Patents

Literature

63results about How to "Steady improvement in quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

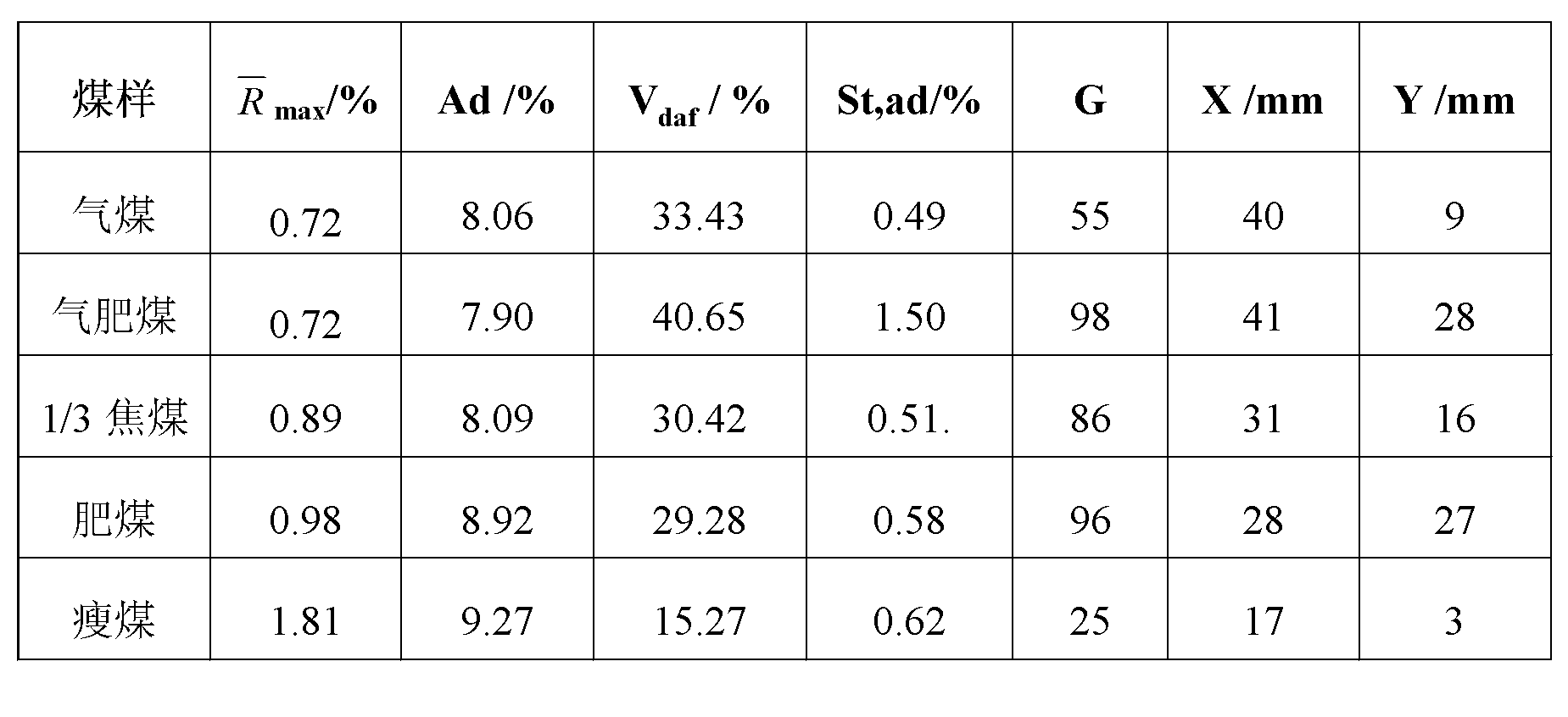

Evaluation method of fat coal quality

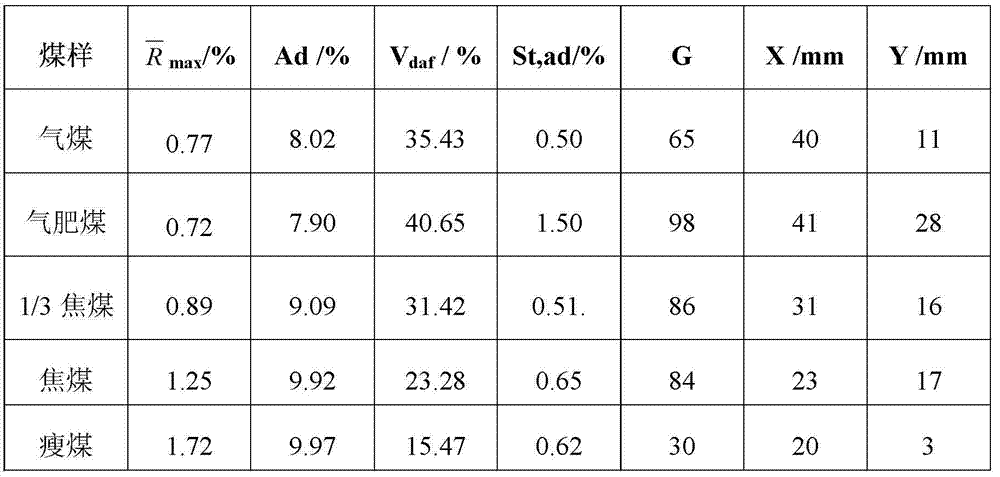

ActiveCN103275740AReduce thermal performance fluctuationsClarify the degree of pros and consData processing applicationsCoke ovensCoalEnvironmental geology

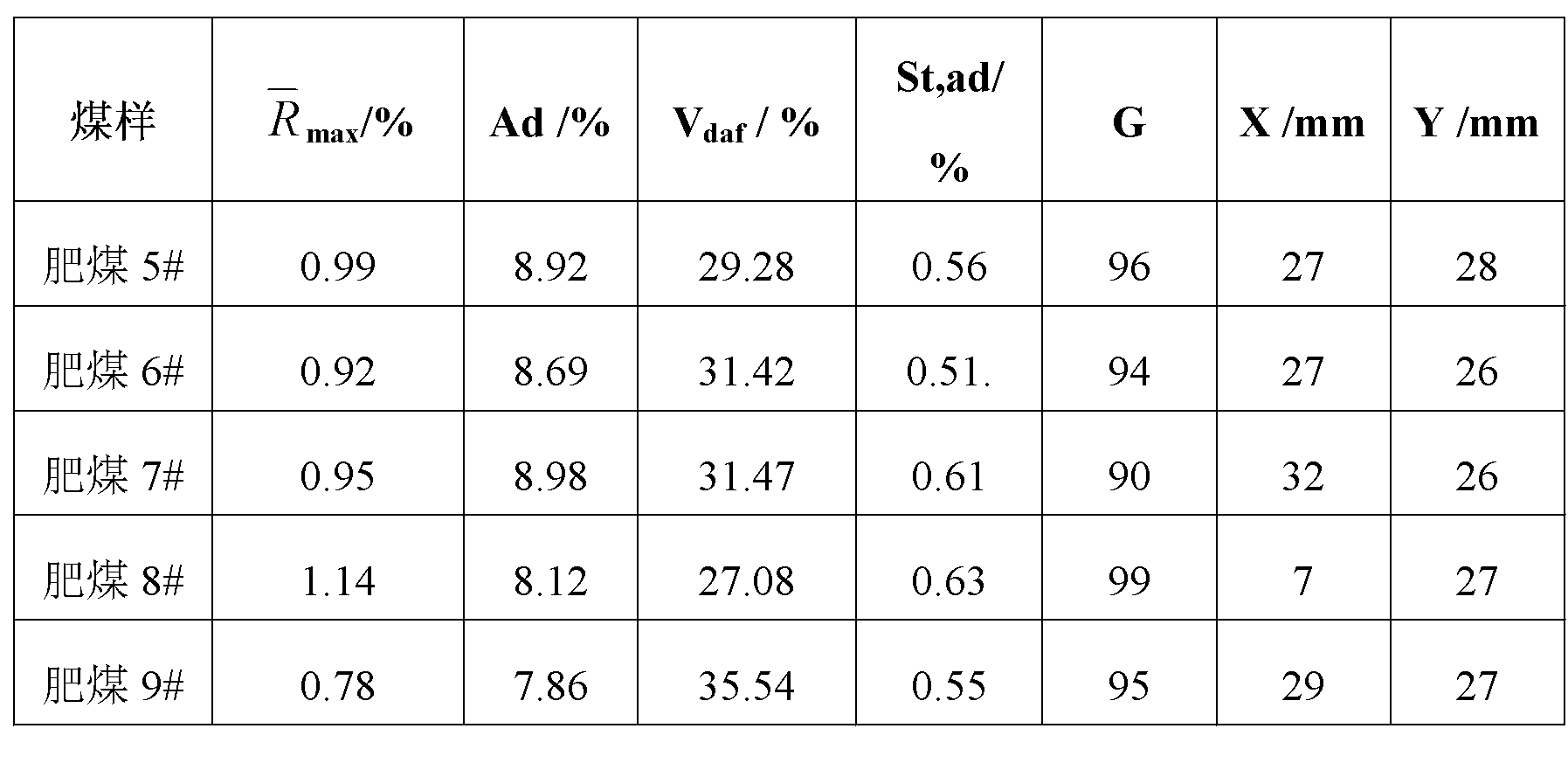

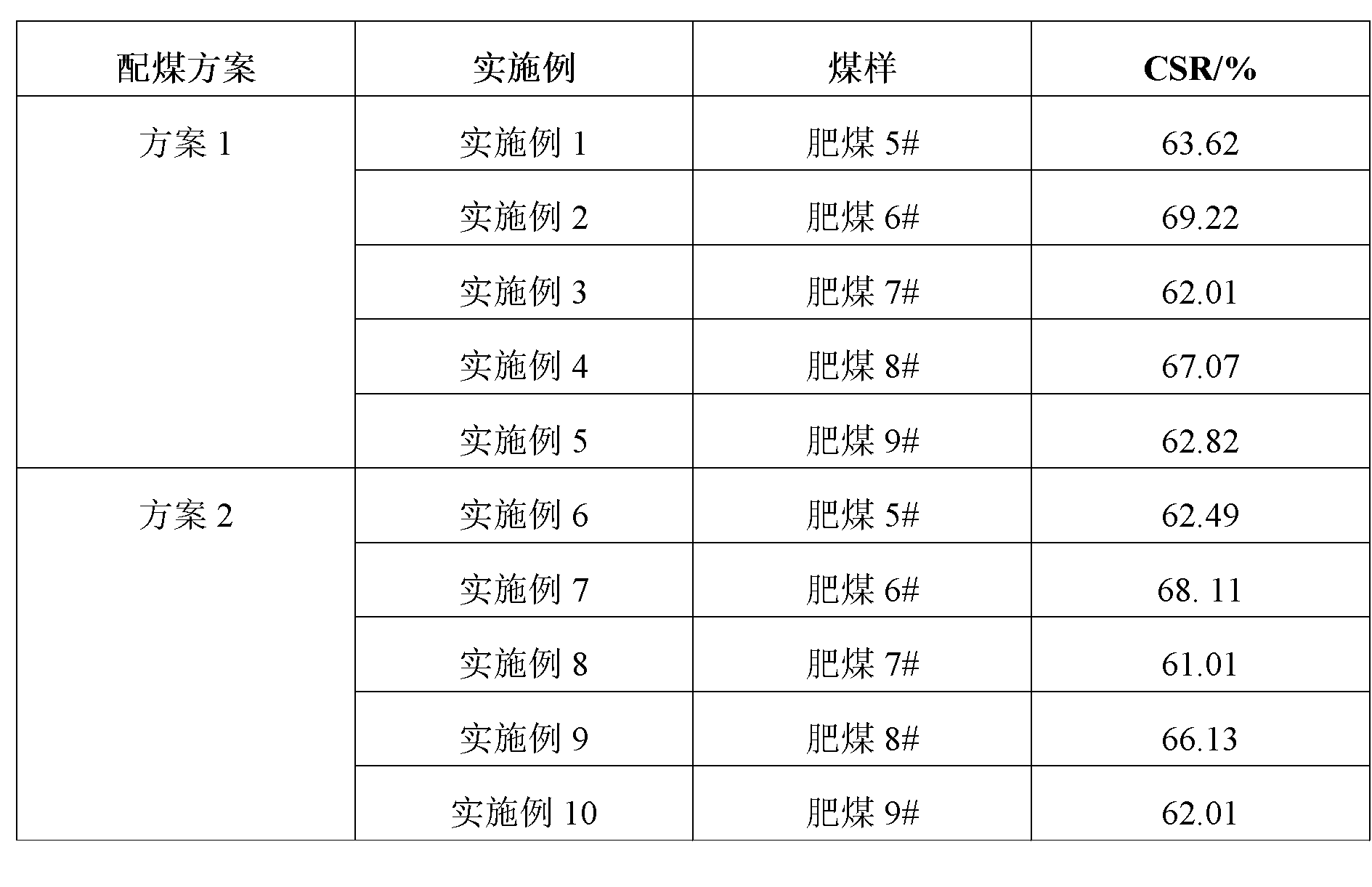

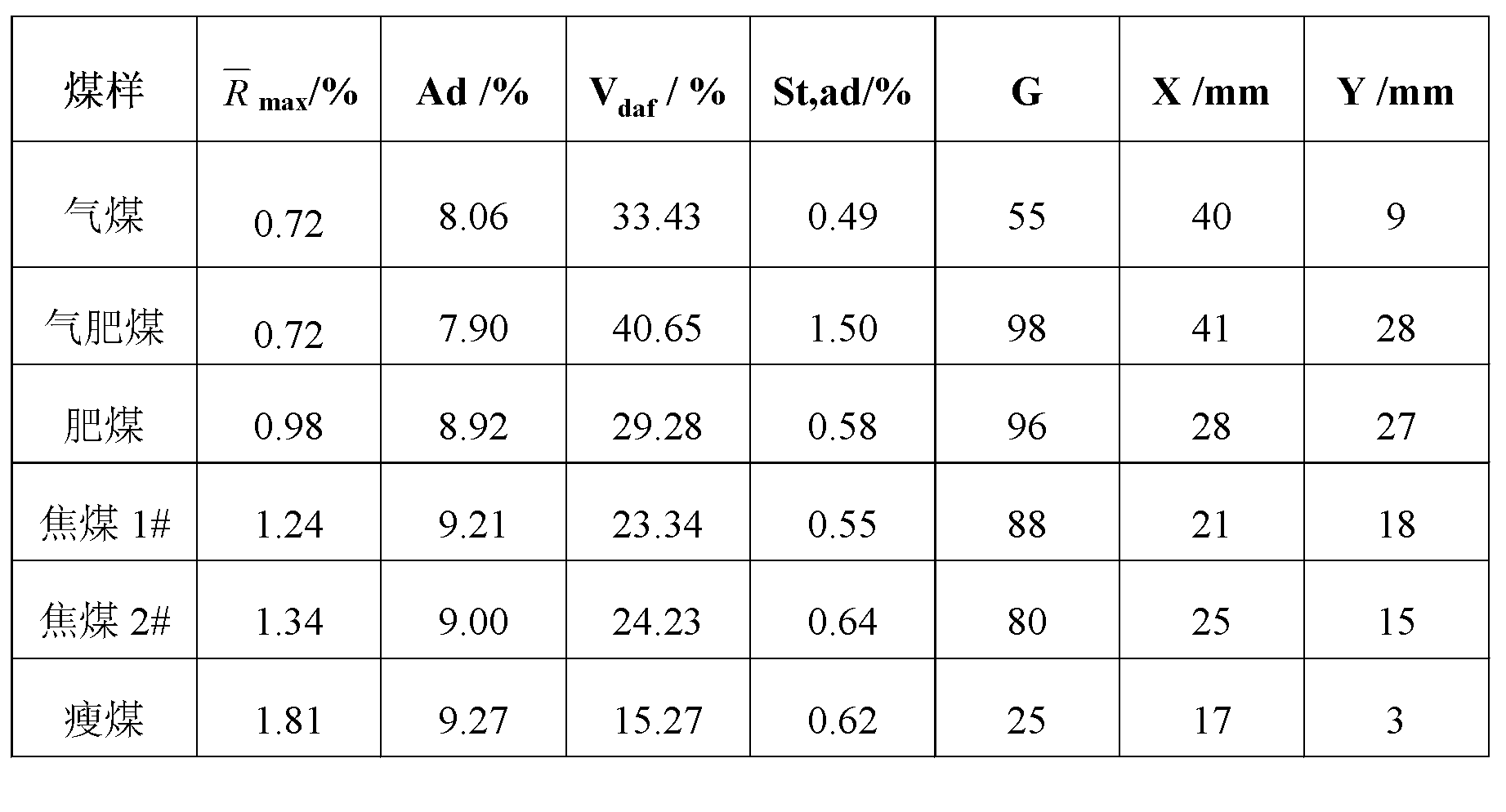

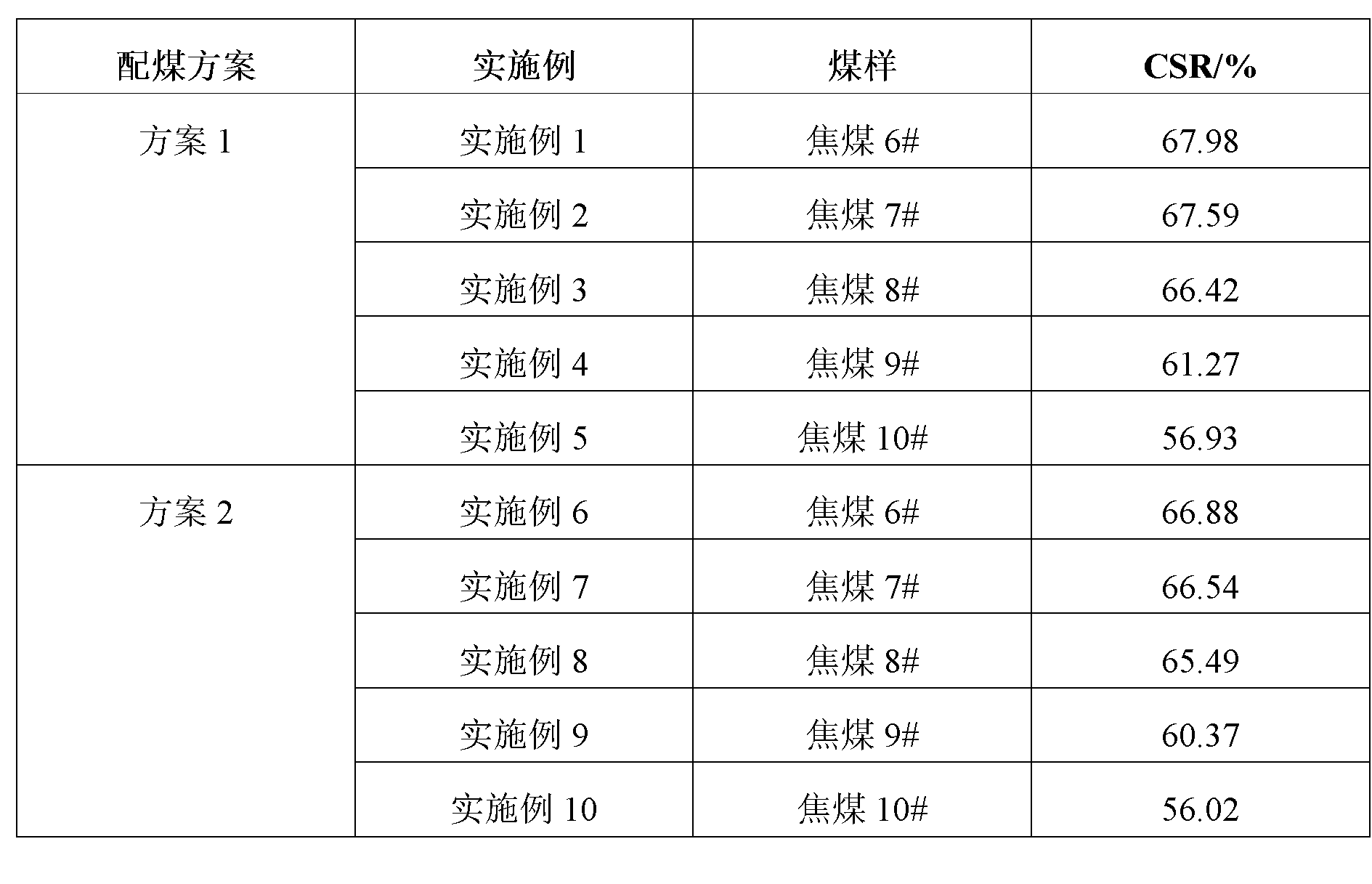

The invention discloses an evaluation method of a fat coal quality. The evaluation method comprises the steps as follows: 1), detecting key indexes of coal quality of the fat coal and obtaining a coarse grain mosaic structure proportion X, a maximum Giseeler fluidity MF and an expansion degree b of the fat coal; 2), setting P to be a fat coal quality evaluation index, P= 100 + 10* [k1* (X-Xj)+ K2* (lgMF-lgMFj) + K3* (b-bj)], wherein Xj, MFj and bj are the coarse grain mosaic structure proportion X, the maximum Giseeler fluidity MF and the expansion degree of standard fat coal respectively, K1, K2 and K3 are constants and related with CSR (coke strength after reaction) as the following relational expression: CSR= K + K1*X + K2* lgMF + K3*b, and K is a constant; and 3), a P value is calculated, and the larger the P value is, the better the fat coal quality is. According to the evaluation method of the fat coal quality, the quality of the fat coal can be effectively evaluated, a price is reasonably determined, and scientific blending is achieved.

