Patents

Literature

43results about How to "Weak retrograde" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

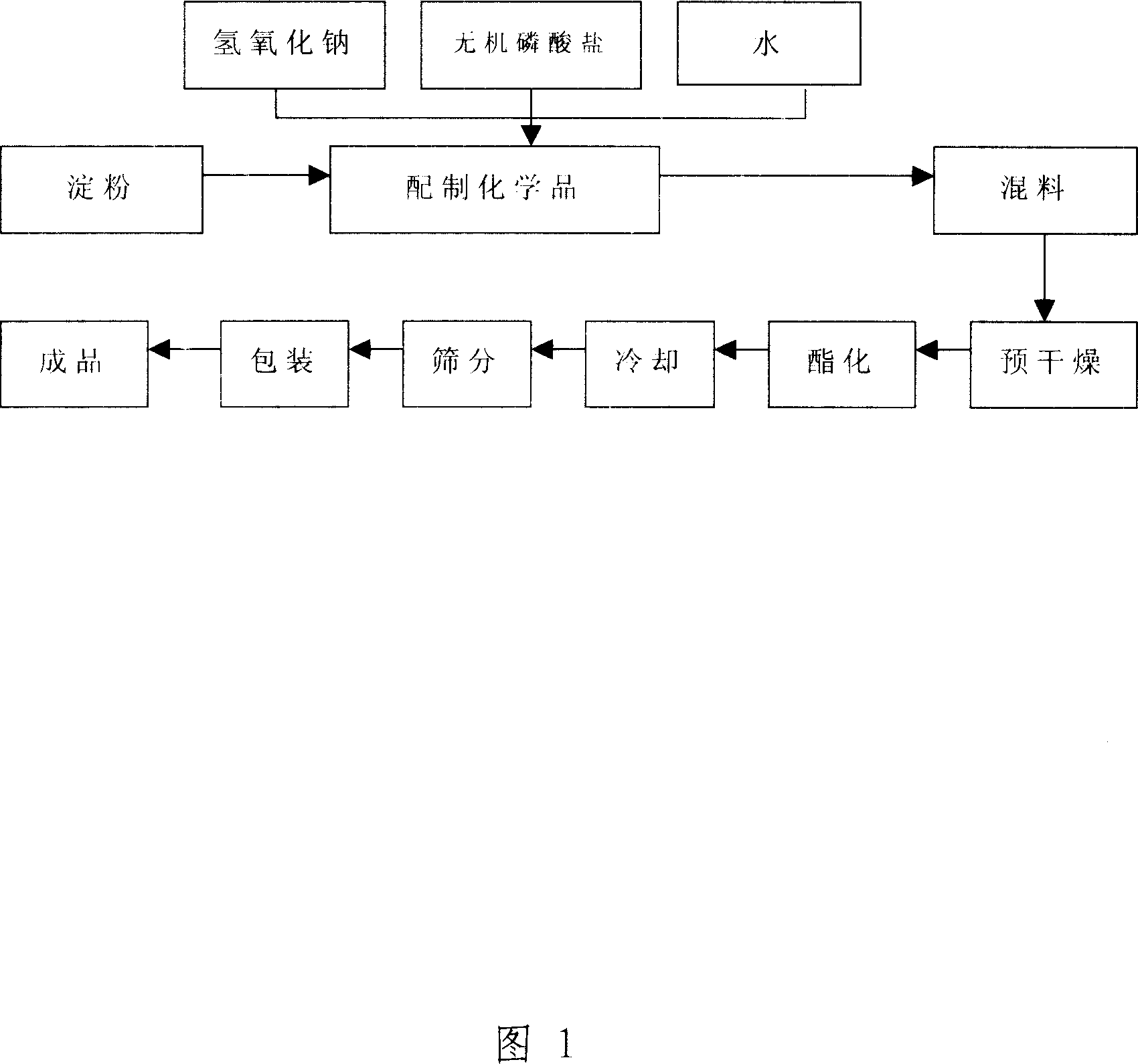

Method of preparing starch phosphate

InactiveCN101033262AThe production process is simple and applicableImprove reaction efficiencyInorganic phosphateStarch paste

This invention relates to a modified starch preparation method, specifically a phosphate starch, which takes starch, urea, inorganic phosphate as raw materials in the double-cones rotary dryer, and conducts seven process steps of preparing chemicals, mixing, pre-drying, esterification, cooling, sieving, packaging to prepare the finished product, which is light yellow to yellow powder particle, and the viscosity peak is from 1000 to 6000BU. When the mass concentration is 6% for starch paste, it can gelatinize at the temperature lower than 66deg.C till cold water.

Owner:四平帝达变性淀粉有限公司

Modified starch and production method thereof

The invention discloses a modified starch and a production method thereof and aims at providing a modified starch which has high viscosity as well as good elasticity and strong binding force of starch slurry. The modified starch is prepared by virtue of the following steps: (1) blending; (2) adding a whiteness stabilizer, mixing for 15-25 minutes, regulating the pH value to 2.0-3.0, regulating the temperature to 35-40DEG C, and performing acid splitting reaction for 1-1.5 hours; (3) adding basic catalyst and regulating the pH value to be 6.0-7.0, adding an inhibitor, reacting for 15-25 minutes, regulating the pH value to be 10.5-11.5; (4) adding the cross-linking agent into the original starch slurry reacted in the step (3), regulating the temperature to be 38-48 DEG C, reacting for 2-4 hours, then reducing the temperature of the original starch slurry to be 25-30 DEG C, and regulating the pH value to be 5.5-6.0 with the neutralizing agent; (5) washing and centrifuging the original starch slurry neutralized in the step (4), and drying to obtain the modified starch. The modified starch and the production method belong to the technical field of starch.

Owner:广西梧州市明阳生化科技有限公司

Environment-friendly type textile sizing agent

Owner:SUZHOU RUNHONG TRADING

Phosphate starch printing paste and preparation method thereof

InactiveCN102154851AHigh viscosityGood viscosity stabilityDyeing processSODIUM METAPHOSPHATEPhosphoric Acid Esters

