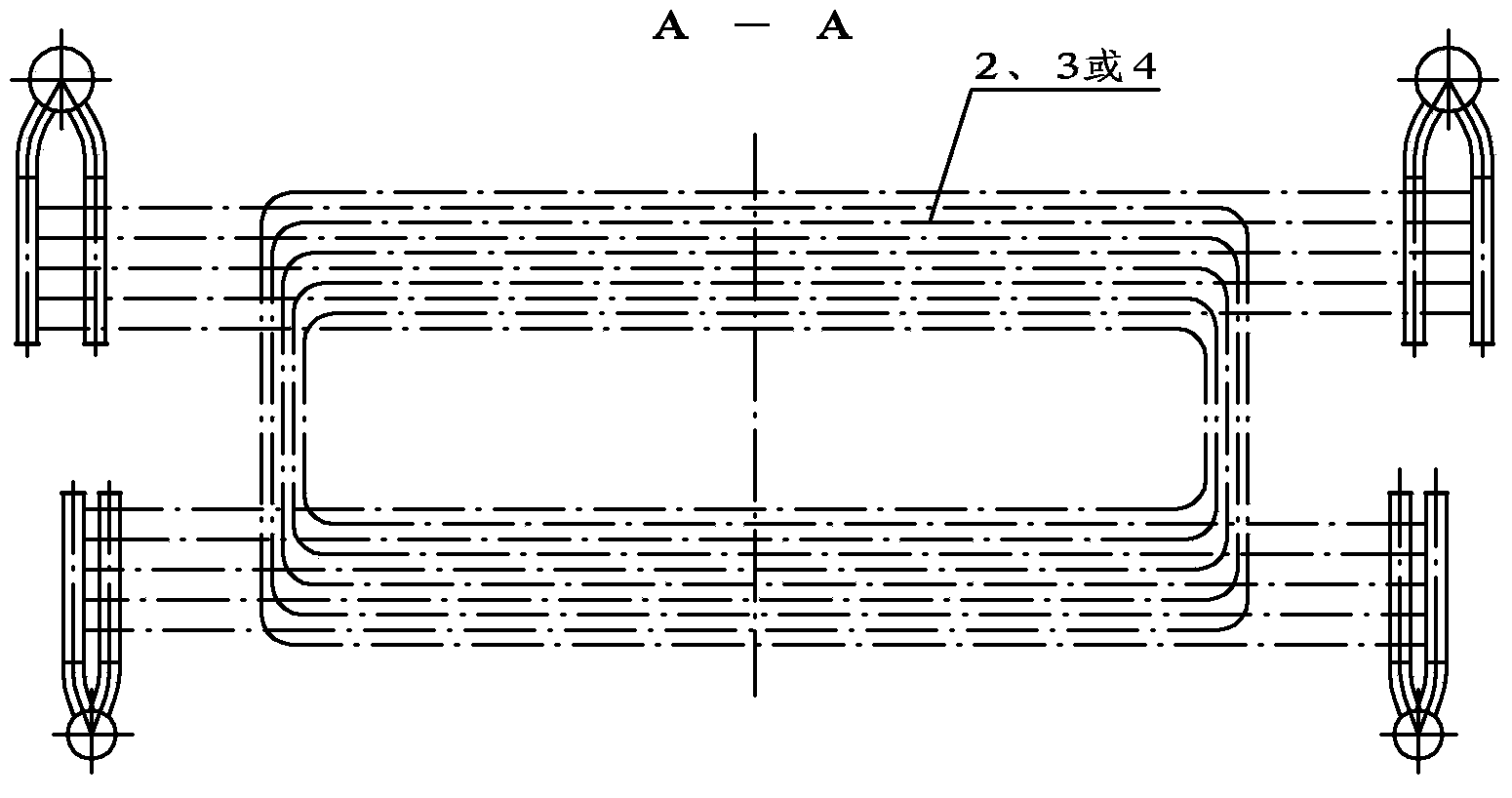

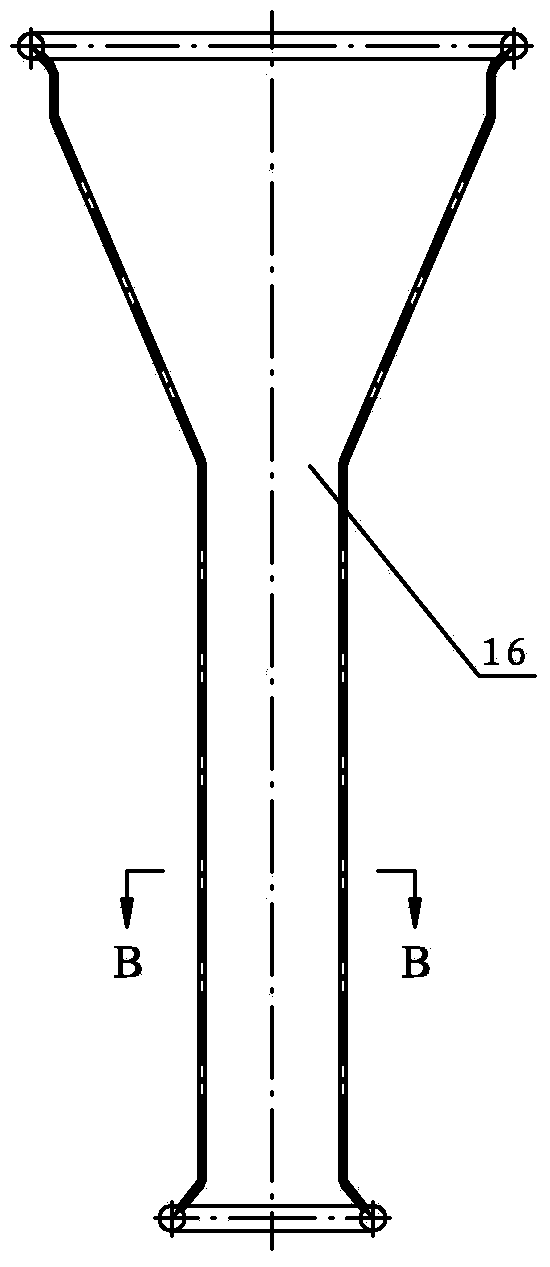

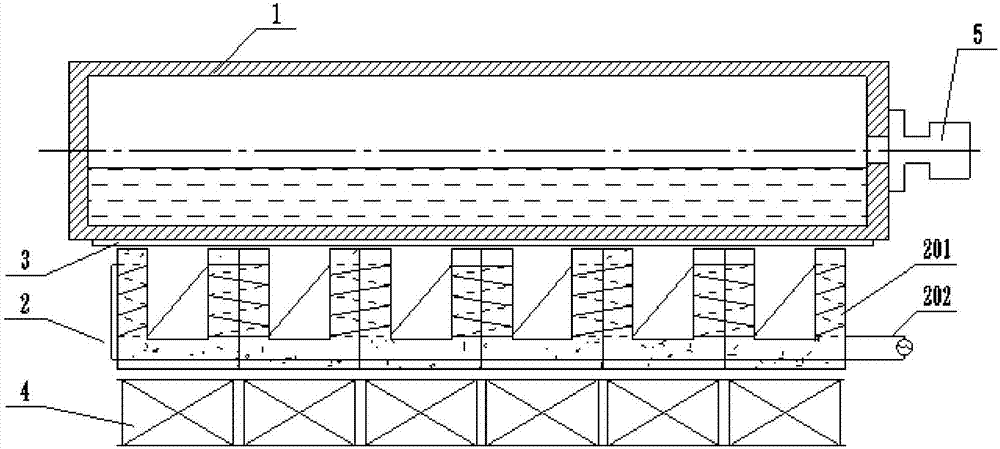

Forced water circulation high-capacity hot water boiler of circulating fluidized bed

ActiveCN103644648AImplement security requirementsAvoid damageFluidized bed combustionWater heatersWater circulationHearth

The invention discloses a forced water circulation high-capacity hot water boiler of a circulating fluidized bed, which relates to a hot water boiler of a fluidized bed, and aims to ensure water circulation safety and power failure protection of a high-capacity hot water boiler of a circulating fluidized bed. A water supply distribution header is connected with lower coal economizers; the lower coal economizers, middle coal economizers and upper coal economizers are sequentially connected with one another; the upper coal economizers are connected with a coal economizer upper header; the coal economizer upper header is connected with a collection water bag by a coal economizer coating pipe; the collection water bag is connected with water cooling wall lower headers by a descending pipe; the water cooling wall lower headers are connected with a hearth water cooling wall; the hearth water cooling wall is connected with water cooling wall upper headers; the water cooling wall upper headers are connected with a boiler cylinder by extraction pipes; the water supply distribution header is connected with a separator water cooling sleeve by a water cooling sleeve water intake pipe; the separator water cooling sleeve is connected with the boiler cylinder by a water cooling sleeve water outlet pipe; the boiler cylinder is connected with the water cooling wall lower headers by communicating pipes, and is connected with the water supply distribution header by a power failure water supply pipe. The forced water circulation high-capacity hot water boiler provided by the invention is applied to large concentrated heat supply and warming.

Owner:哈尔滨红光锅炉总厂有限责任公司

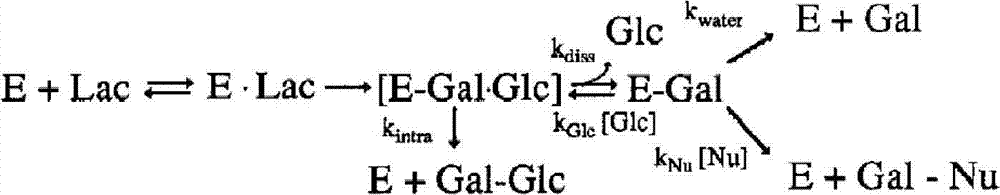

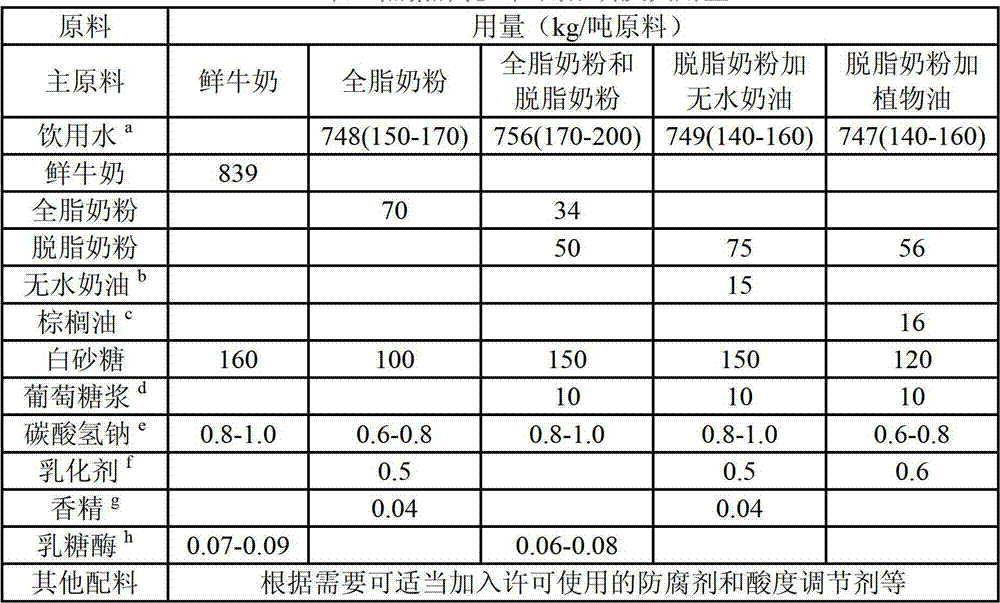

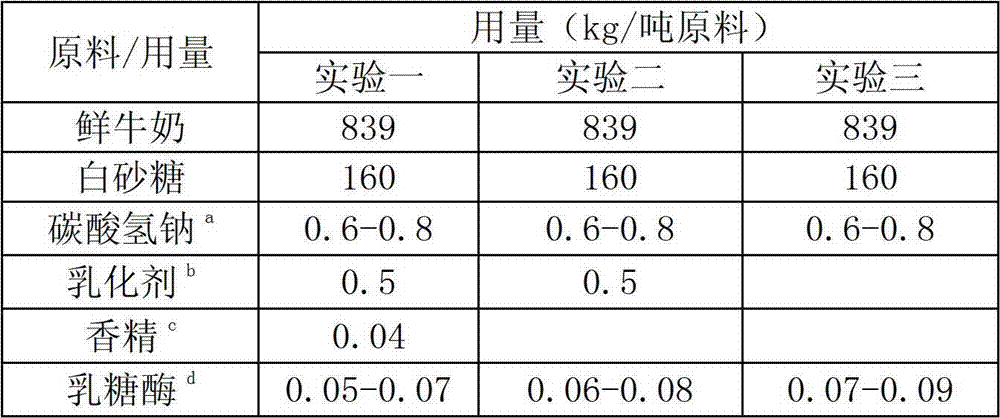

Caramel condensed milk and preparation method and application thereof

ActiveCN102870883ARetain nutrientsSatisfy taste needsMilk preparationPre-extraction tea treatmentFine structureMaillard reaction

The invention discloses caramel condensed milk and a preparation method and application thereof. The caramel condensed milk comprises more than or equal to 1.5 percent of fat, more than or equal to 4.6 percent of protein and less than 30 percent of water, has the titratable acidity of less than or equal to 48 and the sugar degree of 68.5 to 69.5Brix, is uniformly milky yellow, is a glossy viscous semi-solid and has a fine structure, uniform texture, milk aroma and scorch aroma. The preparation method comprises the following steps of: 1) taking a liquid milk raw material with the milk solid content of not more than 70 percent; 2) adding white granulated sugar and sodium bicarbonate into a system obtained in the step 1); 3) heating the system obtained in the step 1) to 95 to 105 DEG C until the system is boiled, continuously boiling, performing Maillard reaction, evaporating water until the sugar degree is 68.5 to 69.5Brix, stopping heating, and cooling; and 4) filling a product obtained in the step 2), sealing a can, sterilizing under high pressure, and cooling. The caramel condensed milk can be applied to food.

Owner:ZHEJIANG PANDA DAIRY GRP COMPANY

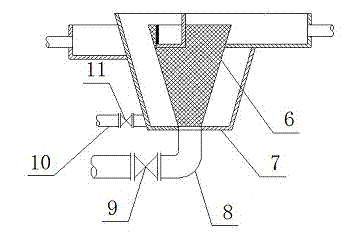

Pollutant separation device of rainwater and sewage pipeline

InactiveCN102392487ASimple structureEasy constructionFatty/oily/floating substances removal devicesInlet channelMunicipal sewage

The invention discloses a pollutant separation device of a rainwater and sewage pipeline, and the device comprises a water inlet pipe, a water inlet channel, an overflow weir, a water outlet channel, a water outlet pipe, an inner conical screen mesh, an outer conical cylinder body, a deslagging pipe, a deslagging valve, a sewage pipe and a sewage valve. The pollutant separation device is combined with the rotational flow principle for introducing municipal sewage and antecedent runoff in rainy days into the inner conical screen mesh through the diversion effect of the overflow weir, solid wastes in the sewage are separated through the interception effect of the inner conical screen mesh, and the pollutant separation device aims at reducing the blockage of the sewage pipeline and reducing the treatment load of a sewage treatment plant. Simultaneously, the device realizes the power-free backwash effect and can effectively prevent the partial blockage of the inner conical screen mesh.

