Patents

Literature

113results about How to "Fully produced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

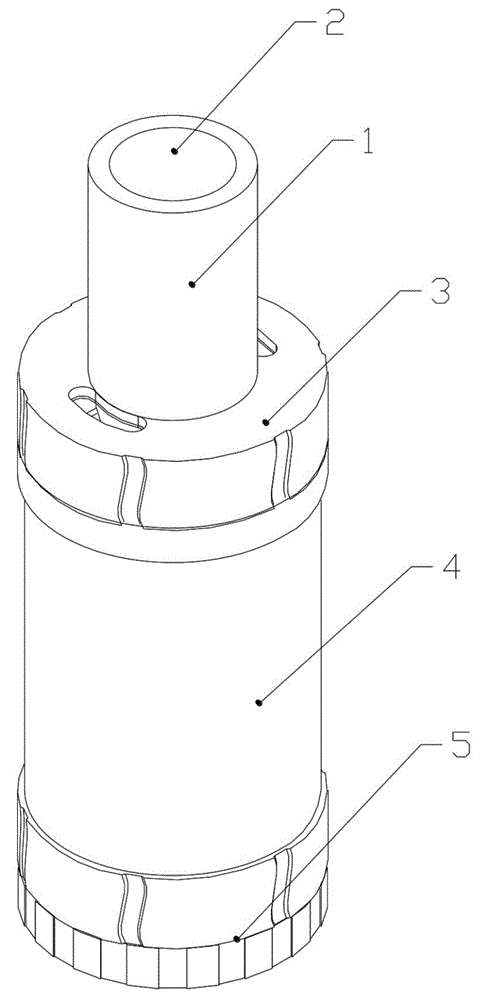

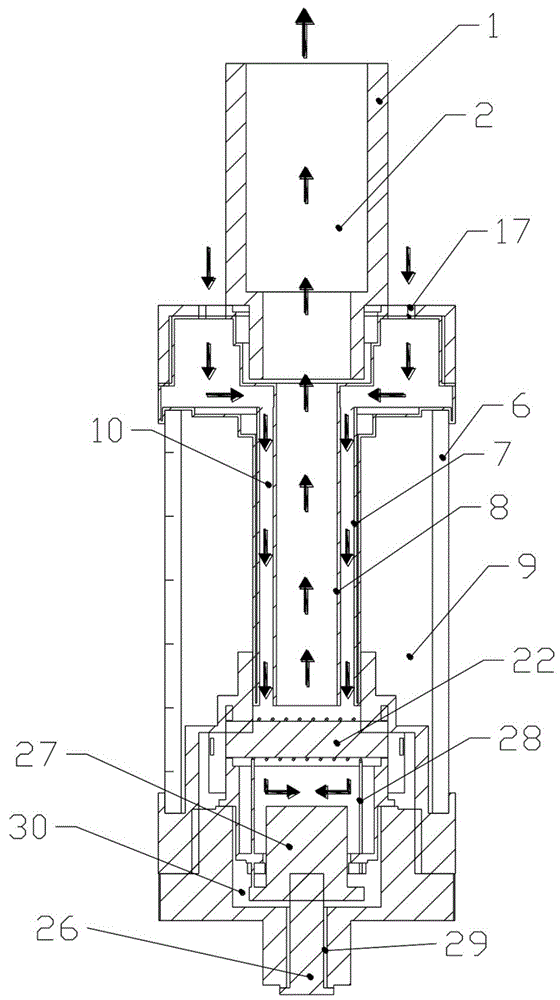

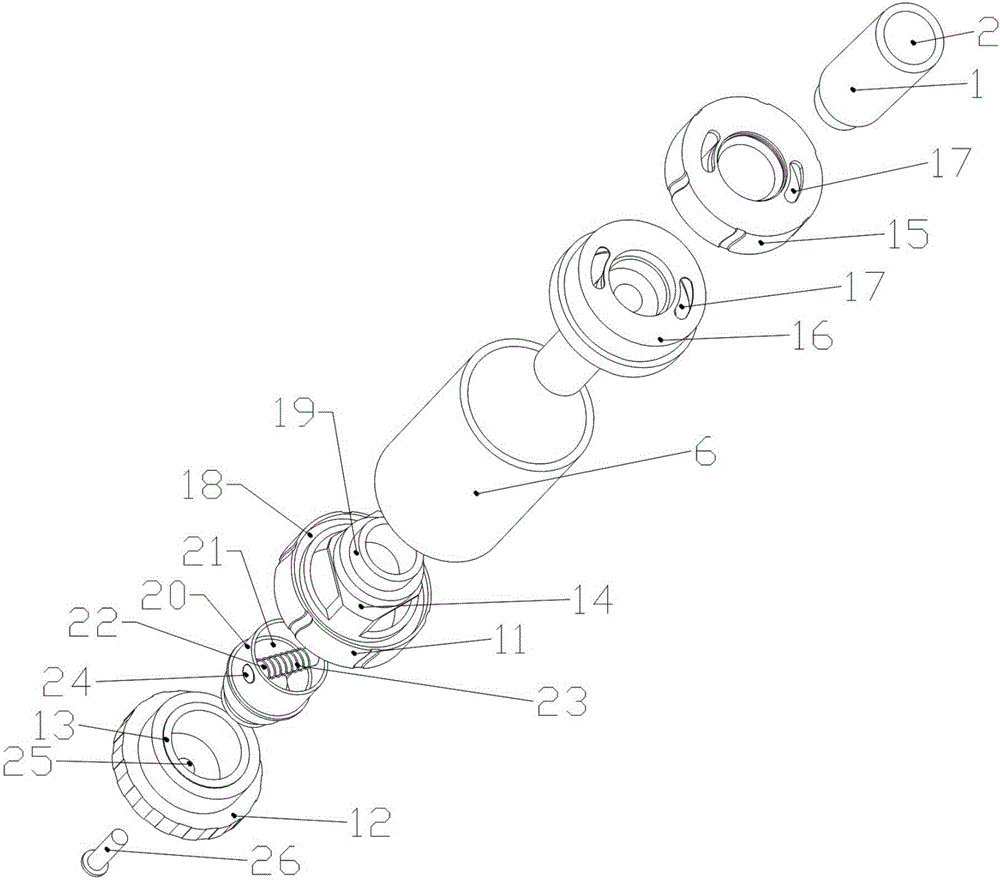

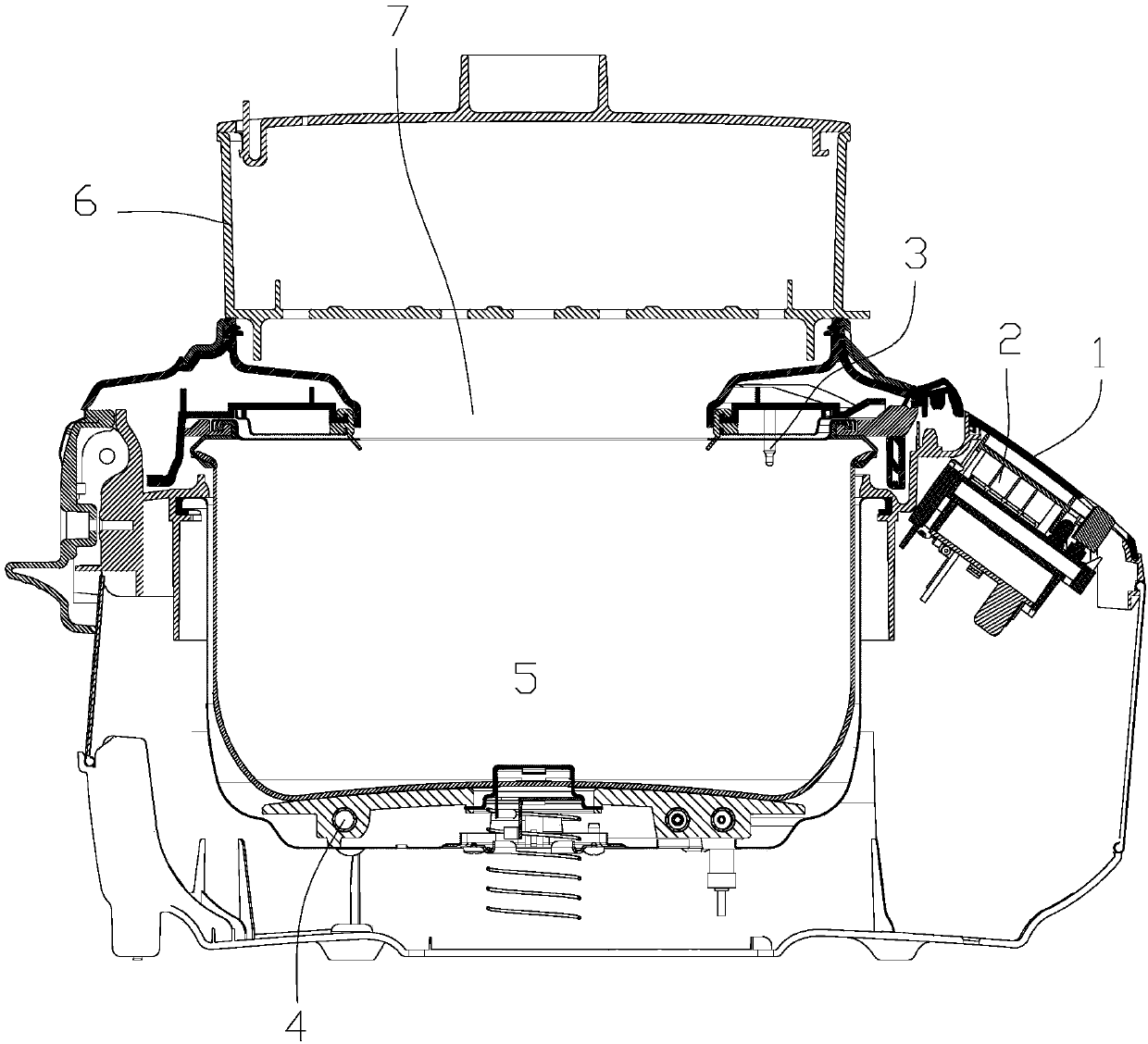

Electronic cigarette atomizer

InactiveCN104939326AAvoid Leakage ProblemsExtended service lifeTobacco devicesEngineeringElectronic cigarette

The invention discloses an electronic cigarette atomizer which is characterized by including a cigarette holder with a smoking hole and an atomizer body detachably connected with the cigarette holder, wherein the cigarette holder includes a cigarette holder body and a sealing part; the cigarette holder body is in threaded connection with the sealing part; the atomizer body includes an atomizing bin and a fixing base; the atomizing bin is in threaded connection with the fixing base. According to the electronic cigarette atomizer provided by the invention, air inlets are formed in the top of the electronic cigarette atomizer, which utilizes the theory that air inflows through the top of the atomizer to form air recirculation, and inner pipes inside the atomizer are connected with an atomizing core at the bottom of the atomizer in a sealing manner, so that liquid leakage of an electronic cigarette is avoided; a liquid guide structure is adopted for sucking nicotine liquid automatically from a liquid storage chamber, so that a large amount of external air enters an atomizing chamber, sufficient air is provided for the atomization of nicotine liquid, the nicotine liquid can be fully atomized to ensure that a large amount of smoke is generated, the dry burning problem caused by insufficient supply of nicotine liquid is avoided, and the service life of the atomizer is prolonged.

Owner:杨卫东

Environment-friendly type textile sizing agent

Owner:SUZHOU RUNHONG TRADING

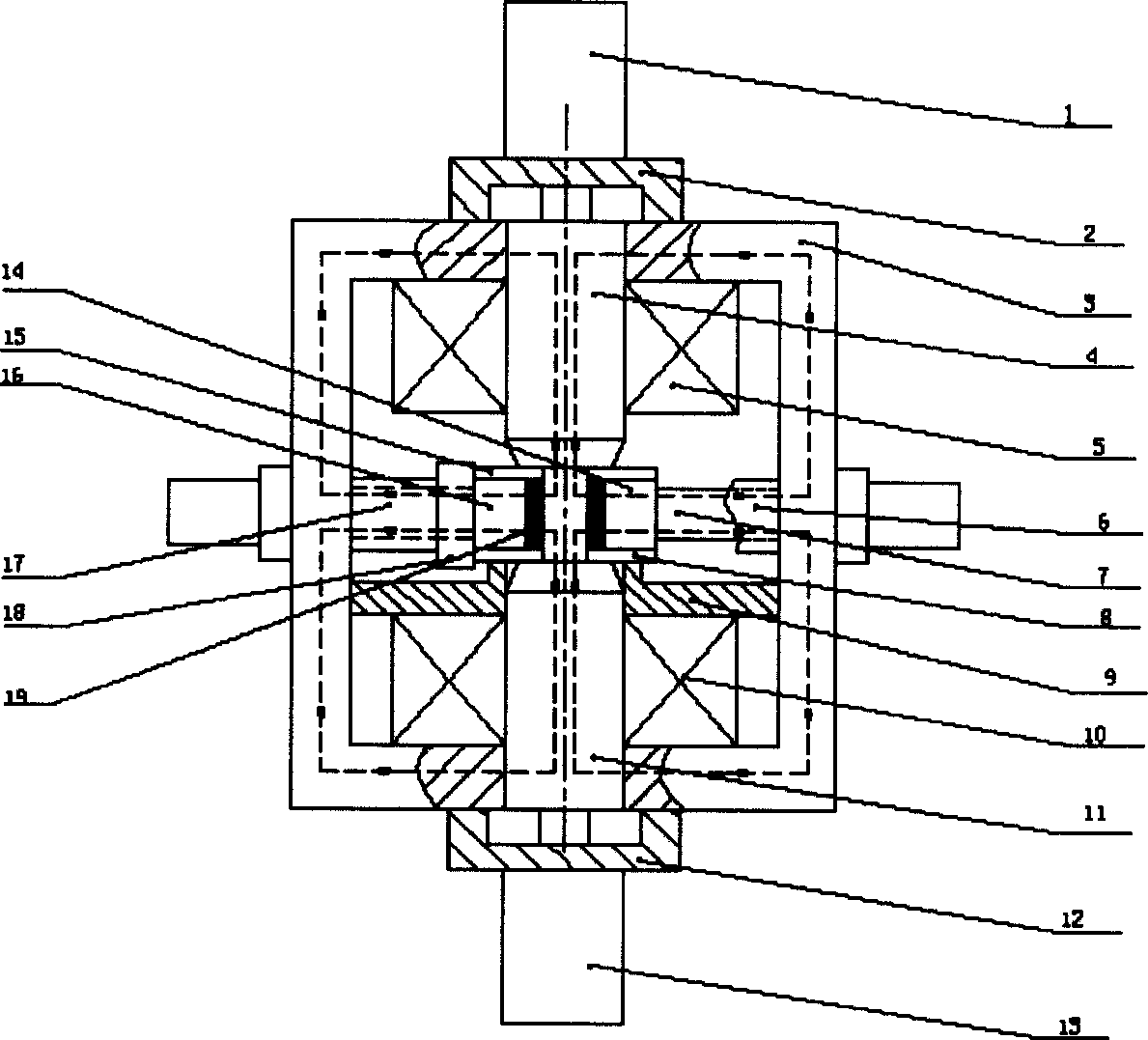

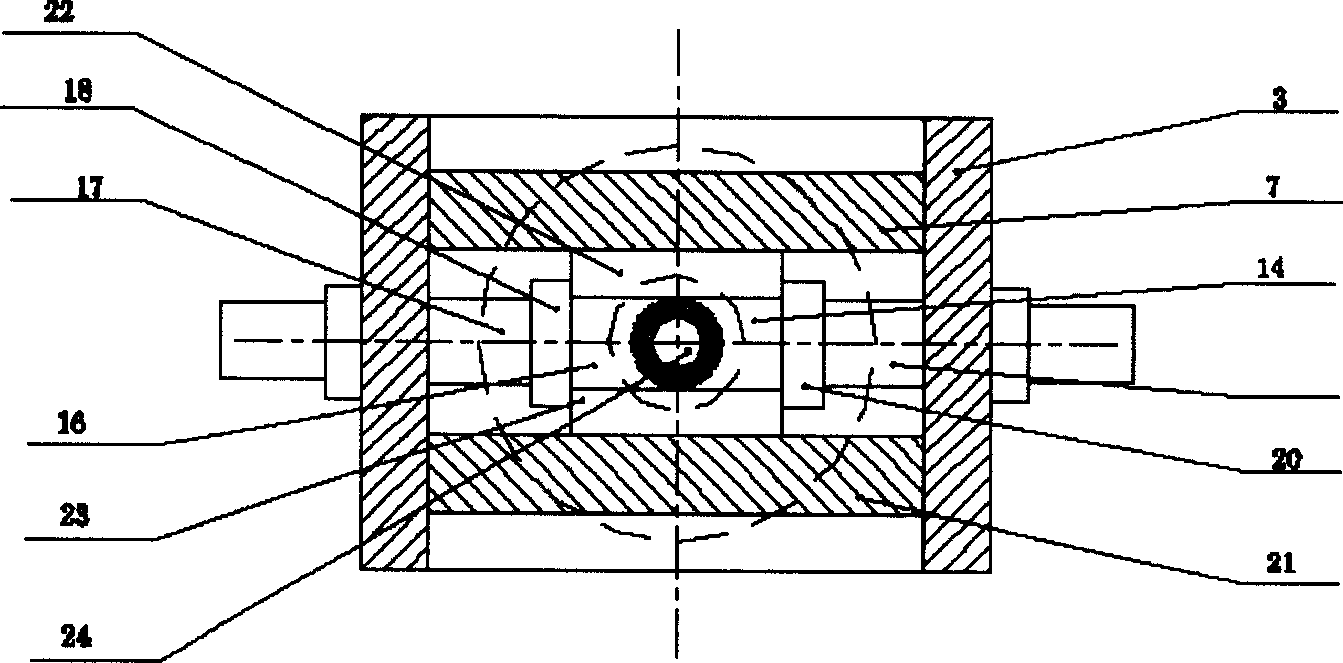

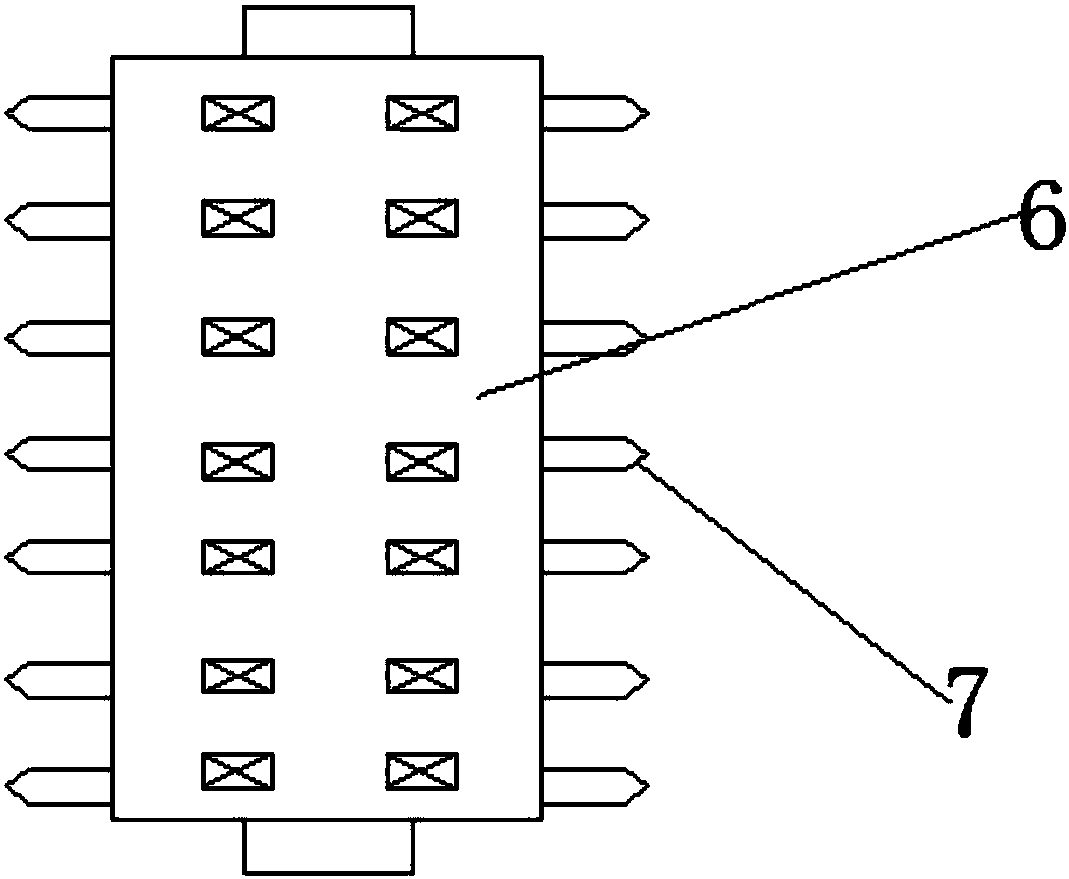

Forming process for radially oriented magnetic ring

InactiveCN1770338AOrderly rowsHigh density and uniformInductances/transformers/magnets manufactureEngineeringConductive materials

This invention discloses one radiating magnetic ring shaping process, which adopts regular four cylinders as processing device and locates magnetic guide board between frames. The shaping mode four sides are made by magnetic conductive materials with direct different current with the process machine. The magnetic ring is put in static machine under certain pressure for a while and is opened and sent to the sintering furnace. The invention is free of special radiating magnetic ring machine and in regular machine for batch production. The shaping materials adopt mode voltage with high shaping intensity.