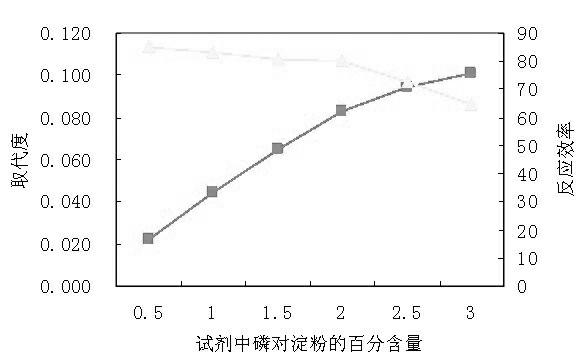

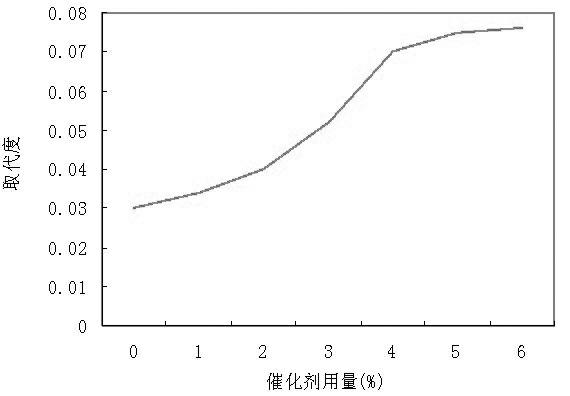

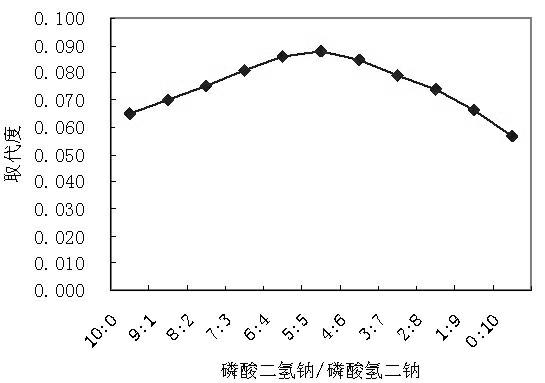

The invention discloses a phosphate starch printing paste and a preparation method thereof. Cassava starch is utilized to be reacted with sodium dihydrogen phosphate and sodium hydrogen phosphate in hot air, and urea is adopted as a catalyst to produce phosphate starch. The sodium dihydrogen phosphate and the sodium hydrogen phosphate generate micro sodium metaphosphate at high temperature, and the sodium metaphosphate is crosslinked with the starch, thus the viscosity of the starch is improved. Simultaneously, the urea is used as the catalyst and in esterification with the starch so as to generate hydrophilic carbamic acid ester starch. The phosphate starch produced by adopting the method can be dissolved in cold water; the paste is transparent and has clean color and luster; the sodium metaphosphate is corsslinked with the starch, thus the viscosity and the viscosity stability of the starch are improved, the PVI (polyvinyl isobutyl ether) value is increased, and the preparation method is more suitable for being applied to the printing paste.

