Patents

Literature

101results about How to "Achieve the purpose of stirring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

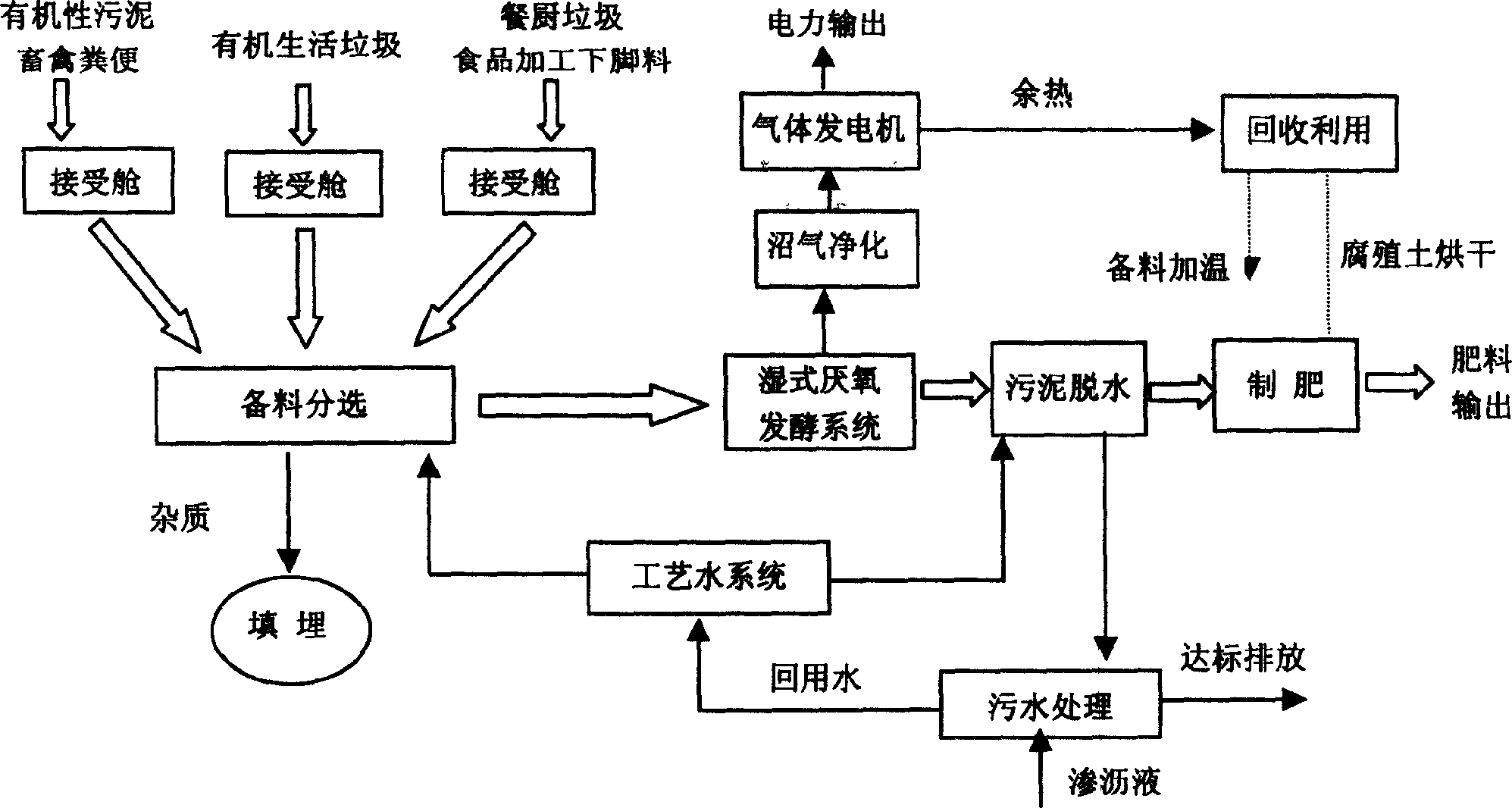

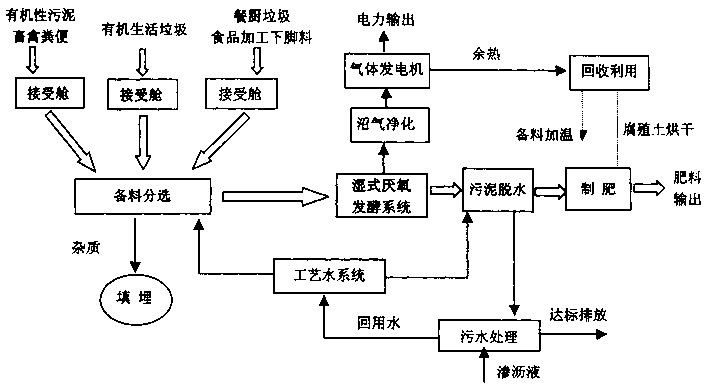

Resources comprehensive treatment technology for organic waste material

InactiveCN1478611AChange the status quo that is difficult to deal with effectivelyAdjustable temperatureBio-organic fraction processingSolid waste disposalMarshElectricity

A process for reclaiming the organic waste includes such steps as mixing it with hot water, pulverizing, removing impurities to obtain a suspended substance at 36-37 deg.C, wet-type anaerobic fermenting for 15-20 days to obtain humus and marsh gas, using humus to prepare fertilizer, and using marsh to generate electricity.

Owner:SHANGHAI SHENGONG ENVIRONMENTAL PROTECTION CO LTD

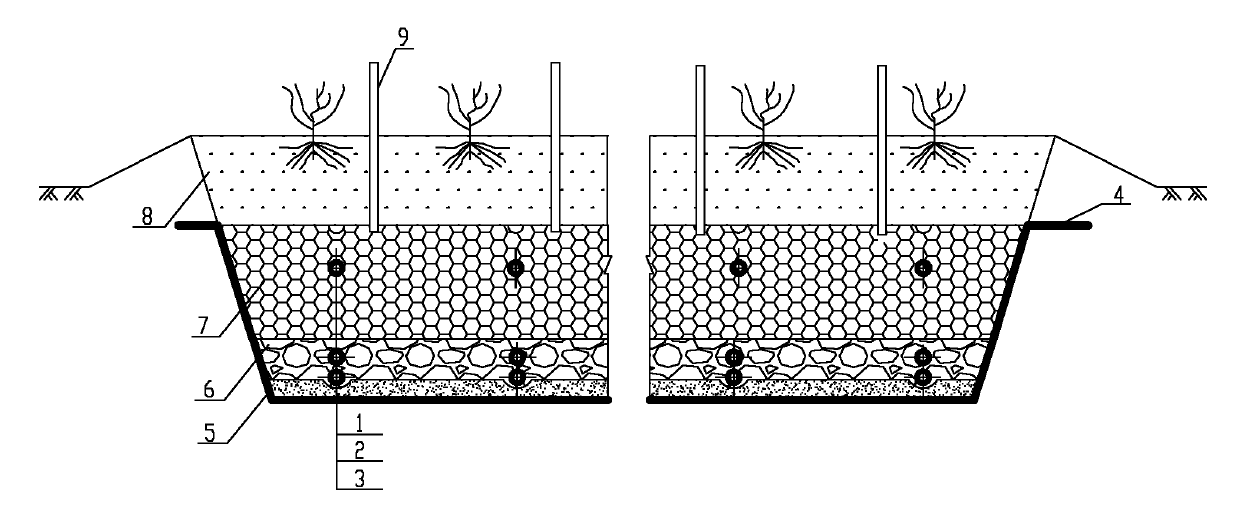

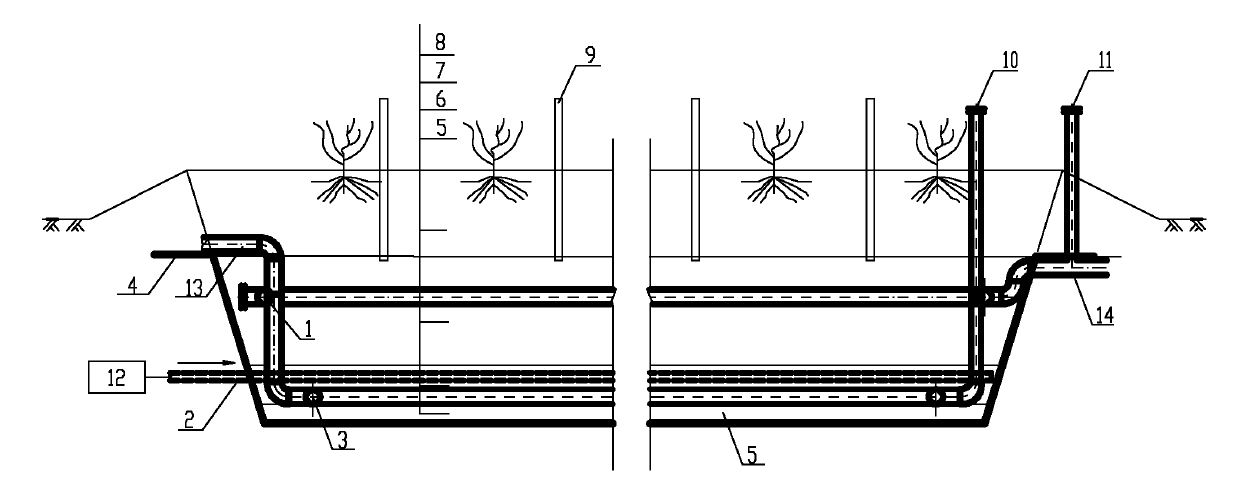

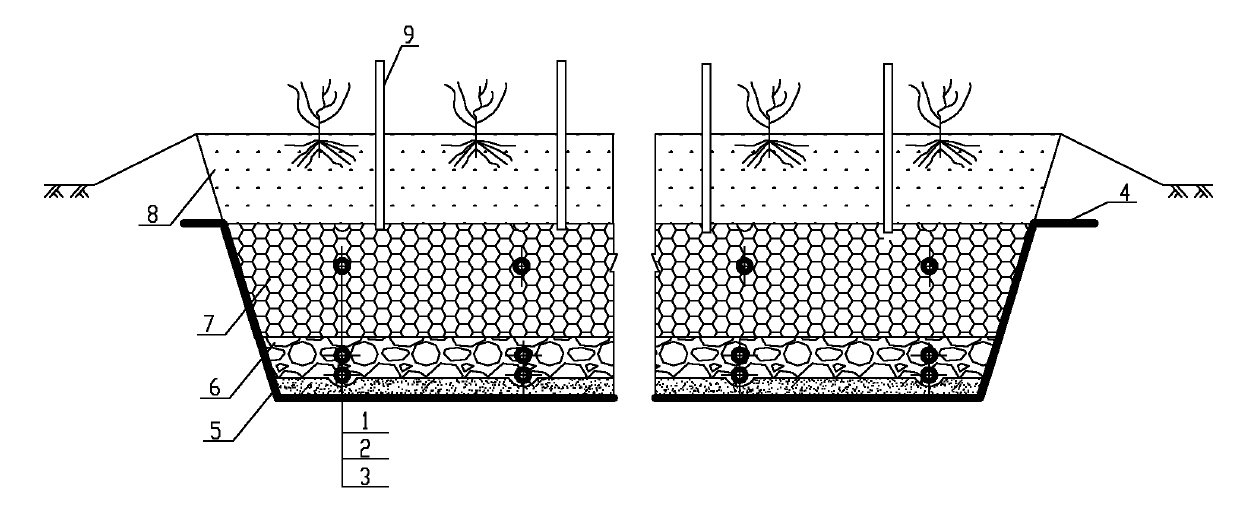

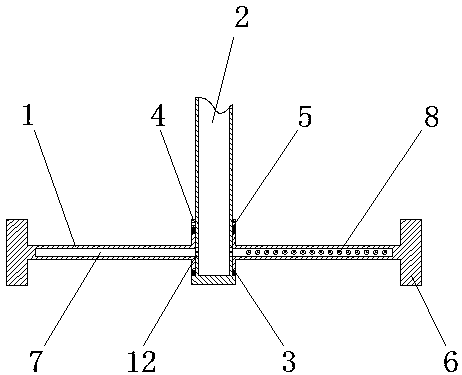

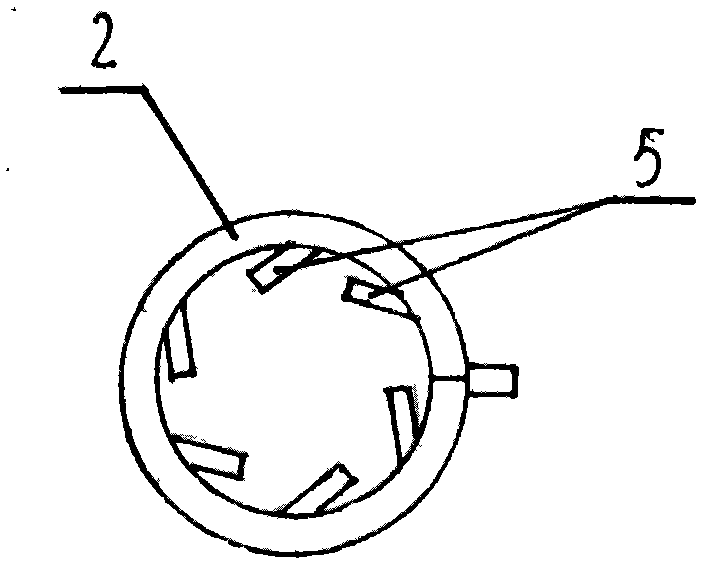

Sewage aerobic land treatment system

ActiveCN102001743ARelieve blockageRealize the function of removing ammonia nitrogenTreatment using aerobic processesEnergy based wastewater treatmentAeration systemPipeflow

The invention discloses a sewage aerobic land treatment system. The system comprises a groove body formed by digging under the ground, wherein impermeable membranes are laid at the periphery and at the bottom of the groove body; and a sand layer, a water distribution layer, a packing and water collecting layer and a soil layer are formed in turn from bottom to top. The sewage aerobic land treatment system is characterized by also comprising a blast aeration system consisting of a blast blower, an air diffusion device and a connecting pipeline, wherein the air diffusion device is positioned below the water surface of the land treatment system and connected with the blast blower through a pipeline; pretreated sewage enters the land treatment system; and air is pressurized by the blast blower and diffused into sewage of the system in the form of small air bubbles through the air diffusion device. Therefore, the aims of charging oxygen into the sewage and stirring are fulfilled, good reoxygenation effect, high mass transfer efficiency, quick bio-membrane updating and high treatment efficiency are achieved, and the problem of blockage of the land treatment system in the operating process is solved effectively.

Owner:QINGDAO LIGONG NEW ENVIRONMENTAL TECH DEV

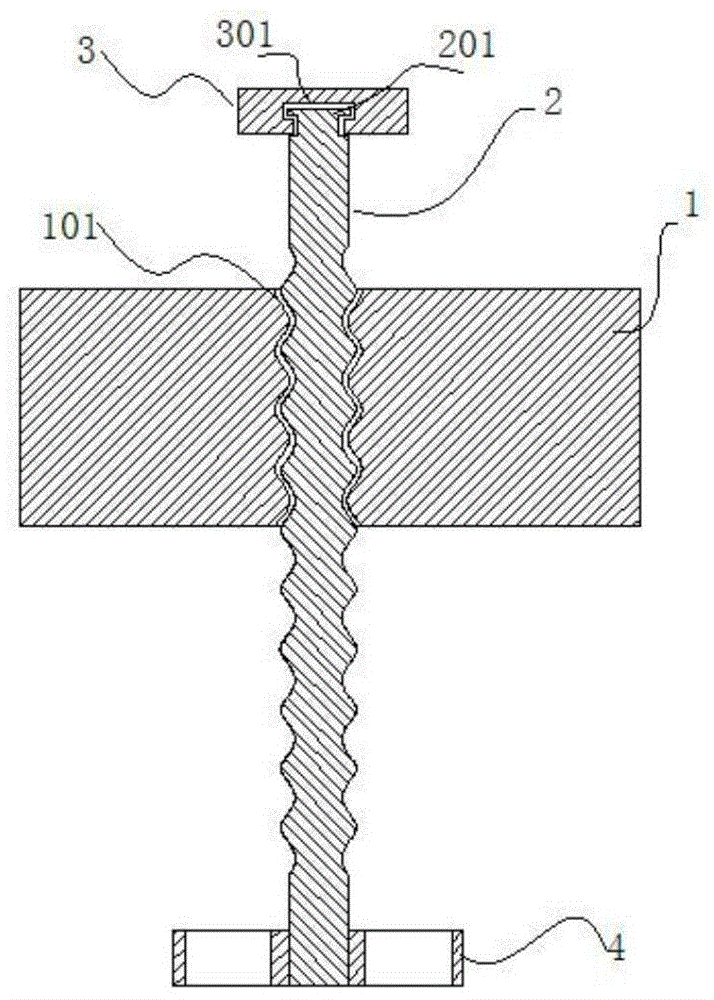

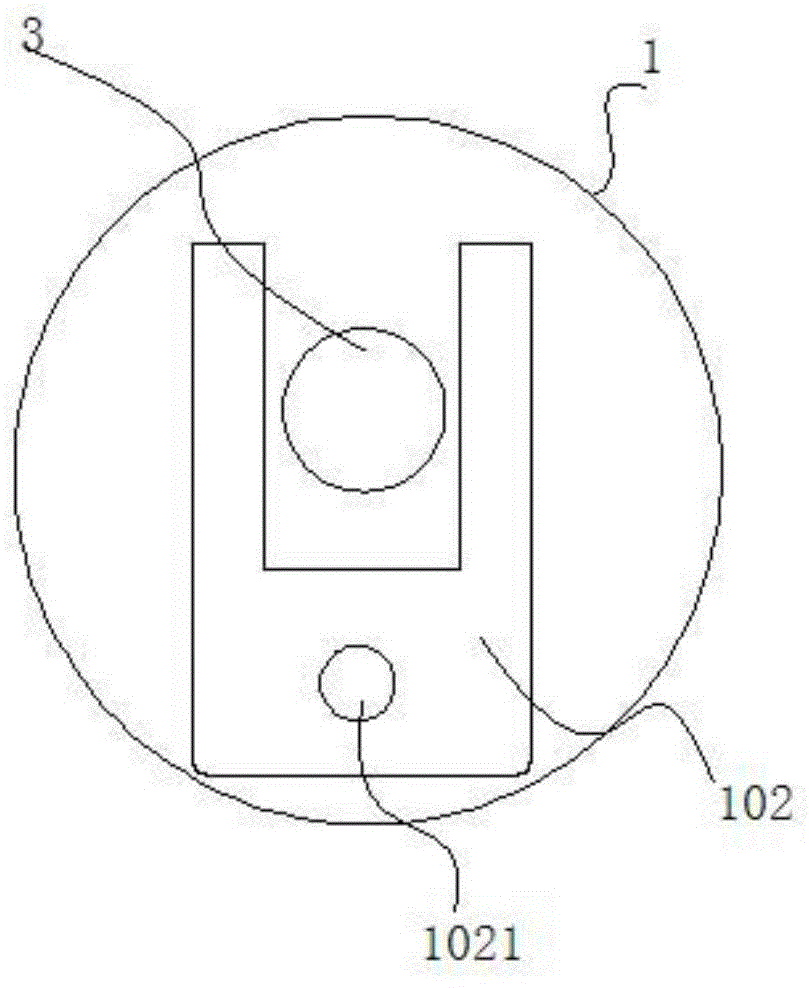

Spiral lifting stirrer, cup lid and cup

InactiveCN105455686AAchieve the purpose of stirringStir wellKitchen equipmentDrinking vesselsEngineeringAgitator

Owner:SICHUAN JIUDINGZHIYUAN INTPROP OPERATIONS CO LTD

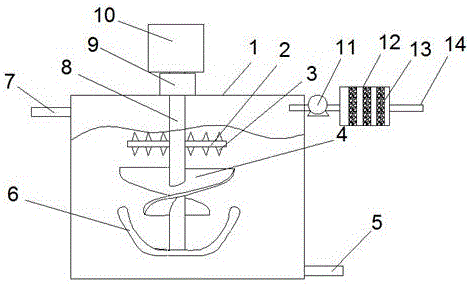

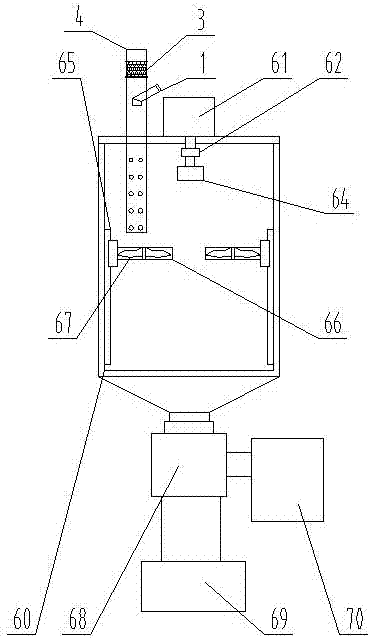

Stirring machine for producing cleaning agent

InactiveCN108636168AAvoid Stirring Dead AnglePerformance impactRotary stirring mixersTransportation and packagingPistonMotor drive

The invention provides a stirring machine for producing a cleaning agent and relates to the field of stirring equipment. The stirring machine for producing the cleaning agent comprises a stirring box,wherein a bearing plate is inserted into the bottom of the stirring box; supporting legs are fixedly mounted at four corners of the bottom of the bearing plate; a valve is communicated with the bottom of the stirring box; baffle plates are fixedly mounted at two sides of the stirring box and are located in the bearing plate; sleeves are fixedly mounted at the bottom of an inner wall of the bearing plate; pistons are arranged in the sleeves. According to the stirring machine for producing the cleaning agent, a first motor drives stirring blades to rotate and the aim of stirring is realized; asecond motor drives a gear to rotate so that a transverse rod shakes leftward and rightward; meanwhile, a rotary rod drives a box body to rotate, and liquid at the bottom of the stirring box is stirred so that the uniform stirring effect is realized; a condition that the bottom of the stirring machine is not sufficiently stirred is avoided and conditions that a stirring dead angle is formed and the utilization performance of the cleaning agent is influenced are avoided.

Owner:新昌县盛南建材有限公司

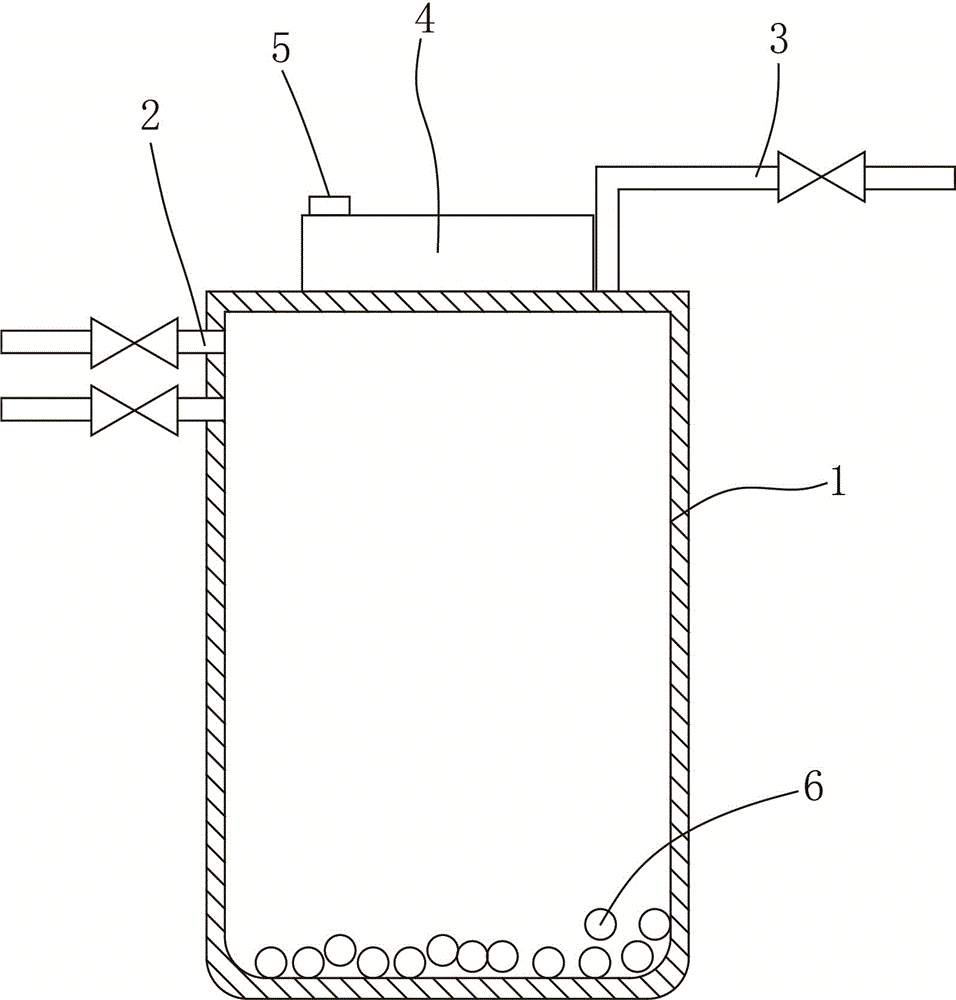

Unordered stirring reaction kettle

A disclosed unordered stirring reaction kettle comprises a reaction kettle shell, the shell is connected with multiple liquid inlet pipes and an air exhaust pipe, electromagnet is arranged on the shell and is connected with a control switch, and the shell is inside provided with multiple steel balls. According to the structure, when stirring is needed in the reaction kettle, steel balls in the shell can continuously rise and descend by turning on and turning off the control switch, so that stirring purpose is realized. The structure does not enable a stirring device to generate gaps, one piece of electromagnet is usable for multiple reaction kettles, and cost is low. Also because the motion of steels balls is unordered, the disclosed unordered stirring reaction kettle has better stirring effect compared with a conventional stirring device.