Owner:ZHEJIANG SHENGHUA MAGNETIC MATERIALS

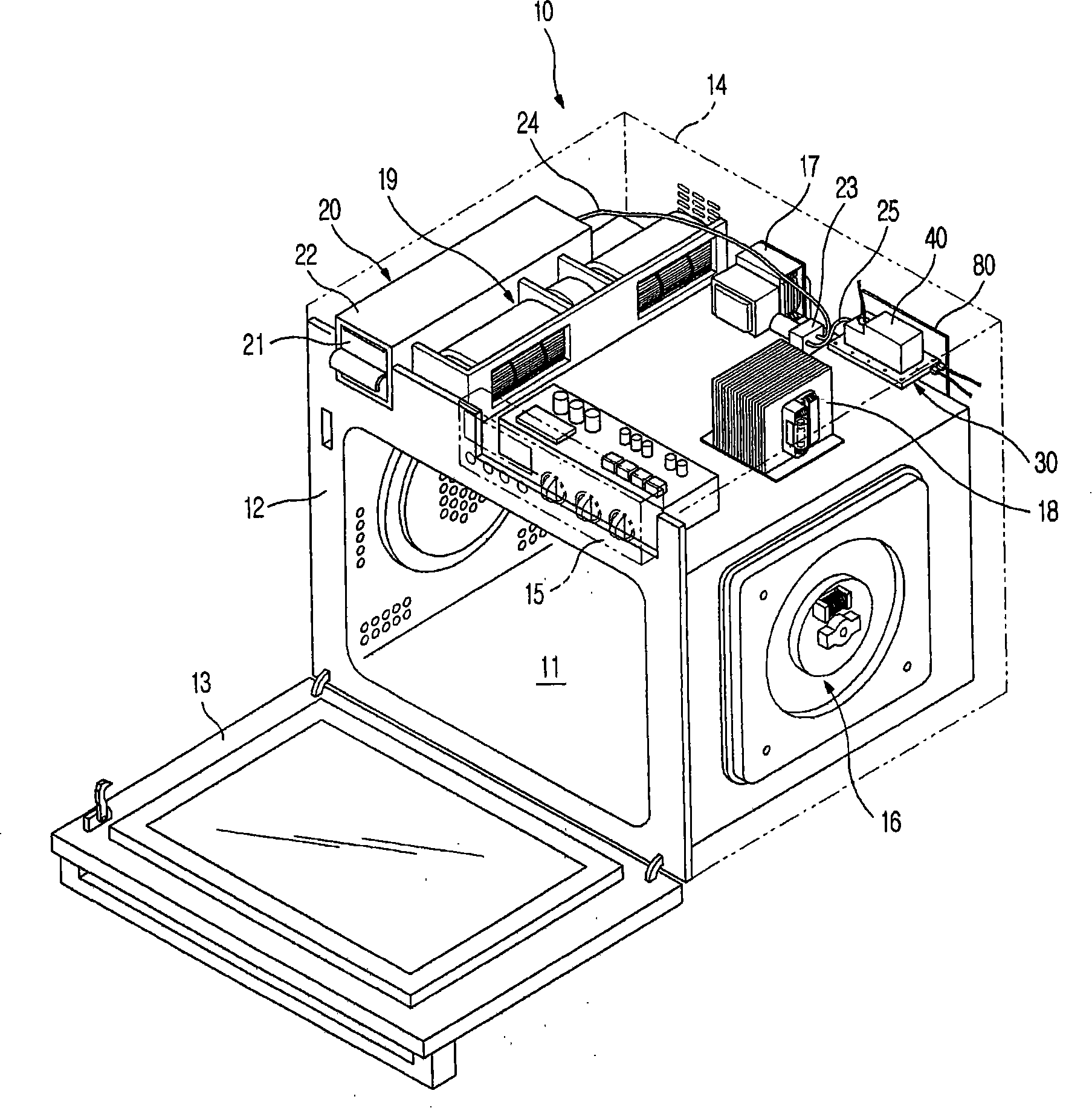

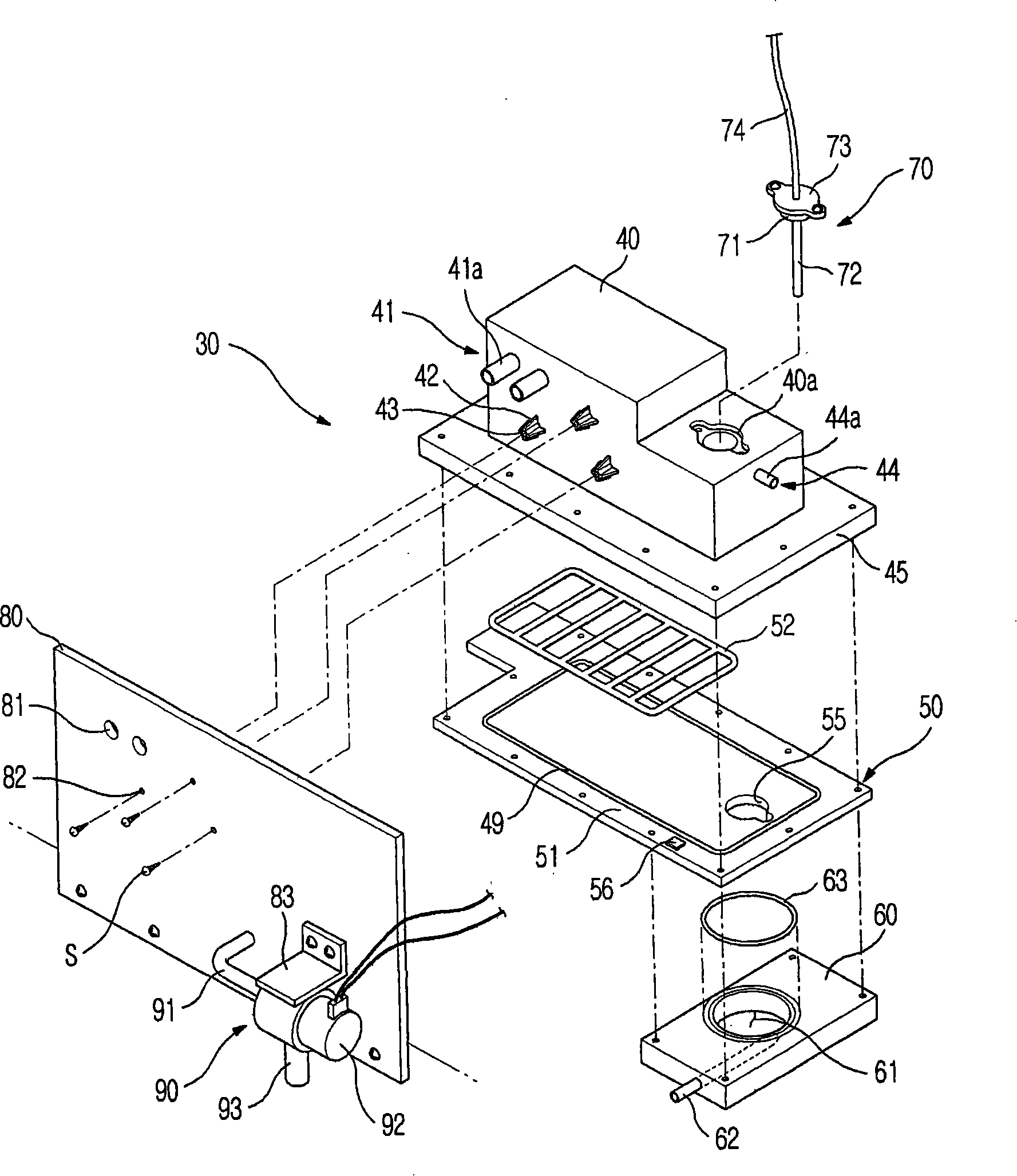

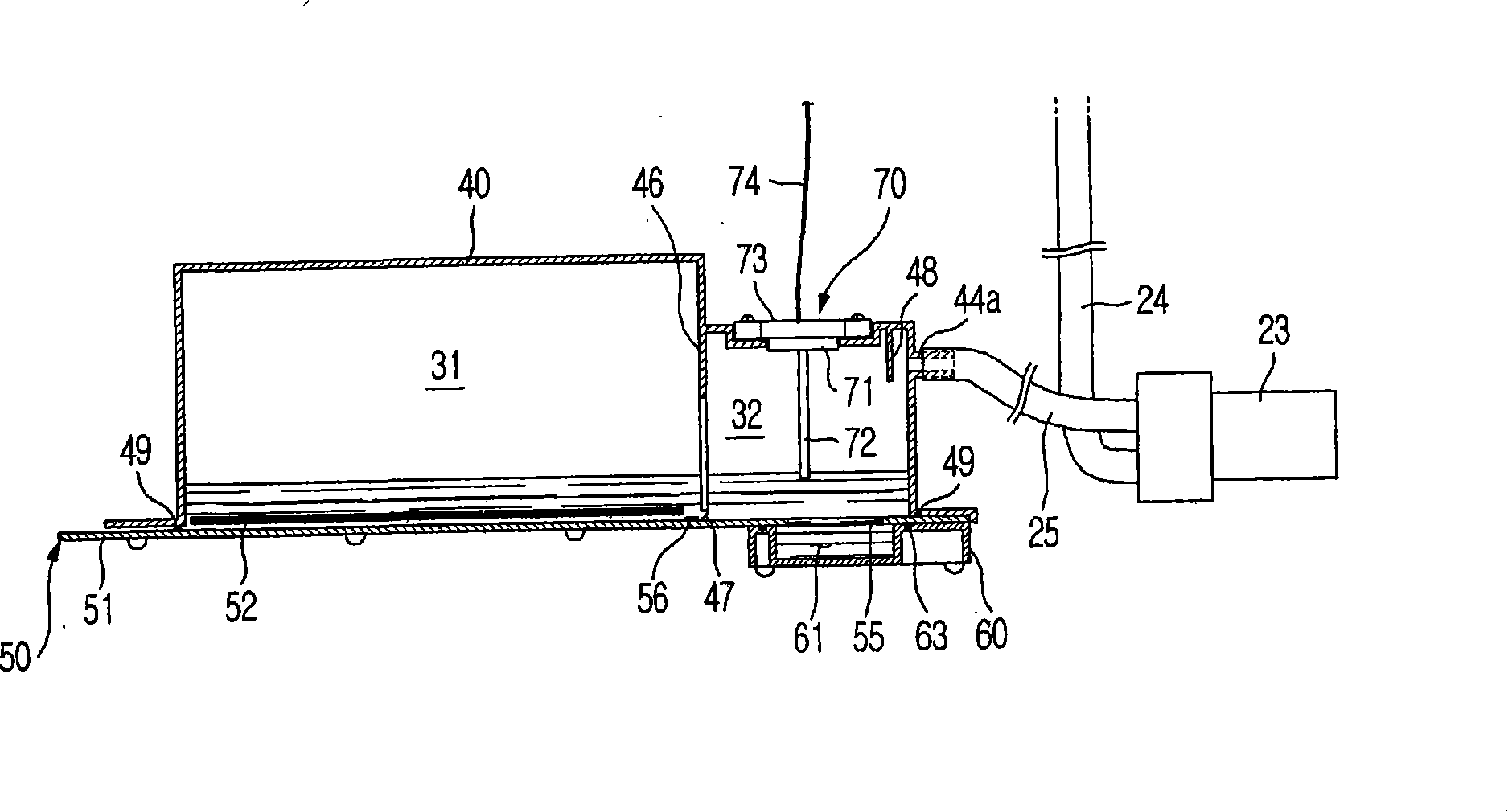

Steam generator, heating cooker having the same and control method thereof

The invention discloses a steam generator, a heating cooker provided with the steam generator, and a control method for controlling the heating cooker, wherein the steam generator prevents degradation of steam generation performance while stably supplying water required for steam production. And generate steam in a short period of time, the heating cooker has the steam generator. The control method of a steam generator having a steam box, a steam heater, and a water level sensor includes: using the water level sensor to determine whether the steam box is facing water shortage; when it is determined that the water in the steam box is less than a predetermined minimum water level, supply water within a first period of time; and when a predetermined minimum water level in the water tank is sensed by the water level sensor after supplying water, the water supply amount is controlled by additionally supplying water within a predetermined second period of time.

Owner:SAMSUNG ELECTRONICS CO LTD

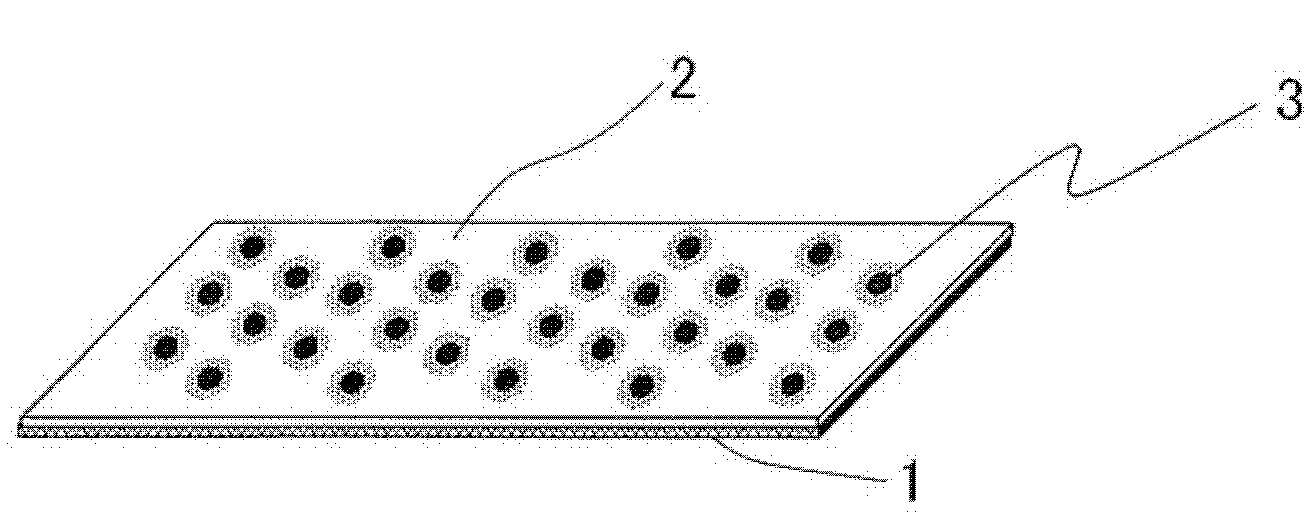

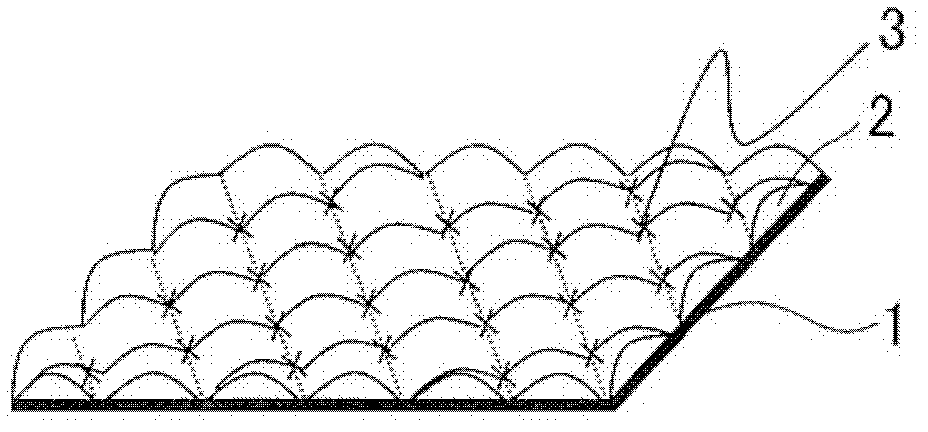

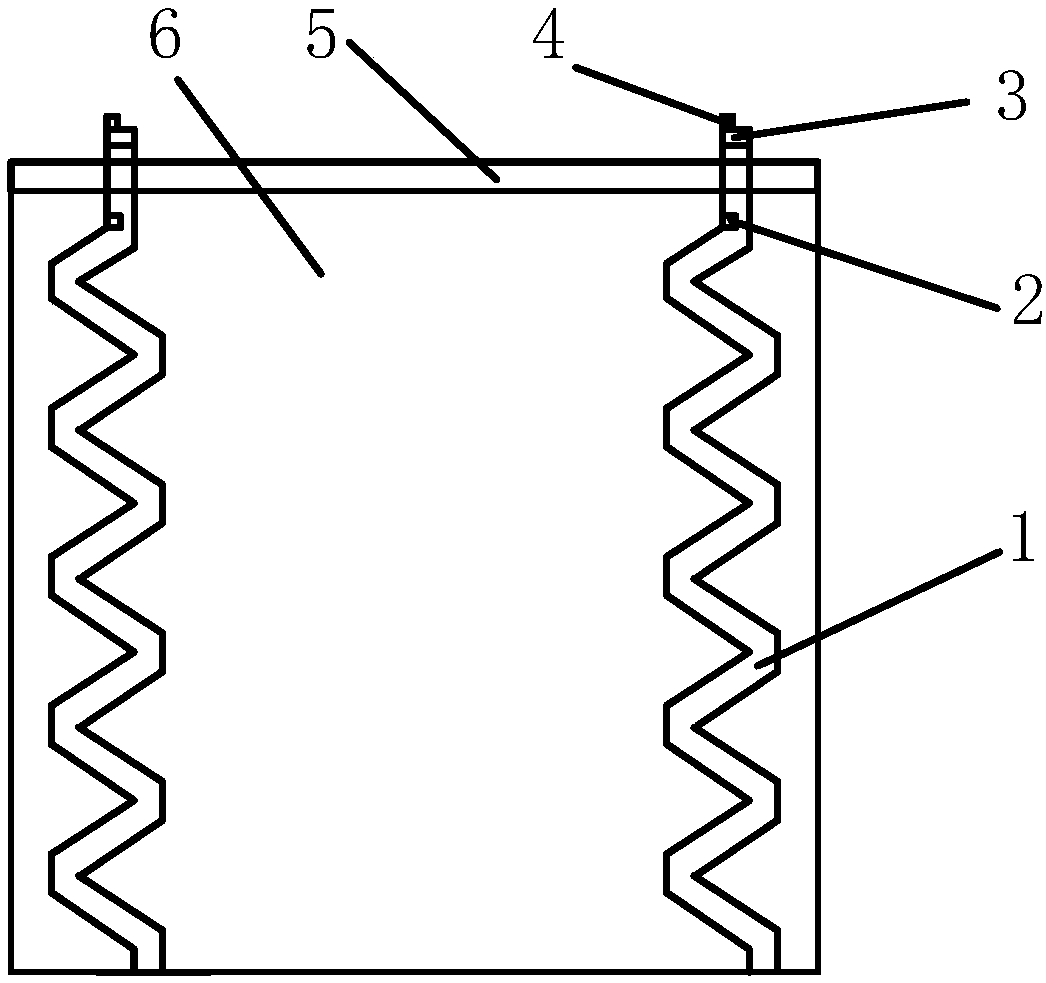

Rugged elastic nonwoven fabric and method for manufacturing the same

ActiveCN102758311APrevent shrinkageImprove flexibilityLayered productsNon-woven fabricsPolymer scienceNonwoven fabric

To provide a rugged elastic nonwoven fabric with high elasticity, high strength and also excellent feeling, in which a first fibrous layer containing heat-shrinkable fibers (1A) being latent crimp conjugate fibers, and a second fibrous layer containing heat-fusible heat-shrinkable fibers (2A) or non-heat-shrinkable fibers (2B) both having smaller shrinkage as compared with the fibers (1A) are laminated, and both of the fibrous layers are partially bonded and united with a number of bonded parts arranged at intervals, wherein a maximum shrinkage development temperature of the first fibrous layer is 135 DEG C or higher, a melting or softening point of a heat-fusible component of the fibers (2A) or (2B) is 70 DEG C or higher to 130 DEG C or lower, the second fibrous layer between the bonded parts is projected in a convex by shrinking of the first fibrous layer, and fibers constituting the first fibrous layer are not bonded with each other.

