Cleaning roller

A cleaning roller, cleaning technology, applied in textile and papermaking, drafting equipment, spinning machines, etc., can solve problems such as low efficiency, damage, affecting yarn evenness, knots and other quality indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

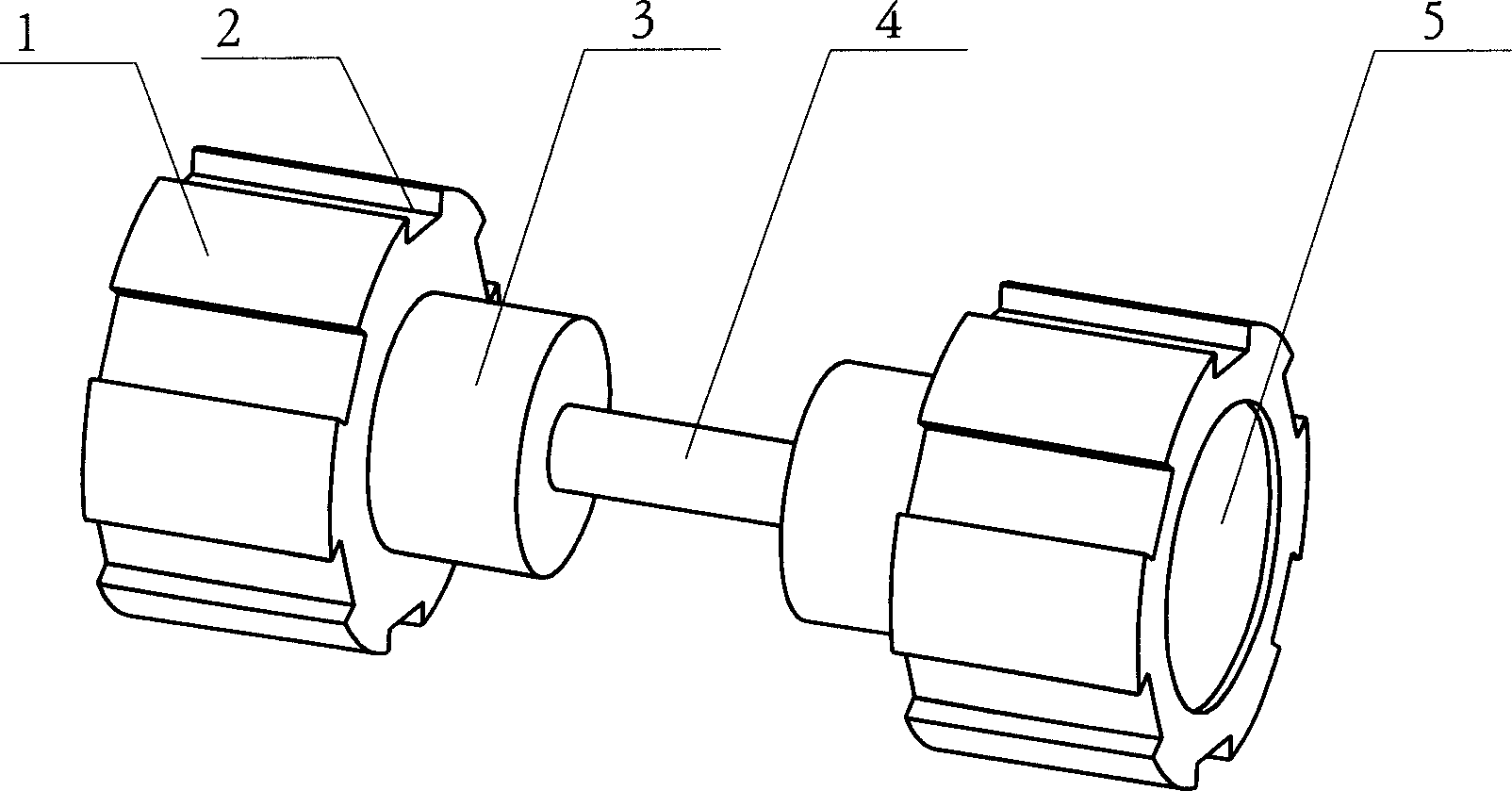

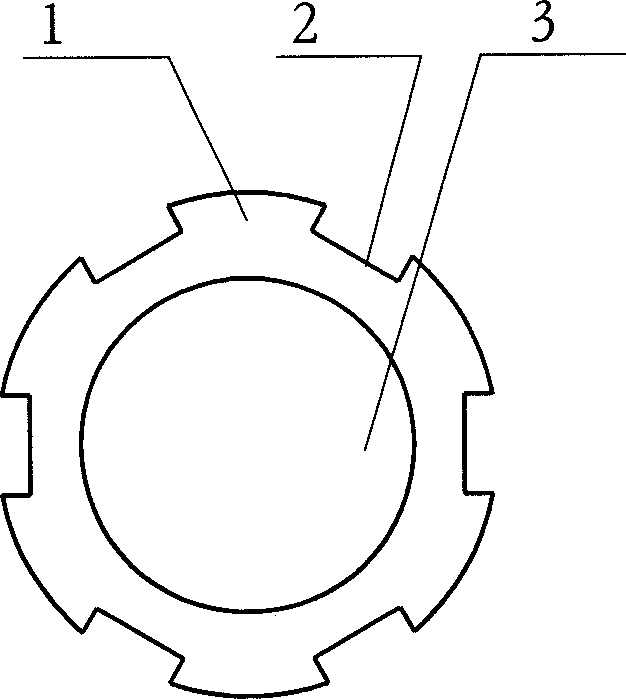

[0011] figure 1 , figure 2 The shown cleaning roller is provided with two cleaning roller bodies 1 at both ends of the mandrel 4, and the outer circumference of the cleaning roller body 1 is uniformly provided with six strip-shaped cleaning grooves 2 extending along its axial direction. An end cap 5 is installed on the outside of the cleaning roller body 1, and a cleaning roller step 3 is arranged on the inner surface of the cleaning roller body 1, and the cleaning roller steps 3 of the two cleaning roller bodies 1 face each other with a certain distance apart. The structure is beneficial to prevent axial movement of the cleaning roller body 1 after it is installed and used. When in use, the cleaning roller body 1 and the surface of the top roller rub against each other and roll. Due to the existence of the cleaning groove 2, the continuous rotation of the cleaning roller body 1 becomes uneven speed rolling, which significantly enhances the cleaning and removal of debris. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com