Efficient grease degrading bacterium and application thereof

A high-efficiency grease and bacteria-degrading technology, applied in the direction of dissolution, bacteria, biochemical equipment and methods, etc., can solve the problems of increasing production costs, hindering effective separation, complex extraction and separation of biosurfactants, etc., to achieve good oil drainage activity, The effect of good emulsifying properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Strain enrichment acclimation and isolation culture

[0035]Collect 5-10g of sludge samples from the grease treatment tank of a food processing factory in Yantai City, Shandong, put them into a 150-300mL triangular flask filled with 50-100mL sterile water and sterile glass beads, place on a shaker, 150-180r / Shake fully for 10-15min, take 5-8mL of the mixed solution, add 35-50mL of sterile enrichment culture solution (NaCl0.5, peptone 5.0, beef extract 0.5, peanut oil 4mL, pH7.2-7.4, dilute with water to 1000mL), cultured at 28-30°C, 150-250r / min. Observe the degradation and dissipation of oil every 24 hours, and add an appropriate amount of peanut oil to 4ml. Transfer 5-10mL culture to 30-50mL new medium every 4-6d to promote the growth of lipolytic bacteria. This acclimatization process lasts for 2 months.

[0036] To prepare an oil-selective plate, take 10 g of tryptone, 5 g of yeast extract, 10 g of NaCl, 12 g of agar powder, 10 g of peanut oil, 1 mL o...

Embodiment 2

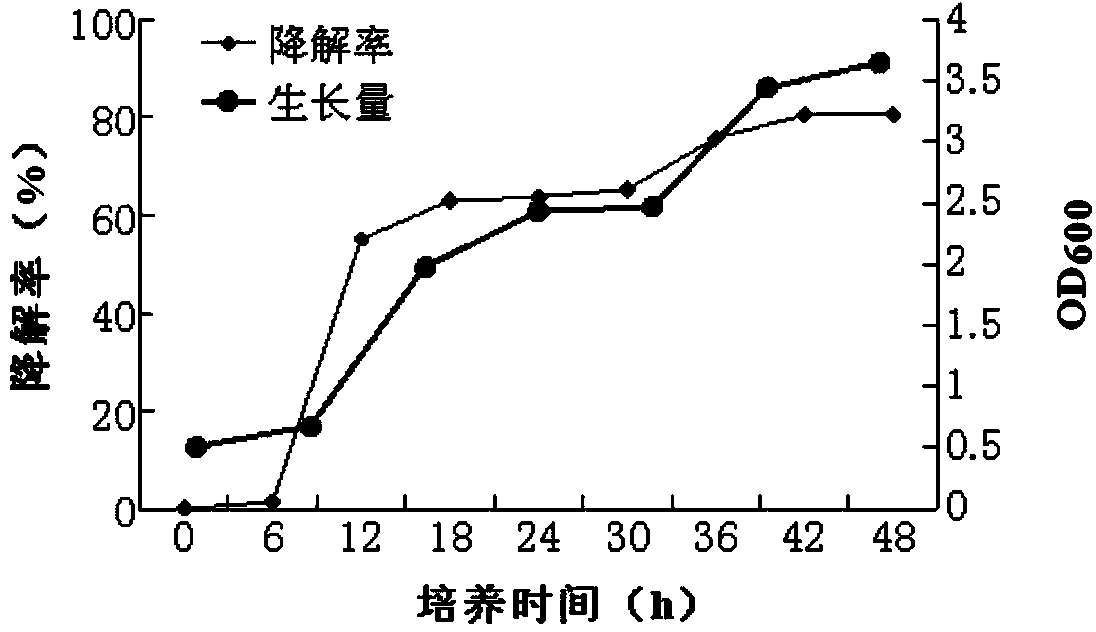

[0037] Embodiment 2: analysis of oil degradation activity

[0038] After the UC13 strain was activated, it was inoculated in a medium with peanut oil as the only carbon source, and the medium components were peanut oil 10 mg / mL, NH 4 NO 3 0.2g / L, K 2 HPO 4 0.5g / L,KH 2 PO 4 0.5g / L, MgSO 4 .7H 2 O0.1g / L; fermented and cultivated in a constant temperature shaking incubator, the culture temperature is 28-30 ℃, the rotation speed is 150-250r / min; respectively take and cultivate until the 0th, 6th, 12th, 24th, 30th, 36th, 42th, 48h of bacteria liquid. Measure the absorbance value of each of the above-mentioned bacterial liquids at 600nm to determine the growth of the bacteria; meanwhile, take 5 mL of the fermentation liquids with different fermentation times, extract twice with an equal volume of n-hexane, and combine the organic phases. The combined organic phases were dehydrated and dried with anhydrous sodium sulfate, placed in a round-bottomed flask, and filtered under r...

Embodiment 3

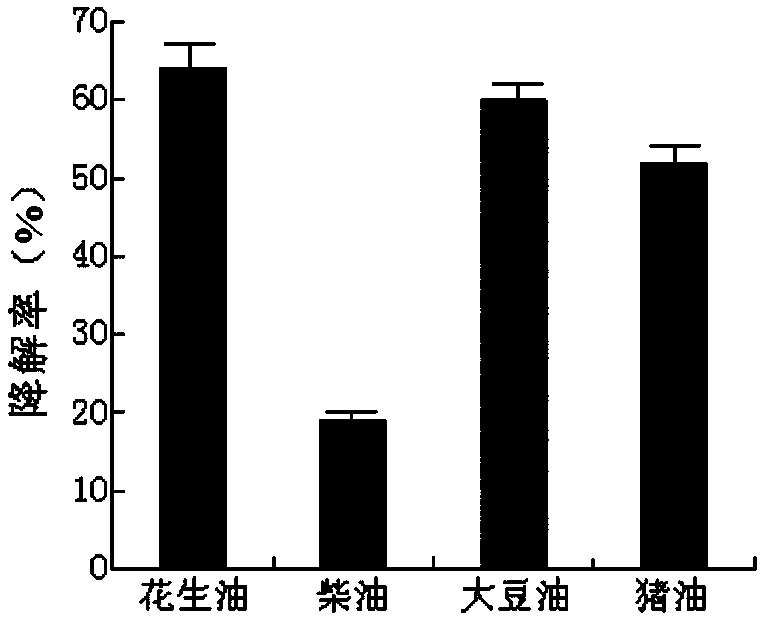

[0039] Example 3: Degradability of UC13 to different oils

[0040] After the UC13 strain was activated, they were respectively inoculated in culture media with peanut oil, soybean oil, sesame oil, lard oil, and diesel oil as the only carbon source. The culture medium has the same composition as that in Example 2 except that the types of oils and fats are different. Fermentation and cultivation of the above-mentioned fermentation liquids in a constant temperature shaking incubator, the cultivation temperature is 28-30° C., and the rotation speed is 150-250 r / min; the bacterial liquid is cultivated to the 24th hour. Measure the absorbance at 600nm to determine the growth of bacteria; take 5mL of fermentation broth and extract with n-hexane. Calculate the degradation rate according to the method of Example 2. The degradation of UC13 to the different oils and fats tested is as follows: figure 2 shown. UC13 has the ability to degrade all the tested oils. The degradation abili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com