Owner:JNC CORP +1

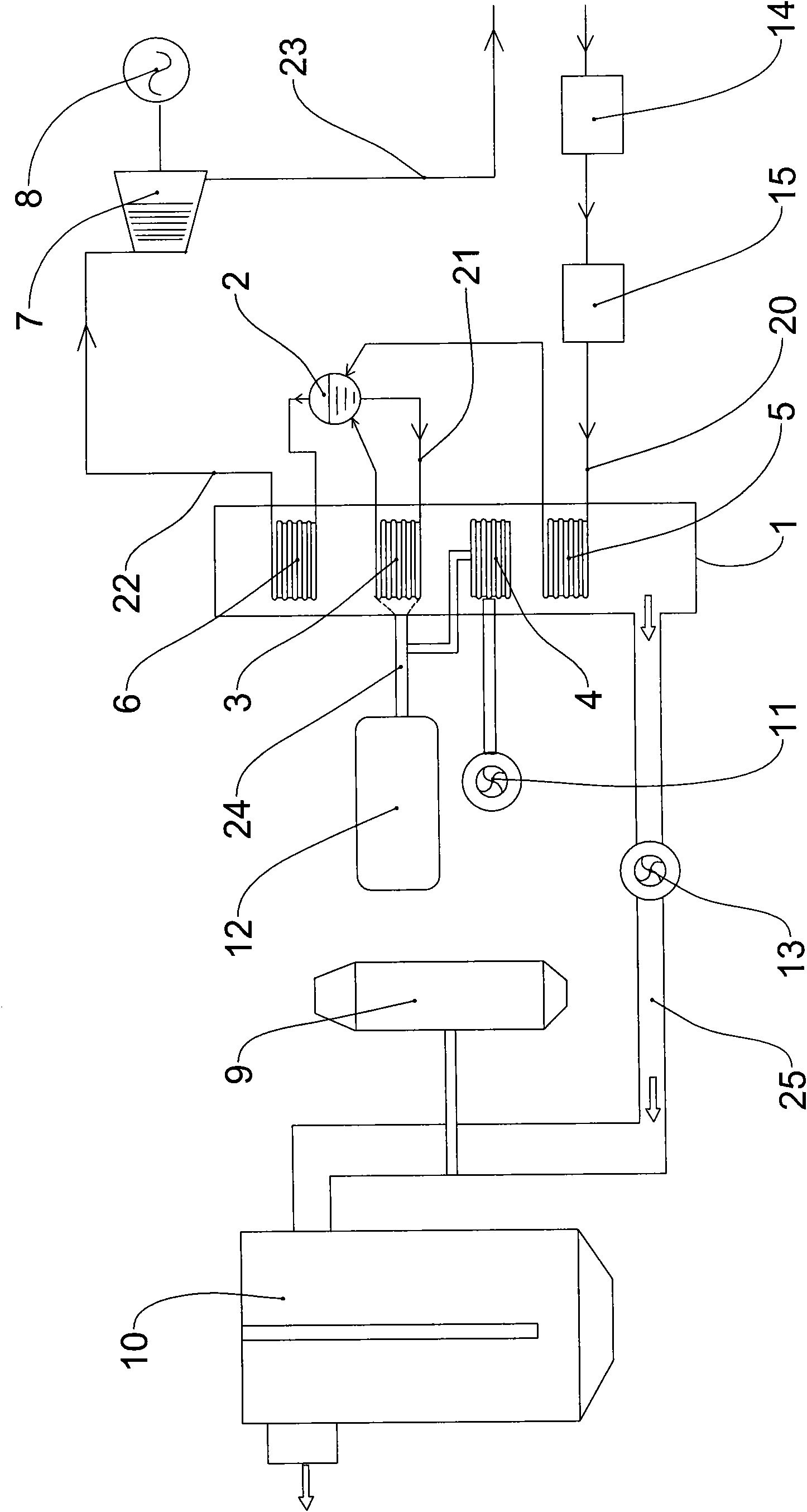

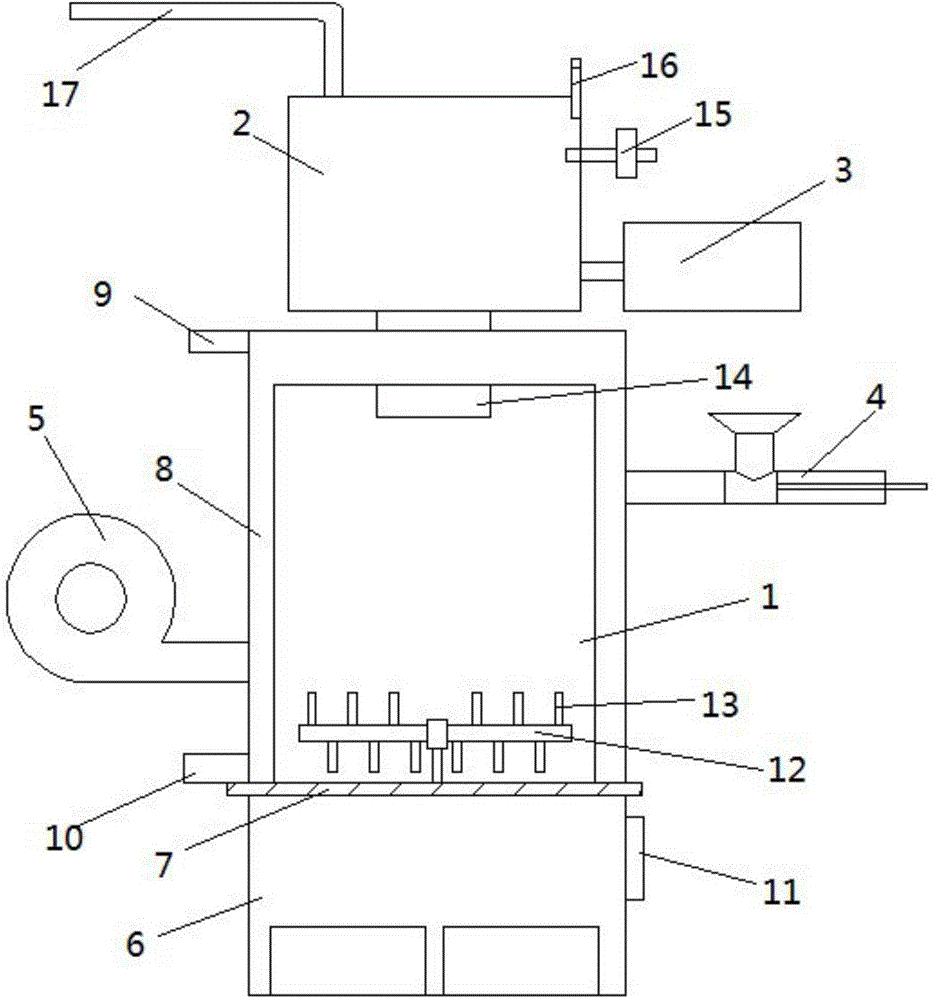

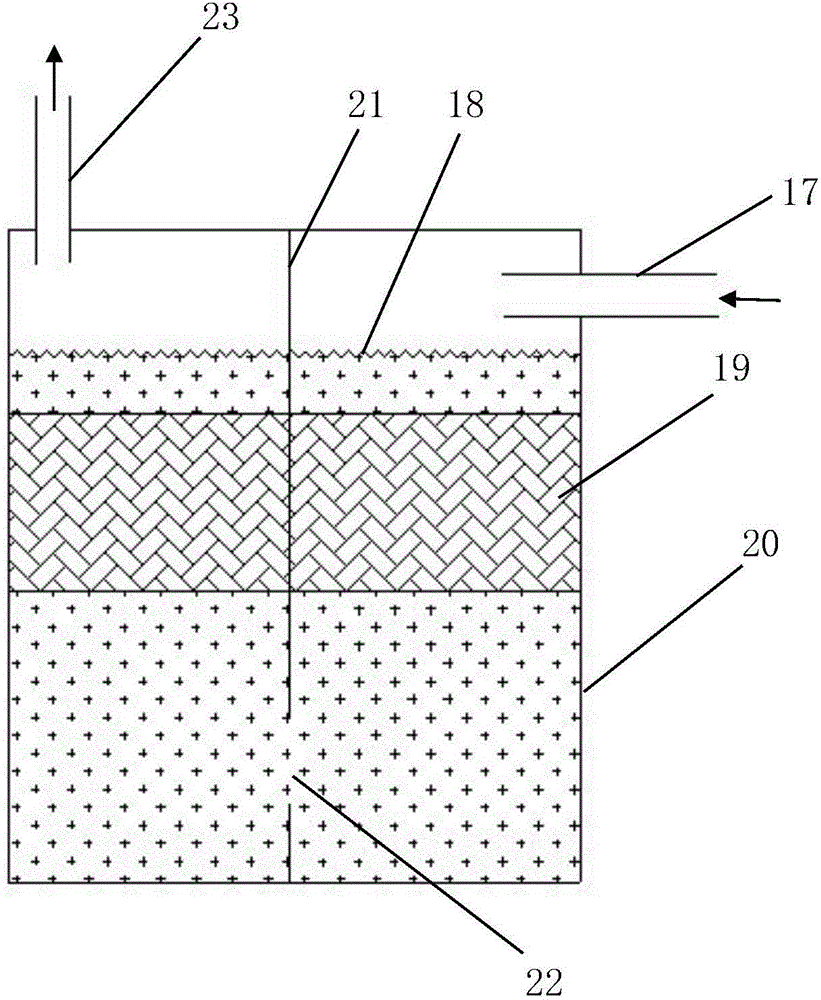

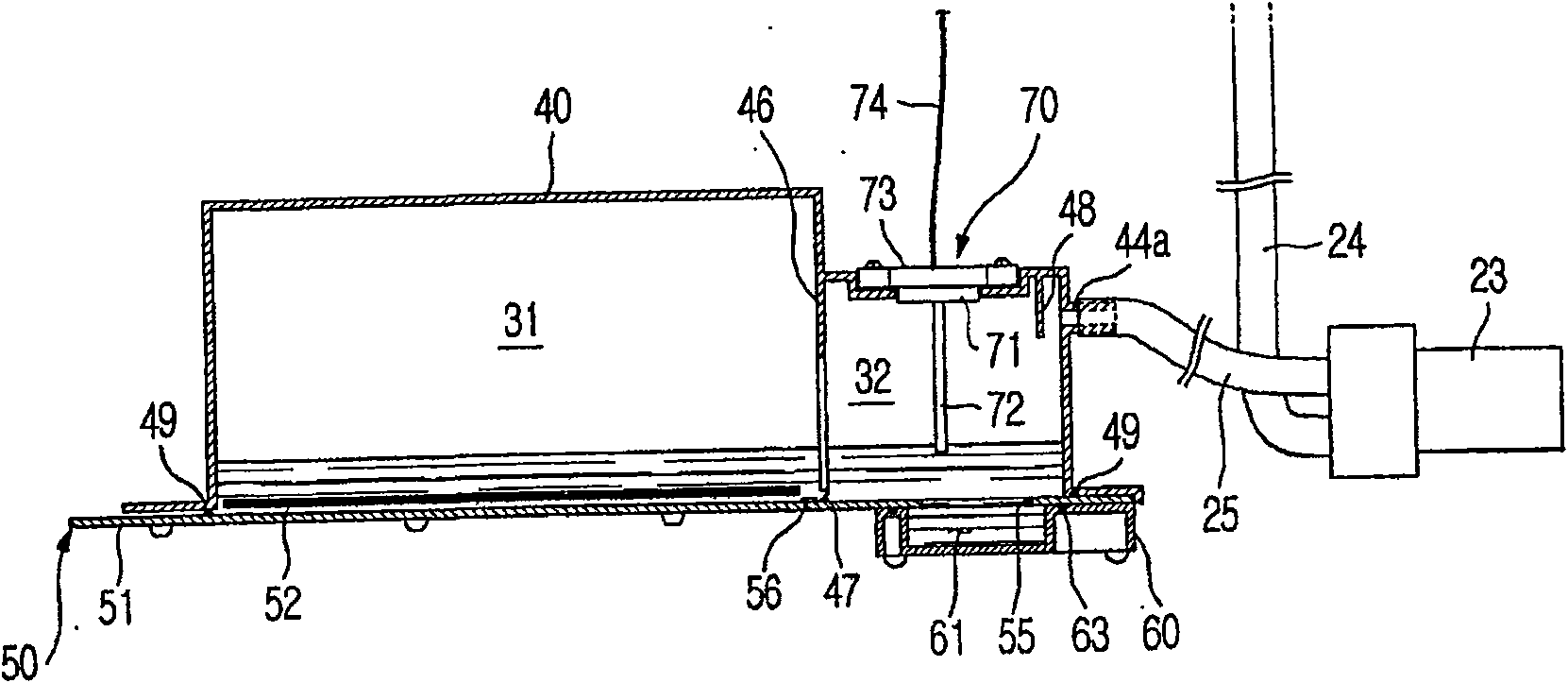

Integrated low-carbon micro-discharge energy-saving and emission-reduction boiler system

ActiveCN101986025AObvious superiorityLower discharge temperatureSteam generation plantsIndirect carbon-dioxide mitigationCombustionEngineering

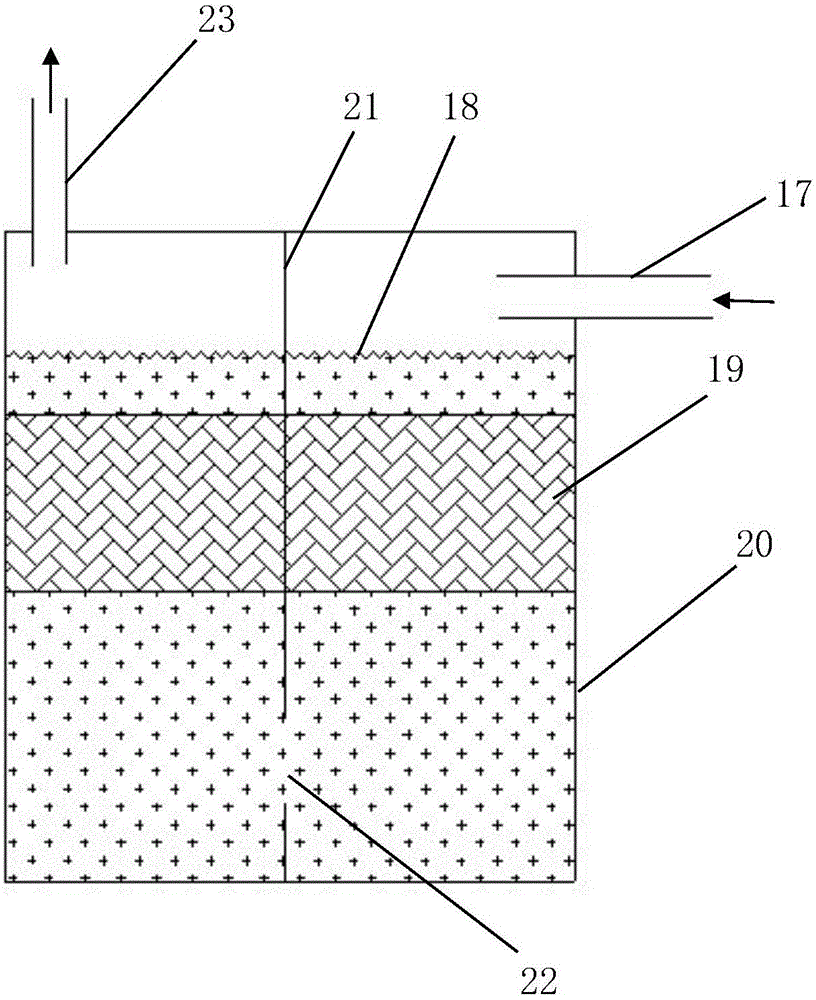

The invention discloses an integrated low-carbon micro-discharge energy-saving and emission-reduction boiler system. The system comprises a boiler body (1), a steam drum (2), a heat exchanger (3), a preheater (4), an economizer (5), a superheater (6), a steam turbine (7), a generator (8), a secondary smoke combustion device (9), a desulfuration and dust collect unit (10), an air blower (11) and a smoke exhauster (13), wherein the steam drum (2) and the heat exchanger (3) constitute a hot-water heating circulation loop, the economizer (5) is connected with the steam drum (2), and the air blower (11) feeds air to the preheater (4); the steam drum (2) is connected with the superheater (6), and then connected with the steam turbine (7) by a superheated steam pipe (22); the steam turbine (7) is connected with a low-pressure steam pipe (23), and the generator (8) is linked with the steam turbine (7); and the outlet of a gas duct of the boiler body (1) is connected with a smoke pipe (25), and the smoke exhauster (13) is arranged on the smoke pipe (25), and sequentially feeds smoke into the secondary smoke combustion device (9) and the desulfuration and dust collect unit (10) so as to process and discharge the smoke.

Owner:慧生能源科技有限公司

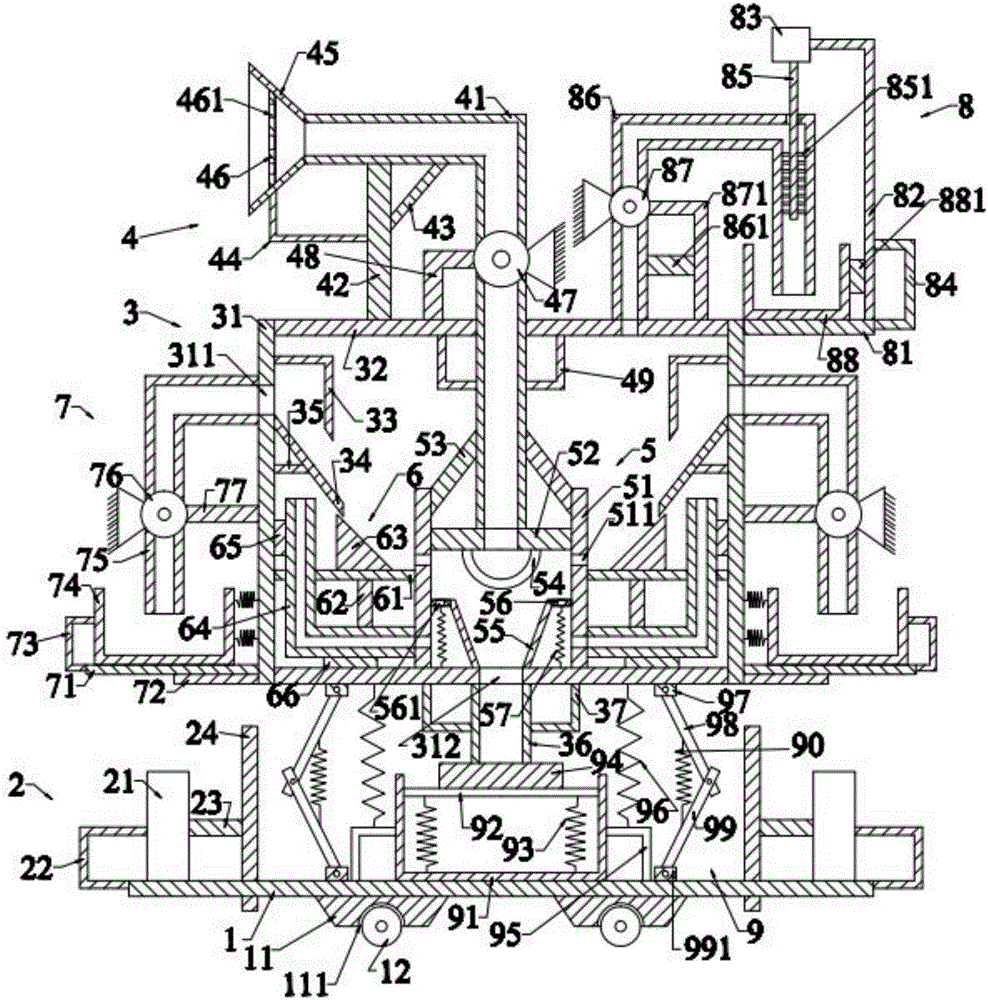

Waste gas purification device for pharmacy and chemical industries

A waste gas purification device for pharmacy and chemical industries comprises a bottom plate, pushing devices, a purification device, a gas inlet device, a concentration device, first gas outlet devices, water inlet devices, a second gas outlet device and a recovery device, wherein first supporting blocks and first rollers are arranged on the bottom plate; each pushing device comprises a first air cylinder, a first support, a first pushing rod and a first pushing plate; the purification device comprises a purification tank, a first transverse plate, a first retaining frame, a first concentration plate, first cross rods, a first pipeline and first fixing frames; the gas inlet device comprises a gas inlet pipe, a first supporting rod, a first oblique rod, a second support, a gas inlet hopper, a first partition board, a first fan, a third support and fourth supports; the concentration device comprises a concentration frame, a second transverse plate, second oblique rods, a first filtering frame, a first concentration hopper and a first sealing ring; each first gas outlet device comprises a second partition board and a first connection rod. The waste gas purification device can completely purify waste gas in workshops of the pharmacy and chemical industries and clear dust and other impurities in the workshops.

Owner:NINGXIA SOFTWARE ENG INST CO LTD

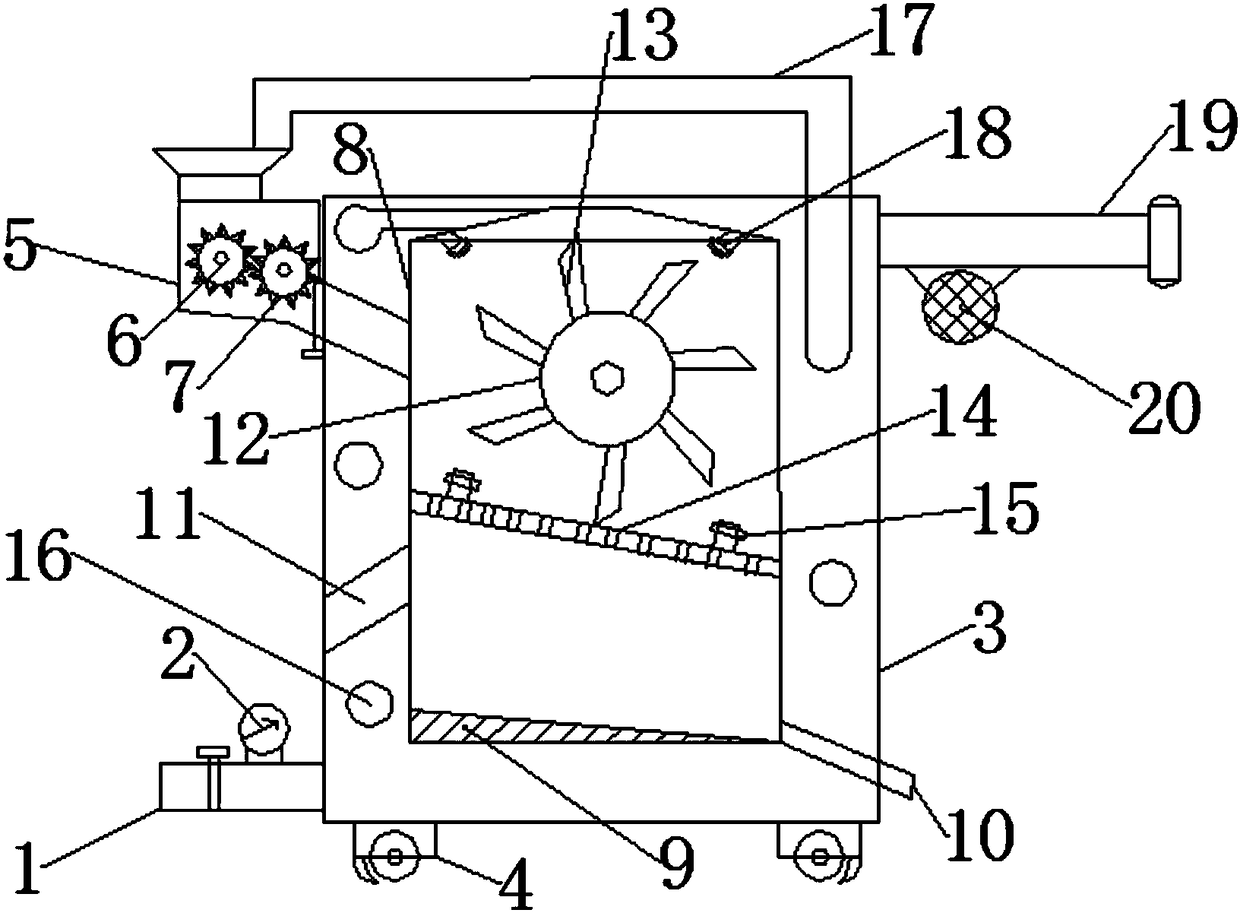

Efficient and energy-saving garbage fuel stirring water heater

InactiveCN108332209AEfficient use ofAvoid wastingWater heatersIncinerator apparatusCombustionHeat losses

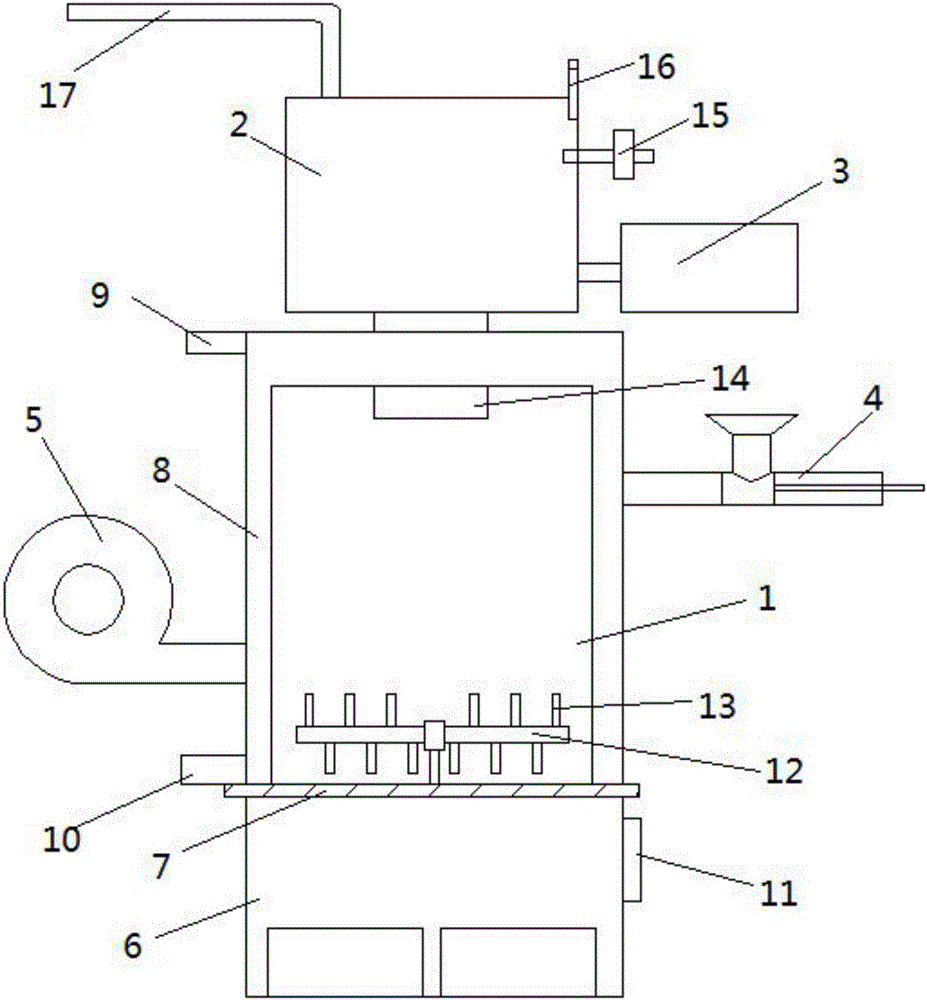

The invention discloses an efficient and energy-saving garbage fuel stirring water heater. The efficient and energy-saving garbage fuel stirring water heater comprises a water inlet pipe, a shell, a pulverizer, a rotary barrel, smashing cutters, a combustion furnace, an air inlet pipe, a stirring roll, stirring blades, a combustion plate, a heat exchange pipe, an air outlet pipe and a water outletpipe. The combustion furnace is arranged in the shell, and the combustion plate is obliquely arranged in the combustion furnace. A plurality of electronic igniters are arranged on the upper surface of the combustion plate, and the air inlet pipe is arranged between the side wall of the shell and the combustion furnace. The stirring roll is arranged in the combustion furnace, and the stirring blades are evenly arranged on the stirring roll, and the rotary barrel is arranged in the pulverizer. The smashing cutters are evenly arranged on the outer wall of the rotary barrel, and a secondary igniter is arranged at the top end of the combustion furnace. The top end of the combustion furnace is connected with one end of the heat exchange pipe, the other end of the heat exchange pipe communicateswith the air outlet pipe, and the outlet end of the air outlet pipe is provided with an air spraying head. According to the efficient and energy-saving garbage fuel stirring water heater, the heatingeffect is improved, energy waste is avoided, and energy is greatly saved; heat losses are reduced, and the utilization rate of energy is increased; and the structure is simple, use is convenient, energy is saved, and the efficient and energy-saving garbage fuel stirring water heater is beneficial to popularization.