Owner:JIANGXI BODA CHEM

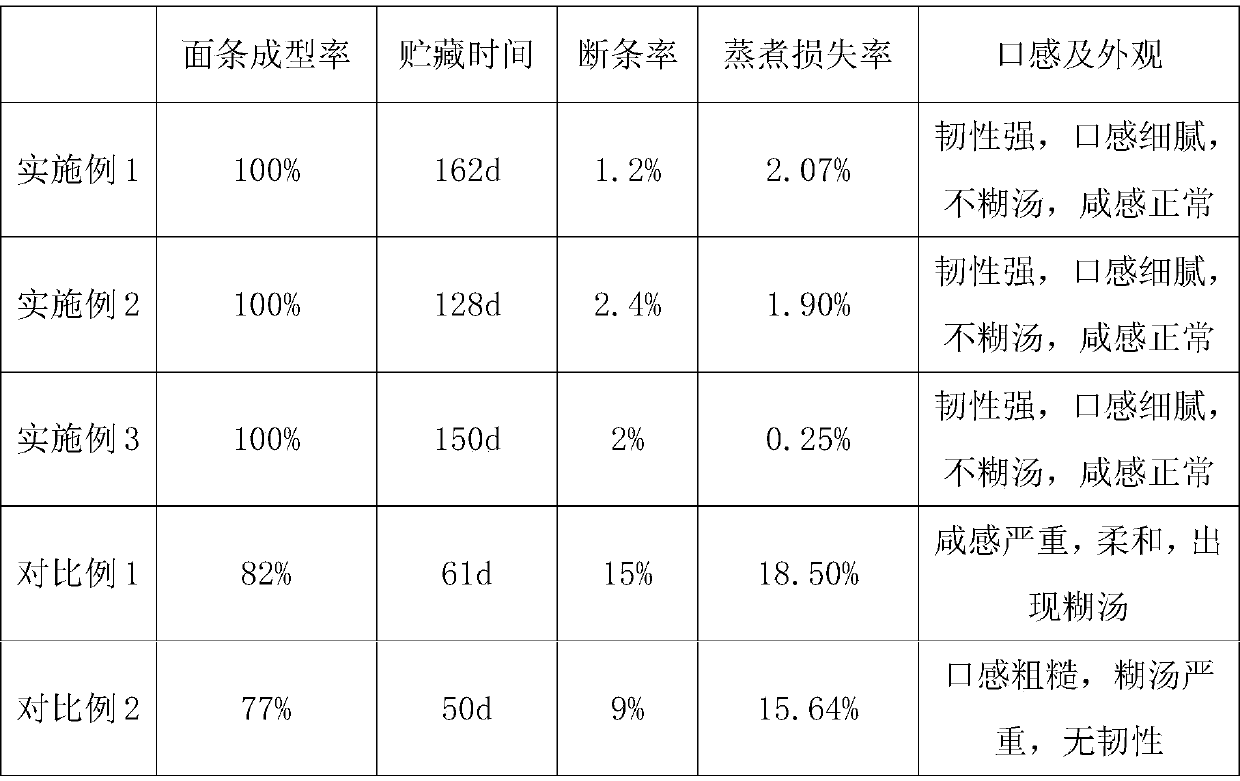

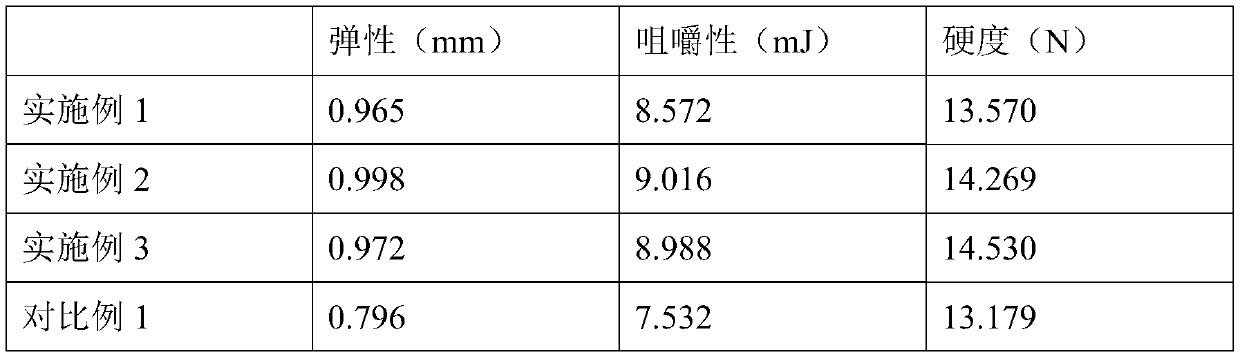

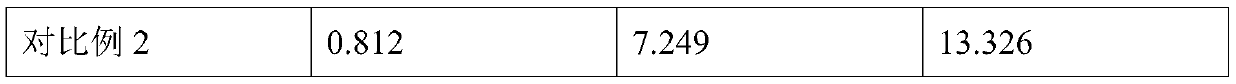

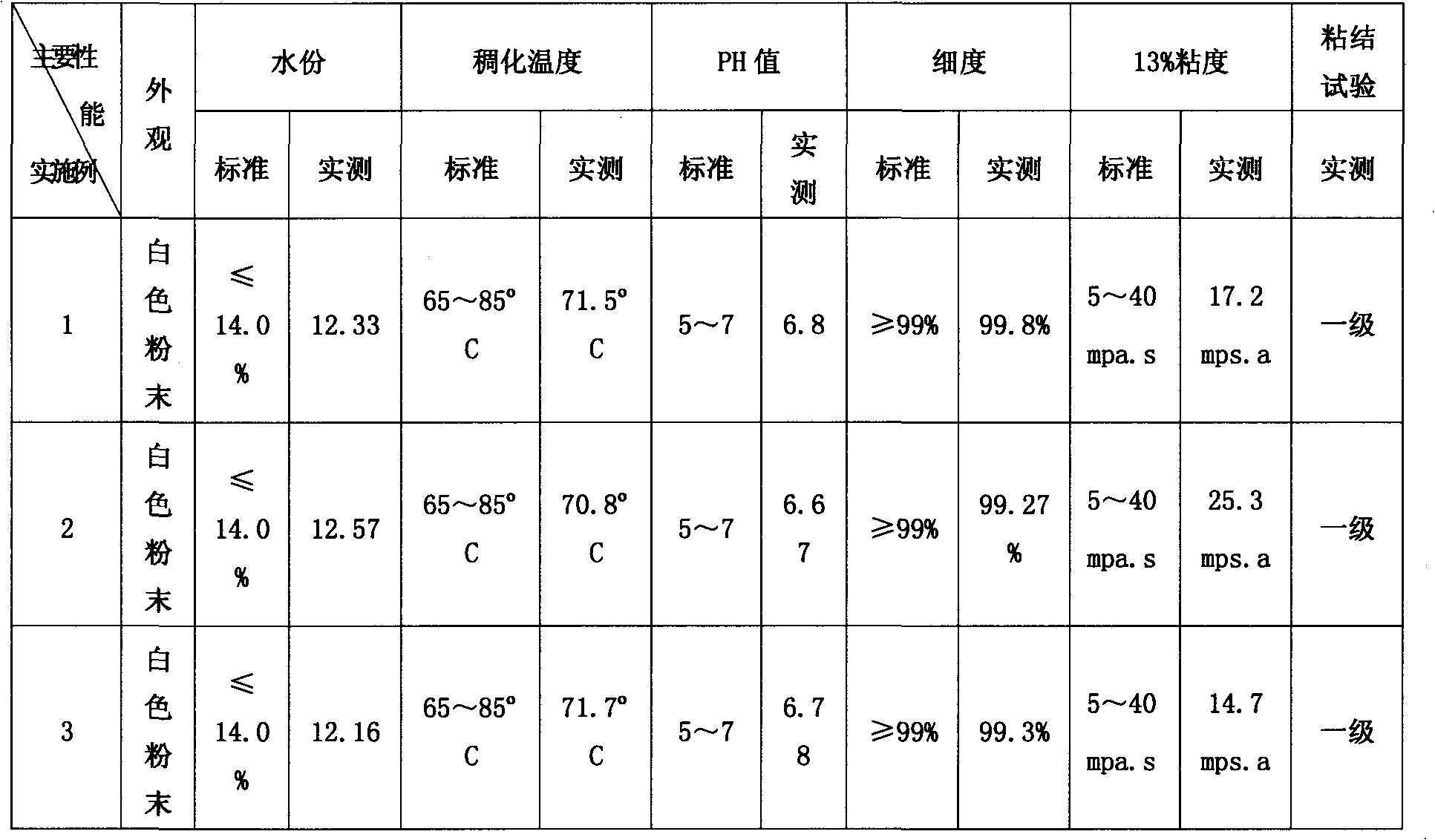

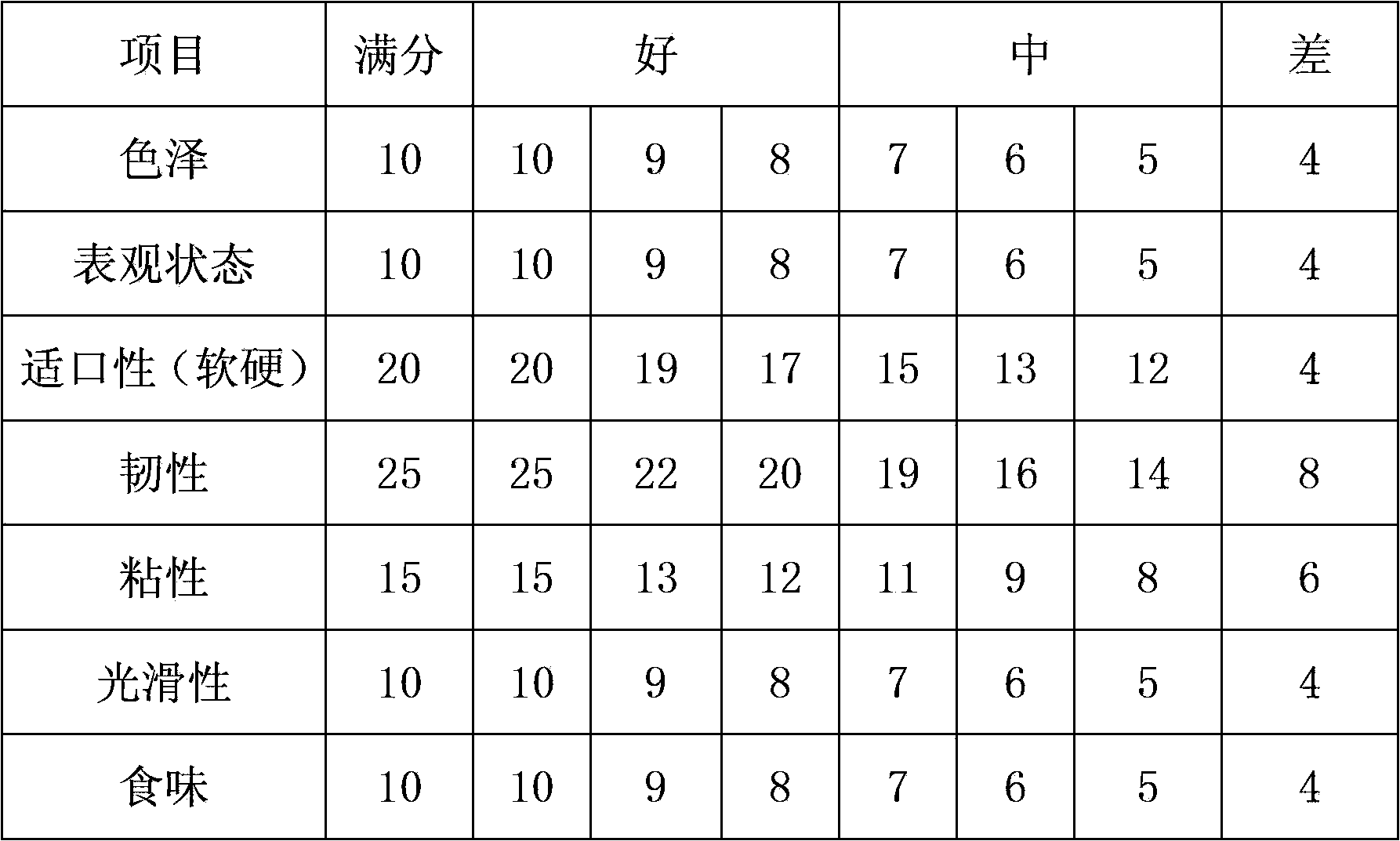

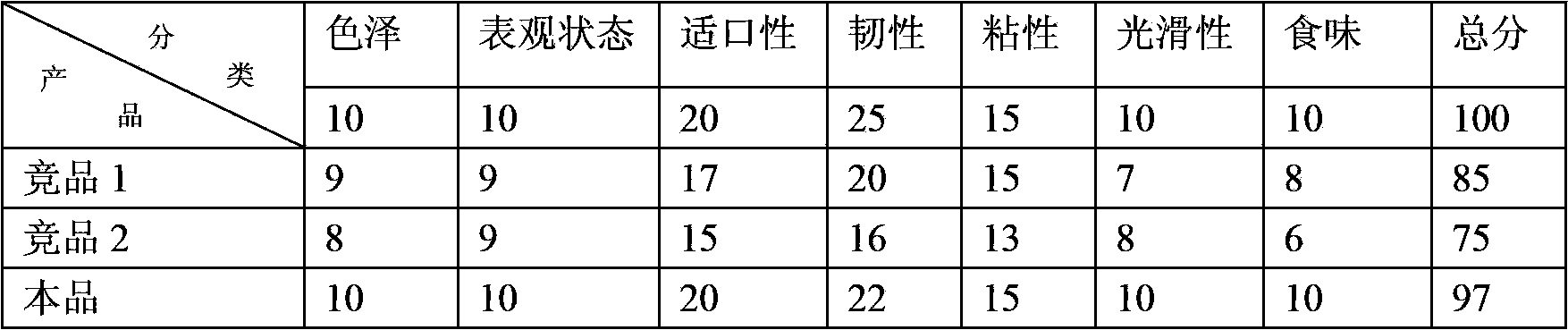

Convenient instant fresh wet noodle and preparation method thereof

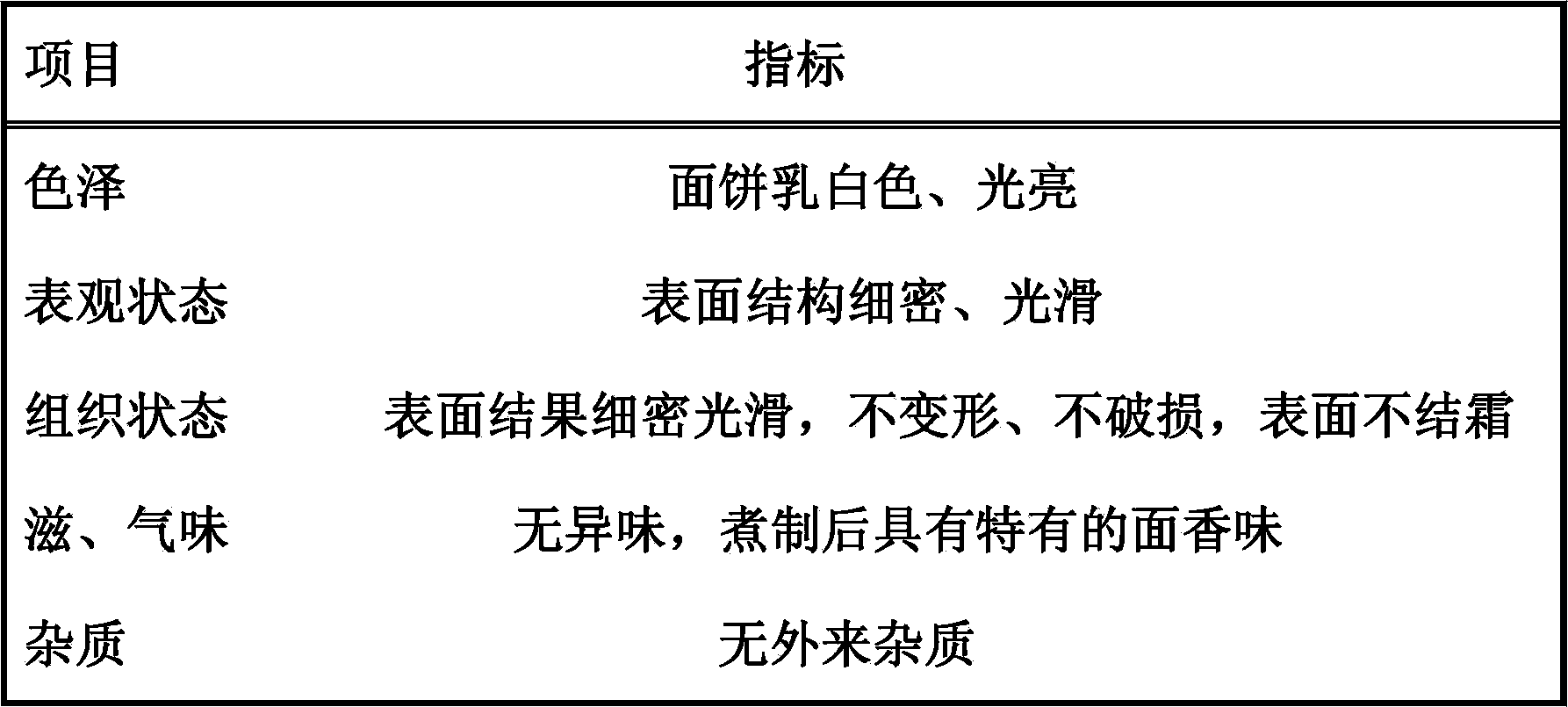

The invention discloses a convenient instant fresh noodle and a preparation method thereof, and relates to the field of food processing. The convenient instant fresh wet noodle is mainly composed of high-gluten wheat flour, modified starch, vital gluten and salt. The addition of additives reduces indicator degradation of color, texture and microorganisms during storage. The noodle adopts an extrusion molding curing process to ensure long shelf life by pickling, modified atmosphere packaging and irradiation sterilization.

Owner:湖北戴氏食品科技股份有限公司

Low-pollution textile sizing agent

The invention relates to a low-pollution textile sizing agent. The low-pollution textile sizing agent comprises following components in parts by mass: 64 parts of nano silicon dioxide modified starch, 18 parts of a protein sizing agent, 5 parts of polyvinyl alcohol, 11 parts of polyacrylate emulsion, 2 parts of a modified silicone oil de-foaming agent, 3 parts of protein amino acid, 4 parts of kaolin, 3 parts of sodium sulfamate and 1 part of polyacrylate. The sizing agent with the formula has good film-forming property and permeability; the formula contains less polyvinyl alcohol so that the pollution to the environment is low.