Owner:武汉钢铁有限公司

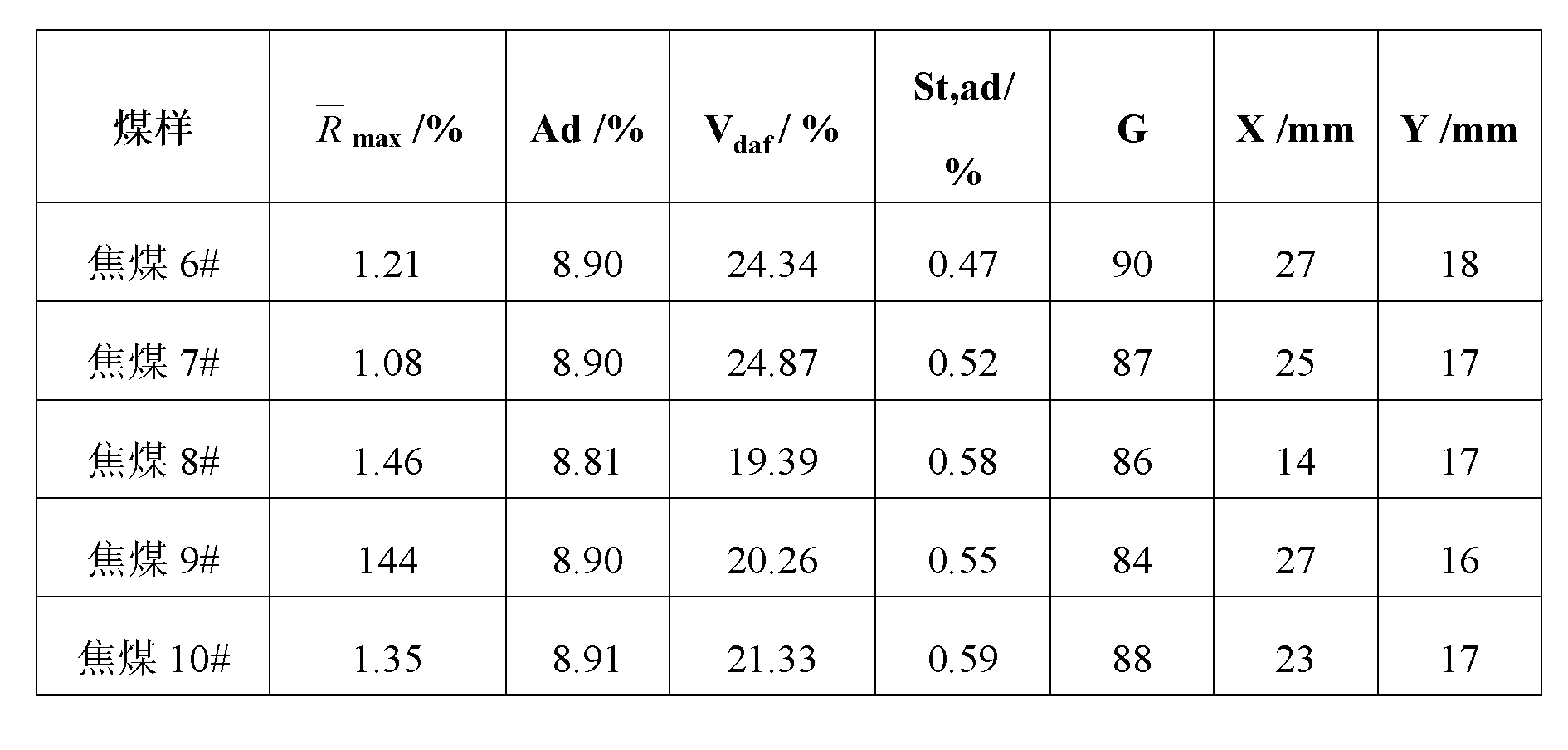

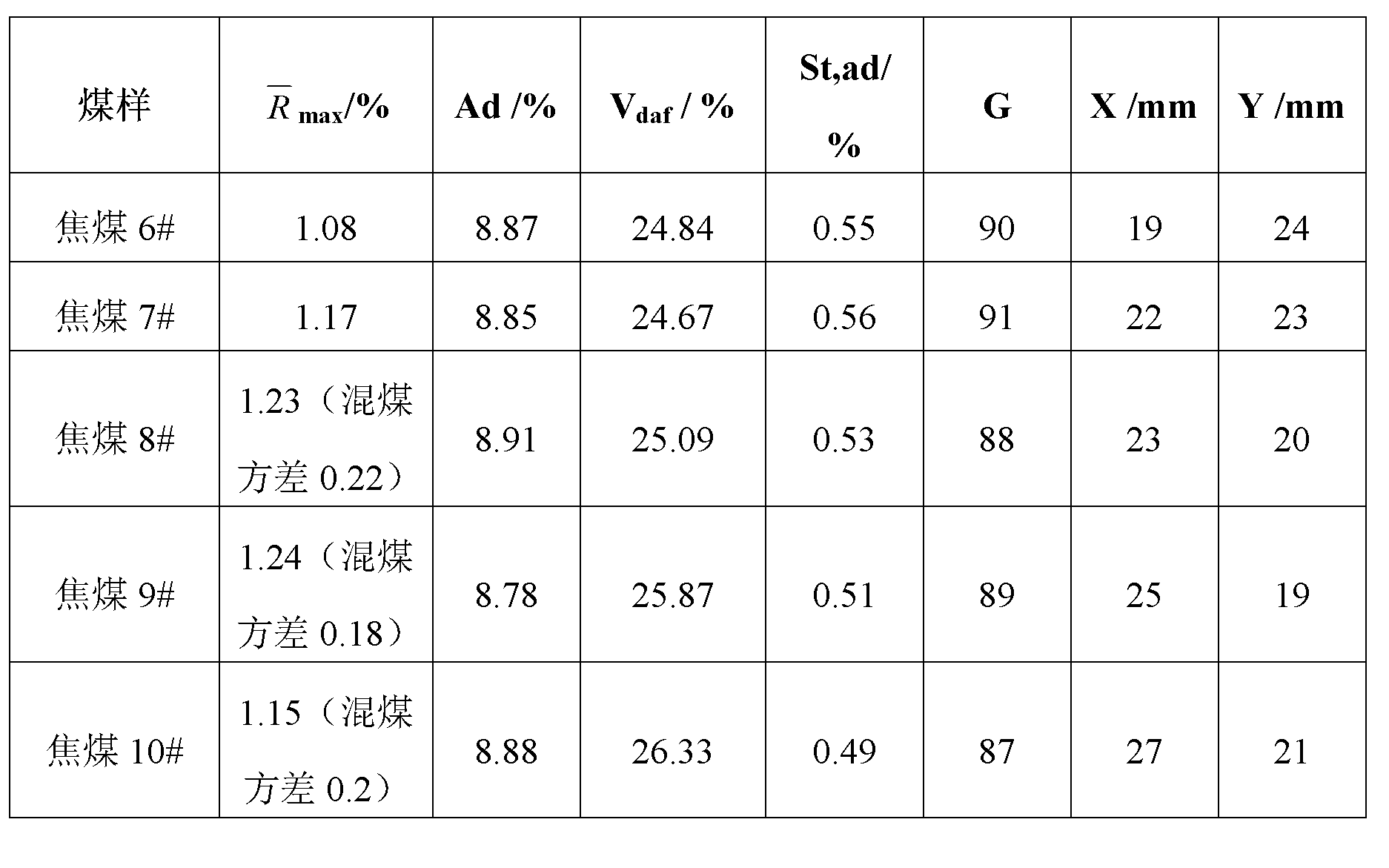

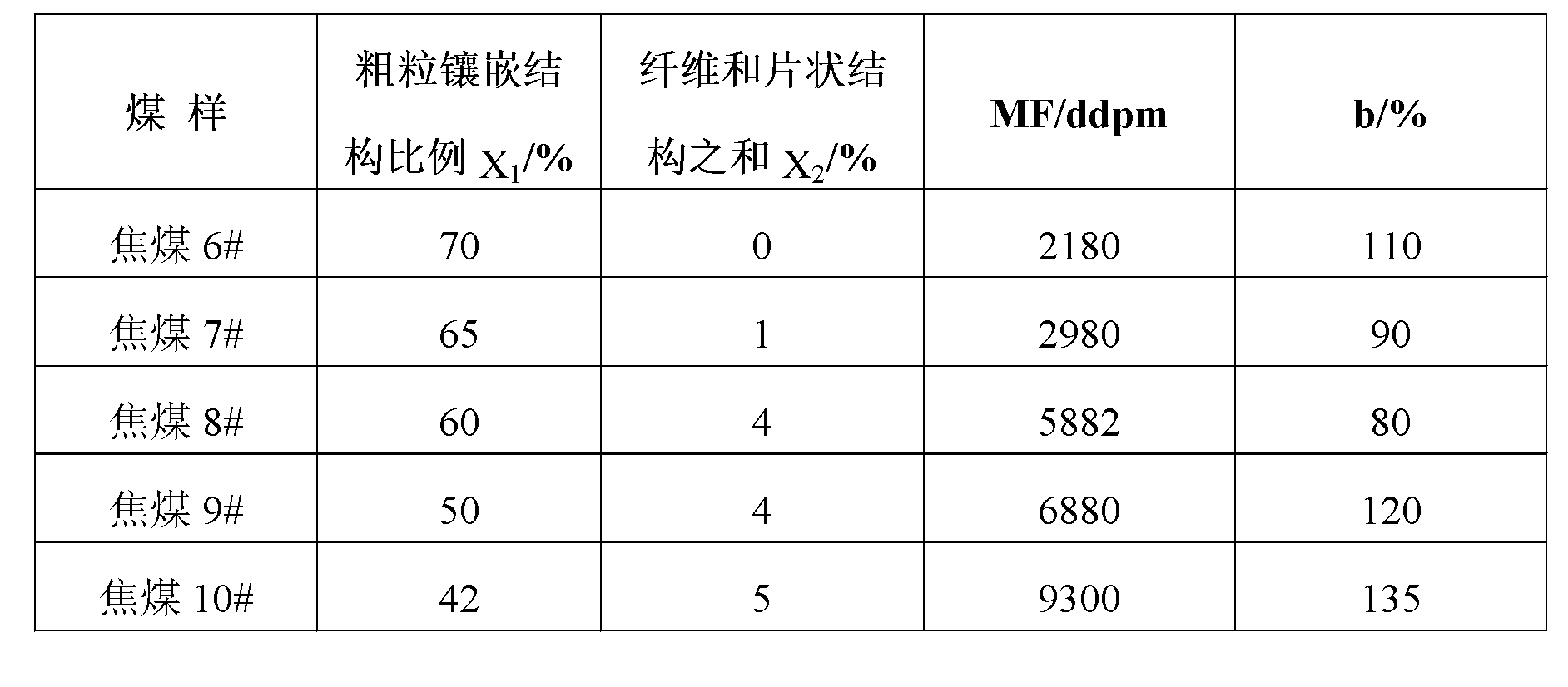

Method for evaluating coal quality of coking coal having largest Gieseler fluidity of 2000ddpm or less

ActiveCN103278610AClarify the degree of pros and consBenefit from reasonable positioningFuel testingFiberCoal

The invention discloses a method for evaluating the coal quality of coking coal having a largest Gieseler fluidity of 2000ddpm or less. The method comprises the following steps: 1, detecting to obtain the coarse grain inlay structure proportion X1, the sum X2 of the proportion of fibers and the proportion of the sheet structure, the largest Gieseler fluidity MF and the expansion degree b of the coking coal; 2, setting P as a coking coal quality evaluating index, and commanding P=100+2*[K1*(X1-Xj1)+K2*(X2-Xj2)+K3*(|MF-800|-|MFj-800|)+K4*(|b-50|-(|bj-50|)], wherein the subscript j represents reference coking coal; and K1, K2, K3 and K4 are constants; and 3, calculating to obtain the P value, wherein the coal quality of the coking coal is better if the P value is larger. The method has the advantages of effective evaluation of the quality of the coking coal, reasonable price determination, and scientific application.

Owner:武汉钢铁有限公司

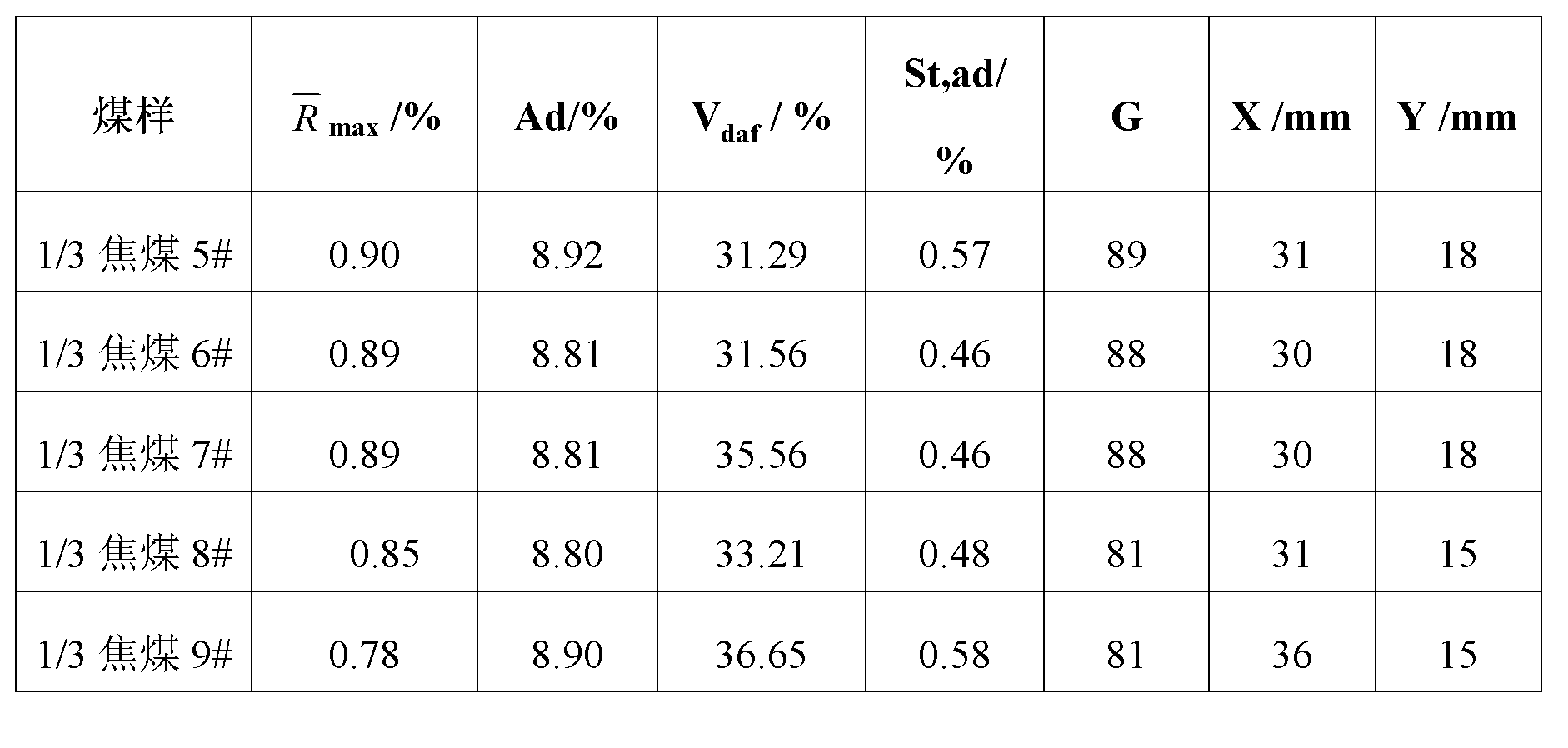

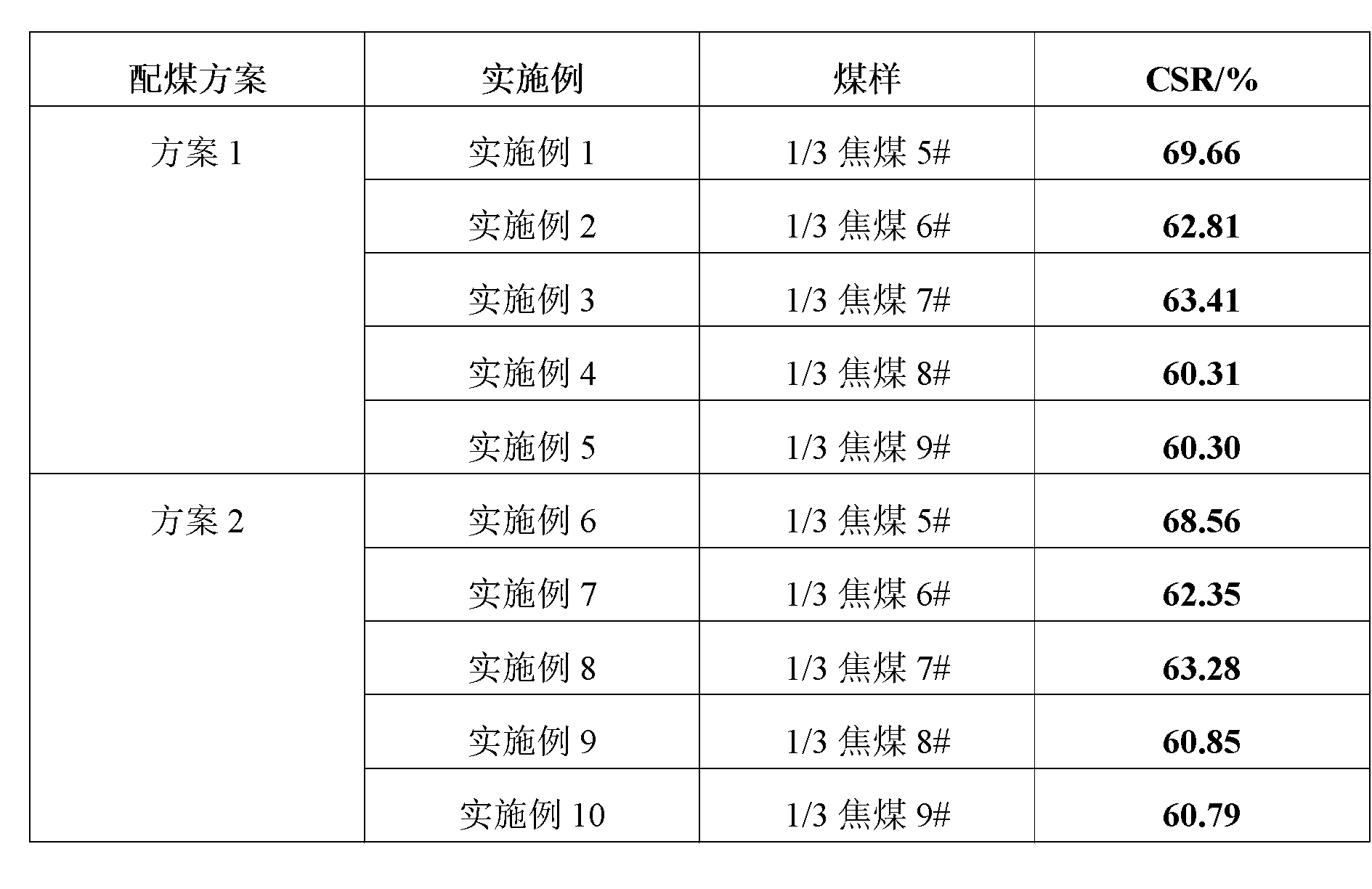

1/3 coking coal quality evaluation method

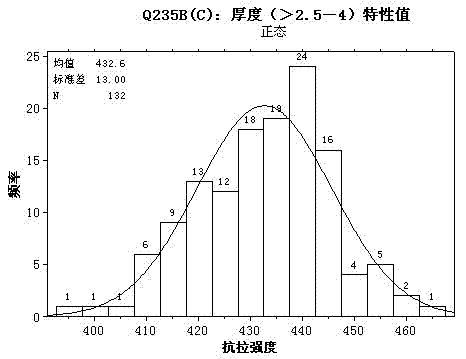

ActiveCN103278611ABenefit from reasonable positioningSteady improvement in qualityFuel testingEngineeringUltimate tensile strength

The invention discloses a 1 / 3 coking coal quality evaluation method which comprises the steps as follows: (1) detecting the coal quality key index of one third coking coal to obtain a coarse grain mosaic texture proportion X, a maximum Gieseler fluidity MF and an expansion degree b; (2) setting P as the 1 / 3 coking coal quality evaluation index, and enabling P to be equal to the sum of 100 and 5*[K1*(X-Xj)+K2*(lgMF-lgMFj)+K3*(b-bj)], wherein Xj, MFj and bj are the coarse grain mosaic texture proportion, the maximum Gieseler fluidity and the expansion degree of the standard 1 / 3 coking coal respectively; K1, K2 and K3 are constants; the strength CSR after a thermal reaction with the coke is associated through the formula CSR=K+K1*X+K2*lgMF+K3*b; and K is a constant; and (3) calculating the value of P, wherein the larger P is, the higher the 1 / 3 coking coal quality is. The 1 / 3 coking coal quality evaluation method can effectively evaluate the coal quality of the 1 / 3 coking coal, so that reasonable pricing and scientific matching for use are achieved.

Owner:武汉钢铁有限公司

Evaluation method of coal quality of coking coal with maximum Giseeler fluidity greater than 2000 ddpm

ActiveCN103279678ABenefit from reasonable positioningSteady improvement in qualitySpecial data processing applicationsFiberSwelling capacity

The invention discloses an evaluation method of coal quality of coking coal with maximum Giseeler fluidity greater than 2000 ddpm. The evaluation method comprises the following steps of: 1) detecting to obtain a coarse grain mosaic structure proportion X1 of the coking coal, the sum of the proportions X2 of fibers and a sheet structure, a maximum Giseeler fluidity MF and a swelling capacity b; 2) setting P as an evaluation index of the coal quality of the coking coal, and enabling P=100+2*[K1*(X1-Xj1)+K2*(X2-Xj2)+K3*(|L*MF-800|-|L*MFj-800|)+K4*(|b-50|-|bj-50|)], wherein the subscript j represents standard coking coal, K1, K2, K3 and K4 are constant numbers; and 3) calculating the P value, wherein the greater the P value is, the better the coal quality of the coking coal is. The evaluation method of the coal quality of the coking coal with the maximum Giseeler fluidity greater than 2000 ddpm can evaluate the quality of the coking coal efficiently, determine the price reasonably and can be used in matching scientifically.

Owner:武汉钢铁有限公司

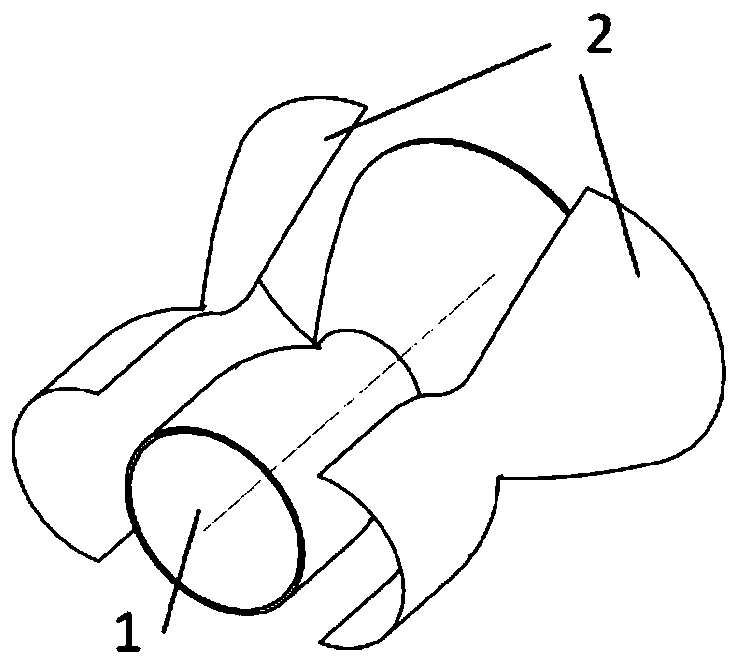

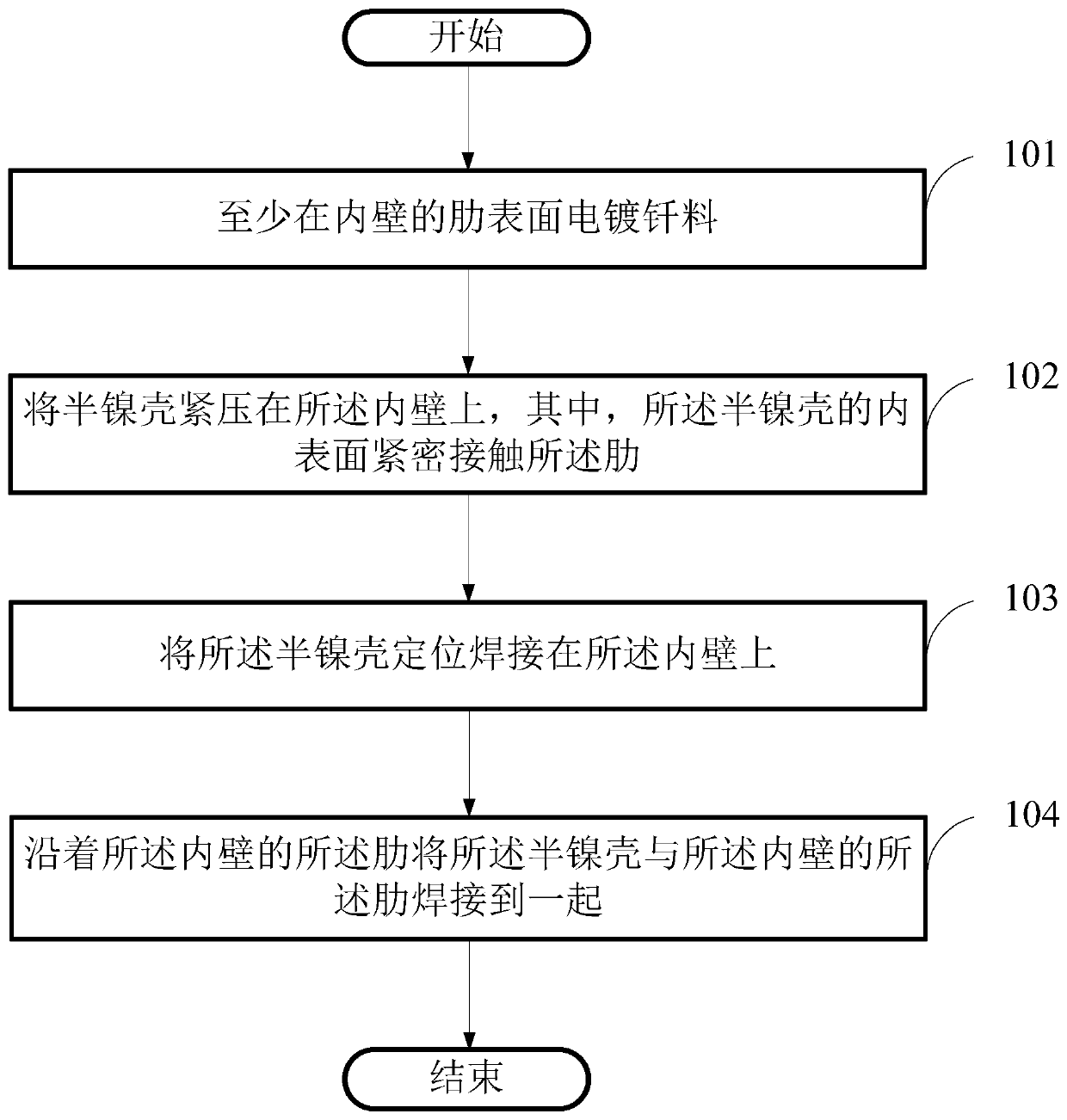

Manufacturing method of pressure-resistant interlayer of thrust chamber of liquid rocket motor

The invention provides a manufacturing method of a pressure-resistant interlayer of a thrust chamber of a liquid rocket motor. The manufacturing method comprises the following steps that brazing filler metal electroplating is conducted on the surface of a rib of an inner wall at least; a half nickel shell is tightly pressed on the inner wall, wherein the inner surface of the half nickel shell is in close contact with the rib; the half nickel shell is located to be welded to the inner wall; the half nickel shell and the rib of the inner wall are welded together along the rib of the inner wall;multiple times of repeating welding are conducted on the half nickel shell and the rib of the inner wall along the rib of the inner wall according to the technology requirements; the outer surface ofthe half nickel shell after being welded is polished smoothly; and nickel layer electroforming or steel bushing wrapping and clamping is conducted on the surface of the half nickel shell. According tothe manufacturing method of the pressure-resistant interlayer of the thrust chamber of the liquid rocket motor, the degree of automation of thrust chamber body part machining can be remarkably improved, the bearing strength of the thrust chamber is improved, the quality is stabilized, and the cost is lowered.