Owner:田迎华

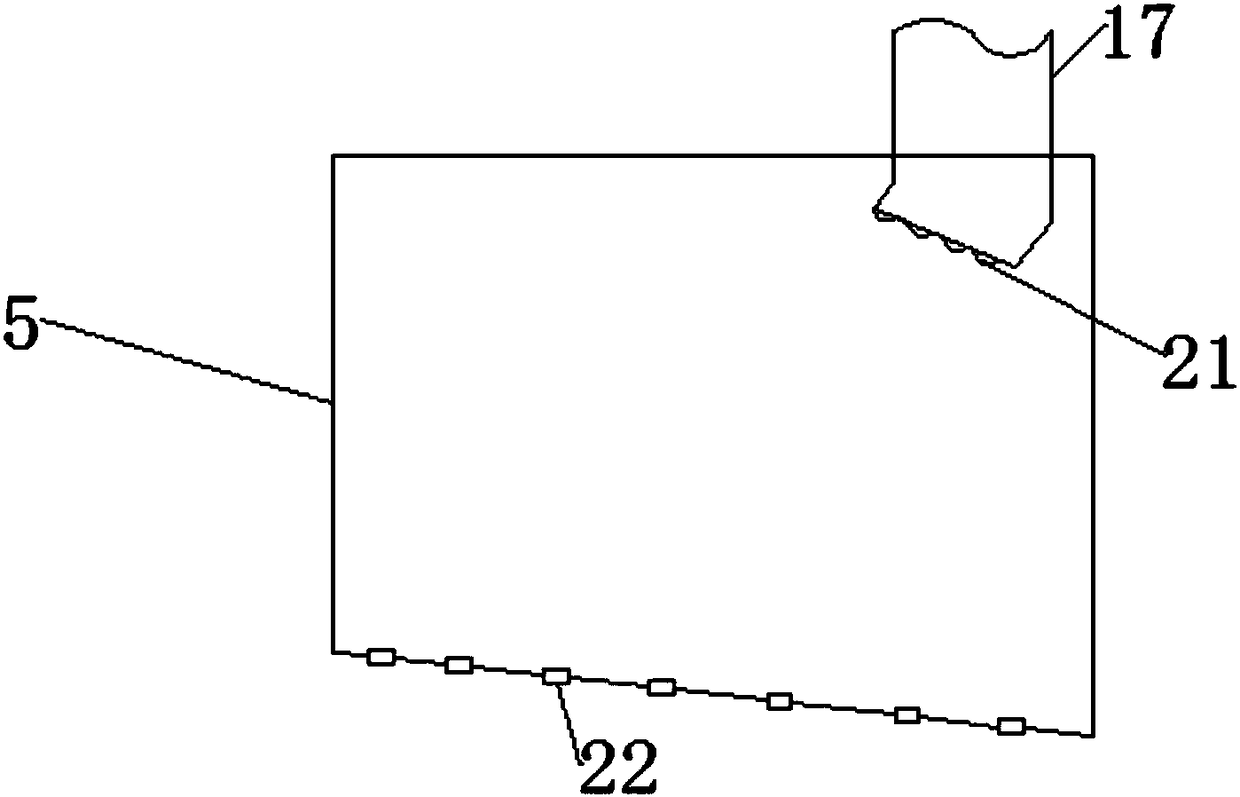

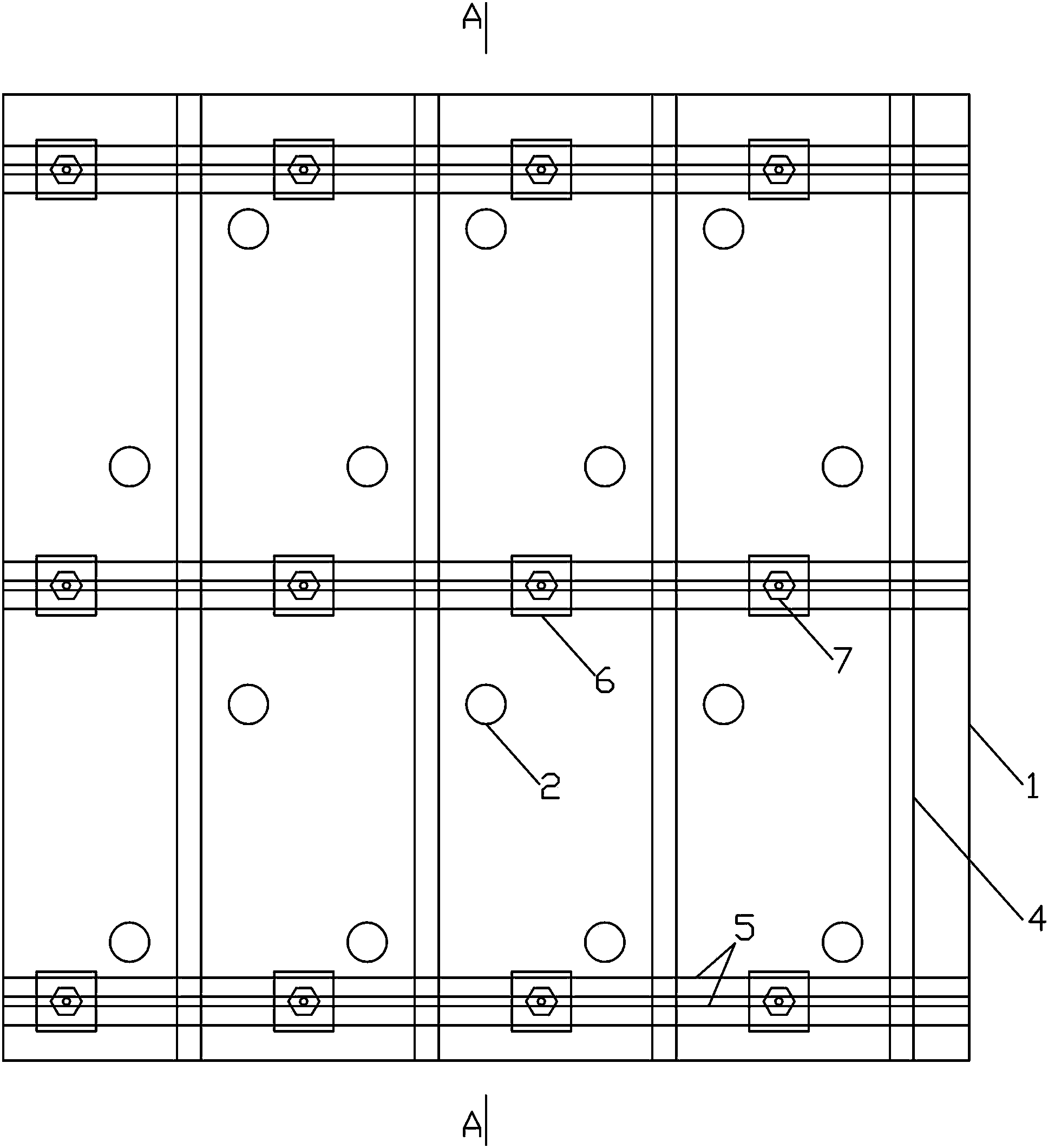

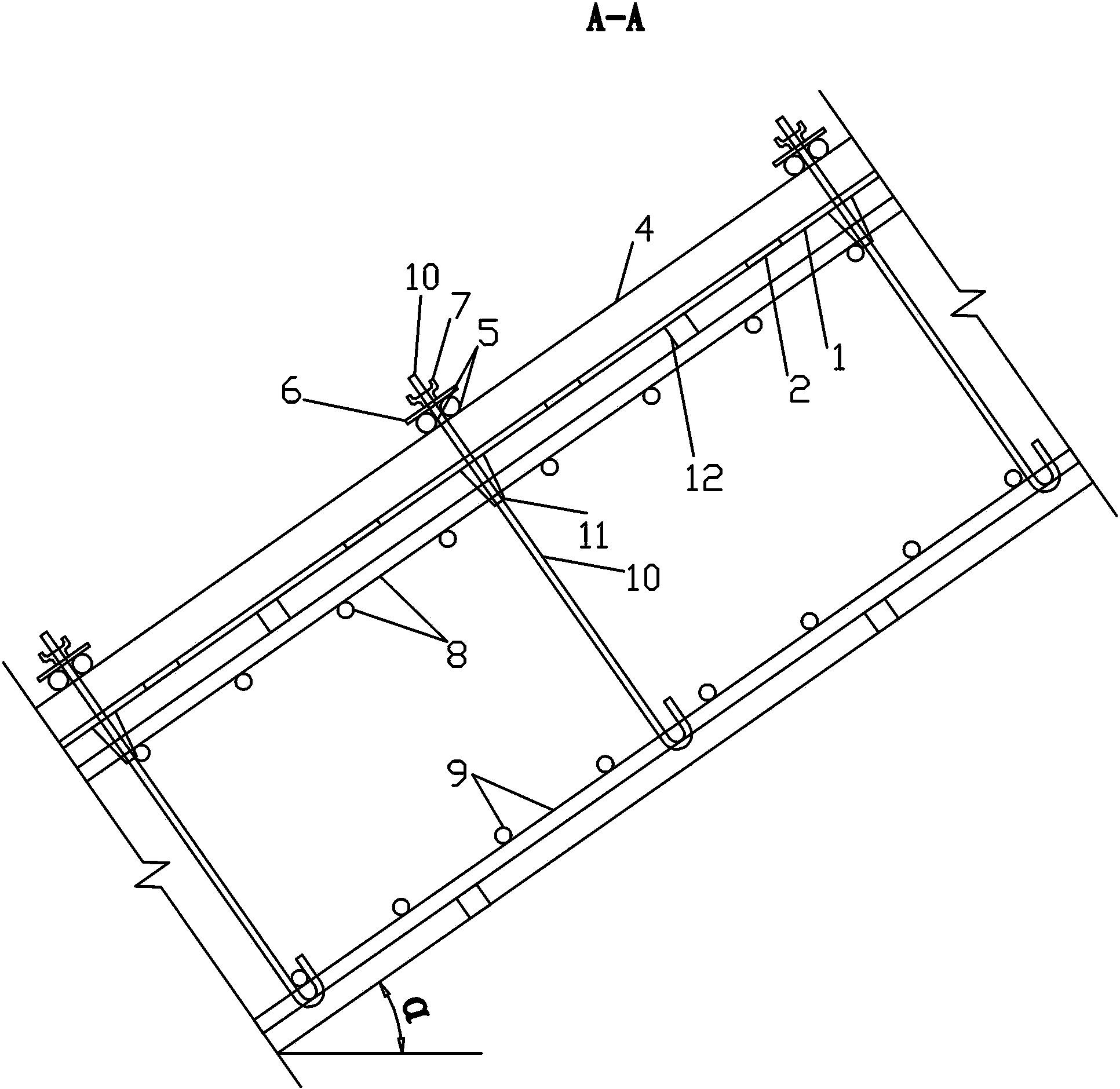

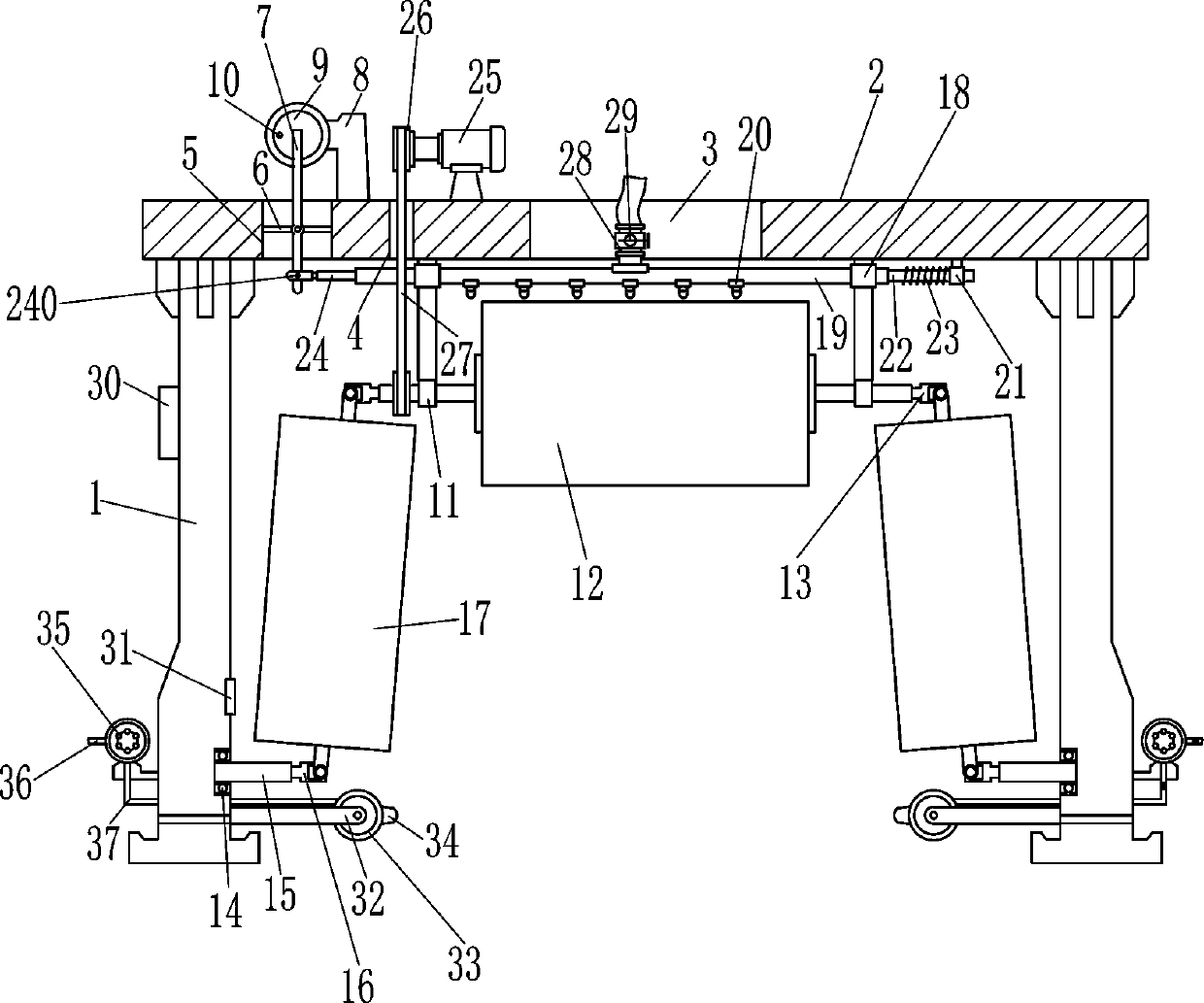

Slope roof concrete construction device and method

ActiveCN103883088AGuaranteed compactnessImprove appearance construction qualityRoof toolsStructural engineeringEngineering

Provided are a slope roof concrete construction device and method. A lower layer steel rib net piece and an upper layer steel rib net piece which are arranged along a slope roof are included. The upper layer steel rib net piece is provided with a plurality of concrete cushion blocks which are provided with formworks. A pulling rod is connected with the upper layer steel rib net piece and the lower layer steel rib net piece. The end of the pulling rod penetrates through the formworks and is connected with a nut. A plurality of concrete vibration holes are formed in the formworks, and vibration hole padding plugs arranged in the concrete vibration holes are further arranged. In the vibration hole padding plugs, padding plug plates are arranged on bottom plates, the padding plug plates and the concrete vibration holes are the same in diameter, the padding plug plates and the formworks are the same in thickness, and the lengths of the bottom plates in at least one direction are larger than the diameters of the padding plates. The compactness of concrete is guaranteed by forming the concrete vibration holes. Through the arranged vibration hole padding plugs, engineering waste formworks can be fully used, the appearance construction quality of concrete can be improved, cost of later concrete protrusion processing is saved, and the site construction progress is accelerated.

Owner:CHINA NUCLEAR IND 22ND CONSTR

Efficient treatment device for medical waste

InactiveCN106196083AAvoid direct burningAvoid direct combustionSolid waste disposalTransportation and packagingCombustion chamberDirect combustion

The invention discloses an efficient treatment device for medical waste. The efficient treatment device comprises a reaction chamber, a reaction chamber, an air blower, a waste residue chamber and an oxygen-enriched air supply system, wherein the reaction chamber is arranged above the waste residue chamber; the reaction chamber and the waste residue chamber form a device tower body; a filter residue screen plate is arranged between the reaction chamber and the waste residue chamber; and a piston feeding device is arranged at the side of the upper end of the reaction chamber. The medical waste is pyrolyzed under an anaerobic condition in the reaction chamber to generate combustible gases and harmless residues, combustion treatment is carried out on the combustible gases in the combustion chamber, and concentrated collection treatment is carried out on the harmless residues, thus generation of harmful gases due to direct combustion is avoided; an oxygen-enriched gas is conveyed in the combustion chamber through the oxygen-enriched air supply system to adjust an oxygen content in the combustion chamber, thus adequate combustion of the different combustible gases is ensured; and a tail gas after the adequate combustion is filtered through a tail gas treatment device, and then clean air is exhausted and is harmless to environment.

Owner:SUZHOU DUOGU ENG DESIGN CO LTD

Method for preparing schizandrin raw material

InactiveCN101177436ASolvent recovery consumes lessShort production cycleOrganic compounds purification/separation/stabilisationLignin derivativesSolventChemistry

The invention discloses a method for preparing the raw materials of schizadrin, which extracts the leach with the effective constituents of schisandra schizadrin by digesting the fruits of schisandra with solvent naphtha and gets the extract of all lignin rich in schizadrin by heating and distilling the enriched digestion solvent, which can be used to prepare high-purity schizadrin by further separation. Combined with prior mature complete extraction equipment, the invention can meet the demand of mass production by adopting the operation method of totally enclosed extraction. Since solvent naphtha is used as extraction solvent, the invention improves the solubility of solvent to lignin dramatically, reduces the consumption of extraction solvent considerably by utilizing prior mature equipment, increases the rate of extraction and output and cuts production cost. In addition, is the invention is environment-friendly, which can be used as a method for extracting the lignans compound of schisandra at large scale.

Owner:XIAN JIASHITE SCI & TECH

Efficient medical waste processing device and manufacturing method thereof

InactiveCN104534484AAvoid direct burningAvoid direct combustionTransportation and packagingSolid waste disposalCombustion chamberDecomposition

The invention discloses an efficient medical waste processing device and a manufacturing method of the efficient medical waste processing device. The efficient medical waste processing device comprises a reaction chamber, a combustion chamber, an air blower, a waste residue chamber and an oxygen-enriched air supply system. The reaction chamber is arranged above the waste residue chamber. A device tower body is composed of the reaction chamber and the waste residue chamber. A residue filtering net plate is arranged between the reaction chamber and the waste residue chamber. A piston feeding device is arranged on the lateral side of the upper end of the reaction chamber. Oxygen-poor pyrogenic decomposition is conducted on medical waste in the reaction chamber to generate combustible gas and harmless residues. In the combustion chamber, the combustible gas is combusted and the harmless residues are collected in a concentrated mode so that harmful gas generated through direct combustion can be avoided. Oxygen-enriched gas is conveyed into the combustion chamber through the oxygen-enriched air supply system, the oxygen content in the combustion chamber is regulated, it is ensured that combustible gas of different types is fully combusted, tail gas which is fully combusted is filtered through a tail gas processing device, clean air can then be discharged, and no harm is caused to the environment.

Owner:寇卫国 +2

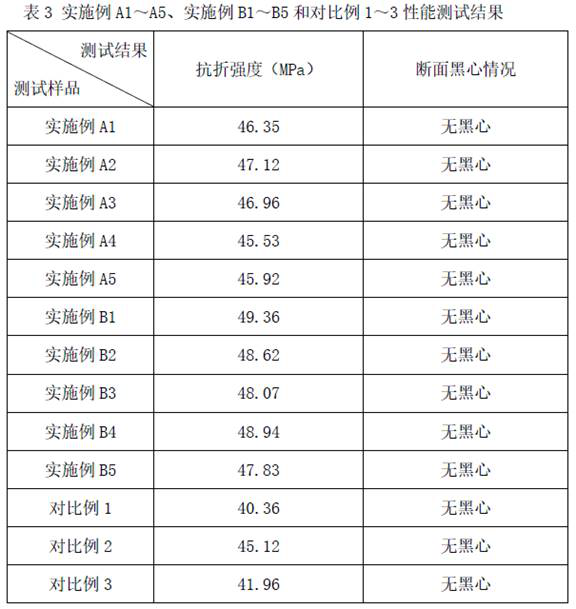

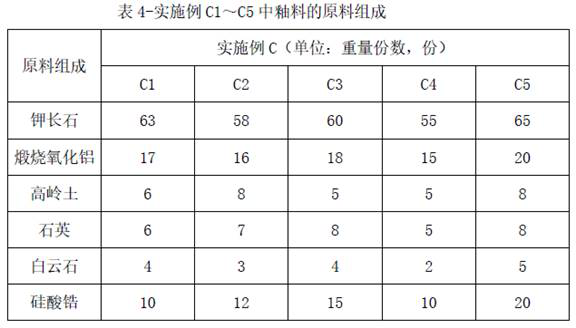

Preparation method of fast-fired ceramic tile and product of fast-fired ceramic tile

The invention discloses a preparation method of a fast-fired ceramic tile and a product thereof. The preparation method of the fast-fired ceramic tile comprises the following steps: A, uniformly mixing green body raw materials, then carrying out ball-milling pulping and drying granulation to prepare green body powder, and carrying out compression molding on the green body powder to obtain a green body, wherein the green body raw materials comprise the following chemical components in percentage by mass: 4.1 to 4.5% of K2O, 1.3 to 1.7% of Na2O and 1.4 to 1.7% of MgO; and B, applying glaze on the surface of the green body; wherein the raw materials of the glaze comprise potassium feldspar, calcined alumina, kaolin, quartz, dolomite and zirconium silicate. According to the preparation method of the fast-fired ceramic tile, fast firing in a short kiln can be achieved, the production speed of the ceramic tile is effectively increased, the productivity of a production line is improved, energy saving is facilitated, and the fast-fired ceramic tile prepared through the preparation method of the fast-fired ceramic tile is high in strength and good in quality.

