Method of preparing starch phosphate

A technology of phosphate ester and starch, which is applied in the field of preparation of phosphate ester starch, can solve the problems of low viscosity of paste liquid, unsmooth cut surface and non-brittle taste, and achieves weak retrogradation, good water retention and good transparency of paste liquid. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

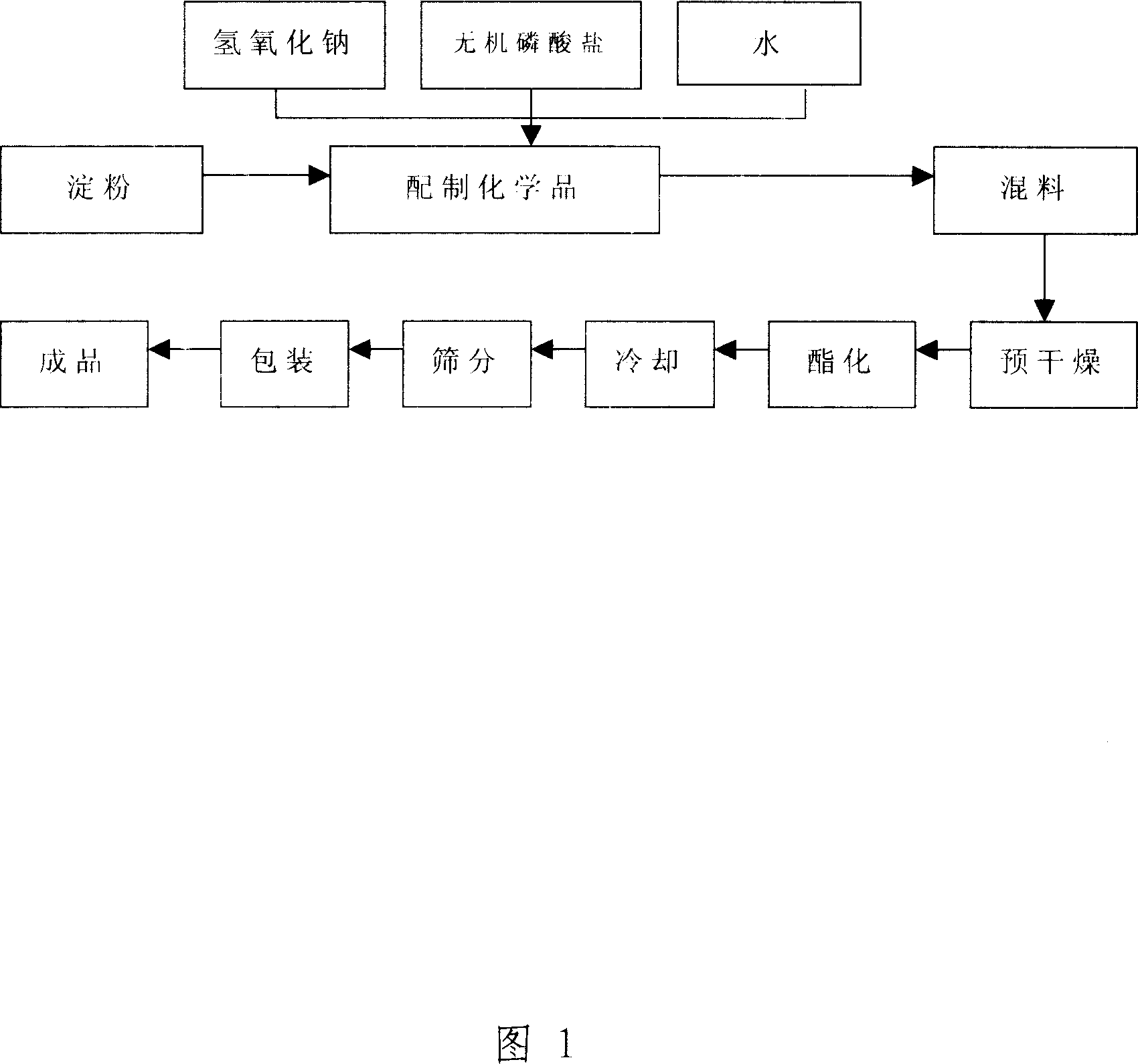

Method used

Image

Examples

Embodiment 1

[0021] First, mix 140L water, 10kg sodium tripolyphosphate, and 10kg urea, spray it on 1000kg cornstarch in the mixer, mix for 45 minutes, and dry the material until the moisture content is ≤10%. The temperature in the cone rises to 140°C, put the materials in, ensure that the vacuum degree is at 0.08MPa, and time the cone temperature at 145°C to ensure that the cone temperature is between 145 and 150°C, react for 4 hours and discharge the material, cool the released starch, and then Pass through a 80-100 mesh vibrating sieve, pack in 25 kg / bag, and finally get the finished product.

Embodiment 2

[0023] The steps are the same as in Example 1, except that the chemical ratio is: 140 L of water, 10 kg of sodium dihydrogen phosphate, and 10 kg of urea. The vacuum degree of the esterification process is 0.07 MPa, and the reaction temperature is kept at 145-155° C.

Embodiment 3

[0025] The steps are the same as in Example 1, except that tapioca starch is used as raw material, the vacuum degree of the esterification process is 0.06 MPa, and the reaction temperature is kept at 145-150° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com