Preparation method of hydroxypropyl starch resistant dextrin

A technology of hydroxypropyl starch and resistant dextrin, which is applied in the field of preparation of hydroxypropyl starch resistant dextrin, can solve the problems of high free glucose content, low content of resistant dextrin, and reduced product yield, etc. High transparency, strong fluidity, and the effect of increasing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

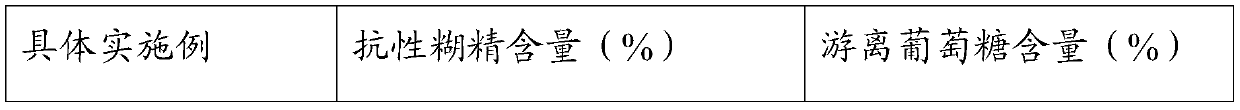

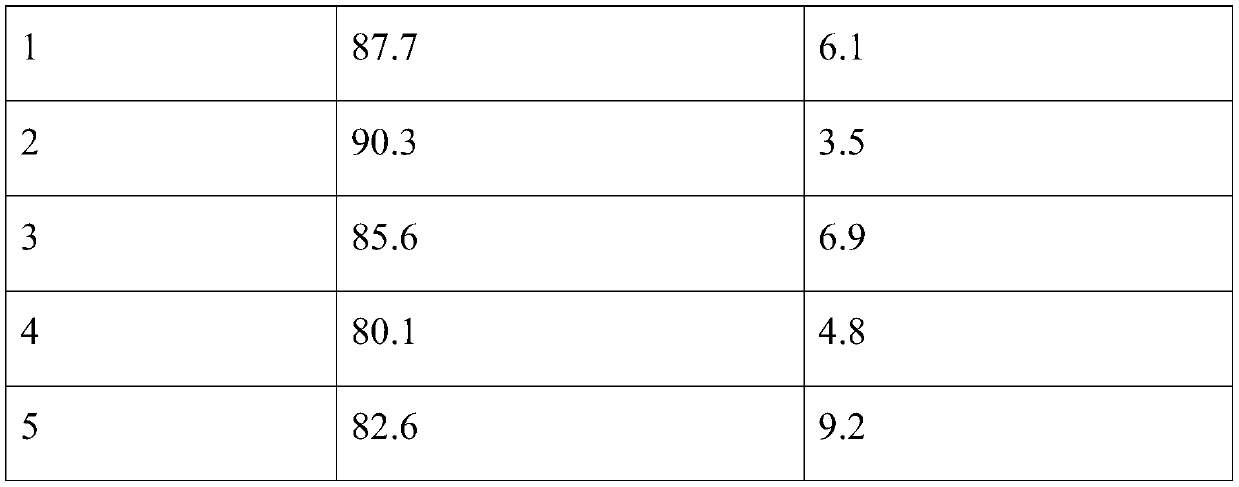

Examples

preparation example Construction

[0026] The embodiment of the present invention provides a preparation method of hydroxypropyl starch resistant dextrin, comprising the following steps:

[0027] a. Heat the acid-treated hydroxypropyl starch to 105-220°C and keep it for 5-600 minutes to obtain pyrodextrin containing hydroxypropyl starch. The water content of the acid-treated hydroxypropyl starch is 3-15 %;

[0028] b. Mix pyrodextrin containing hydroxypropyl starch and water at a weight ratio of 1:1-6 to make milky, adjust the pH to 6-8, add α-amylase, and react at 30-105°C for 0.1-5h , the added amount of the α-amylase is 1-10000U / g dry weight of hydroxypropyl starch;

[0029] c. Adding starch branching enzyme, reacting at 30-80°C for 0.1-5h to obtain a semi-finished product, the addition amount of the starch branching enzyme is 1-10000U / g dry weight of hydroxypropyl starch;

[0030] d. The semi-finished product is subjected to enzyme inactivation treatment, filtration treatment, drying treatment, decoloriza...

specific Embodiment 1

[0033] A preparation method of hydroxypropyl starch resistant dextrin, comprising the following steps:

[0034] a. heating the acid-treated hydroxypropyl starch with a water content of 15% to 220° C. and keeping it for 160 minutes to obtain pyrodextrin containing hydroxypropyl starch;

[0035] b. Mix pyrodextrin containing hydroxypropyl starch and water at a weight ratio of 1:6 to make milky, adjust the pH to 6, add α-amylase, and react at 30°C for 5 hours, the α-amylase The addition amount is 1000U / g hydroxypropyl starch dry weight;

[0036] c. adding starch branching enzyme, reacting at 30°C for 5h to obtain a semi-finished product, the addition of the starch branching enzyme is 1000U / g dry weight of hydroxypropyl starch;

[0037] d. The semi-finished product is subjected to enzyme inactivation treatment, filtration treatment, drying treatment, decolorization treatment, desalination treatment, and pulverization treatment to obtain hydroxypropyl starch resistant dextrin.

specific Embodiment 2

[0039] A preparation method of hydroxypropyl starch resistant dextrin, comprising the following steps:

[0040] a. heating the acid-treated hydroxypropyl starch with a water content of 10% to 200°C and keeping it for 60 minutes to obtain pyrodextrin containing hydroxypropyl starch;

[0041] b. Mix pyrodextrin containing hydroxypropyl starch and water at a weight ratio of 1:4 to make milk, adjust the pH to 7, add α-amylase, and react at 50°C for 2 hours. The α-amylase The addition amount is 10000U / g dry weight of hydroxypropyl starch;

[0042] c. Add starch branching enzyme and react at 50°C for 2 hours to obtain a semi-finished product, the amount of starch branching enzyme added is 10000U / g dry weight of hydroxypropyl starch;

[0043] d. The semi-finished product is subjected to enzyme inactivation treatment, filtration treatment, drying treatment, decolorization treatment, desalination treatment, and pulverization treatment to obtain hydroxypropyl starch resistant dextrin. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com