Owner:FOSHAN DONGPENG CERAMIC +3

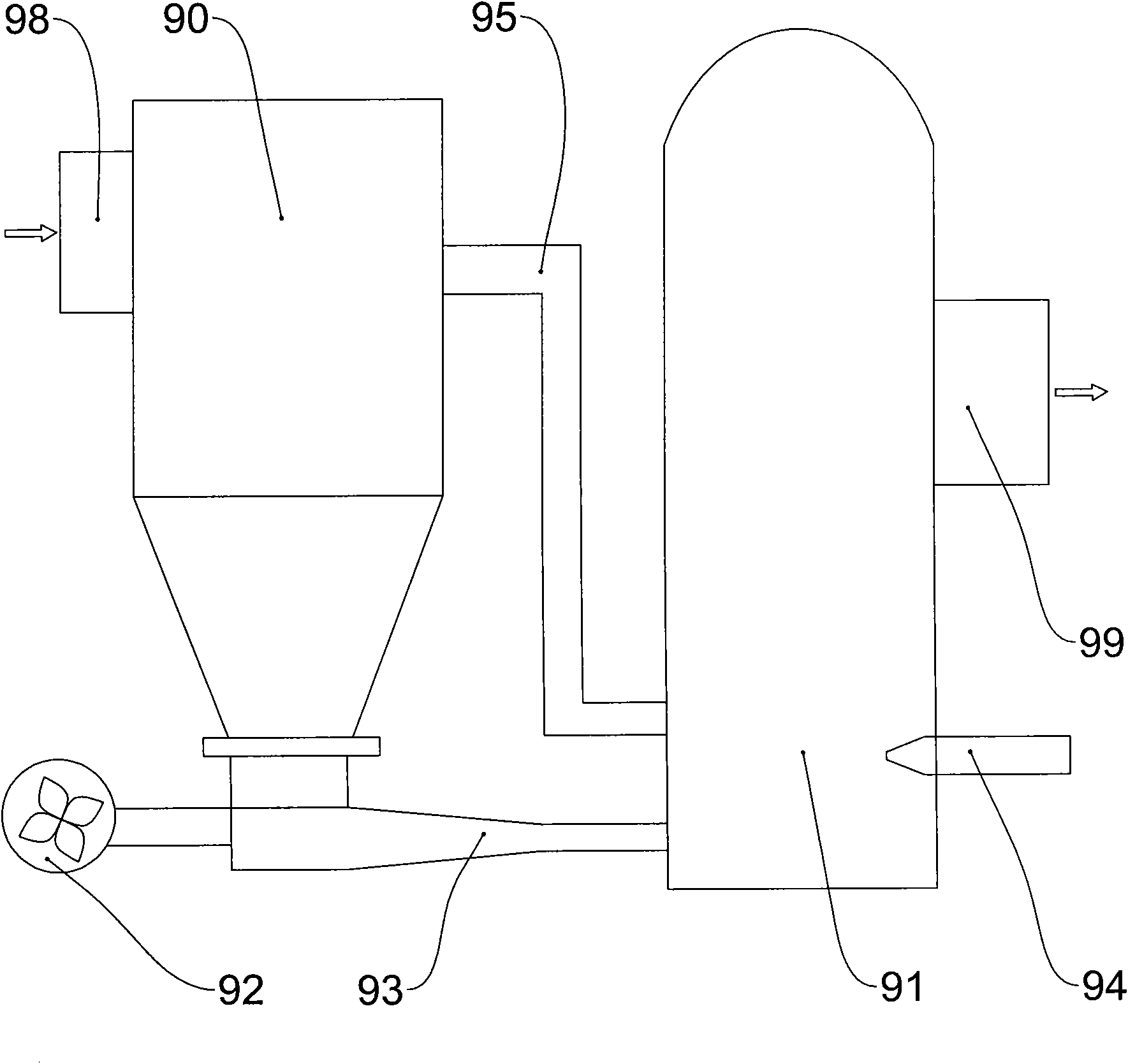

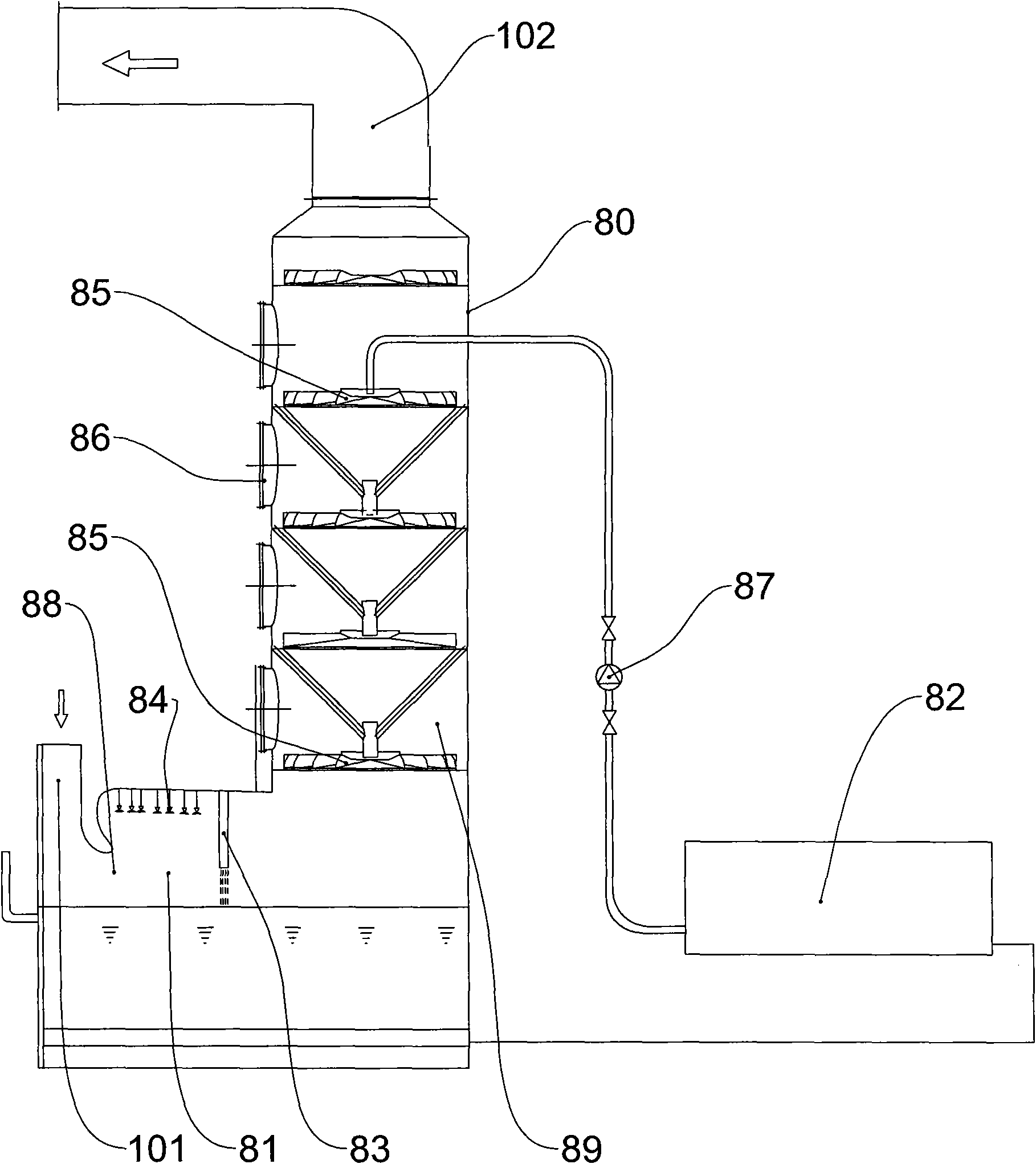

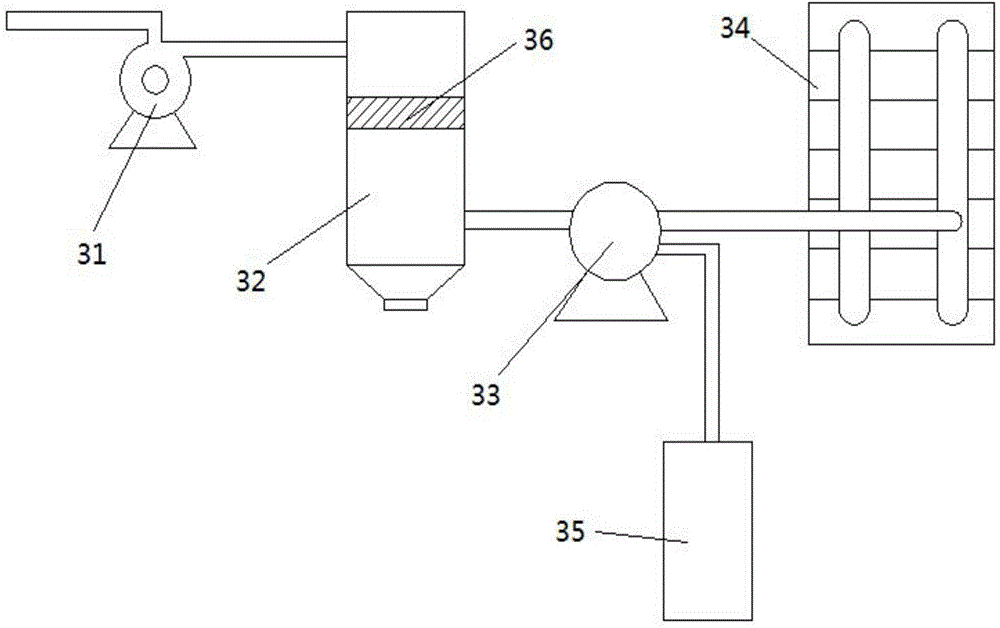

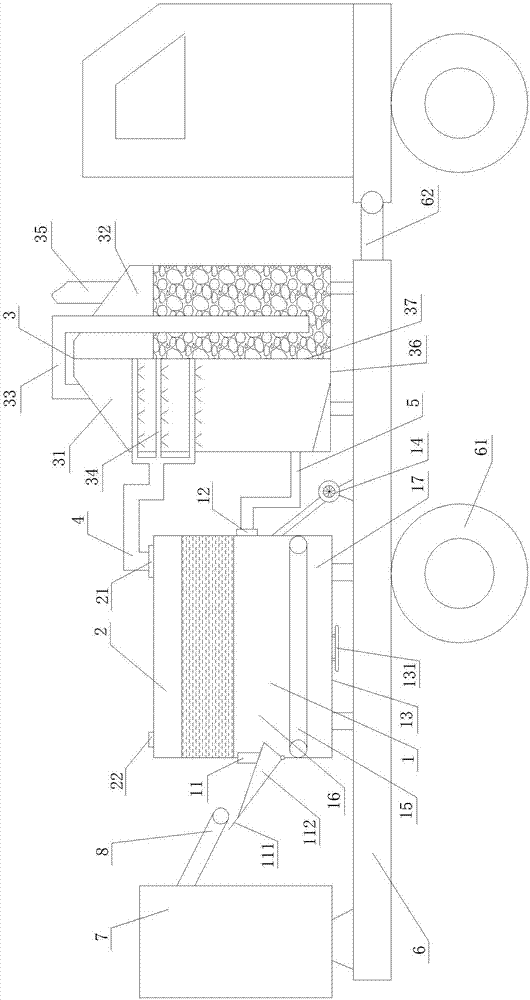

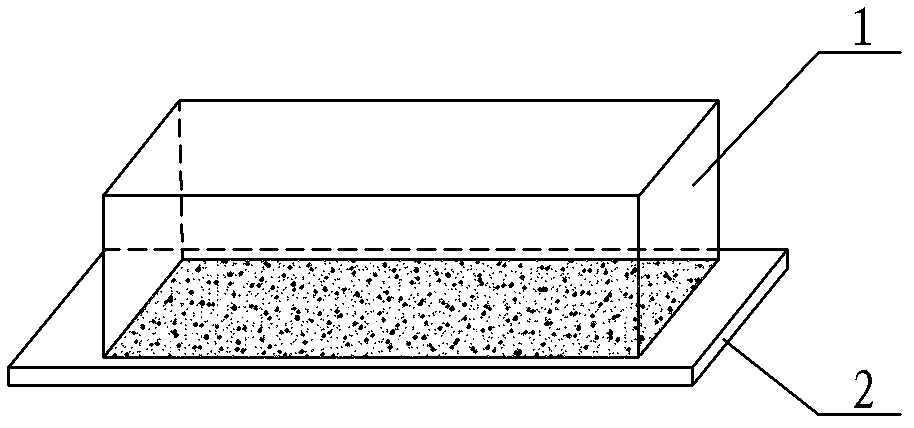

Fast and environment-friendly straw treating method and device

InactiveCN107044648ALow costFully producedEmission preventionIncinerator apparatusWood ashHazardous substance

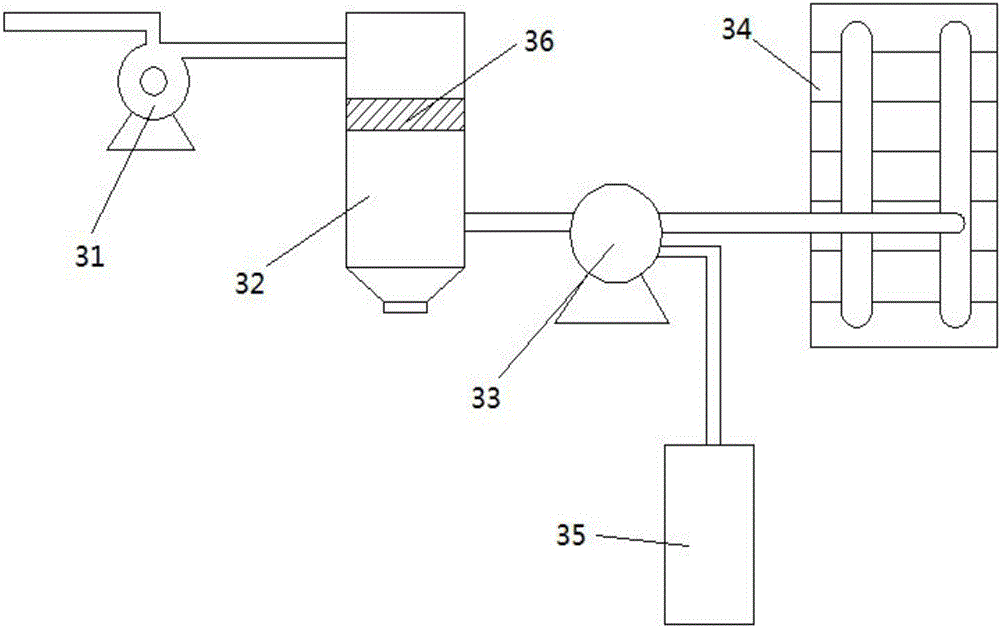

The invention discloses a fast and environment-friendly straw treating method. The method comprises the steps that crushed straw is incinerated in a sealed container, and plant ash generated after incineration is returned to the field; generated smoke sprayed water mist is dedusted, harmful substances in the smoke sprayed water mist are adsorbed by adsorbing substances, and then the smoke sprayed water mist is exhausted into the atmosphere; and after treatment is completed, a device is moved to a next straw pile. The invention discloses the treating device which comprises a transporter, and an incinerator, a steam boiler, a purification can and a pulverizer which are mounted on the transporter. The pulverizer is connected with a feed inlet of the incinerator through a conveyer; the steam boiler is arranged on the incinerator; the purification can is partitioned into a dedusting cavity and a smoke removing cavity; the dedusting cavity communicates with the smoke removing cavity through a connecting pipeline; the dedusting cavity is provided with spray pipes connected with a steam port of the steam boiler through a steam pipe; the dedusting cavity is connected with an air outlet of the incinerator through a smoke exhaust pipe; and the smoke removing cavity is filled with adsorbing substances, and an air exhaust pipe is arranged at the top end of the smoke removing cavity. According to the fast and environment-friendly straw treating method and device, operation is convenient, the cost is low, the straw treating efficiency is high, the straw treating time is short, and the smoke purification effect is good.

Owner:刘剑

Sizing method of environment-friendly textile slurry

ActiveCN103882709ASizing fitImprove sizing effectSucessive textile treatmentsFibre treatmentEngineeringSlurry

The invention relates to a sizing method of environment-friendly textile slurry, which comprises the following steps: pouring slurry into a slurry trough, and heating the slurry in the slurry trough to 55 DEG C; immersing the fabric into the slurry in the slurry trough for 5 minutes while winding the fabric on a frame to tighten the fabric and rolling the fabric at uniform speed so that the slurry is sufficiently and uniformly filled into the fabric, wherein the pressure of the squeezing roller is 13KN; taking out the fabric, putting the fabric in a drying oven, and drying the fabric; immersing the dried fabric into the slurry again for 2 minutes, and rolling the fabric at uniform speed, wherein the pressure of the squeezing roller is 15KN; and taking out the fabric, putting the fabric in a drying oven, and drying the fabric to finish the sizing technique. The method completes the fabric sizing in a twice sizing mode, and designs the technological parameters (mainly temperature of the slurry trough, immersion time for two sizing processes, and pressure of the squeezing roller) according to the specific slurry. The sizing technique is especially suitable for sizing high-count cotton fabrics, and has favorable sizing effect.

Owner:SUZHOU RUNHONG TRADING

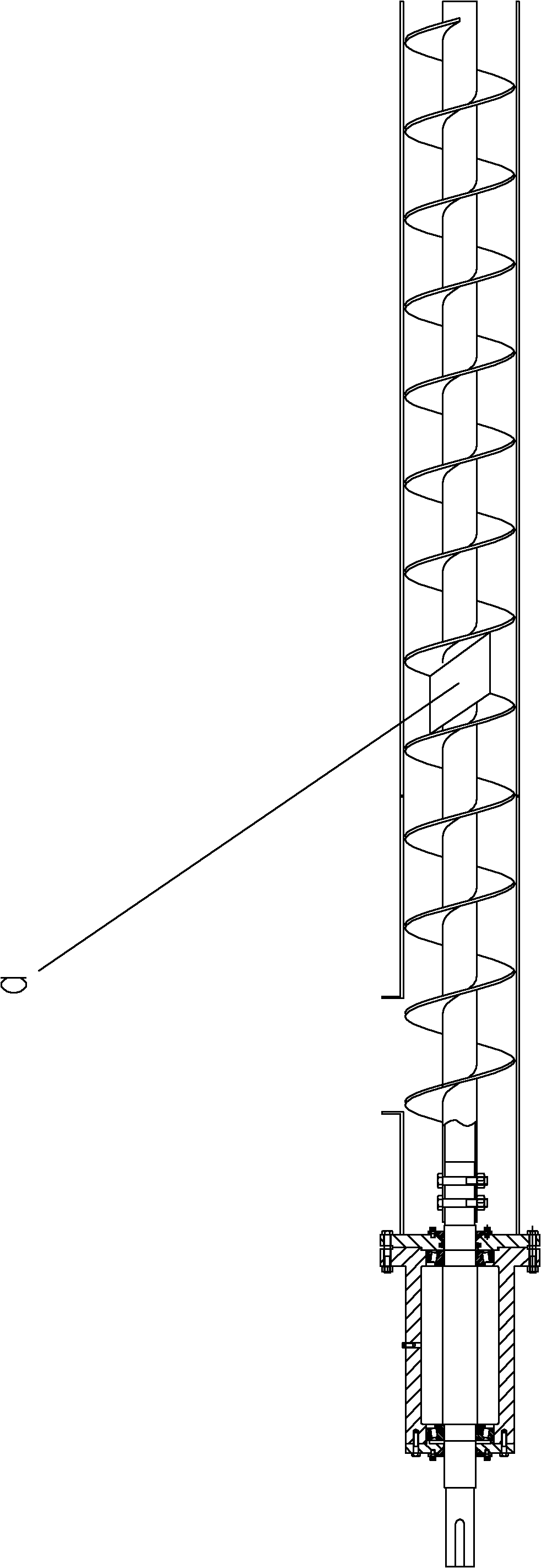

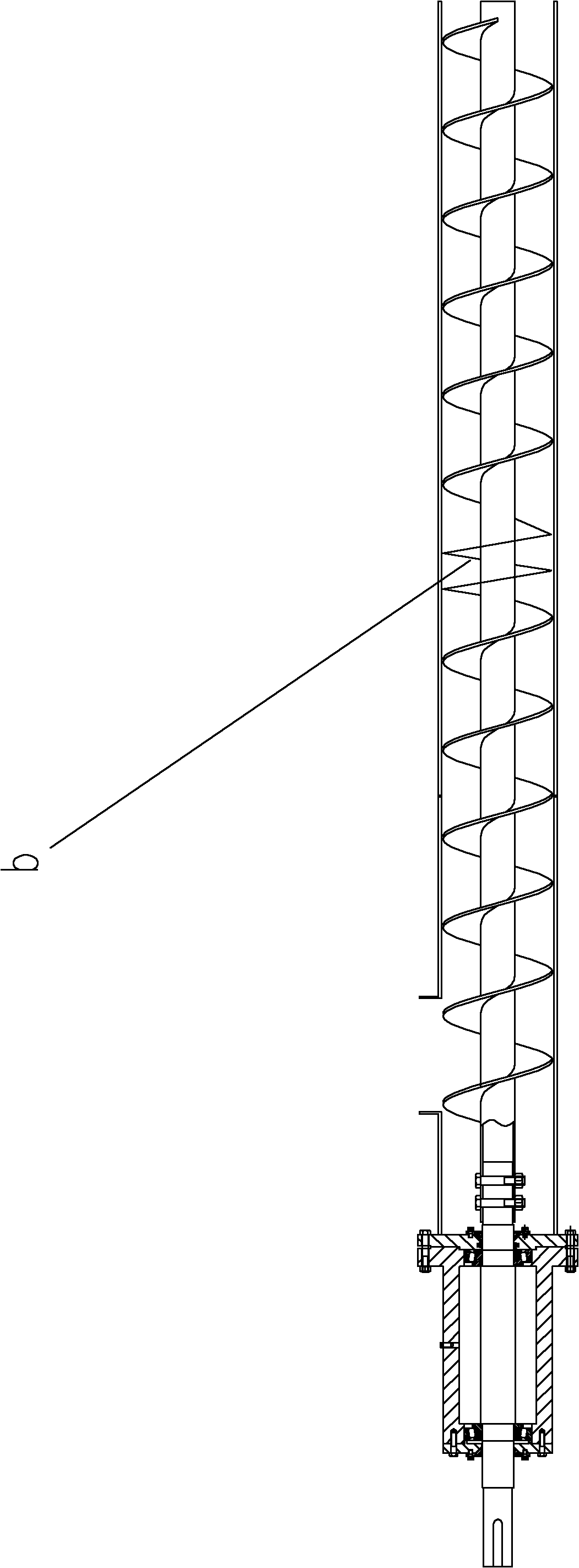

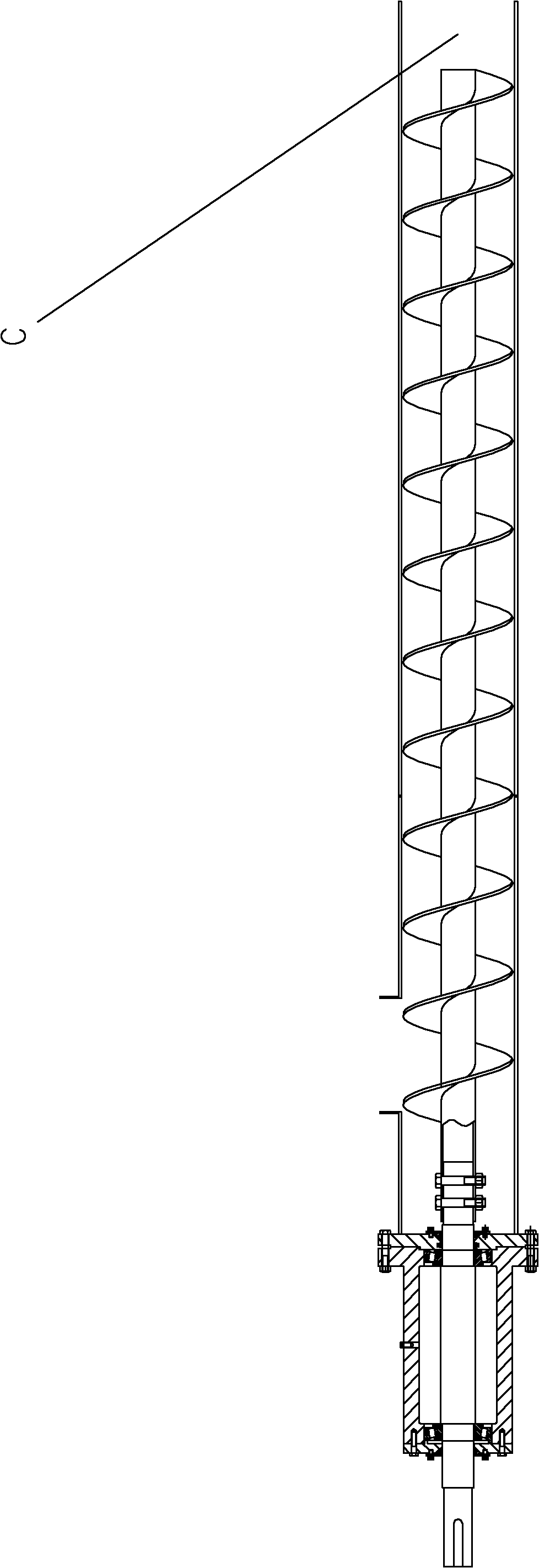

Air-locking feeding device and biomass gasification system using same

ActiveCN101967404ARealize airtight air lockAvoid safety hazardsProductsReagentsSpontaneous combustionHelical blade

The invention discloses an air-locking feeding device, which comprises: an electric motor and a reduction gear connected therewith; a rotating shaft which is driven by the electric motor and the reduction gear to rotate and which extends toward a feeding port of a fluidized bed gasification reactor; a helical blade fixedly sleeved on the rotating shaft; and a feeding tube sleeved outside the helical blade, wherein the feeding tube is provided with a feeding port, which is positioned below a discharging port of a front storage device, and a discharging port, which is connected with a feeding port of the fluidized bed gasification reactor; the air-locking feeding device is provided with one or a plurality of air-locking structures. As the air-locking structures arranged inside the feeding device can prevent the gas, generated by the fluidized bed gasification reactor, from leakage into the air and the front storage device through the feeding device, spontaneous combustion, explosion, poisoning of people and other dangers caused by gas leakage are avoided and equipment, raw materials and operating staff are safeguarded.