Owner:NINGBO YUANOU FINE CHEM

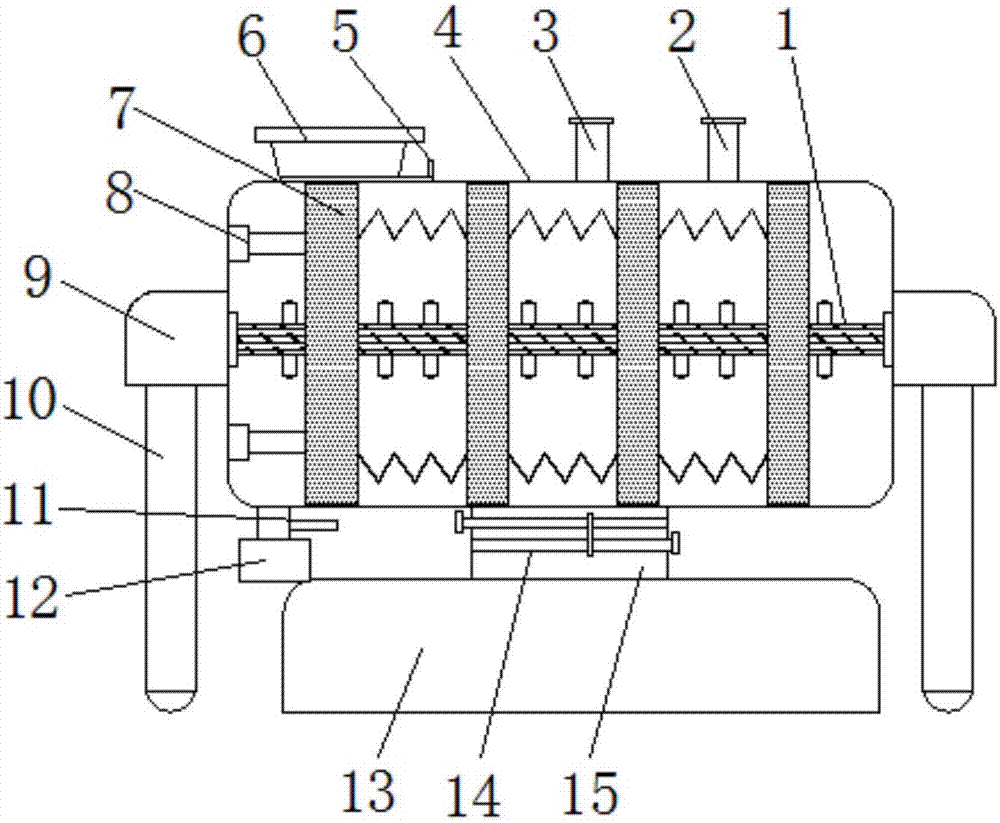

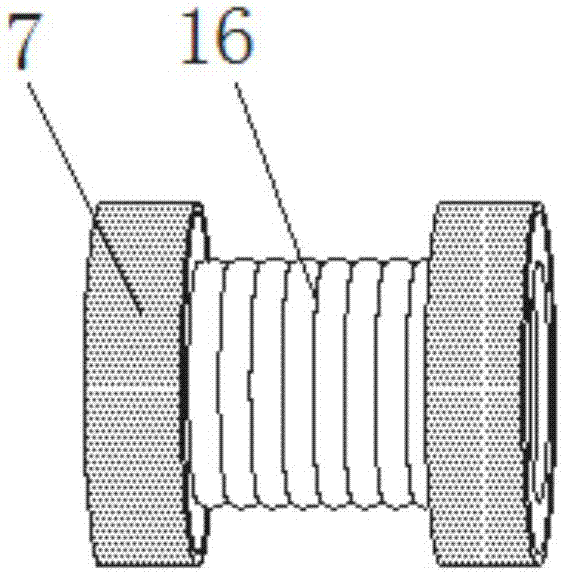

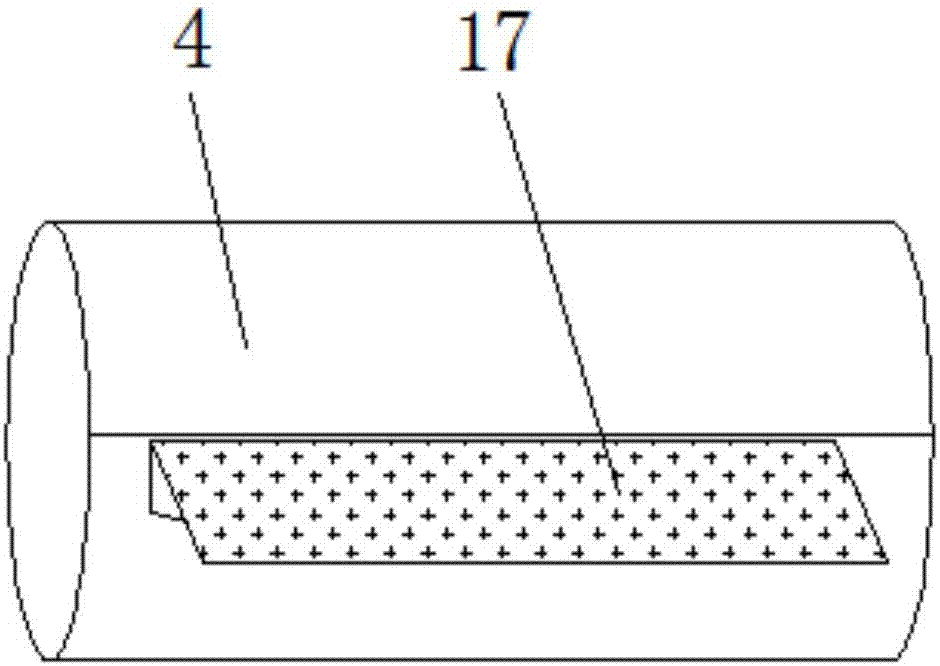

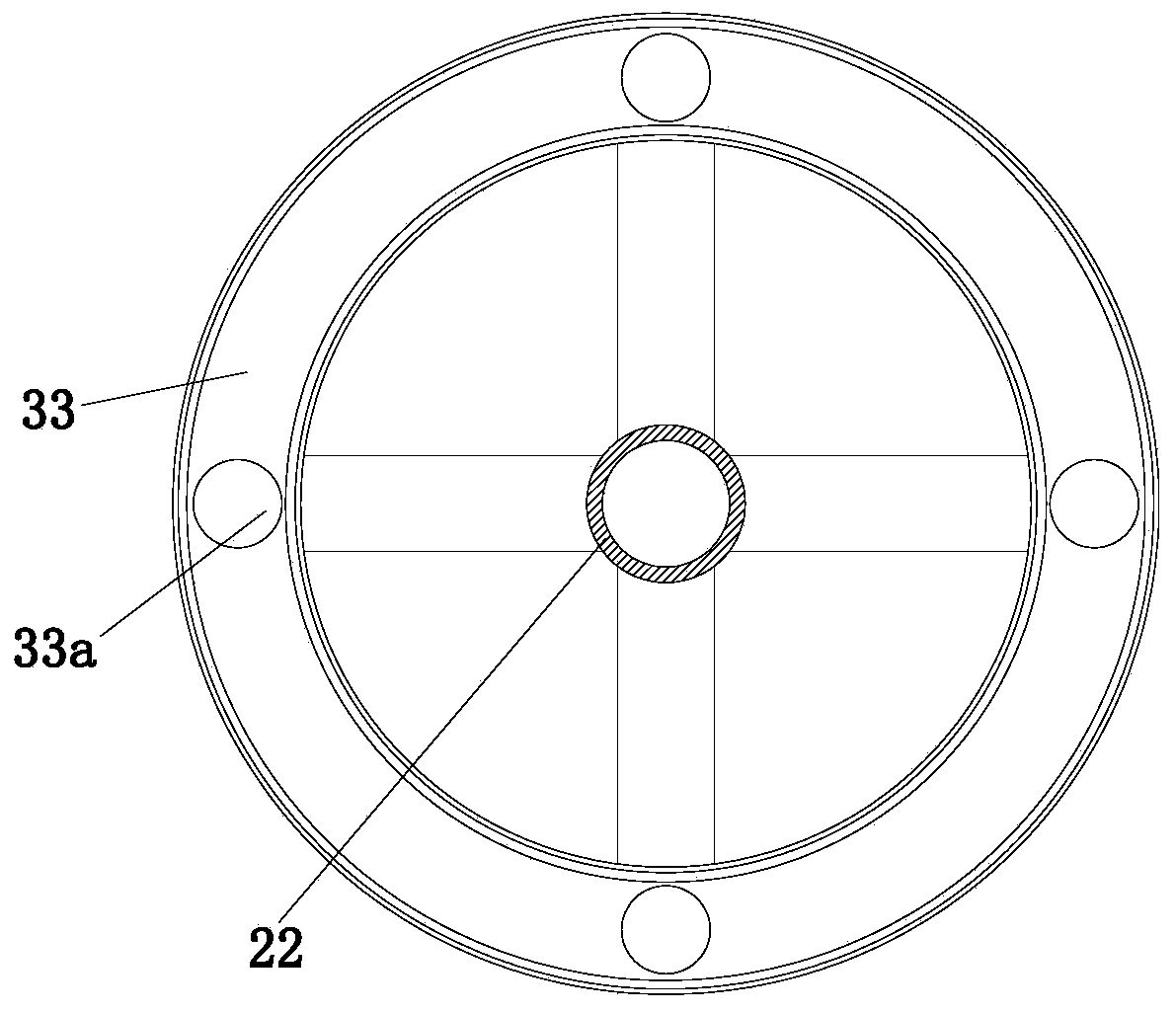

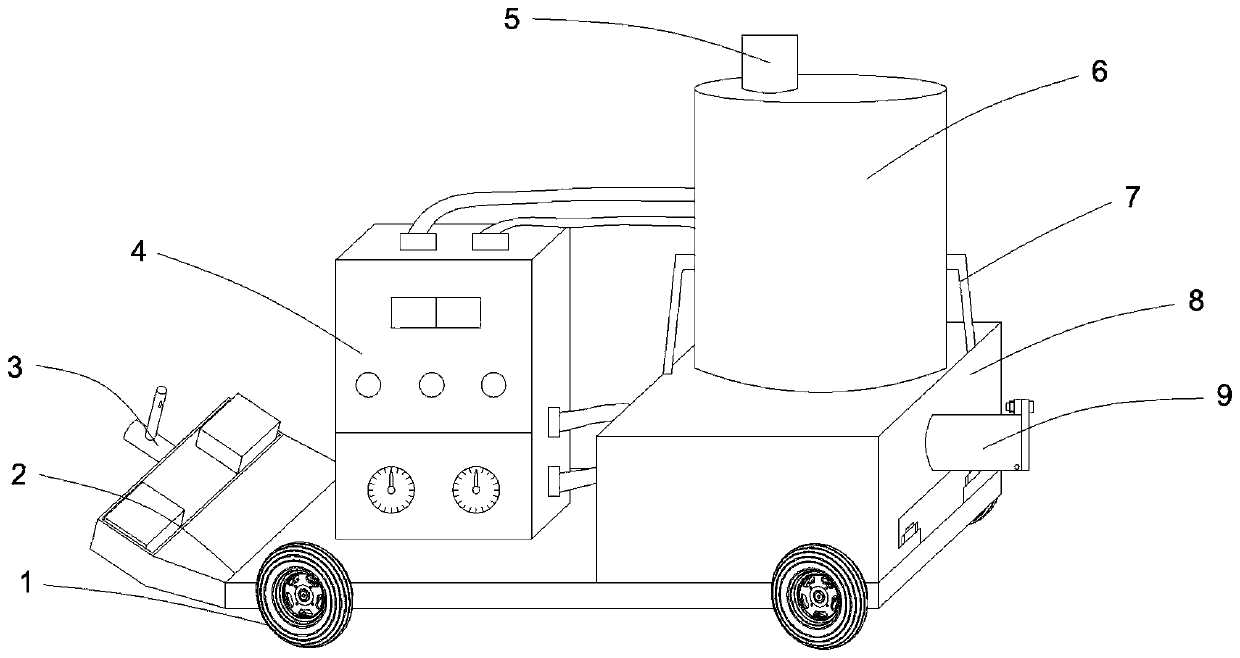

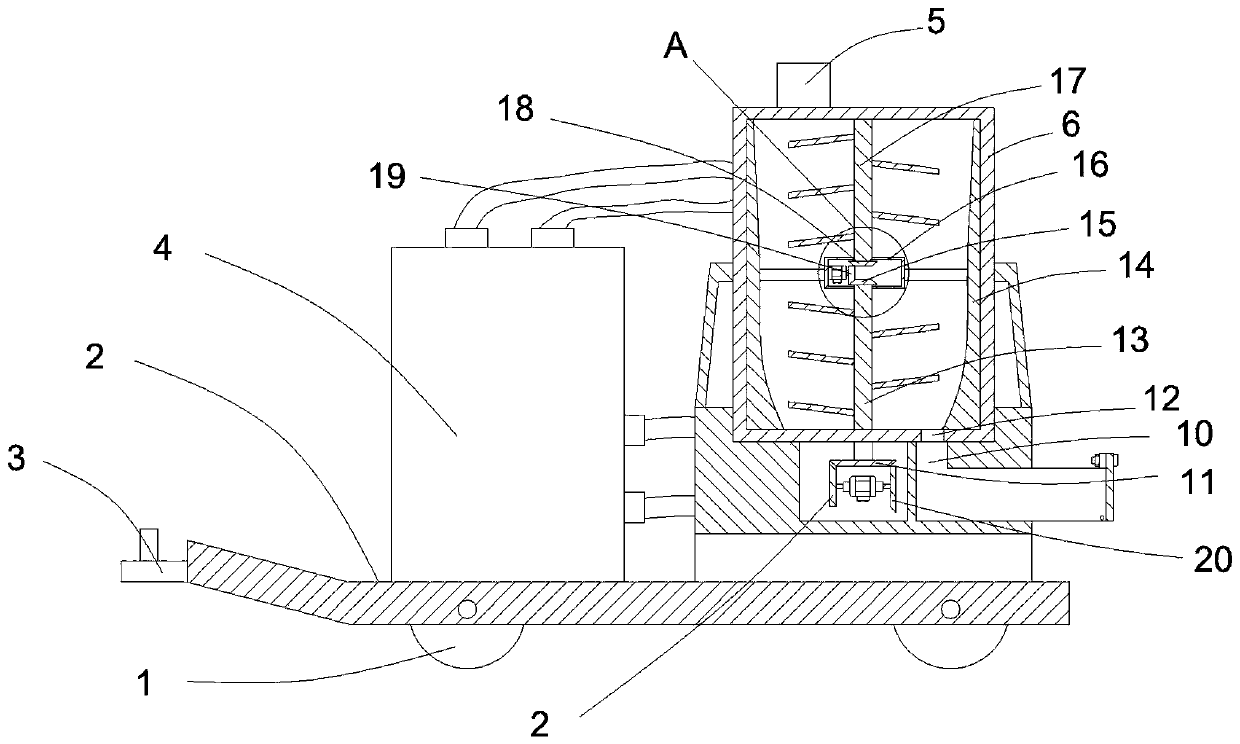

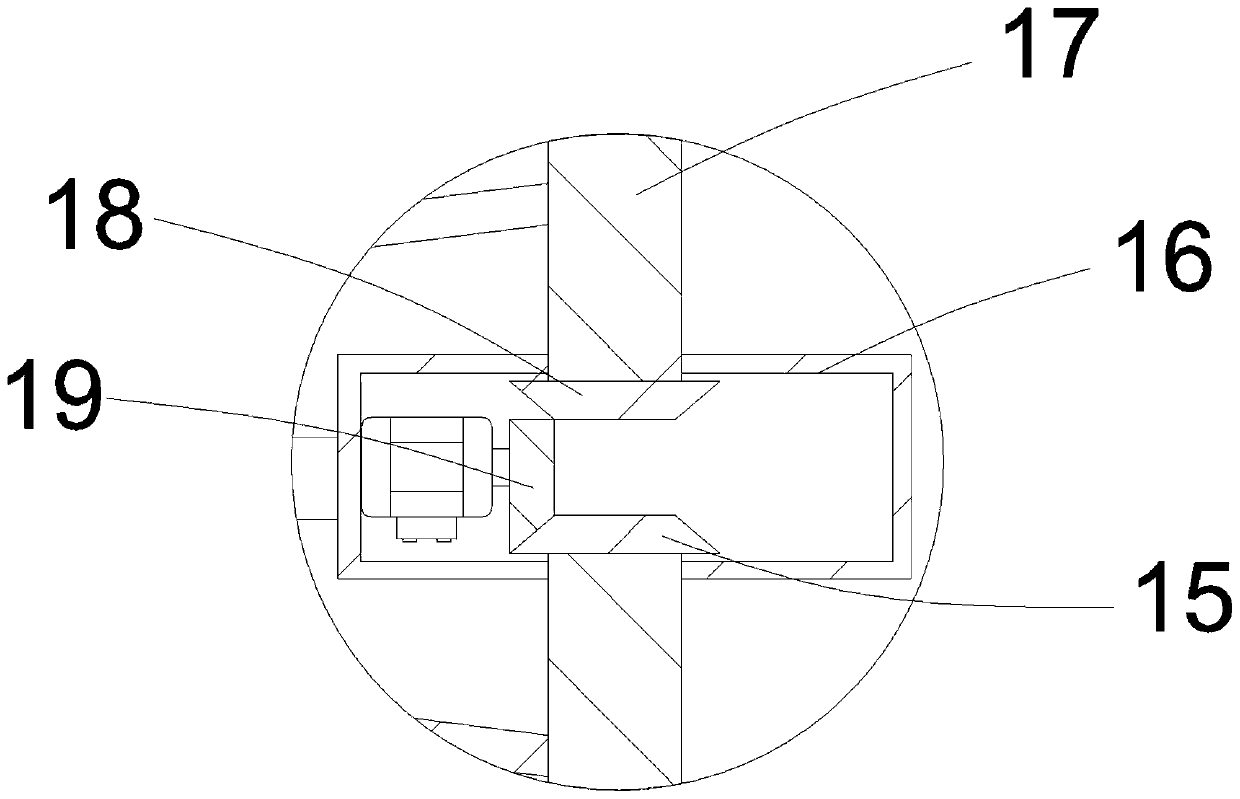

Novel energy sludge drier

InactiveCN107226604AImprove drying efficiencyPracticalSludge treatment by de-watering/drying/thickeningRotary stirring mixersSludgeReciprocating motion

The invention discloses a novel energy sludge drier. The novel energy sludge drier comprises a machine body, wherein a feeding opening is formed in one side of the upper part of the machine body in a sleeving manner; a pulling plate is clamped at the bottom of the feeding opening; in addition, an air inlet is formed in the other side of the feeding opening; an air heater is arranged on one side below the machine body through a conduit in the sleeving manner; besides, a discharging pipe is arranged in the center below the machine body in the sleeving manner; an electromagnetic switch valve is arranged inside the discharging pipe; a dried sludge collecting tank is arranged below the discharging pipe in a sleeving manner. According to the novel energy sludge drier disclosed by the invention, a solar silicon plate is arranged on the back of the novel energy sludge drier and used for gathering solar energy used as an energy source; a stirring rod is mainly arranged inside the novel energy sludge drier and can rotate through the rotation of the motor, so that the aim of stirring is achieved; a circular scraper is connected to the inner part of the machine body through an XTL electric telescopic rod; through the stretching of the XTL electric telescopic rod, the circular scraper can do left-right reciprocating motions, so that sludge on the inner wall of the machine body can be scraped off.

Owner:成都尚智恒达科技有限公司

Chemical engineering sewage treatment front-mounted deodorization device

InactiveCN106365223AGood mixing effectSimple and reasonable structural designGas treatmentRotary stirring mixersDrive motorActivated carbon

The invention discloses a chemical engineering sewage treatment front-mounted deodorization device. The chemical engineering sewage treatment front-mounted deodorization device comprises a stirring tank body, wherein a driving motor is arranged at the upper end of the stirring tank body, and is connected with a rotating shaft through a speed reducer; the rotating shaft extends into the stirring tank body; anchor type stirring paddles are arranged at the bottom end of the rotating shaft; a spiral defoaming blades are arranged in the middle of the rotating shaft; two defoaming transverse shafts are symmetrically arranged at the upper part of the rotating shaft; a plurality of defoaming saw teeth are arranged on the defoaming transverse shafts; a water inlet tube is arranged at the upper end of the left side of the stirring tank body; a water outlet tube is arranged at the lower end of the right side of the stirring tank body. The chemical engineering sewage treatment front-mounted deodorization device is simple and reasonable in structural design and convenient to use, through multiple stirring and defoaming functions, odor in sewage can be sufficiently released, harmful smell substances can be adsorbed by using an activated carbon adsorption device and are discharged out later, and thus an ambient environment can be prevented from being affected by the odor.

