Sulfur blockage preventing system based on wet redox desulfurization process

A desulfurization process and wet oxidation technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as affecting the safe operation of equipment, sulfur recovery, and sulfur blockage, etc., to ensure continuous and efficient operation, The effect of shortening the residence time and reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

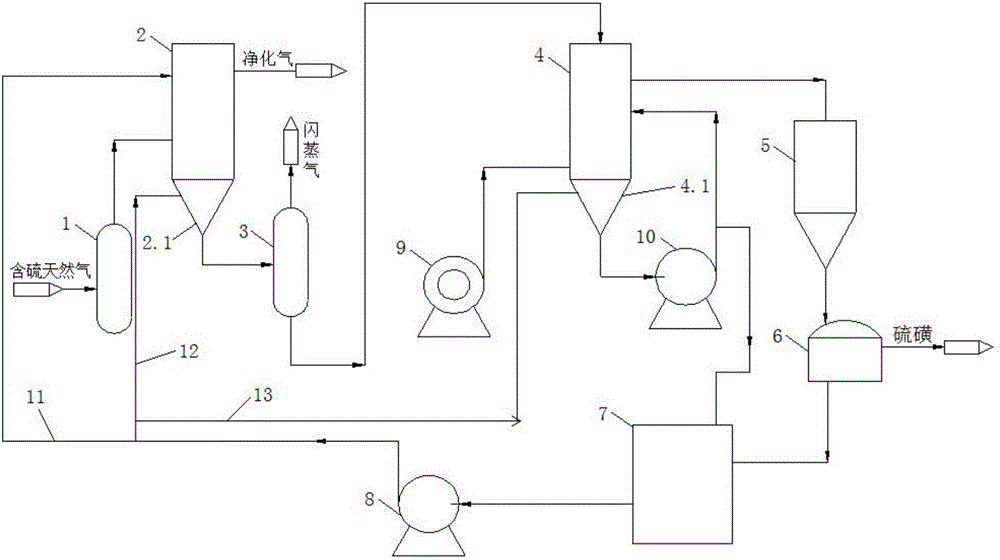

[0018] Such as figure 1 An anti-sulfur plugging system based on wet redox desulfurization process is shown, including separator 1, absorption tower 2, flash tank 3, regeneration tower 4, circulation pump 8, blower 9, centrifuge 6, and lean liquid tank 7 and the sulfur foam tank 5, the inlet of the separator 1 is connected with the sulfur-containing natural gas pipeline, the outlet of the separator 2 is connected with the inlet of the absorption tower 2, and the gas outlet of the absorption tower 2 is connected with the external purified gas pipeline, and the absorption tower The rich liquid outlet of flash tank 2 is connected to the feed port of flash tank 3, and the gas outlet of flash tank 3 is connected to the flash steam pipeline; the discharge port of flash tank 3 is connected to the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com