Three-dimensional liquid-phase fermentation helical stirring device

A technology of spiral stirring and three-dimensional liquid phase is applied in the field of spiral stirring devices, which can solve the problems of difficulty in stirring and stirring organic fermentation materials, the production of biogas needs to be improved, and the stirring ability and effect are poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

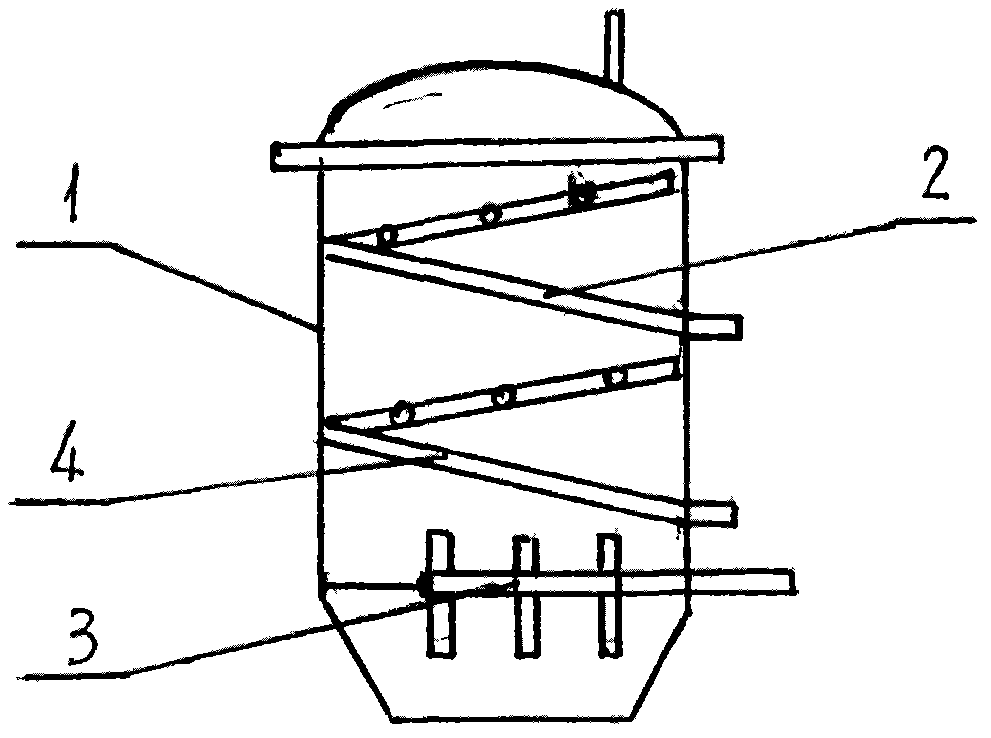

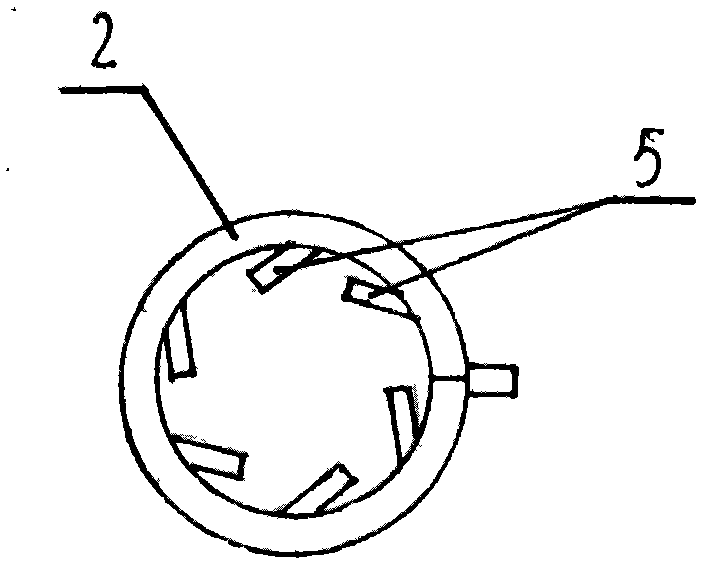

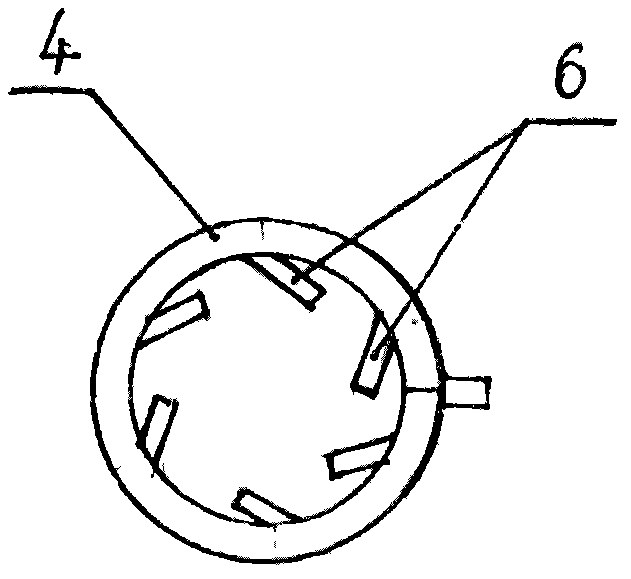

[0012] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A three-dimensional liquid-phase fermentation spiral stirring device includes a fermentation reaction tank 1, and the fermentation reaction tank 1 is equipped with a biogas slurry horizontal counterclockwise screw conveying main pipe 2, a biogas slurry horizontal clockwise spiral conveying main pipe 4 and a biogas slurry annular vertical conveying The main pipe 3, the biogas slurry ring-shaped vertical conveying main pipe 3 is located at the bottom side of the fermentation reaction tank 1; the biogas slurry is installed on the inner side of the biogas slurry horizontal counterclockwise spiral conveying main pipe 2 along the circumference counterclockwise The horizontal counterclockwise ejection pipe 5 is equipped with a biogas slurry horizontal clockwise ejection pipe 6 on the inner side of the biogas slurry horizontal clockwise spiral conveying main pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com