Owner:GUANGXI UNIV

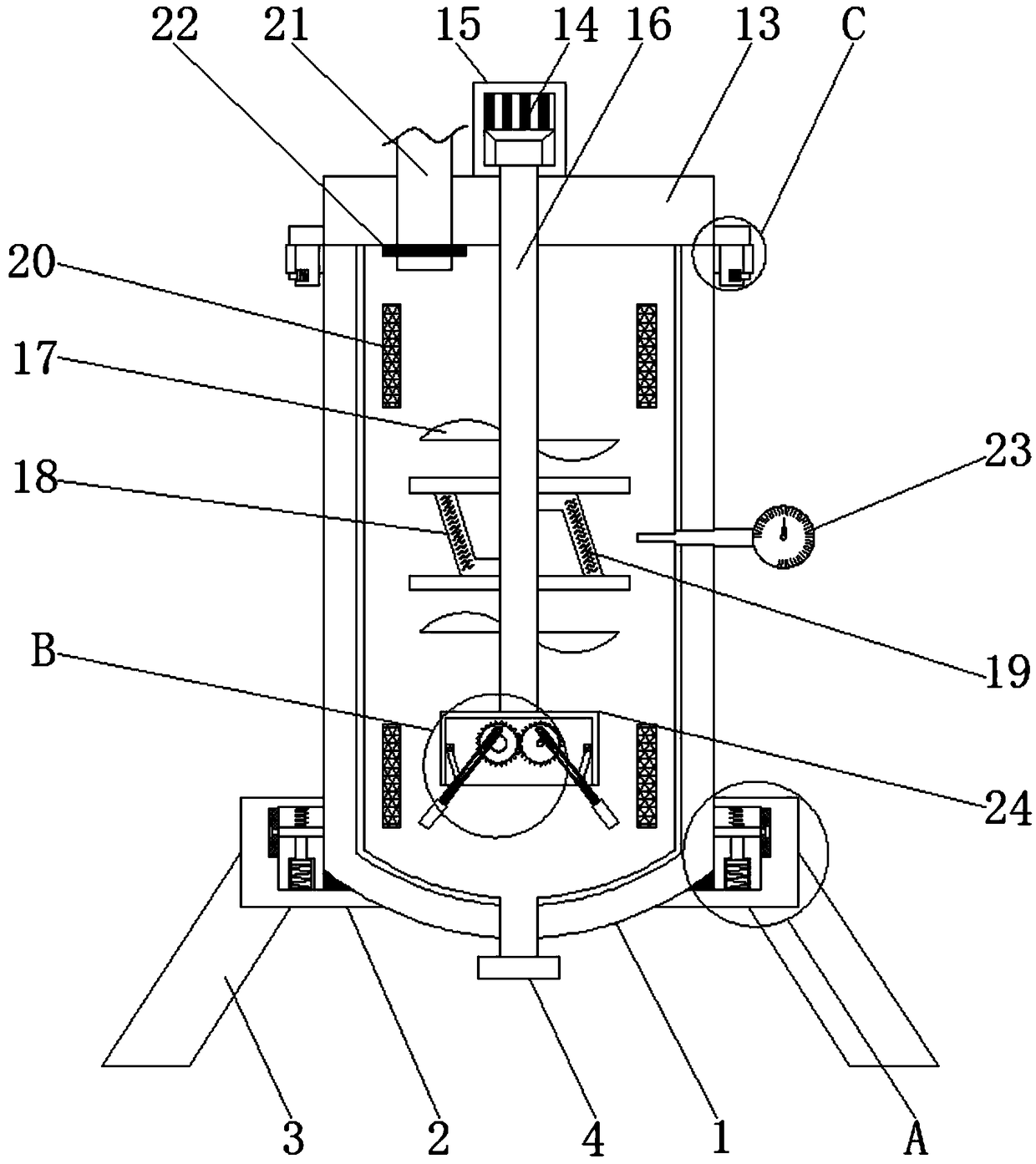

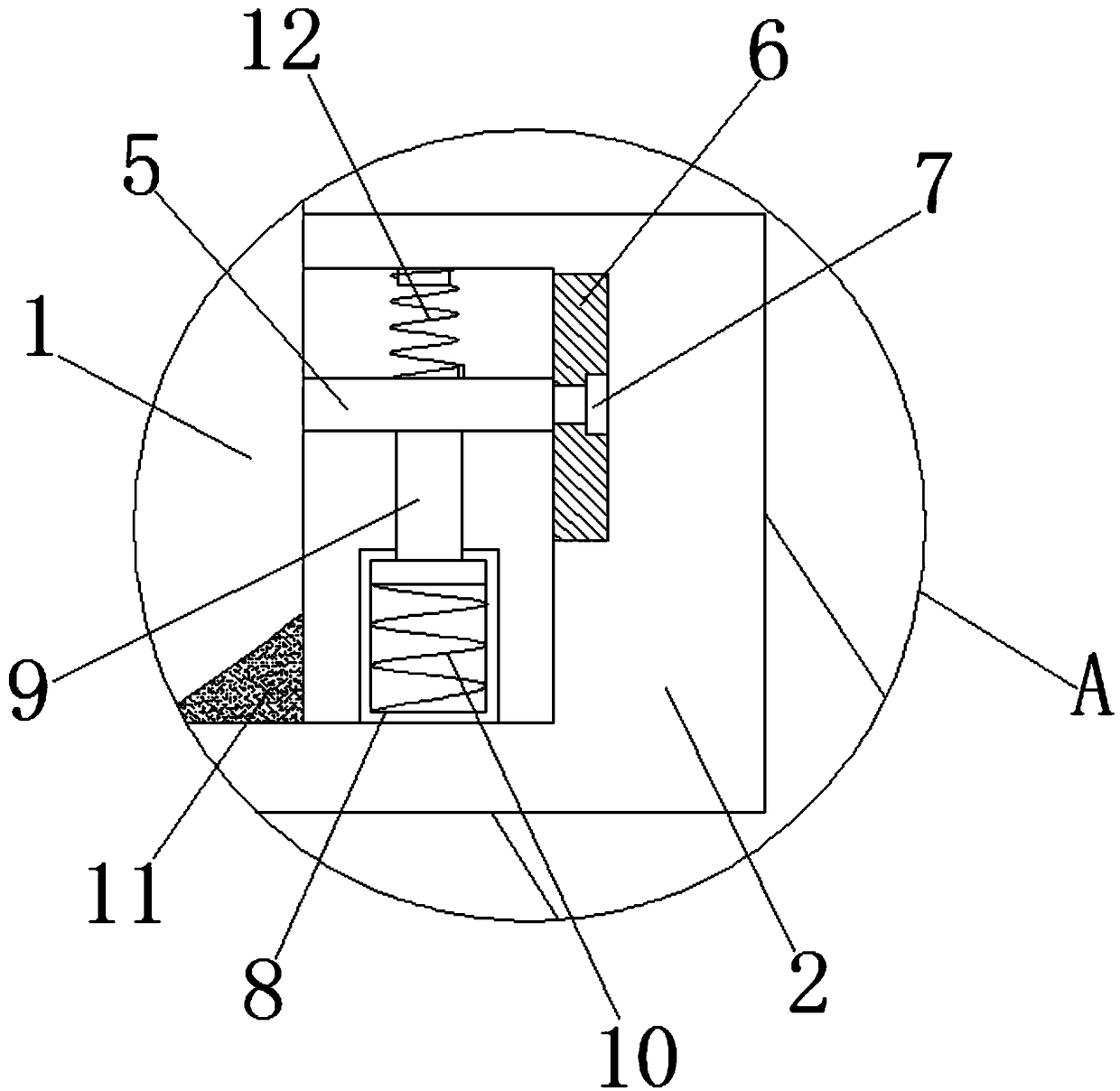

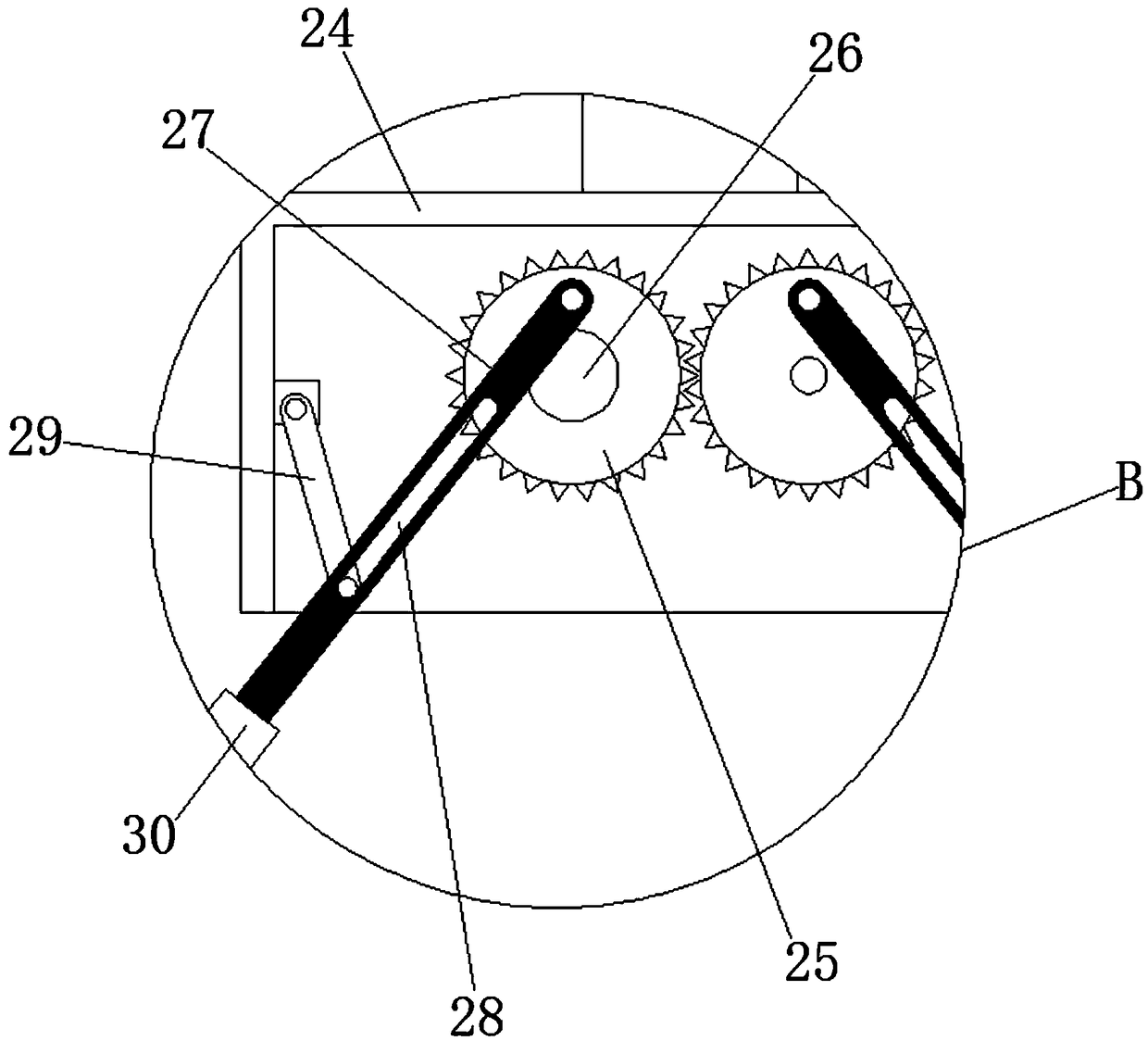

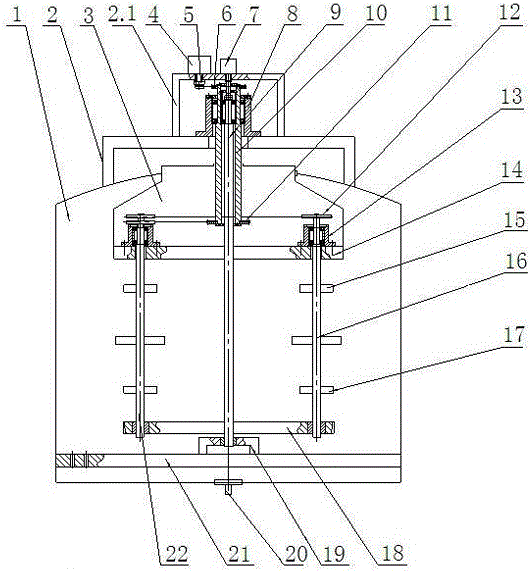

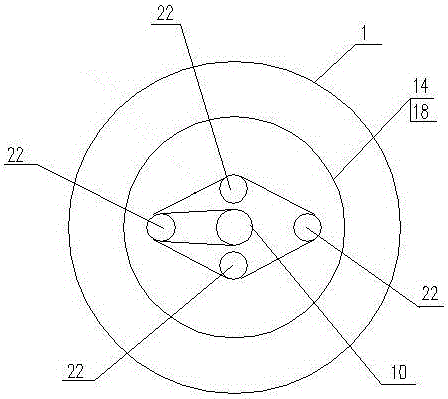

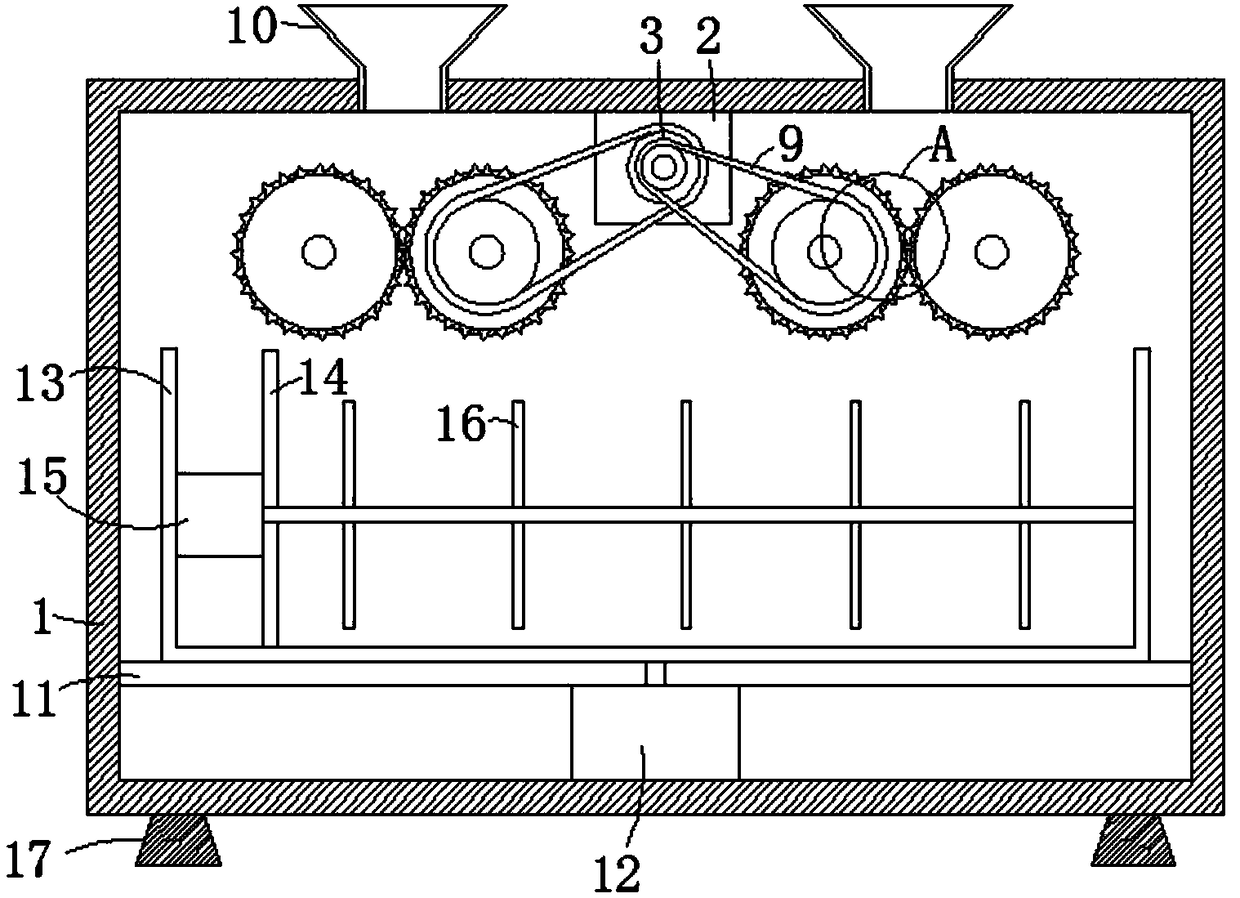

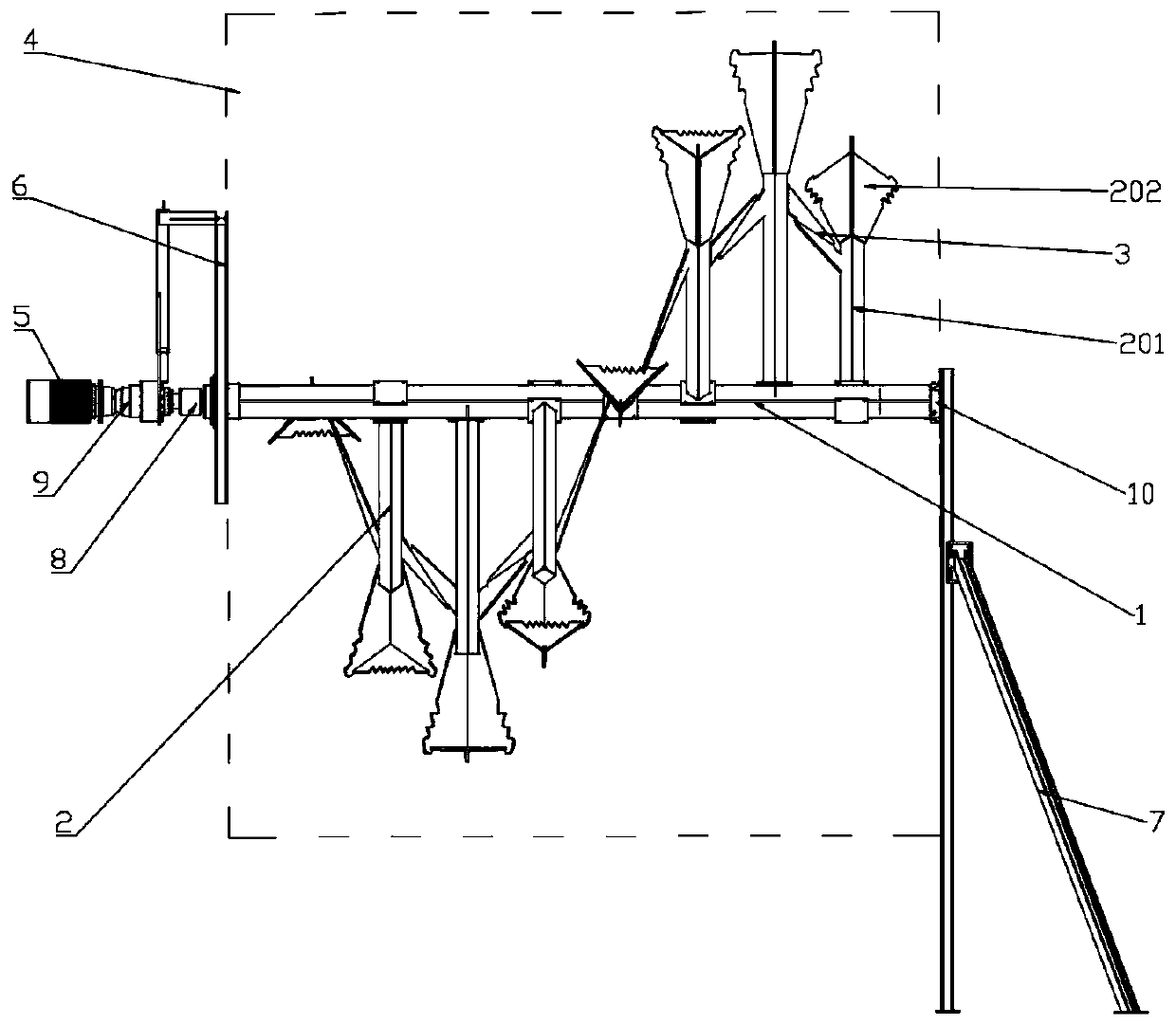

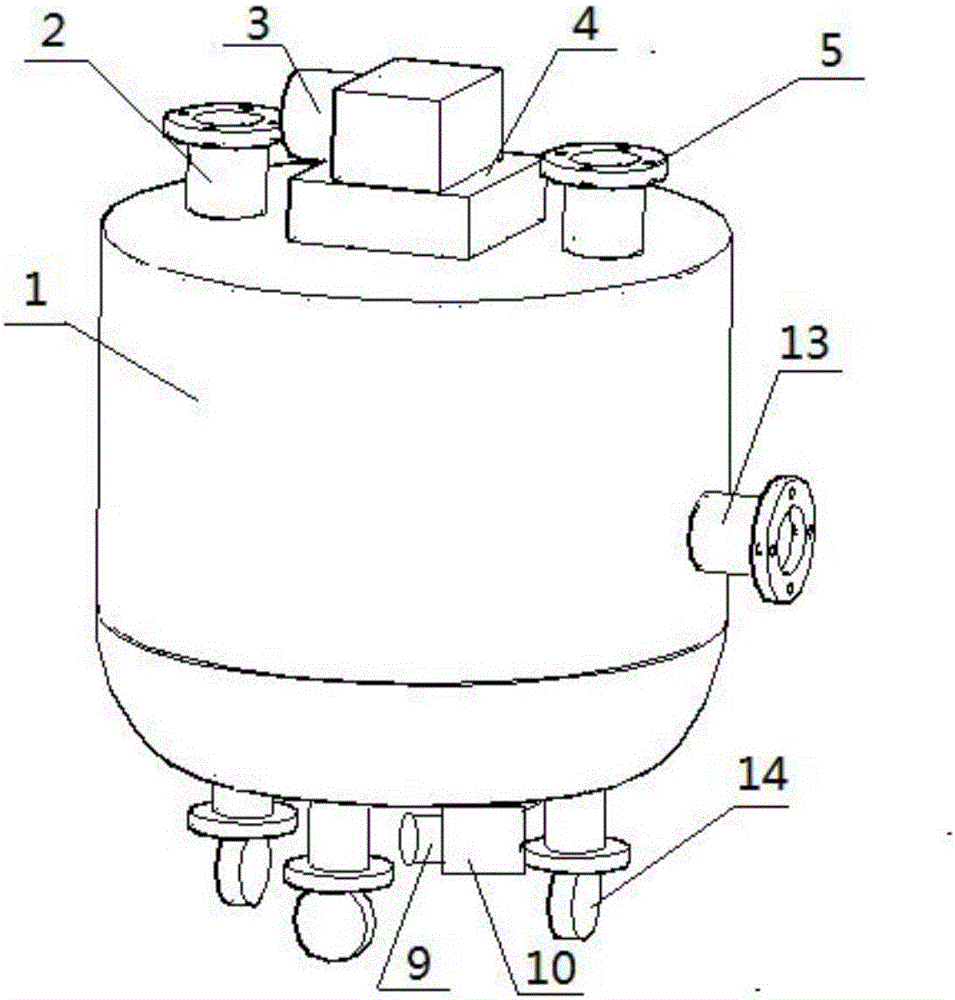

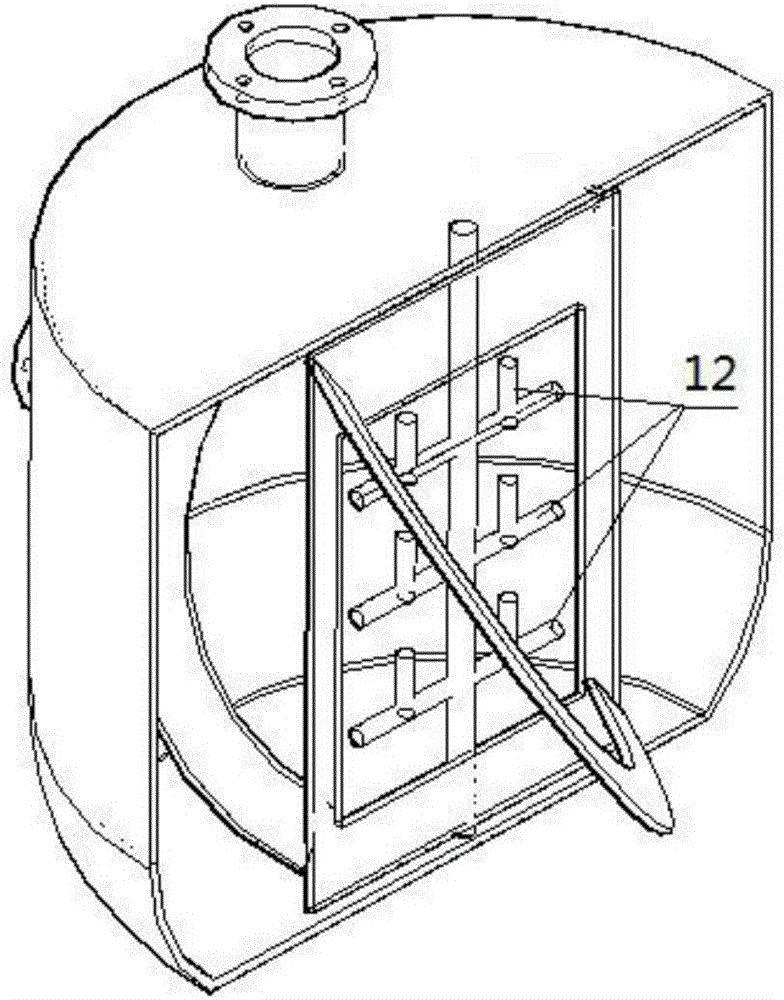

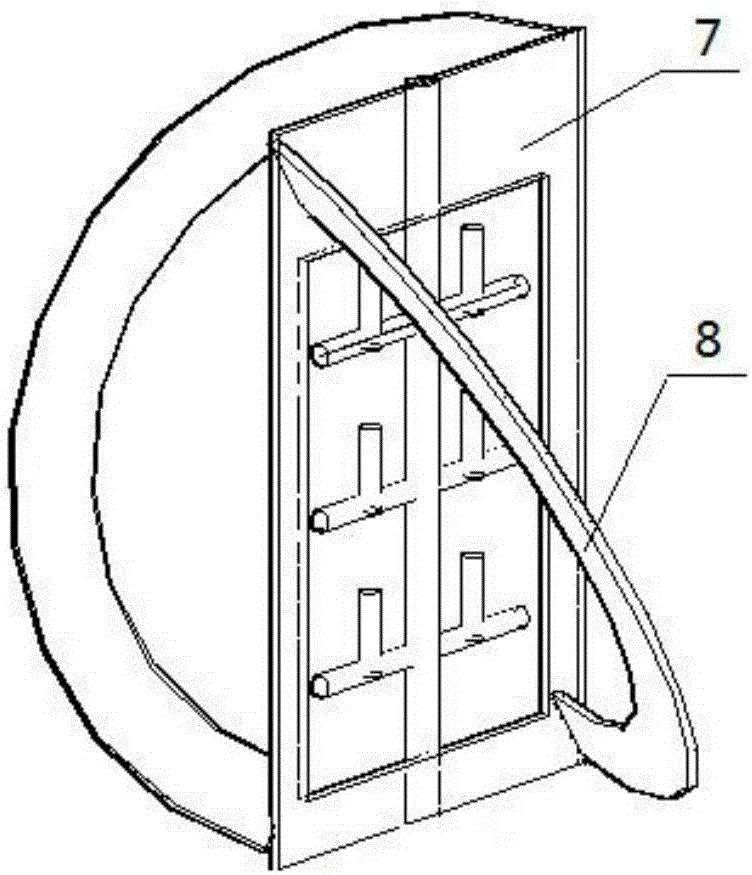

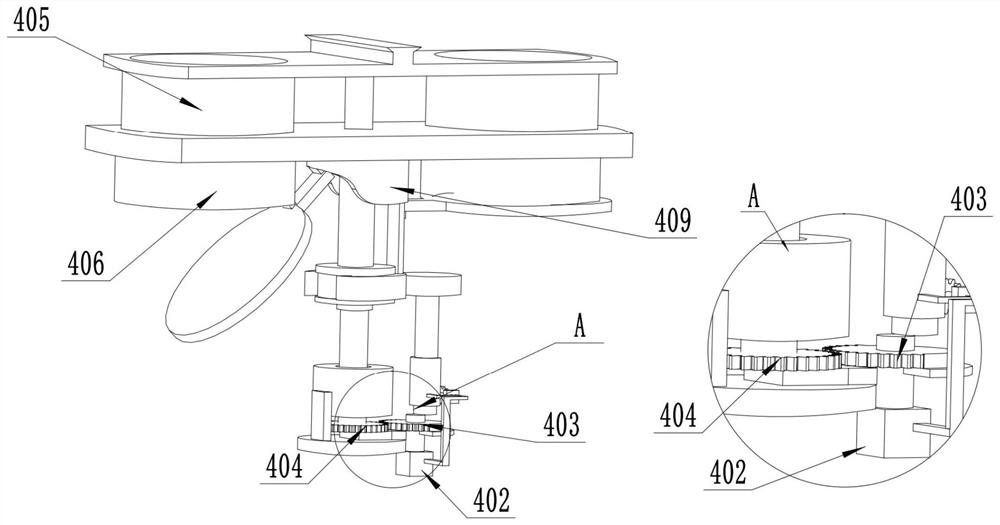

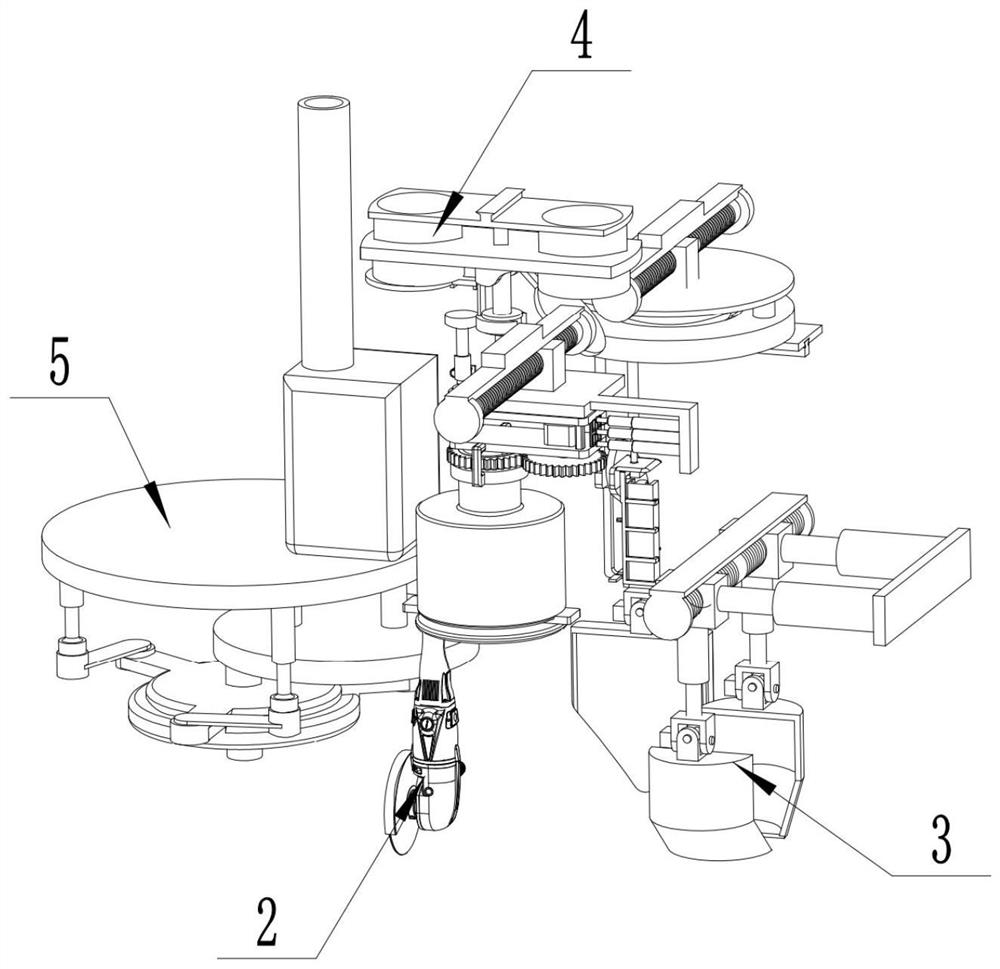

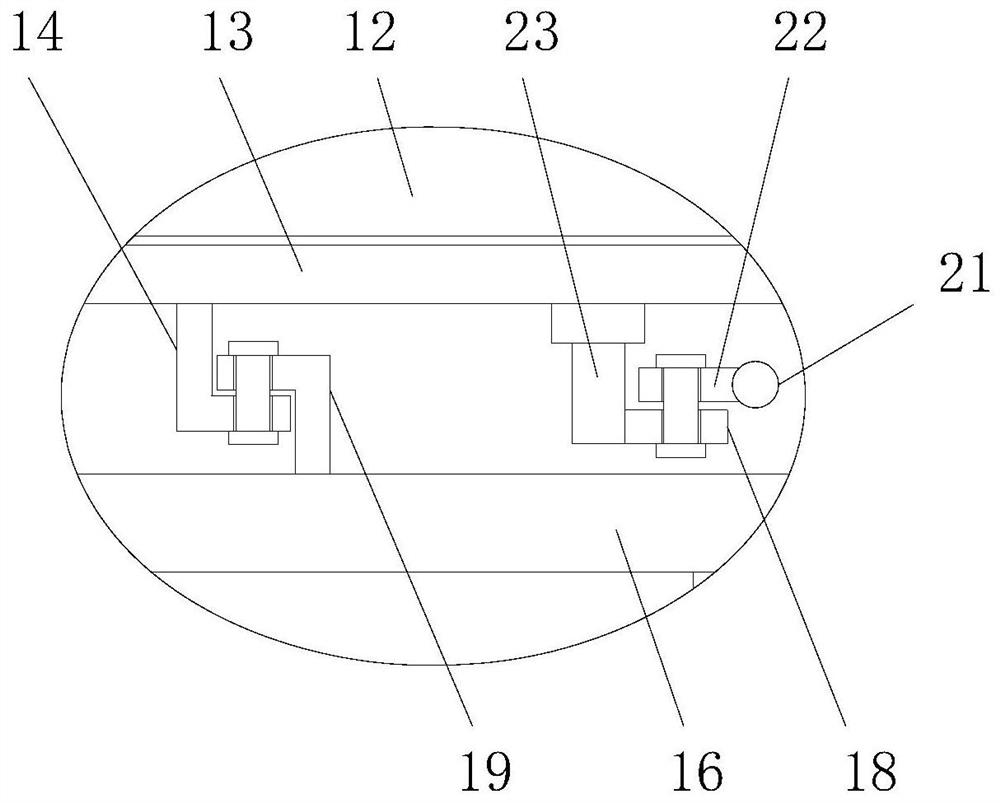

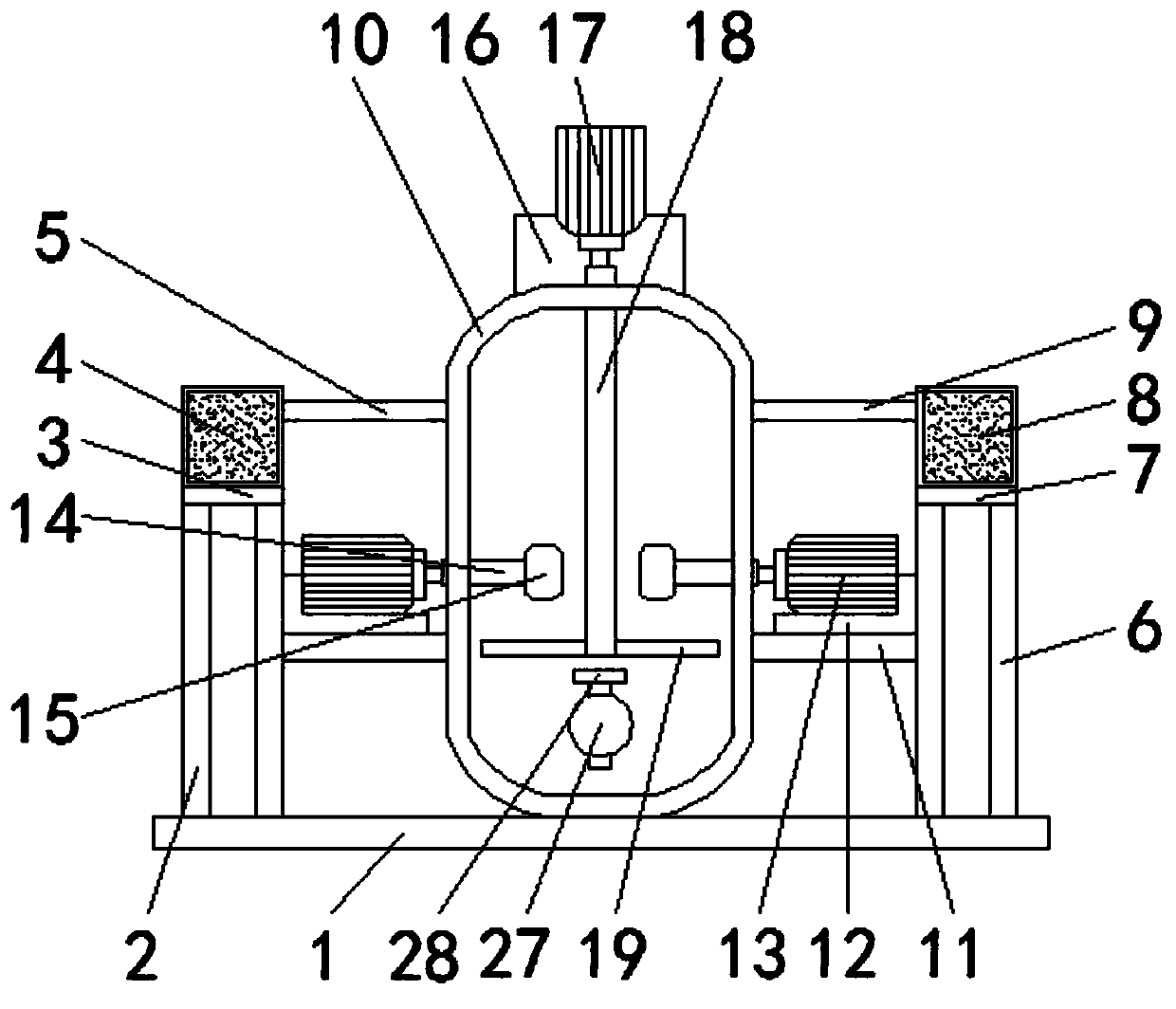

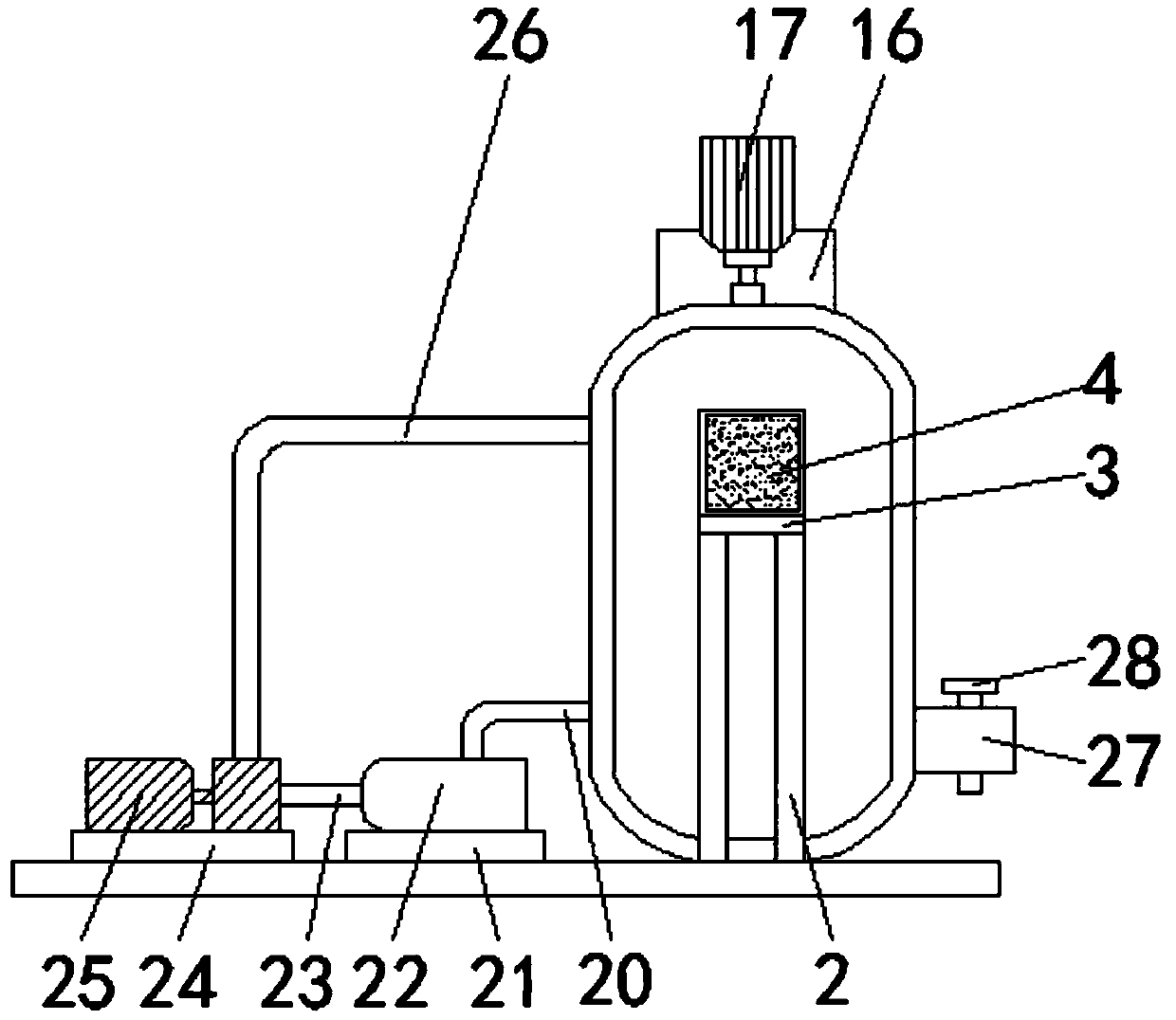

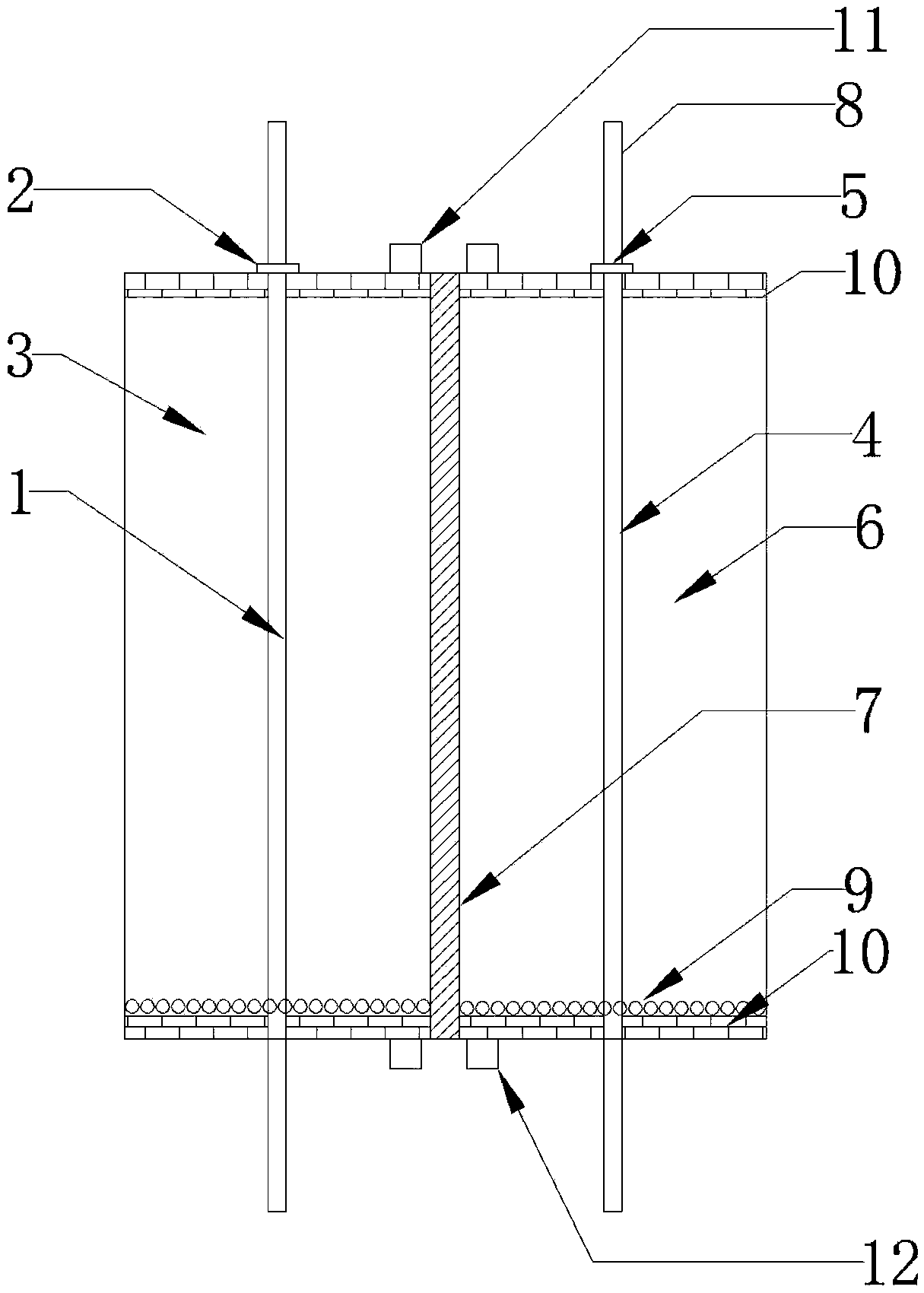

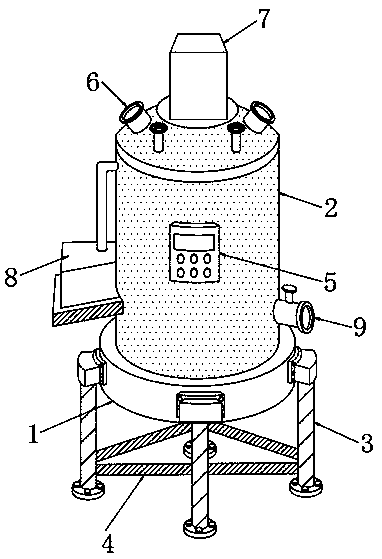

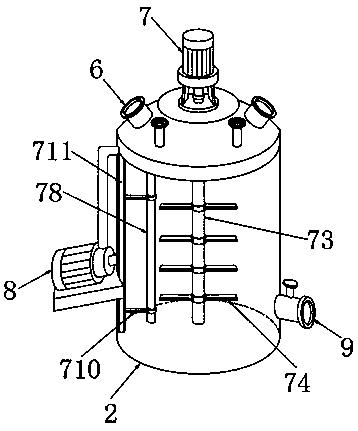

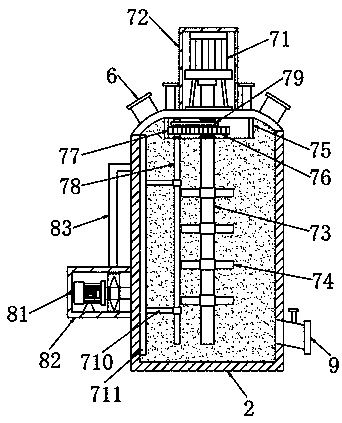

Large fermentation tank stirring device and stirring method

ActiveCN105695305AWide range of design diametersLower the altitudeBioreactor/fermenter combinationsBiological substance pretreatmentsControl systemDrive motor

The invention provides a large fermentation tank stirring device and a stirring method. The large fermentation tank stirring device comprises a tank body, a stirring device body in the tank body and a control system. The large fermentation tank stirring device is characterized in that the stirring device body comprises a central shaft and at least two blade shafts, the central shaft is vertically arranged in the middle of the tank body, a rotary disc is arranged on the central shaft, the central shaft is driven by a central shaft movement driving motor and drives the rotary disc to rotate, the blade shafts are arranged on the rotary disc, stirring blades are arranged on each blade shaft, and each blade shaft is driven by a blade shaft driving motor to be in autorotation while being along with revolution of the rotary disc. The control system controls linkage and rotating speed of the central shaft movement driving motor and the blade shaft driving motor and rotating direction of the blade shafts to realize autorotation and revolution of the blade shafts, and materials in the tank body are stirred by the blades on the blade shafts. By using the large fermentation tank stirring device, fermentation liquid can be fully stirred, fermentation quality can be improved, and stirring energy consumption and power consumption in delivering filtered air into the bottom of the tank body can be lowered.

