Salty and fragrant yoghurt sauce and preparation method thereof

A technology for yogurt sauce and flavor, applied in the direction of milk preparations, bacteria and dairy products used in food preparation, etc., can solve the problems that the water holding performance cannot meet the needs of smearing, the viscosity and thickness of the product decrease, and the smearing performance is weakened. , to achieve the effects of low temperature storage and freeze-thaw stability improvement, gelatinization temperature reduction, and weak retrogradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

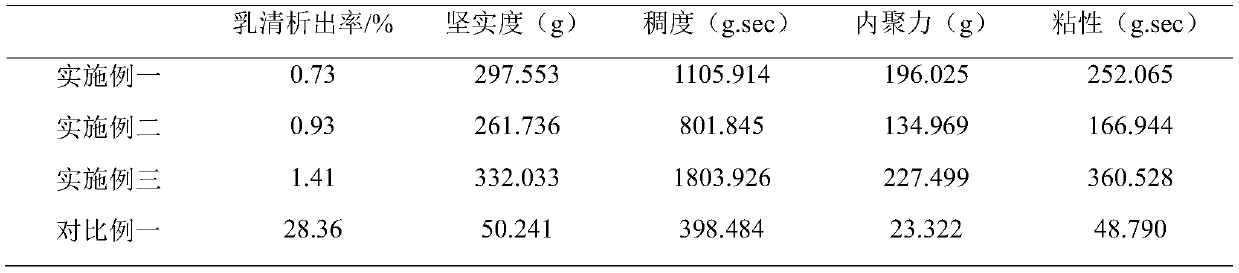

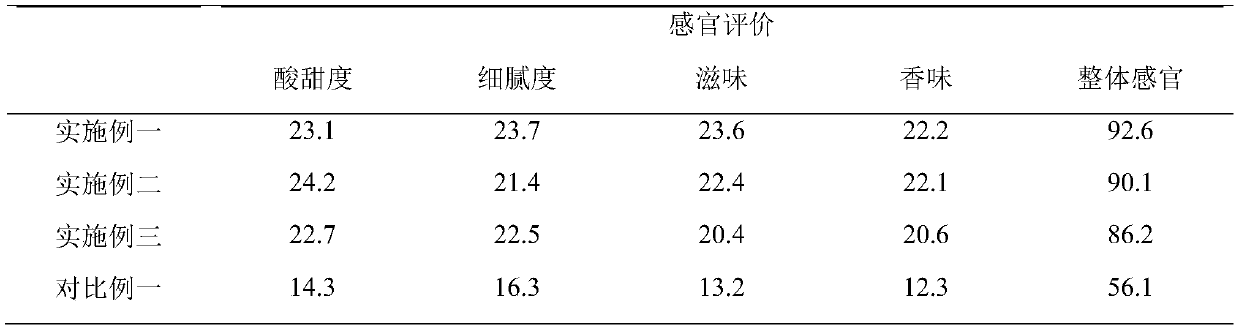

Examples

Embodiment 1

[0041] A kind of salty flavor yogurt sauce, the yogurt sauce in the present embodiment is made through the following steps:

[0042] (1) Ingredients, weighing: white sugar 70kg, milk protein powder 6kg, acetylated distarch oxalate 4kg, gelatin 3kg, sodium caseinate 2kg, pectin 0.8kg, refined salt 0.8kg, honey 20kg, spicy Root paste 0.6kg, fresh milk 892.8kg, above-mentioned components are evenly mixed.

[0043] (2) Homogenization: heat the mixed material to about 55°C, and homogenize the mixed material under a pressure of about 20MPa.

[0044] (3) Pasteurization: pasteurize the homogenized material, the sterilization temperature is 95° C., and the sterilization time is 5 minutes.

[0045] (4) Inoculation and fermentation: After pasteurization, cool the mixed material to about 43°C, add Lactobacillus bulgaricus and Streptococcus thermophilus at an amount of about 200U / ton, and statically ferment until the acidity is ≥70°T.

[0046] (5) Stirring and demulsification: stir at a lo...

Embodiment 2

[0051] A kind of salty flavor yogurt sauce, the yogurt sauce in the present embodiment is made through the following steps:

[0052] (1) Ingredients, weighing: white granulated sugar 70kg, whey protein powder 12kg, acetylated distarch oxalate 4kg, gelatin 3kg, sodium caseinate 2kg, pectin 0.8kg, refined salt 0.8kg, honey 20kg, Horseradish sauce 0.6kg, raw milk 886.8kg, above-mentioned components are evenly mixed.

[0053] (2) Homogenization: heat the mixed material to about 55°C, and homogenize the mixed material under a pressure of about 18MPa.

[0054] (3) Pasteurization: pasteurize the homogenized material, the sterilization temperature is 95° C., and the sterilization time is 5 minutes.

[0055] (4) Inoculation and fermentation: After pasteurization, cool the mixed material to about 40°C, add Lactobacillus bulgaricus and Streptococcus thermophilus at an amount of about 250U / ton, and statically ferment until the acidity is ≥70°T.

[0056] (5) Stirring and demulsification:...

Embodiment 3

[0061] A kind of salty flavor yogurt sauce, the yogurt sauce in the present embodiment is made through the following steps:

[0062] (1) Ingredients, weighing: white granulated sugar 70kg, milk protein powder 6kg, acetylated distarch oxalate 6kg, gelatin 4.5kg, sodium caseinate 3kg, pectin 1.2kg, refined salt 0.8kg, honey 20kg, Horseradish sauce 0.6kg, raw milk 887.9kg, above-mentioned components are evenly mixed.

[0063] (2) Homogenization: heat the mixed material to about 55°C, and homogenize the mixed material under a pressure of about 20MPa.

[0064] (3) Pasteurization: pasteurize the homogenized material, the sterilization temperature is 95° C., and the sterilization time is 5 minutes.

[0065] (4) Inoculation and fermentation: After pasteurization, cool the mixed material to about 40°C, add Lactobacillus bulgaricus and Streptococcus thermophilus at an amount of about 150U / ton, and statically ferment until the acidity is ≥70°T.

[0066] (5) Stirring and demulsification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com