Owner:SUZHOU RUNHONG TRADING

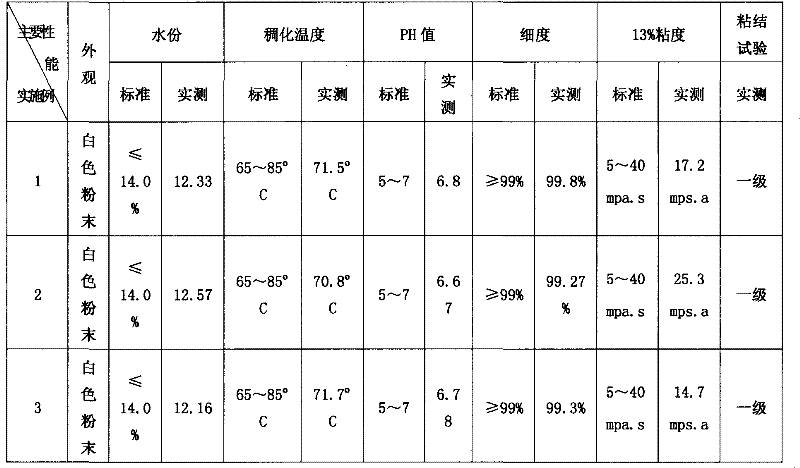

Production technology of plasterboard modified starch

The invention discloses a production technology of plasterboard modified starch, comprising the following steps of mixing, degeneration reaction, neutralization reaction, physical synergism, screening, weighing and packaging. The invention combines the advantages of various modified starches, has the advantages of strong size film strength, transparency, good water absorption, good dispersion, good gliding property, low gelatinization temperature, strong paste liquid bond force, good adsorbability, easy dissolution, good film forming ability, weak retrogradation, good elasticity, smoothness, flexibility, tough and elastic size film, nontoxicity, tastelessness, safe use, convenient operation, large production scale, little investment, low energy consumption, less pollution, high production efficiency, stable and reliable product quality and the like and is widely applied to gypsum products.

Owner:四川省蓬溪县弘桥实业有限公司

Sizing method of low-pollution textile slurry

The invention relates to a sizing method of low-pollution textile slurry, which comprises the following steps: pouring slurry into a slurry trough, and heating the slurry in the slurry trough to 52 DEG C; immersing the fabric into the slurry in the slurry trough for 6 minutes while winding the fabric on a frame to tighten the fabric and rolling the fabric at uniform speed so that the slurry is sufficiently and uniformly filled into the fabric, wherein the pressure of the squeezing roller is 12KN; taking out the fabric, putting the fabric in a drying oven, and drying the fabric; immersing the dried fabric into the slurry again for 3 minutes, and rolling the fabric at uniform speed, wherein the pressure of the squeezing roller is 14KN; and taking out the fabric, putting the fabric in a drying oven, and drying the fabric to finish the sizing technique. The method completes the fabric sizing in a twice sizing mode, and designs the technological parameters (mainly temperature of the slurry trough, immersion time for two sizing processes, and pressure of the squeezing roller) according to the specific slurry. The sizing technique is especially suitable for sizing high-count cotton fabrics, and has favorable sizing effect.

Owner:SUZHOU RUNHONG TRADING

Placenta preservation solution and preparation method thereof

InactiveCN108684653APrevents acidification or alkalinization of cellsImprove the survival rateDead animal preservationChemistryTrisodium citrate

The present invention relates to a composition for tissue preservation, and more particularly to a placenta preservation solution and a preparation method thereof. The placenta preservation solution comprises, in 1000 ml of an aqueous solution, 204 mg to 340 mg of potassium dihydrogen phosphate, 1.40 g to 1.50 g of disodium hydrogen phosphate, 7.6 g to 8.2 g of sodium chloride, 149 mg to 261 mg ofpotassium chloride, 100000U-1000000U of penicillin, 60mg-100mg of streptomycin, 12.5g of glucose, 5g of dextran-40, 7.35g of trisodium citrate and 352mg-528mg of vitamin C, and solution pH is 7.33-7.83. The placenta preservation solution is simple in components, stable and safe, has no toxic side effects, and has low cost. The placenta preservation solution is simple in preparation process and can be prepared in a large amount in a short time.

Owner:杭州联泽生物科技有限公司

Sizing method of environment-friendly textile slurry

ActiveCN103882709ASizing fitImprove sizing effectSucessive textile treatmentsFibre treatmentEngineeringSlurry

The invention relates to a sizing method of environment-friendly textile slurry, which comprises the following steps: pouring slurry into a slurry trough, and heating the slurry in the slurry trough to 55 DEG C; immersing the fabric into the slurry in the slurry trough for 5 minutes while winding the fabric on a frame to tighten the fabric and rolling the fabric at uniform speed so that the slurry is sufficiently and uniformly filled into the fabric, wherein the pressure of the squeezing roller is 13KN; taking out the fabric, putting the fabric in a drying oven, and drying the fabric; immersing the dried fabric into the slurry again for 2 minutes, and rolling the fabric at uniform speed, wherein the pressure of the squeezing roller is 15KN; and taking out the fabric, putting the fabric in a drying oven, and drying the fabric to finish the sizing technique. The method completes the fabric sizing in a twice sizing mode, and designs the technological parameters (mainly temperature of the slurry trough, immersion time for two sizing processes, and pressure of the squeezing roller) according to the specific slurry. The sizing technique is especially suitable for sizing high-count cotton fabrics, and has favorable sizing effect.

Owner:SUZHOU RUNHONG TRADING

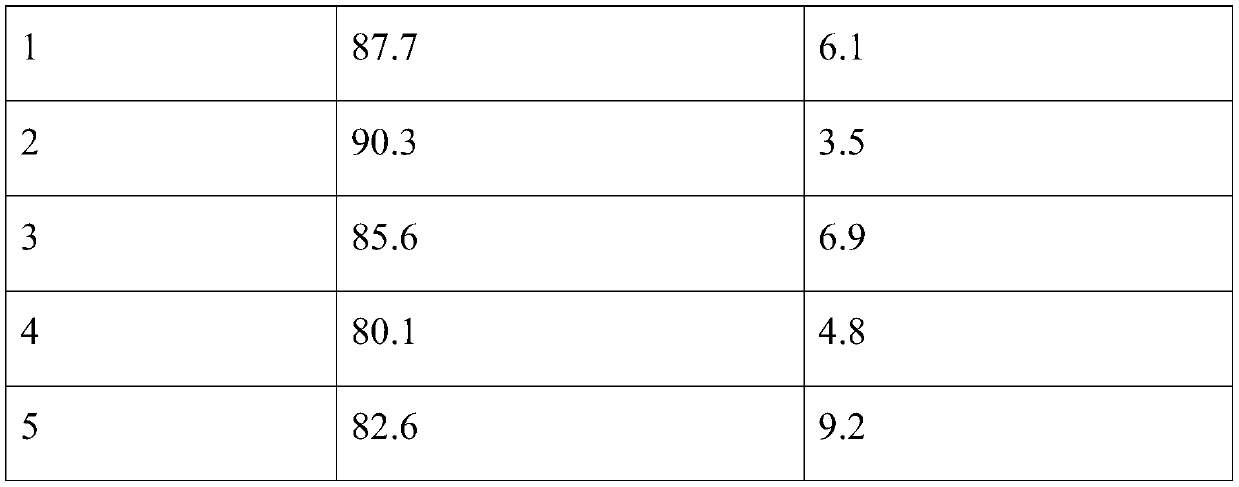

Preparation method of hydroxypropyl starch resistant dextrin

The invention discloses a preparation method of hydroxypropyl starch resistant dextrin, and relates to the technical field of resistant dextrin. According to the method, hydroxypropyl starch is used as a raw material, prepared starch paste has high transparency, high fluidity, weak retrogradation performance, high stability and good freeze-thaw stability, then alpha-amylase is added for hydrolysis, the solubility of glucose is improved, the content of free glucose in the product can be effectively reduced, and the content of the resistant dextrin is increased; then a starch branching enzyme isadded, the digestion resistance of the starch paste is improved, and therefore the content of the resistant dextrin is more effectively increased. The preparation process for preparing the resistantdextrin by using the hydroxypropyl starch is simple, the yield is high, detection is carried out by means of the method which accords with the national food safety standard GB 5009.88-2014, the content of the resistant dextrin reaches 80% or above, the content of free glucose is 10% or below, and the method has industrial production value.