Owner:JIANGSU UNIV

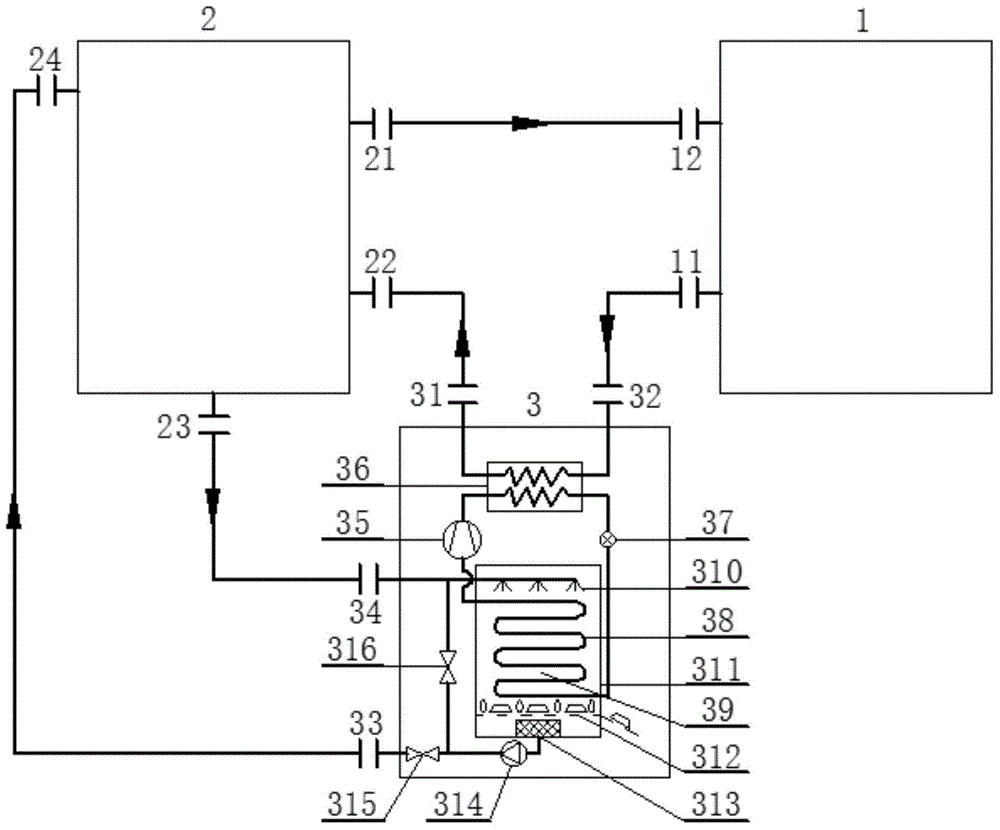

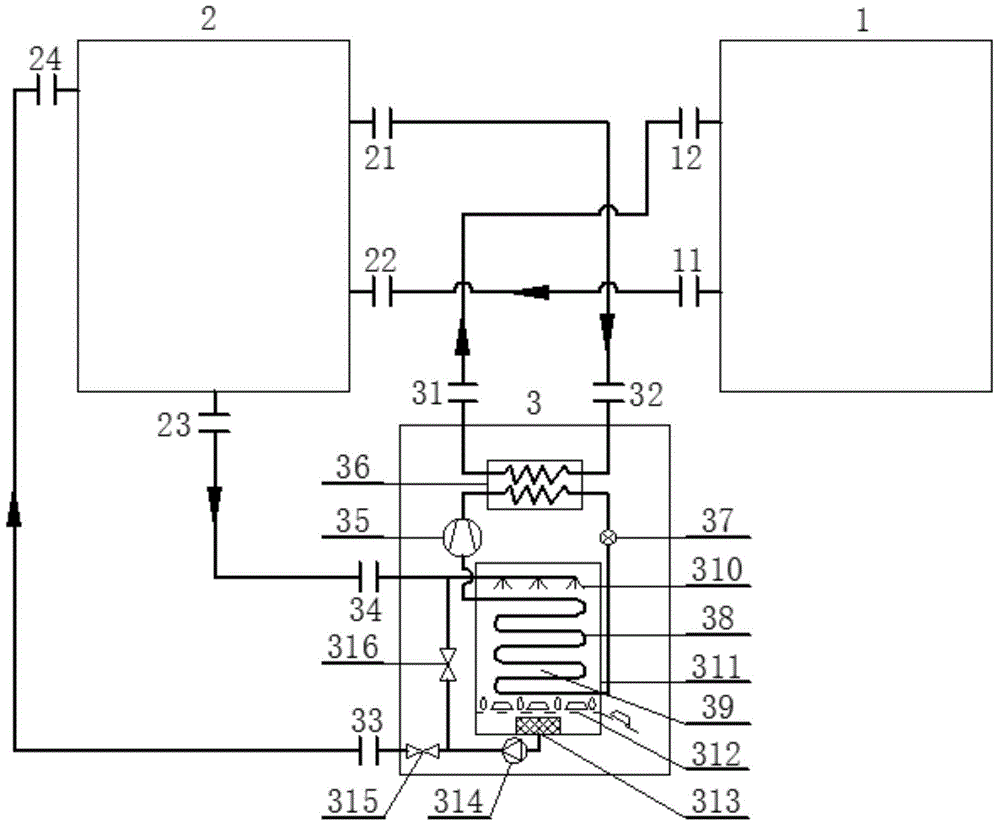

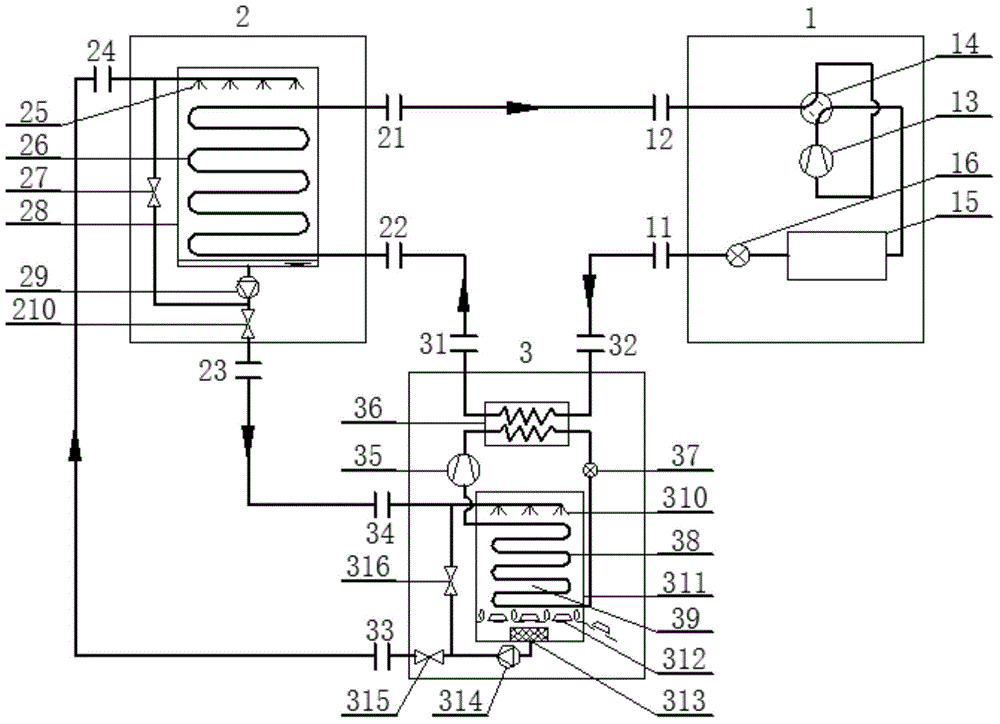

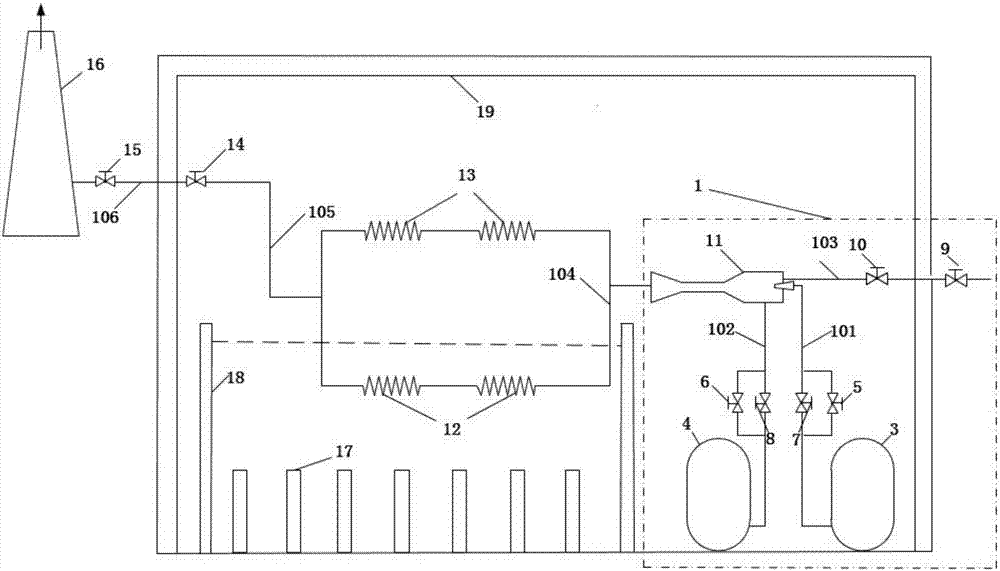

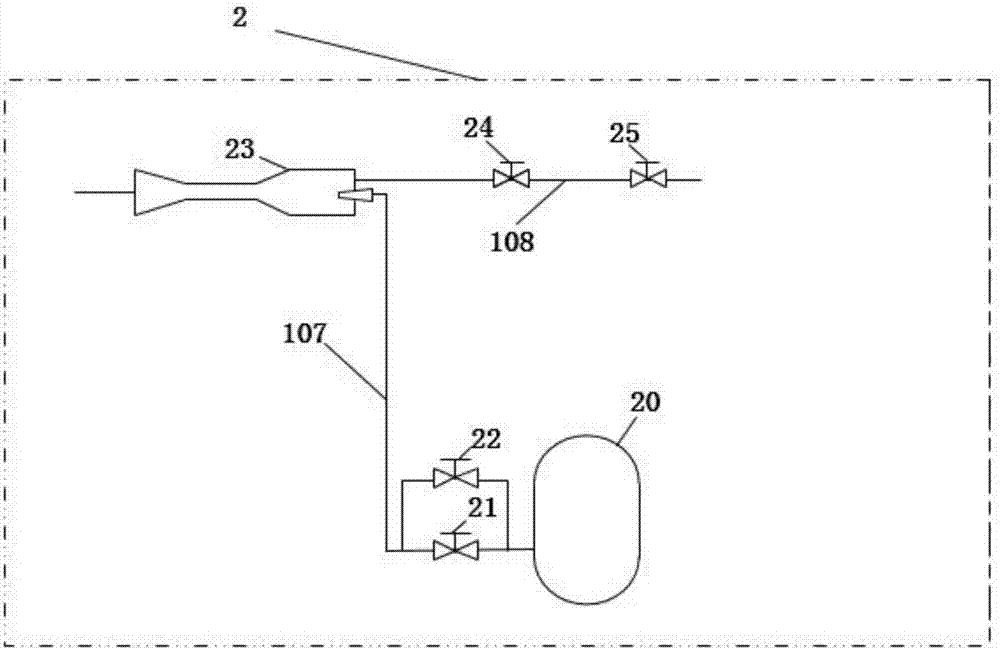

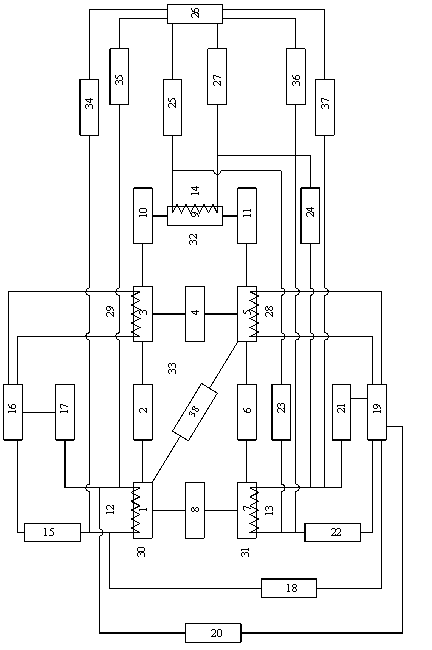

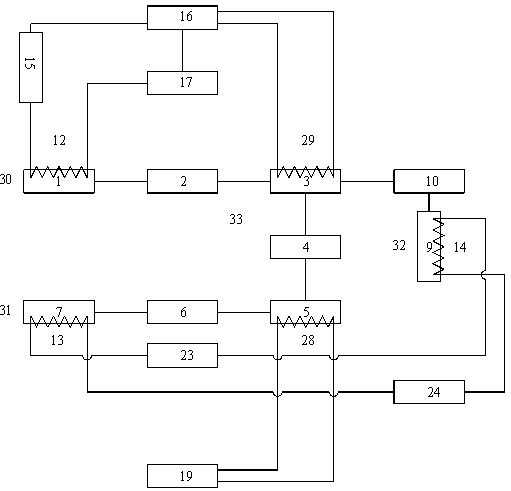

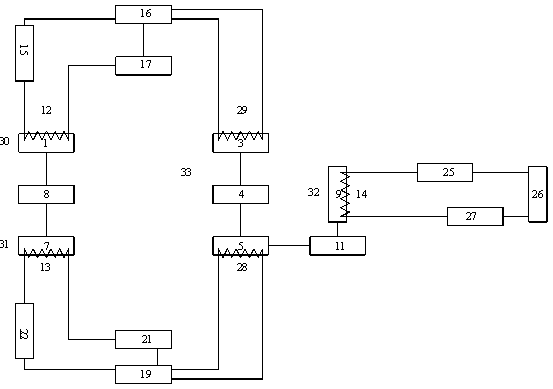

Solution heat pump system based on freezing regeneration and heat recovery thereof

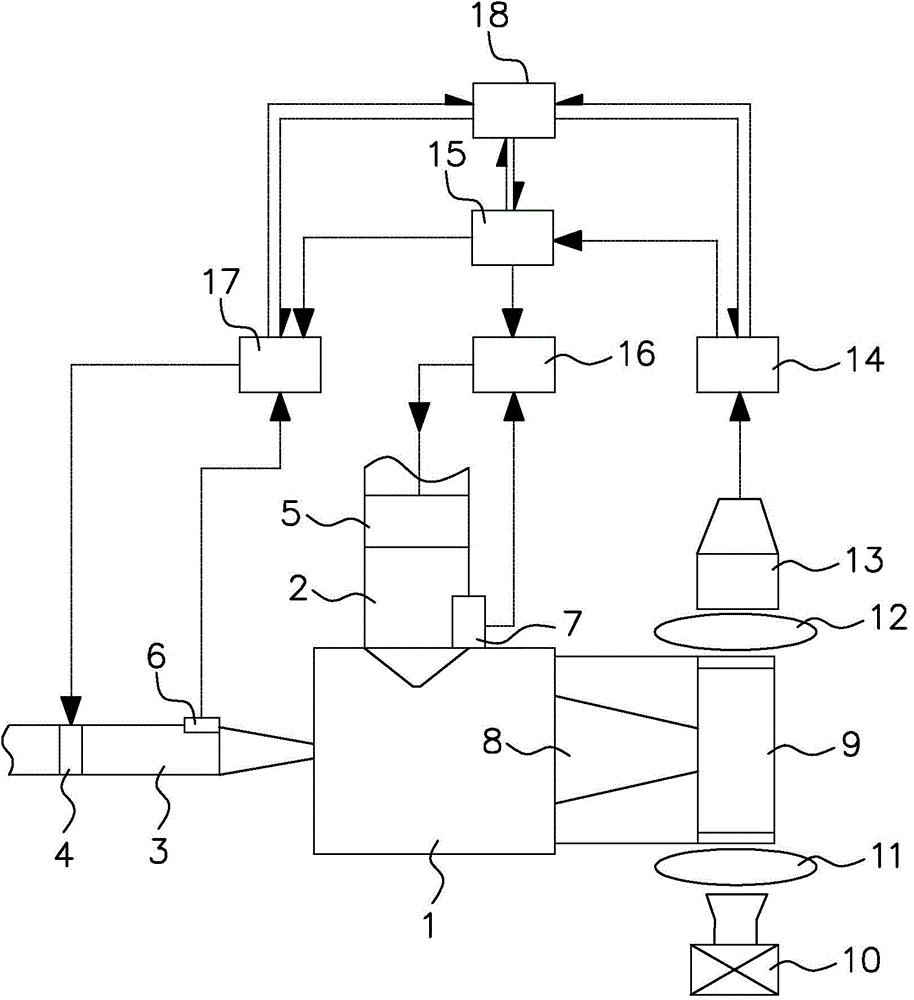

ActiveCN104567104AReduce usageEnsure continuous and efficient operationMechanical apparatusHeat pumpsCyclic processProcess engineering

A solution heat pump system based on freezing regeneration and heat recovery thereof belongs to the field of heat pump air conditioning devices. The system comprises a user side unit, an energy tower unit and a freezing method solution regeneration unit, wherein the freezing method solution regeneration unit mainly includes a refrigeration cycle formed by connecting a freezing regeneration ice tank, a compressor, a heat recovery condenser and a throttling valve through a refrigerant pipeline. A dilute solution to be regenerated in the energy tower unit is delivered into the freezing regeneration ice tank of the freezing method solution regeneration unit to enable a part of water in the solution to be frozen and precipitated and separated through an ice-solution separation device to obtain the a dense solution to further achieve solution regeneration. Meanwhile, condensed heat generated in the regeneration refrigeration cycle process is recovered through a heat recovery condenser of the freezing method solution regeneration unit to improve the operation efficiency of the whole system. The system has the advantages of being small in solution quantity, small in investment and occupation area, high in regeneration efficiency, high in heat pump operation stability and efficiency and the like.

