Production technology of plasterboard modified starch

A paper-faced gypsum board and modified starch technology, which is applied in the field of production technology of paper-faced gypsum board modified starch, can solve the problems of weak market competitiveness of products, increased cost of production enterprises, small scale of modified starch, etc., and achieves good elasticity. , low cost and energy consumption, good water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 1,000 parts of raw starch into the mixer, start the stirring motor, spray 25 parts of diluted hydrochloric acid with a concentration of 10% and 20 parts of hydrogen peroxide with a concentration of 10% to 27.5%, stir at room temperature for 10 to 15 minutes, and then After being fully mixed by a high-speed mixer, it is sent to the material inlet of the microwave far-infrared equipment. Adjust the thickness of the material layer to 3-6cm, turn on the microwave far-infrared equipment, adjust the temperature of the material at 50-150°C, and keep it for 10-30 minutes. After the index of 10-12% and viscosity of 2-5mpa.s reaches the required value, put the material into the cooling compounding machine and wait for the temperature to drop below 40°C, spray the concentration at 4%-10% 10 parts of potassium hydroxide solution (containing 5 parts of methanol) are mixed evenly, and then 5-10 parts of microcrystalline cellulose are added, mixed thoroughly for 10-20 minutes, then...

Embodiment 2

[0021] Add 1000 parts of raw starch into the mixer, start the stirring motor, spray 18 parts of diluted hydrochloric acid with a concentration of 12%, 10 parts of ammonium persulfate with a concentration of 12%, stir at room temperature for 10 to 15 minutes, and follow-up procedures are the same as in Example 1 , and finally spray 5-10 parts of sodium hydroxide solution with a concentration of 10% (containing 5 parts of methanol) and mix evenly, then add 6-12 parts of silicon dioxide, mix thoroughly for 10-20 minutes, and then sieve and pack. Obtain the product of the present invention.

Embodiment 3

[0023] Add 1000 parts of raw starch into the mixer, start the stirring motor, then spray 15 parts of diluted sulfuric acid with a concentration of 5%, and 10 parts of hydrogen peroxide with a concentration of 10%, stir at room temperature for 10 to 15 minutes, follow-up procedures and Example 1 Similarly, spray 15 parts of sodium silicate solution with a concentration of 9% at the end, add 12 parts of silicon dioxide after mixing evenly, mix thoroughly for 10 to 20 minutes, then sieve and pack to obtain the product of the present invention.

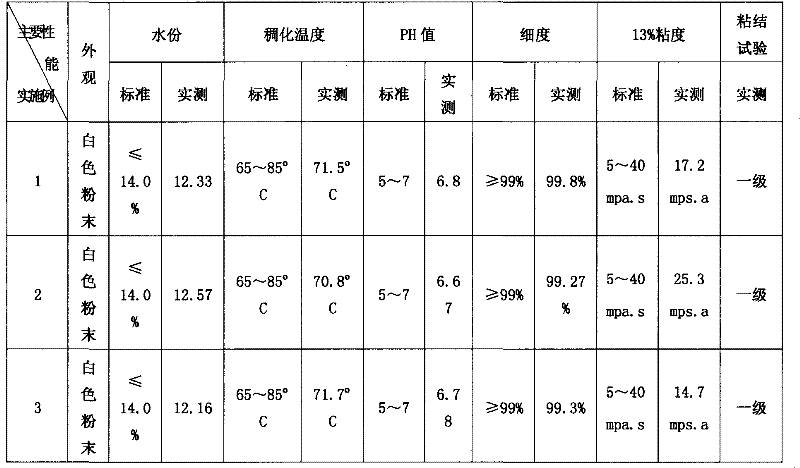

[0024] The modified starch obtained in the above examples is mainly used in the addition of paper-faced gypsum boards, and its main properties are shown in the table (taking the product standard of a well-known domestic paper-making enterprise as an example)

[0025]

[0026] The results show that the main properties of the gypsum board starch of the present invention meet or exceed the standards and performance requirements specified b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com