Owner:深圳市悠阳天颂科技发展有限公司

Textile size applicable to high-count cotton fabrics

The invention relates to a textile size applicable to high-count cotton fabrics. The textile size comprises the following components in mass ratio: 80 parts of nano silicon dioxide modified starch, 10 parts of protein size, 8 parts of polyacrylate emulsion, 2 parts of modified silicone oil defoaming agent, 5 parts of argine monohydrochloride, 2 parts of sodium sulfamate and 2 part of polyacrylate. The size has favorable film forming property and permeability, is particularly applicable to the sizing of the high-count cotton fabrics and is more environment-friendly as the formula does not contain polyvinyl alcohol.

Owner:SUZHOU RUNHONG TRADING

Preparation method of low-pollution textile sizing agent

The invention relates to a preparation method of a low-pollution textile sizing agent. The method comprises the steps of mixing hydroxypropyl modified starch and silicon powder, then feeding the mixture into deionized water, and feeding sodium hydroxide and methyl alcohol into the mixed solution; carrying out hydrolysis, drying and purifying to obtain nanosilicon dioxide modified starch; feeding soyabean protein into sodium hydroxide solution, stirring at constant speed for 15 minutes at the temperature of 45 DEG C, and filtering out precipitate to obtain protein slurry; pouring the nanosilicon dioxide modified starch, the protein slurry, polyvinyl alcohol, polyacrylate emulsion and an organic silicon defoamer into a mixer, and mixing to obtain the low pollution textile sizing agent. The low-pollution textile sizing agent prepared by the method is good in film-forming property and permeability; furthermore, the content of the polyvinyl alcohol in the formulation is lower, so that the low-pollution textile sizing agent is lower in environmental pollution.

Owner:SUZHOU RUNHONG TRADING

Novel preparation method of crosslinking modified starch microspheres

ActiveCN107151336AHigh molecular weightGelatinization difficultySurgical adhesivesPharmaceutical delivery mechanismMicrosphereOil phase

The invention discloses a novel preparation method of crosslinking modified starch microspheres. The novel preparation method of the crosslinking modified starch microspheres comprises the following steps: firstly, using modified starch as a raw material, and preparing a modified starch solution with the concentration of 5 to 30 percent g / ml; secondly, adding a certain amount of polyvinyl alcohol solution as a modifier, adding the prepared modified starch solution into an oil phase containing an emulsifier; thirdly, carrying out high speed emulsification by a shearing machine, wherein the emulsifying speed is 500 to 2000rpm and the time is 10 to 20 minutes, and the like. According to the novel preparation method disclosed by the invention, a unique cross-linking agent which is divinyl sulfone (DVS) or sodium tetraborate decahydrate is adopted and the existing cross-linking problems are greatly improved, thereby obtaining a more stable and rapid crosslinking reaction and better product performance.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

A preparation method of textile size suitable for high-count cotton fabrics

The invention relates to a preparation method of a textile size applicable to high-count cotton fabrics. The preparation method comprises the steps of: mixing hydroxypropyl modified starch with silicon powder, adding into deionized water, adding sodium hydroxide and methyl alcohol, and carrying out drying and purification after hydrolysis to obtain nano silicon dioxide modified starch; adding soybean protein in sodium hydroxide solution, stirring at a constant speed at 40 DEG C for 15 minutes, and filtering out the precipitates to obtain protein size; pouring the nano silicon dioxide modified starch, the protein size, polyacrylate emulsion and modified silicon oil defoaming agent in a stirrer for stirring and mixing to obtain the textile size applicable to high-count cotton fabrics. The size prepared by the method has favorable film forming property and permeability, is particularly applicable to the sizing of high-count cotton fabrics as the sizing property is excellent, and is more environment-friendly as the formula does not contain polyvinyl alcohol.

Owner:SUZHOU RUNHONG TRADING

Method for preparing environmentally friendly tableware by using corn starch and wheat straw

The invention discloses a method for preparing environmentally friendly tableware by using corn starch and wheat straw. The method includes the following steps: ball-milling the corn starch and aceticacid, adding a catalyst, setting a certain temperature, rotating speed and time, washing the materials with distilled water and then ethanol, and drying by baking to obtain corn acetate starch; dissolving the corn acetate starch in distilled water, dropping a plasticizer, and stirring the materials at a certain temperature, rotating speed and time for reaction to obtain corn acetate starch glue;evenly mixing the corn acetate starch glue, a filler and corn straw, drying the materials at a certain temperature, taking the materials, placing the materials in a mold for hot pressing to form the tableware, and setting a certain pressure, temperature and time; and spraying a waterproof membrane on the pressed tableware. The method is simple, easy in operation, harmless to human body and degradable, has less environmental pollution, and is suitable for industrial production. The produced environmentally friendly tableware is hygienic, non-toxic, heat-resistant and waterproof, is not prone todeformation and damage, has a wide range of raw materials, and is low in cost.

Owner:广西南宁桂尔创环保科技有限公司

Sizing method for lockram textile slurry

The invention relates to a sizing method for lockram textile slurry, which comprises the following steps: pouring slurry into a slurry trough, and heating the slurry in the slurry trough to 58 DEG C; immersing the fabric into the slurry in the slurry trough for 12 minutes while winding the fabric on a frame to tighten the fabric and rolling the fabric at uniform speed so that the slurry is sufficiently and uniformly filled into the fabric, wherein the pressure of the squeezing roller is 13KN; taking out the fabric, putting the fabric in a drying oven, and drying the fabric; immersing the dried fabric into the slurry again for 6 minutes, and rolling the fabric at uniform speed, wherein the pressure of the squeezing roller is 16KN; and taking out the fabric, putting the fabric in a drying oven, and drying the fabric to finish the sizing technique. The method completes the fabric sizing in a twice sizing mode, and designs the technological parameters (mainly temperature of the slurry trough, immersion time for two sizing processes, and pressure of the squeezing roller) according to the specific slurry. The sizing technique is especially suitable for sizing lockrams, and has favorable sizing effect.

Owner:SUZHOU RUNHONG TRADING

Textile size applicable to real silk fabrics

ActiveCN103898757AGood film formation and permeabilityGood film formingAnimal fibresEmulsionProteinogenic amino acid

The invention relates to textile size applicable to real silk fabrics. The textile size comprises the following components in mass ratio: 70 parts of protein size, 20 parts of nano silicon dioxide modified starch, 8 parts of polyacrylate emulsion, 2 parts of modified silicone oil defoaming agent, 6 parts of argine monohydrochloride, 3 parts of sodium sulfamate and 1 part of polyacrylate. According to the textile size applicable to real silk fabrics, the protein size is taken as a primary raw material, the nano silicon dioxide modified starch and the polyacrylate emulsion are taken as secondary raw materials, the modified silicone oil is taken as a defoaming agent, and the four components are proportioned, so that the size has favorable film forming property and permeability; experiments show that the textile size is particularly applicable to the sizing of the real silk fabrics; as the formula does not contain polyvinyl alcohol, the textile size is more environment-friendly.