Owner:BEIJING LANDSPACETECH CO LTD

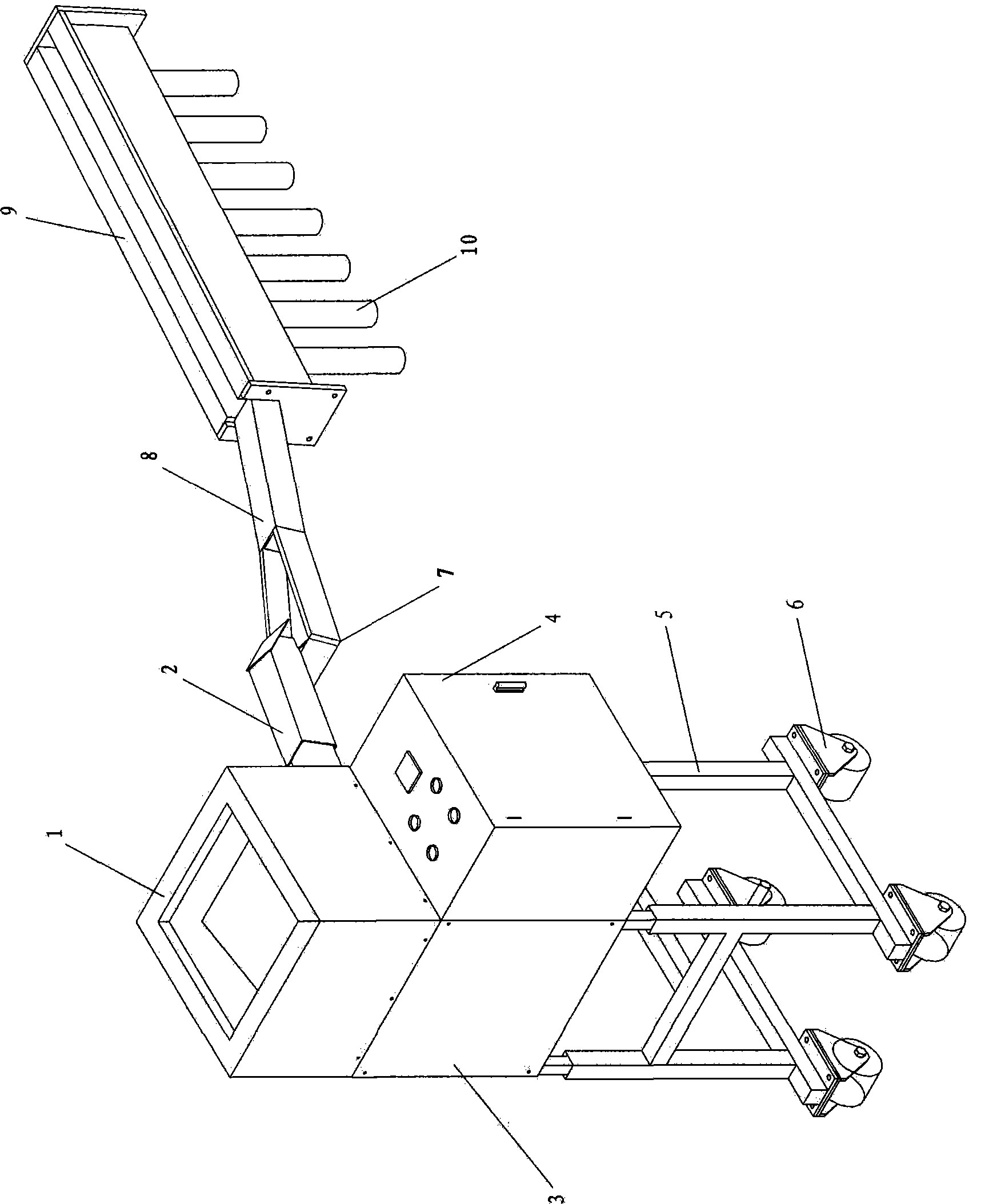

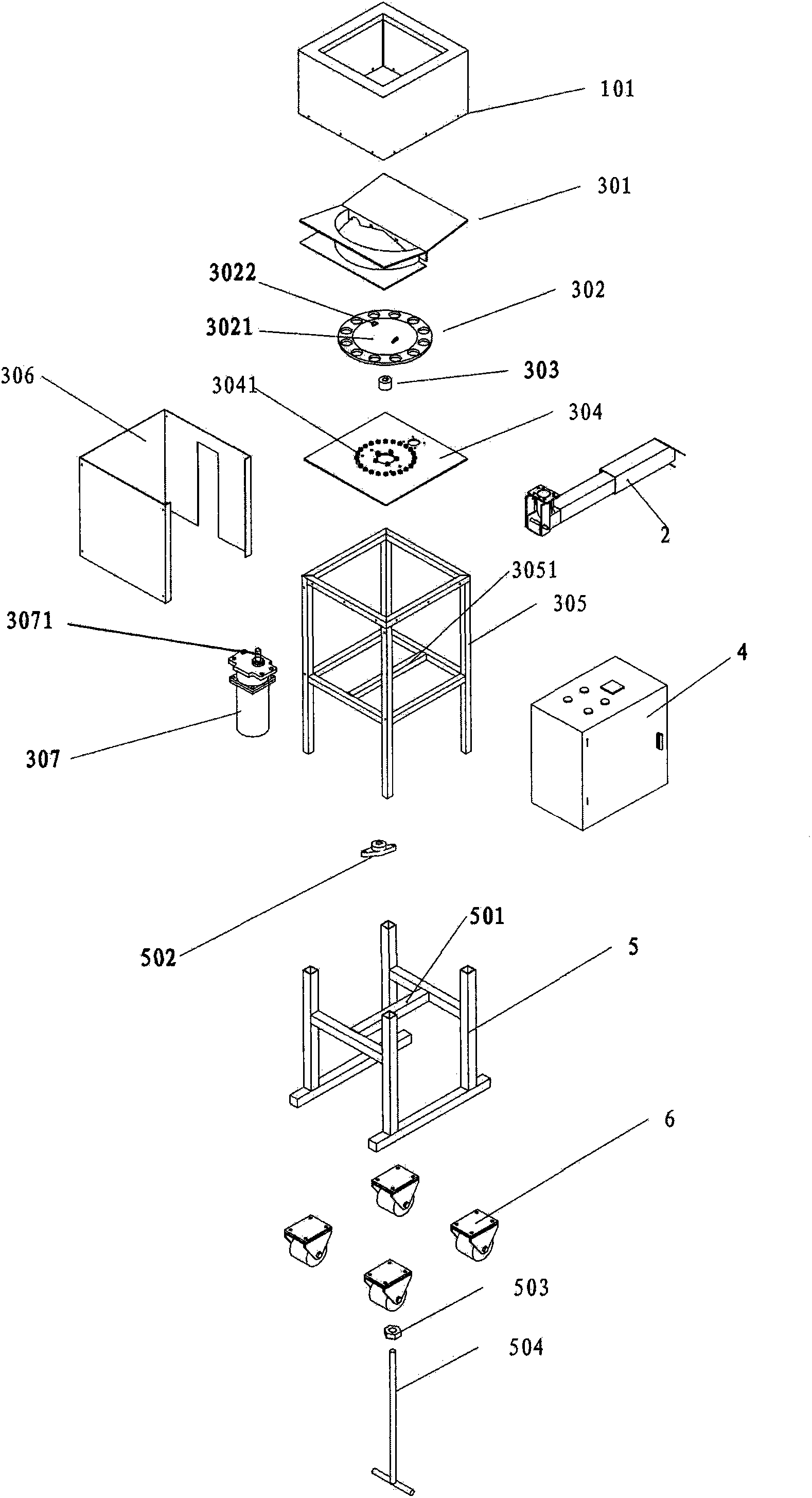

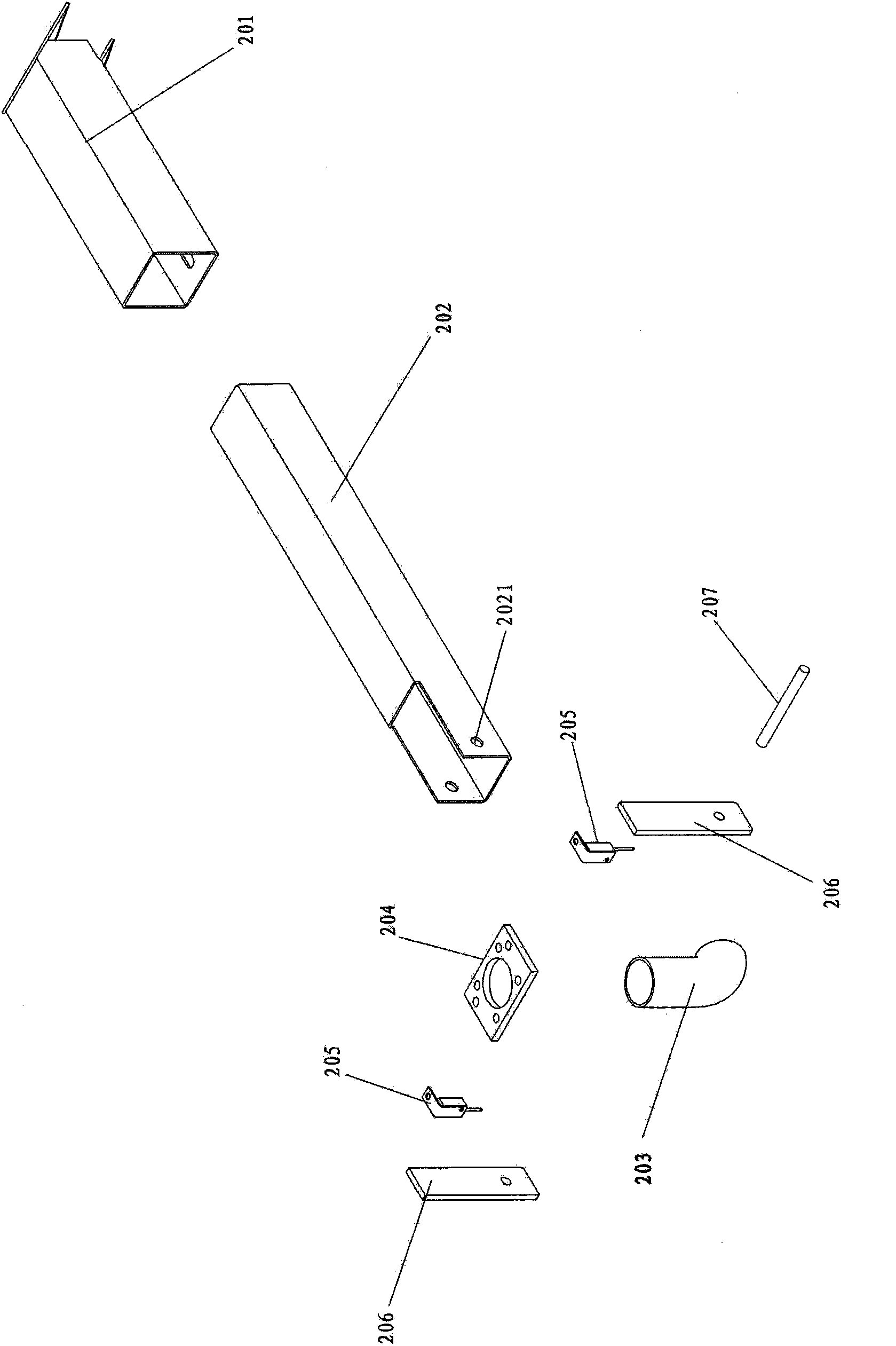

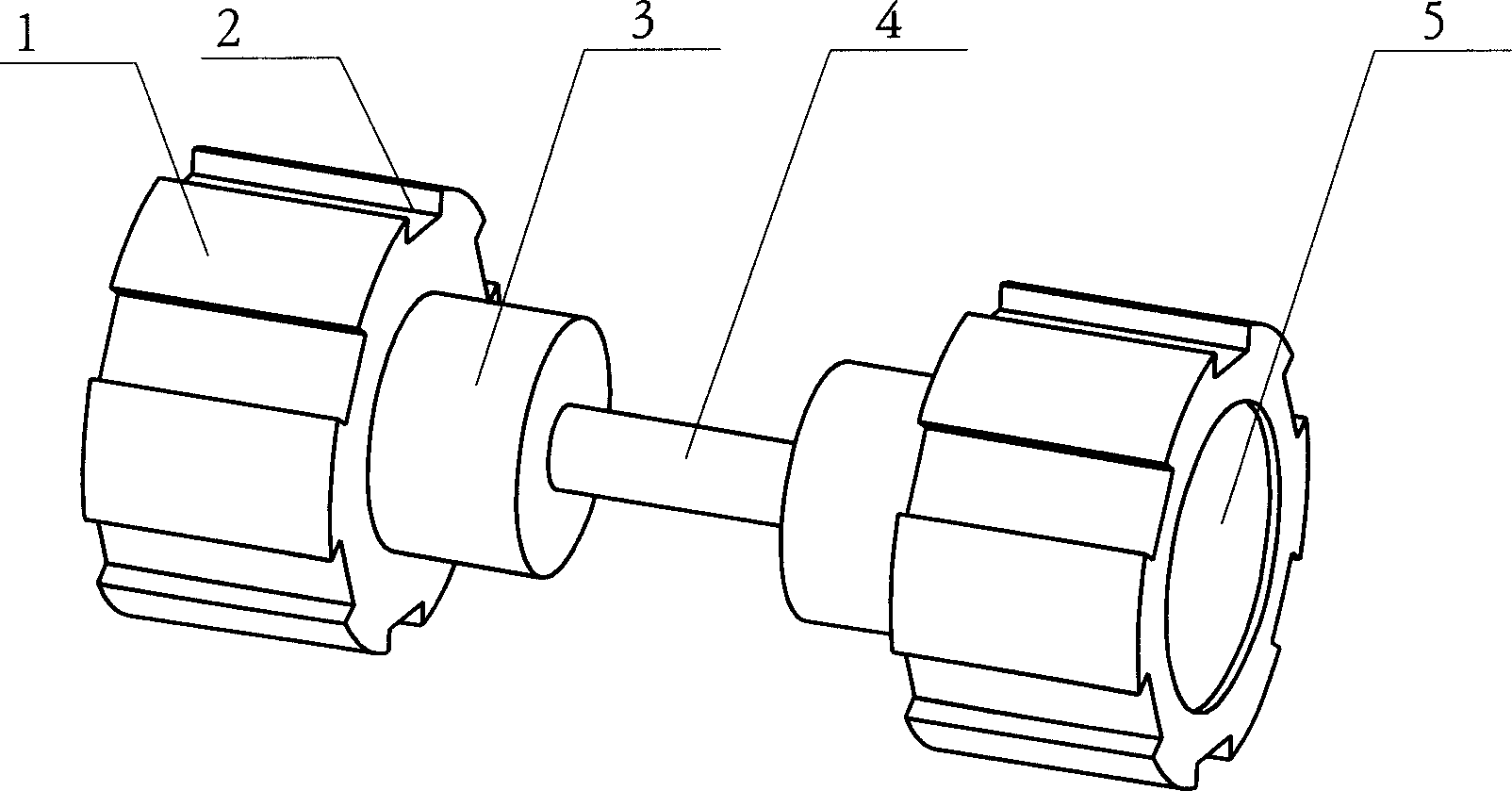

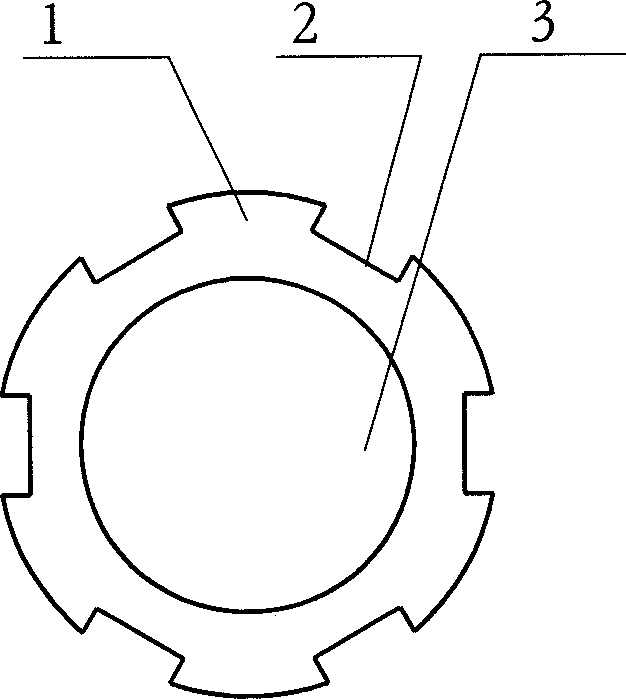

Automatic copper ball feeder

InactiveCN102618909AAvoid affecting productionSave human effortElectrolysis componentsAutomatic controlEngineering

The invention discloses an automatic copper ball feeder, which belongs to the technical field of copper feeders for electroplating equipment titanium baskets and comprises a ball box with an inner ball guide device, a feeder, an electrical box and a stand with firmly connected casters at the bottom. The ball box, the feeder, the electrical box and the stand are mutually and fixedly connected in a mechanical way. A ball guide passage is connected onto the feeder and communicated with a channel through a chute and a ball guide duct while the lower portion of the channel is connected with a titanium basket. The automatic copper ball feeder is capable of automatically controlling copper balls to be fed into the titanium basket and capable of automatically controlling the mount of copper balls to be fed and feeding speed and counting the total amount, so that production efficiency and production quality of electroplating equipment are improved and cost is reduced.