Owner:吴文宇 +1

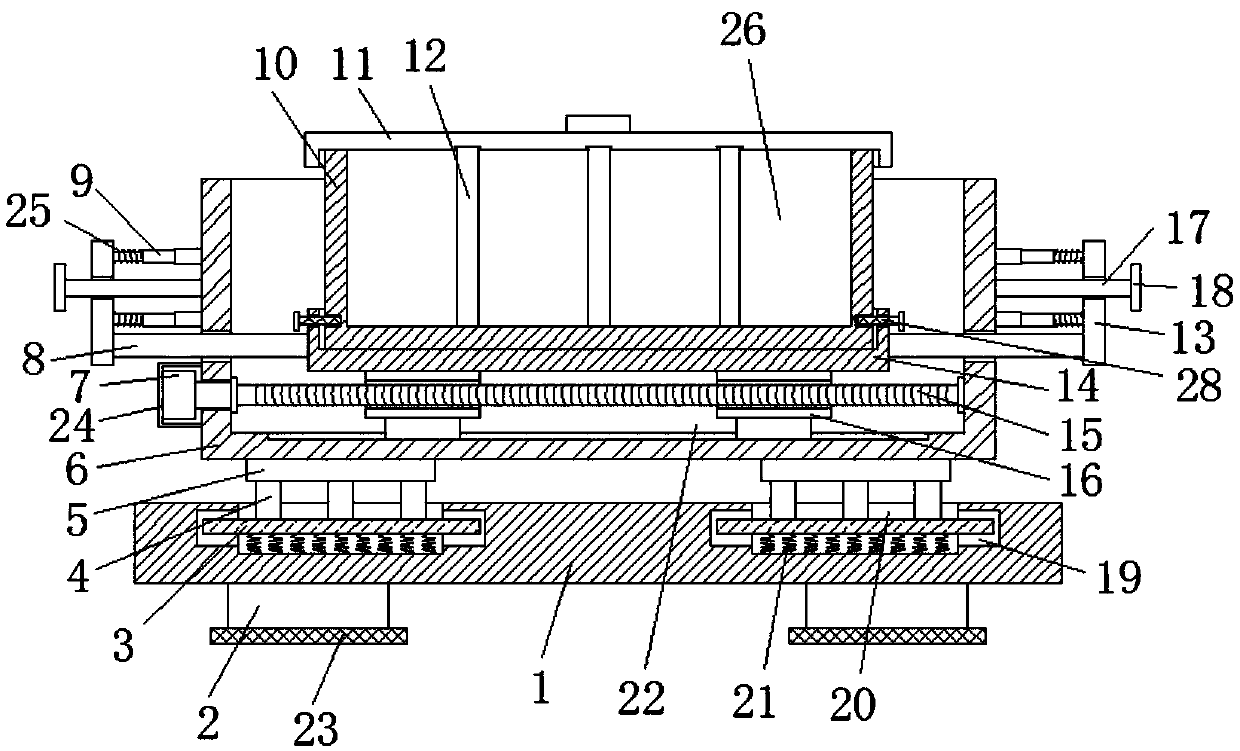

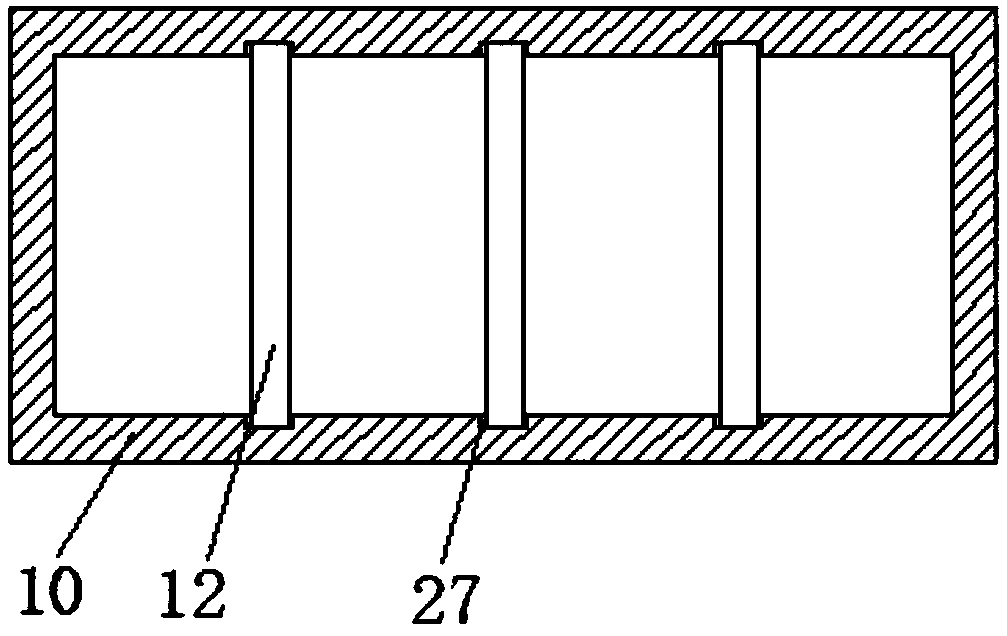

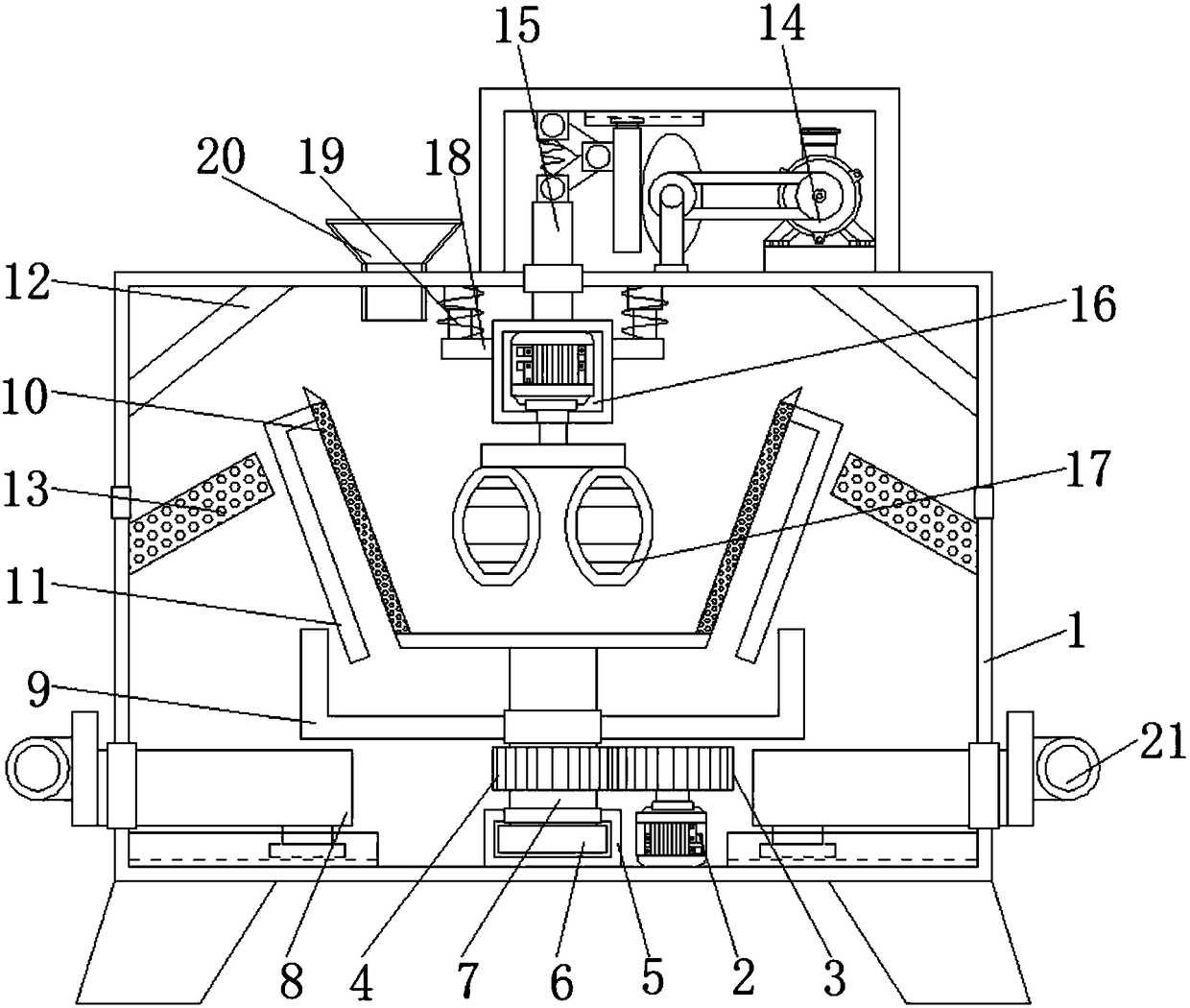

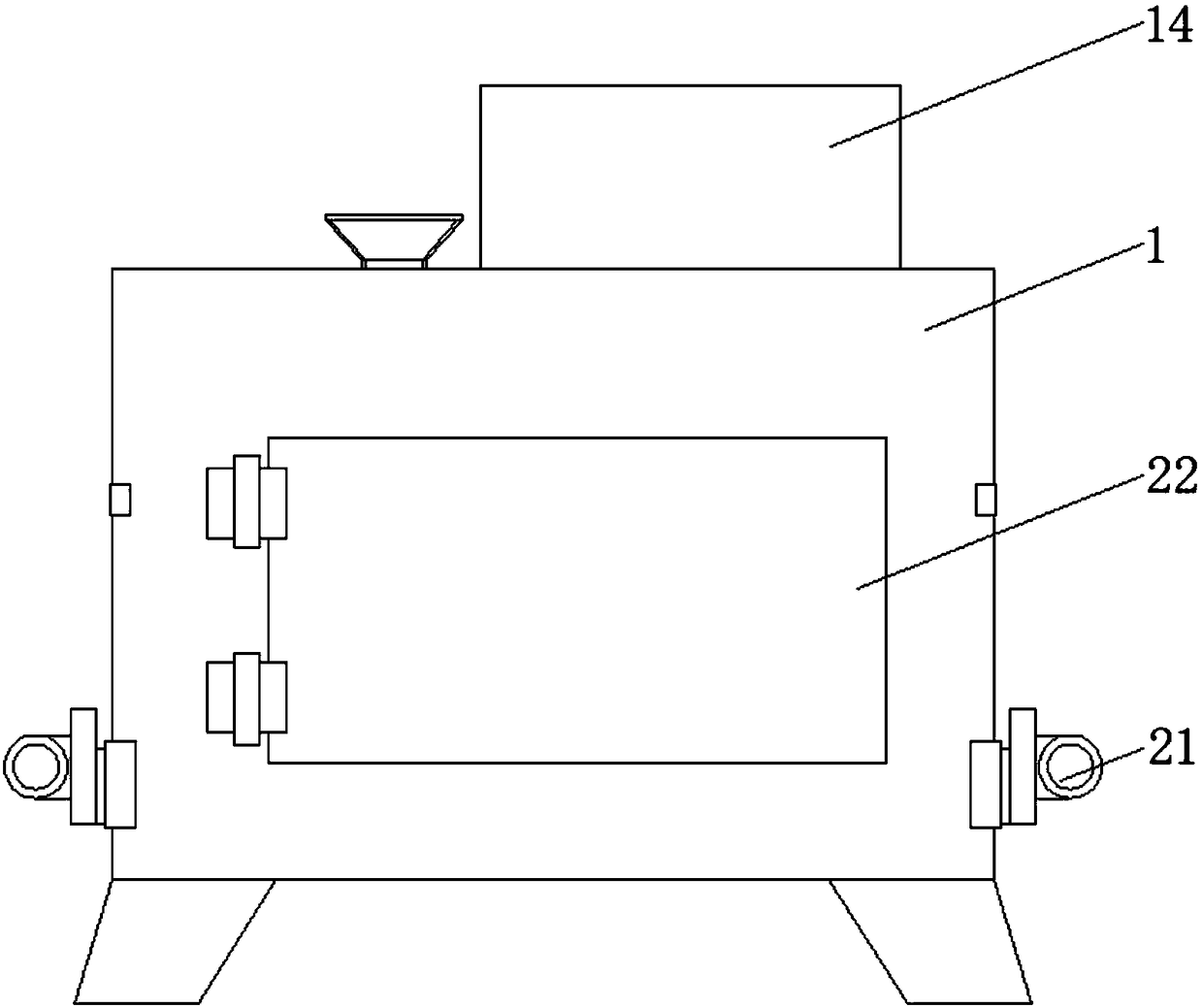

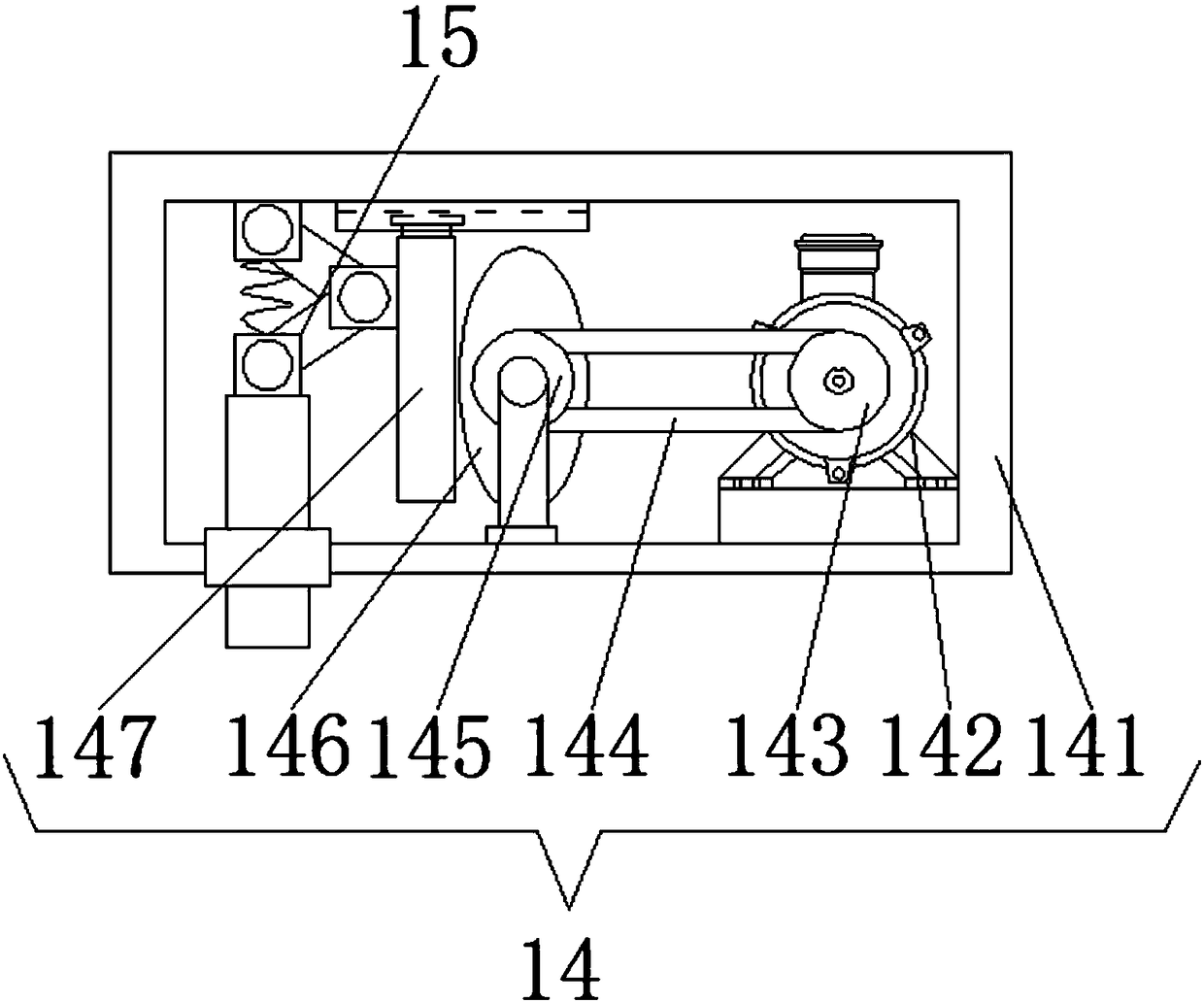

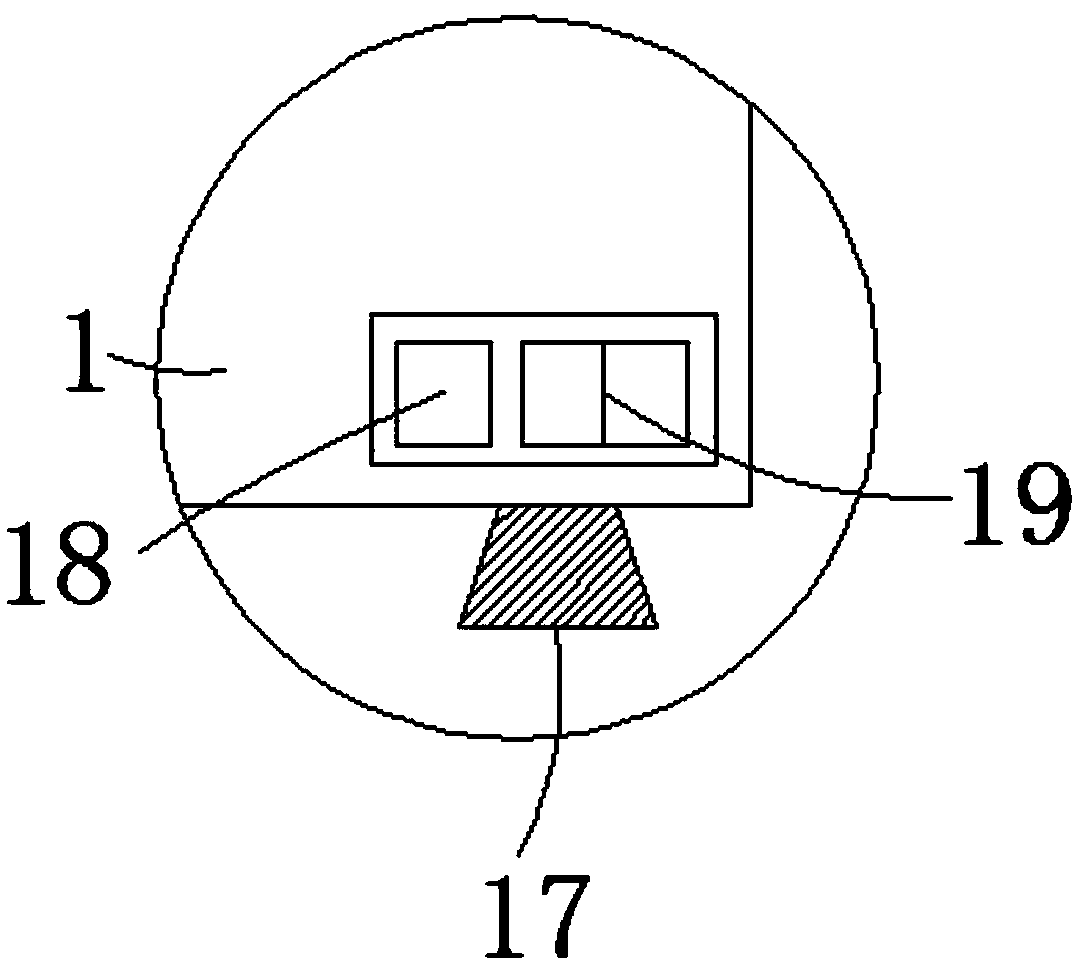

Vibration platform for environment-friendly cement balancing weight

PendingCN107825596AWell mixedPlay the role of cushioning and shock absorptionCement mixing apparatusMaterials scienceProduction quality

The invention discloses a vibration platform for an environment-friendly cement balancing weight. The vibration platform comprises a base and a platform body. The vibration platform disclosed by the invention is simple in structure and convenient to operate; and a cement mixture is adequately stirred and mixed through vibration, and a high mixing degree is achieved, so that the production qualityof a finished cement balancing weight product is improved, and a great use effect is achieved.

Owner:武汉市华力机械铸造有限公司

Gravel sorting device applied to civil engineering

InactiveCN108160487AReduce the burden onTo achieve the purpose of centrifugal screeningSievingGas current separationGear wheelCivil engineering

The invention discloses a gravel sorting device applied to civil engineering. The gravel sorting device comprises an outer frame; a first motor is fixedly connected to the bottom of the inner wall ofthe outer frame; a first gear is fixedly connected to one end of an output shaft of the first motor; one side of the first gear meshes with a second gear; a rotating rod penetrates through the axis ofthe second gear; a rotating base is fixedly connected to the bottom end of the rotating rod; and a rotating sleeve matched with the rotating base is fixedly connected to the bottom of the inner wallof the outer frame. The invention relates to the technical field of civil engineering associated equipment. The gravel sorting device applied to civil engineering has the advantages that the purpose of centrifugal screening can be achieved, the purpose of sorting gravel with different particle sizes can be achieved, manual sorting is not needed, the burden of workers can be relieved, the working efficiency can be improved, centrifugal sorting can be better facilitated, waste of time can be reduced, the gravel with different particle sizes can be conveniently separated, and the practicability of the device can be improved.

Owner:蒋杰

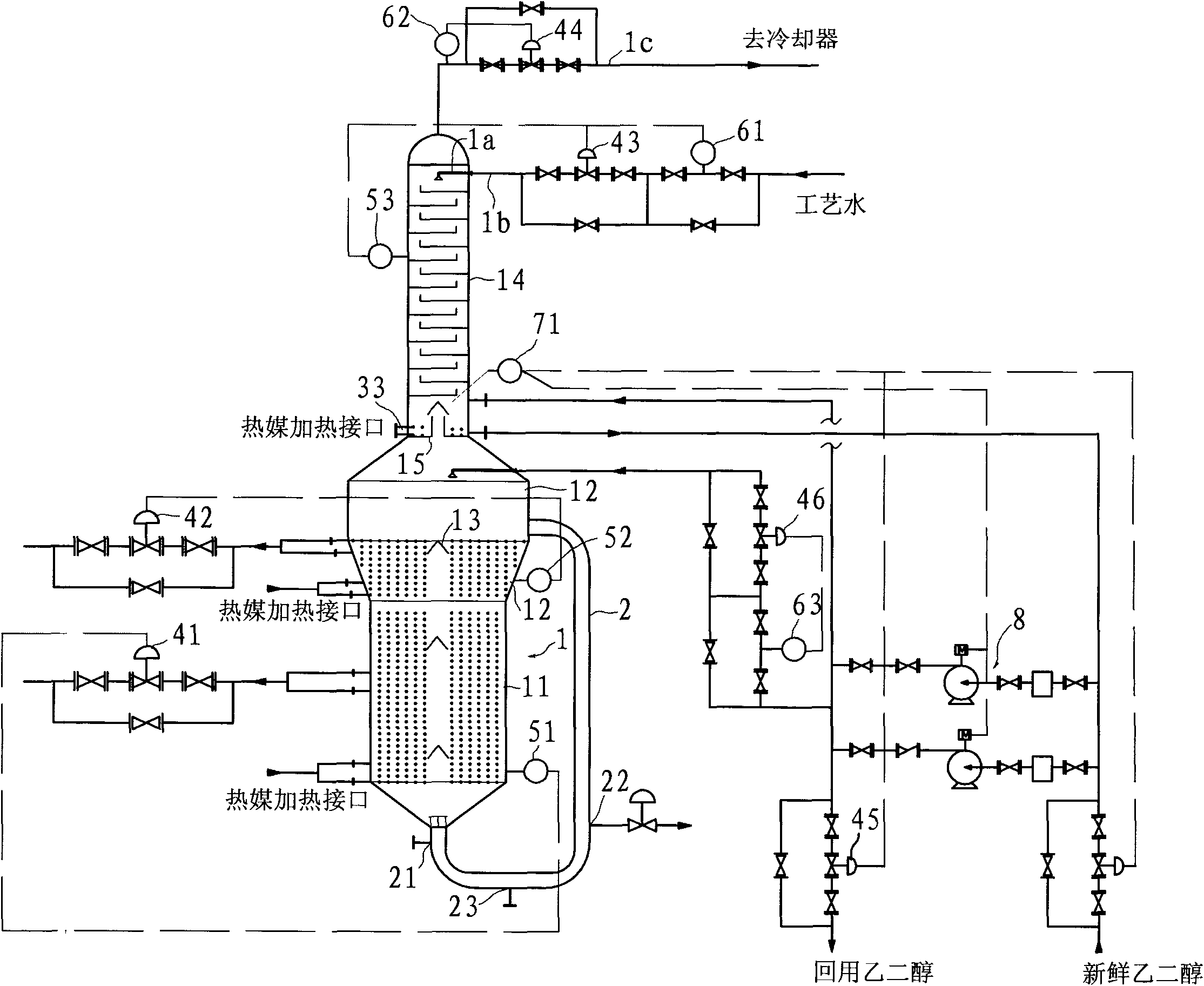

Polyethylene terephthalate (PET) esterification reaction kettle

The invention discloses a polyethylene terephthalate (PET) esterification reaction kettle, which comprises a kettle body. The PET esterification reaction kettle is characterized in that: the kettle body comprises a small cavity at the lower end and a big cavity at the upper end; a lower heating coil and an upper heating coil are arranged corresponding to the lower ends of the small cavity and the big cavity respectively; and the outer side of the kettle body is provided with a circulating pipeline, the feeding port of the circulating pipeline at the upper part is communicated with the big cavity, the discharge port of the circulating pipeline at the lower part is communicated with the small cavity, and the circulating pipeline is also provided with a slurry injection port and an esterification discharge hole spaced with the slurry injection port. Compared with the prior art, a stirrer is replaced by adopting the external circulating pipeline, so the purposes of saving energy and reducing consumption are fulfilled; and fund investment of stirrer equipment and supporting facilities of the traditional esterification reaction kettle is reduced, the production and operation costs are reduced, equipment maintenance operation in the production process is reduced, and production control is simplified.

