Phosphate starch printing paste and preparation method thereof

A technology of printing paste and phosphate ester, which is applied in the field of textile dyeing and printing, and can solve problems such as narrow application fields, unsatisfactory performance, and low technical content of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

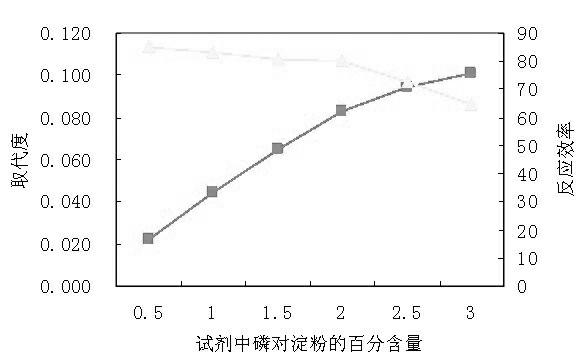

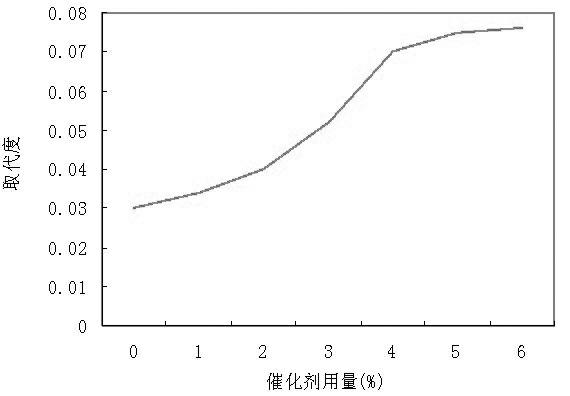

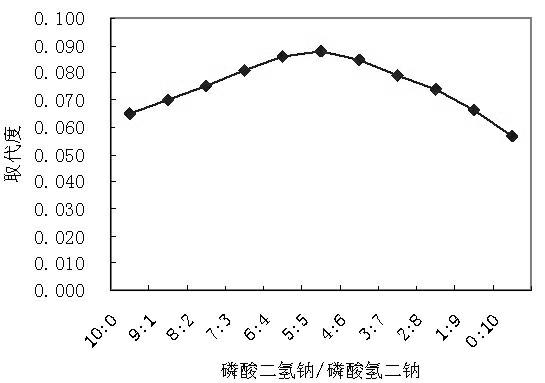

[0044] Dissolve 6 parts of sodium dihydrogen phosphate, 6 parts of disodium hydrogen phosphate, 4 parts of urea, and 20 parts of water in a dissolving barrel with heating and stirring, and spray it into 100 parts of tapioca starch in stirring, After being fully mixed, it is slowly sent into the hot air reactor through a rotary conveyor, and the esterification reaction is carried out at 180°C for 45 minutes. Urea is used as a catalyst to fully mix tapioca starch, sodium dihydrogen phosphate, and disodium hydrogen phosphate. In the high-temperature airflow, the esterification reaction occurs rapidly, and a substituent-phosphate group is inserted on the hydroxyl group of the starch to obtain phosphate ester starch; while the esterification reaction of phosphate occurs, a small amount of triple partial is produced at a high temperature of 180 °C Sodium phosphate crosslinks starch to generate phosphodiester; while urea acts as a catalyst, it also reacts with tapioca starch to genera...

Embodiment 2

[0046] Dissolve 5 parts of sodium dihydrogen phosphate, 8 parts of disodium hydrogen phosphate, 3 parts of urea, and 20 parts of water in a dissolving barrel with heating and stirring, and spray it into 100 parts of tapioca starch in stirring, After being fully mixed, it is slowly sent into the hot air reactor through a rotary conveyor, and the esterification reaction is carried out at 180°C for 40 minutes. Urea is used as a catalyst to fully mix tapioca starch, sodium dihydrogen phosphate, and disodium hydrogen phosphate. In the high-temperature airflow, the esterification reaction occurs rapidly, and a substituent-phosphate group is inserted on the hydroxyl group of the starch to obtain phosphate ester starch; while the esterification reaction of phosphate occurs, a small amount of triple partial is produced at a high temperature of 180 °C Sodium phosphate crosslinks starch to generate phosphodiester; while urea acts as a catalyst, it also reacts with tapioca starch to genera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com