Owner:陈焕宗

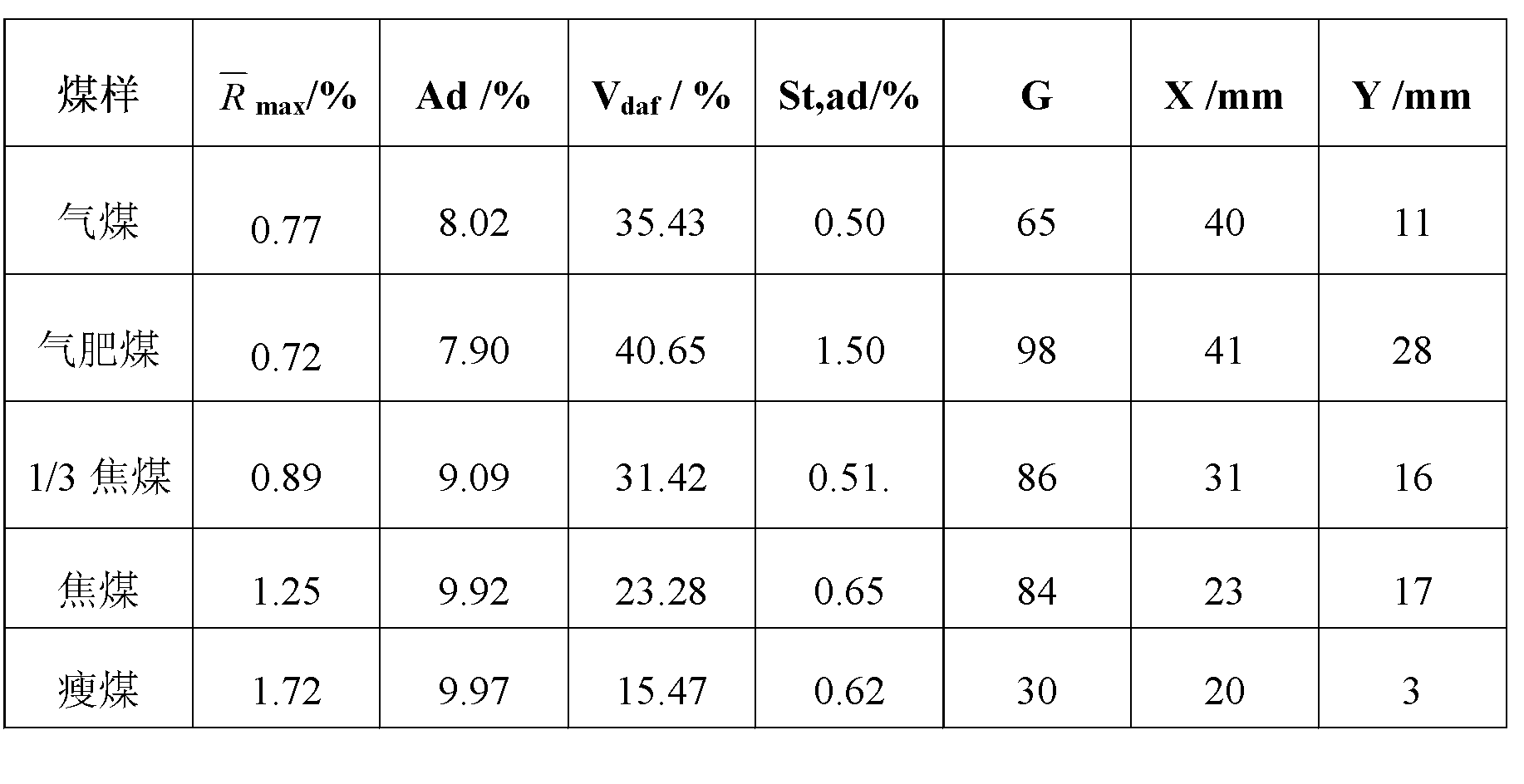

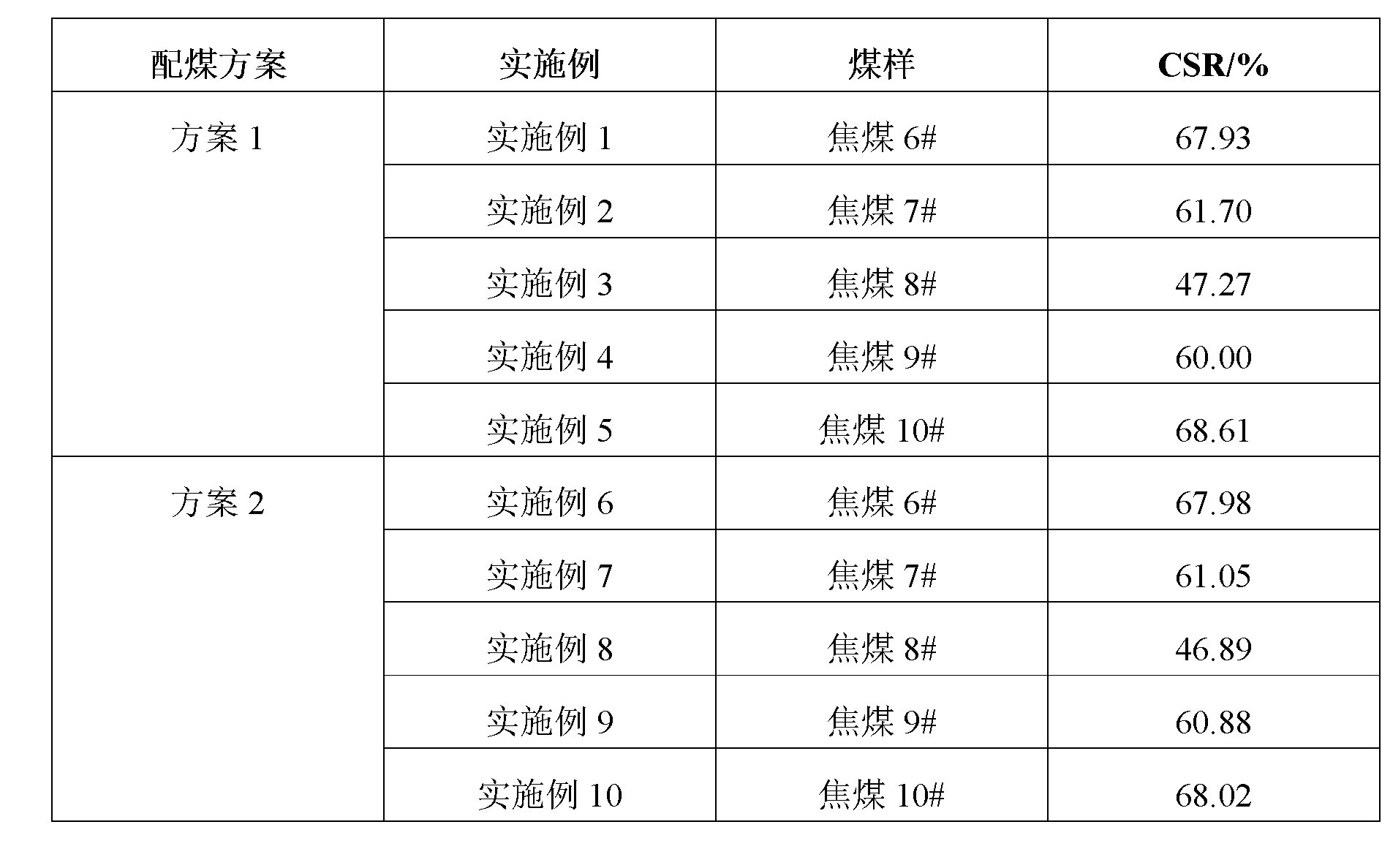

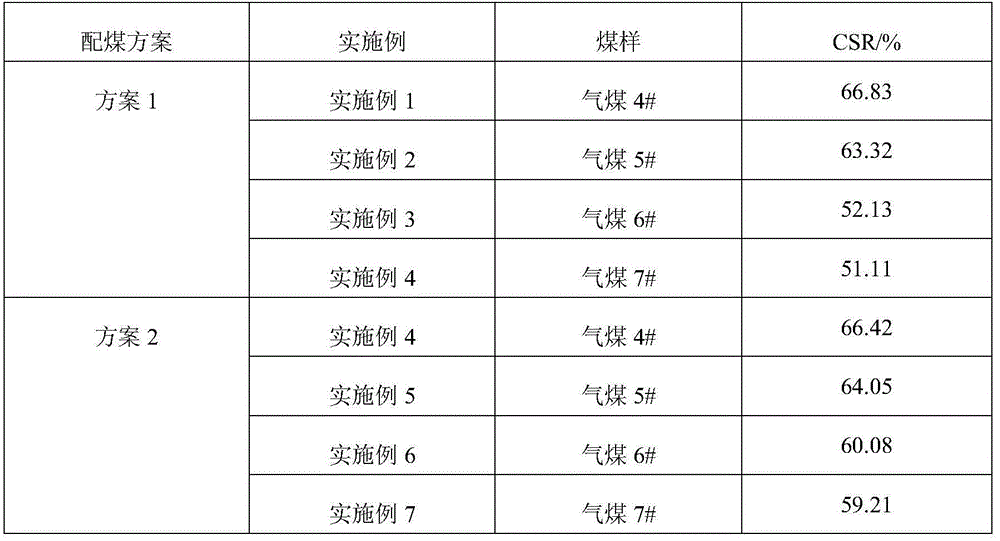

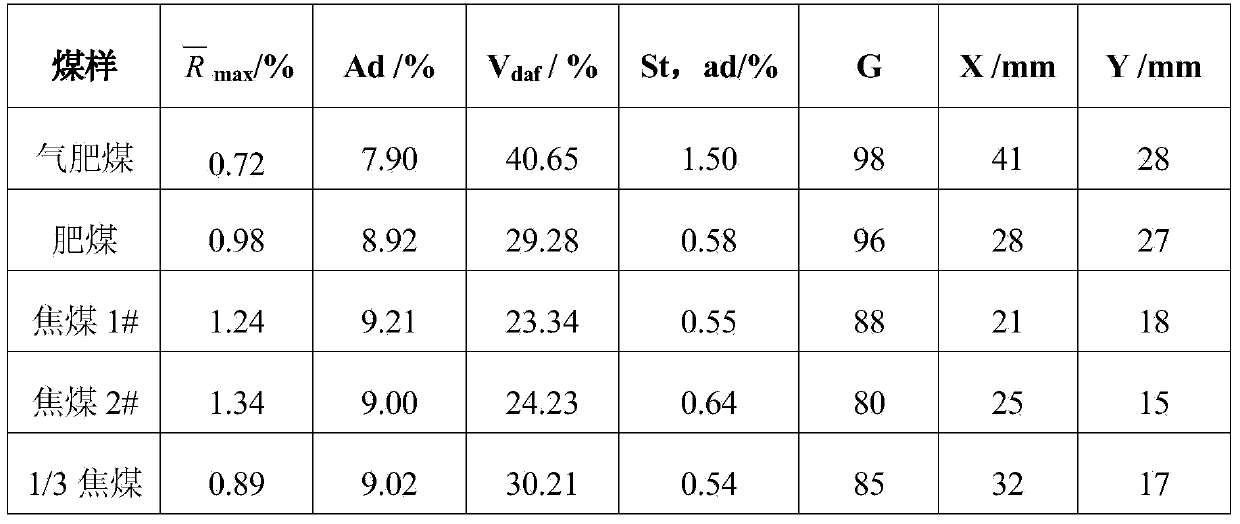

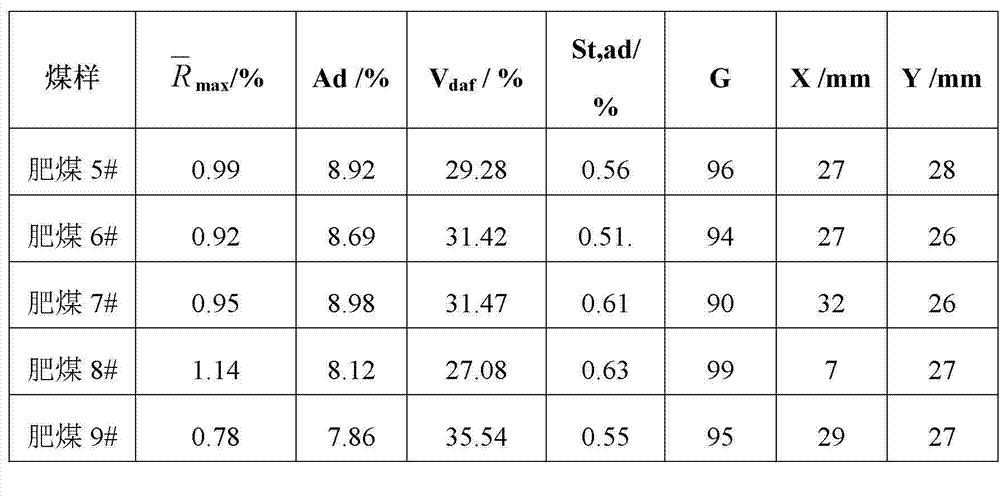

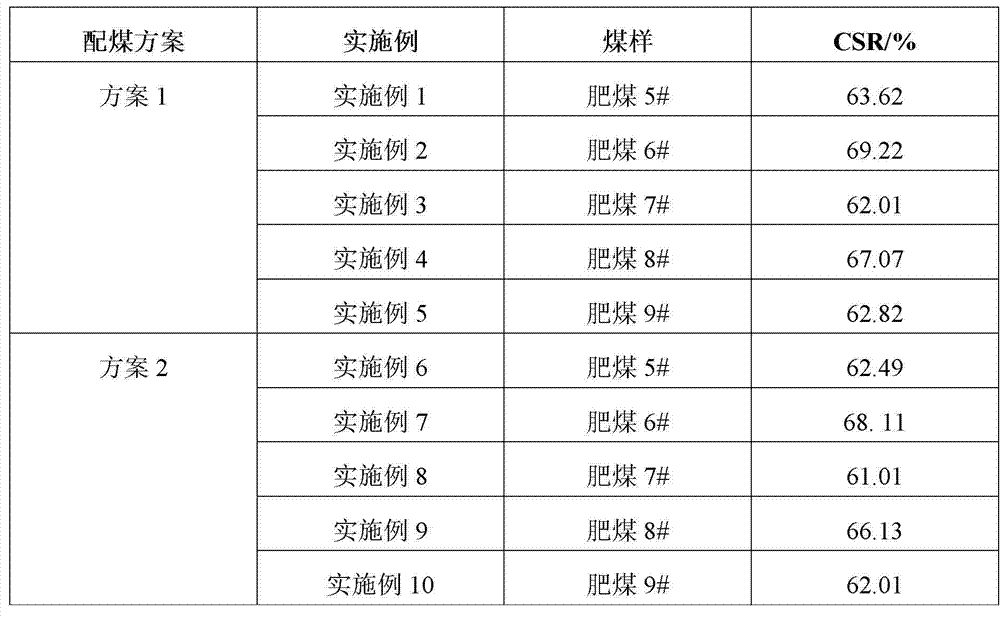

Method for high-volatile fat coal to participate in coking and blending coal

ActiveCN102827625ATake advantage ofSteady improvement in qualityCoke ovensUltimate tensile strengthCoal blending

The invention discloses a method for a high-volatile fat coal to participate in coking and blending coal with Vdaf greater than or equal to 34%, the method determines Gieseler fluidity of the high-volatile fat coal and Audiberts-Arnu dilatation b value; the high-volatile fat coal which is characterized in that the Audiberts-Arnu dilatation b value is greater than 120%, the maximum fluidity MF is greater than 50000ddpm, the solid soft region is greater than 100 DEG C is taken as a fat coal 1#, the high-volatile fat coal which is characterized in that the above index can not be satisfied is taken as a fat coal 2#; the fat coal 1# and the fat coal 2# are respectively used for high-quality fat coal, gas coal or 1 / 3 coking coal, the quality index of the mixed coal is satisfied by 26-28% of volatile component, less than 10% of ash content, -6-10% of Audiberts-Arnu dilatation b value and 375-385 DEG C of the softening temperature. The coal blending and coking are carried out according to the method of the invention, the coke quality can be effectively enhanced, the coal blending cost is reduced, and the coke intensity through coking is high.

Owner:武汉钢铁有限公司

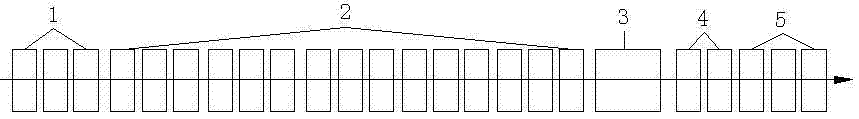

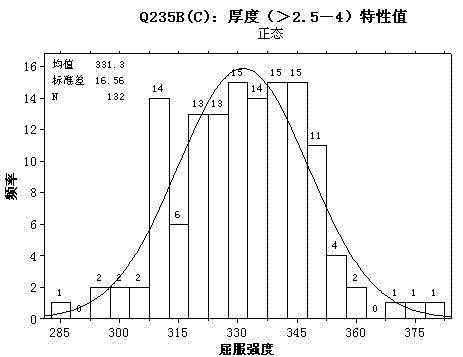

Hot-rolled board strip production line laminar cooling method

ActiveCN103286147ASteady improvement in qualityReduce smelting and rolling production costsWork treatment devicesMetal rolling arrangementsProduction lineLaminar cooling

The invention discloses a hot-rolled board strip production line laminar cooling method. A laminar cooling area between a finishing mill set and a coiling machine is divided into a rapid cooling section I, a coarse adjusting section, an air cooling section, a rapid cooling section II and a fine adjusting section. A board strip with the thickness of 2.5-12mm and the temperature of 850-900 DEG C is made to pass through the laminar cooling area with the speed of 8-10m / s. Water spraying pressure of a nozzle above the laminar cooling area is 0.068Mpa to 0.0735MPa, water spraying pressure of a nozzle below the laminar cooling area is 0.068MPa to 0.0735MPa, water spraying pressure of nozzles at the two sides of the laminar cooling area is 0.95Mpa to 1.05MPa, and air jetting pressure of an air jetting nozzle is 1MPa. When strip steel is conveyed on the laminar cooling area, the strip steel is cooled through the nozzles arranged above, below and at the two sides of the laminar cooling area. Cooling performance is good, a controlling effect is better, qualified performance of steel coil products is ensured, comprehensive quality of steel coils is stably improved, and refining and rolling production cost of the steel coil products is greatly reduced.

Owner:CHONGQING IRON & STEEL CO LTD

Preparation method of high-purity fudosteine

ActiveCN104418779ASteady improvement in qualityGood effectSulfide preparation1-PropanolReaction step

The invention provides a preparation method of a novel antitussive phlegm-eliminating drug high-purity fudosteine, wherein the preparation method includes the steps: (1) synthesizing an intermediate 3-bromo-1-propanol; (2) carrying out a reaction of cysteine hydrochloride with 3-bromo-1-propanol to obtain a crude product; and (3) carrying out crystallization refining on the obtained crude product to obtain the high-purity fudosteine. The domestic cheap easily-available raw materials of cysteine hydrochloride, hydrobromic acid and 1,3-propylene glycol materials are utilized, monitoring of a gas chromatograph, a liquid chromatograph and a refractometer is used for tracking a catalytic reaction process and a reaction terminal point. The preparation method has the advantages of less reaction steps, high selectivity, low pollution, low cost and stable quality, and is suitable for industrialized production.

Owner:TOPFOND PHARMA CO LTD

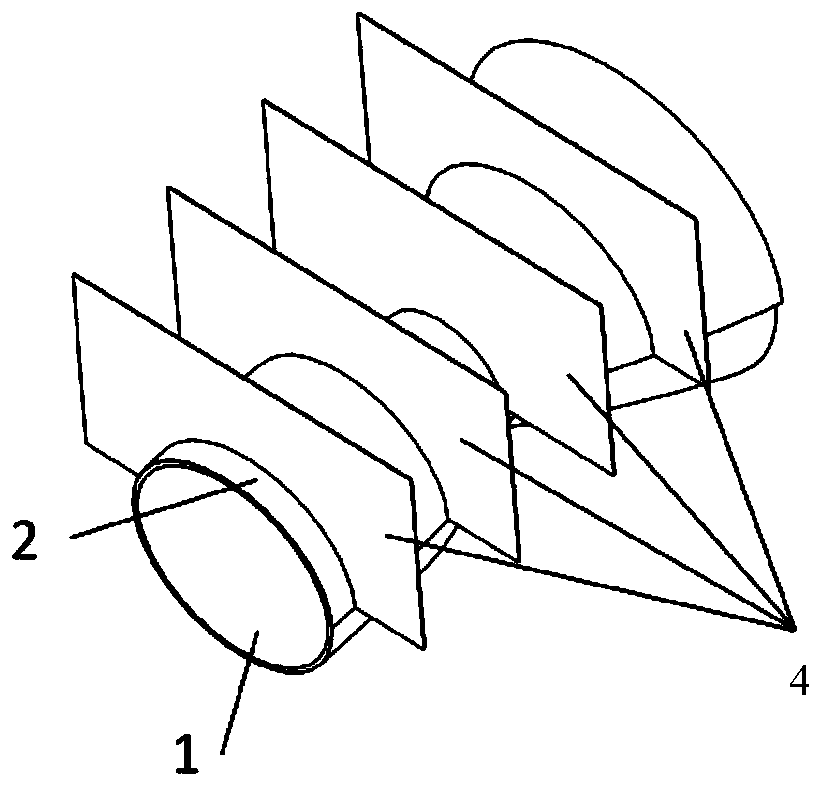

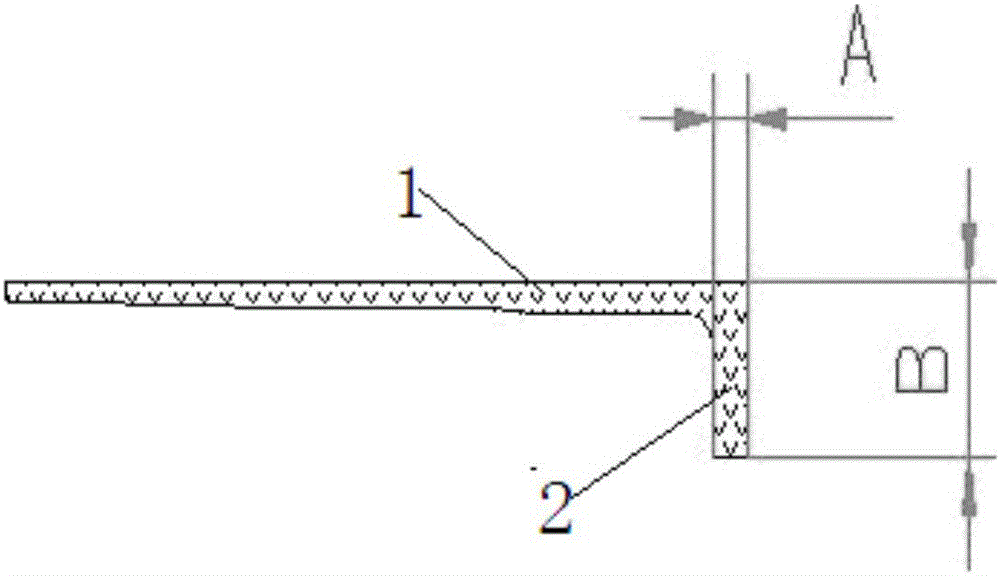

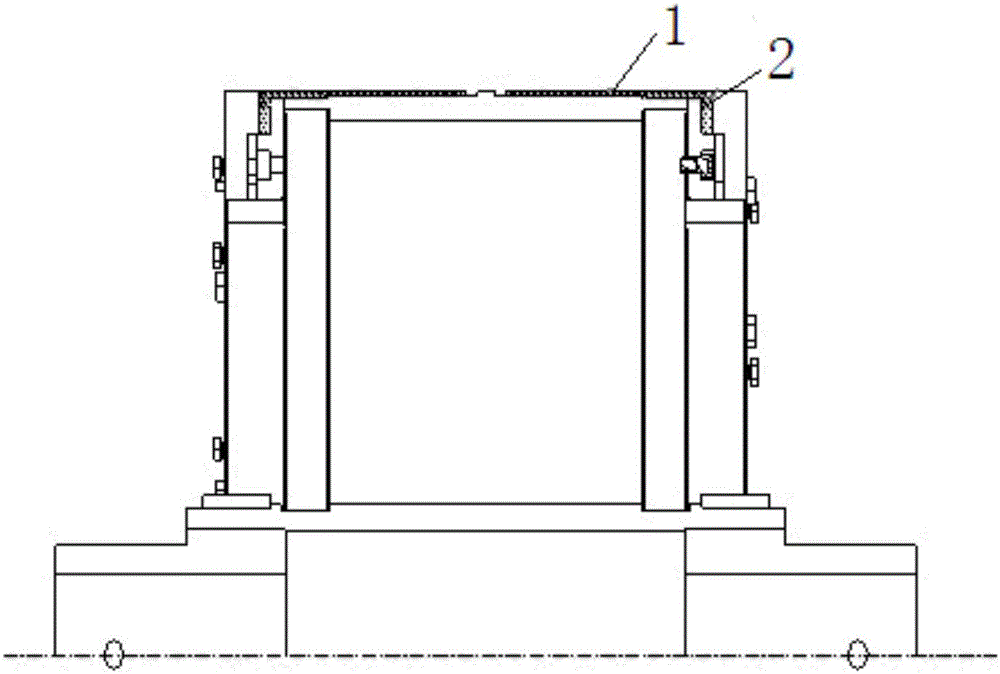

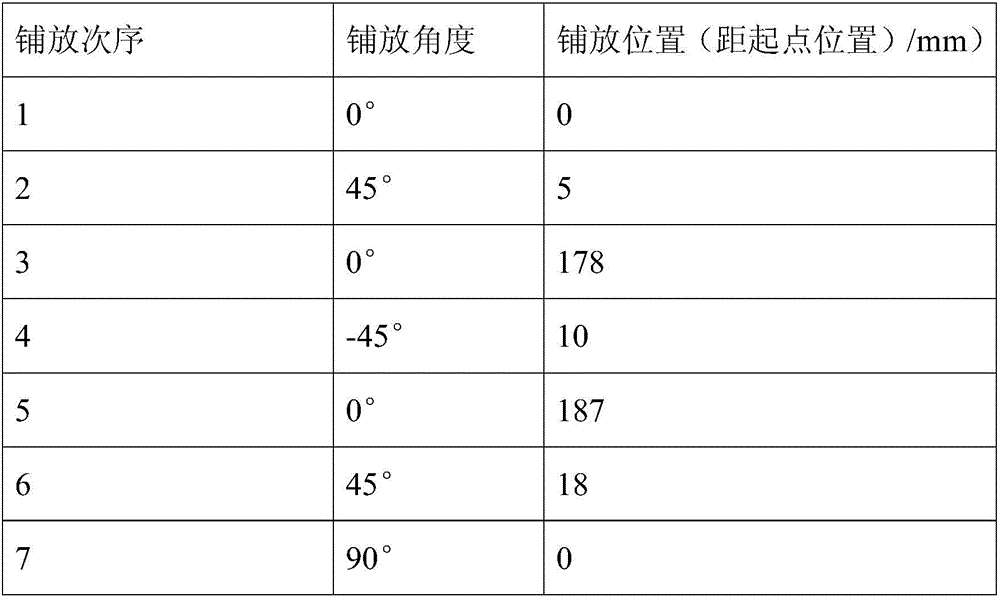

Automatic laying molding method for composite connection skirt

ActiveCN106515045ARealize automatic laying and formingControllable and adjustable angleDomestic articlesYarnEngineering

The invention discloses an automatic laying molding method for a composite connection skirt. The automatic laying molding method comprises the steps of 1, manufacturing a molding mold; 2, cutting preimpregnation filaments; 3, laying the preimpregnation filaments on the surface of the molding mold automatically with a laying-winding integrated machine, wherein in the automatic filament laying process, after the filaments are completely laid on an annular face through a laying head, the filaments are laid to corners between end faces and the annular face, a compression roller is made to break away from the surface of the molding mold, filament laying is conducted in a suspended manner for the height equivalent to 1-2.5 times the end face height through the laying head, filament bundles are cut off, then the molding mold rotates for the angle equivalent to one time the yarn tape width, the laying head returns to the starting laying point, after single-layer filament laying action is completed, the preimpregnation filaments on the end faces are compacted, and the filaments are laid circularly layer by layer till laying is completed; 4, conducting curing; and 5, conducting demolding. By means of the automatic laying molding method for the composite connection skirt, automated production is technologically achieved; the production cycle is greatly shortened, and production efficiency is greatly improved; and a connection skirt product obtained through the automatic laying molding method is smooth in surface, and a skirt body is precise in dimension and high and stable in quality.