Owner:TSINGHUA UNIV

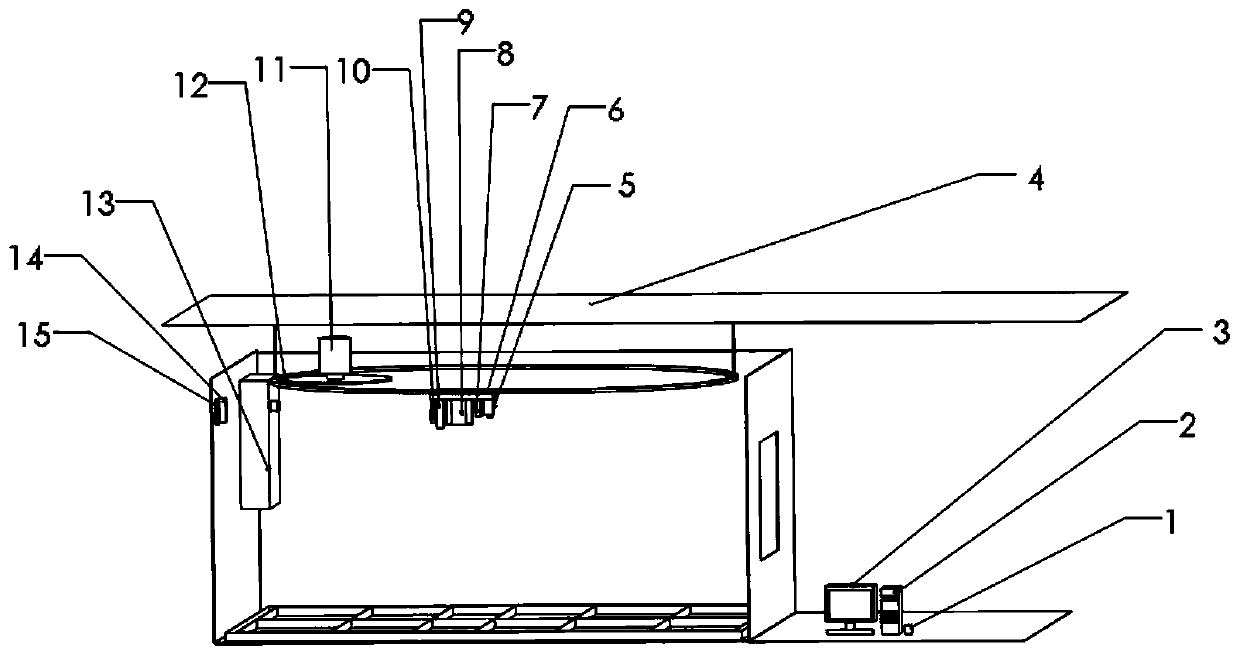

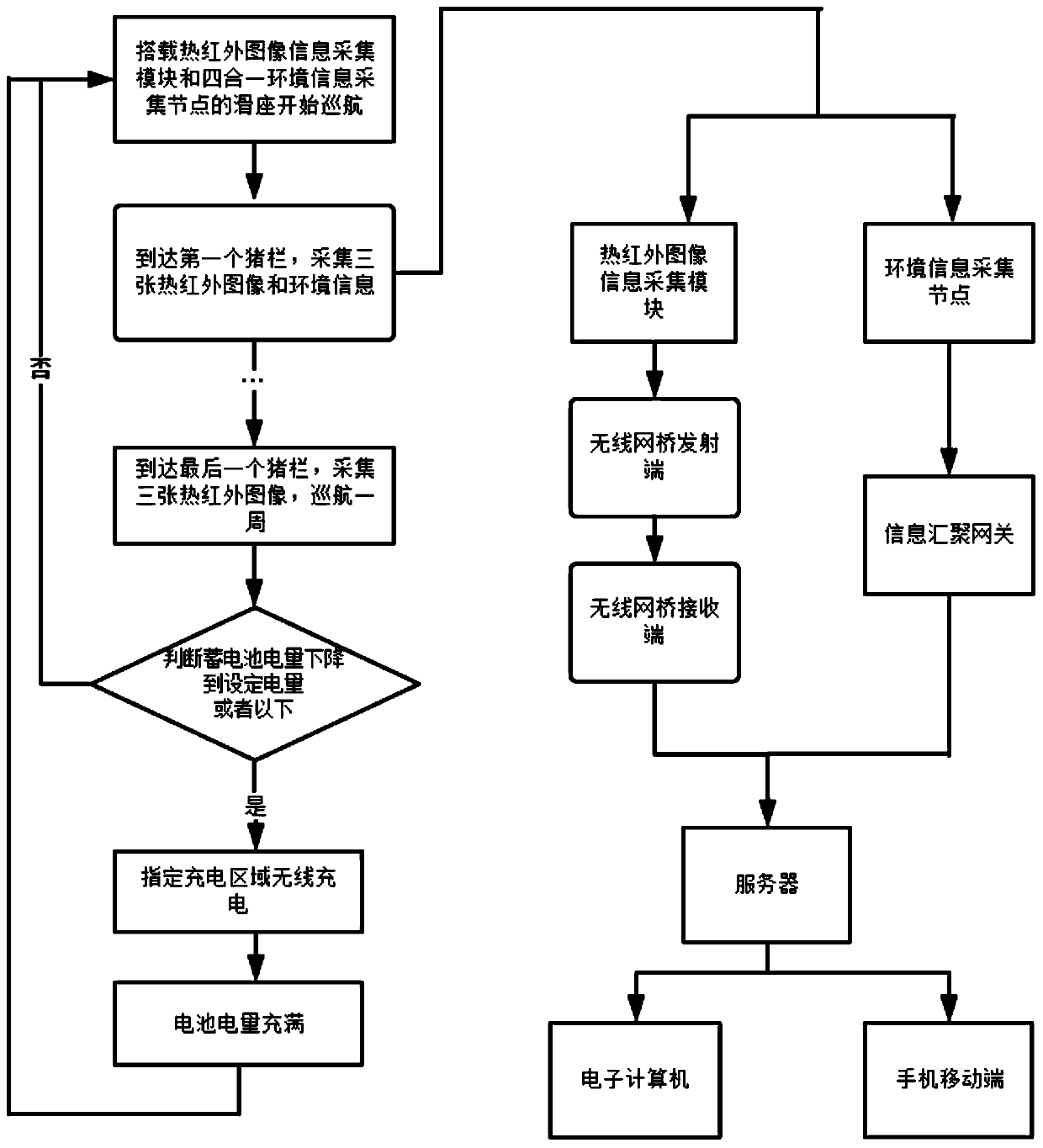

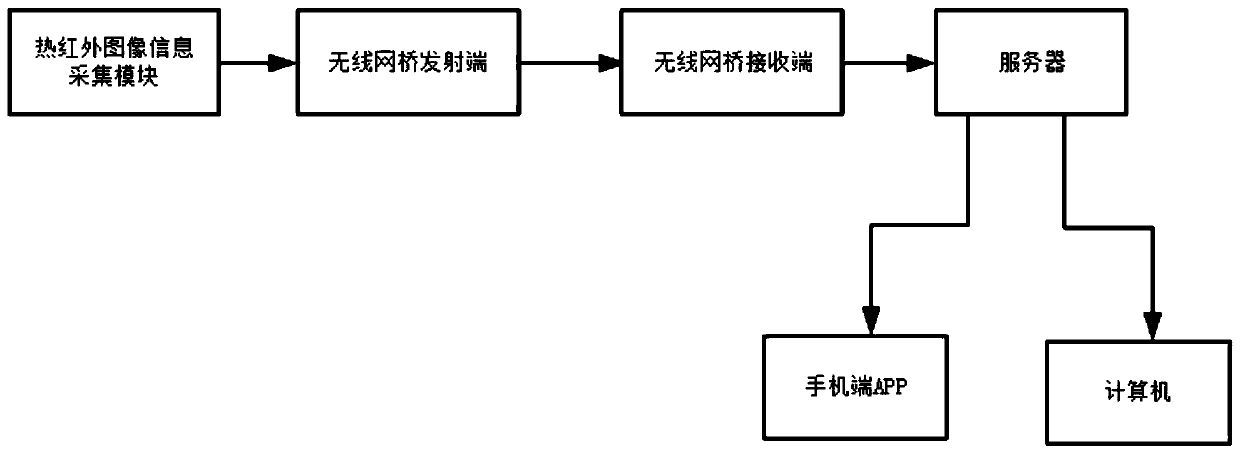

Swine fever automatic monitoring diagnosis system based on thermal infrared

ActiveCN110333692AAvoid infectionPrevent proliferationProgramme control in sequence/logic controllersTreatment feverHealth condition

The invention discloses a swine fever automatic monitoring diagnosis system based on thermal infrared. The system is characterized by comprising a wireless bridge receiving end, a server, a computer,a thermal infrared image collection module, a slide rest, a four-in-one environment information collection node, an accumulator, a wireless bridge emitting end, a wireless charging module, a servo motor, an annular guide rail, a PLC controller, a wireless charging module emitting end. The swine thermal infrared image can be dynamically and all-weather collected, the image can be analyzed to monitor the swine heat change, a model is established by combining the swine thermal infrared image, the temperature and humidity, the carbon dioxide concentration, the illumination intensity and like environment information, the swine heat variation diagram can be acquired, and then the health status of the swine can be judged; a breeder can take the corresponding measure for the sick swine in time according to the swine heat status, thereby preventing the swine epidemic situation from infecting and diffusing, reducing the economic loss and the labor management cost and lowering the labor intensity.

Owner:NANJING AGRICULTURAL UNIVERSITY

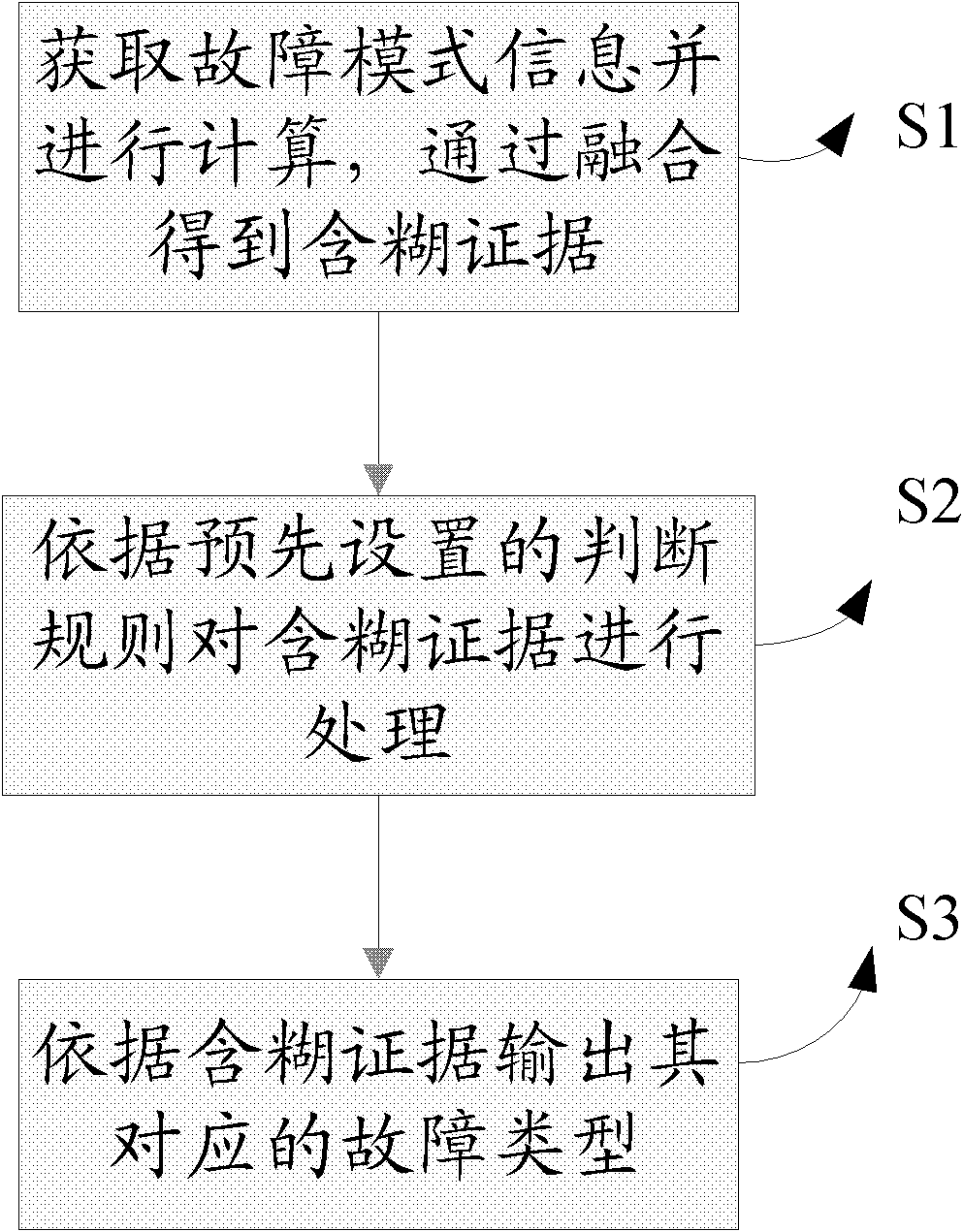

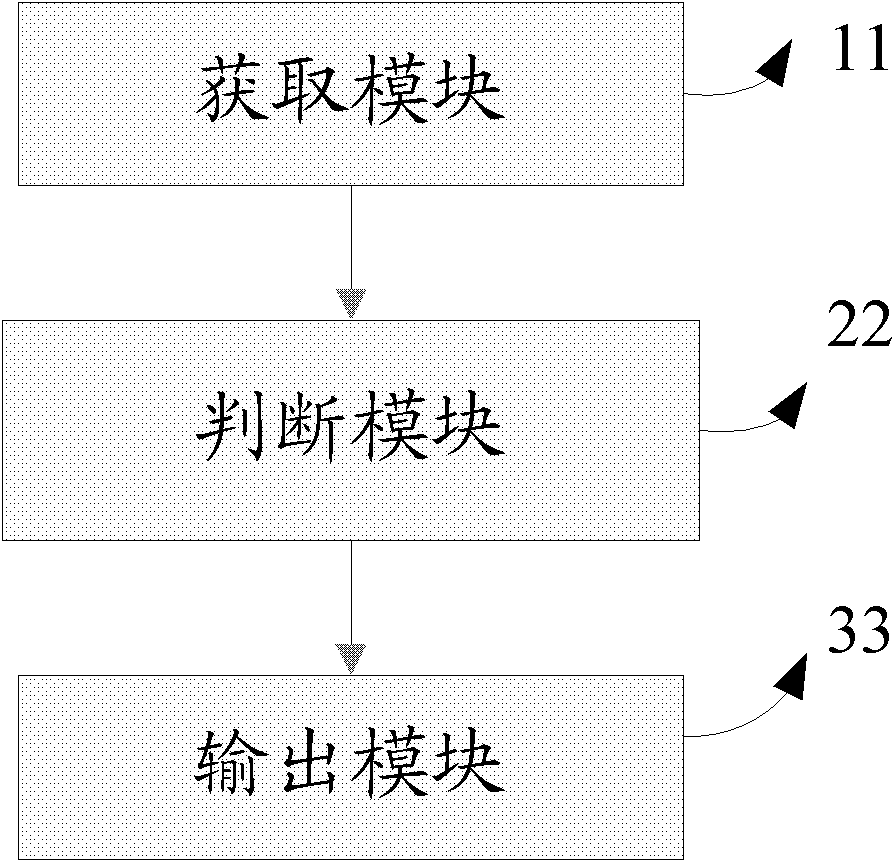

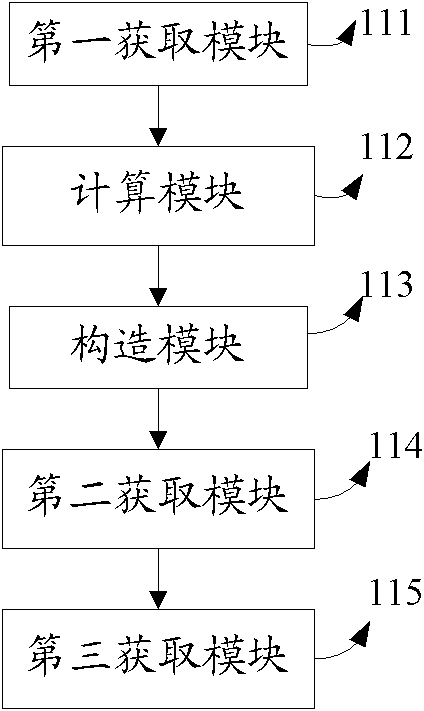

Method and device for judging faults of wind turbine generator systems

InactiveCN102253340AEarly detection of faultsReduce the risk of failureDynamo-electric machine testingTurbineElectric generator

The invention discloses a method and device for judging faults of wind turbine generator systems. The method and the device have the following beneficial effects: the possible faults of the wind turbine generator systems are discovered ahead of time by obtaining and computing the fault mode information and obtaining ambiguous evidences through fusion, processing the ambiguous evidences according to the preset judgment rule and outputting the fault types corresponding to the ambiguous evidences according to the ambiguous evidences, thus effectively reducing the fault risks of the wind turbine generators and effectively guaranteeing continuous and efficient operation of the wind turbine generators.