Owner:GUANGZHOU DEVOTION THERMAL TECH

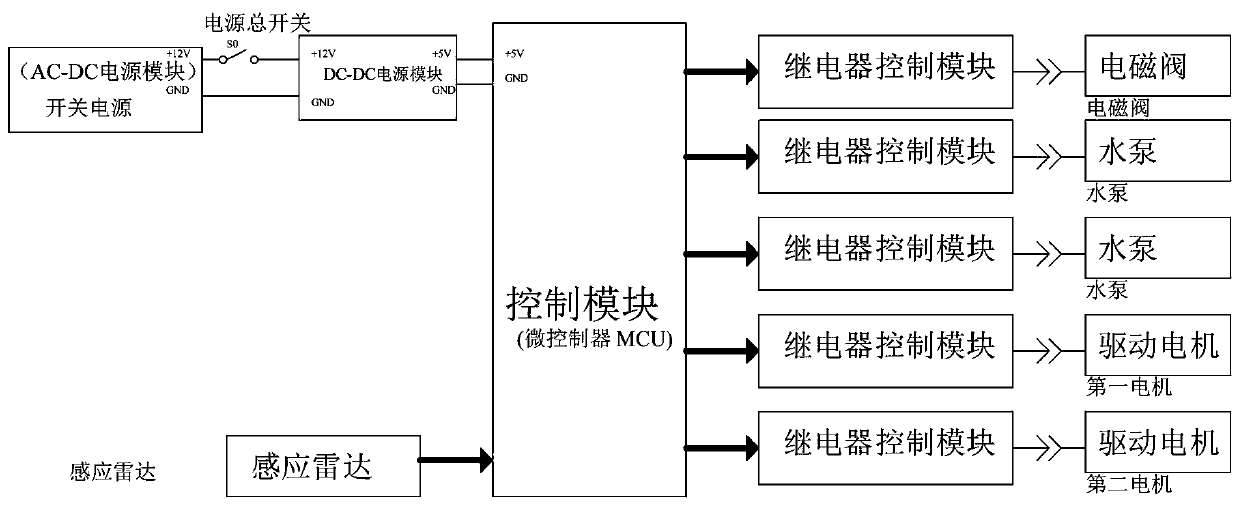

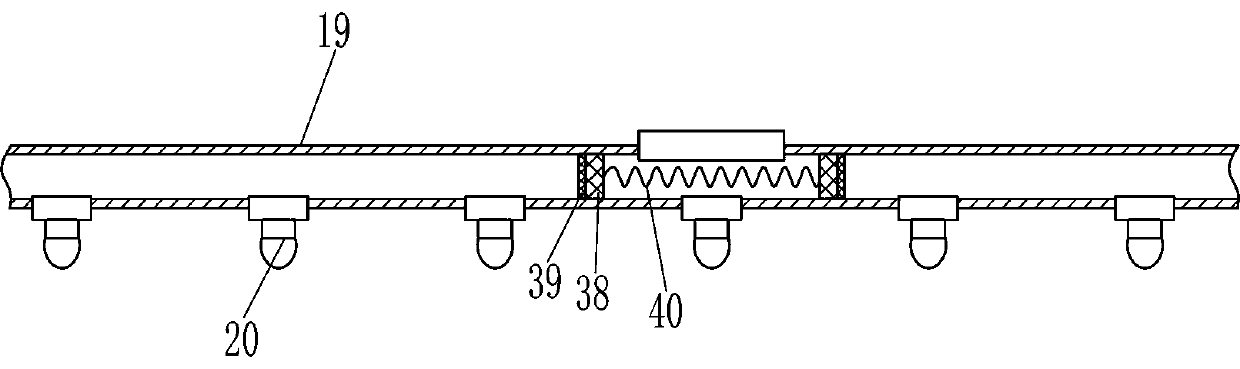

Vehicle body automatic brushing facility

ActiveCN110606052AFully scrubScrub clean and brightCleaning apparatus for vehicle exteriorsMotor driveRadar

The invention relates to a brushing facility, in particular to a vehicle body automatic brushing facility. Consequently, according to the technical problem, the vehicle body automatic brushing facility which can automatically and fully brush a vehicle body and a footrest, can clean the footrest and is high in cleaning efficiency is provided. According to the technical scheme, the vehicle body automatic brushing facility comprises supporting plates, an installation plate, a first supporting rod, a first rotating rod, a first motor, a rotary table, a push rod, first bearing pedestals, a first brush barrel and the like. The supporting plates are connected with the left side and the right side of the bottom of the installation plate. By the adoption of the vehicle body automatic brushing facility, the position of an automobile is detected by an induction radar, when the automobile runs through the right side of the induction radar, a control module can control the first motor, a second motor, a solenoid valve and water pumps to be started, and the first motor can drive a first hollow pipe to move left and right so that water can be sprayed out through first spray nozzles, and the spraying range can be broader; and the second motor drives the first brush barrel and second brush barrels to rotate, and therefore the vehicle body is fully brushed.

Owner:车泊喜智能科技(山东)有限公司

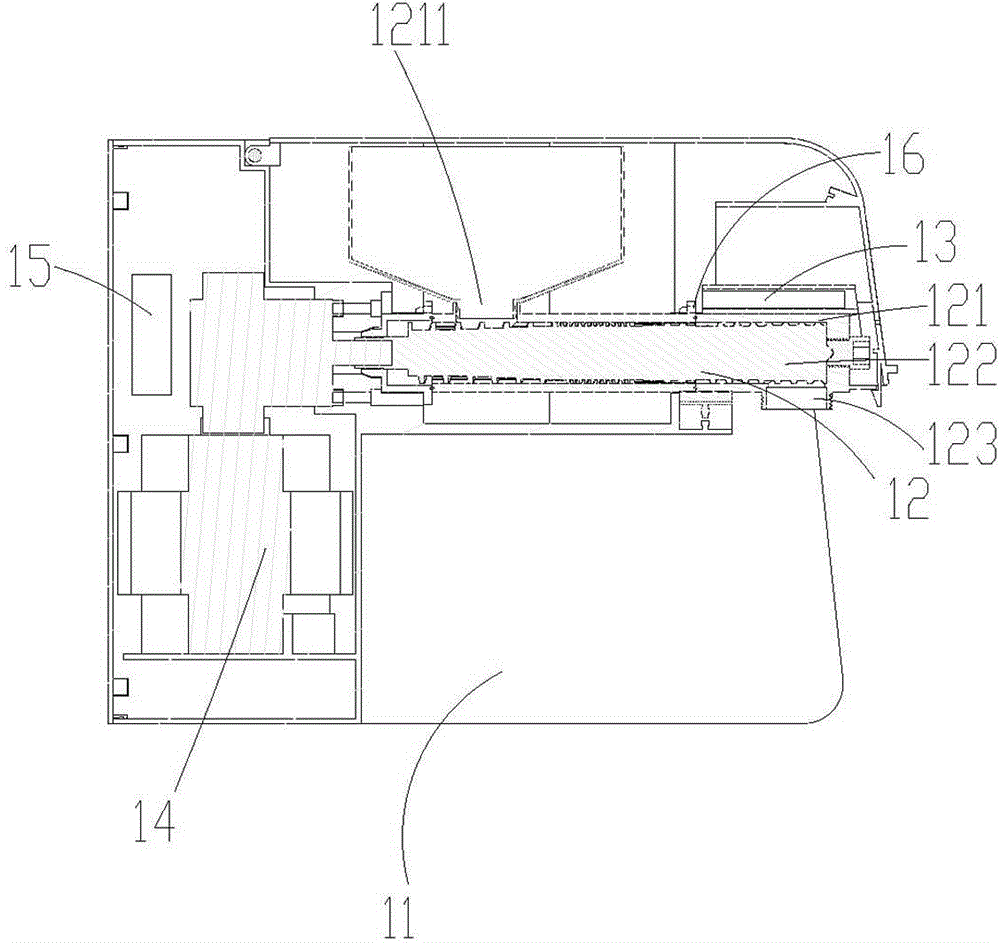

Rice noodle preparation method of household rice noodle machine and household rice noodle machine

ActiveCN104621443AHelp shapeImprove gelatinization efficiencyFood shapingFood preparationWarming processEngineering

The invention relates to a rice noodle preparation method of a household rice noodle machine and the household rice noodle machine. The rice noodles preparation method of the household rice noodle machine comprises the following steps: a feeding stage, namely driving a screw rod to rotate by a drive system and feeding raw materials into an extrusion grinding cavity by the screw rod; a curing and noodle-extruding stage, namely driving the screw rod to rotate by the drive system, grinding the raw materials by the screw rod, mixing, simultaneously curing the raw materials, and extruding into rice noodles from the ground, crushed, mixed and cured raw materials through a molding die head; and a once warming process, namely heating a extrusion crushing cavity by a heating device before the curing and noodle-extruding stage, so that the temperature of the extrusion crushing cavity ascends to T1, and the range of T1 is 80-110 DEG C, and feeding the rice material into the extrusion grinding cavity for curing after the once warming process is additionally added in the rice noodle preparation process, so that the hardness of the rice material is reduced, and the crushing of the rice material by virtue of a crushing, extruding and molding system in the curing and noodle-extruding stage is facilitated, and forming of the rice noodles are facilitated.

Owner:JOYOUNG CO LTD

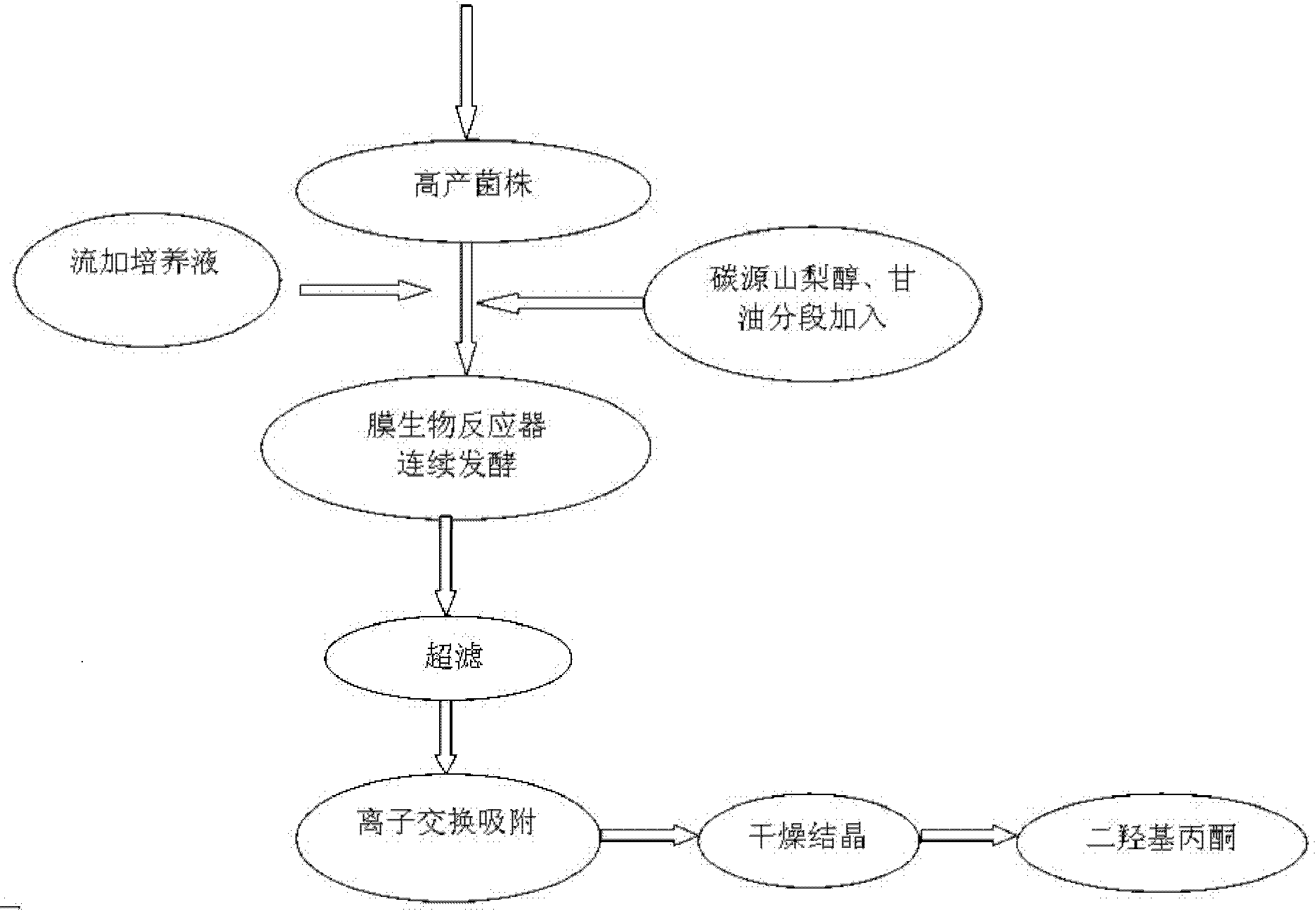

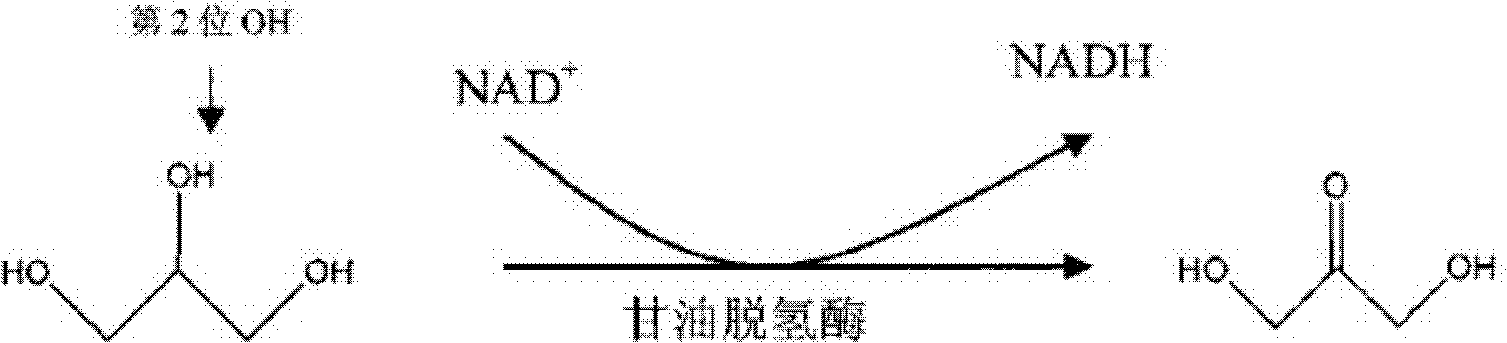

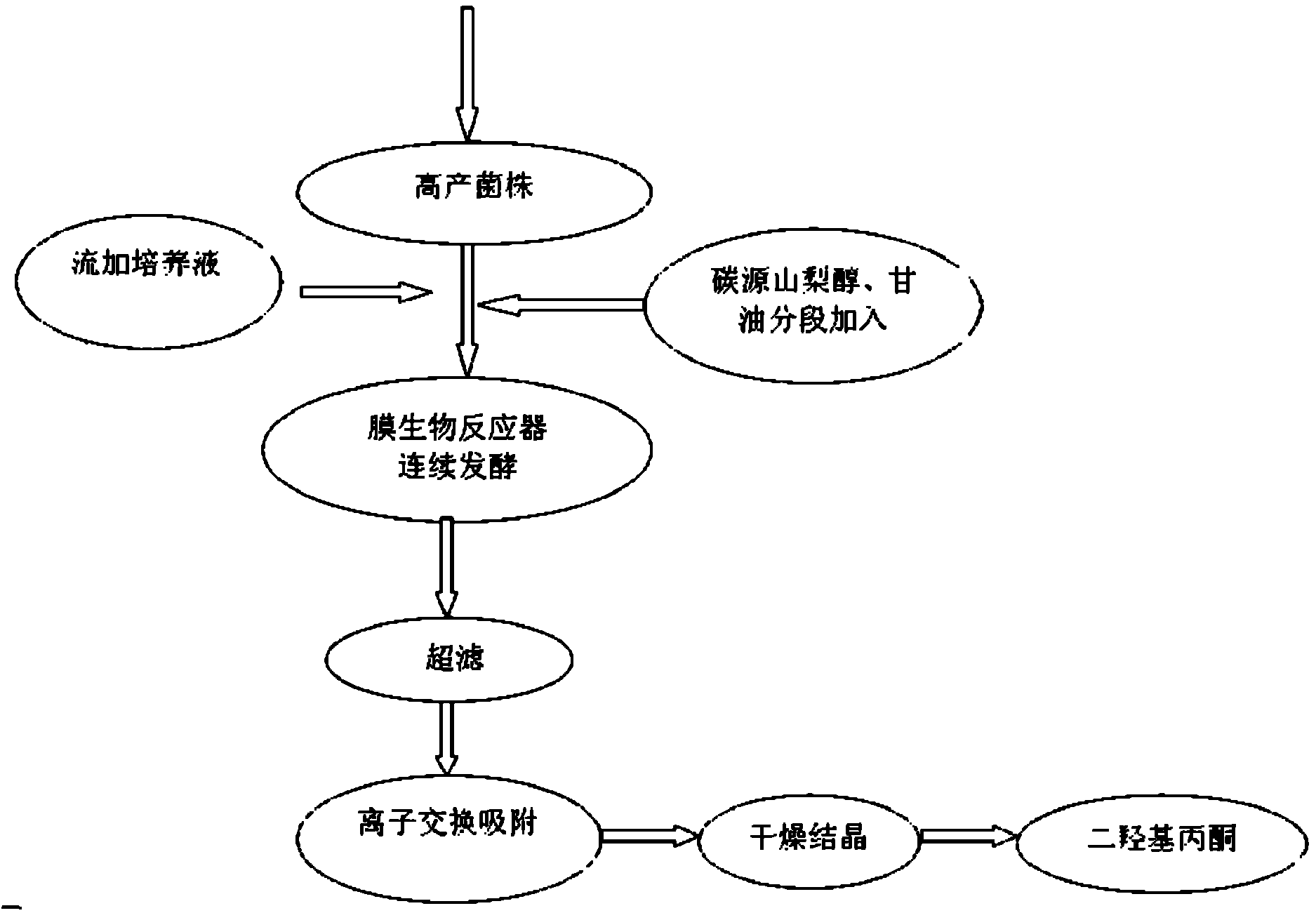

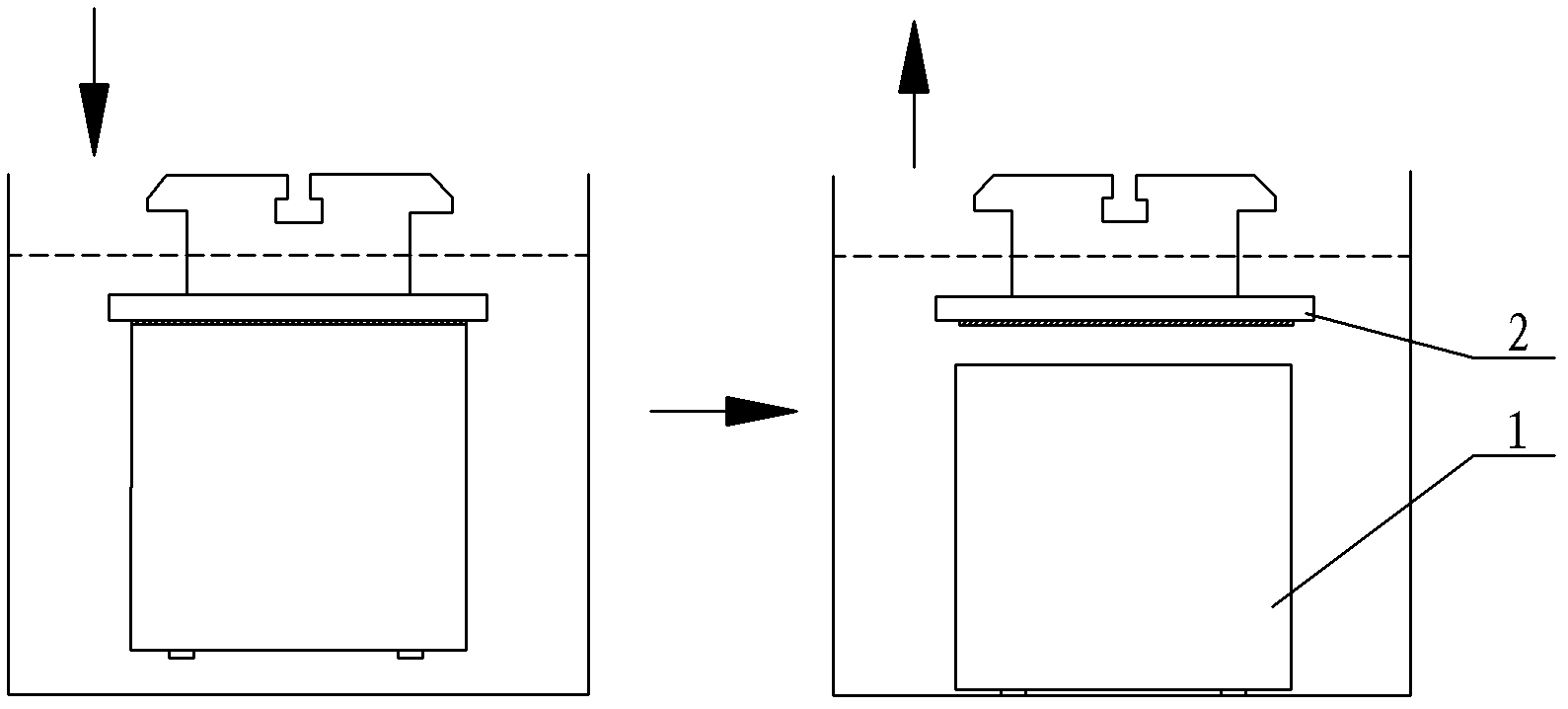

Method for producing dihydroxyacetone by using gluconobacter sp.

ActiveCN102382868AFully producedFull proliferationSugar derivativesMicroorganism based processesContinuous fermentationDihydroxyacetone

The invention provides a method for producing dihydroxyacetone by using gluconobacter sp. CGMCC No. 5146. The method comprises the following steps of: performing initial fermentation culture by using a culture medium using sorbitol as a substrate till the thalli of the gluconobacter sp. are grown to a stable stage, putting the obtained solution containing the thalli and the dihydroxyacetone product into a membrane bioreactor, performing continuous fermentation by using a culture medium using glycerol as a substrate, continuously filtering the fermentation solution containing no thalli throughthe membrane bioreactor, meanwhile, constantly supplementing fresh culture medium using glycerol as the substrate to the membrane bioreactor, separating the dihydroxyacetone in the fermentation solution, and purifying the dihydroxyacetone. When the glycerol concentration of the substrate is 60g / L, the concentration of the dihydroxyacetone (DHA) is 56.75g / L, the volume yield of the DHA is 9.02 g / (L. h), the conversion rate of the glycerol reaches over 90 percent, and the yield of the DHA reaches over 80 percent; and the technical bottlenecks of low yield and high cost in a microbial fermentation method for preparing the dihydroxyacetone are broken. The method has the characteristics of simplicity and convenience in operation, energy conservation, high production efficiency and the like, and is suitable for industrialized large-scale production.

Owner:中科医药行业生产力促进中心有限公司

Method for preparing low-sugar-content enzyme by using fed-batch fermentation

InactiveCN107897898ALow alcohol contentAvoid inhibitionYeast food ingredientsFood ingredient functionsBatch fermentationHigh sugar

The invention discloses a method for preparing low-sugar-content enzyme by using fed-batch fermentation. The method for preparing the low-sugar-content enzyme by using fed-batch fermentation comprisesthe following steps: firstly, performing fermentation on a mixture of a high-sugar-content fruit and vegetable stock fermentation solution and a freshly beaten fruit and vegetable juice so as to obtain a low-sugar-content fermented fruit and vegetable solution; and then, adopting a fed-batch fermentation method so as to continuously performing fermentation on a mixture of the high-sugar-content fruit and vegetable fermentation solution and the low-sugar-content fermented fruit and vegetable solution, and thus, the low-sugar-content enzyme is continuously prepared. The method for preparing thelow-sugar-content enzyme by using fed-batch fermentation is simple in production method, short in fermentation cycle, low in cost, and reduced in pollution risk; moreover, influence of seasons on fruit and vegetable production is avoided so that the problems of discontinuous production, as well as inhibition on bacillus aceticus growth caused by high sugar content, and so on are solved. The method for preparing the low-sugar-content enzyme by using fed-batch fermentation is suitable for large-scale industrial production; moreover, the method is also of great significance to the enzyme industry.