Owner:湖北三江航天江北机械工程有限公司

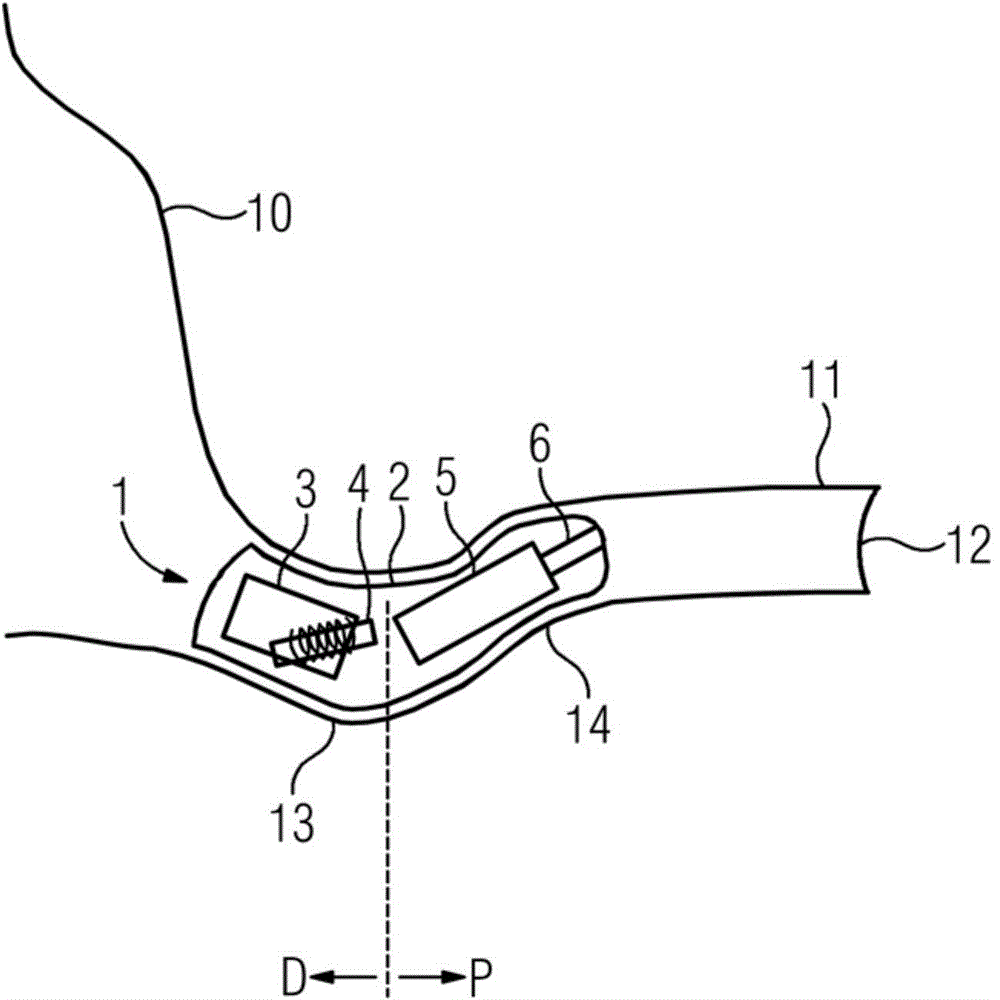

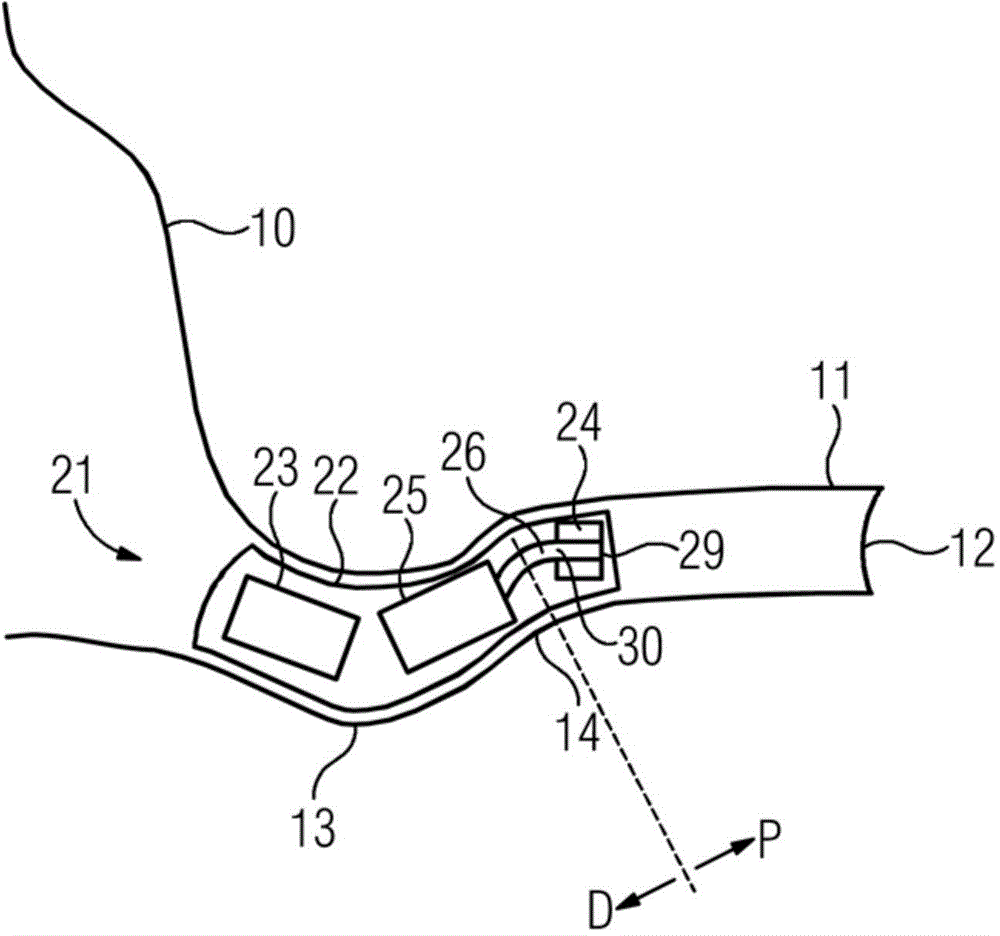

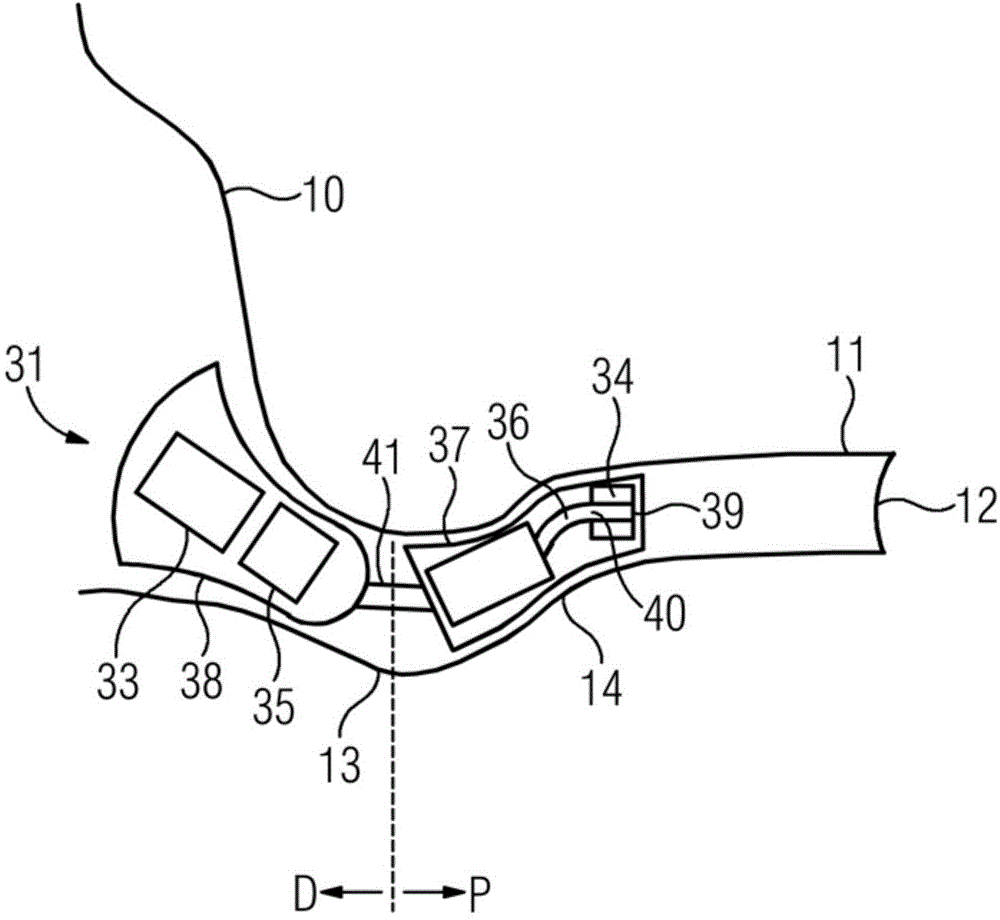

Binaural Hearing Instrument And Earpiece

ActiveCN104066042AInterference Affects StabilitySteady improvement in qualityCompletely in canal hearing aidsEar supported setsEngineeringHeadphones

The invention relates to a binaural hearing instrument and an earpiece. The binaural hearing instrument and an earpiece for the binaural hearing instrument are enabled for broadband wireless data transmission to a further binaural hearing instrument. Wireless broadband binaural data transmission with high bandwidth and low resource requirement is afforded, while the devices can be manufactured easily and inexpensively. The hearing instrument has a housing, a signal processor, a receiver and an antenna for binaural data transmission. The housing can be worn at least partly in an auditory canal. A distal section houses the signal processor and the receiver. A proximal section adjacent to the eardrum and separated spatially from the proximal section houses the antenna. The antenna is disposed between the receiver and the sound outlet as far in the auditory canal as possible. The distance between the antennas of the two binaural hearing instruments is reduced by 1 to 2cm. regulated minimum distance is guaranteed between the antennas and the earpiece and th hybrid and compared with conventional positioning and the bit error rate is significantly improved.

Owner:SIVANTOS PTE LTD

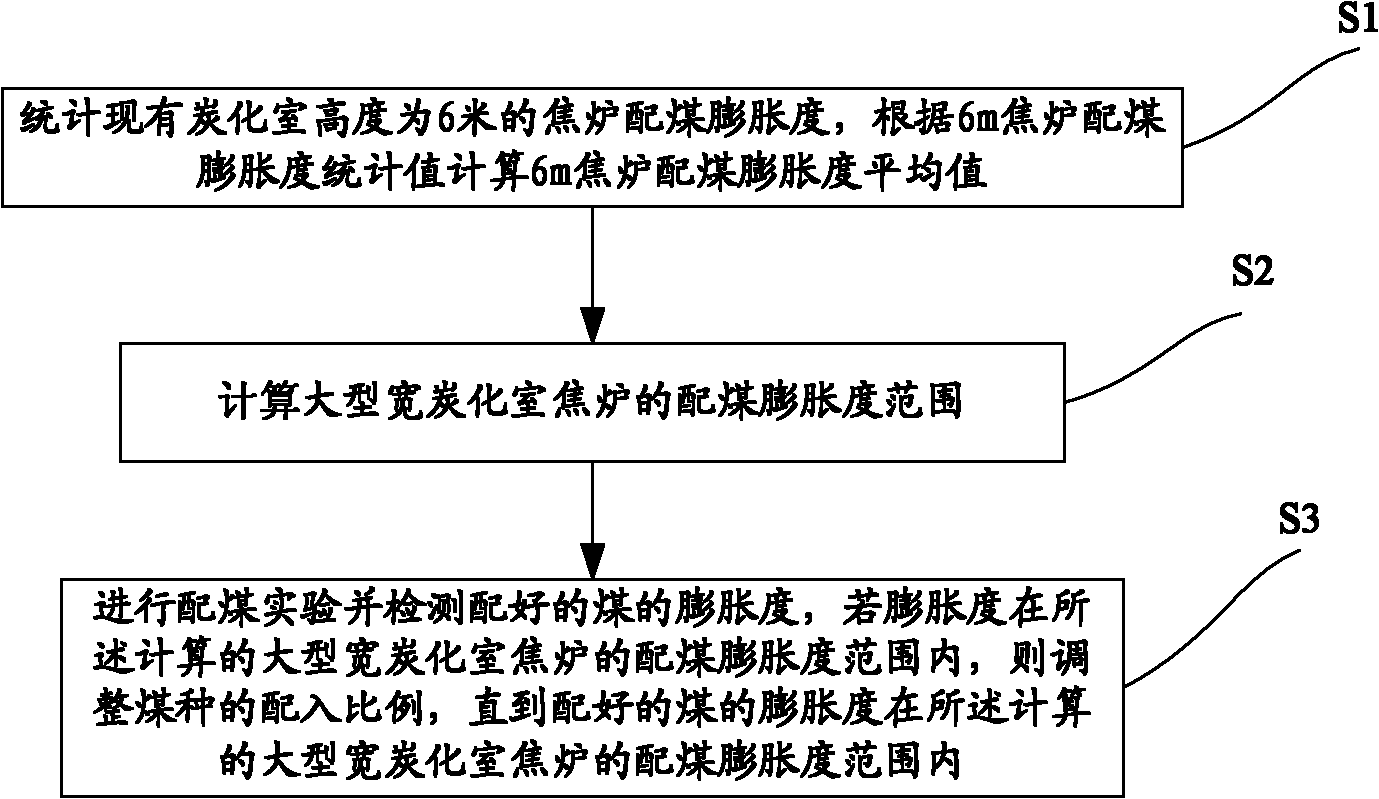

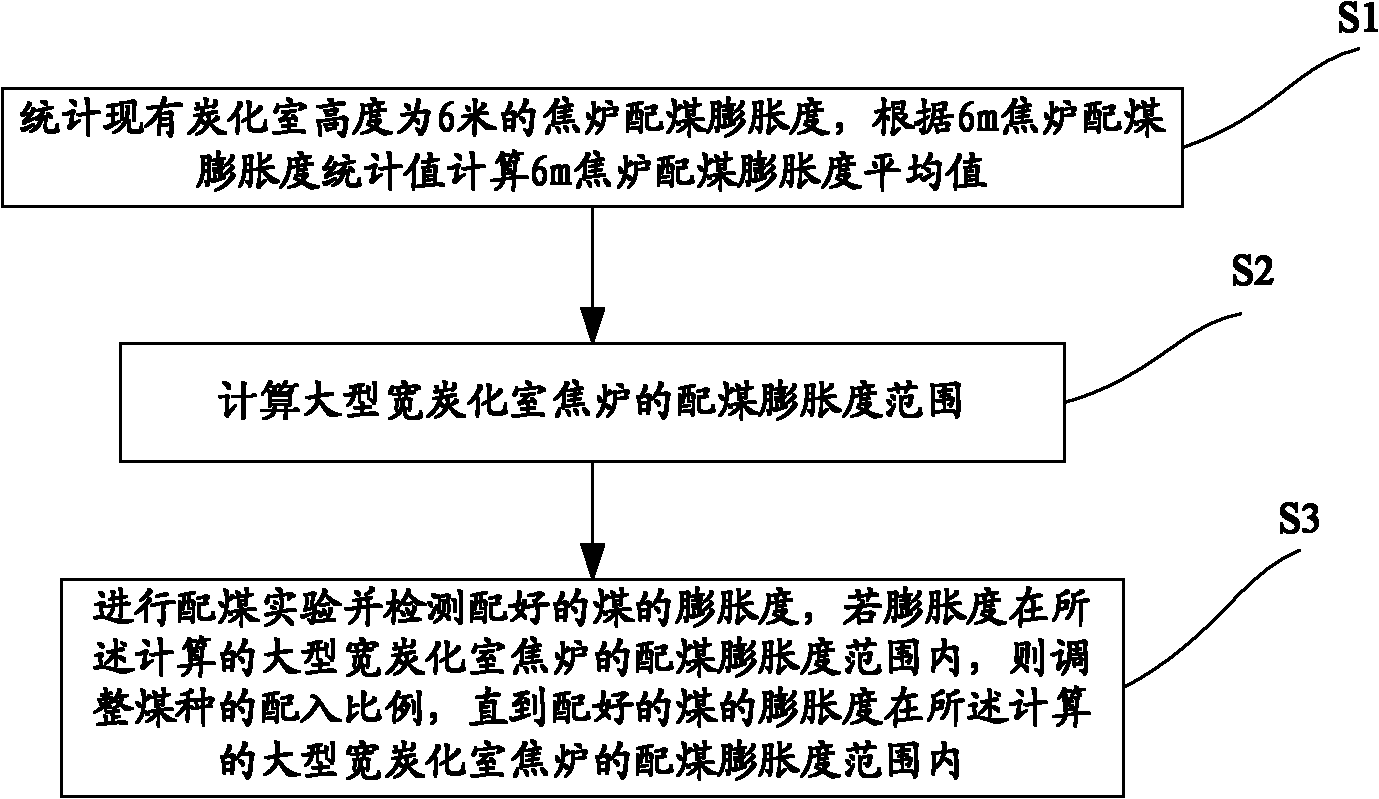

Coal blending method for controlling coal as fired dilatation of large-scale coke oven with wide coking chamber

The invention discloses a coal blending method for controlling coal as fired dilatation of a coke oven with a large-scale wide coking chamber. The method comprises the following steps: carrying out statistics on coal blending dilatation of the existing coke oven with a 6-meter-high coking chamber, and calculating an average value of the coal blending dilation of the 6-meter-high coke oven in accordance with the statistic of the coal blending dilatation of the 6-meter-high coke oven; calculating the coal blending dilatation range of the coke oven with the large-scale wide coking chamber; correspondingly increasing the proportion of varieties of high-dilatation coking coals for coal blending in accordance with the calculated coal blending dilatation range of the coke oven with the large-scale wide coking chamber, determining the obtained coal blending dilatation; if the dilatation is in the control range, determining a coal blending scheme to carry out coal blending coking; and if the dilatation is not in the control range, correspondingly increasing and decreasing the proportion of varieties of high-dilatation coking coals, carrying out coal blending and dilatation detection until the measured value of the coal blending dilatation in the obtained coal blending scheme is in the control range, namely, the coal blending scheme for the coke oven with the large-scale wide coking chamber. The coals blended by the method are subject to reasonable dilation in the large-scale wide coking chamber in the coking process, thus improving the coke quality.

Owner:武钢集团有限公司

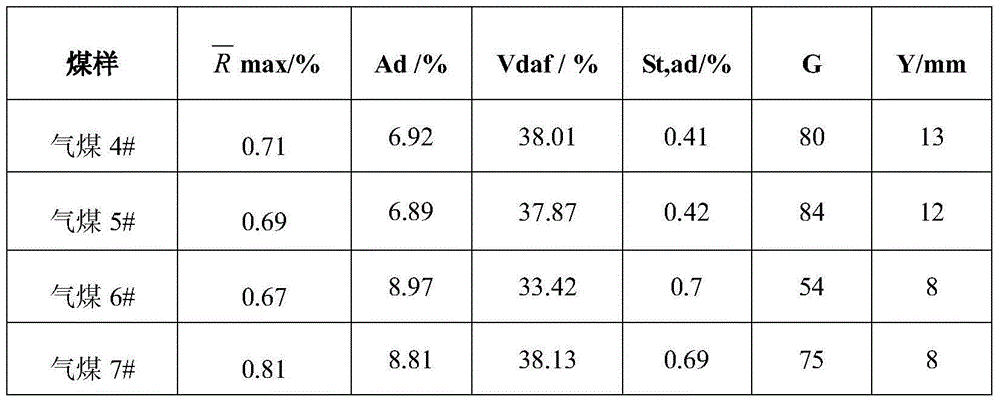

Method for establishing gas coal quality evaluation model

ActiveCN104102821AClarify the degree of pros and consBenefit from reasonable positioningSpecial data processing applicationsUltimate tensile strengthCoal

The invention discloses a method for establishing a gas coal quality evaluation model. The method comprises the following steps: 1) setting P as a gas coal quality evaluation index, and setting P=Pj+K1*(M-Mj)+K2*(N-Nj), wherein M, N, Mj and Nj respectively refer to the granular mosaic structure proportion of to-be-evaluated gas coal, the proportion sum of isotropic and inert structures of the to-be-evaluated gas coal, the granular mosaic structure proportion of standard gas coal and the proportion sum of isotropic and inert structures of the standard gas coal; K1 and K2 are constants, and are associated with the strength CSR of coke after thermal reaction by the following formula: CSR=K+K1*M+K2*N, wherein K is a constant; 2) obtaining K, K1 and K2 by substituting values of the granular mosaic structure proportions, the proportion sums of the isotropic and inert structures of three different groups of gas coal, and the strength CSR of coke after thermal reaction into the second formula in the previous step; obtaining P by substituting K1 and K2 and indexes of Mj and Nj of the standard gas coal into the first formula, wherein the greater the P value is, the better the gas coal quality is. By adopting the method, the quality of gas coal of different sources can be determined favorably, coking enterprises can use gas coal of different sources reasonably, the coke quality stability is improved favorably, and the thermal fluctuation is reduced.

Owner:武汉钢铁有限公司

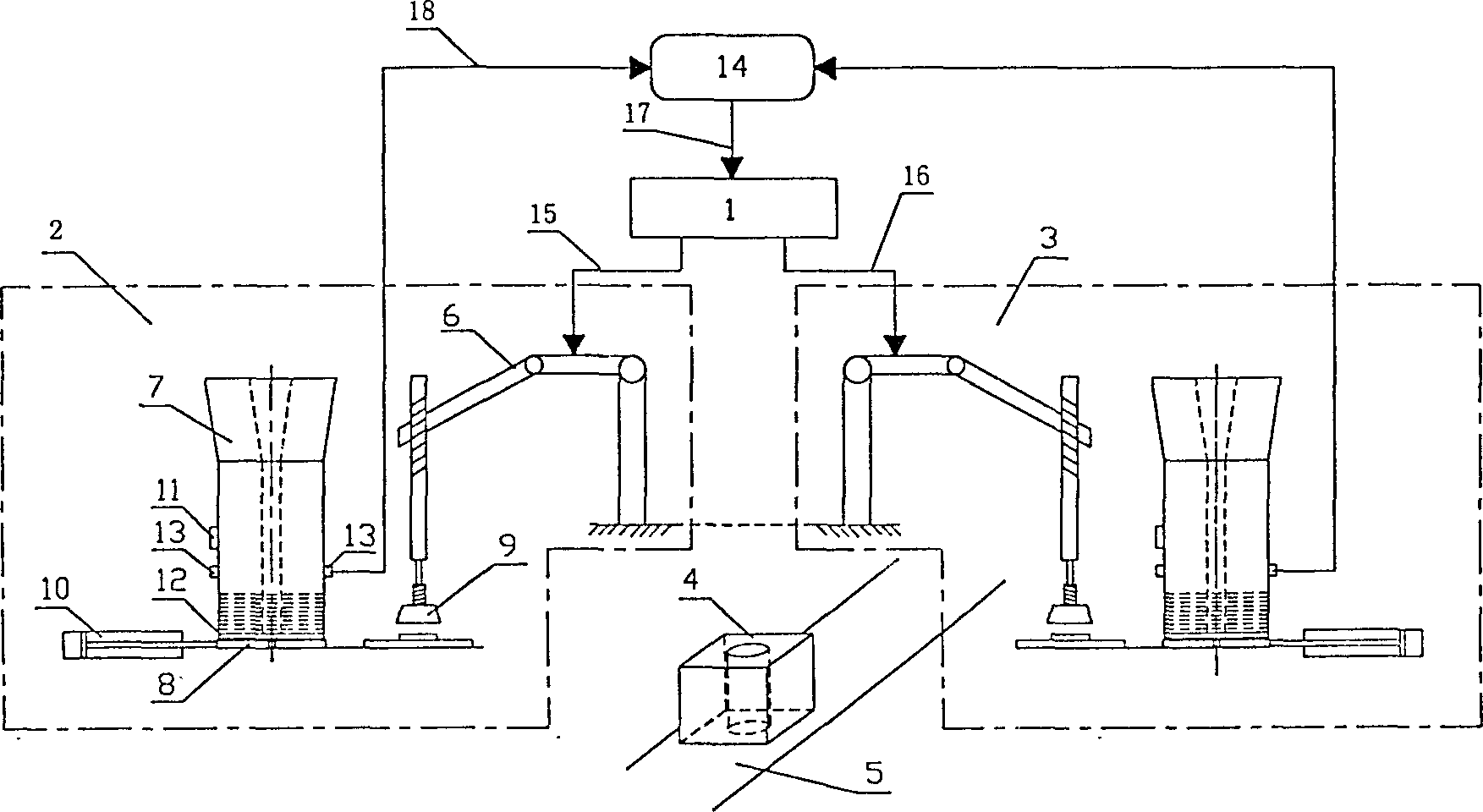

Automatic production line for assembling block composted in splinter shaped

InactiveCN1415408AIncrease productivityHigh degree of automationPressurized chemical processProduction lineWood splinter

An automatic production line for assembling the laminated sheet block is composed of manipulator controller, graphite sheet assembling unit, catalyst sheet assembling unit, assembling block and conveying belt. Its advantages are high productivity, high quality of product and high autoamtic level.

Owner:SHANGHAI JIAO TONG UNIV

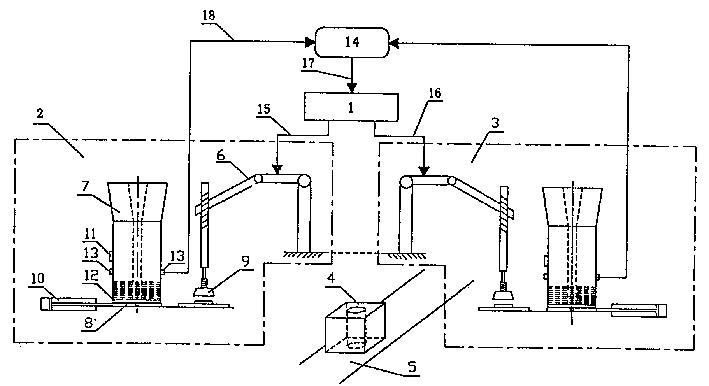

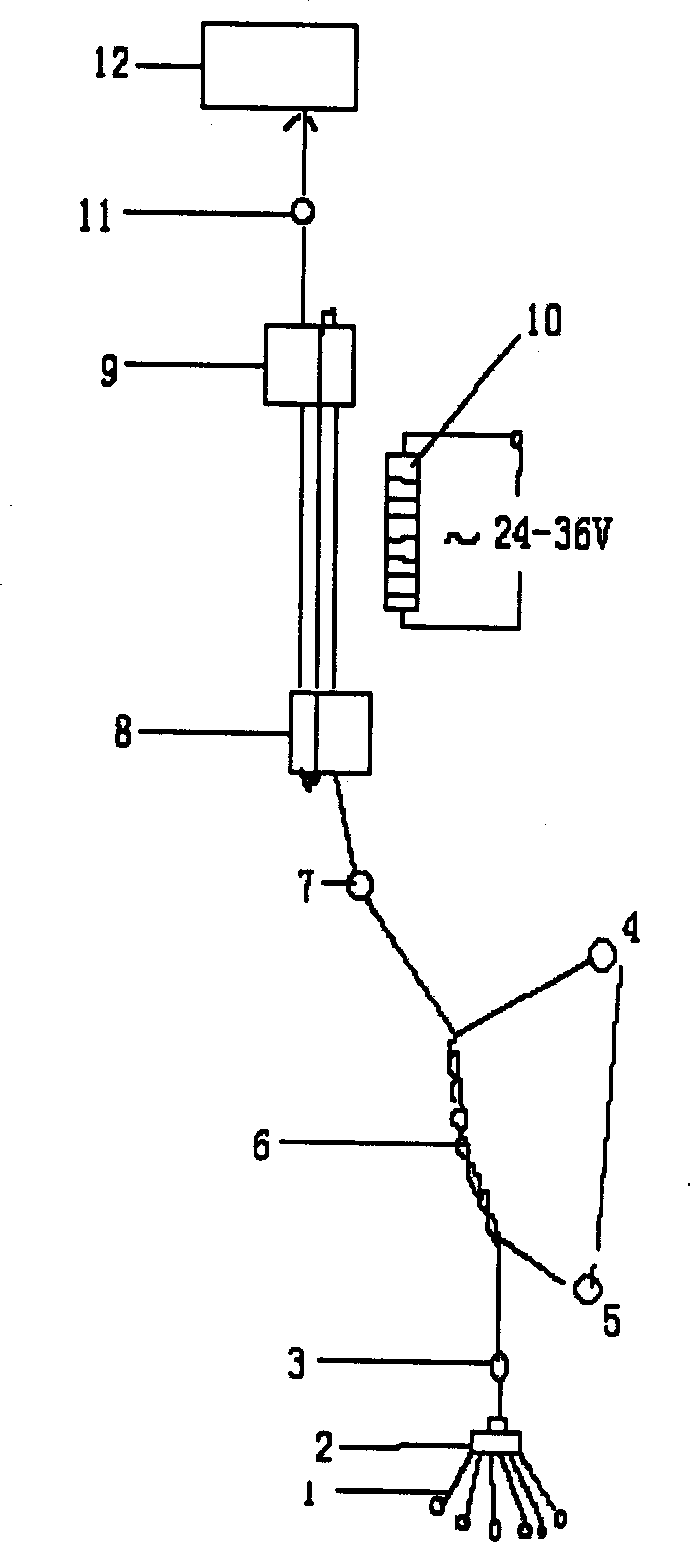

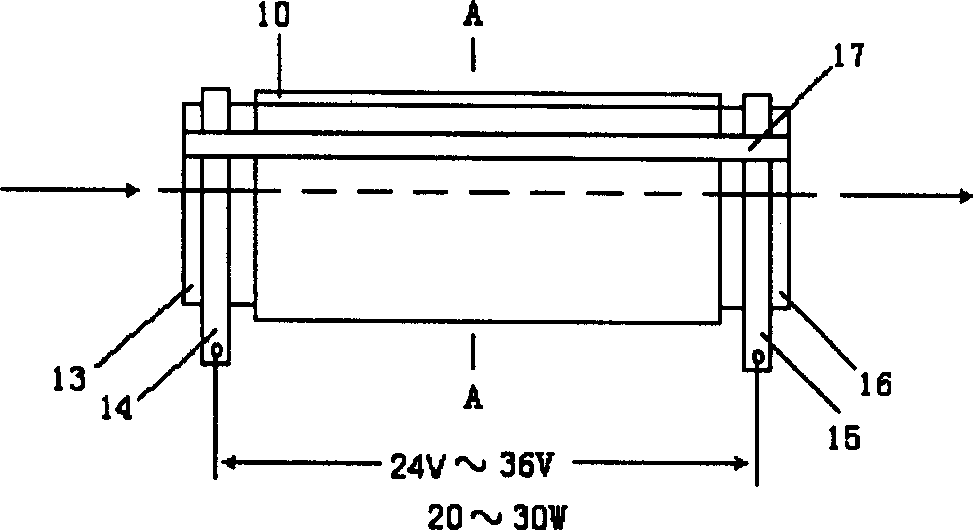

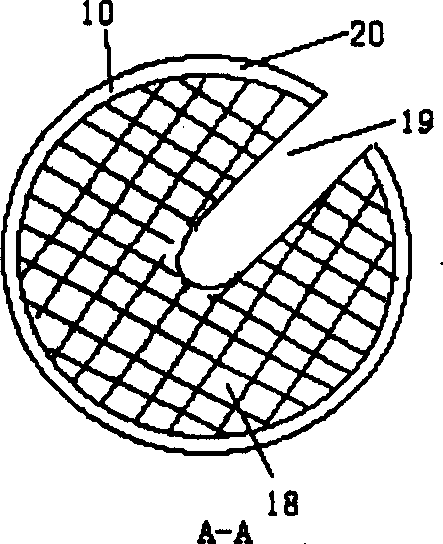

Drying equipment for filature

InactiveCN1446948ADry evenlyLight in massDrying solid materials with heatSilk reelingCopperConductor Coil

A drier for reeling silk features that its upper and lower multi-groove pulleys are respectively connected to the silk-guiding hooks for winding and locating, and the drier arranged at side of multi-groove pulley is composed of ceramic holder, screw rod copper rod, quartz tube, tungsten wire passing in the quartz tube, and electrothermal wire. Its advantages are simple structure high drying quality and high heat efficiency up to 50-55%.