Owner:SHANGHAI DIANJI UNIV

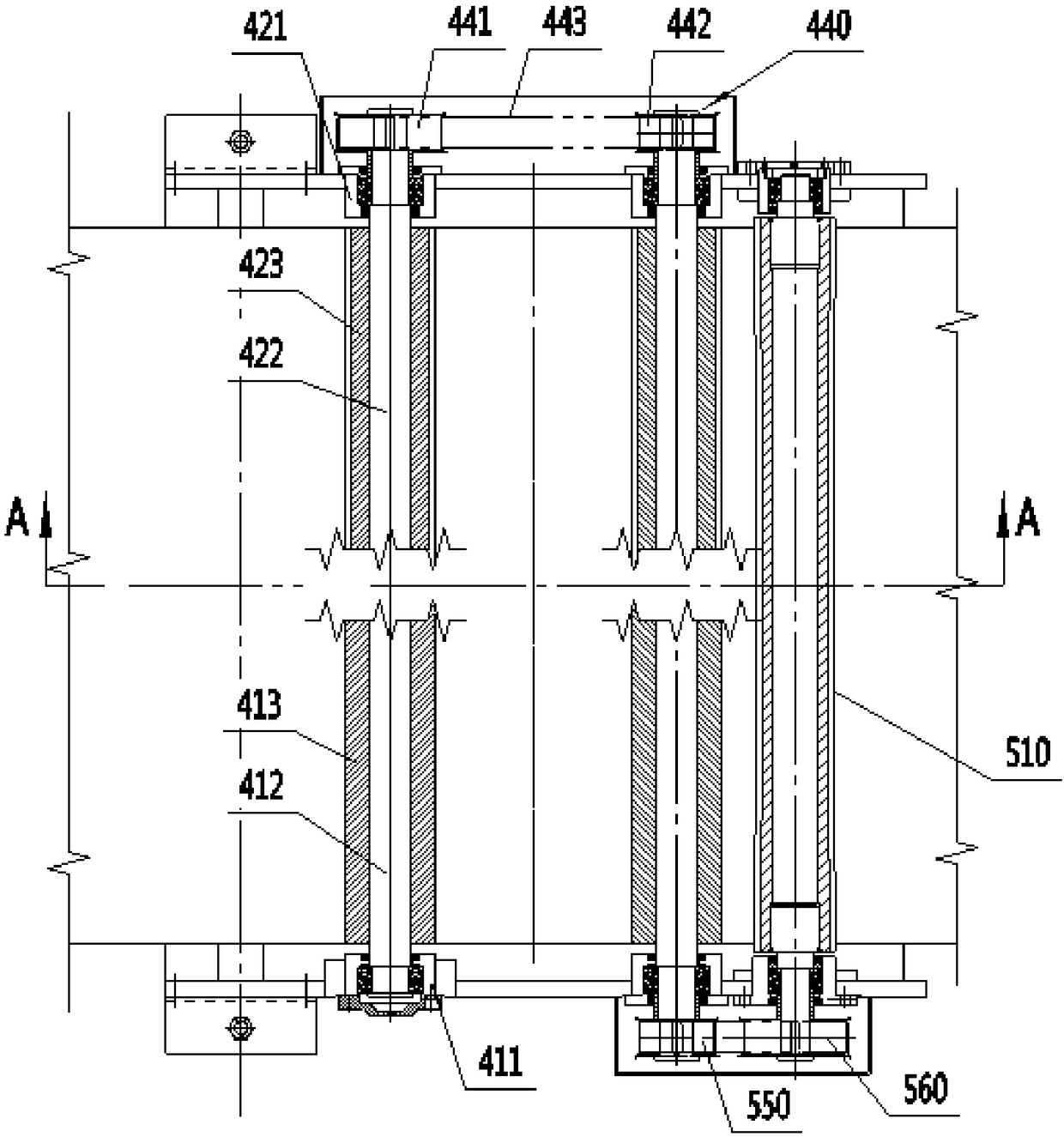

Electromagnetic heating roller used for corrugating machine, application of electromagnetic heating roller and corrugating machine electromagnetic heating method

PendingCN106903932AIncreased complexitySimplify complexityMechanical working/deformationStorage heatersMagnetic heatingEngineering

The invention discloses an electromagnetic heating roller used for a corrugating machine, an application of the electromagnetic heating roller and a corrugating machine electromagnetic heating method, and belongs to the technical field of electromagnetic heating. The electromagnetic heating roller comprises a roller body and an electromagnetic heater. The electromagnetic heater is used for heating the roller body. The roller body is provided with a cavity for encapsulating heat-conducting liquid. The electromagnetic heater can heat the heat-conducting liquid through the roller body, so that steam is produced in the cavity of the roller body. The electromagnetic heater comprises a plurality of U-shaped magnets and an electromagnetic wire. The multiple U-shaped magnets are arranged on a straight line side by side in the axis direction of the roller body. The electromagnetic wire is wound at the two ends of the U-shaped magnets in a single-loop wire winding mode to form a coil. Corrugated paper can be uniformly heated through the electromagnetic heating roller, moisture balance of the corrugated paper in the whole width direction is ensured, and the product quality is improved.

Owner:ANHUI RESUDA ELECTRONICS TECH

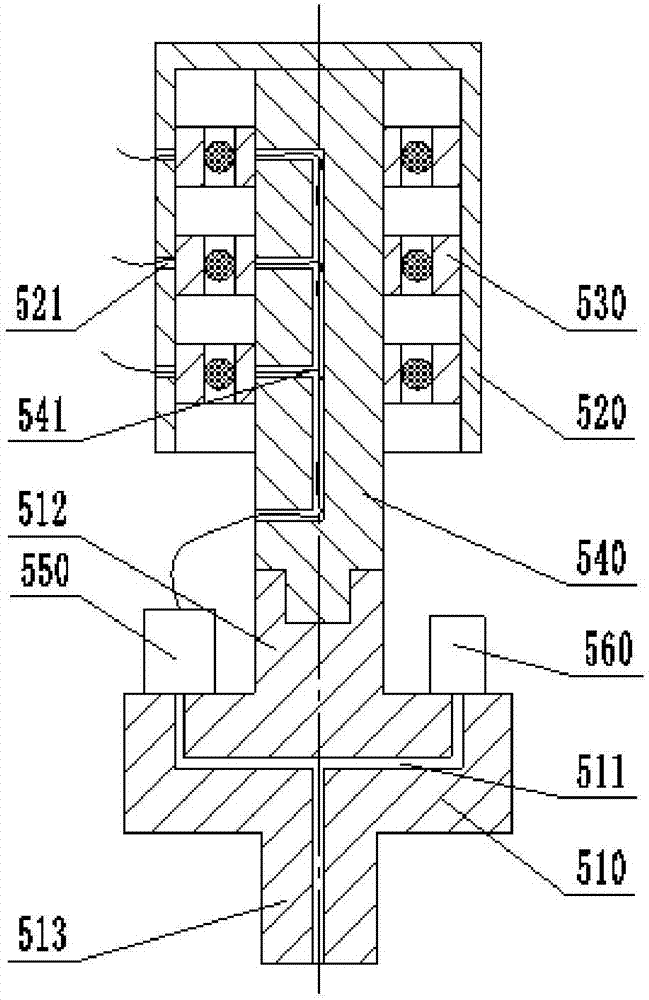

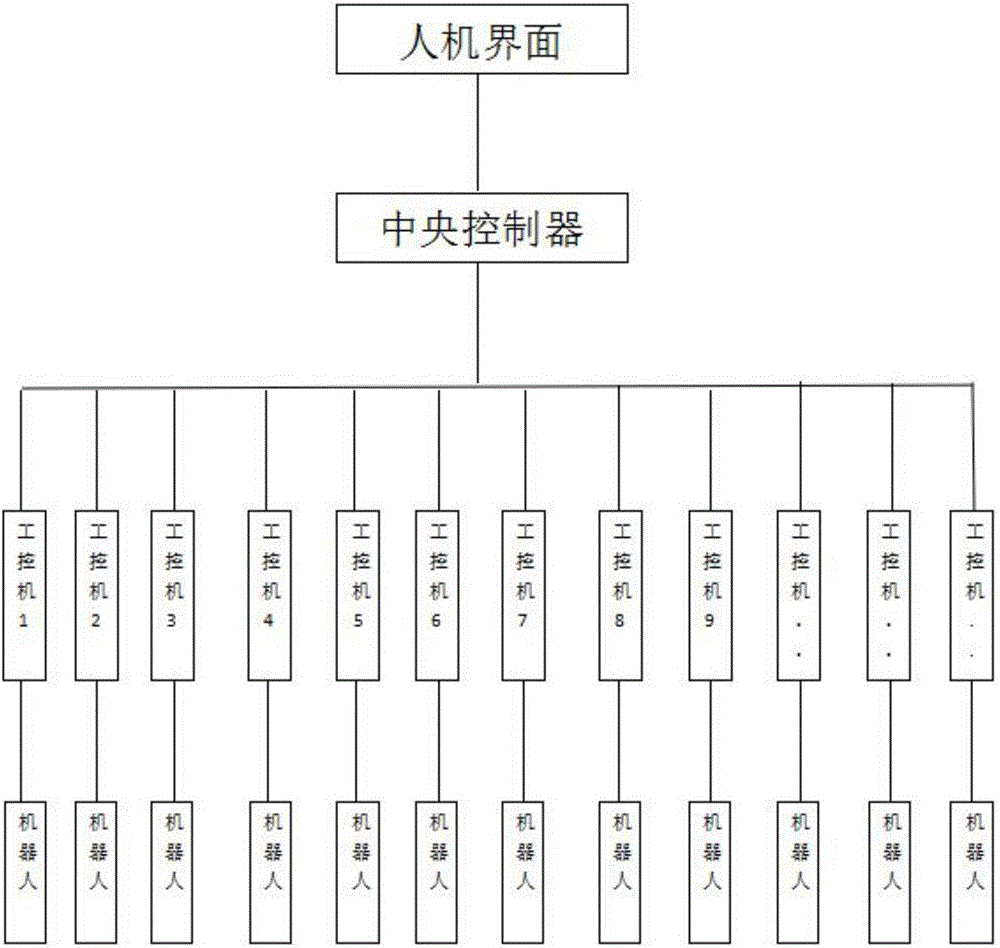

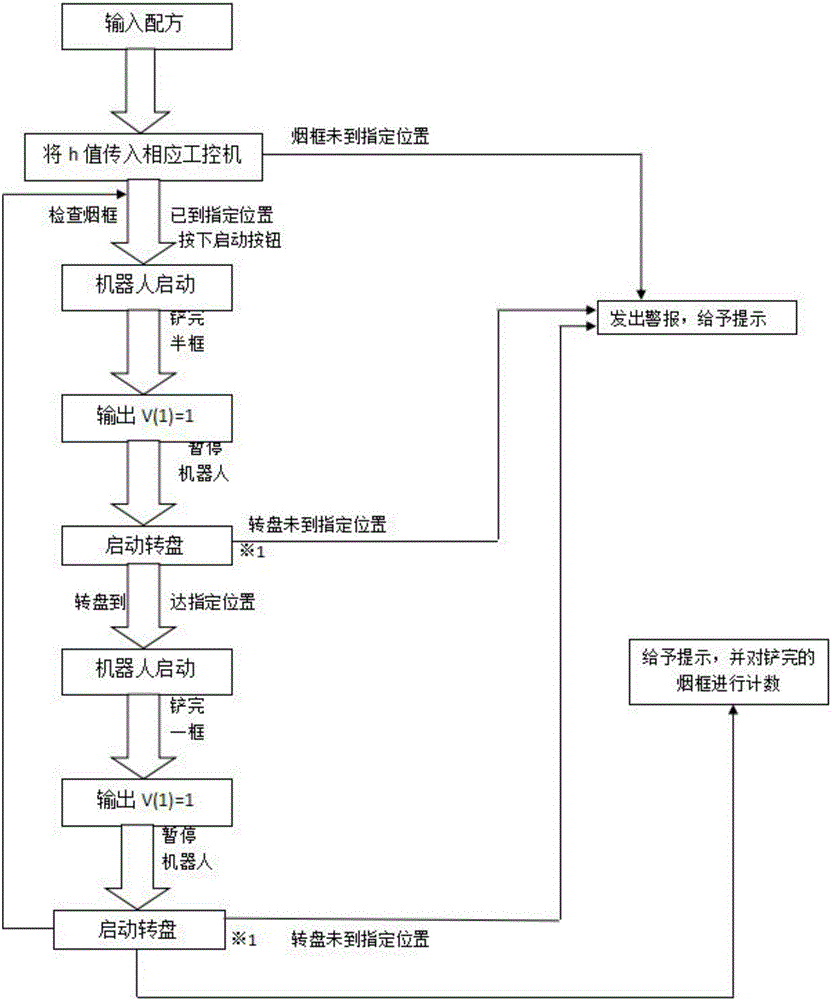

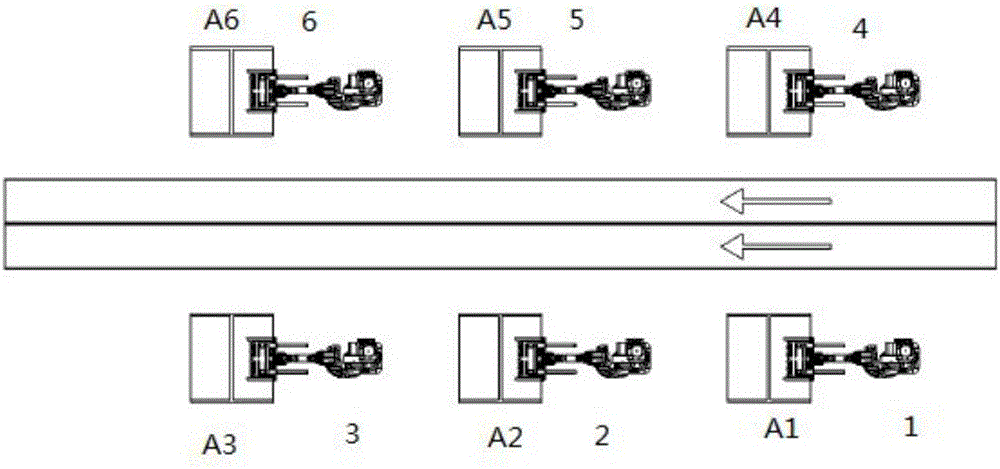

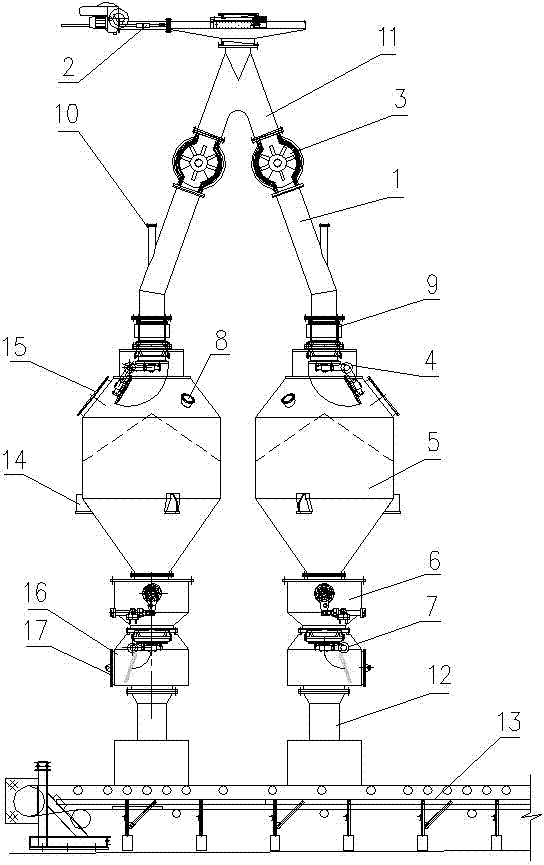

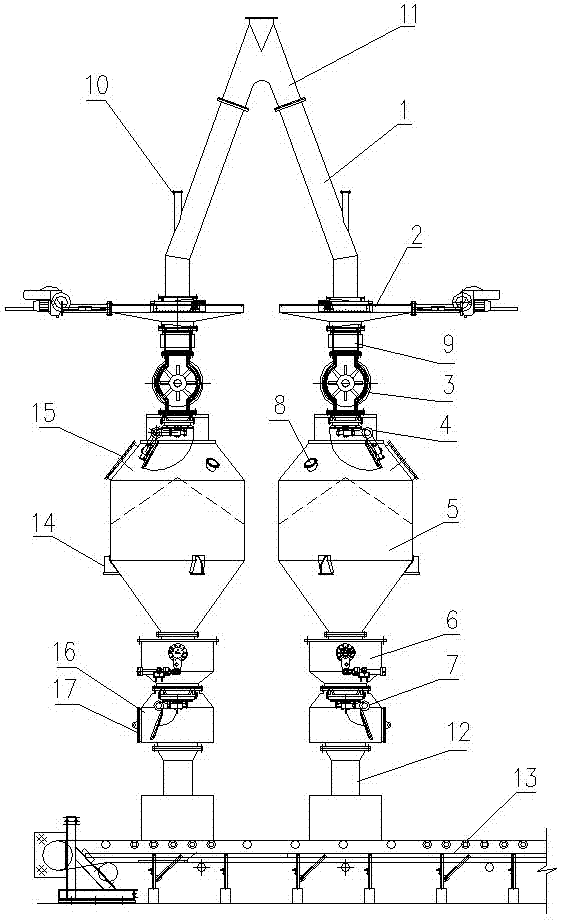

Control method for tobacco redrying automatic swinging and batching robot clusters

InactiveCN105768169AQuality improvementImprove recipe accuracyTobacco preparationTotal factory controlProduction lineCluster systems

The invention relates to a control method for tobacco redrying automatic swinging and batching robot clusters. The clusters include a central controller, industrial personal computers, swinging and batching robots, a conveyor belt and a tobacco frame. The swinging and batching robots and the conveyor belts are provided with the industrial personal computers and connected through an industrial field bus. The central controller controls shoveling motions of the swinging and batching robot and the conveying speed of the conveyor belt by controlling the industrial personal computers. Swinging and batching robots on multiple tobacco swinging production lines are configured into one cluster system, tobacco of different quality grades is automatically shoveled by controlling the thickness of the tobacco shoveled by the swinging and batching robots, the shoveling frequency and the speed of the conveyor belt, the tobacco of different grades can be mixed according to the batching proportion while automatic swinging is achieved, automatic batching is achieved, the novel method for tobacco redrying automatic swinging and batching is implemented and replaces a traditional manual swinging and batching method, the batching precision is improved, and the redried tobacco quality is improved.

