Caramel condensed milk and preparation method and application thereof

A technology of condensed milk and caramel, which is applied in the field of condensed caramel milk and its preparation, and can solve problems such as not involving condensed caramel milk and lack of production technology for condensed caramel milk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

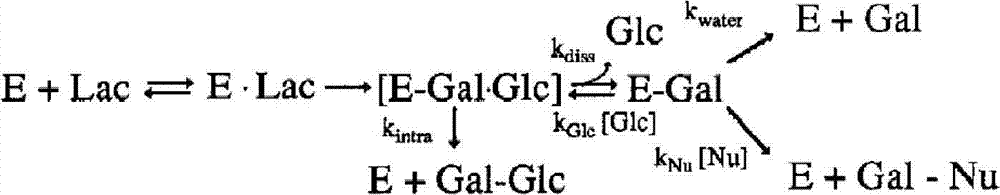

Method used

Image

Examples

Embodiment 1

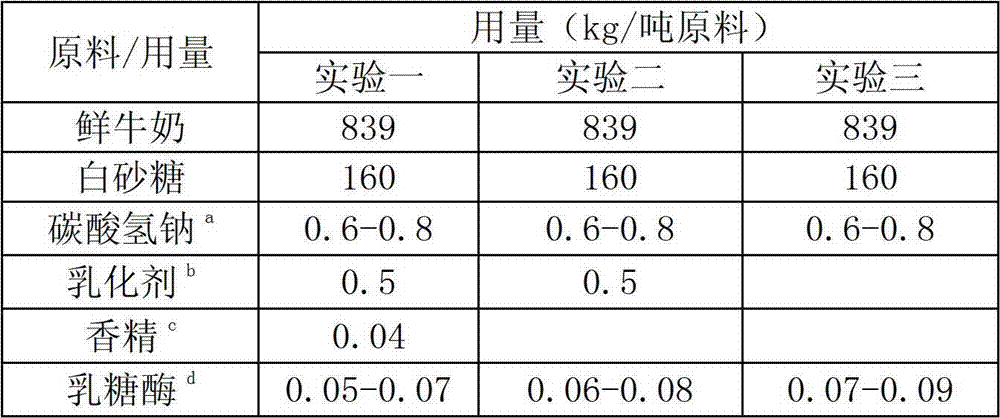

[0275] Example 1: Production of caramelized condensed milk with fresh milk as the main raw material and its application in pastry making

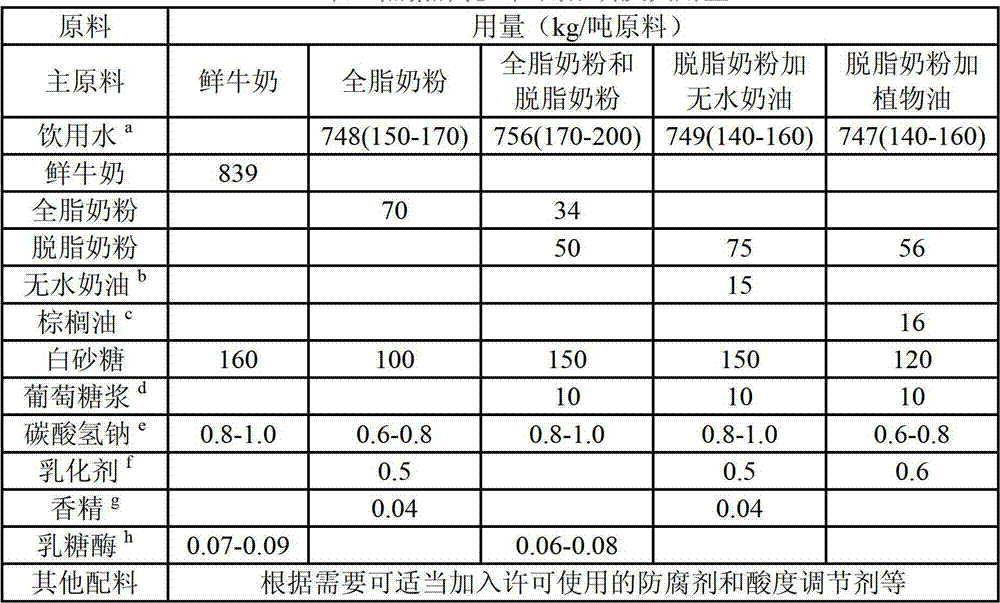

[0276] 1. Raw materials for production and their dosage

[0277] Fresh milk 839kg, white sugar 160kg, sodium bicarbonate 0.8-1.0kg, lactase 0.07-0.09kg.

[0278] 2. Production method and process technical parameters

[0279] The fresh milk is cooled and centrifuged to remove somatic cells, some bacteria and impurities, inspected and set aside. Fresh milk requirements: protein ≥ 3.2%; fat ≥ 3.0%; non-fat milk solids ≥ 8.1%; somatic cells < 400,000 / ml; total number of bacteria < 100,000 CFU / ml; -0.518°C; acidity 14-17°T; pH 6.55-6.75.

[0280] Take 1 / 4 fresh milk and pour it into a high-pressure stirring cooking pot, add lactase, react at room temperature for 50-60 minutes at a stirring speed of 50-60 rpm / min, add white sugar and sodium bicarbonate to dissolve and mix at a stirring speed of 50-60 rpm / min Evenly, heat to 95-105°C and boil,...

Embodiment 2

[0285] Example 2: Production and Application of Caramel Condensed Milk Using Whole Milk Powder as Main Raw Material to Brew Coffee and Black Tea

[0286] 1. Raw materials for production

[0287] Drinking water 140-160kg, whole milk powder 100kg, white sugar 100kg, sodium bicarbonate 0.8-1.0kg, emulsifier (model E-471) 0.5kg, essence (model 108318) 0.04kg.

[0288] 2. Production method and process technical parameters

[0289] Heat water to 45-55°C, add whole milk powder and mix evenly to make concentrated milk. Take concentrated milk and pour it into a high-pressure stirring cooking pot, add white sugar and sodium bicarbonate to dissolve and mix evenly at a stirring speed of 50-60rpm / min, heat to 95-105°C to boil, and continue boiling to carry out Maillard reaction and evaporate water until the sugar content When the system temperature reaches 68.5-69.5Brix, stop heating. When the system temperature reaches 50-60°C, add emulsifier to dissolve and mix evenly under stirring at...

Embodiment 3

[0294] Embodiment 3: Production and application of caramelized condensed milk with whole milk powder plus skimmed milk powder main raw material

[0295] 1. Raw materials for production

[0296] Drinking water 170-200kg, whole milk powder 34kg, skimmed milk powder 50kg, white sugar 150kg, glucose syrup (brix 42-44Brix) 10kg, sodium bicarbonate 0.8-1.0kg, lactase 0.04-0.06kg.

[0297] 2. Production method and process technical parameters

[0298] Heat the water to 45-55°C, add whole milk powder and skimmed milk powder and mix evenly to make concentrated milk. Take the concentrated milk and pour it into the high-pressure stirring cooking pot, add lactase, and carry out the decomposition reaction at room temperature at a stirring speed of 50-60rpm / min for 50-60 minutes, stir the decomposition reaction and add white sugar and glucose syrup to dissolve and mix evenly, and stir at 50-60rpm Add sodium bicarbonate to dissolve and mix evenly, heat to 95-105°C to boil, continue to boil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total number of bacteria | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com