Owner:SICHUAN UNIV TIANYOU BIOLOGIC ENG

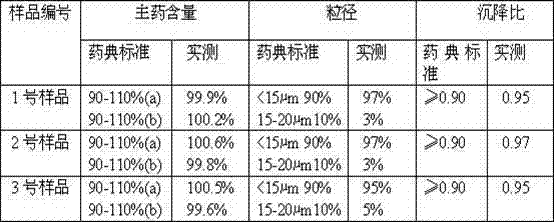

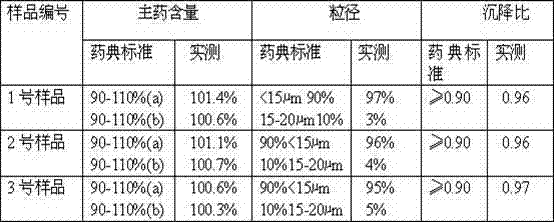

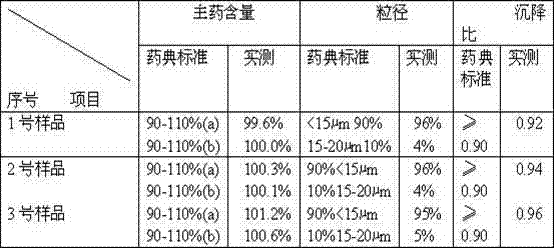

Method for preparing compound amoxicillin and potassium clavulanate injections

ActiveCN102846606AFast absorptionGood curative effectAntibacterial agentsSolution deliveryAmoxicillin-clavulanate potassiumPhysical chemistry

The invention discloses a novel method for preparing compound amoxicillin and potassium clavulanate injections. The novel method includes the steps of heating oil for injection to 130-150 DEG C, insulating, sterilizing and then cooling the oil for injection to the temperature of 60-90 DEG C; adding aluminium stearate into a part of the sterilized oil for injection, stirring, insulating, cooling to the room temperature after the mixture is uniform, filtering, slowly mixing the mixture with amoxicillin and potassium clavulanate mixture with a certain mass ratio while stirring, and stirring so as to disperse the mixture uniformly until the mixture is completely dispersed into suspension; and refining the mixture via a ball mill, replenishing the sterilized oil for injection to reach a full dose, and continuing stirring till uniform so as to obtain the compound amoxicillin and potassium clavulanate injections. Compared with the prior art, the novel method for preparing the compound amoxicillin and potassium clavulanate injections is simple in preparation process, raw materials and auxiliary materials are low in prices and easy to obtain, the prepared injections are stable in performance and obvious in treatment effect, and is high in cost performance as compared with a like product, the quality of the prepared injections is higher than the quality specified in relative standards of the current pharmacopoeia, and the prepared injections are suitable to be industrially produced in batches.

Owner:SHANGHAI TONGREN PHARM CO LTD

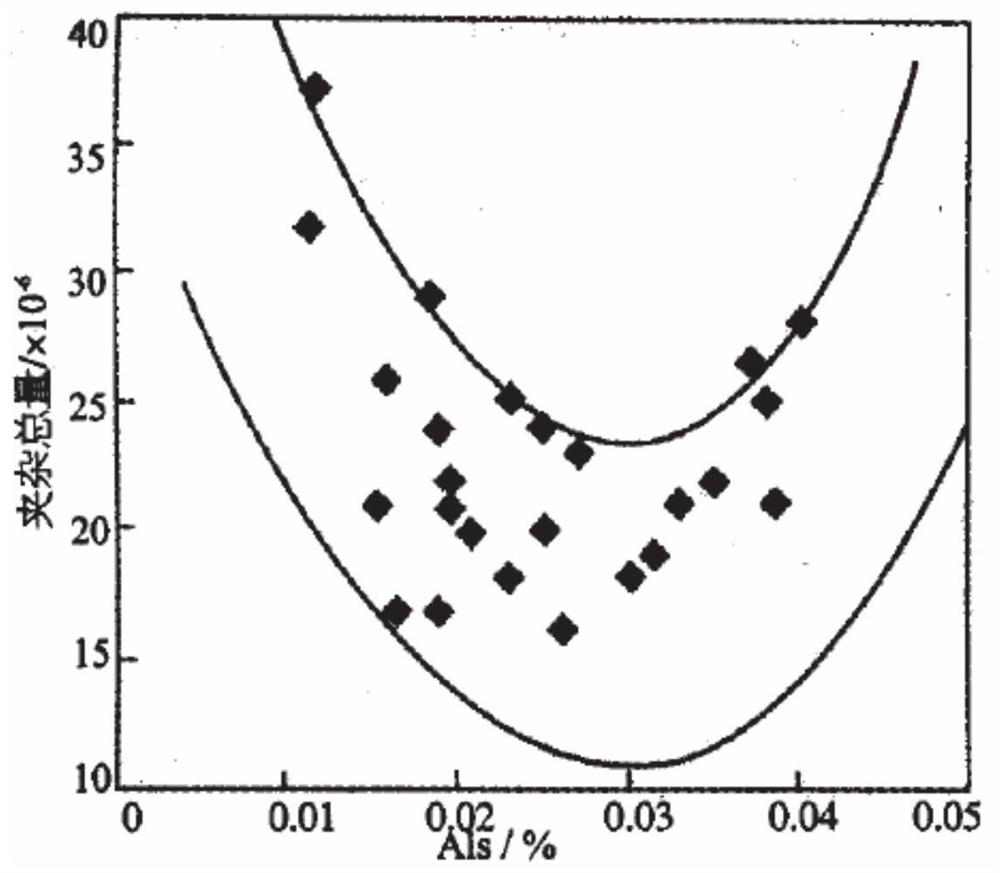

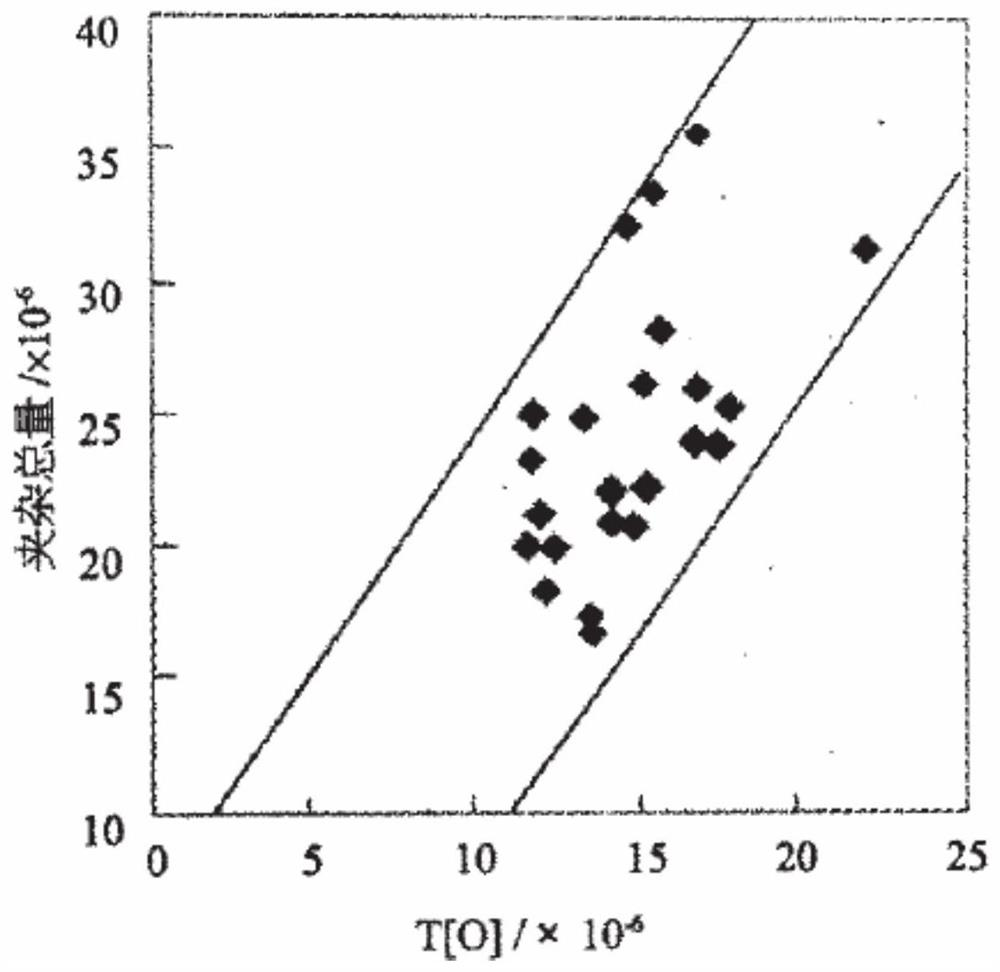

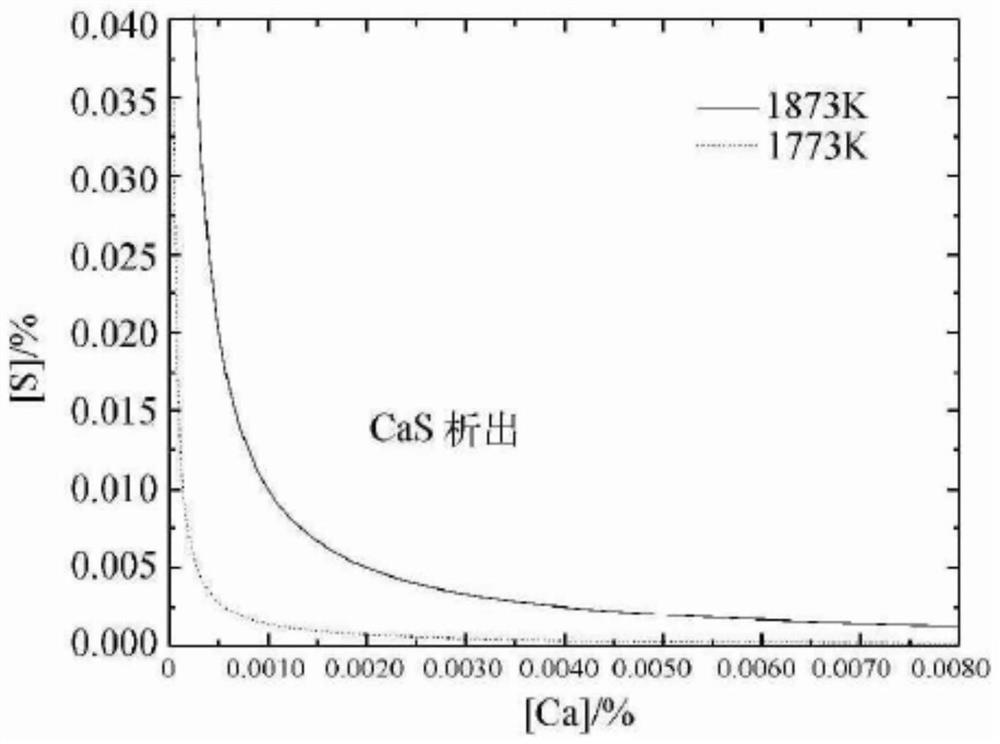

Control method of cold heading steel flocculent flow

The invention relates to the field of cold heading steel, in particular to a control method of a cold heading steel flocculent flow. The cold heading steel ML08AL comprises the following chemical components of, in percentage by mass, 0.06% to 0.09% of C, small than or equal to 0.08% of Si, 0.35% to 0.45% of Mn, small than or equal to 0.017% of P, small than or equal to 0.015% of S, 0.02% to 0.05%of Als, 0.03% to 0.05% of N, and the balance Fe. The production process comprises the following steps of preparing an iron mixer, pretreating molten iron, blowing a converter in a top-bottom combinedblowing manner, pre-deoxidizing molten steel, refining in an LF furnace and continuously casting square billets. During LF furnace refining, slag blocking and tapping are conducted, the thickness of slag in a steel ladle is controlled to be not larger than 50 mm, carbide slag and aluminum particles are mixed for deoxidation, the atmosphere in the LF furnace is controlled to be a reducing atmosphere, and argon bottom blowing and stirring are conducted. According to the method, the problem of cold upsetting cracking of the cold heading steel M108AL caused by many inclusions in the steel is solved, the non-metallic inclusions are graded, the grade is mainly 0.5 and 1.0, the grade 1.5 or above account for 5% or below of the total detected amount, the grain size reaches 8.5 or above, and the cold upsetting performance meets the requirement of 1 / 4.

Owner:BENGANG STEEL PLATES

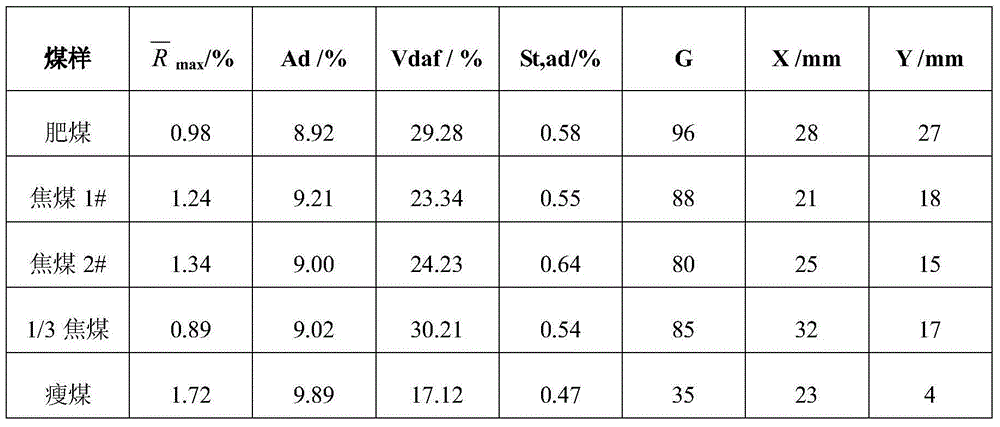

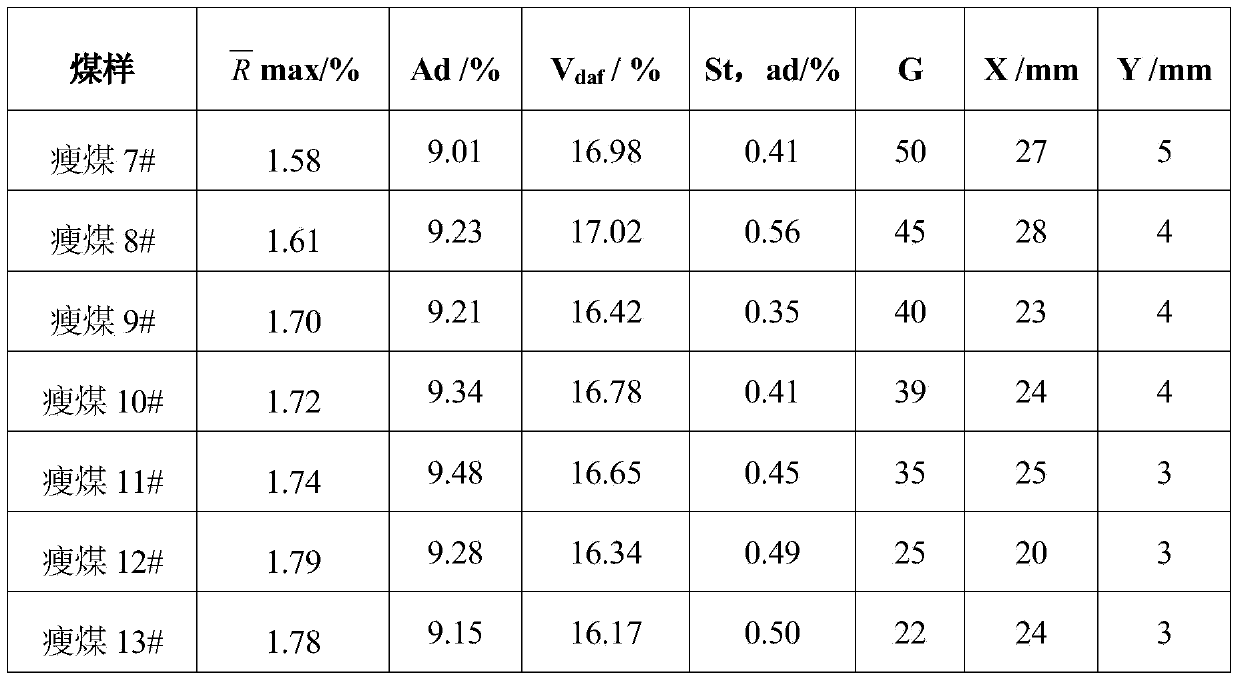

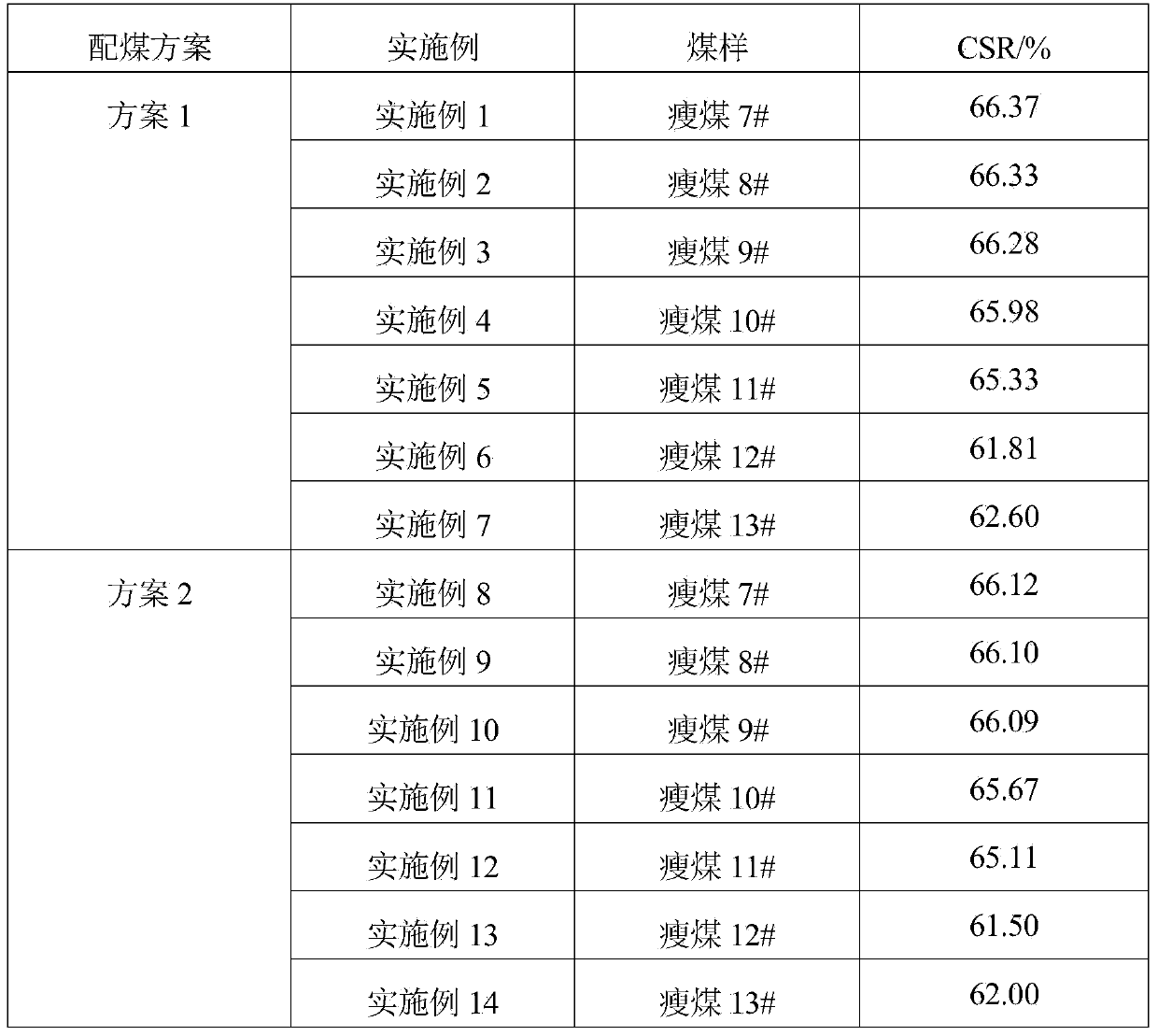

Method for establishing lean coal quality evaluation model

ActiveCN103995964AClarify the degree of pros and consBenefit from reasonable positioningSpecial data processing applicationsFiberEngineering

The invention discloses a method for establishing a lean coal quality evaluation model. The method includes the following steps that firstly, P is set as a lean coal quality evaluation index, wherein P = Pj + 10 * [K1 (M-Mj) + K2 * (N-Nj)], M, N, Mj and Nj represent a coarse grain mosaic structure proportion of lean coal to be evaluated, the sum of fiber and sheet structure proportions of the lean coal to be evaluated, a coarse grain mosaic structure proportion of reference lean coal, and the sum of fiber and sheet structure proportions of the reference lean coal respectively, K1 and K2 are constants, the relation between K1, K2 and strength CSR after thermal reaction of the lean coal and coke is represented by the following relational expression: CSR= K+ K1 * M + K2 * N, and K is a constant; secondly, the numerical values of M, N and CSR of three different groups of the lean coal are substituted into the second formula in the first step, and then K, K1 and K2 are obtained; the numerical values of K1, K2, Mj, Nj, M and N are substituted into the first formula, P is obtained, and the larger P is, the better the lean coal quality is. The degree of the quality of lean coal from different sources can be determined, the lean coal from different sources can be reasonably distributed and utilized by coke making enterprises, the quality of the coke is stably improved, and the fluctuation range of thermal performance is reduced.