Owner:HUIDONG REDRYING FACTORY OF SICHUAN LEAF TOBACCO RE DRYING CO LTD

Treatment method of electroplating rinsewater

InactiveCN101694007APromote migrationAvoid conductive propertiesCellsDispersed particle separationStrong acidsIon-exchange resin

The invention relates to a treatment method of electroplating rinsewater which is treated by adopting an electrodeionization membrane stacking device. An electrodeionization membrane stack comprises five chambers which are sequentially separated by an anion exchange membrane, a cation exchange membrane, a bipolar membrane, an anion exchange membrane from a negative electrode to a positive electrode and the five chambers include an electrode chamber, a concentration chamber, a first desalting chamber, a second desalting chamber and a positive electrode chamber in sequence. The concentration chamber and the first desalting chamber are filled with macroporous strong-acid cation exchange resin, and the second desalting chamber is filled with macroporous strong-basic anion exchange resin. The rinsewater to be treated flows through the first desalting chamber and the second desalting chamber sequentially to obtain desalted pure water by cation and anion removing processes; and cations are transferred to the concentration chamber via the first desalting chamber and anions are transferred to the concentration chamber via the second desalting chamber, the positive electrode chamber and the negative electrode chamber in sequence, thus, concentrated water current is obtained. H+ and OH- ions which are products of bipolar membrane water dissociation respectively carry on high-efficiency real-time dynamic regeneration on the cation / anion exchange resin filled in the two desalting chambers. The wastewater treatment technology avoids scaling inside the electrodeionization membrane stack, does not need acid-alkali regeneration ion exchange resin in the treatment process, has no secondary pollution, and is beneficial to realizing the harmless and reclamation treatment.

Owner:NANKAI UNIV

Ultrasonic wave dry fog dust-fall device and multi-loop cascade stage PID control method thereof

InactiveCN104607349ALow costEffective dry fogLiquid spraying apparatusProgramme control in sequence/logic controllersSolenoid valveQuality control system

The invention discloses an ultrasonic wave dry fog dust-fall device and a multi-loop cascade stage PID control method thereof. The ultrasonic wave dry fog dust-fall device comprises a dry fog quality control system. The dry fog quality control system comprises a first signal collection unit, a second signal collection unit, a third signal collection unit, a master controller, an air pressure regulator and a water pressure regulator, wherein the first signal collection unit is used for collecting fog-drop quality parameter information; the second signal collection unit is used for detecting an air pressure value in an air inlet pipe; the third signal collection unit is used for detecting a water pressure value in a water inlet pipe; the master controller is used for receiving the fog-drop quality parameter information, making comparison between the fog-drop quality parameter information and a preset value, and determining whether to output a given air pressure value and a given water pressure value according to a comparison result; the air pressure regulator is used for receiving the air pressure value and the given air pressure value, making comparison between the two, and adjusting power of an air pump according to the comparison result; the water pressure regulator is used for receiving the water pressure value and the given water pressure value, making comparison between the two, and adjusting an opening degree of a solenoid valve according to the comparison result. By means of the dry fog quality control system, it is guaranteed that the device is capable of generating effective dry fog continuously and equipment life is prolonged.

Owner:ZHEJIANG UNIV

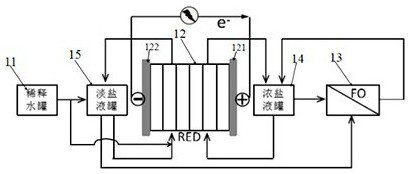

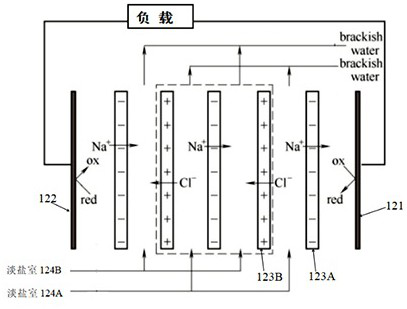

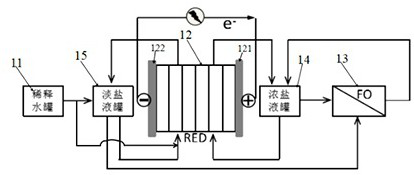

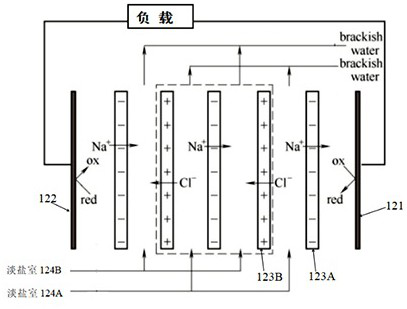

Continuous salinity gradient power generation device and method

ActiveCN112713808AImprove concentration efficiencyLower resistanceKinetic-electric generatorEngineeringReversed electrodialysis

The invention relates to a continuous salinity gradient power generation device. The device comprises a dilution device, a reverse electrodialyzer, a forward osmosis device, a concentrated salt liquid tank and a light salt liquid tank; the concentrated salt solution tank contains a concentrated salt solution, the light salt solution tank contains a light salt solution, and the concentration of the concentrated salt solution is greater than that of the light salt solution; the reverse electrodialyzer is provided with a cathode and an anode, and a cation exchange membrane, an anion exchange membrane, a thick liquid chamber and a thin liquid chamber are alternately arranged between the cathode and the anode; a potential difference is formed between the cathode and the anode of the reverse electrodialyzer; the concentrated salt solution circulates between a concentrated solution chamber and a concentrated salt solution tank of the reverse electrodialyzer, the light salt solution circulates between a light solution chamber and a light salt solution tank of the reverse electrodialyzer, the dilution device provides a diluent to maintain the light salt solution at a low concentration, the forward osmosis device provides a concentration effect to maintain the concentrated salt solution at a high concentration, and part of the light salt solution is concentrated and then is used for supplementing the strong salt solution. The device disclosed by the invention can realize cyclic continuous power generation by utilizing the salt concentration difference and has the characteristic of high power generation efficiency.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

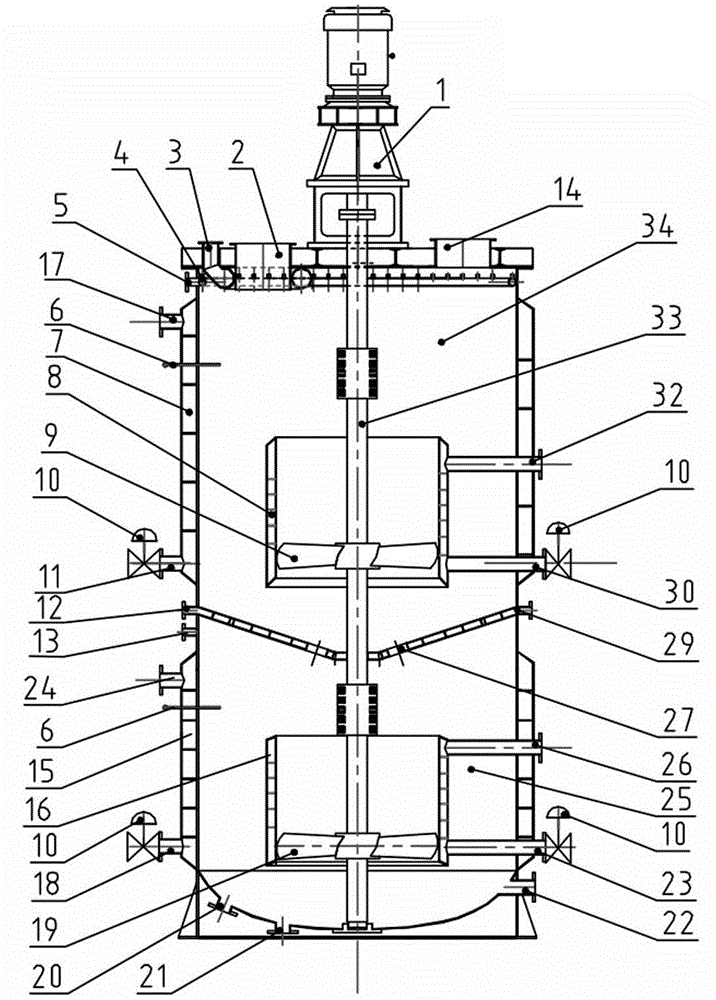

Novel high efficiency reactor

ActiveCN104941554AUniform temperatureQuality improvementMixer accessoriesChemical/physical/physico-chemical stationary reactorsAutomatic controlNuclear engineering

The invention discloses a novel high efficiency reactor, which comprises a reactor body, the reactor body comprises an upper reaction zone and a bottom reaction zone, an intermediate heat exchange separator plate is arranged between the upper reaction zone and the lower reaction zone, a mixer shaft passes through the reactor body, the mixer shaft is connected to a speed reducer arranged on the upper part of the reactor body, an upper heat exchange jacket and an upper inner heat exchange guide shell are respectively arranged on the upper reaction zone; a lower heat exchange jacket and an lower inner heat exchange guide shell are respectively arranged on the lower reaction zone; a temperature sensor arranged on the reactor body and an automatic regulating valve are respectively connected to an automatic control device, and automatic accurate control of the reaction of the materials in the reactor body can be realized. Compared with prior art, a structure of the high efficiency reactor is simple, accurate automatic control can be realized, continuous high efficiency operation of the high efficiency reactor can be carried out, material reaction effect is ensured, effect of the large-scale reactor is more protruding, and a novel development of the novel reactor can be provided.

Owner:吴巴特尔 +2

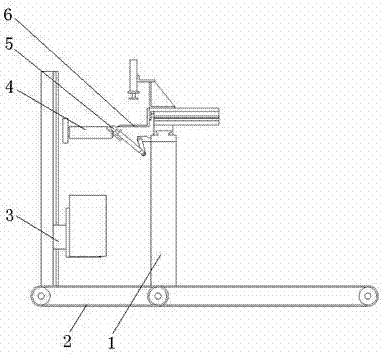

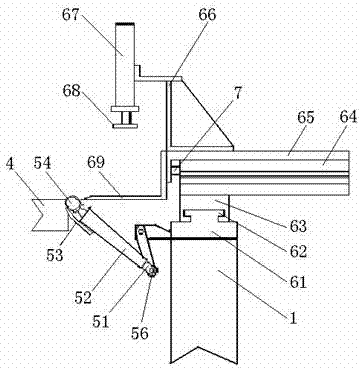

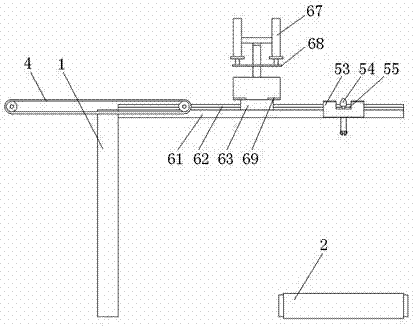

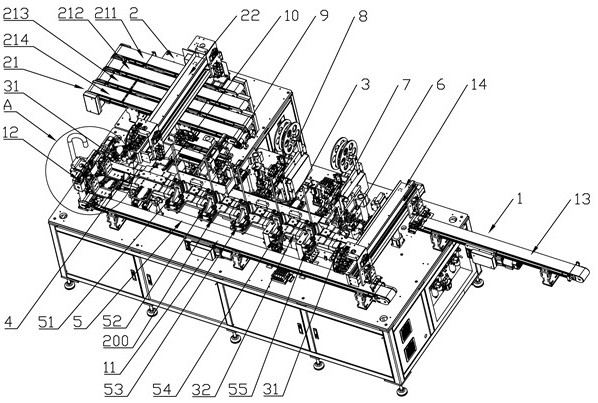

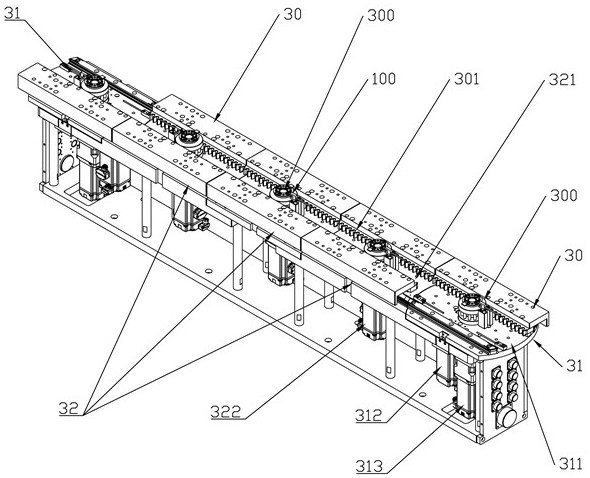

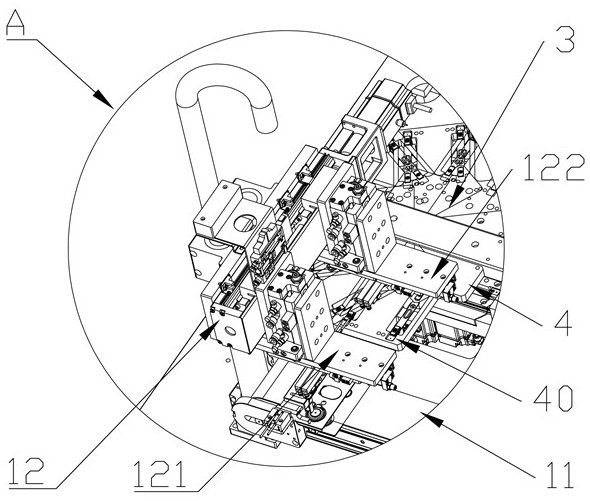

Printing paper stack dividing and conveying device

ActiveCN107416472AEnsure continuous and efficient operationNo longer damageConveyor partsStructural engineeringPrinting press

The invention provides a printing paper stack dividing and conveying device. The printing paper stack dividing and conveying device comprises a rack, a low-position conveying belt, a high-position conveying belt and a lifting machine, the low-position conveying belt and the high-position conveying belt are arranged on the rack, the low-position end of the lifting machine is connected with the output end of the low-position conveying belt in a matched manner, and the high-position end of the lifting machine is connected with the input end of the high-position conveying belt in a matched manner; and the printing paper stack dividing and conveying device is characterized in that a stack forking, holding and transverse movement mechanism and a stack dividing mechanism are arranged between the lifting machine and the high-position conveying belt. After paper stacks rise along with the lifting machine to be in place, the paper stack on the uppermost part is jacked open through the stack dividing mechanism to be separated from the paper stack on the lower portion, the stack forking, holding and transverse movement mechanism is inserted into a gap between the separated paper stacks, holds the corresponding separated paper stack and transversely moves the paper stack to the high-position conveying belt so as to feed the paper stack to a printing machine for completing cutter plate adhesion removing, meanwhile, the stack forking, holding and transverse movement mechanism and the stack dividing mechanism backwards move, separation, holding and movement of the next small paper stack are continuously completed, finally the large paper stack is divided into multiple small paper stacks to be conveyed out, paper and machine damage caused by paper stack collapse is avoided, and the printing machine can continuously run efficiently.

Owner:KUNMING COLOR PRINTING

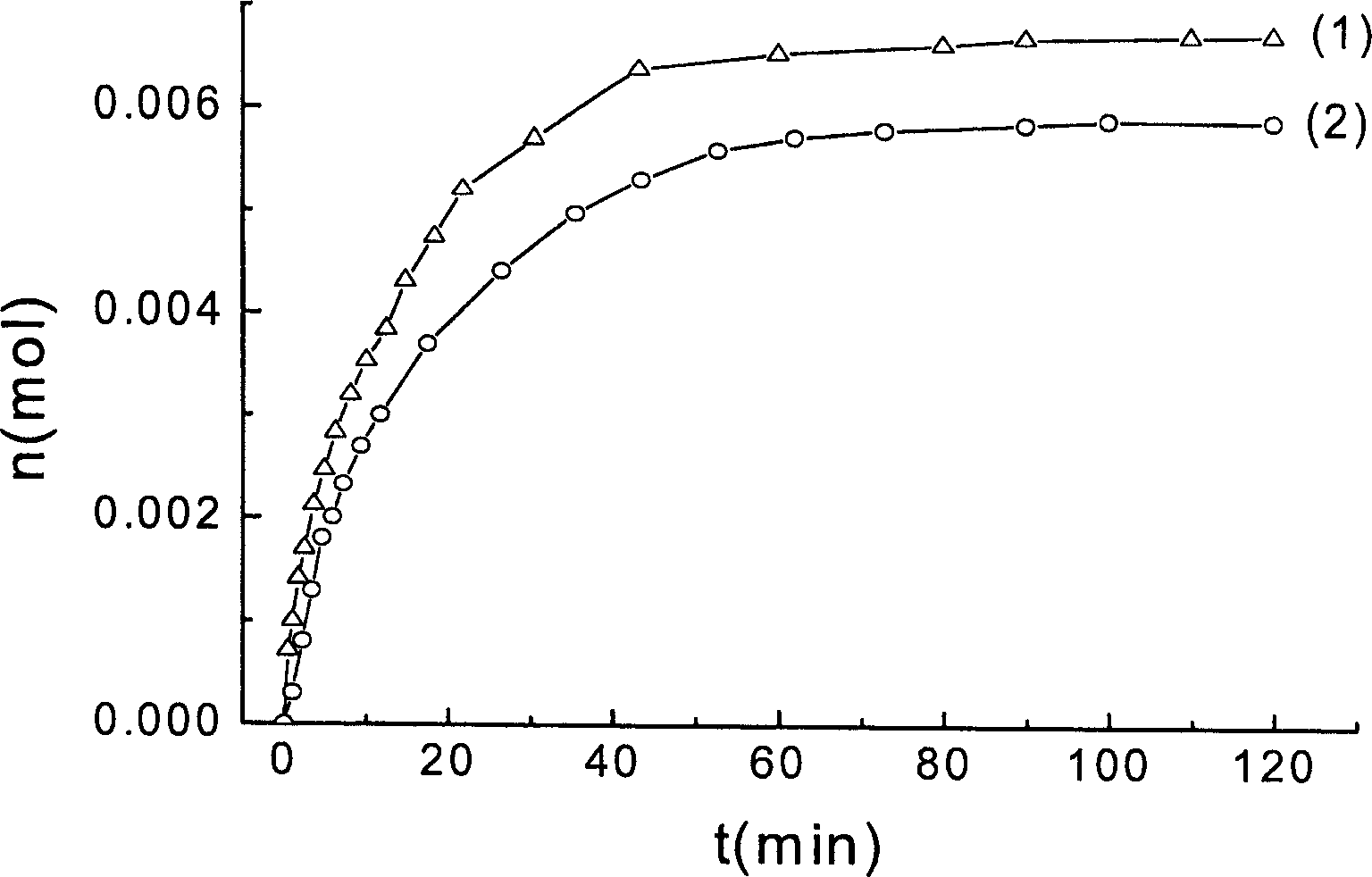

Method for generating aqua compound

InactiveCN1814714AUniform and stable dispersionWon't clogRefining by water treatmentGaseous mixture working upProduct gasHydrocarbon

