A hot dog sausage production equipment

A technology for production equipment and hot dog sausages, which is applied in the field of high-efficiency, labor-saving and energy-saving production technology and production equipment for hot dog sausages, which can solve the problems of waste of resources, insufficient economy and environmental protection, and low efficiency, so as to improve production efficiency, reduce labor costs, and reduce error rates Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

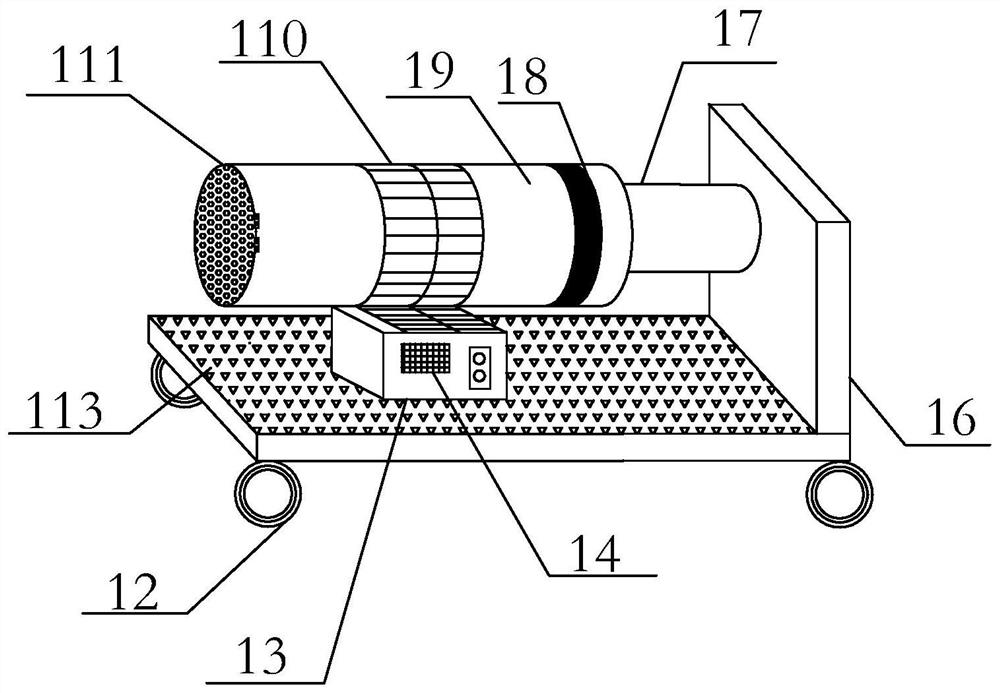

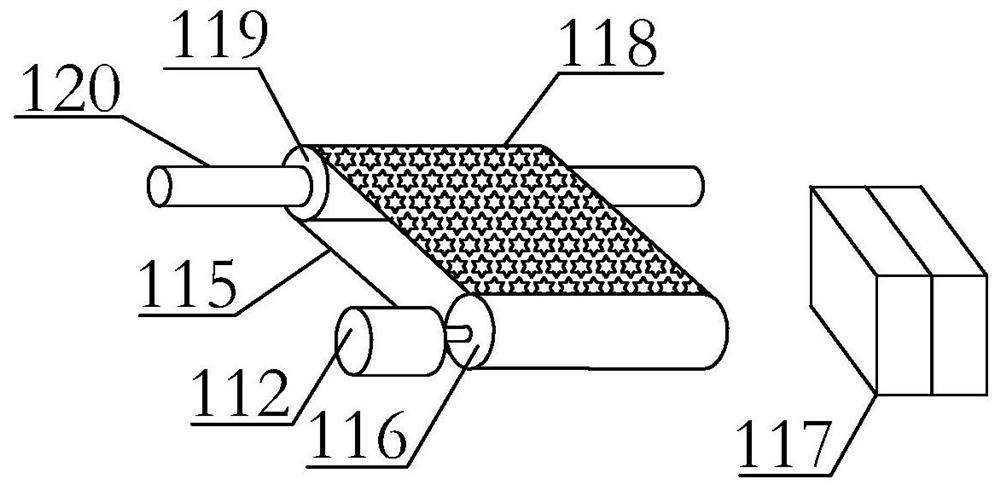

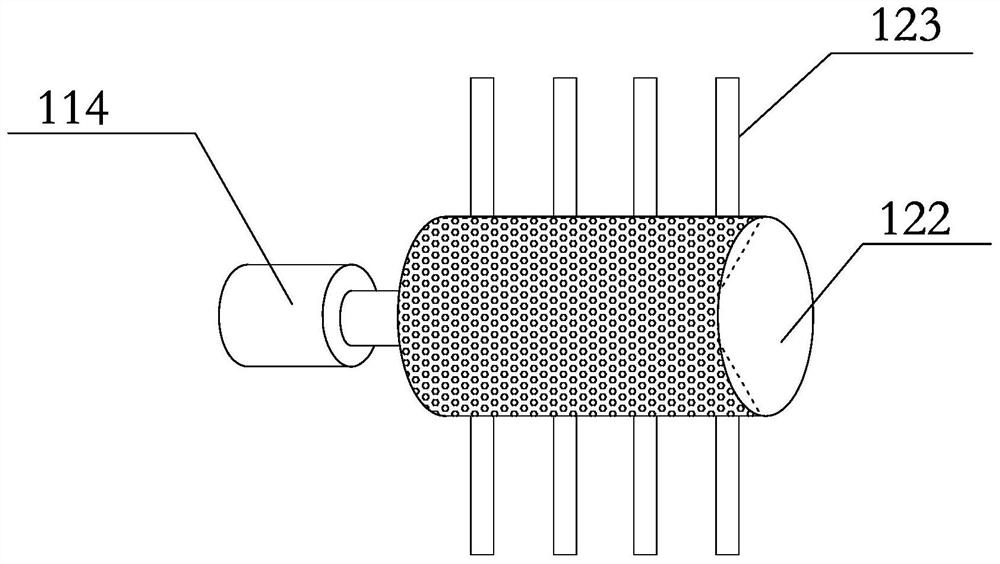

[0047] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0048] refer to Figure 20 As shown, the present invention provides a kind of high-efficiency, labor-saving and energy-saving production technology of hot dog sausage, it is characterized in that, comprises the following steps:

[0049] 1) Ingredients: Based on the weight of pork, prepare salt, sugar, sodium nitrite, pepper, monosodium glutamate, and white wine;

[0050] 2) Meat cutting: chop lean meat and fat meat separately;

[0051] 3) Stirring: Mix the ingredients obtained in step 1) with those obtained in step 2) evenly in proportion;

[0052] 4) Enema: Enema the mixture obtained in step 3) to obtain several intestinal bodies;

[0053] 5) Smoke: smoke the intestines obtained in step 4) for 1-1.5 hours;

[0054] 6) Exhaust air cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com