Owner:SUZHOU RUNHONG TRADING

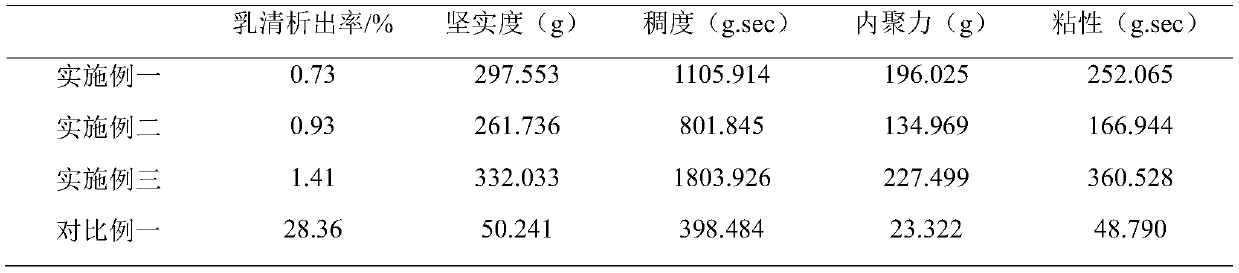

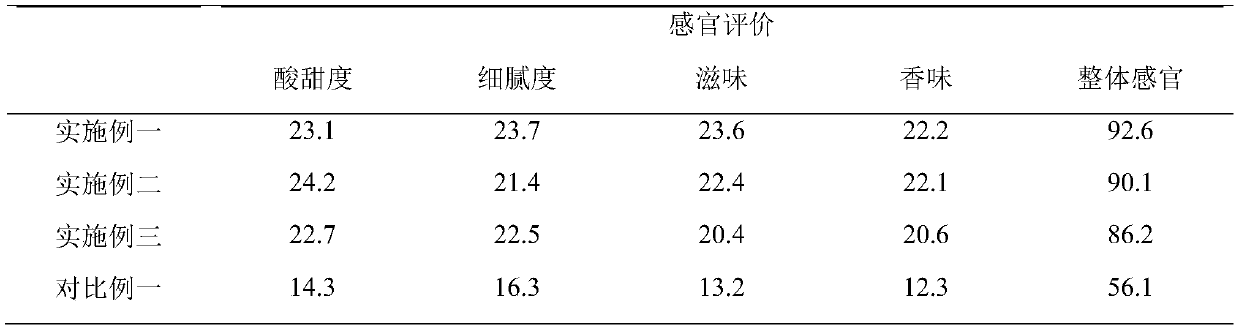

Salty and fragrant yoghurt sauce and preparation method thereof

PendingCN111034798AGood emulsifying effectGood thickening effectMilk preparationFood ingredient as thickening agentBiotechnologySodium Caseinate

The invention discloses salty and fragrant yoghurt sauce and a preparation method thereof. The yoghurt sauce is prepared from the following raw materials: salts, a protein supplement, compound stabilizers, a flavor regulator, a sweetening agent, 150-250U / ton of strains and raw milk. The compound stabilizers comprise acetylated distarch oxalate, gelatin, sodium caseinate and pectin. The salts comprise edible salt, an emulsifying salt and a mineral salt. The protein supplement is an animal protein or a vegetable protein. When the yoghurt sauce is prepared, the materials are mixed and homogenized, then pasteurization is carried out, then strains are inoculated and fermented, and finally filling and after-ripening are carried out. The salty and fragrant yoghourt sauce disclosed by the invention is prepared from the raw materials of the raw milk, the salts, the protein supplement, the compound stabilizers, the flavor regulator and the sweetening agent, is moderate in salty and fragrant taste, rich in fragrance and good in water binding capacity, can stably meet smearing requirements, and is deeply loved by consumers.

Owner:NEW HOPE DAIRY HLDG

A kind of modified starch and its production method

The invention discloses a modified starch and a production method thereof and aims at providing a modified starch which has high viscosity as well as good elasticity and strong binding force of starch slurry. The modified starch is prepared by virtue of the following steps: (1) blending; (2) adding a whiteness stabilizer, mixing for 15-25 minutes, regulating the pH value to 2.0-3.0, regulating the temperature to 35-40DEG C, and performing acid splitting reaction for 1-1.5 hours; (3) adding basic catalyst and regulating the pH value to be 6.0-7.0, adding an inhibitor, reacting for 15-25 minutes, regulating the pH value to be 10.5-11.5; (4) adding the cross-linking agent into the original starch slurry reacted in the step (3), regulating the temperature to be 38-48 DEG C, reacting for 2-4 hours, then reducing the temperature of the original starch slurry to be 25-30 DEG C, and regulating the pH value to be 5.5-6.0 with the neutralizing agent; (5) washing and centrifuging the original starch slurry neutralized in the step (4), and drying to obtain the modified starch. The modified starch and the production method belong to the technical field of starch.

Owner:广西梧州市明阳生化科技有限公司

Sizing method of textile slurry for real silk fabrics

ActiveCN103898758AGood film formation and permeabilityGood film formingLiquid/gas/vapor textile treatmentAnimal fibresSizingEngineering

The invention relates to a sizing method of textile slurry for real silk fabrics, which comprises the following steps: pouring slurry into a slurry trough, and heating the slurry in the slurry trough to 52 DEG C; immersing the fabric into the slurry in the slurry trough for 10 minutes while winding the fabric on a frame to tighten the fabric and rolling the fabric at uniform speed so that the slurry is sufficiently and uniformly filled into the fabric, wherein the pressure of the squeezing roller is 12KN; taking out the fabric, putting the fabric in a drying oven, and drying the fabric; immersing the dried fabric into the slurry again for 4 minutes, and rolling the fabric at uniform speed, wherein the pressure of the squeezing roller is 14KN; and taking out the fabric, putting the fabric in a drying oven, and drying the fabric to finish the sizing technique. The method completes the fabric sizing in a twice sizing mode, and designs the technological parameters (mainly temperature of the slurry trough, immersion time for two sizing processes, and pressure of the squeezing roller) according to the specific slurry. The sizing technique is especially suitable for sizing real silk fabrics, and has favorable sizing effect.

Owner:SUZHOU RUNHONG TRADING

Production technology of plasterboard modified starch

The invention discloses a production technology of plasterboard modified starch, comprising the following steps of mixing, degeneration reaction, neutralization reaction, physical synergism, screening, weighing and packaging. The invention combines the advantages of various modified starches, has the advantages of strong size film strength, transparency, good water absorption, good dispersion, good gliding property, low gelatinization temperature, strong paste liquid bond force, good adsorbability, easy dissolution, good film forming ability, weak retrogradation, good elasticity, smoothness, flexibility, tough and elastic size film, nontoxicity, tastelessness, safe use, convenient operation, large production scale, little investment, low energy consumption, less pollution, high productionefficiency, stable and reliable product quality and the like and is widely applied to gypsum products.