This invention relates to a method for generating hydrates, in which, gas or a mixture of gas generates hydrates in a water / oil emulsification system, said water / oil emulsification system is formed by adding hydrocarbon liquid and hydrates inhibitor into water. This method increases the generation speed of hydrates and enables them to flow out of the reactor and enters into the dissolver smoothly via pipeline during the process of separating gas mixtures

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

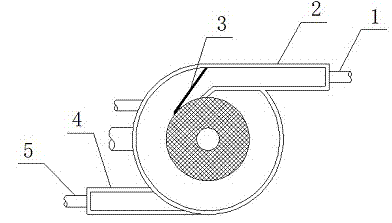

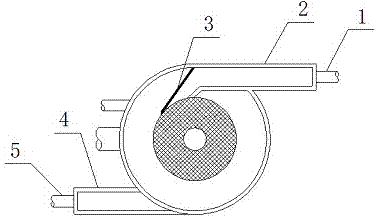

Differential rotary type cleaning device and belt cleaner as well as method thereof

The invention discloses a differential rotary type cleaning device and a belt cleaner as well as a method thereof, and belongs to the field of mineral aggregate belt cleaning equipment. The differential rotary type cleaning device comprises two pairs of roller mechanisms, wherein each pair of roller mechanisms comprises a pressing wheel assembly and a scrapping wheel assembly which are oppositelyarranged on a non-working surface side and a working surface side of a conveyor belt of the belt conveyor; each pressing wheel assembly comprises a pressing wheel, and each scraping wheel assembly comprises a scraping wheel, wherein the pressing wheel and / or scraping wheel can press the conveyor belt through a pressing mechanism; and two scraping wheels of two pairs of roller mechanisms are connected in a differential mode. According to the differential rotary type cleaning device disclosed by the invention, mineral aggregates with relatively great viscosity on the working surface of the conveyor belt can be cleared by two scraping wheels with rotation speed difference, two scraping wheels are driven by the conveyor belt, and extra power is not needed; and moreover, master-slave relation is variable, the scraped-off mineral aggregates can be rotatably thrown out along with the scraping wheels and do not deposit, clearing ability is relatively strong on the mineral aggregates with relatively great viscosity, efficiency is high and abrasion is small.

Owner:马鞍山市方正机械制造有限责任公司

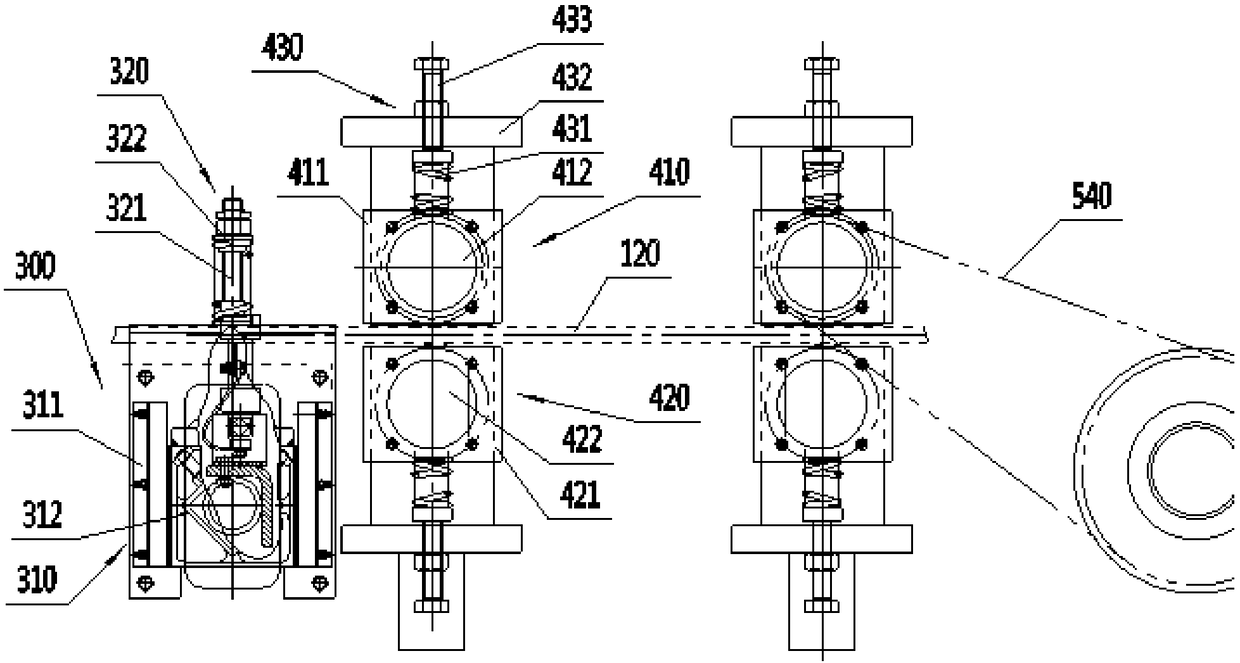

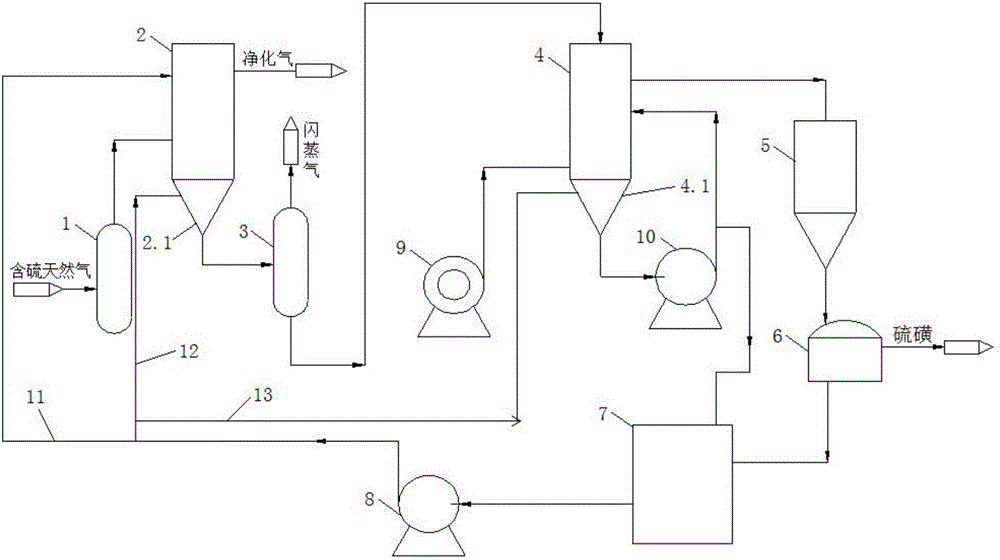

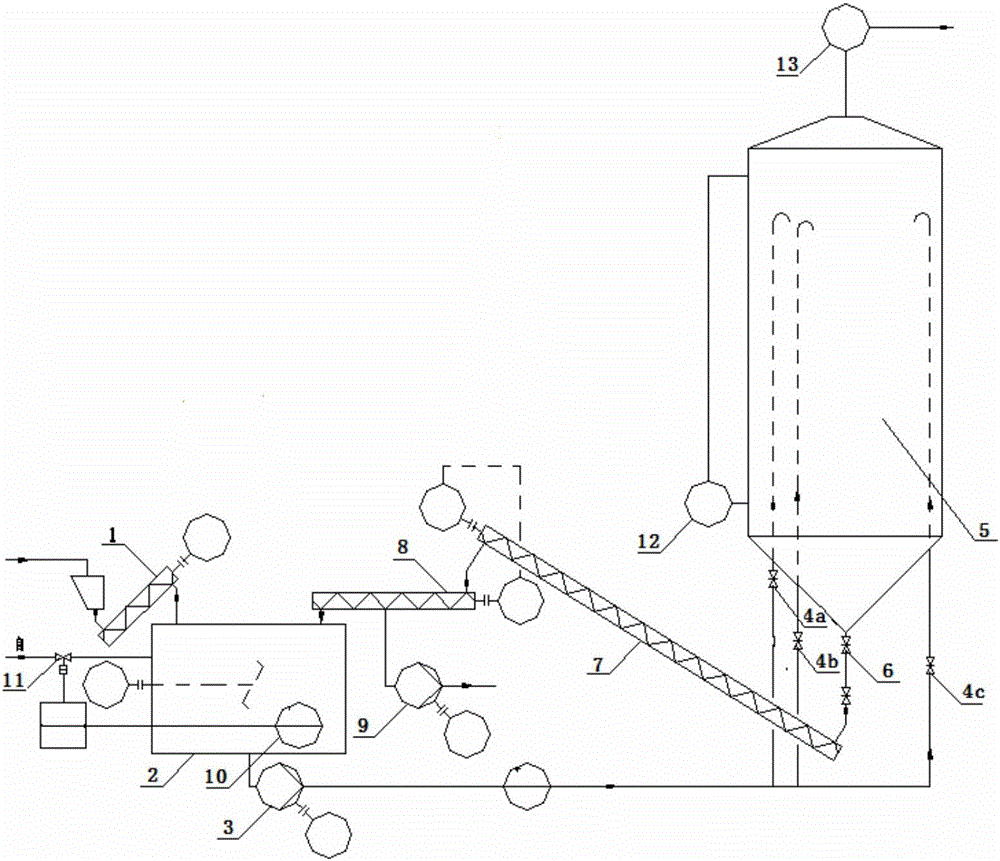

Sulfur blockage preventing system based on wet redox desulfurization process

ActiveCN105879606APrevent adhesion and precipitationEnsure continuous and efficient operationDispersed particle separationSulfurOxidation-Reduction Agent

The invention discloses a sulfur blockage preventing system based on a wet redox desulfurization process. The sulfur blockage preventing system comprises a separator, an absorption tower, a flash tank, a regeneration tower, a circulating pump, an air blower, a centrifuge, a barren liquor tank and a sulphur foam trough. The separator is connected with a gas inlet of the absorption tower, a rich liquor outlet of the absorption tower is connected with a feeding port of the flash tank, and a discharging port of the flash tank is connected with a feeding port of the regeneration tower; a barren liquor outlet of the regeneration tower is connected with the barren liquor tank, and the barren liquor tank is connected with a barren liquor inlet of the absorption tower through a first pipeline; the top of the regeneration tower is communicated with an inlet of the sulphur foam trough, and an outlet of the sulphur foam trough is communicated with a feeding port of the centrifuge; a washing liquid inlet is formed in the absorption tower, the desulfurization system further comprises a second pipeline, an inlet of the second pipeline is communicated with the first pipeline, and an outlet of the second pipeline is communicated with the washing liquid inlet in the absorption tower. According to the sulfur blockage preventing system, washing pipelines are installed at the bottoms of the absorption tower and the regeneration tower respectively to wash the absorption tower and the regeneration tower regularly, so that sulphur particles are preventing from adhering to or settling on the walls of the absorption tower and the regeneration tower.

Owner:SINOPEC ENERGY & ENVIRONMENTAL ENG CO LTD

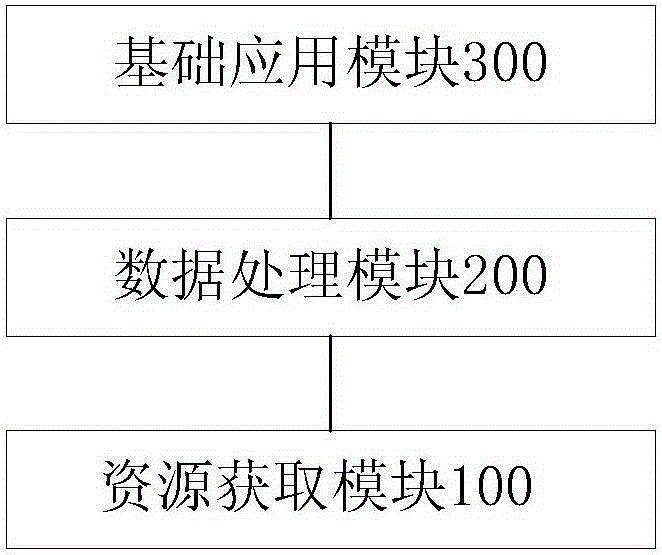

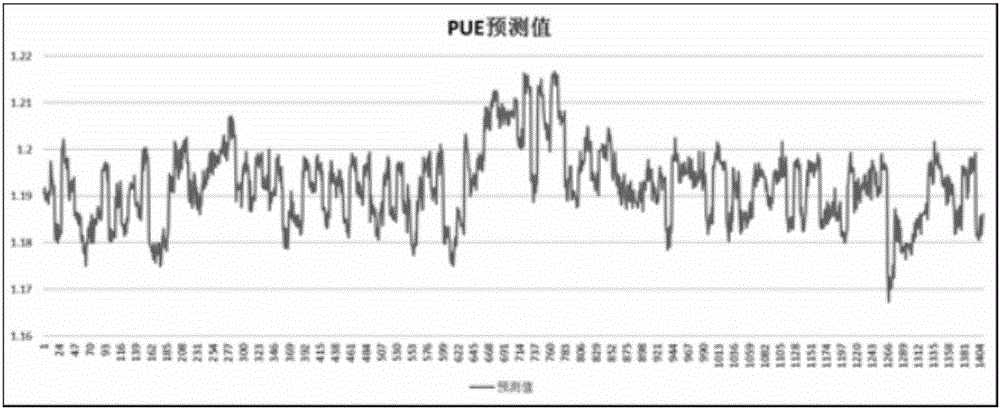

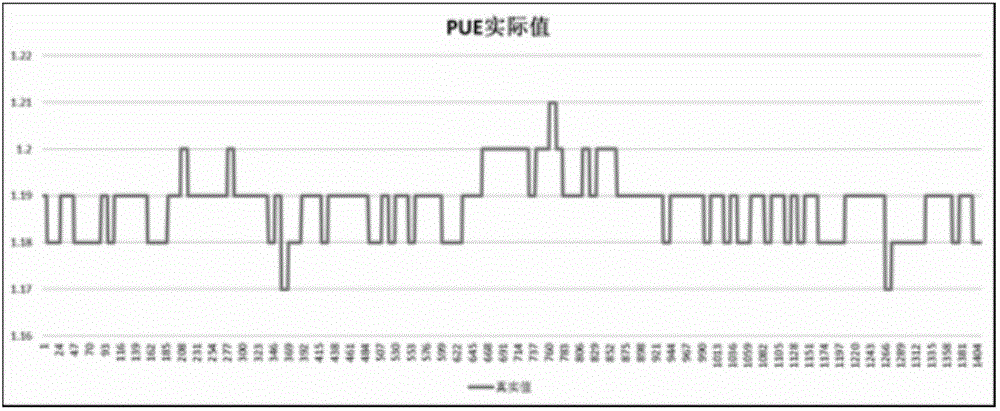

Data center operation data analysis system based on machine learning

InactiveCN105204978AEnsure continuous and efficient operationRun energy savingHardware monitoringData centerData analysis system

The invention discloses a data center operation data analysis system based on machine learning. The system comprises a resource acquisition module, a data processing module and a basic application module, wherein the resource acquisition module is used for collecting PUE-related data of a data center and sending the PUE-related data to the data processing module; the data processing module is used for receiving the PUE-related data, conducting processing on the PUE-related data, conducting data standardization on the PUE-related data, establishing a prediction model according to PUE-related data obtained after the data standardization and updating the prediction model according to the historical PUE-related data; the basic application module is used for receiving an input PUE target value, obtaining PUE-related data corresponding to the PUE target value according to the prediction model, or obtaining current PUE-related data and predicting out PUE-related data corresponding to a next moment according to the prediction model.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

A continuous salt difference power generation device and method

ActiveCN112713808BImprove concentration efficiencyLower resistanceKinetic-electric generatorReversed electrodialysisSalt solution

The invention relates to a continuous salt difference power generation device, which includes a dilution device, a reverse electrodialyzer, a forward osmosis device, a concentrated salt liquid tank and a light salt liquid tank; the concentrated salt liquid tank contains the concentrated salt liquid, and the light salt liquid tank contains Light salt solution, the concentration of the concentrated salt solution is greater than that of the light salt solution; the reverse electrodialyzer is provided with a cathode and an anode, and between the cathode and the anode are alternately arranged cation exchange membranes and anion exchange membranes and alternately distributed concentrated solution chambers and Dilute liquid chamber; a potential difference is formed between the cathode and anode of the reverse electrodialyzer; the concentrated salt solution circulates between the concentrated liquid chamber of the reverse electrodialyzer and the concentrated salt liquid tank, and the light salt solution is circulated in the reverse electrodialyzer Circulation between the light liquid chamber and the light salt liquid tank, the dilution device provides diluent to maintain the light salt solution at a low concentration, the forward osmosis device provides concentration to maintain the concentrated salt solution at a high concentration, and concentrates part of the light salt solution Used to replenish concentrated brine. The device of the invention can utilize the salt concentration difference to realize cycle continuous power generation, and has the characteristics of high power generation efficiency.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

Efficient passive spent fuel pool cooling system adopting jet technology

ActiveCN107578828APrevent leakageEnsure safetyNuclear energy generationCooling arrangementNuclear engineeringWater storage tank

The invention provides an efficient passive spent fuel pool cooling system adopting a jet technology, and belongs to the field of nuclear power plant safety. The system comprises a jet subsystem, a heat exchanger inlet pipe section, a water space heat exchanger, a gas space heat exchanger, a heat exchanger outlet pipe section, a chimney and related pipeline values. When the temperature of a spentfuel pool is higher than a warning value, the system puts into operation automatically, air outside a fuel plant is injected through high pressure gas ejected by a high pressure gas storage tank in the jet subsystem, or water inside a water storage tank and air outside the fuel plant are injected at the same time, and powerful driving force is provided for a cooling loop while the total quantity of a cooling fluid is increased. When the water or gas inside the subsystem in the jet subsystem is used up, the system still can form passive natural circulation in virtue of the density difference ofair in cold and hot sections, and long-term cooling is carried out on the spent fuel pool, so that effectively passive cooling of the spent fuel pool in 3 to 6 days or even longer time can be guaranteed in accident conditions and when an external power supply is lost.