Owner:重庆万凯新材料科技有限公司

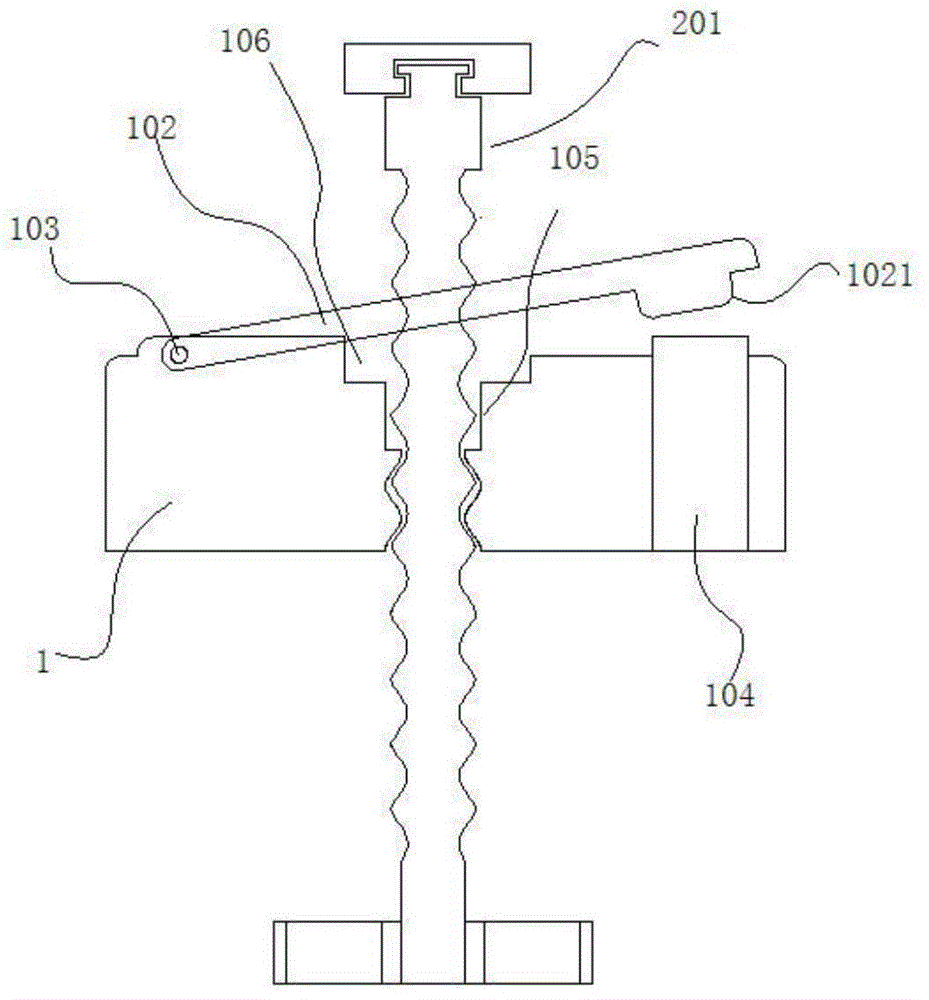

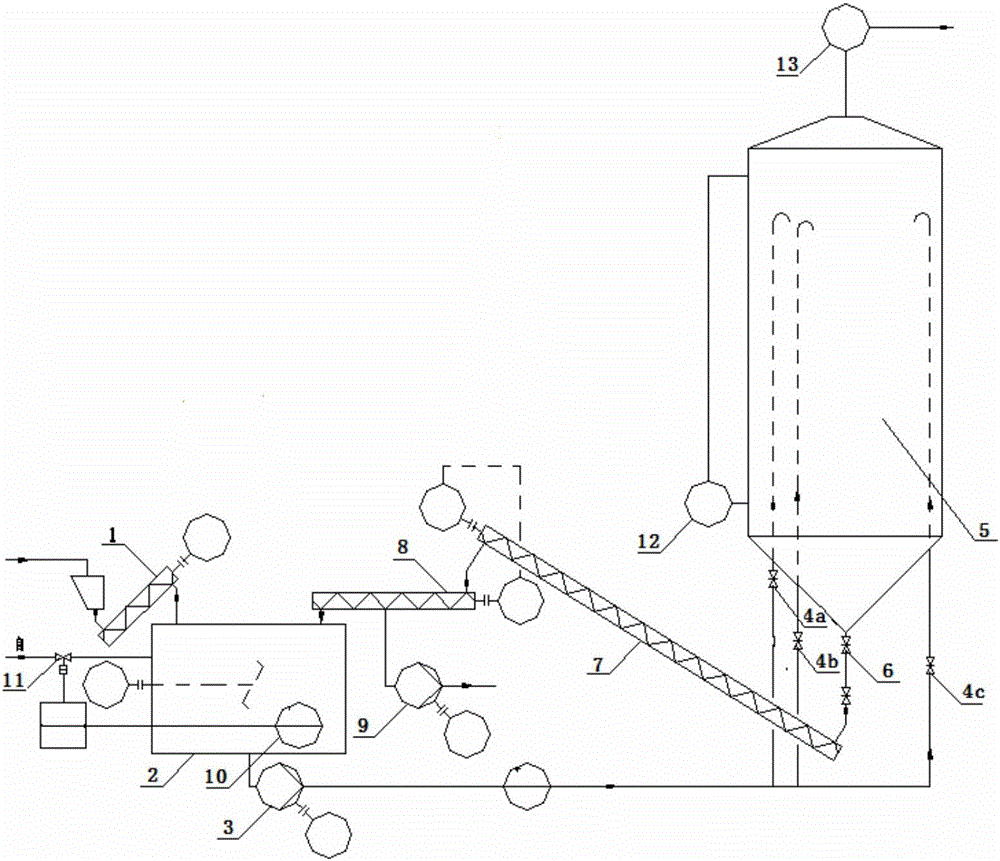

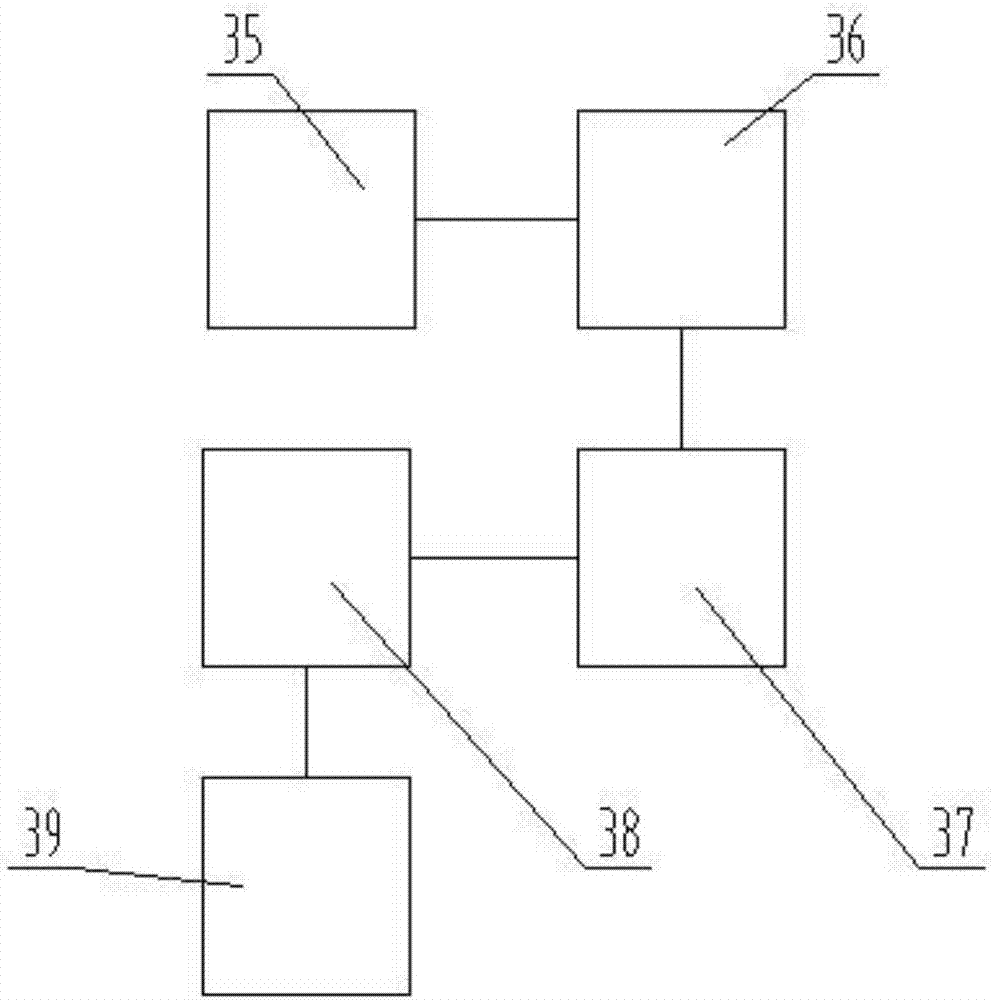

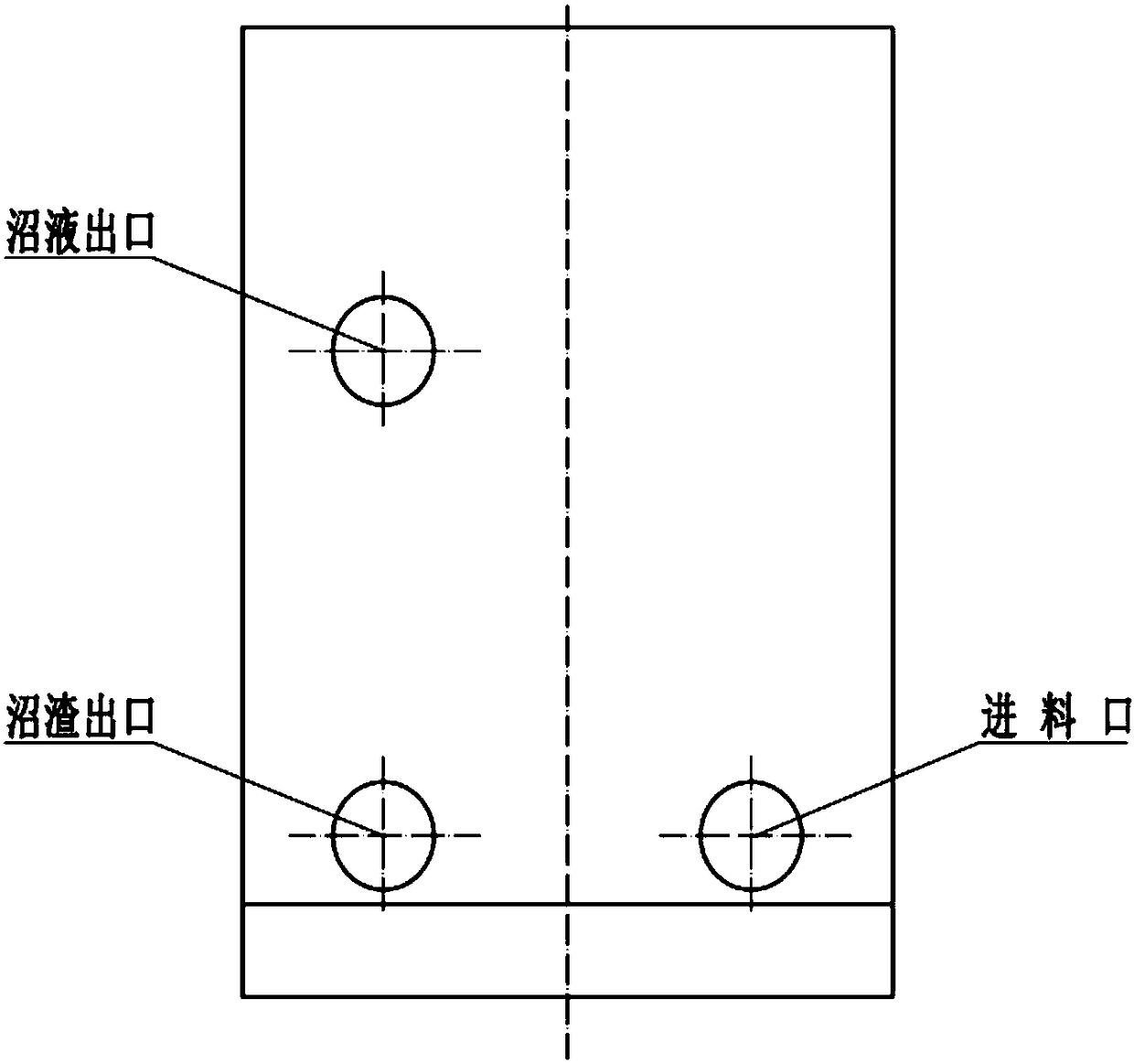

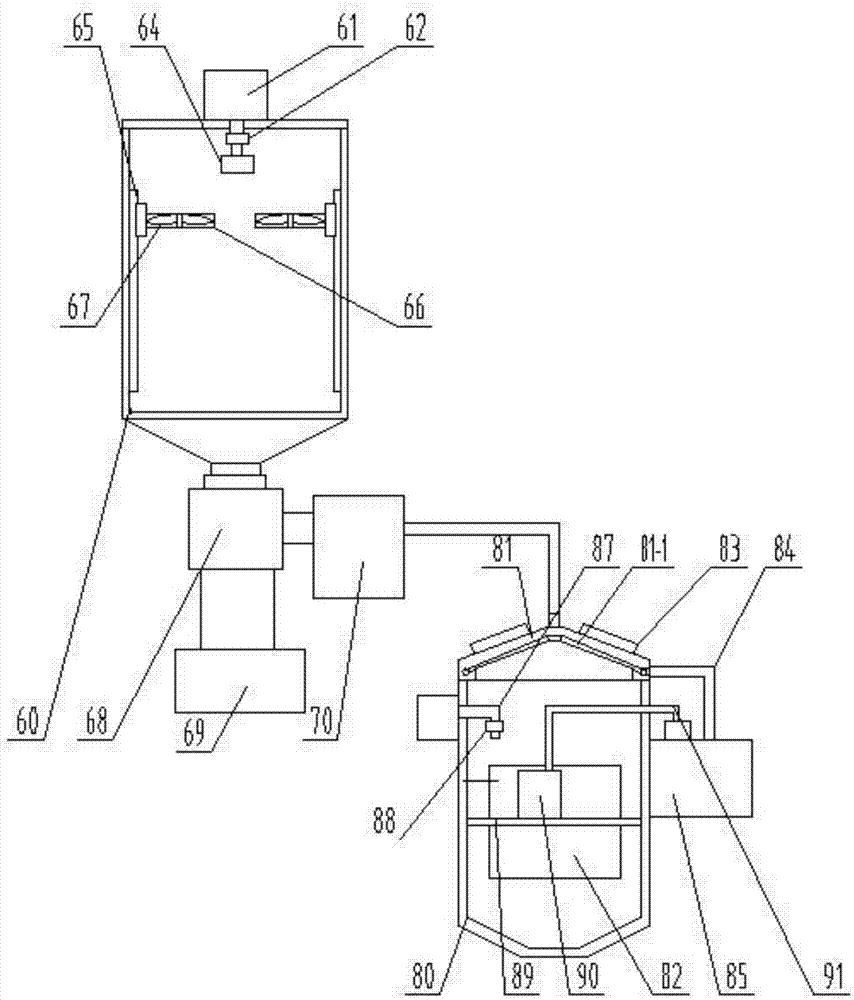

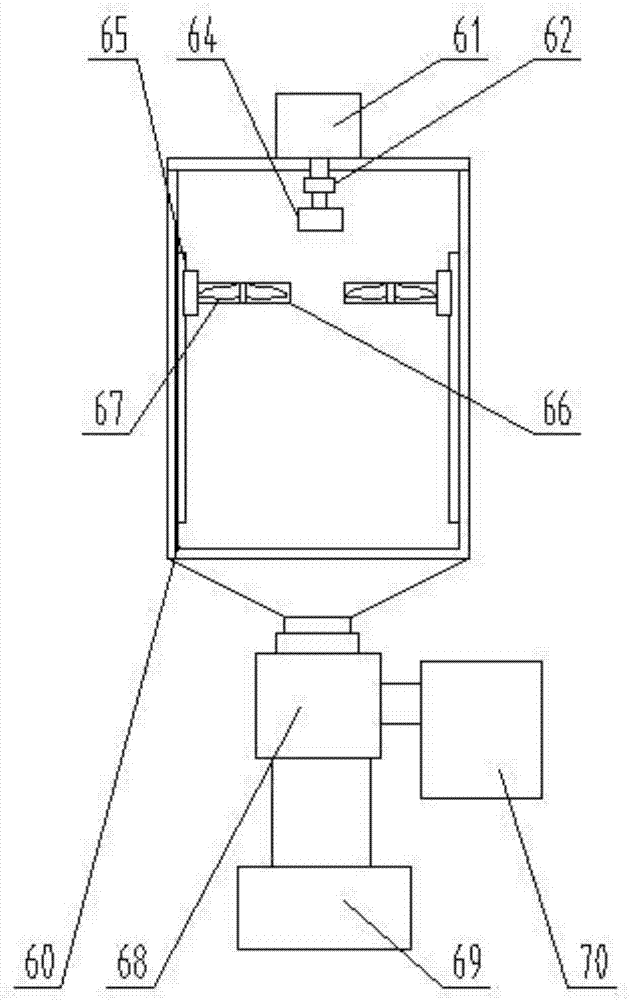

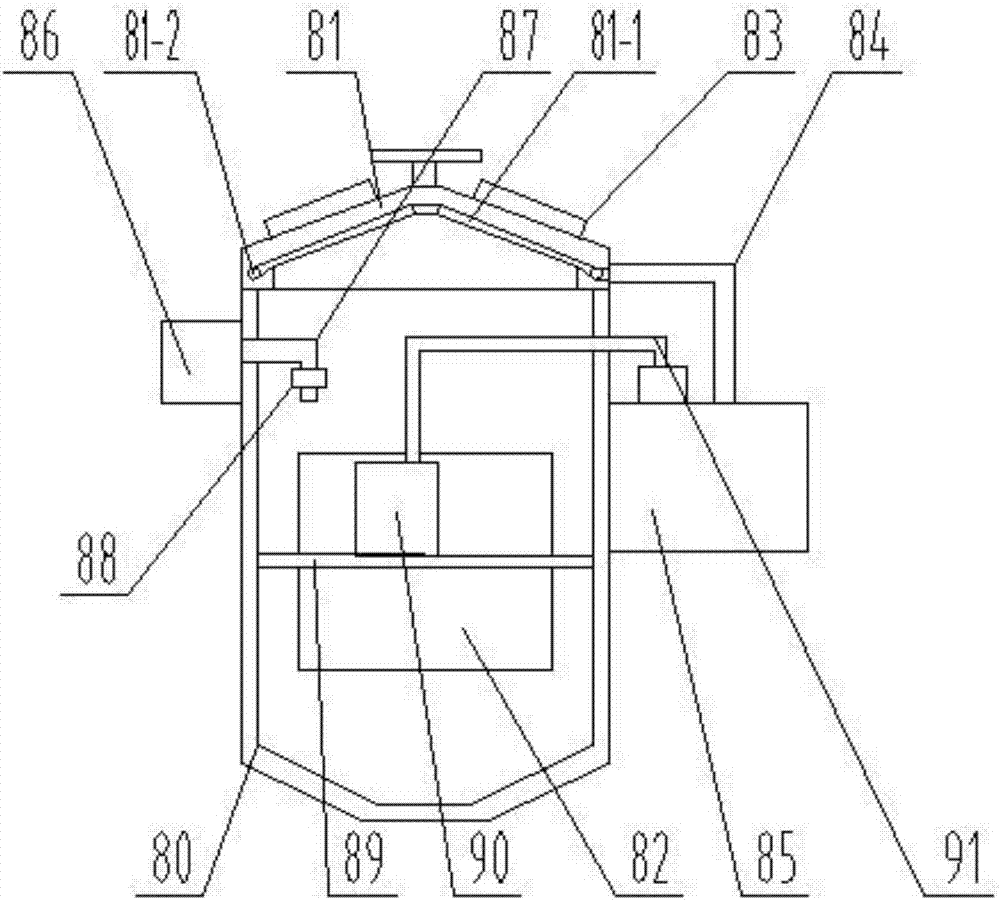

Control method and control system of utilizing high-concentration organic raw material for biogas fermentation

InactiveCN105039604AAchieve the purpose of stirringEnsure continuous and efficient operationBioreactor/fermenter combinationsBiological substance pretreatmentsHigh concentrationControl system

The invention belongs to the technical field of renewable energy source development and environment protection, and particularly relates to a control method and a control system of utilizing a high-concentration organic raw material for biogas fermentation. The control method includes that the material enters a stirring temperature rise adjusting tank through a first feeding device, a thermocouple in the stirring temperature rise adjusting tank heats the inside of the same and sends a temperature signal to a PLC (programmable logic controller) of a system, and the PLC controls temperature in the tank to meet a set value according to the signal which is sent; the material after being treated by the stirring temperature rise adjusting tank enters a vertical anaerobic fermentation tank through three discharging valves, and the PLC controls the discharging valves to be on alternately for 2-5min. Fermentation circulating of the high-concentration raw material in the biogas system is realized through the PLC to achieve the objective of stirring the fermentation raw material, potential, of the fermentation raw material, in producing biogas is developed fully, and continuous and efficient running of the high-concentration raw material biogas fermentation system is realized.

Owner:辽宁省能源研究所有限公司

Premixing treatment method for ink production and preparation

InactiveCN111359529AReduce work intensityImprove uniformityTransportation and packagingMixer accessoriesElectric machineryProcess engineering

The invention relates to a premixing treatment method for ink production and preparation. Automatic mixing equipment is used in the method. The automatic mixing equipment comprises a stirring tank, astirring mechanism and a feeding mechanism, when the automatic mixing equipment is used for manufacturing printing ink, the specific method comprises the following steps of material proportioning, primary feeding, stirring, secondary feeding and discharging, the stirring mechanism comprises a stirring motor, a stirring shaft, a stirring frame, a first bevel gear, a second bevel gear and a supporting rod, and the feeding mechanism comprises a conveying pipe, a storage tank, a rotating plate, a guide hopper and an annular plate. The stirring mechanism and the feeding mechanism are jointly matched to complete the material mixing action, in the low-speed stirring process, the stirring mechanism can drive the feeding mechanism to add a small amount of materials into the stirring tank many times, the working intensity of the stirring mechanism can be relieved, and the stirring and mixing uniformity is improved.

Owner:张晓锋

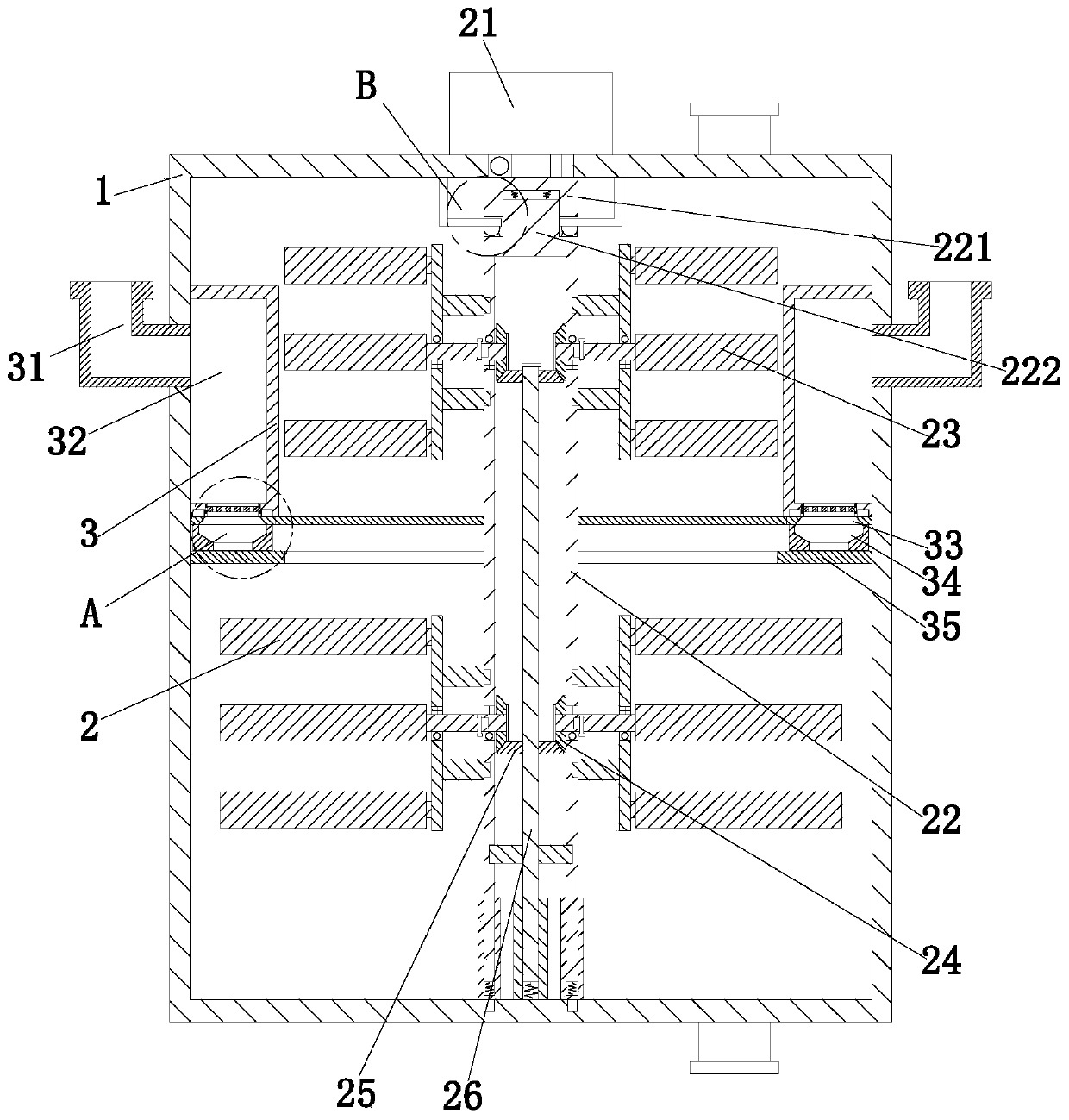

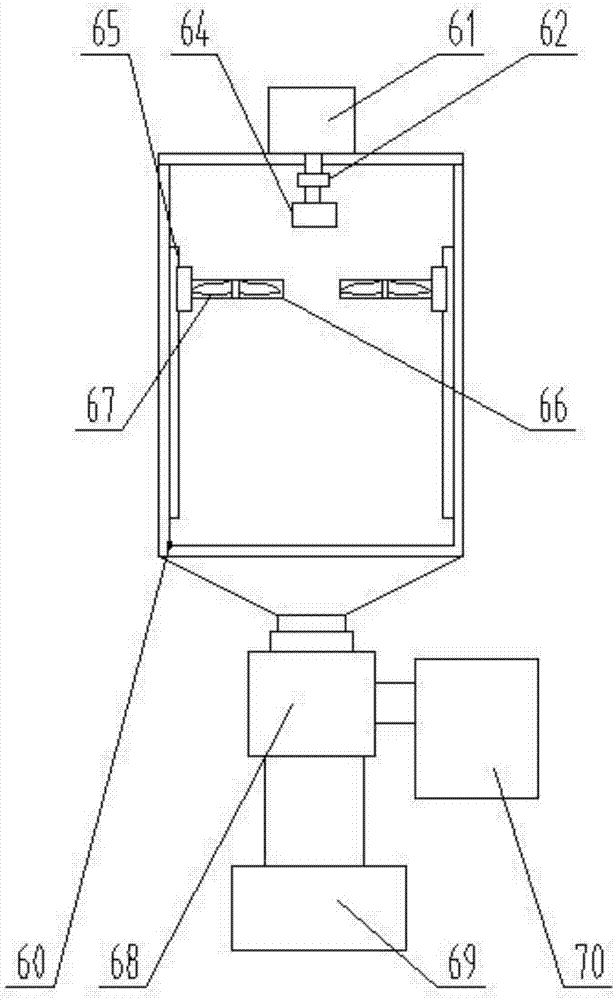

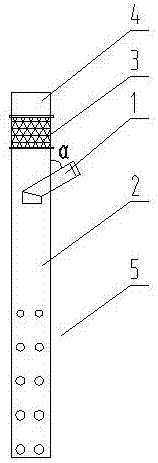

Amino acid powder mixing equipment

InactiveCN108144499AAchieve the purpose of stirringAchieve the purpose of crushingRotating receptacle mixersTransportation and packagingBiochemical engineeringAmino acid

The invention discloses amino acid powder mixing equipment, which comprises a box body. The amino acid powder mixing equipment is characterized in that the lower surface of the top plate of the box body is fixedly connected with a first motor; the output shaft of the first motor is fixedly connected with a first belt pulley; the inner side of the box body is provided with a plurality of pulverizing units; each pulverizing unit comprises a driving pulverizing roller and a driven pulverizing roller, wherein the driving pulverizing roller and the driven pulverizing roller are both rotatably connected into the box body; the driving pulverizing roller is fixedly connected with a rotation driving gear; the driven pulverizing roller is fixedly connected with a driven gear; the driven gear and thedriving gear are meshed; the driving gear is fixedly provided with a second belt pulley; the second belt pulley is connected with the first belt pulley through a belt; the upper side of the driving gear is provided with a feeding funnel. According to the amino acid powder mixing equipment, a purpose of massive amino acid pulverization is realized, meanwhile, different amino acids are mixed, and therefore, the amino acid powder mixing equipment is worth popularizing.

Owner:NANJING HANERSI BIOLOGY TECHNOLOGY CO LTD

Production line for tenofovir

ActiveCN107383100ALow powerReasonable structural designGroup 5/15 element organic compoundsChemical industryProduction lineDistillation

The invention discloses a production line for tenofovir. The production line comprises a primary reaction still, a low-temperature reaction still, a distillation type reaction still, a secondary reaction still and a recovery settling tank, wherein the primary reaction still comprises a reaction still body and at least two material uniformizing boards; rotating shafts are respectively arranged at two ends of the material uniformizing boards; a material uniformizing board mounting support is arranged in the reaction still; a gear is arranged on the rotating shaft at one end of each material uniform distribution board. The production line disclosed by the invention is reasonable in structural design; the primary reaction still blocks rotating liquid in the reaction still by the material uniformizing boards, so that the stirring efficiency is improved; meanwhile, angles of the material uniformizing boards can be adjusted according to the stirring progress of the liquid in the reaction still, so as to change the flowing speed of the liquid in the reaction still; the low-temperature reaction still adopts an electric sliding table to drive fan type stirring blades; because of a fluid principle, the stirring blades automatically rotate in a vertical moving process, and further the aim of stirring is achieved; besides, motor power and a calorific value are both reduced; the efficiency of an evolution reaction is high, distillation efficiency of the distillation type reaction still is high, the purity of a product is high, and a good practical value is realized.

Owner:XINING KEJIN INDUSTRIAL DESIGN CO LTD

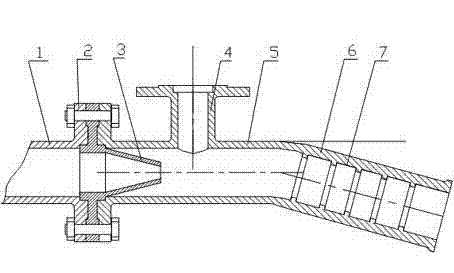

Combined jet flow aeration device

InactiveCN103159318AIncrease contact areaImprove oxygen transfer rateTreatment using aerobic processesWater aerationJet flowEnvironmental engineering

The invention provides a combined jet flow aeration device. The combined jet flow aeration device comprises a high-pressure water inlet pipe, a jet flow nozzle and an aeration three-way pipe. A right end of the high-pressure water inlet pipe and a left end of the aeration three-way pipe are provided with flanges. A left end of the jet flow nozzle is provided with a flange. The flange of the jet flow nozzle is arranged between the flanges at the right end of the high-pressure water inlet pipe and at the left end of the aeration three-way pipe. The three flanges are fixed by bolts. A tapered nozzle tip of the jet flow nozzle extends into the aeration three-way pipe. A right side of the left end of the aeration three-way pipe is provided with a gas inlet pipe. A lower end of the gas inlet pipe is located at upper right of the tapered nozzle tip of the jet flow nozzle. A right side of the gas inlet pipe of the aeration three-way pipe is provided a bend pipe. An inner wall of the bend pipe is provided with turbulent flow grooves.

Owner:王全勇

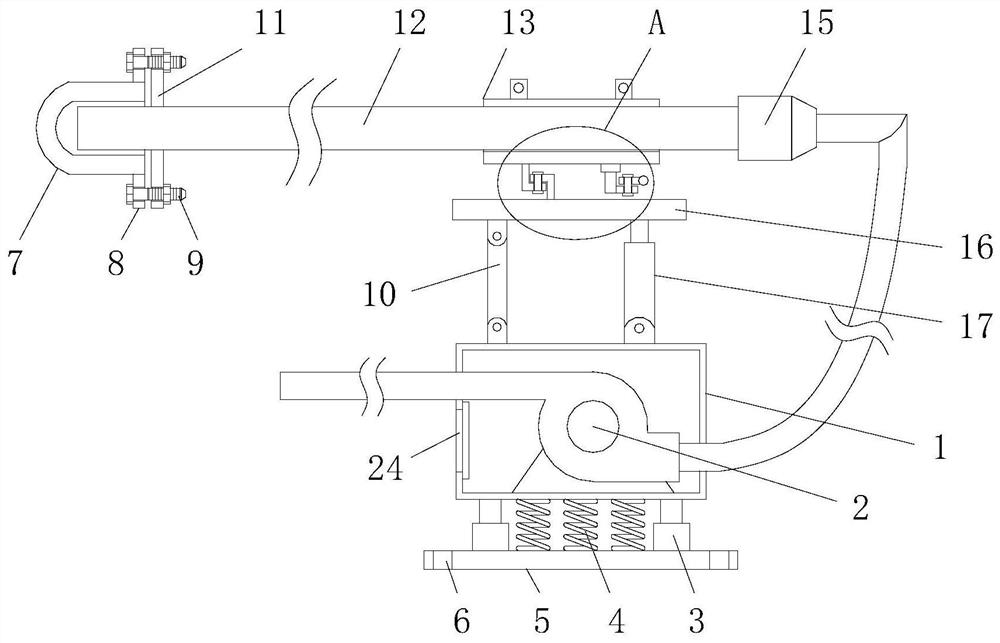

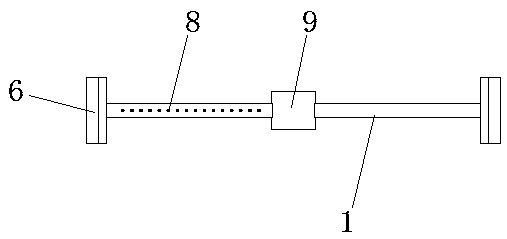

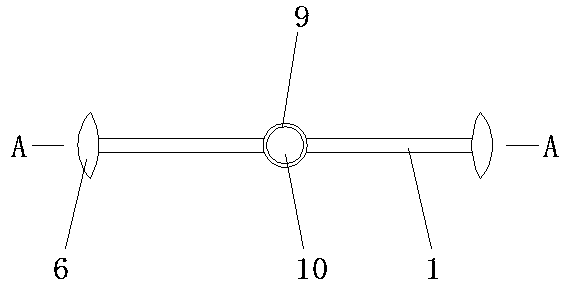

Low temperature reaction kettle provided with feeding device

ActiveCN107308903AReasonable structural designReduce motor powerGroup 5/15 element organic compoundsChemical/physical/physico-chemical stationary reactorsMotor powerTemperature control

A low temperature reaction kettle provided with a feeding device comprises a low temperature reaction kettle body, the feeding device, a low temperature control device, a stirring device and a centrifugal solid-liquid separation device, the top of the low temperature reaction kettle body is provided with a feeding opening, the bottom of the low temperature reaction kettle body is provided with a discharging opening, the feeding device comprises a bent discharging tube, a homogenizing tube, a filler box and a fan, two ends of the homogenizing tube are openmouthed, one end of the homogenizing tube is positioned in the low temperature reaction kettle body, and the tube wall of one end, positioned in the low temperature reaction kettle body, of the homogenizing tube is provided with a plurality of groups of holes. The low temperature reaction kettle provided with the feeding device has a reasonable structure design, and adopts electric slide tables to drive fan type stirring blades, and a material automatically rotates due to a fluid principle in the up-and-down movement process of the stirring blades in order to reach a stirring purpose, so the motor power is reduced, the generated heat is reduced, the precipitation reaction efficiency is high, and the kettle has very high practical values.