Owner:LIAONING SHENGQI HEAVEN BIO MEDICAL SCI TECH CO LTD

Industrial sludge solid waste treatment method

InactiveCN106348552AReduce pollutionReduce generationSolid waste managementFixation/solidifcation sludge treatmentSludgeTherapeutic effect

The invention discloses an industrial sludge solid waste treatment method which comprises the following steps: proportioning parameters of cement, wastes, a medicament and water, conveying sludge wastes, stirring by a stirring machine, conveying the materials to a building block forming machine through a belt conveyor for forming and maintenance of building blocks, and finally performing landfilling. The method is simple in process, convenient to operate, obvious in treatment effect and extremely low in pollution to underground water; furthermore, generation of solid wastes can be reduced, and the solid wastes can be fully and cyclically used as much as possible.

Owner:赵卫平

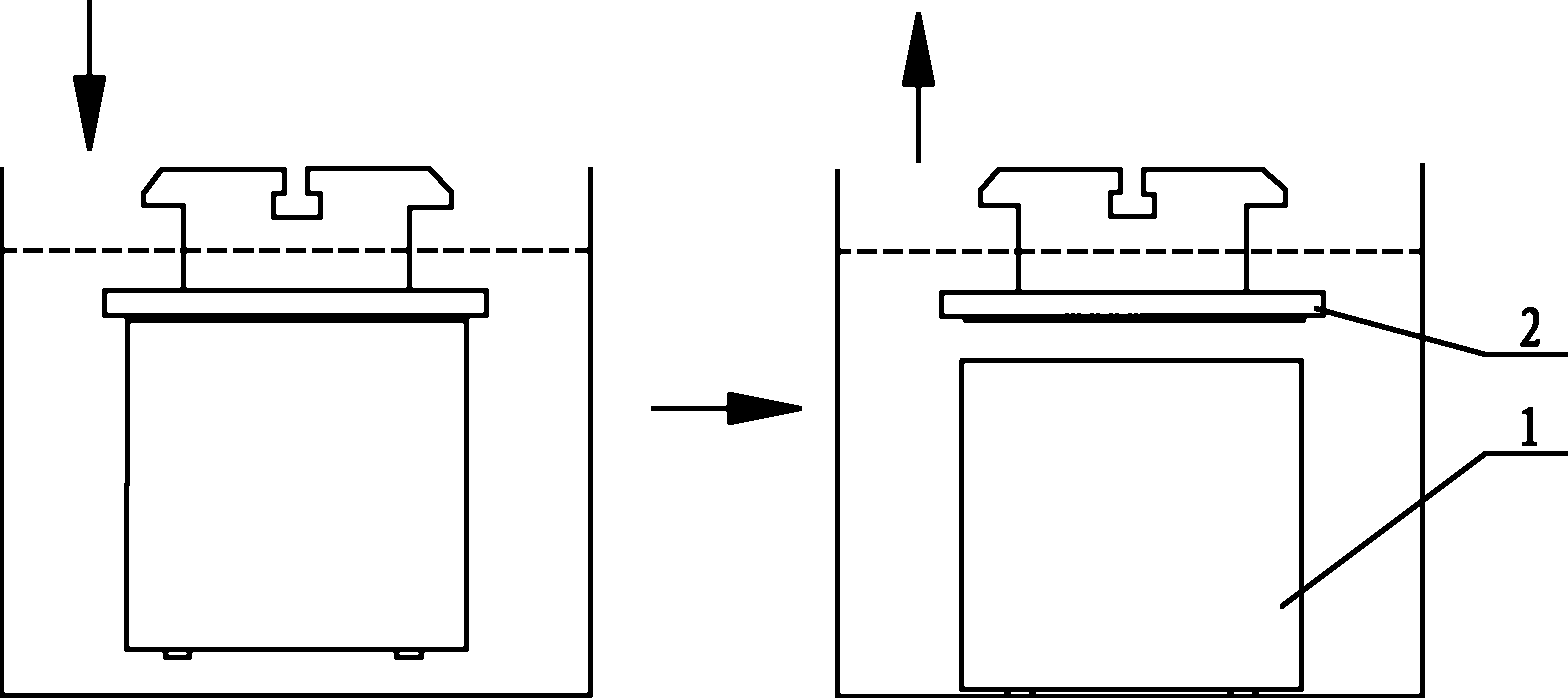

Degumming technology for aqueous solution of methanesulfonic acid

InactiveCN102500569AOut of fullFully producedFinal product manufactureCleaning using liquidsAqueous solutionHeating temperature

The invention discloses a degumming technology for the aqueous solution of methanesulfonic acid. The technology comprises the following steps of: a, adding a certain amount of water into an acid soaking tank of a degumming machine, setting the heating temperature, and turning on a switch for heating; b, adding a certain amount of methanesulfonic acid with a prepared concentration into the acid soaking tank of the degumming machine; c, putting a silicon wafer after flushing and ultrasonic washing and a cutting substrate together into the acid soaking tank to soak for some time; and d, lifting the cutting substrate by a special tool, and taking down a few silicon wafers which do not drop. The technology adopts the aqueous solution of methanesulfonic acid in the acid soaking process, has the advantages of sufficient silicon wafer separation and low cost, can shorten the degumming time and does not produce gas with irritant odor.

Owner:KONCA SOLAR CELL

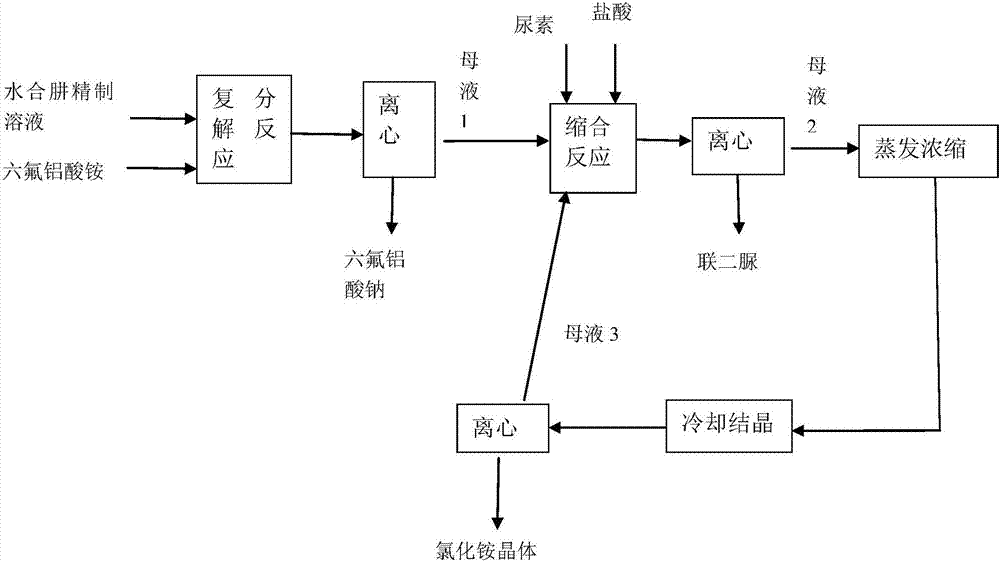

Method for co-producing sodium hexafluoroaluminate and biurea

InactiveCN107055581ANo emissionsFully producedOrganic chemistryAluminium fluoridesAmmonium hexafluoroaluminateBiurea

The invention discloses a method for co-producing sodium hexafluoroaluminate and biurea. The method comprises the following steps: (1) adding ammonium hexafluoaluminate into a sodium carbonate-removed refined hydrazine hydrate solution wherein sodium chloride in the refined hydrazine hydrate solution performs double decomposition reaction with the ammonium hexafluoaluminate, thus generating the sodium hexafluoroaluminate and ammonium chloride, and separating the sodium fluoroaluminate, thus obtaining a mother solution 1; (2) adding urea and hydrochloric acid into the mother solution 1 where hydrazine hydrate and urea in the mother solution 1 performs condensation reaction with the hydrochloric acid, thus generating the biurea and ammonium chloride, and separating the biurea, thus obtaining a mother liquid 2. According to the method, the sodium hexafluoroaluminate, the biurea and the ammonium chloride which are high in yield and high in purity can be respectively produced; the yield of the sodium hexafluoroaluminate is up to 99.3 percent or above, and the contents of fluorine and aluminum in the sodium hexafluoroaluminate can meet the requirement of the national standard; the yield of the biurea is up to 97 percent or above, and the purity is 98 percent or above; the yield of the ammonium chloride is 98 percent or above, and the purity can meet the industrial standard.

Owner:衡阳市锦轩化工有限公司

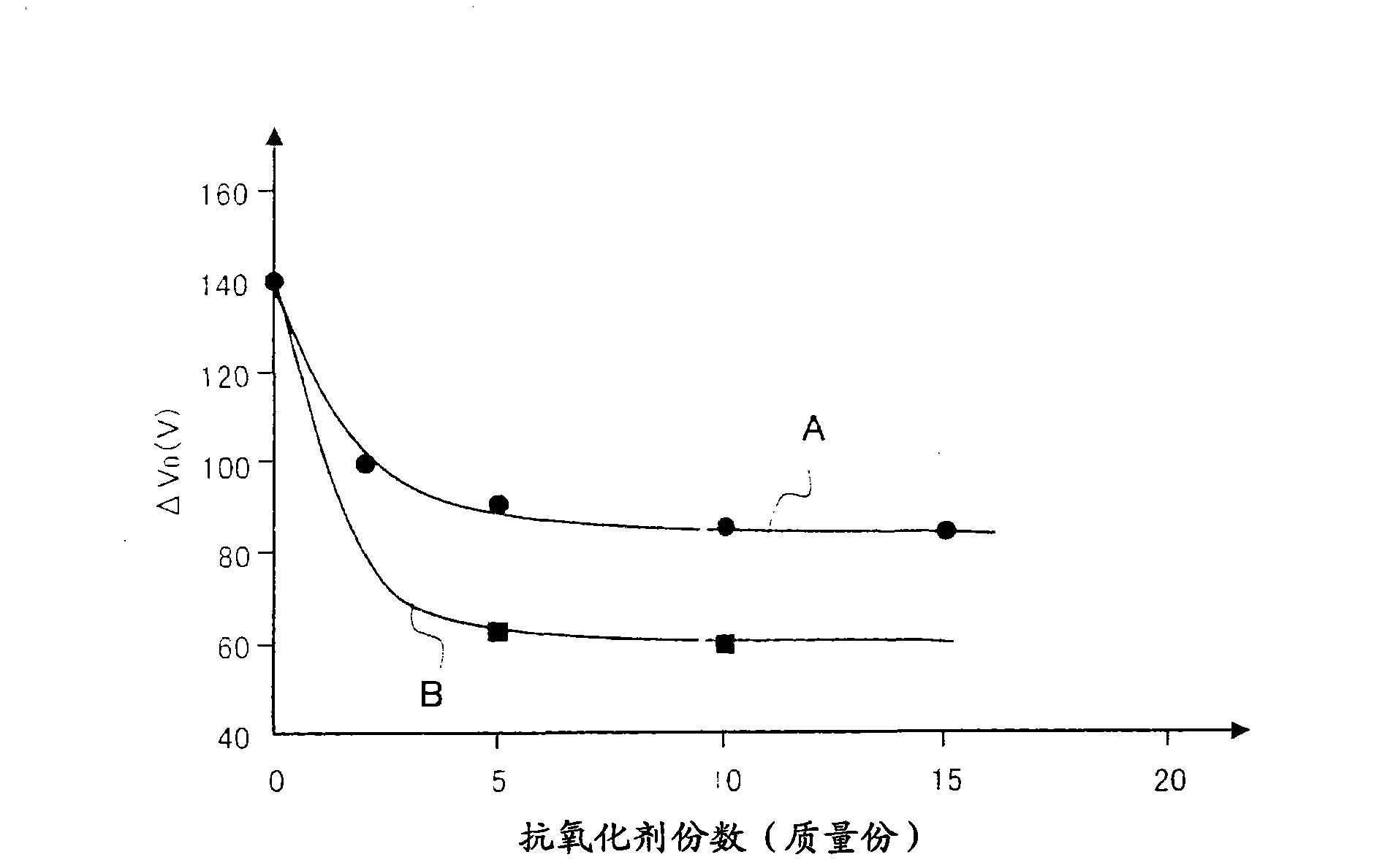

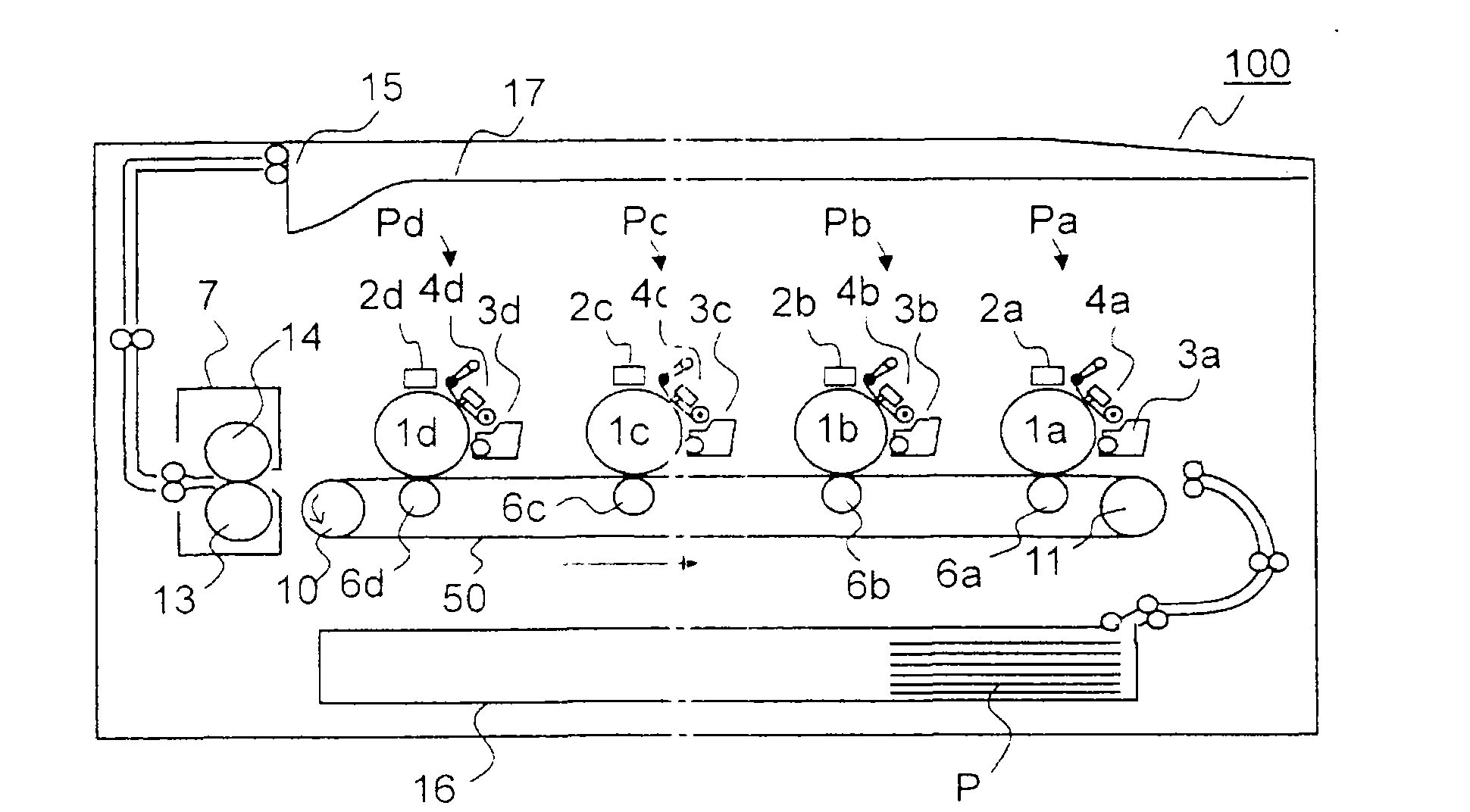

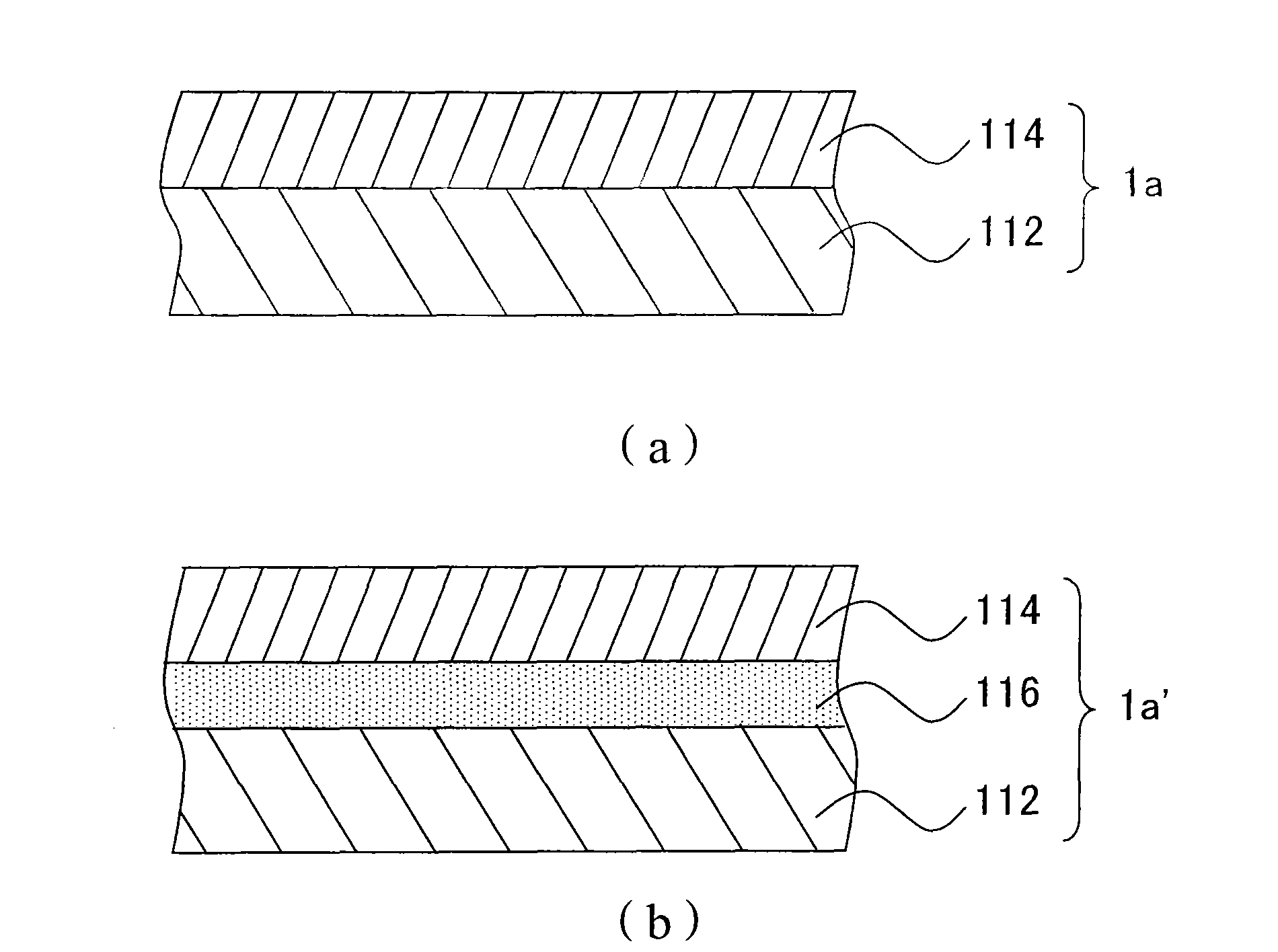

Electronic photographic photoreceptor and image forming apparatus

ActiveCN101794090AAchieve high speedSuppresses charge potential dropElectrographic process apparatusImage formationUltraviolet

The invention provides a electronic photographic photoreceptor which can effectively restrain reduction of electrified electric potential, and an image forming apparatus having the electronic photographic photoreceptor. The electronic photographic photoreceptor of the invention has a basal body and a photographic layer configured on the basal body, wherein the photographic layer contains TiOPc crystal as charge generating agent, and contains antioxidant and ultraviolet absorbent as additive.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

