Drying equipment for filature

A technology of drying device and dryer, which is applied in the directions of silk reeling, drying solid materials, and heating to dry solid materials, etc. It can solve the problems of non-compliance between water content of silk flakes and process standards, poor drying quality of silk flakes, and large differences in drying degree, etc. problems, to achieve the effect of maintaining the health of workers, saving operating costs, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

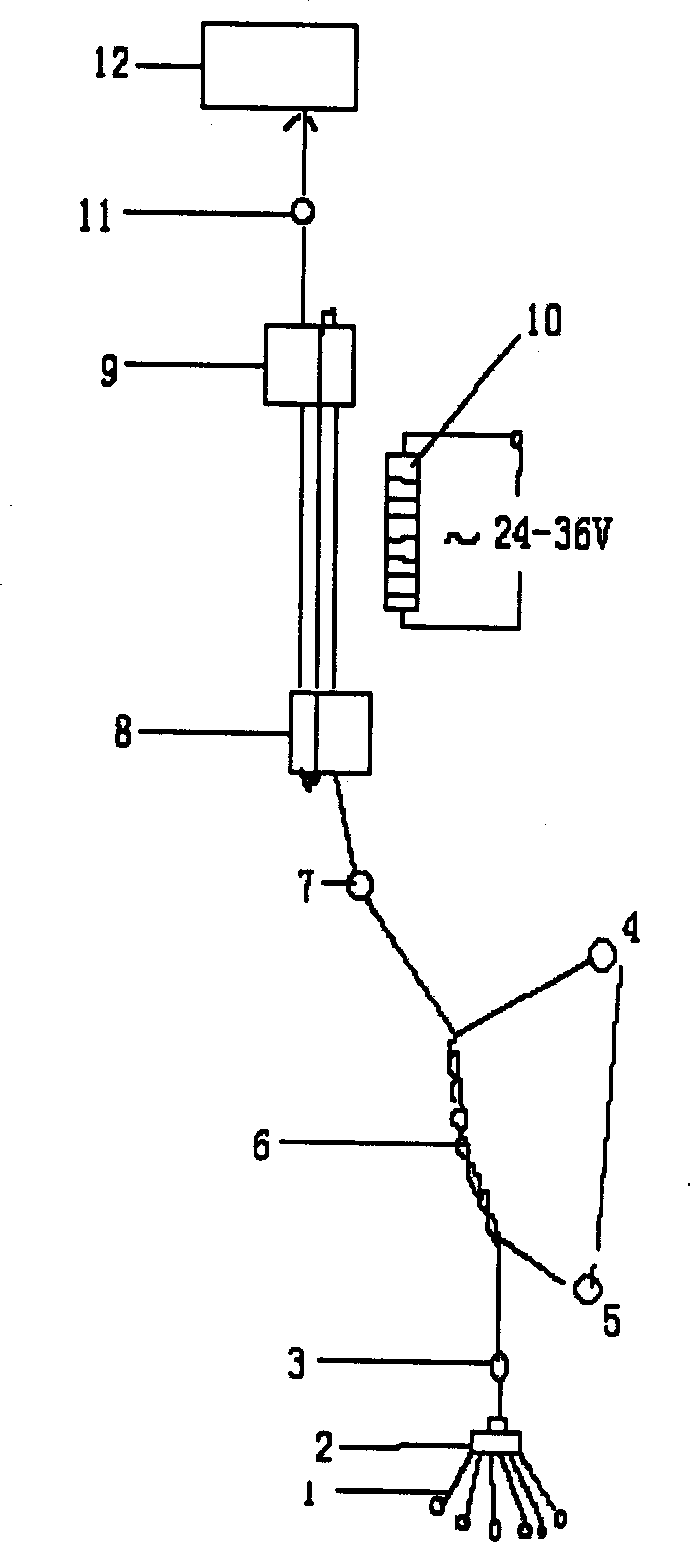

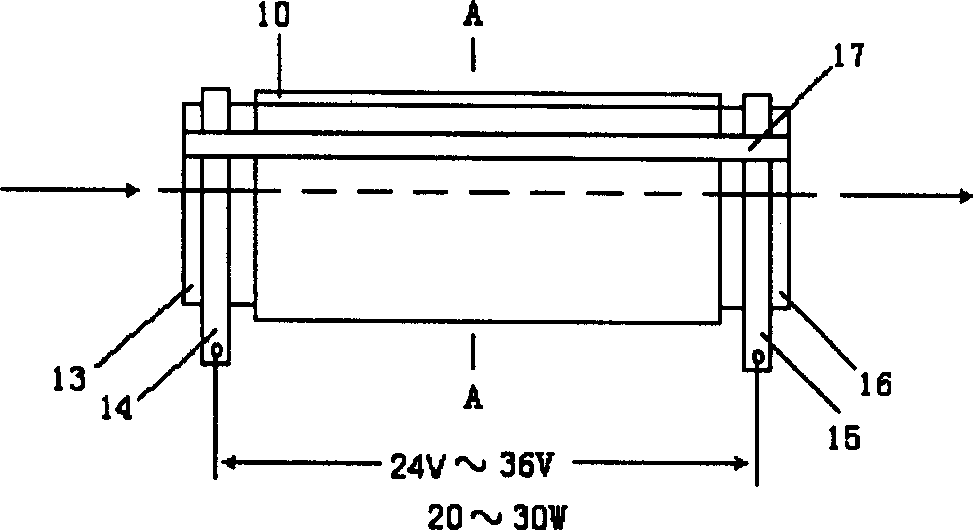

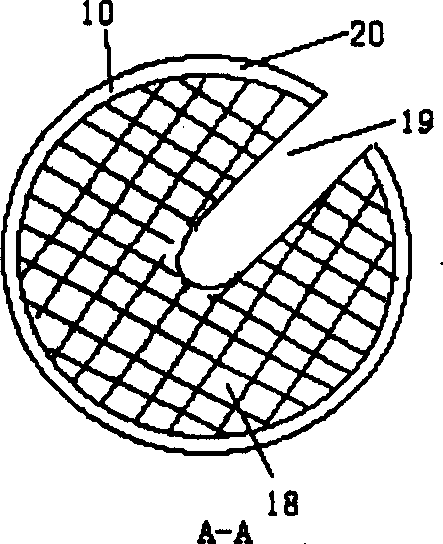

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0022] according to figure 1 , figure 2 , image 3 It is known that the thread heads of several Zhengxu cocoons 1 are wound and adhered by the thread splicer 2 to form a thread group, and the thread group rises through the thread splicer, and then passes through the thread splicer 3 to gather into filaments, The thread is inserted into the upper and lower drums 4, 5 and then twisted to form a sheath 6. The thread continues to rise and is placed on the upper and lower multi-groove pulleys 9 and 8 of the thread drying device after being positioned by the guide wire hook 7. The thread is in between. Heated by the thread drier 10 during several times of orbital movement, when the moisture regain dropped to 13-16%, the thread rose and passed through the intertwining guide wire hook 11 of the winding device to continue the post-processing. According to the formation and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com