Owner:JINGMEN SHUAIBANG CHEM SCI & TECHCO

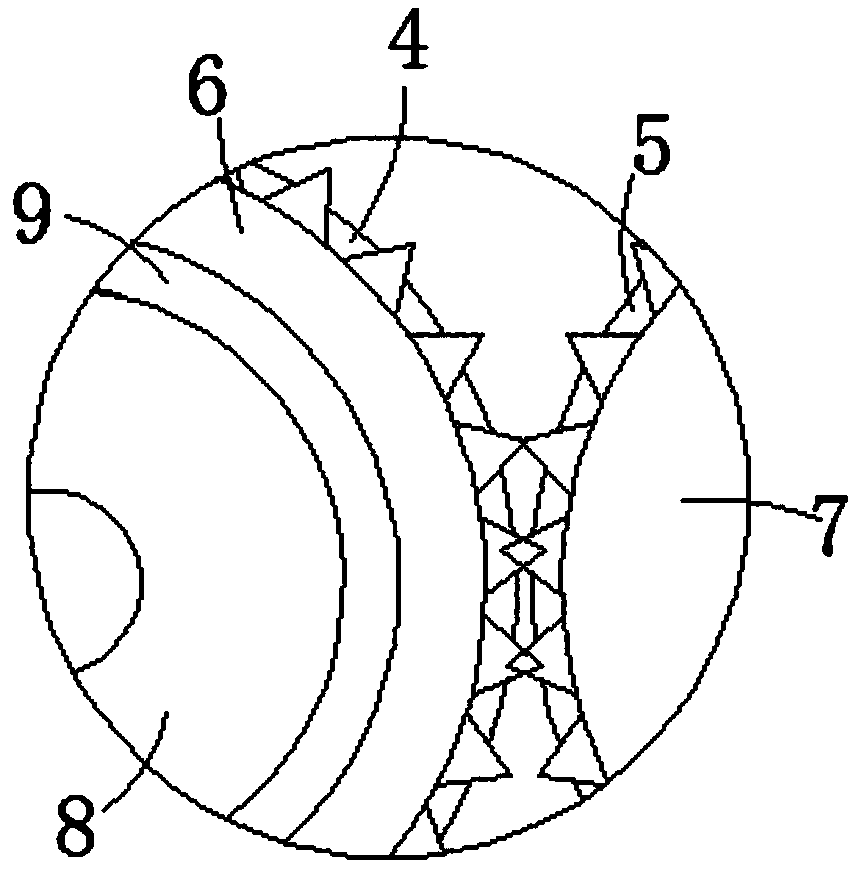

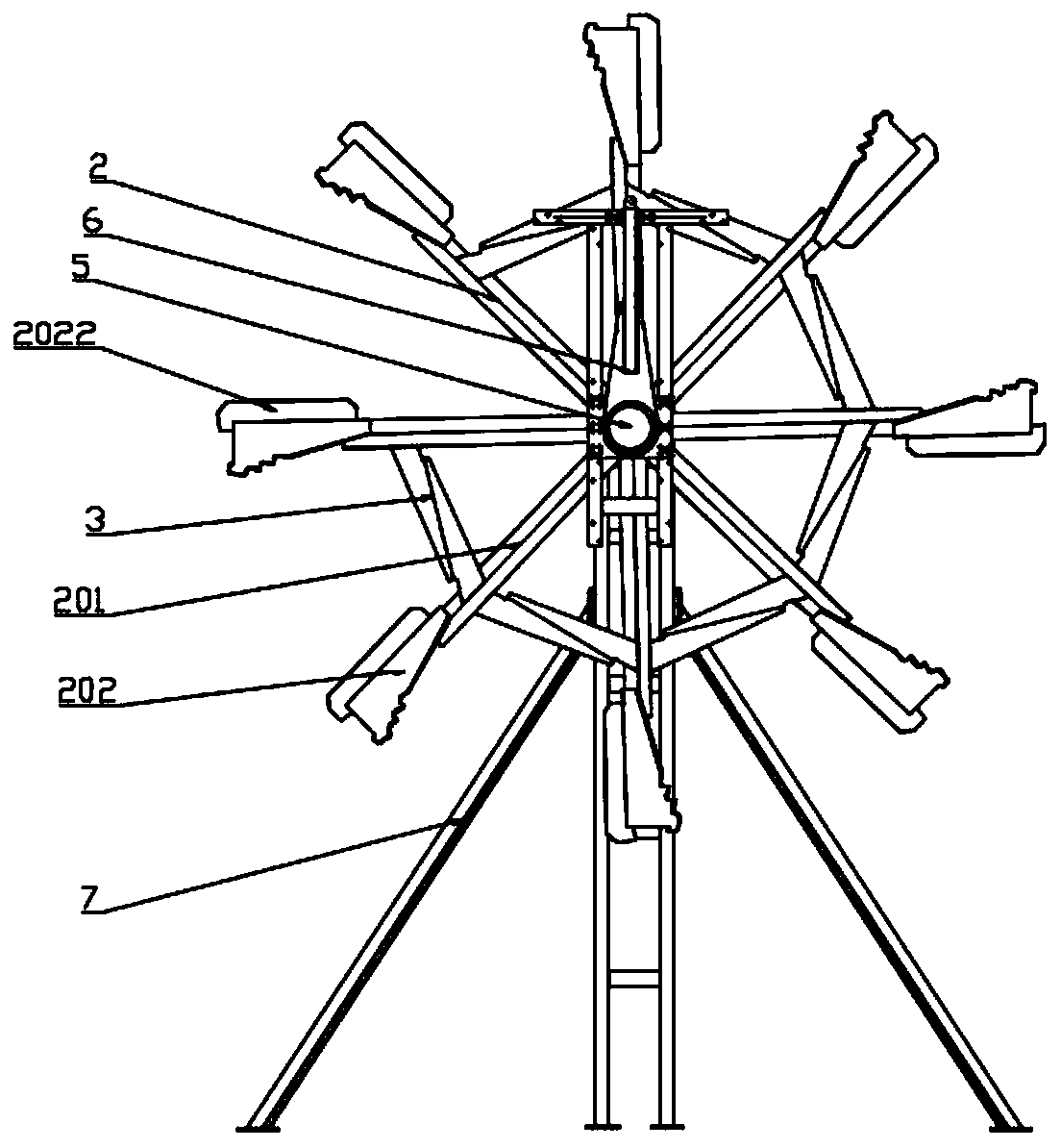

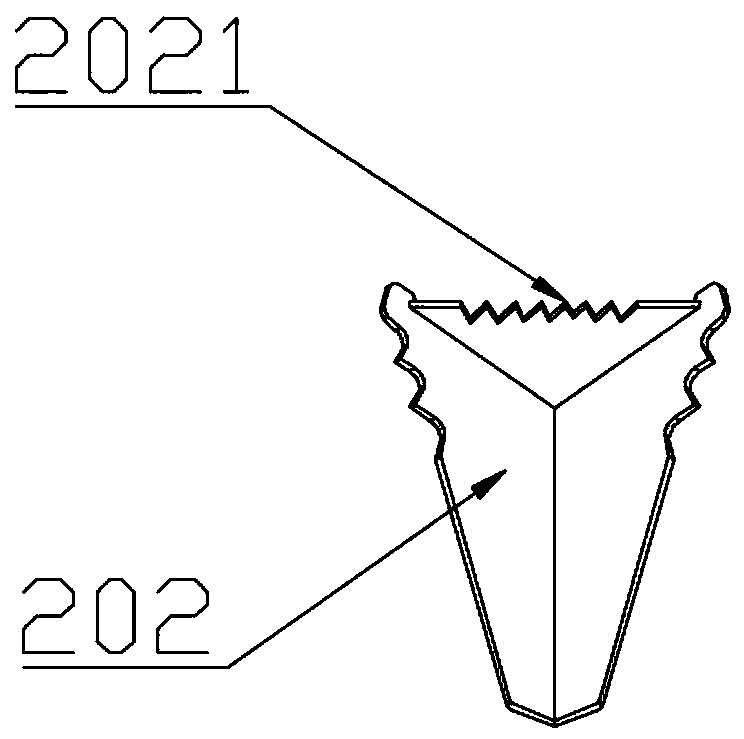

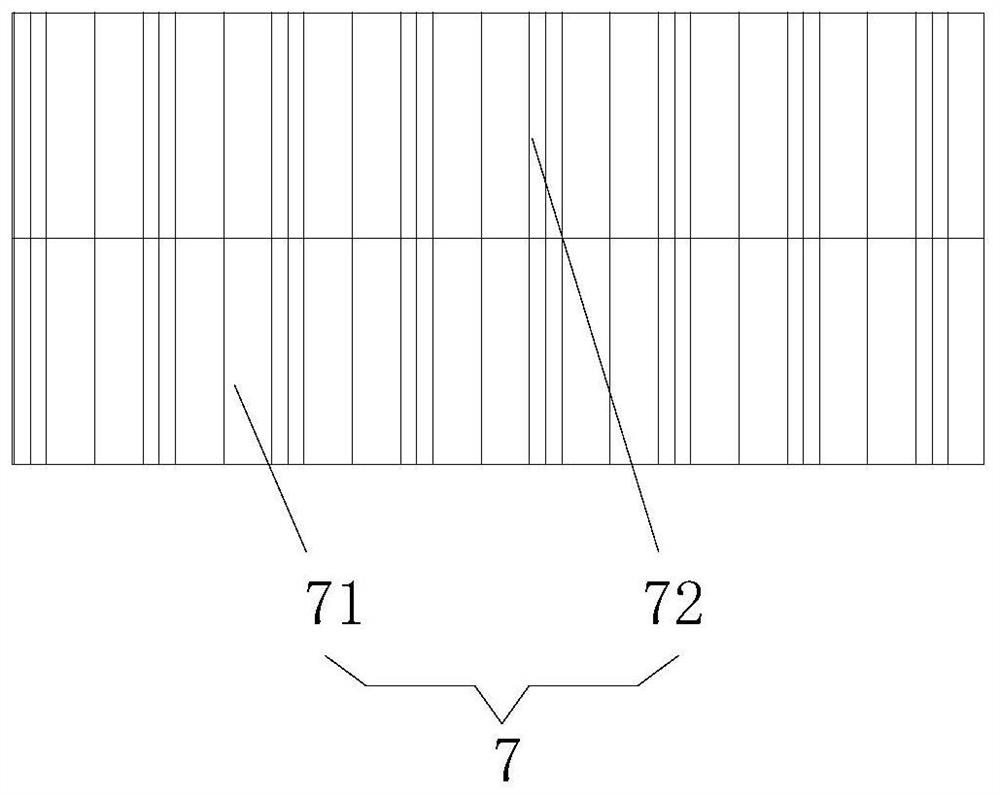

Paddle stirrer with shell breaking function

PendingCN110452805ASolve the floating layer problemImprove stirring efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsHigh concentrationElectricity

The invention relates to a paddle stirrer with a shell breaking function. The paddle stirrer comprises a rotating shaft and stirring paddles, the rotating shaft and the stirring paddles are connectedwith each other, and the stirring paddles are perpendicular to the rotating shaft; one end of each stirring paddle is fixedly connected with the rotating shaft, the other end of each stirring paddle is provided with a bucket-shaped blade, the edge of a bucket-shaped opening in each paddle is in a sawtooth shape, and the direction of the bucket-shaped openings of the blades is consistent with the force applying direction during forward stirring; the blades are provided with plate knives, the plate knives are arranged away from the bucket-shaped openings, the knife edge direction of the plate knives is consistent with the force applying direction during reverse stirring, and the stirring paddles are uniformly and spirally mounted on the rotating shaft along the axis of the rotating shaft. The paddle stirrer is especially suitable for a high-concentration continuous fermentation technology of mixed raw materials, easy stirring can still be achieved when the concentration of fermentation liquor is high, the shell breaking capacity is high, the electricity consumption is low, the energy consumption is reduced, and the operation cost is reduced.

Owner:湖北绿鑫生态科技有限公司

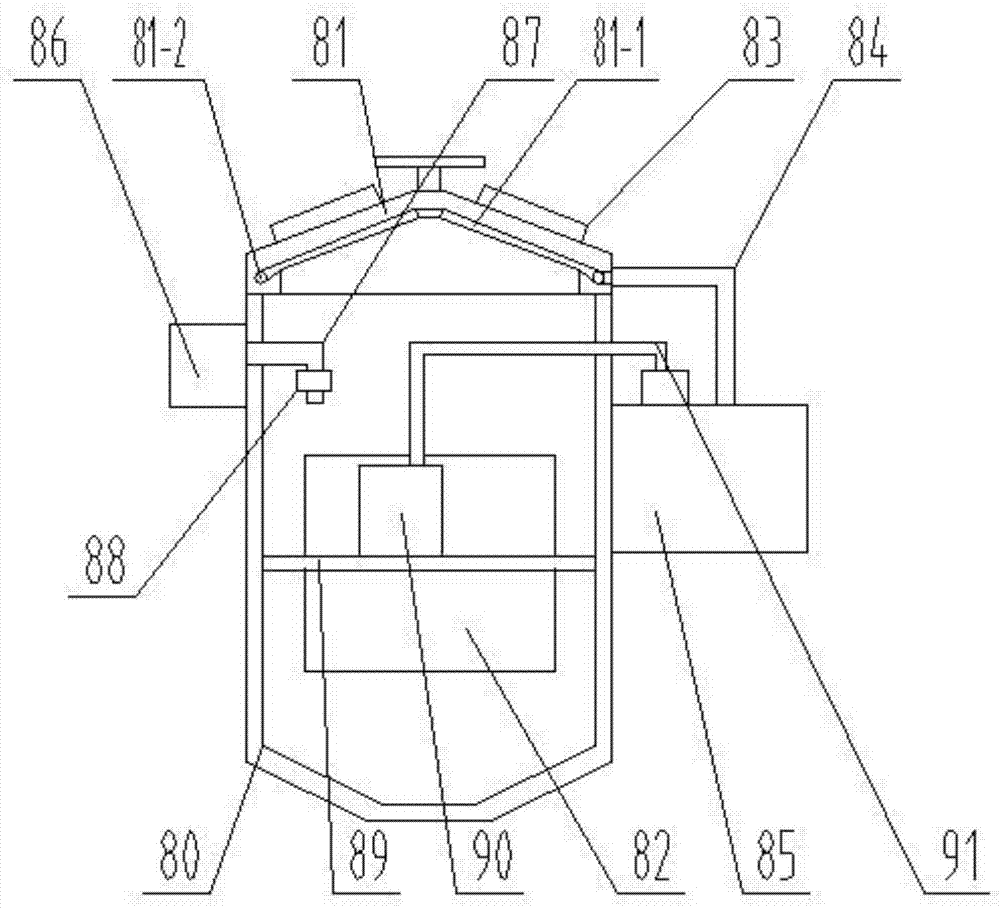

Stirring device for biological medicine preparation

ActiveCN105833761AAchieve the purpose of stirringWell mixedRotary stirring mixersTransportation and packagingAgricultural engineeringSpeed reduction

The invention relates to a stirring device for biological medicine preparation. The stirring device comprises a bucket body, a left feeding hole, a top electromotor, a top speed reduction device, a right feeding hole, a sleeve shaft, a square frame, arc-shaped stirring paddles, a bottom electromotor, a bottom speed reduction device, an inner rotating shaft, a vertical stirring paddle, a discharge hole and universal wheels, wherein the top electromotor is connected with the top speed reduction device; the top speed reduction device is connected with the sleeve shaft; the sleeve shaft is connected with the square frame; the arc-shaped stirring paddles are arranged on the square frame; the arc-shaped stirring paddle are arranged at opposite corners of the square frame; the bottom electromotor is arranged at the lower part of the bucket body; the bottom electromotor is connected with the bottom speed reduction device; the bottom speed reduction device is connected with the inner rotating shaft; the vertical stirring paddle is arranged on the inner rotating shaft; the vertical stirring paddle is arranged in the center of the bucket body; the sleeve shaft and the inner rotating shaft are arranged in a concentric manner. On the basis of conventional stirring equipment, the stirring device provided by the invention is uniform in stirring, high in efficiency, time and labor saving and high in security.

Owner:重庆西南制药二厂有限责任公司

Preparing machine of composition which contains alginic acid or salts of alginic acid, and is used for ophthalmology

InactiveCN107398207AAchieve the purpose of stirringEasy to operateRotary stirring mixersTransportation and packagingEngineeringAlginic acid

The invention relates to a composition preparing machine, and especially relates to a preparing machine of a composition which contains alginic acid or salts of alginic acid, and is used for ophthalmology. The preparing machine is used for realizing full stirring mixing, and preventing internal wall adhesion. The preparing machine comprises a preparing box; the left side and the right side of the top wall of the preparing box, and the middle part of the bottom wall of the preparing box are connected with material pipes; the material pipes are provided with valves; the internal part of the preparing box is connected with a preparation mechanism; the left side and the right side of the internal part of the preparing box are connected with shaking mechanisms; and the shaking mechanism are connected with the preparation mechanism. The preparation mechanism and the shaking mechanisms are used for realizing clockwise and anti-clockwise alternative rotating and upward-downward shaking of the composition; and a first rubber gasket is used for preventing overhigh friction of a contact block with the ground, and avoiding damage of the ground.

Owner:杨文龙

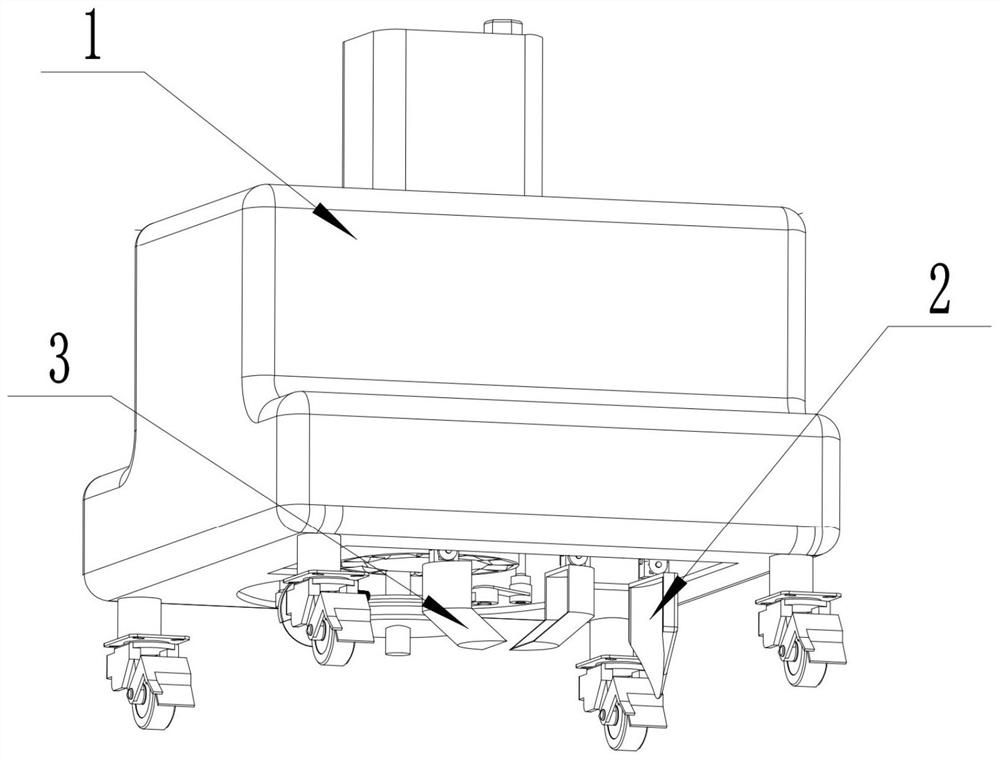

Plastic track repairing equipment

ActiveCN113250063AEasy to patch and fillExtended service lifeRoads maintainenceEnvironmental geologyStructural engineering

The invention discloses plastic track repairing equipment, and the equipment comprises a shell part, a cutting and shoveling part, a soil holding part, a rotary filler placing part and a pressing and stirring part. The interior of the shell is designed to be hollow, four sliding wheels are installed at the bottom of the shell, two round holes are formed in the upper end face of the shell, one round hole is connected with an output port of the filler storage box, and the filler storage box is fixedly installed on the shell; the number of the sliding lead screw mechanisms A is two, and the two sliding lead screw mechanisms A are installed at the upper end of the cutting mechanism and the upper end of the damaged runway shoveling part correspondingly. The cutting mechanism and the damaged runway shoveling part are driven by the sliding lead screw mechanism A to slide, so the same place can be treated in sequence; the periphery of the plastic runway needing to be repaired is cut through the cutting mechanism, then the cut place is shoveled by shoveling the damaged runway part, the large plastic runway is changed into small pieces, and digging out in the later period is facilitated.

Owner:湖南星踏体育新材料开发有限公司

Coal mine central sump sludge cleaning device

InactiveCN112160366AAdjust the tilt angleGreat suctionMechanical machines/dredgersProcess engineeringCoal

The invention discloses a coal mine central water sump sludge cleaning device which comprises a shell and a filter cover, wherein a pump with an output end in communication with a pipeline is fixedlyinstalled at the bottom of an inner cavity of the shell, supporting rods are movably connected to the front side and the rear side of the left end of the top of the shell through rotating shafts, anda supporting plate is movably connected to the tops of the supporting rods through rotating shafts. Through arrangement of a sludge pumping pipe, a sleeve, the pipeline and the pump, the pump pumps out sludge through the sludge pumping pipe and the pipeline; through arrangement of the supporting rods, the rotating shafts, first electric telescopic rods and the supporting plate, the purpose of adjusting an inclination angle of the sludge pumping pipe can be achieved, and people can conveniently pump out sludge at different positions; and through arrangement of a second clamping rod, a first clamping rod, a second connecting rod, a second electric telescopic rod, a fourth connecting rod, a third connecting rod, a first connecting rod, a bearing and a clamping plate, the purpose of adjustinga horizontal angle of the sludge pumping pipe can be achieved, and people can conveniently pump out sludge at different positions.

Owner:ANHUI HUITENG INTELLIGENT TRANSPORTATION TECH CO LTD

Emulsifying device for improving emulsifying efficiency of cosmetics

PendingCN107737538AImprove emulsification efficiencyBoost Product TherapyMixing methodsTransportation and packagingEngineering

The invention relates to the technical field of making of cosmetics, and discloses an emulsifying device for improving the emulsifying efficiency of cosmetics, comprising a base, wherein a support rodI is fixedly connected to the left end of the top of the base, a load bearing table I is fixedly connected to the top of the support rod I, an aqueous phase pot is fixedly connected to the top of theload bearing table I, a connecting pipe I is fixedly connected to the right side of the aqueous phase pot, and a support rod II is fixedly connected to the right end of the top of the base. Accordingto the emulsifying device for improving the emulsifying efficiency of cosmetics, due to the arrangement of a motor I, an emulsifying head, a motor II and impellers, after materials are delivered intoan emulsifying pot by an oil phase pot and the aqueous pot, the motor I normally works and then drives the emulsifying heat to emulsify the materials, and the motor II normally works and then drivesthe impellers to rotate, so as to achieve the aim of stirring the materials, thus achieving an effect of uniformly stirring the emulsified material, and further achieving the effects of improving theemulsifying efficiency and promoting product therapeutic effect.

Owner:MYC PACKAGING TECH (SUZHOU) CO LTD

Stirring structure and stirring type slurry energy storage device

InactiveCN109046149AAchieve the purpose of stirringSimple structureElectrode manufacturing processesTransportation and packagingEngineeringSlurry

The invention provides a stirring structure. The stirring structure comprises a cavity, electromagnets, and a magnet, wherein the electromagnets are arranged at both ends of the cavity; the magnet isarranged in the cavity; the energizing and deenergizing of the electromagnets are switched, and the magnet is moved under the magnetic field function of the electromagnets. The stirring structure hasthe advantages that the magnetic field is switched by energizing and deenergizing the electromagnets at the two ends, so that the magnet is moved along different directions, thereby reaching the stirring purpose; the structure is simple, the operation is easy, and the stirring effect is better.

Owner:CENT SOUTH UNIV

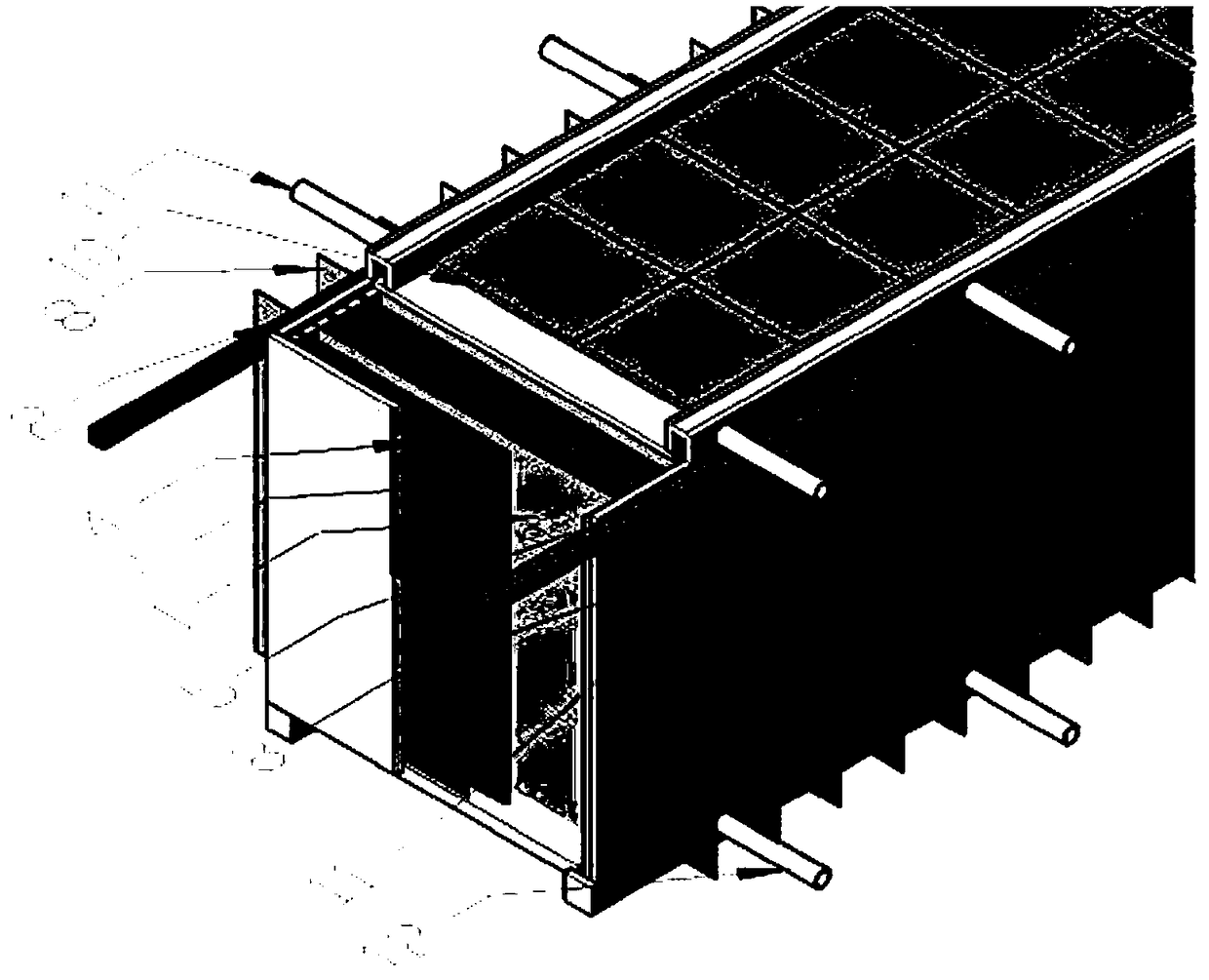

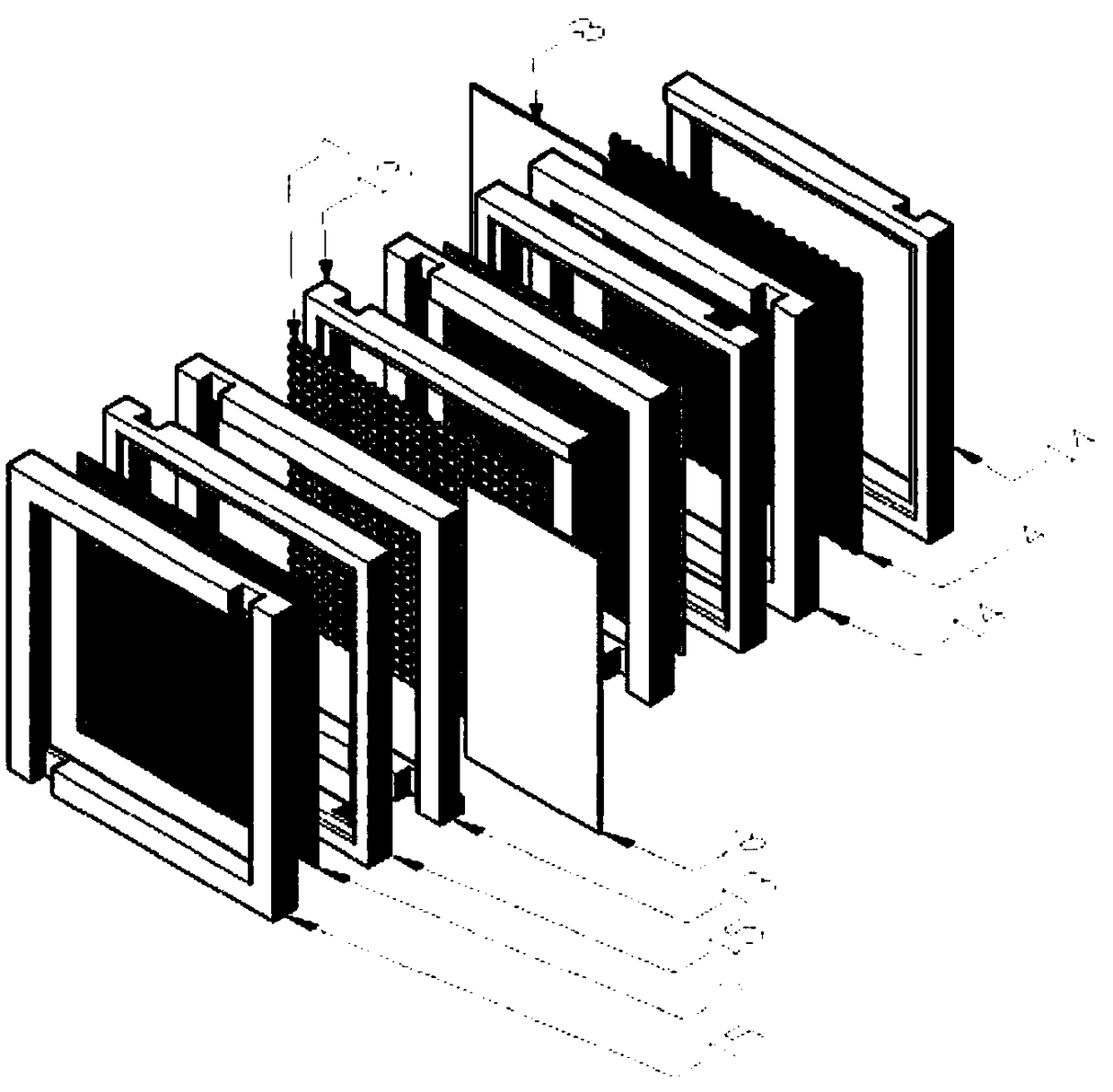

Method for stirring fermentation materials in dry fermentation tank

InactiveCN108130265ALow affinityAchieve the purpose of stirringBioreactor/fermenter combinationsBiological substance pretreatmentsHigh pressure waterHigh pressure

The invention relates to a method for stirring fermentation materials in a dry fermentation tank and belongs to the field of fermentation of organic matter. Dry fermentation and wet fermentation are adopted for fermentation of the organic matter in the field. Dry fermentation is better than wet fermentation in production efficiency, energy consumption and other aspects. However, stirring is difficult in production process of dry fermentation, which always restricts popularization of the dry fermentation process. A stirring method in the dry fermentation process is always a problem in the fieldof fermentation. Compared with the traditional mechanical stirring, high-pressure water stirring, high-pressure gas stirring methods, the stirring method has the following advantages: (1) the problemthat high-viscosity substances cannot be dispersed or uniformly stirred by mechanical stirring is solved; (2) the problems that stirred substances can be only segmented into a plurality of medium andsmall blocks but cannot be dispersed completely or uniformly stirred when the high-viscosity substances are stirred with high-pressure water are solved; (3) the problem that the stirred substances can be only loosened, that is, the affinity is reduced, but the stirred substances cannot be pulled to flow to be stirred when the high-viscosity substances are stirred with high-pressure gas is solved.