Owner:武汉钢铁有限公司

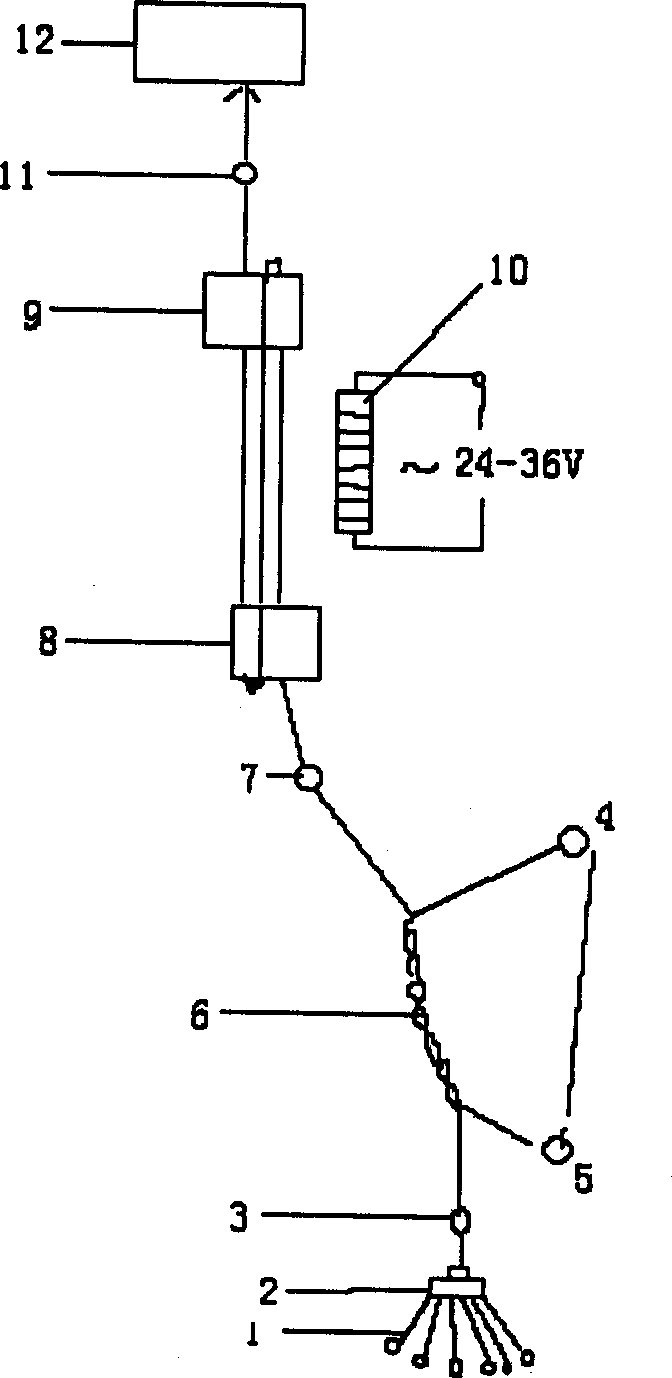

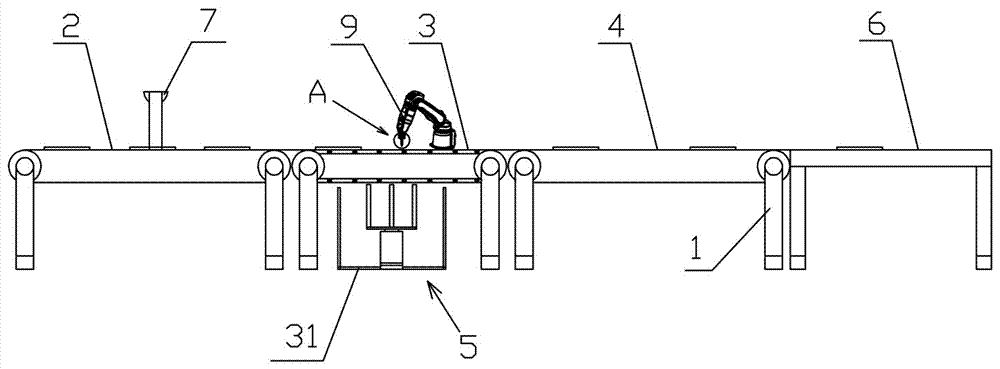

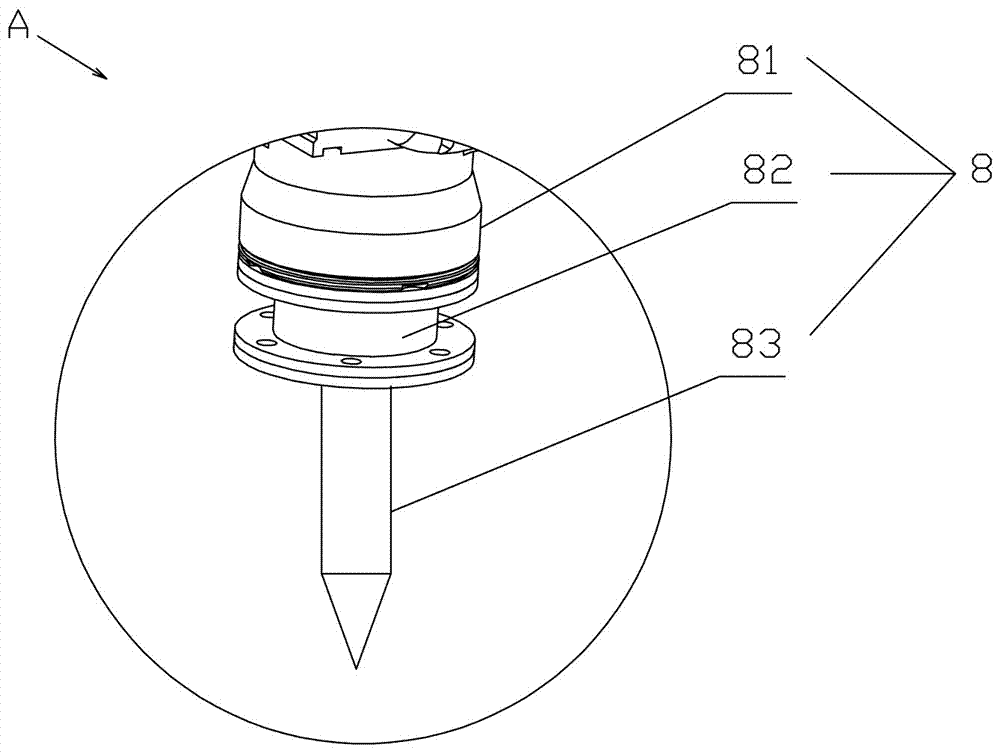

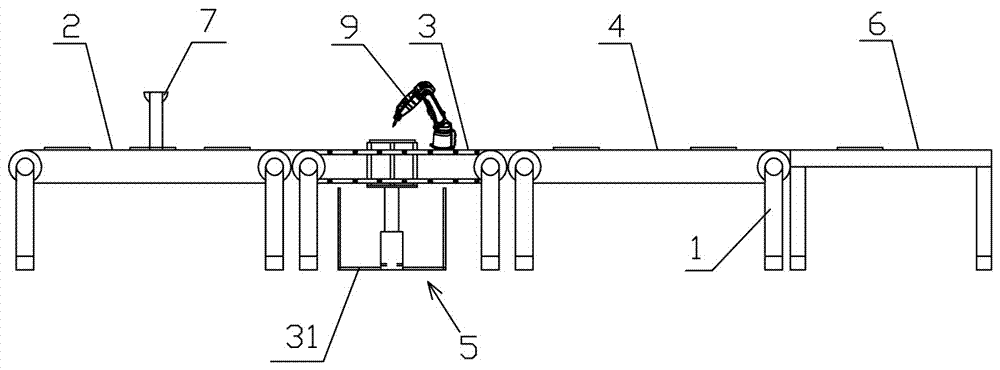

Overflowed sole glue automatically ultrasonic-cutting robot and application method thereof

InactiveCN107455846AAchieve upgrades and improvementsRealize intelligent technical requirementsShoe gluingMechanical engineeringRobot

The invention discloses an overflowed sole glue automatically ultrasonic-cutting robot. The overflowed sole glue automatically ultrasonic-cutting robot comprises a robot frame, the robot frame is provided in a matched mode with a first conveying belt, a second conveying chain and a third conveying belt which are sequentially connected, wherein the first conveying belt and the third conveying belt are fixedly assembled and arranged on the left and the right of the second conveying chain respectively, the lower portion of the second conveying chain is matched with a lifting device which is used for vertically lifting up and down soles conveyed onto the second conveying chain, and the conveying tail end of the third conveying belt is provided with a collecting table. The invention also discloses an application method of the overflowed sole glue automatically ultrasonic-cutting robot. The overflowed sole glue automatically ultrasonic-cutting robot achieves intelligent identification, judgment and screening as well as sole glue spraying and polishing, and safely, environmentally and intelligently polishes the soles and cuts glue, thereby being of innovative significance to the field of shoe manufacturing and bringing competitive technical advantages to enterprises.

Owner:FUJIAN TIEGONG INTELLIGENT ROBOT CO LTD

Drying equipment for filature

InactiveCN1446949ADry evenlyLight in massDrying solid materials with heatSilk reelingWater contentEngineering

A drier for reeling silk has winding unit and silk-guiding hooks for locating. The upper and lower multi-groove pulleys are respectively connected to the silk-guiding hooks for winding and locating. A PTC drier arranged at side of said pulleys has the coated far infrared layer in the thermosensitive semiconductor ceramic channel and the joint clamps at both ends. Its advantages are sipmle structure high drying quality and high thermal efficiency up to 50-55%.

Owner:SICHUAN UNIV TIANYOU BIOLOGIC ENG

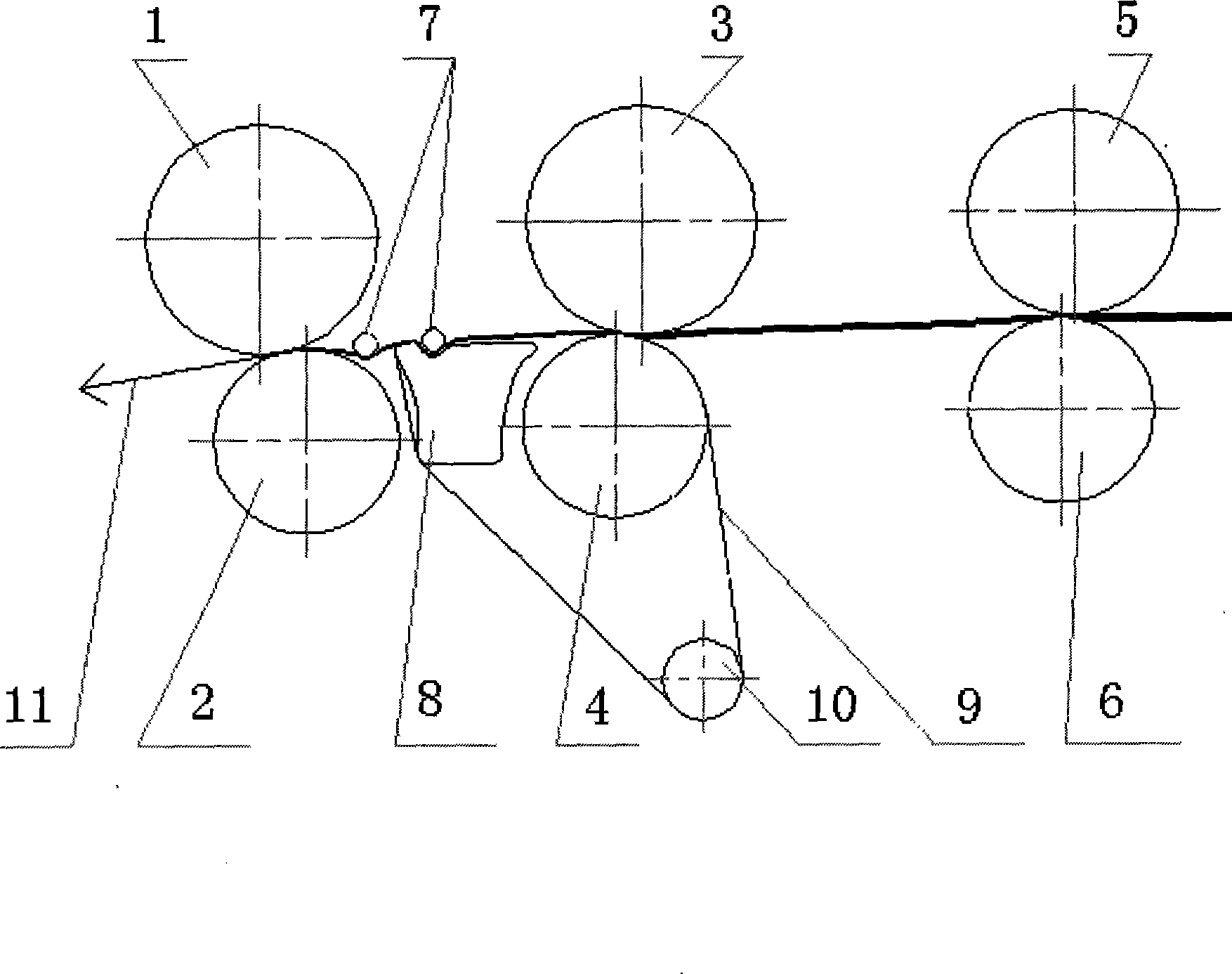

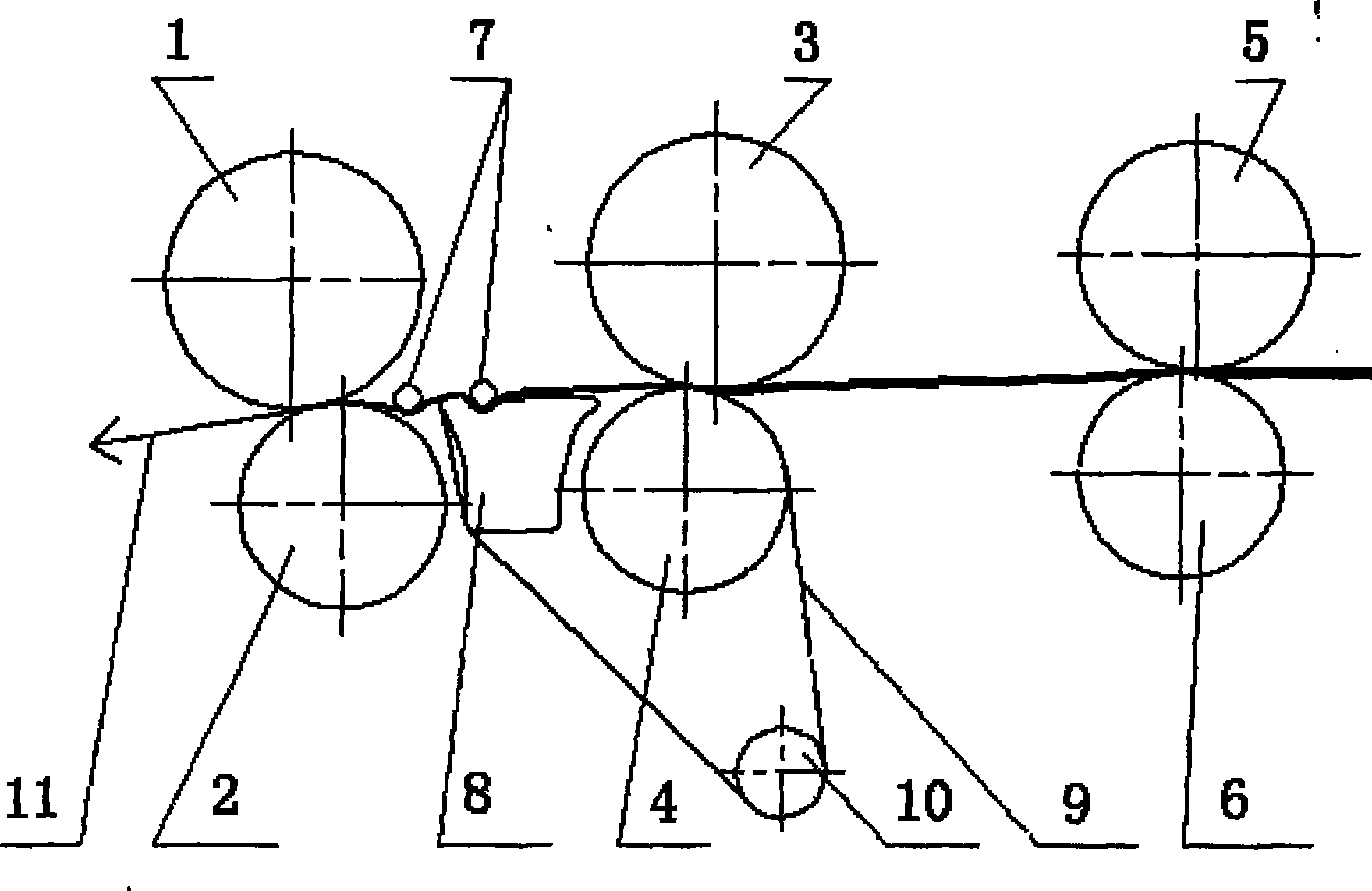

Spinning device

The invention relates to a spinning device which solves not only the defects of complicated equipment, high production cost and great difficulty in managing of the existing compact spinning device, but also the defect that an elastic jaw with the yarn quality in a main traction area of spinning. The concrete method comprises the following steps: in a front traction area of a normal spinning machine, all components in the elastic jaw are removed, and a group of control rods, a negative pressure tube and a grid ring are additionally arranged. When working, fiber strands in the main traction area gather on the surface of the grid ring under the force of an air suction groove on the negative pressure tube, and the fiber strands move forwards along with the grid ring; and when almost reaching a front jaw, the fiber strands are held softly by a plurality of pressure rods and the grid ring until the fiber strands are sent to the front jaw. The fiber control in the traction area is more reasonable and steadier, thus ensuring the speed change point of the fiber to be more forward, concentrated and steady and reducing the yarn filoplume more than 3mm greatly. The device has the advantages of compact spinning and overcomes the defects of high investment cost and high production cost of the compact spinning.

Owner:潘思敏

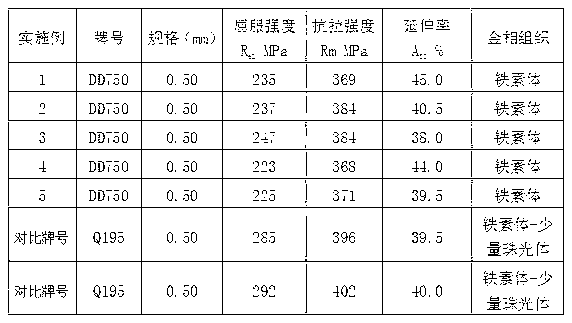

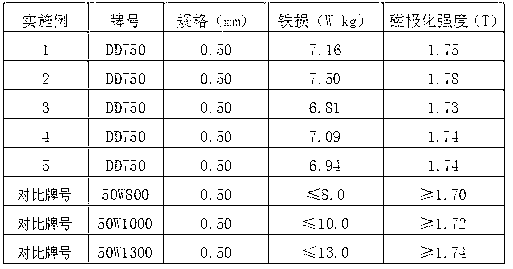

DD750 cold-rolled low-carbon steel strip for electricians, and manufacturing method thereof

The invention discloses a DD750 cold-rolled low-carbon steel strip for electricians, and a manufacturing method thereof. The DD750 cold-rolled low-carbon steel strip comprises the following chemical components in percentage by weight: no more than 0.015% of C, 0.20-0.45% of Mn, 0.15-0.60% of Si, 0.040-0.100% of P, no more than 0.015% of S, and the balance of Fe and inevitable impurity elements. The manufacturing method comprises the following steps of: steelmaking compositions control: conducting refining treatment to molten steel through an RH vacuum furnace, adding alloy regulation compositions, so as to enable the chemical compositions to achieve the design requirement; hot continuous rolling process, wherein the finishing rolling temperature of the hot continuous rolling is at 800-900 DEG C, the coiling temperature is at 640-740 DEG C; cold continuous rolling process: pickling and rolling, wherein the total reduction rate of the cold rolling can achieve 72.0-86.0%; and continuous annealing process, wherein the annealing temperature is at 750-850 DEG C. The product manufactured by adopting the method is low in cost, can entirely replace low-mark non-oriented electrical steel, and the quality can be guaranteed.

Owner:XINYU IRON & STEEL CO LTD

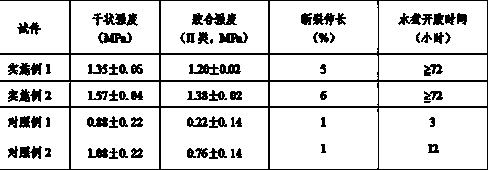

Tough soybean meal protein adhesive and preparation method thereof

ActiveCN109679578AIncrease the number ofIncrease varietyProtein adhesivesFood processingSolubilityAdhesive

The invention discloses a protein adhesive raw material and a preparation method thereof. The protein adhesive raw material is prepared from 35 parts by weight of soybean meal powder, 0.1-0.3 parts byweight of polysaccharase, 70 parts by weight of water as a dispersion medium, 2-5 parts by weight of sodium hypochlorite, 0.2-0.5 parts by weight of triethylene tetramine, 1-3 parts by weight of a toughening agent and 2-4 parts by weight of polyether polyol diglycidyl ether. The toughening agent is a vinyl acetate, acrylamide and glyoxal polymer. The protein adhesive raw material and the preparation method thereof have the advantages as follows: soybean meal molecules are linked with the toughening agent by polyether polyol diglycidyl ether, a toughness system is formed, so that molecular reactivity, water solubility and toughness of the adhesive are improved, water resistance and bonding performance of the adhesive are high, and a floor base material prepared from the adhesive is high instability and good in water resistance; the requirement for water resistance of the adhesive for the floor base material can be met, and practicability of the protein adhesive is guaranteed.

Owner:SCHOLAR HOME SHANGHAI NEW MATERIAL CO LTD

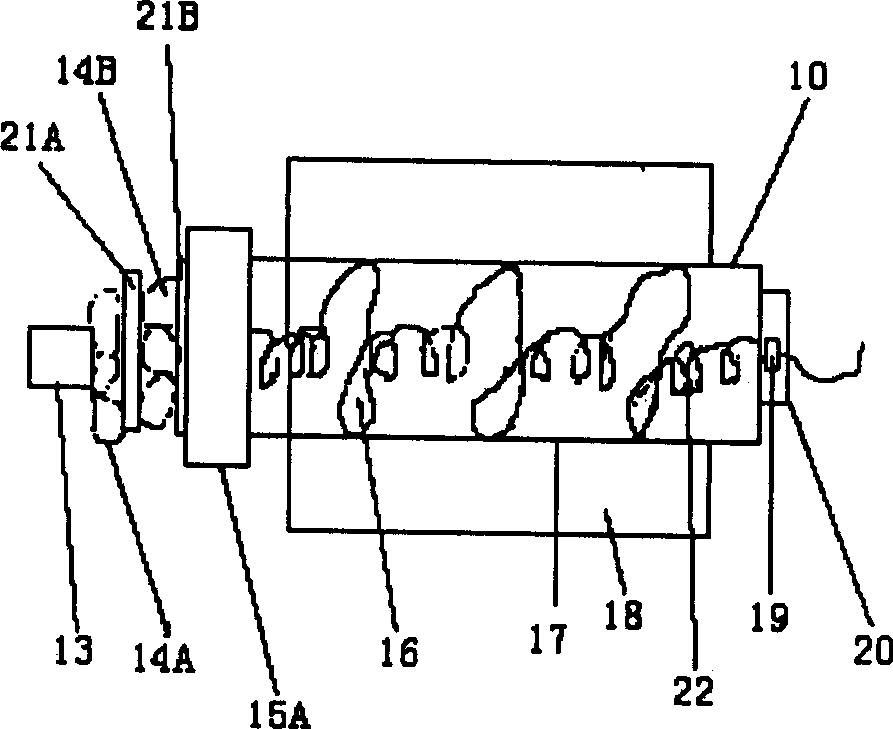

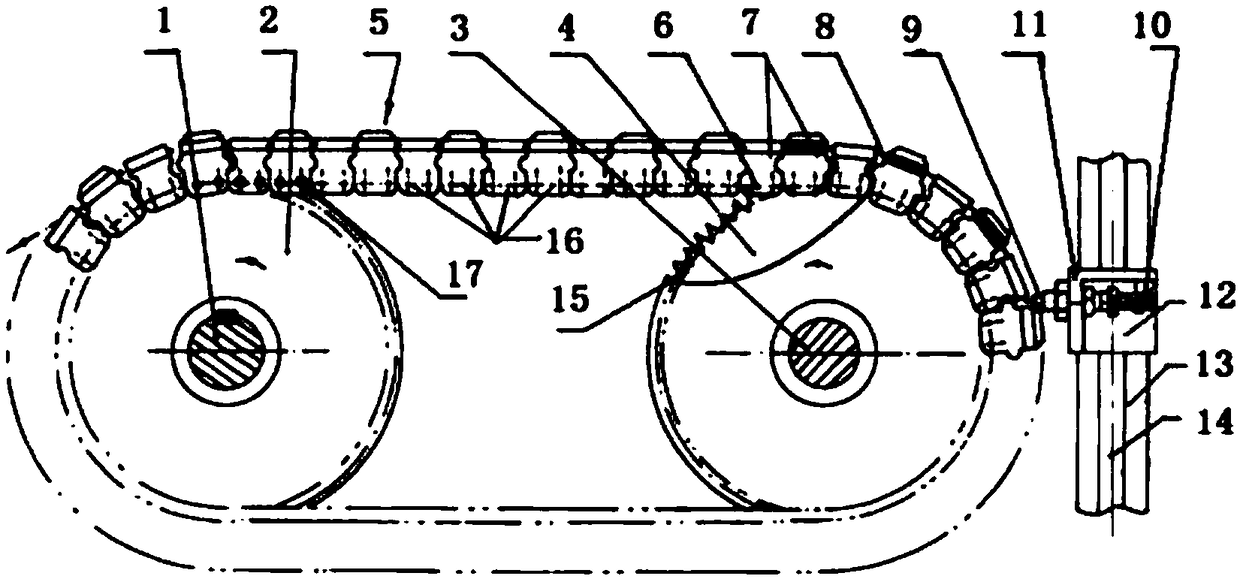

Wire stripping and wrapping machine

InactiveCN108092196AIncrease productivityHigh and stable qualityLine/current collector detailsApparatus for removing/armouring cablesDrive wheelDrive shaft

The invention provides a wire stripping and wrapping machine which is characterized by comprising a driving shaft, a driving wheel, a driven shaft, a driven wheel, a conveying belt, a chain, wire fixing blocks, a lead, a wire inlet tube, a lead guide wheel, a support, a slide block, a slideway, clamp teeth, wire stripping mechanisms and wire wrapping mechanisms. The driving wheel is installed on the driving shaft. The driven wheel is installed on the driven shaft. The wire fixing blocks are installed on the conveying belt. The driving wheel and the driven wheel are the chain wheels provided with teeth. The combining part of the conveying belt and the chain wheels is provided with the chain of which the two sides are provided with the wire stripping mechanisms and the wire wrapping mechanisms. The wire stripping mechanisms and the wire wrapping mechanisms are matched with the operation lead. The advantages of the wire stripping and wrapping machine are that the wire stripping and wrapping machine is enabled to perform mechanically continuous, efficient and high-quality production work.