Owner:HARBIN ENG UNIV

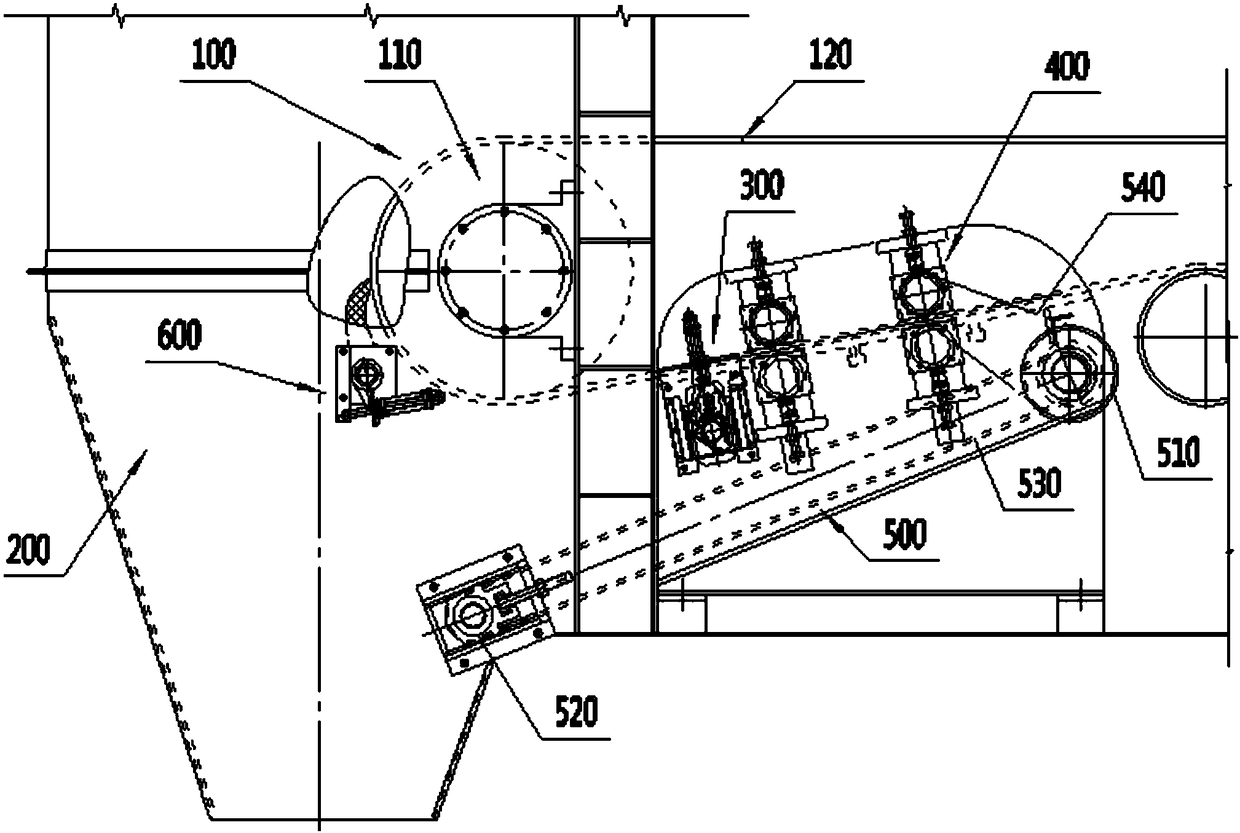

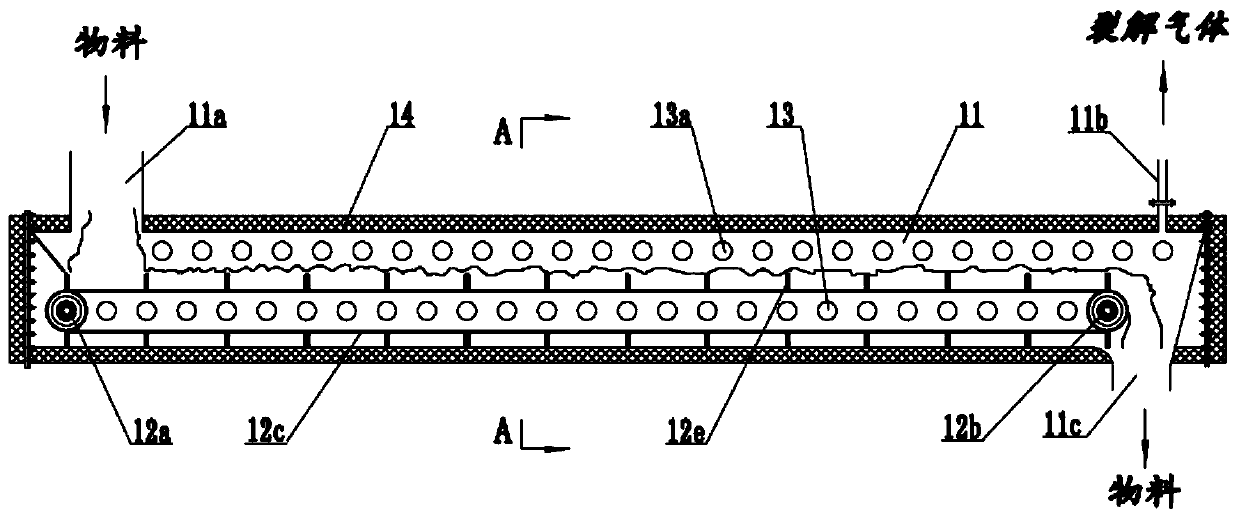

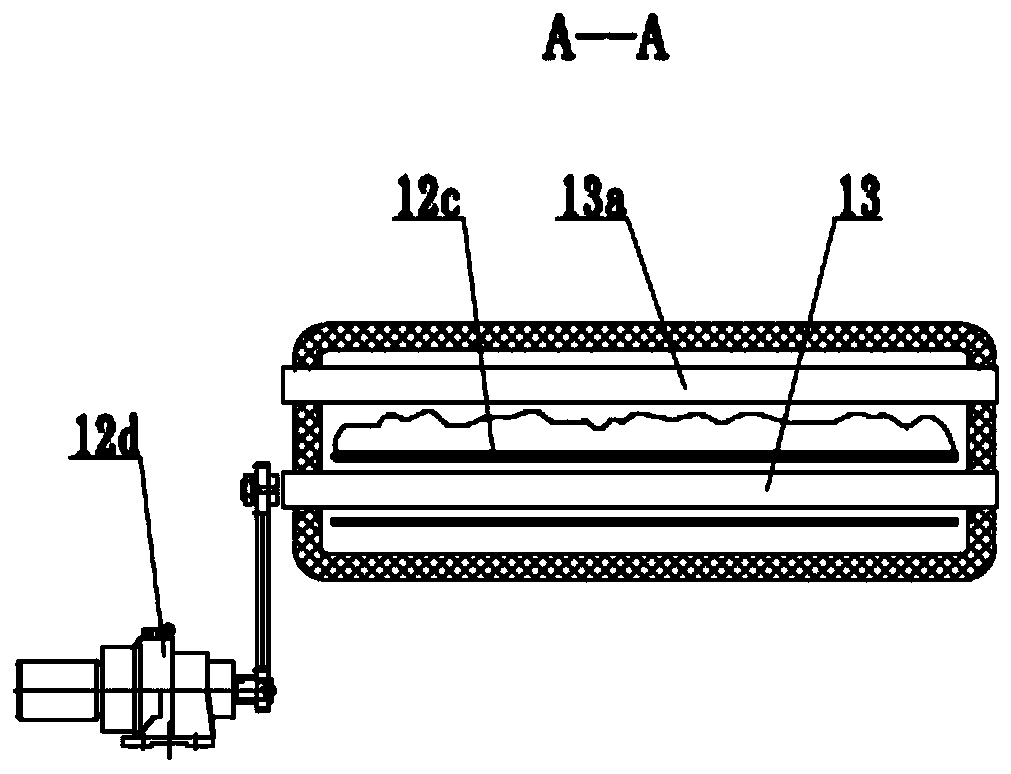

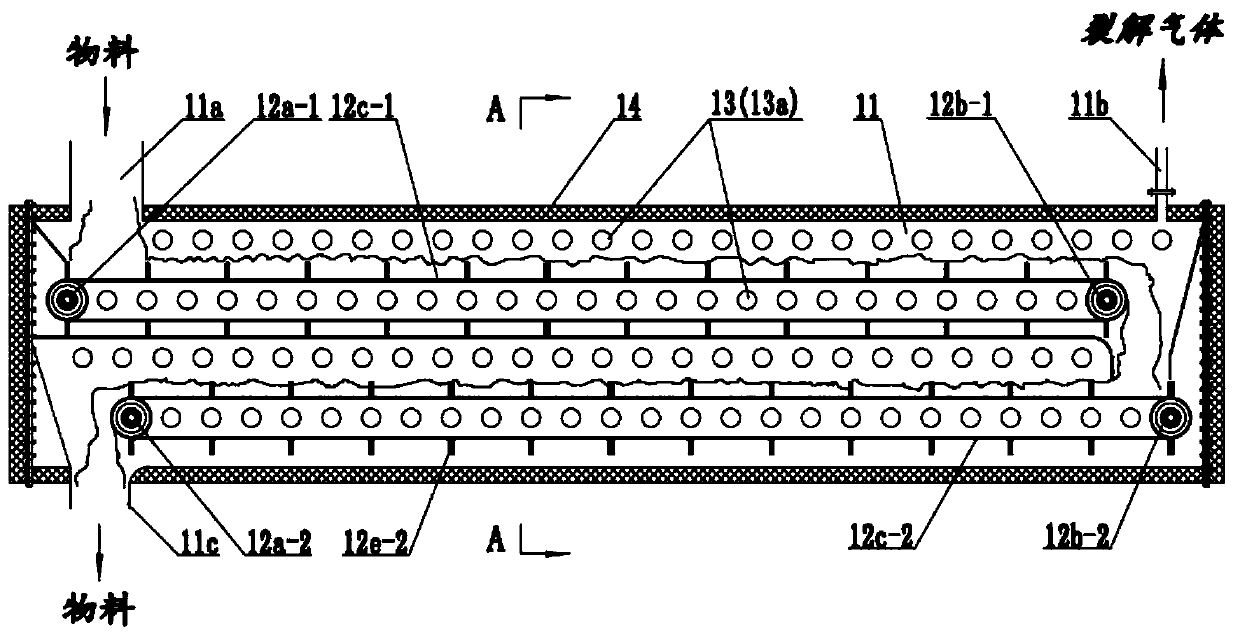

Material treatment device and material treatment system

PendingCN109824228AImprove cracking performanceGuarantee the predetermined temperatureSludge treatment by pyrolysisElectric heatingSprocket

The invention relates to a material treatment device for oil sludge cracking and a material treatment system for oil sludge treatment. The material treatment device comprises a shell, a conveying mechanism and a heating device. The shell comprises an upper wall with a feeding port and an exhaust port and a lower wall with a discharging port. The conveying mechanism comprises a driving chain wheel,a driven chain wheel and a conveying belt engaged with the driving chain wheel and the driven chain wheel, and the conveying belt is configured to receive and convey materials to be treated. The heating device comprises multiple electric heating tubes. The electric heating tubes are evenly arranged in parallel to the conveying belt at preset intervals, the feeding port corresponds to the feedingend of the conveying mechanism, and the discharging port corresponds to the discharging end of the conveying mechanism.

Owner:SHAN DONG HI LINK ELECTRICITY

Online self-cleaning medium filtering device

ActiveCN111228866ALong runEnsure continuous and efficient operationTreatment involving filtrationMultistage water/sewage treatmentAutomatic controlProcess engineering

The invention discloses an online self-cleaning medium filtering device. The online self-cleaning medium filtering device comprises a water inlet pipe, a backwashing one-way valve, a water inlet one-way valve, a shell, a shell filtering material, an inner cylinder body, an inner cylinder body filtering material, a lower screen plate, a water distributor, a control valve, a backwashing water collecting chamber, a water outlet collecting chamber, a backwashing pump, a water outlet pipe, a blow-off pipe, an upper screen plate and an electric control system. The method is characterized in that a plurality of filtering spaces which work independently are arranged in the shell; each filtering space can work independently or simultaneously as required; when a certain filtering space needs to be self-cleaned, the backwashing pump is started, a filtering liquid is pumped, backwashing is performed on the filtering materials in the filtering space, backwashing water generated by the backwashing is distributed to other filtering spaces to be filtered, and suspended solids are intercepted at the lower part of the inner cylinder body and need to be discharged regularly. And all the filtering spaces can be self-cleaned through automatic control, so that online self-cleaning of the medium filtering device can be realized, and no cleaning wastewater is generated and discharged. The online self-cleaning medium filtering device can be used for updating the existing medium filter, the use efficiency of the medium filter can be improved, a large amount of backwashing wastewater is saved, and the investment is reduced.

Owner:北京奥博水处理有限责任公司

Material discharge device for vertical furnace

InactiveCN102925614ARealize continuous dischargeEnsure continuous and efficient operationShaft furnaceEngineeringGate valve

The invention discloses a material discharge device for a vertical furnace, comprising a material blanking pipe, a gate valve, a rotating material discharge valve, an upper sealing valve, a discharged material tank, a material flow regulating valve and a lower sealing valve. The material discharge pipe is provided with at least two material dividing pipes; the gate valve is arranged at the inlet of the material discharge pipe or the outlets of the material dividing pipes; the rotating material discharge valve is arranged on the material dividing pipes and below the gate valve; the upper sealing valve is connected with the outlet of the rotating material discharge valve or the outlets of the material dividing pipes; the discharged material tank is connected with the outlet of the upper sealing valve; the material flow regulating valve is connected with the outlet of the discharged material tank; the lower sealing valve is connected with the outlet of the material flow regulating valve; and the discharged material tank is provided with a uniform pressure discharge interface. Due to the alternative work of equipment on the material flow paths of the material dividing pipes, the furnace material can be discharged continuously, and the vertical furnace can work continuously and efficiently. As the discharged material tank is provided with the uniform pressure discharge interface, the vertical furnace can discharge materials smoothly under pressure or normal pressure, and the material discharge device can work reliably and stably. The equipment in the material discharge device adopts the module design and can be repaired independently, so that the repair time is saved, and the maintenance cost is reduced.

Owner:CISDI ENG CO LTD

Variable temperature heat source driving efficient adsorption refrigeration system and refrigeration method

ActiveCN103075836AEfficient outputEnsure continuous and efficient operationEnergy efficient heating/coolingClimate change adaptationFluid controlAdsorption refrigeration

The invention relates to a variable temperature heat source driving efficient adsorption refrigeration system and a refrigeration method and belongs to the technical field of a refrigeration air conditioner. The system is filled with gas adsorption media and comprises a reactor, a heat source, a fluid control valve, a gas regulation valve, an evaporator and a condenser, wherein a heating and / or cooling pipeline is arranged inside the reactor and is connected with the heat source through the fluid control valve, the reactor is connected with the evaporator and the condenser through the gas regulation valve, and solid adsorbing agents are filled in the reactor. The refrigeration system and the refrigeration method have the advantages that the performance of the adsorption refrigeration system can be obviously improved, and in addition, the continuous refrigeration can be realized under the condition of driving heat source temperature changes.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

Control method and control system of utilizing high-concentration organic raw material for biogas fermentation

InactiveCN105039604AAchieve the purpose of stirringEnsure continuous and efficient operationBioreactor/fermenter combinationsBiological substance pretreatmentsHigh concentrationControl system

The invention belongs to the technical field of renewable energy source development and environment protection, and particularly relates to a control method and a control system of utilizing a high-concentration organic raw material for biogas fermentation. The control method includes that the material enters a stirring temperature rise adjusting tank through a first feeding device, a thermocouple in the stirring temperature rise adjusting tank heats the inside of the same and sends a temperature signal to a PLC (programmable logic controller) of a system, and the PLC controls temperature in the tank to meet a set value according to the signal which is sent; the material after being treated by the stirring temperature rise adjusting tank enters a vertical anaerobic fermentation tank through three discharging valves, and the PLC controls the discharging valves to be on alternately for 2-5min. Fermentation circulating of the high-concentration raw material in the biogas system is realized through the PLC to achieve the objective of stirring the fermentation raw material, potential, of the fermentation raw material, in producing biogas is developed fully, and continuous and efficient running of the high-concentration raw material biogas fermentation system is realized.