Owner:BEIJING HAOHAI TIANJI TECH +2

Asphalt concrete stirring apparatus

InactiveCN110465228AAvoid uneven mixingFirmly connectedShaking/oscillating/vibrating mixersTransportation and packagingEngineeringMaterial storage

The invention relates to the technical field of asphalt stirring equipment, and discloses an asphalt concrete stirring apparatus, which comprises a base, wherein an adjusting box is arranged on the base, the upper side of the adjusting box is provided with a stirring drum in an opposite reciprocating type rotating manner, a first adjusting mechanism for driving the stirring drum to rotate is arranged inside the adjusting box, the middle portion of the inner cavity of the stirring drum is provided with a basal seat, the upper side and the lower side of the basal seat are respectively and rotatably provided with a first stirring shaft and a second stirring shaft, a second adjusting mechanism for driving the first stirring shaft and the second stirring shaft to sequentially rotate is arrangedin the basal seat, the upper side of the basal seat is provided with an electric box matched with the first adjusting mechanism and the second adjusting mechanism, the upper side and the lower side of the stirring drum are respectively provided with a material inlet pipe and a material discharge port, an arc-shaped material storage groove matched with the material discharge port and capable of rotating back and forth is arranged in the adjusting box, one side of the adjusting box is provided with a material discharge pipe communicated to the arc-shaped material storage groove, and one side, away from the adjusting box, of the material discharge pipe is provided with a sealing cover. According to the present invention, the asphalt concrete stirring apparatus can solve the problem of non-uniform stirring of the existing stirring device.

Owner:河南征远沥青砼有限公司

Stirring device with aeration function and manufacturing method thereof

PendingCN111170479AImprove production efficiencyReduce the temperatureWater aerationSustainable biological treatmentMechanical equipmentIndustrial engineering

The invention discloses a stirring device with an aeration function and a manufacturing method thereof. The invention belongs to the technical field of environment-friendly mechanical equipment. On the basis of an impeller-free design, the stirring device is driven to rotate through aerodynamic force, thus stirring materials; an air jet hole has a unique venturi structure, which can effectively reduce the temperature of waste water and waste liquid, so that flocculation and deposition of floccules in waste water and waste liquid are promoted; in order to facilitate smooth processing of the venturi air nozzle structure, the manufacturing method is scientific, not only can the manufacturing efficiency of the stirring device be improved, but also the manufacturing cost is low, and compared with a traditional machining method. The manufacturing method is simple in process, free of rough machining and cutting links, capable of saving a large number of raw materials, capable of achieving batch production and capable of well solving the machining problem of the novel stirring device.

Owner:YANGZHOU UNIV

Chemical Reaction Kettle for Research of Non-ferrous Alloy Materials

InactiveCN110681337AImprove stabilityReduce vibrationHollow article cleaningChemical/physical/physico-chemical stationary reactorsChemical reactionEngineering

The invention discloses a chemical reaction kettle for the research of non-ferrous metal alloy materials and relates to the technical field of non-ferrous metals. The chemical reaction kettle comprises a fixing seat, wherein the top of the fixing seat is fixedly provided with a reaction kettle body, and a supporting leg is fixedly installed at the position below the outer side of the fixing seat,the inner side of the supporting leg is provided with a fixing frame, the front side of the reaction kettle body is provided with a control panel, and the top of the reaction kettle body is provided with a feed port. As that structure of the invention is scientific and reasonable, by providing the fixing seat, a shock absorbing spring can be used, so as to reduce the vibration phenomenon in the working process of the equipment and improve its stability; the arranged stirring mechanism can stir the materials inside the reaction kettle, and can scrape off the materials adhered to the inner wallof the reaction kettle in time, so as to improve the uniformity of the material reaction and provide convenience for the cleaning work of the reaction kettle. The arranged circulation mechanism can carry out secondary reaction on the materials inside the reaction kettle to ensure the uniformity.

Owner:CHANGDE XINRUI NEW MATERIAL CO LTD

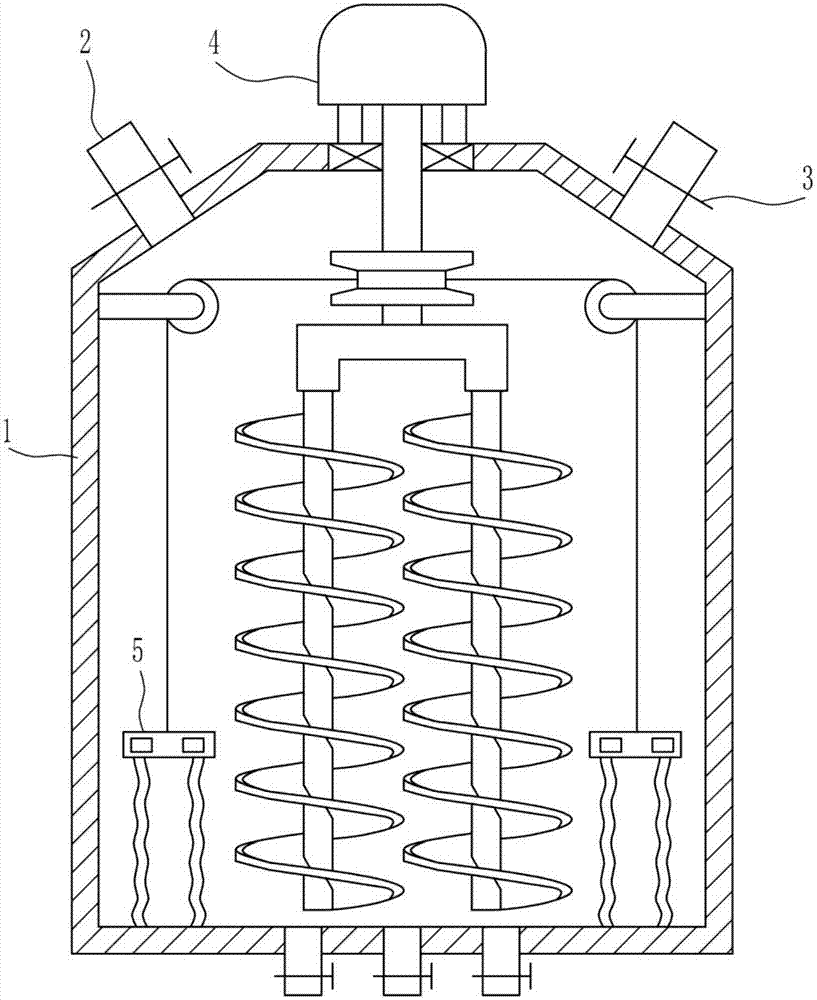

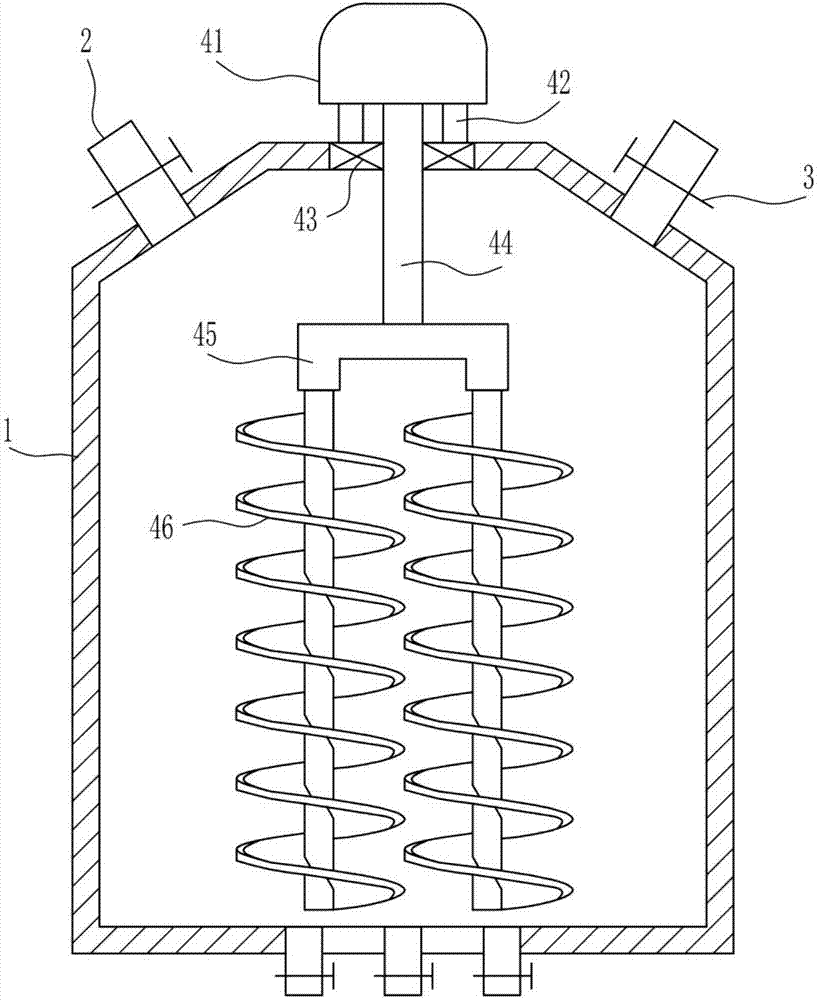

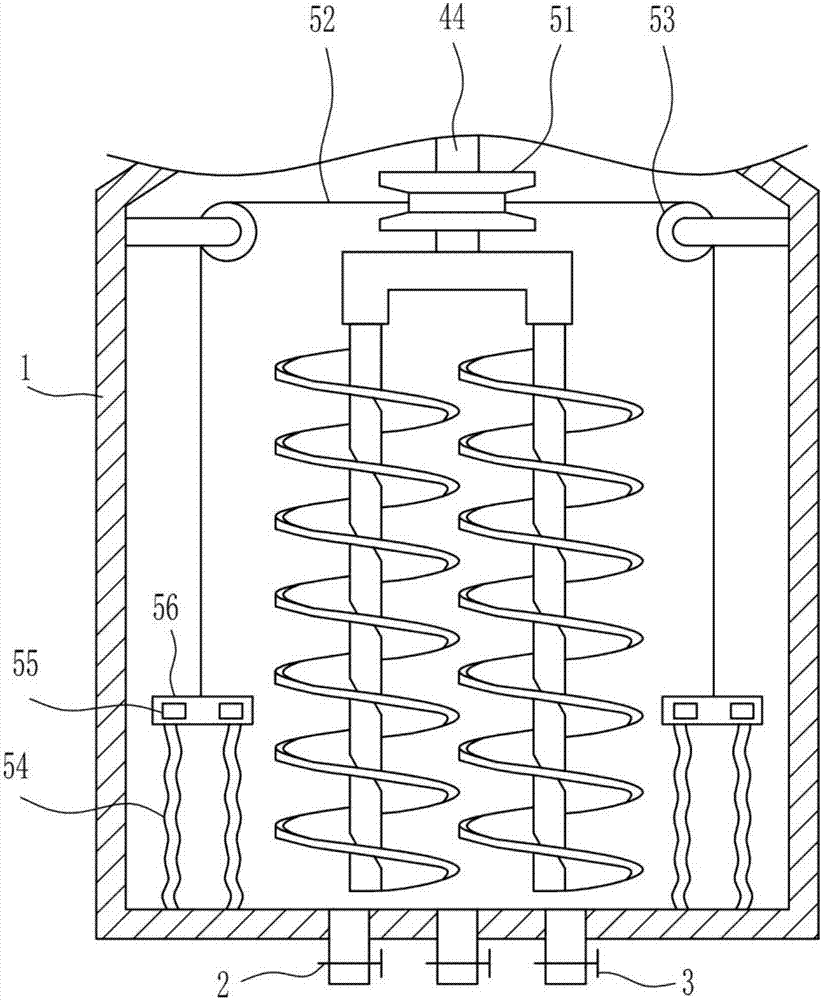

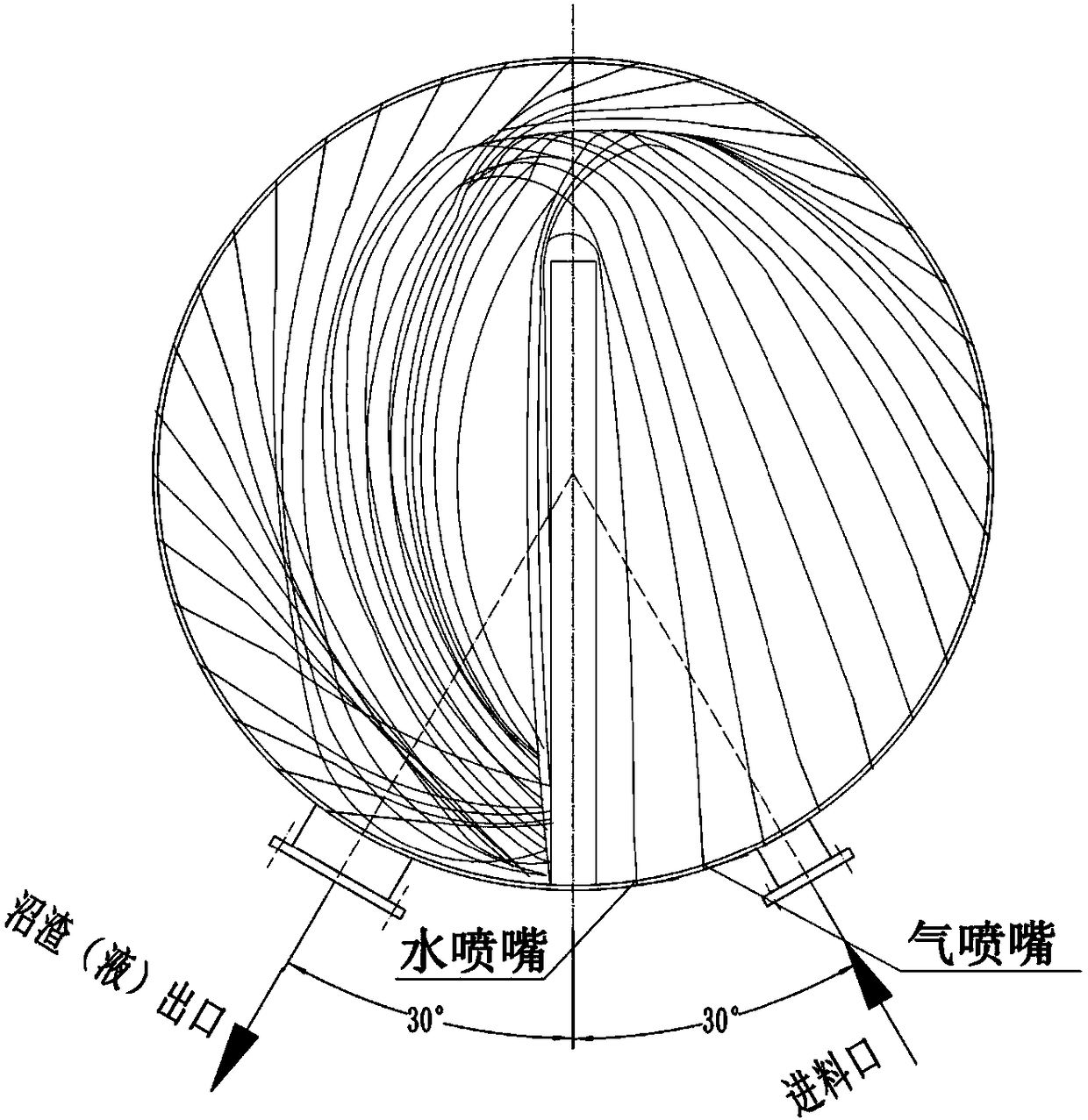

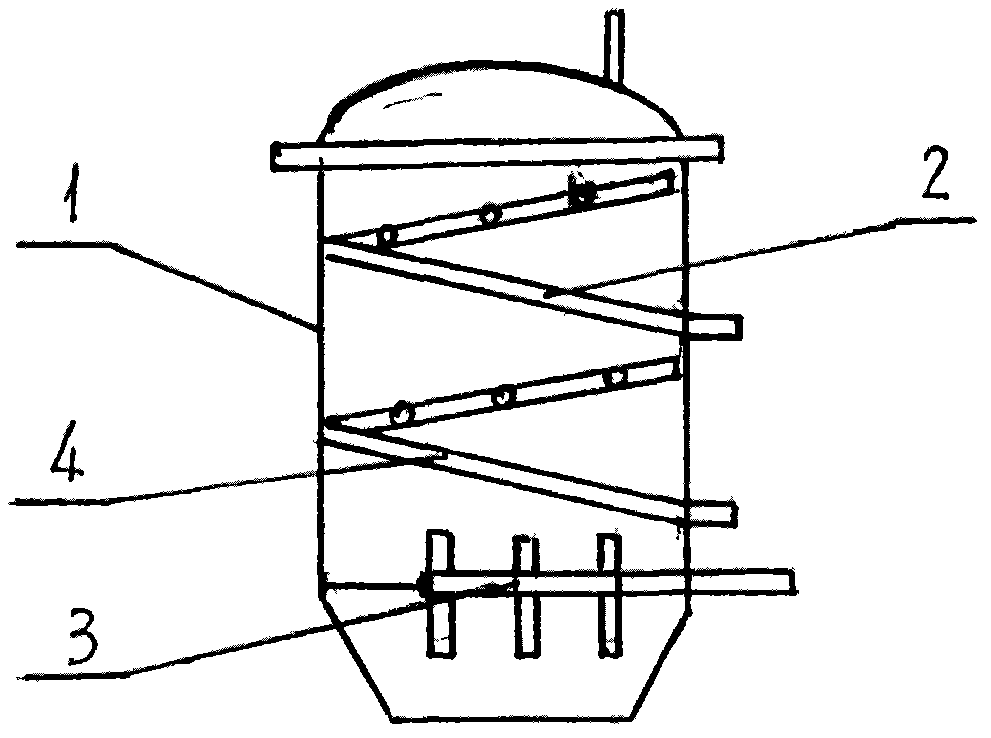

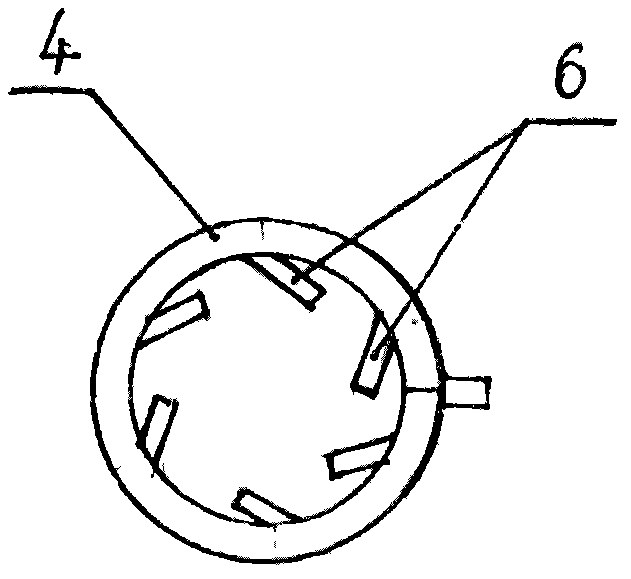

Three-dimensional liquid-phase fermentation helical stirring device

InactiveCN103194378AGas production starts quicklyUniform temperatureBioreactor/fermenter combinationsBiological substance pretreatmentsMethane fermentationAgricultural engineering

The invention relates to a three-dimensional liquid-phase fermentation helical stirring device, which belongs to the methane fermentation technology. A biogass slurry horizontal anticlockwise helical conveying main pipe, a biogass slurry horizontal clockwise helical conveying main pipe and a biogass slurry annular vertical conveying main pipe are installed in a fermentation reaction tank body, wherein the biogass slurry annular conveying main pipe is arranged on the bottom side part of the fermentation reaction tank body, a biogass slurry horizontal anticlockwise ejection pipe is installed on the inner side part of the biogass slurry horizontal anticlockwise helical conveying main pipe, a biogass slurry horizontal clockwise ejection pipe is installed on the inner side part of the biogass slurry horizontal clockwise helical conveying main pipe, and a biogass slurry vertical ejection pipe is installed on the biogass slurry annular vertical conveying main pipe. The three-dimensional liquid-phase fermentation helical stirring device is simple and reasonable in structure, uniform in stirring and high in gas yield.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

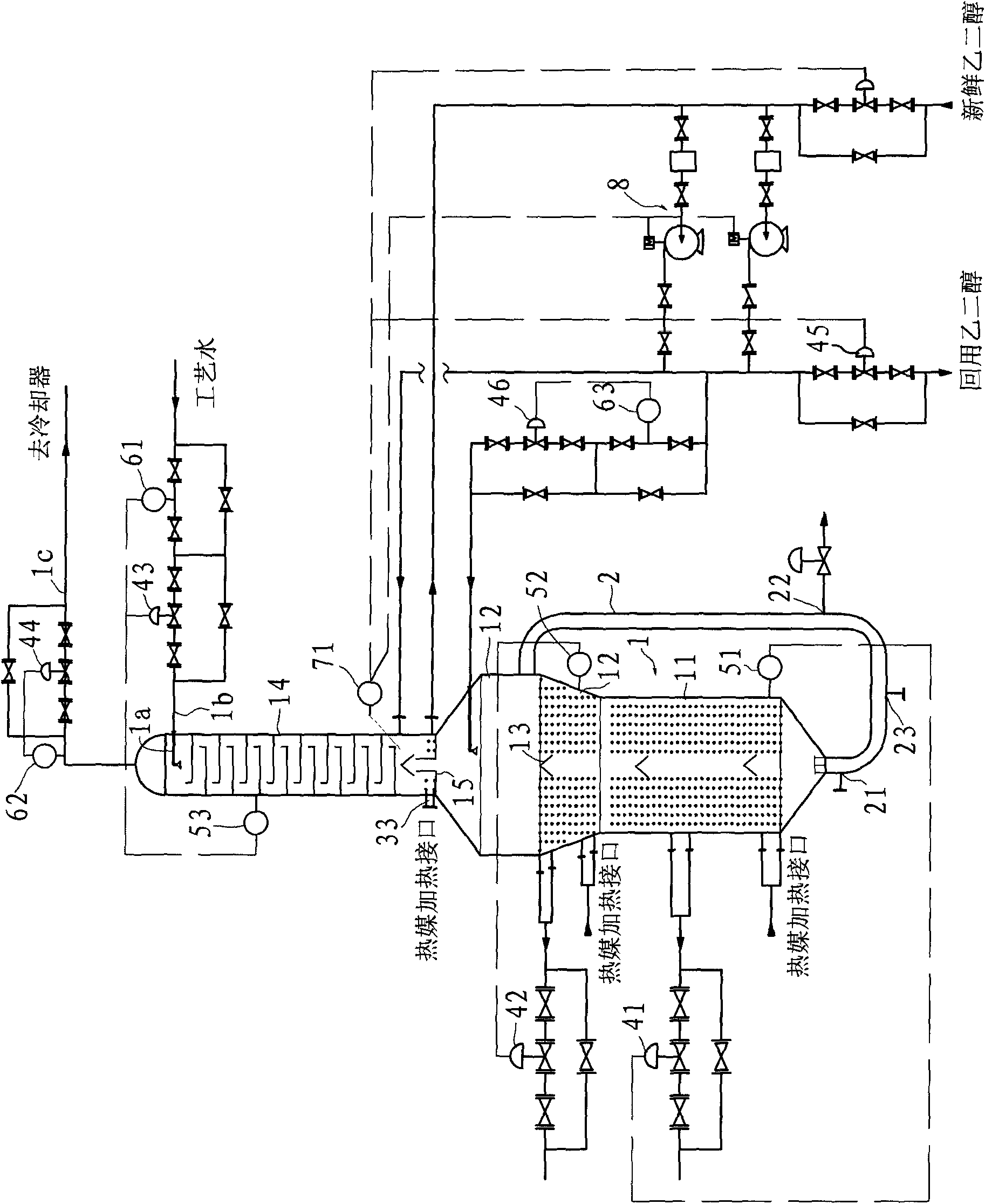

Crystallization reaction system of tenofovir production line

ActiveCN107266500ALow powerReasonable structural designGroup 5/15 element organic compoundsTransportation and packagingProduction lineAlcohol

A crystallization reaction system of a tenofovir production line comprises a low-temperature reaction kettle and a distilled type reaction kettle, wherein the low-temperature reaction kettle comprises a low-temperature reaction kettle body, a low-temperature control device, a stirring device and a centrifugal type solid-liquid separating device; a feeding opening is formed in the top of the low-temperature reaction kettle body; a discharging opening is formed in the bottom of the low-temperature reaction kettle body; the low-temperature control device comprises an alcohol box, an electronic control valve and a rotary atomizing sprayer; and the alcohol box is fixedly mounted on the top of the low-temperature reaction kettle body. The crystallization reaction system of the tenofovir production line is reasonable in structural design, the low-temperature reaction kettle drives fan type stirring blades by an electric sliding table, the stirring blades automatically rotate in a vertical moving process due to a fluid principle, and therefore, the stirring purpose is achieved; the power of a motor is reduced, the heating amount is further reduced, and the crystallization reaction efficiency is high; and by the distilled type reaction kettle, distillation reaction of diethyl tenofovir as a semi-finished product of tenofovir can be efficiently finished, the distillation efficiency is high, the purity of the product is also high, and the practical value is high.

Owner:XINING KEJIN INDUSTRIAL DESIGN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com