Owner:新昌县七星街道同亨模具厂

Method for removing dicyclopentadiene from ethylene cracked carbon 9 fraction

ActiveCN107137948AAvoid prone to explosionAvoid clogging equipmentDistillation purification/separationVacuum distillation separationActive componentBoiling point

The invention provides a method for removing dicyclopentadiene from ethylene cracked carbon 9 fraction. The method includes: adding a selective solvent to the ethylene cracked carbon 9 fraction to carry out distillation under reduced pressure, selectively separating the dicyclopentadiene from the carbon 9 fraction extremely complex in component, approximate in boiling point and difficult to separate with common distillation methods, further treating the removed dicyclopentadiene containing the selective solvent, and then recycling the separated selective solvent to obtain the high-purity dicyclopentadiene. The selective solvent is utilized to highly selectively separate the dicyclopentadiene, content of the dicyclopentadiene in the carbon 9 fraction can be lowered to below 1%, and the influence of the residual of the dicyclopentadiene on the quality of the subsequent petroleum resin is removed; the problem that active components in the high temperature cracking method are prone to implosion resulting in blockage to equipment is avoided, potential risks brought by frequent cleaning are completely eradicated, production cost is lowered, and long-cycle, continuous and stable production is realized.

Owner:TIANJIN CLEANTECH TECH

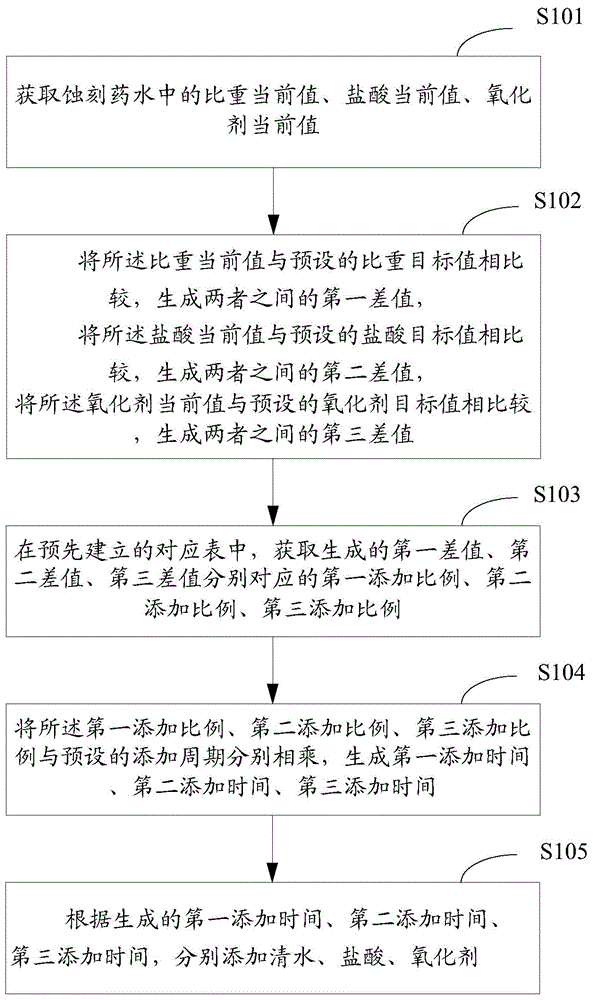

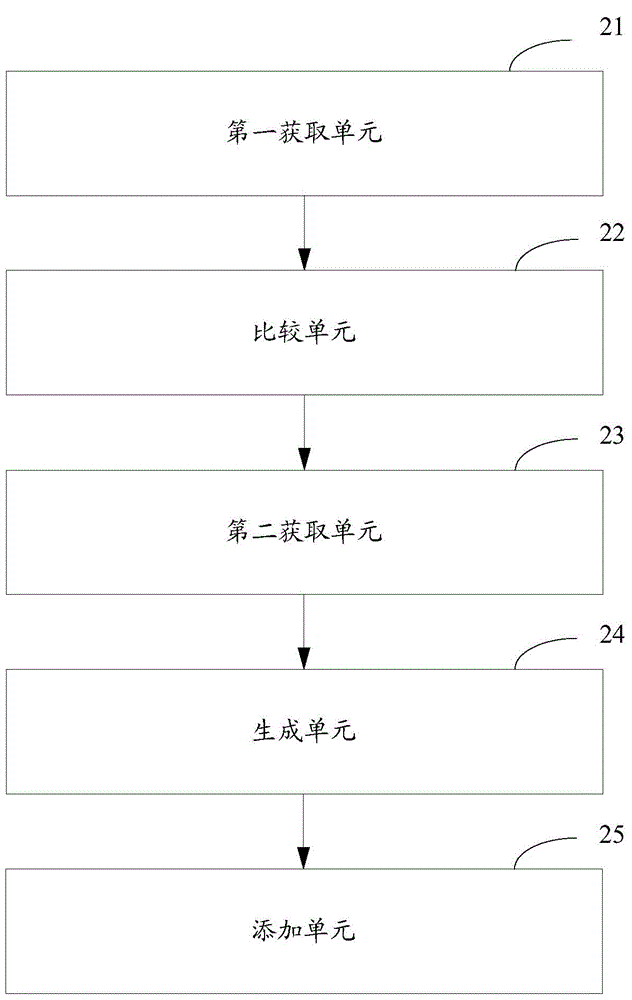

Etching liquid adding method, device, and system

ActiveCN104902688AControl etch abilitySolve the etching abilityConductive material chemical/electrolytical removalOxidizing agentChemistry

The invention belongs to the field of etching technology and provides an etching liquid adding method, device, and system. The method comprises: acquiring a specific gravity current value, a hydrochloric acid current value, and an oxidizing agent current value in the etching liquid; comparing the specific gravity current value with a preset specific gravity target value to generate a first difference value thereof, comparing the hydrochloric acid current value with a preset hydrochloric acid target value to generate a second difference value thereof, and comparing the oxidizing agent current value with a preset oxidizing agent target value to generate a third difference value thereof; acquiring a first adding proportion, a second adding proportion, and a third adding proportion which correspond to the first difference value, the second difference value, and the third difference value respectively; multiplying the first adding proportion by an adding period to generate a first adding time, multiplying the second adding proportion by the adding period to generate a second adding time, and multiplying the third adding proportion by the adding period to generate a third adding time; and adding clear water, hydrochloric acid, and oxidizing agent according to the first adding time, the second adding time, and the third adding time respectively.

Owner:UNIVERSAL P C B EQUIP SHENZHEN

Cleaning roller

This invention discloses a cleaning roller for the spinning machine, which includes cleaning roller noumenon, which has several cleaning grooves on it; the two cleaning rollers are mounted oppositely on the both extremities of the main axis. The cleaning roller uses the plastic as the material, which is applied widely in the spinning machine such as the roving machine, the spun yarn machine and so on.

Owner:DONGTAI TEXTILE MASCH CO LTD

Evaluation method of fat coal quality

ActiveCN103275740BClarify the degree of pros and consBenefit from reasonable positioningData processing applicationsCoke ovensCoke strength after reactionCoal

The invention discloses an evaluation method of a fat coal quality. The evaluation method comprises the steps as follows: 1), detecting key indexes of coal quality of the fat coal and obtaining a coarse grain mosaic structure proportion X, a maximum Giseeler fluidity MF and an expansion degree b of the fat coal; 2), setting P to be a fat coal quality evaluation index, P= 100 + 10* [k1* (X-Xj)+ K2* (lgMF-lgMFj) + K3* (b-bj)], wherein Xj, MFj and bj are the coarse grain mosaic structure proportion X, the maximum Giseeler fluidity MF and the expansion degree of standard fat coal respectively, K1, K2 and K3 are constants and related with CSR (coke strength after reaction) as the following relational expression: CSR= K + K1*X + K2* lgMF + K3*b, and K is a constant; and 3), a P value is calculated, and the larger the P value is, the better the fat coal quality is. According to the evaluation method of the fat coal quality, the quality of the fat coal can be effectively evaluated, a price is reasonably determined, and scientific blending is achieved.

Owner:武汉钢铁有限公司

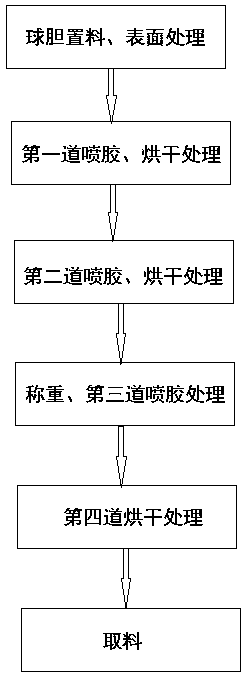

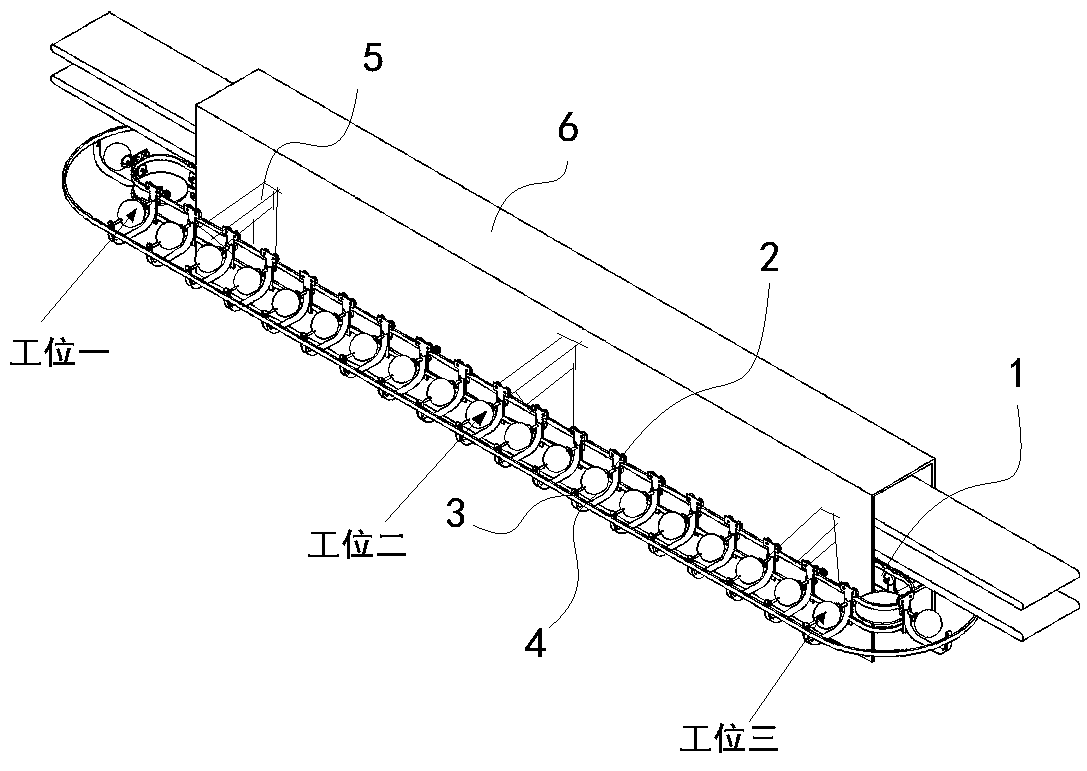

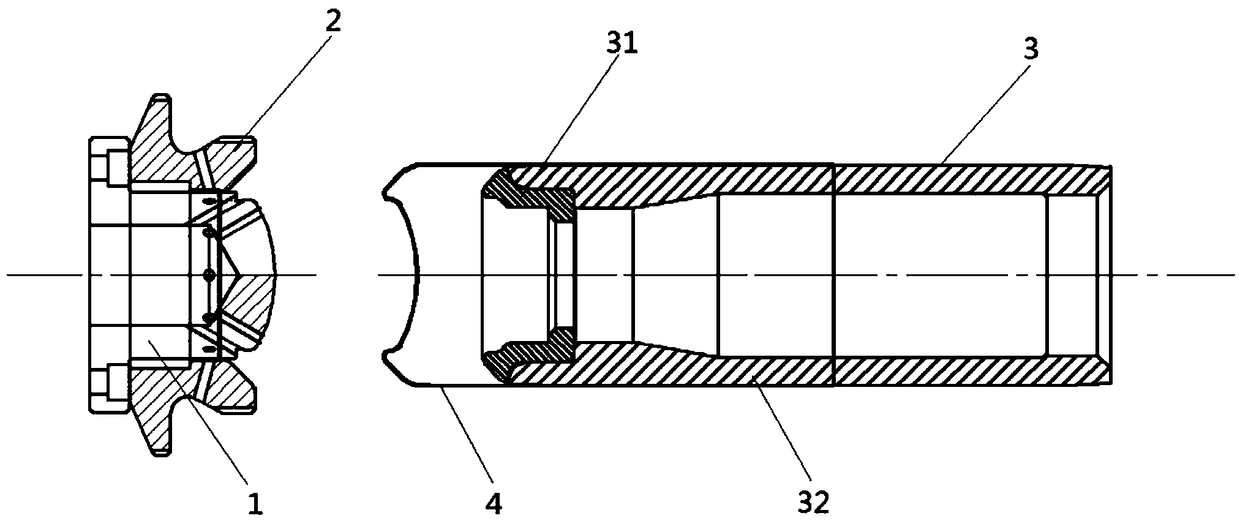

Automatic adhesive spraying process of rubber bladder

InactiveCN109395991ASave manpower spaceShorten the timePretreated surfacesCoatingsAdhesiveEngineering

The invention discloses an automatic adhesive spraying process of a rubber bladder. Materials are placed from the rubber bladder; an inner container adhesive spraying machine is provided with at leastthree stations, and a conveying mechanism is arranged between each station, and is provided with a grabbing mechanism, a fixing mechanism and a rubber bladder containing guiding support; the rubber bladder is clamped by the grabbing mechanism, and the conveying mechanism is provided with a rotating part; the grabbing mechanism is matched with the rotating part; the fixing mechanism penetrates through the inflating hole position of the rubber bladder, and the rubber bladder is in a rotating state in a hanging manner; a first surface treatment device performs surface treatment on the rubber bladder, and then first adhesive spraying treatment, first drying treatment, second adhesive spraying and second drying treatment are performed; weighing, third adhesive spraying treatment and fourth adhesive spraying treatment are performed, operation from the surface treatment to the first spraying drying and the second spraying drying is completed at a time by one person, procedure carrying of allwork stations is omitted, waiting and mistaking are avoided, the manpower space and time are saved, the outer surface of the rubber bladder can be uniformly subjected to adhesive spraying, stable improvement of the quality is guaranteed, and the production cost is lowered.

Owner:江苏谐丰自动化科技有限公司

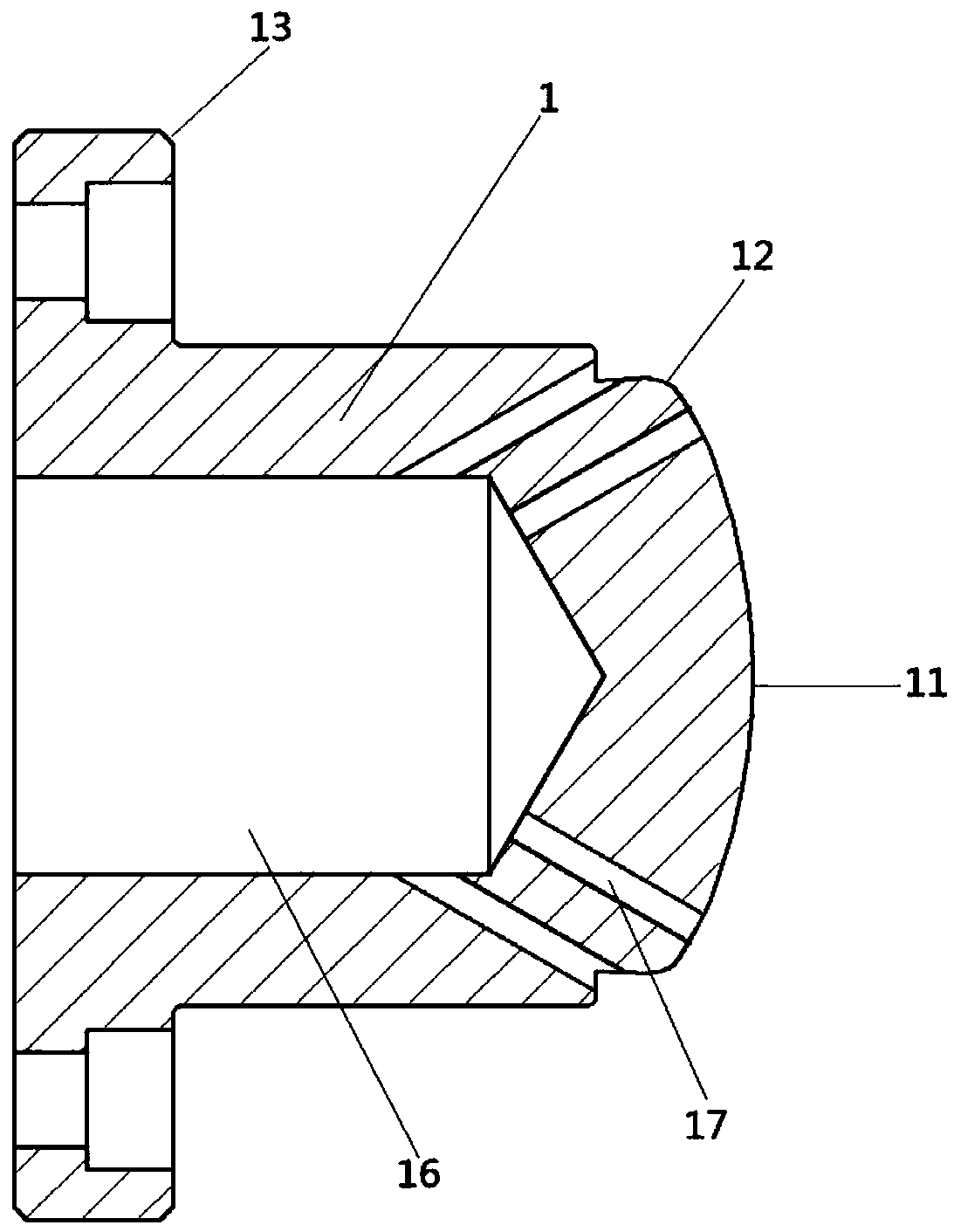

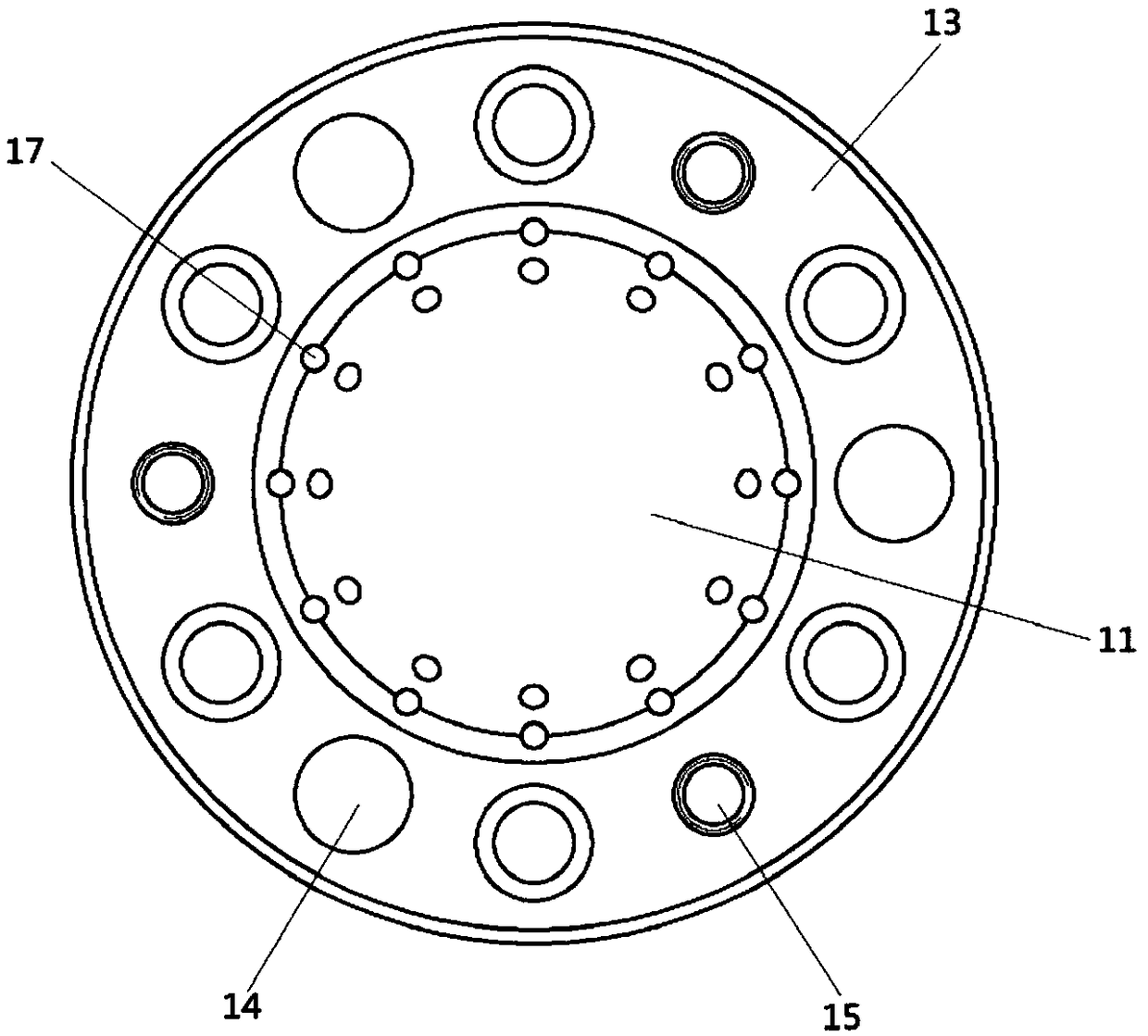

High-strength thick-wall bottle and can die

The invention provides a high-strength thick-wall bottle and can die. The high-strength thick-wall bottle and can die is characterized in that one end, facing a punch, of an inner bottom die is equipped with an arc-shaped protruded surface, wherein R angle of the arc-shaped protruded surface is 45-46mm; the side edge of the arc-shaped protruded surface is in smooth transition with the outer wall of the inner bottom die through a circular arc section, and the R angle of the circular arc section is 24.5-25.5mm; an outer bottom die sleeves the inner bottom die; one side, facing the punch, of theouter bottom die is provided with a concave chamber; an inclination angle between the inner wall surface of the concave chamber and an axis of the outer bottom die is 45 degrees; the arc-shaped protruded surface is arranged in the concave chamber; a clearance for forming an inclination angle of the bottom part of the bottle or can is arranged between the inner wall surface of the concave chamber and the outer wall of the inner bottom die; one side, facing the outer bottom die, of a punching nose is provided with an inclined surface which is matched with the concave chamber; an included angle between the inclined surface and an axis of the punching nose is 45 degrees; and a step surface for controlling the wall thickness of the bottle or can is arranged at the outer wall of a punch body. The high-strength thick-wall bottle and can die solves the problem that the pressure resistance of the bottom of the bottle or the can manufactured through an existing die is low, and a can body is easily wrinkled, and the wall of a can body is thin, and the can is easily broken.

Owner:GUANGZHOU RONGXIN CONTAINER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com