Owner:辽宁省能源研究所有限公司

Automatic detection equipment for battery cover plate

ActiveCN113716149AImprove alignment accuracyImprove space utilizationWrapping material feeding apparatusMeasurement devicesProduction lineElectrical battery

The invention discloses automatic detection equipment for a battery cover plate. The automatic detection equipment comprises an automatic feeding device, an automatic discharging device and a rotary circulation conveying line, wherein a feeding station, an electric detection station set, an anti-explosion valve puncturing station, a first film pasting station, a second film pasting station, a flatness detection station and a discharging station are sequentially arranged on the circulation path of the rotary circulation conveying line. According to the equipment, the automatic operation of more abundant detection stations can be provided, the space utilization rate can be greatly improved through the rotary circulation conveying line, meanwhile, the alignment precision of each station is improved, and the operation process is efficient and stable. The requirement for butt joint matching with a front-end automatic production line is met, a buffer stroke is provided, production line speed allocation of automatic production is facilitated, and meanwhile, the design that a feeding circulation conveyor belt is parallel to the rotary circulation conveying line is more compact. The anti-reversing, accurate positioning and code scanning detection design of the feeding end is adopted, so that the pre-detection and carrying precision requirements are met, and the overall detection operation is smoother and more efficient. Efficient and continuous operation can be maintained.

Owner:苏州明益信智能设备有限公司

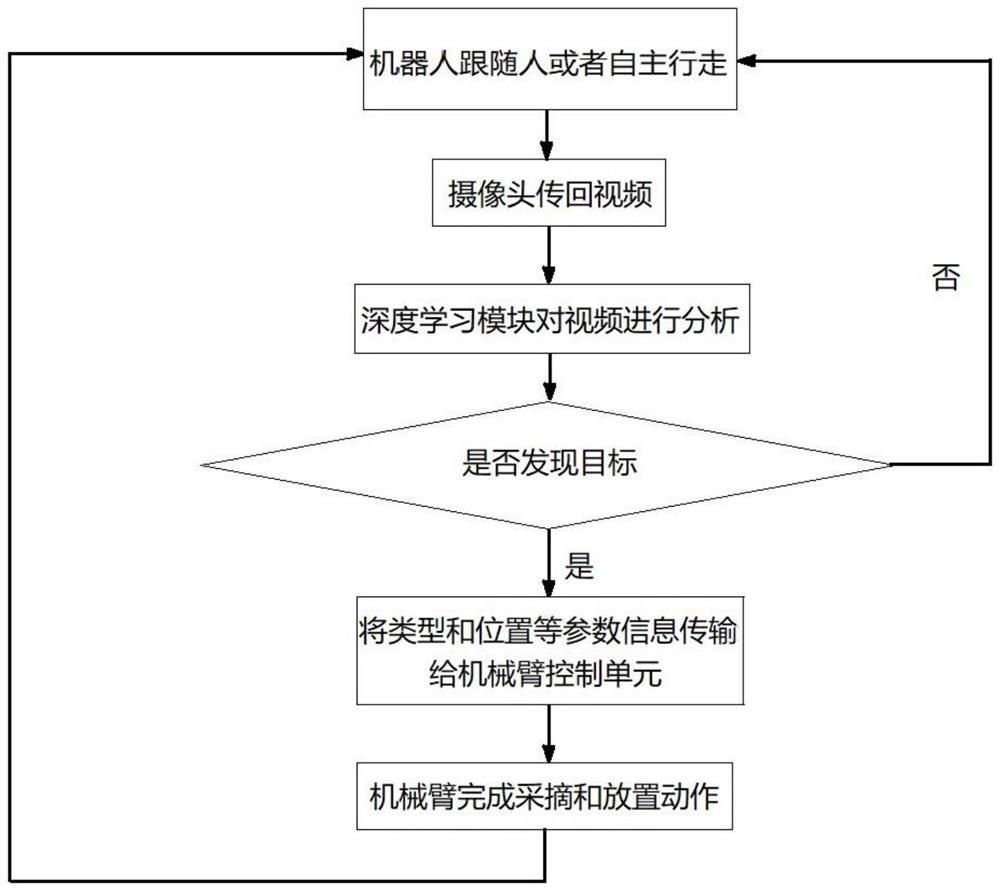

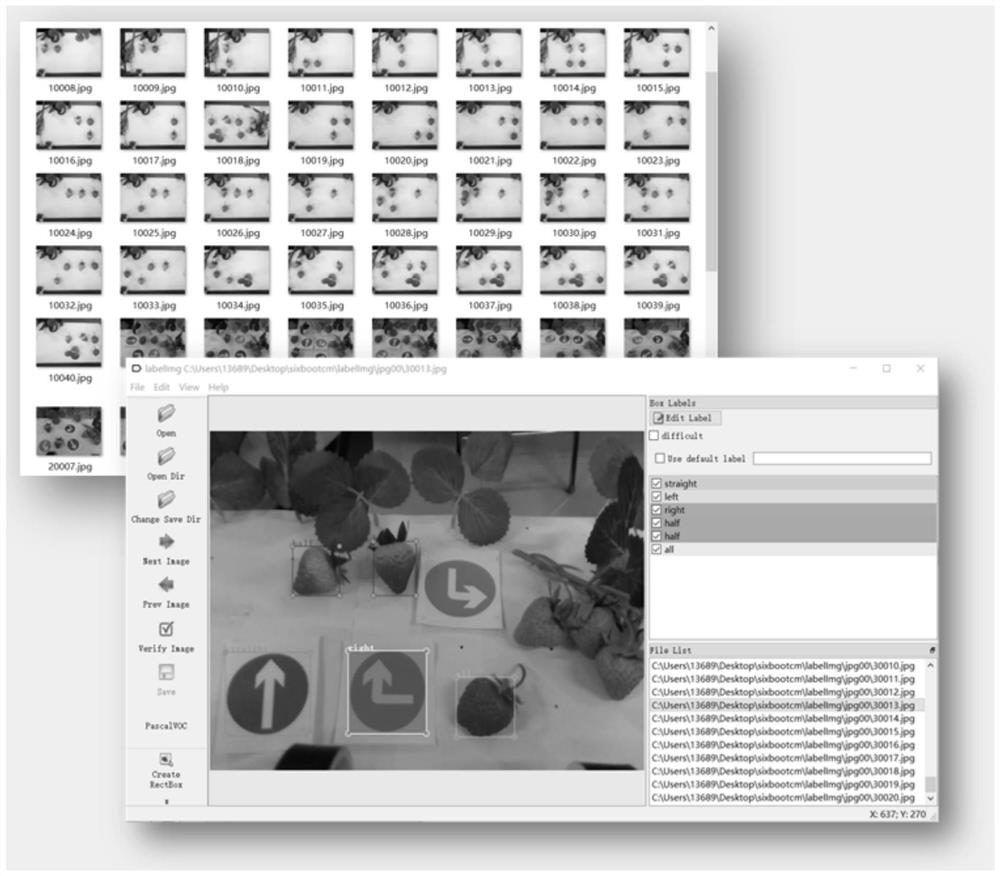

Agricultural picked object recognition algorithm based on database

PendingCN114429310AReduce lossImprove sales product qualityDatabase management systemsOffice automationFragariaAgricultural engineering

The invention belongs to the technical field of image recognition, and particularly relates to an agricultural picked object recognition algorithm based on a database, which is characterized in that a computer sets a maturity index according to a plurality of indexes such as colors, sizes and wrinkles of fruits to be picked and characteristics associated with maturity height, and establishes a model for the maturity degree and storage time of the fruits; the computer carries out artificial intelligence recognition on fruit pictures collected by the picking robot and transmits fruit types and coordinate information to a motion control unit of the picking robot, and finally grabbing, sorting and obstacle-avoiding walking are achieved. Compared with the prior art, the method has the beneficial effects that the maturity of strawberries can be divided into multiple grades according to market requirements, the maturity of picked strawberries with long storage time or long transportation distance is slightly lower, so that the distance of mailing and selling areas can be selected according to the maturity, the loss of the strawberries in transportation is reduced, and the economic benefit is increased. Sales areas are expanded, and economic benefits are improved.

Owner:UNIV OF SCI & TECH LIAONING

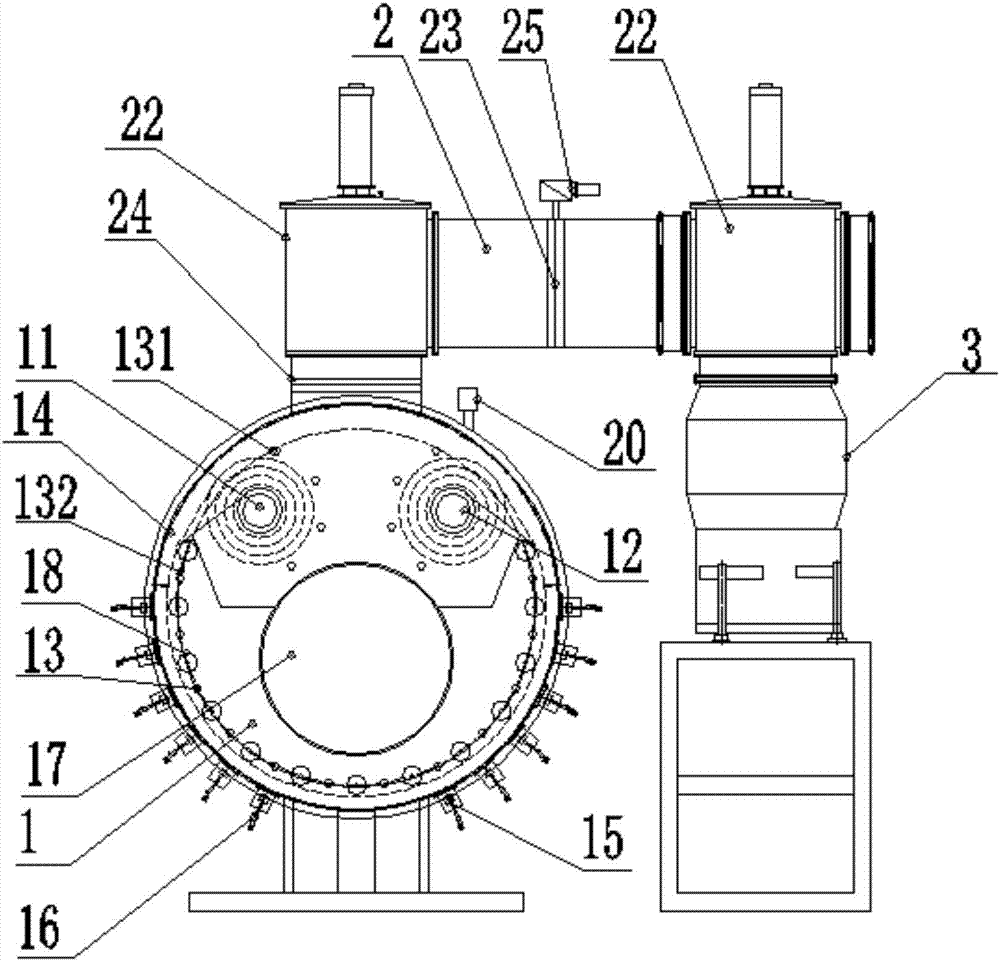

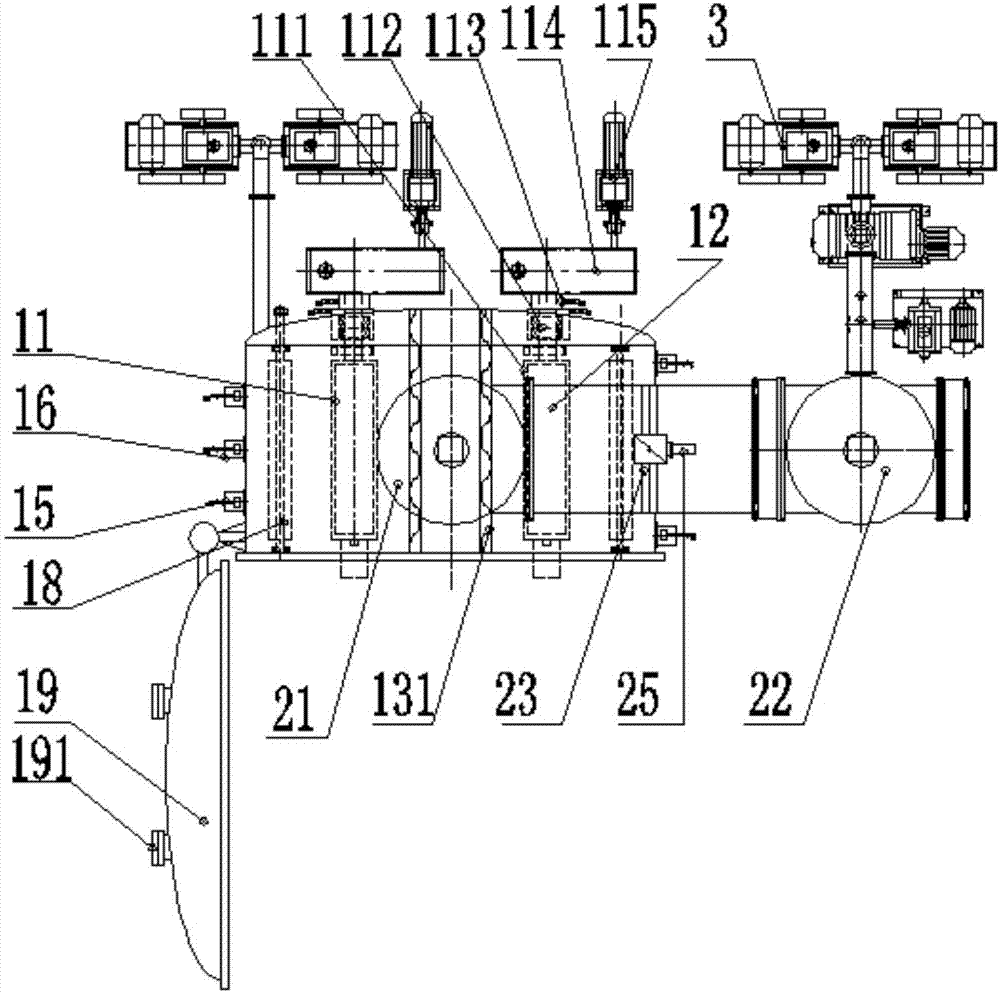

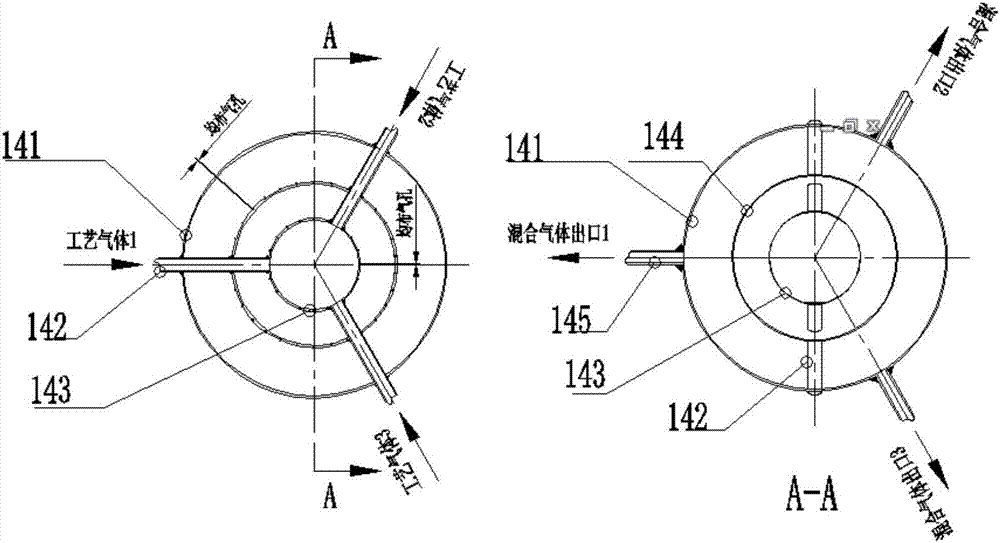

Strip vacuum plasma film-plating system

ActiveCN106917070ASimple structureEasy to makeVacuum evaporation coatingSputtering coatingEngineeringAutomation

The invention discloses a strip vacuum plasma film-plating system. A vacuum obtaining system is connected to multiple continuous type film-plating chambers through a vacuum connection pipeline. Each continuous type film-plating chamber comprises an unreeling device, a reeling device, and a heating tube mechanism, which are arranged in the continuous type film-plating chamber, and also comprises an inlet air and outlet air mixing device and a filter cathode target generation device, which are arranged on the lateral wall of the continuous type film-plating chamber. A first valve and a second valve are arranged on the vacuum connection pipeline. The first valve is arranged in the outlet of the vacuum obtaining system. The second valve is arranged above the joint between the vacuum connection pipe and the continuous type film-plating chambers. The design of the provided strip vacuum plasma film-plating system is scientific and reasonable. The operation is stable, the deviation is avoided, the automation degree is improved, at the same time, the product quality is largely improved, the production efficiency is improved, and more economic benefits are generated.

Owner:广州市中昊装饰材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com