Owner:四川省蓬溪县弘桥实业有限公司

Frozen instant noodles

ActiveCN102771531BConvenient and instantEasy cookingDough treatmentFood preparationFreeze thawingRetrogradation

The invention relates to flour for frozen instant noodles, flour cakes and frozen instant noodles prepared by the flour. The flour for frozen instant noodles comprises raw materials in parts by weight as follows: 45-55 parts of wheatmeal and 5-10 parts of starch acetate or cassava starch. The wheatmeal used in the flour provided by the invention is high quality wheatmeal which is from a ''golden wheat field'', and green and natural with pure flavor. The starch acetate is used as a thickener in food, wherein the starch acetate is high in viscosity, high in clarity, weak in retrogradation, stable to store, high stability to acids, alkalis and heat, low in gelatinization temperature, and good in film formation, so that the product has a clean and smooth surface and good freeze-thaw stability, and hydrogen bonds are not easy to form among molecules. The frozen instant noodles prepared by the flour for frozen instant noodles provided by the invention not only have fast food property of instant noodles, but also have the advantages of health and nutrition and high quality compared with fried instant noodles.

Owner:云鹤食品有限公司

Method for preparing environmentally friendly tableware by using cassava starch sugarcane corn straw

The invention discloses a method for preparing environmentally friendly tableware by using cassava starch sugarcane corn straw. The method includes the following steps: ball-milling the cassava starchand acetic acid, adding a catalyst, setting a certain temperature, rotating speed and time, washing the materials with distilled water and then ethanol, and drying by baking to obtain cassava acetatestarch; dissolving the cassava acetate starch in distilled water, dropping a plasticizer, and stirring the materials at a certain temperature, rotating speed and time for reaction to obtain cassava acetate starch glue; evenly mixing the cassava acetate starch glue, a filler and sugarcane straw, drying the materials at a certain temperature, taking the materials, placing the materials in a mold for hot pressing to form the tableware, and setting a certain pressure, temperature and time; and spraying a waterproof membrane on the pressed tableware. The method is simple, easy in operation, harmless to human body and degradable, has less environmental pollution, and is suitable for industrial production. The produced environmentally friendly tableware is hygienic, non-toxic, heat-resistant andwaterproof, is not prone to deformation and damage, has a wide range of raw materials, and is low in cost.

Owner:广西南宁桂尔创环保科技有限公司

A textile size suitable for silk fabrics

Owner:SUZHOU RUNHONG TRADING

A sizing method suitable for textile size of high-count cotton fabric

The invention relates to a sizing method of textile slurry high-count cotton fabrics, which comprises the following steps: pouring slurry into a slurry trough, and heating the slurry in the slurry trough to 58 DEG C; immersing the fabric into the slurry in the slurry trough for 8 minutes while winding the fabric on a frame to tighten the fabric and rolling the fabric at uniform speed so that the slurry is sufficiently and uniformly filled into the fabric, wherein the pressure of the squeezing roller is 14KN; taking out the fabric, putting the fabric in a drying oven, and drying the fabric; immersing the dried fabric into the slurry again for 3 minutes, and rolling the fabric at uniform speed, wherein the pressure of the squeezing roller is 16KN; and taking out the fabric, putting the fabric in a drying oven, and drying the fabric to finish the sizing technique. The method completes the fabric sizing in a twice sizing mode, and designs the technological parameters (mainly temperature of the slurry trough, immersion time for two sizing processes, and pressure of the squeezing roller) according to the specific slurry. The sizing technique is especially suitable for sizing high-count cotton fabrics, and has favorable sizing effect.

Owner:SUZHOU RUNHONG TRADING

A kind of sizing method of environment-friendly textile pulp

ActiveCN103882709BSizing fitImprove sizing effectSucessive textile treatmentsFibre treatmentPulp and paper industrySlurry

The invention relates to a sizing method of environment-friendly textile slurry, which comprises the following steps: pouring slurry into a slurry trough, and heating the slurry in the slurry trough to 55 DEG C; immersing the fabric into the slurry in the slurry trough for 5 minutes while winding the fabric on a frame to tighten the fabric and rolling the fabric at uniform speed so that the slurry is sufficiently and uniformly filled into the fabric, wherein the pressure of the squeezing roller is 13KN; taking out the fabric, putting the fabric in a drying oven, and drying the fabric; immersing the dried fabric into the slurry again for 2 minutes, and rolling the fabric at uniform speed, wherein the pressure of the squeezing roller is 15KN; and taking out the fabric, putting the fabric in a drying oven, and drying the fabric to finish the sizing technique. The method completes the fabric sizing in a twice sizing mode, and designs the technological parameters (mainly temperature of the slurry trough, immersion time for two sizing processes, and pressure of the squeezing roller) according to the specific slurry. The sizing technique is especially suitable for sizing high-count cotton fabrics, and has favorable sizing effect.

Owner:SUZHOU RUNHONG TRADING

A sizing method suitable for textile size of linen fabric

The invention relates to a sizing method for lockram textile slurry, which comprises the following steps: pouring slurry into a slurry trough, and heating the slurry in the slurry trough to 58 DEG C; immersing the fabric into the slurry in the slurry trough for 12 minutes while winding the fabric on a frame to tighten the fabric and rolling the fabric at uniform speed so that the slurry is sufficiently and uniformly filled into the fabric, wherein the pressure of the squeezing roller is 13KN; taking out the fabric, putting the fabric in a drying oven, and drying the fabric; immersing the dried fabric into the slurry again for 6 minutes, and rolling the fabric at uniform speed, wherein the pressure of the squeezing roller is 16KN; and taking out the fabric, putting the fabric in a drying oven, and drying the fabric to finish the sizing technique. The method completes the fabric sizing in a twice sizing mode, and designs the technological parameters (mainly temperature of the slurry trough, immersion time for two sizing processes, and pressure of the squeezing roller) according to the specific slurry. The sizing technique is especially suitable for sizing lockrams, and has favorable sizing effect.

Owner:SUZHOU RUNHONG TRADING

A kind of textile size suitable for high-count cotton fabric

The invention relates to a textile size applicable to high-count cotton fabrics. The textile size comprises the following components in mass ratio: 80 parts of nano silicon dioxide modified starch, 10 parts of protein size, 8 parts of polyacrylate emulsion, 2 parts of modified silicone oil defoaming agent, 5 parts of argine monohydrochloride, 2 parts of sodium sulfamate and 2 part of polyacrylate. The size has favorable film forming property and permeability, is particularly applicable to the sizing of the high-count cotton fabrics and is more environment-friendly as the formula does not contain polyvinyl alcohol.

Owner:SUZHOU RUNHONG TRADING

A kind of preparation method of environment-friendly textile size

The invention relates to a preparation method for environment-friendly type textile sizing agent. The preparation method comprises the following steps: mixing hydroxypropyl modified starch and silicon powder and adding a mixture into de-ionized water; adding sodium hydroxide and methanol; carrying out hydrolysis, and drying and purifying to obtain nano silicon dioxide modified starch; adding soybean protein into a sodium hydroxide solution and agitating at 45 DEG C at uniform speed for 15 minutes; filtering and removing sediment to obtain a protein sizing agent; pouring the nano silicon dioxide modified starch, the protein sizing agent, polyacrylate emulsion and an organic silicon de-foaming agent into an agitator to be agitated and mixed to obtain the environment-friendly type textile sizing agent. The sizing agent prepared by the invention has good film forming property and permeability; the sizing performance is good and a formula does not contain polyvinyl alcohol, thus the environment-friendly type textile sizing agent is very environment-friendly.

Owner:SUZHOU RUNHONG TRADING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com