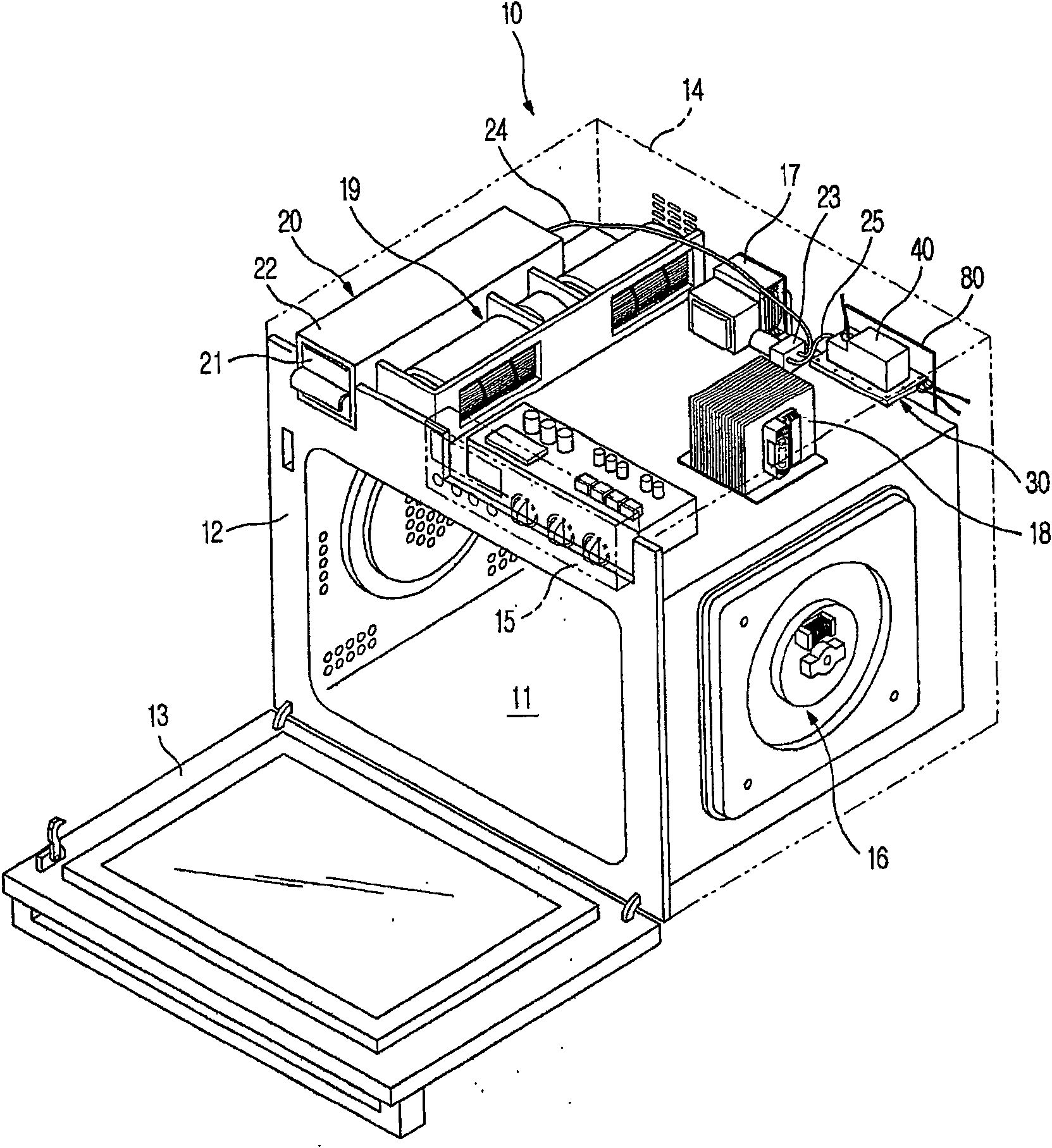

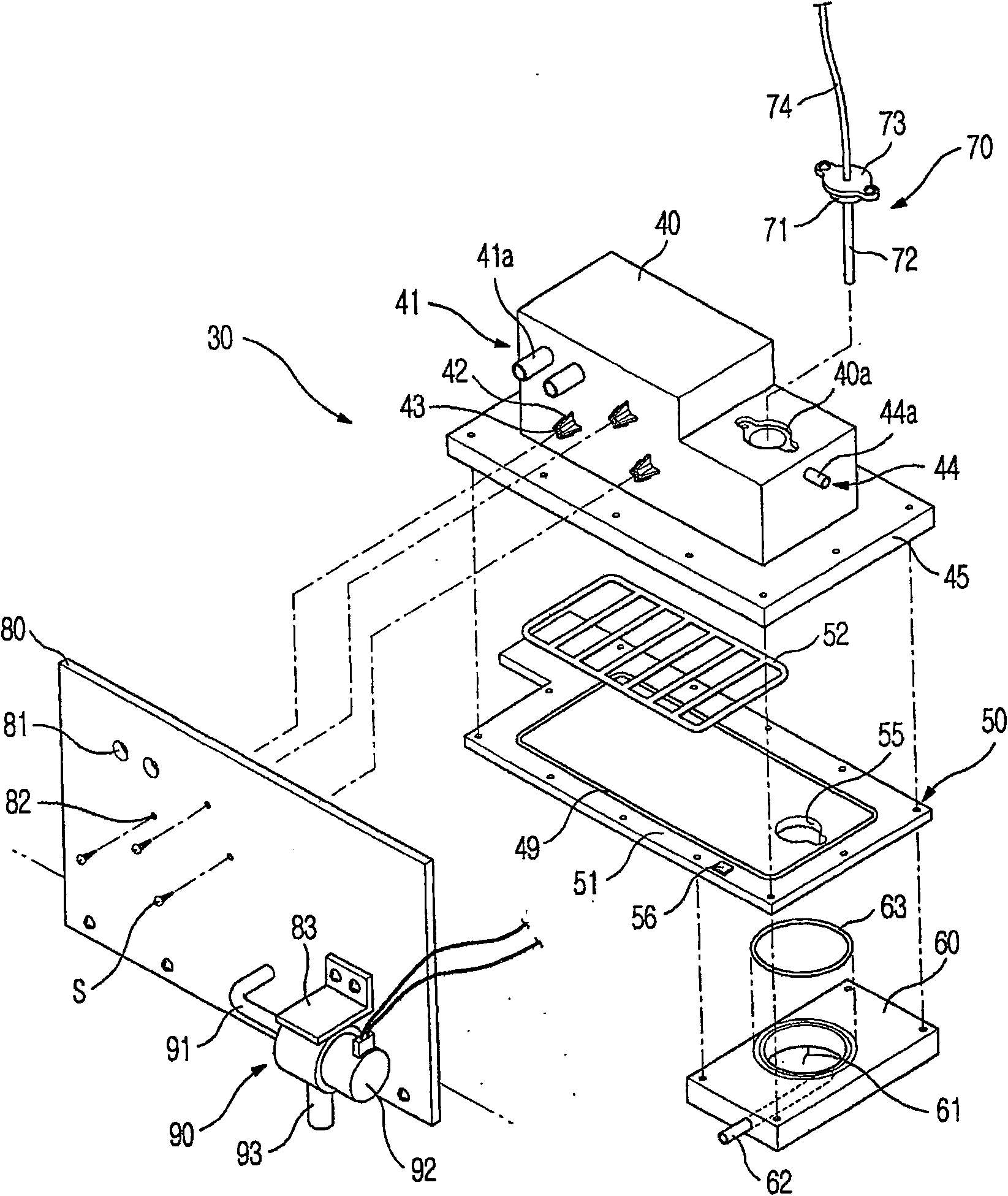

Steam generator, heating cooker having the same and control method thereof

InactiveCN100572913CFully producedDomestic stoves or rangesCarpet cleanersThermodynamicsProcess engineering

The invention discloses a steam generator, a heating cooker provided with the steam generator, and a control method for controlling the heating cooker, wherein the steam generator prevents degradation of steam generation performance while stably supplying water required for steam production. And generate steam in a short period of time, the heating cooker has the steam generator. The control method of a steam generator having a steam box, a steam heater, and a water level sensor includes: using the water level sensor to determine whether the steam box is facing water shortage; when it is determined that the water in the steam box is less than a predetermined minimum water level, supply water within a first period of time; and when a predetermined minimum water level in the water tank is sensed by the water level sensor after supplying water, controlling the water supply amount by additionally supplying water within a predetermined second period of time.

Owner:SAMSUNG ELECTRONICS CO LTD

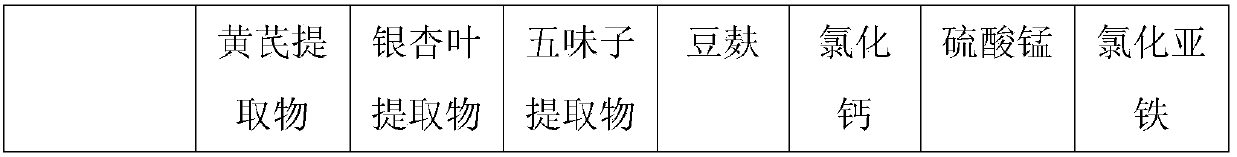

Pennisetum purpureum Schumab cv.Purple feed and preparation method and application thereof

The invention discloses a pennisetum purpureum Schumab cv.Purple feed and a preparation method and application thereof. The pennisetum purpureum Schumab cv.Purple feed is prepared from the following raw materials in percentage by weight of 55%-70% of pennisetum purpureum Schumab cv.Purple, 20%-30% of fermentation additives and 10%-15% of mixed microorganisms through anaerobic fermentation, whereinthe fermentation additives comprise astragalus extracts, ginkgo leaf extracts, Chinese magnoliavine fruit extracts, soyabean bran, 5%-10% calcium chloride, manganese sulfate, and ferrous disulfide; and the mixed microorganisms comprise cellulose decomposing bacteria, flavobacterium, bacillus subtilis and lactobacilli. The pennisetum purpureum Schumab cv.Purple feed disclosed by the invention hasthe advantages that the obtained pennisetum purpureum Schumab cv.Purple feed has acid flavor, and the storing condition is not high; and according to the pennisetum purpureum Schumab cv.Purple feed disclosed by the invention, the palatability of the feed is improved, the appetite of animals is stimulated, and the food consumption is increased.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION INST OF ANIMAL HUSBANDRY

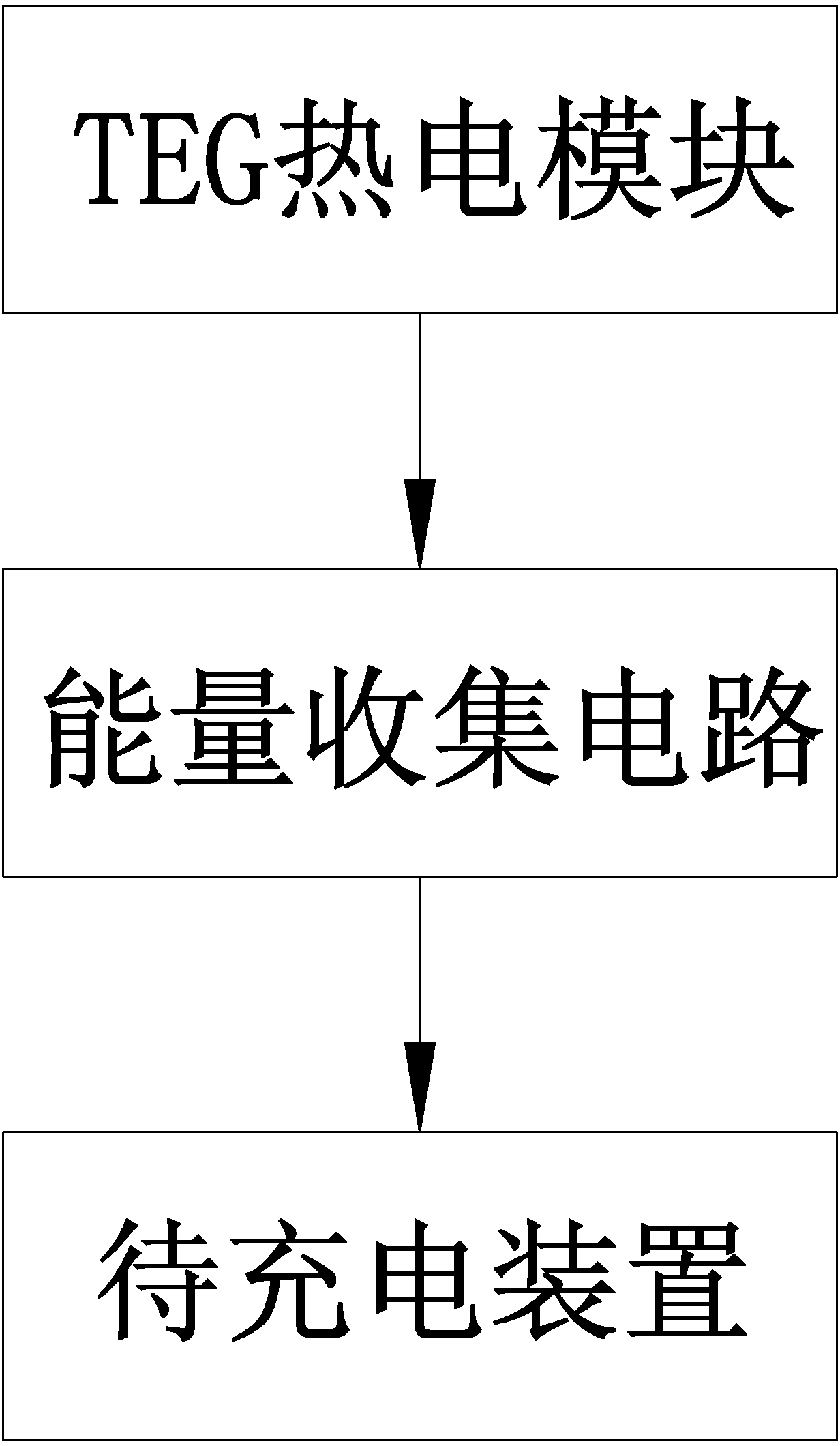

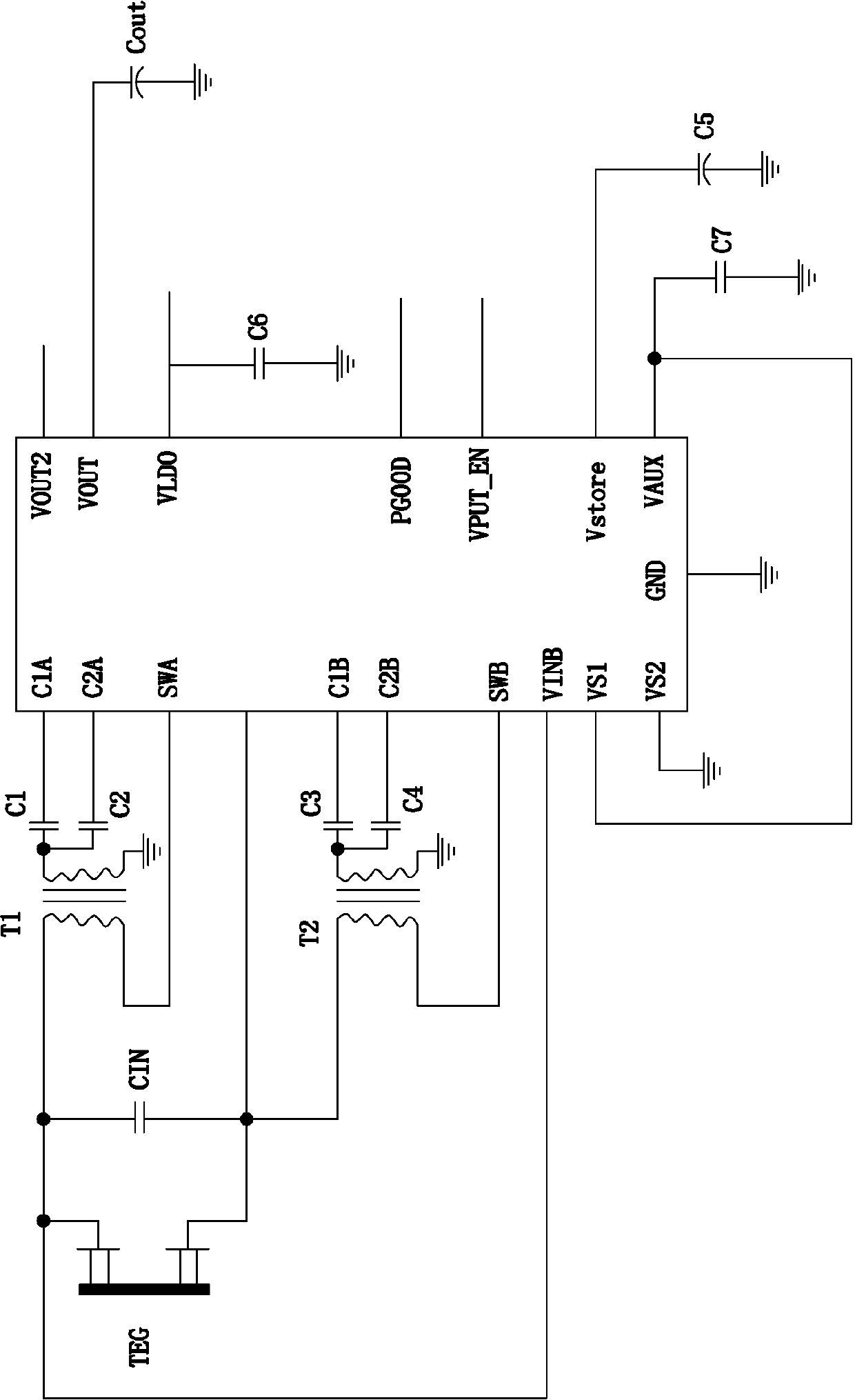

Air conditioner TEG energy collector

ActiveCN103746606AAvoid generatingFully producedEnergy recovery in ventilation and heatingBatteries circuit arrangementsElectrical batteryEngineering

The invention provides an air conditioner TEG energy collector which is characterized by comprising a TEG thermoelectricity module, an energy collection circuit and a device to be charged, wherein the TEG thermoelectricity module is arranged on an air conditioner chassis or a wind guide bar with large temperature difference; the TEG thermoelectricity module is electrically connected with the power source input end of the energy collection circuit; the power source output end of the energy collection circuit is electrically connected with the device to be charged. The efficient energy collection circuit is converted into a standard power source, then external air conditioner components such as a battery and a remote controller are charged by the standard power source, the generation of condensate water on the components with large temperature difference is effectively avoided, the temperature difference of an air conditioner is fully utilized to produce electric energy, energy-saving and environment-friendly effects are realized, and the air conditioner TEG energy collector is particularly suitable for being used in remote engineering machines and base station air conditioners.

Owner:GUANGDONG CHIGO AIR CONDITIONING

Electric heating distiller

InactiveCN105329960AFully recycleEfficient recyclingWater/sewage treatment by heatingChemical industryAutomatic control

The invention relates to an electric heating distiller which is composed of a water inlet, a condenser pipe, a condensing chamber, a heating chamber, a heat preservation layer, an electric heating pipe, a temperature sensor, a zinc ion antiscale rod, an air collecting cover, a water level sensor, an electric control valve and a distilled water outlet. The water inlet is located on the side wall face of the condensing chamber; the heating chamber is of a double-layer stainless steel structure; the condensing chamber is located in the heating chamber, and the condenser pipe is contained in the condensing chamber; an outlet of the condenser pipe serves as the distilled water outlet; the heating pipe is installed at the bottom of the heating chamber; the temperature sensor and the zinc ion antiscale rod are installed in the heating chamber; the water level sensor and the electric control valve form an automatic control system; the heat preservation layer is located in the interlayer of the double-layer structure of the heating chamber. The electric heating distiller can utilize condensing heat of distilled water at the evaporation position as a preheating part of water and save the energy sources, is high in temperature rising speed, easy to operate, high in water producing efficiency and capable of being widely applied to industries such as medical health, pharmacy, scientific research, chemical industry and food and is ideal equipment for producing the high-quality distilled water.

Owner:天津盛丰源机械设备有限公司

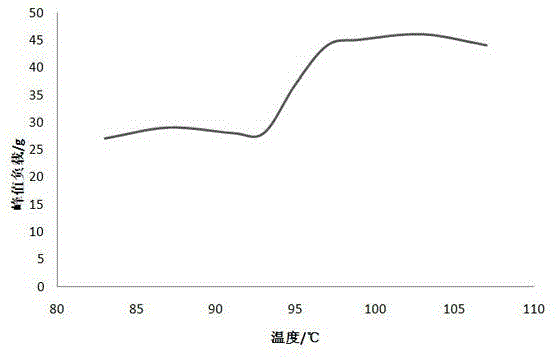

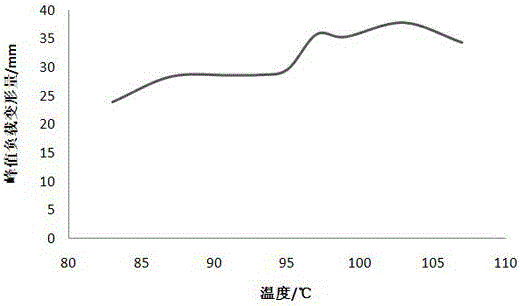

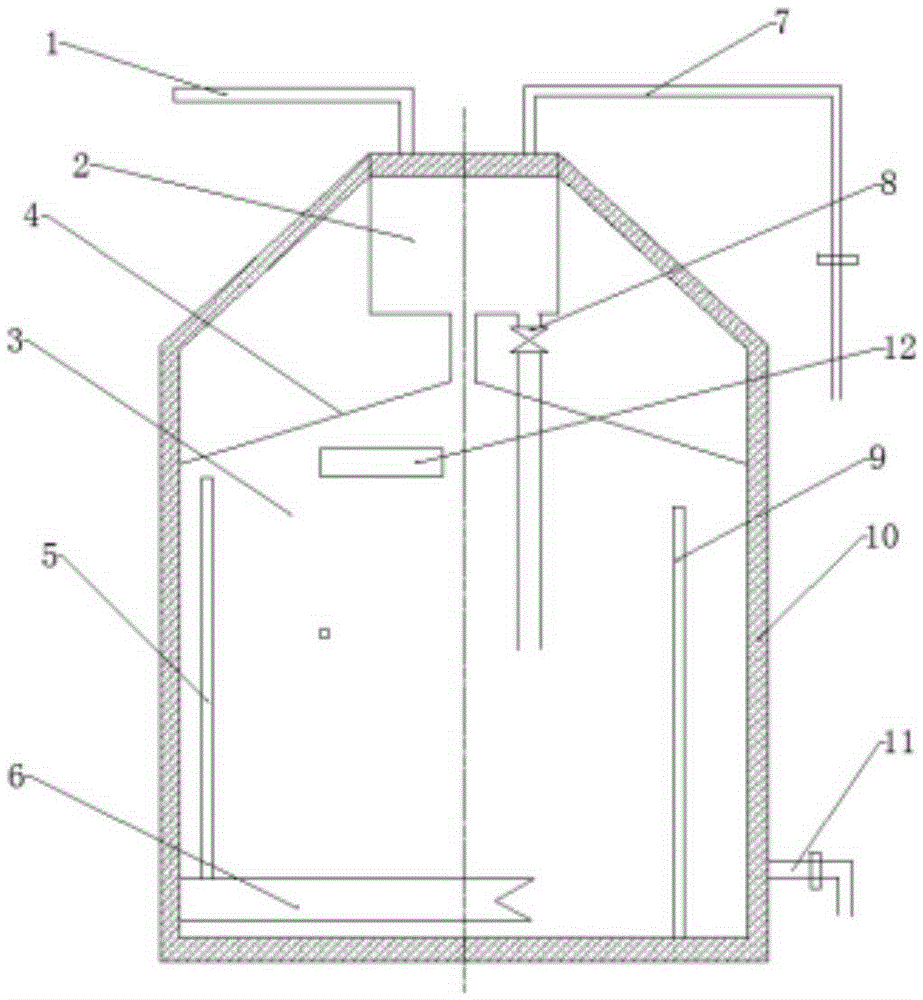

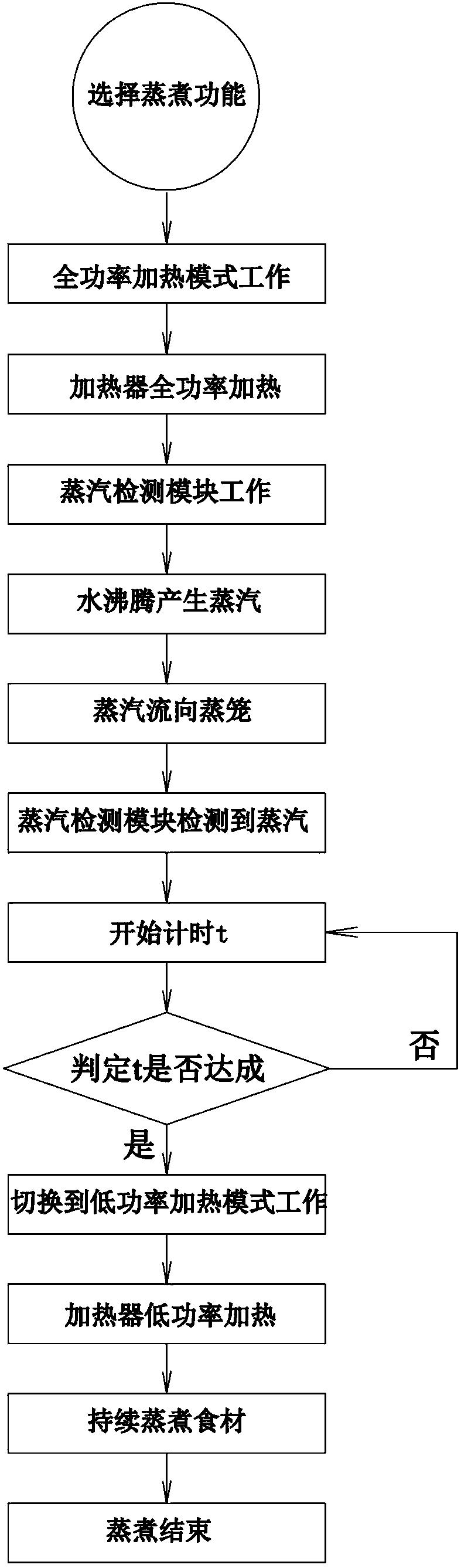

Cooking control method, cooking utensil body and cooking utensil

PendingCN110279283AAdjust heating powerProduce quicklyTemperatue controlSteam cooking vesselsHeating timeSteam cooking

The invention relates to the technical field of steam cooking, and discloses a cooking control method, a cooking utensil body and a cooking utensil. The cooking control method comprises the steps that a high-power heating mode is selected for heating; after steam generated by water boiling is detected, a first heating time t in which the high-power heating mode continues to be used for heating is started to be timed, and when the first heating time t reaches a preset value, a low-power heating mode is started to continue heating, wherein the heating power of the low-power heating mode is less than the heating power of the high-power heating mode. According to the cooking control method, the steam can be quickly generated to cook food earlier, and it is ensured that enough steam heat is provided for the food to be steamed, so that the problem of dry burning due to the fact that water in a pot is burnt dry quickly is solved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Method for producing shrimp shell meal for feed using crayfish shell waste

The invention discloses a method for producing feed shrimp shell powder by utilizing abandoned crawfish, and the method comprises the following steps: the shells of the abandoned crawfish are firstly collected and washed to be clean; then the clean shells of the crawfish are carried out the high-temperature disinfection and sterilization; the shells of the crawfish after the disinfection and the sterilization are finally carried out drying, smashing and screening treatment, thereby obtaining the finished product. The method recycles the shells of the abandoned crawfish and carried out the appropriate treatment for comprehensive utilization and production of the shrimp shell powder, the method can not only avoid the waste of resources and reduce the production cost, but can also have short production cycle, high product yield and stable product quality and avoid the environmental pollution.

Owner:长沙兴悦天华生态农业开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com