Automatic adhesive spraying process of rubber bladder

A bladder and glue spraying technology, which is applied in the direction of pretreatment surface, coating, and liquid coating device on the surface, etc., can solve the problems of thin top and bottom thick bladder, low production efficiency, and increased production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

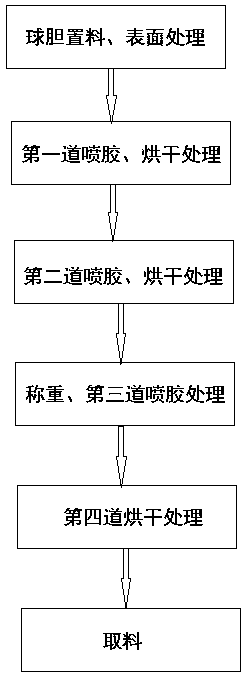

[0023] Such as figure 1 Shown, a kind of bladder automatic glue spraying process, this process comprises the steps:

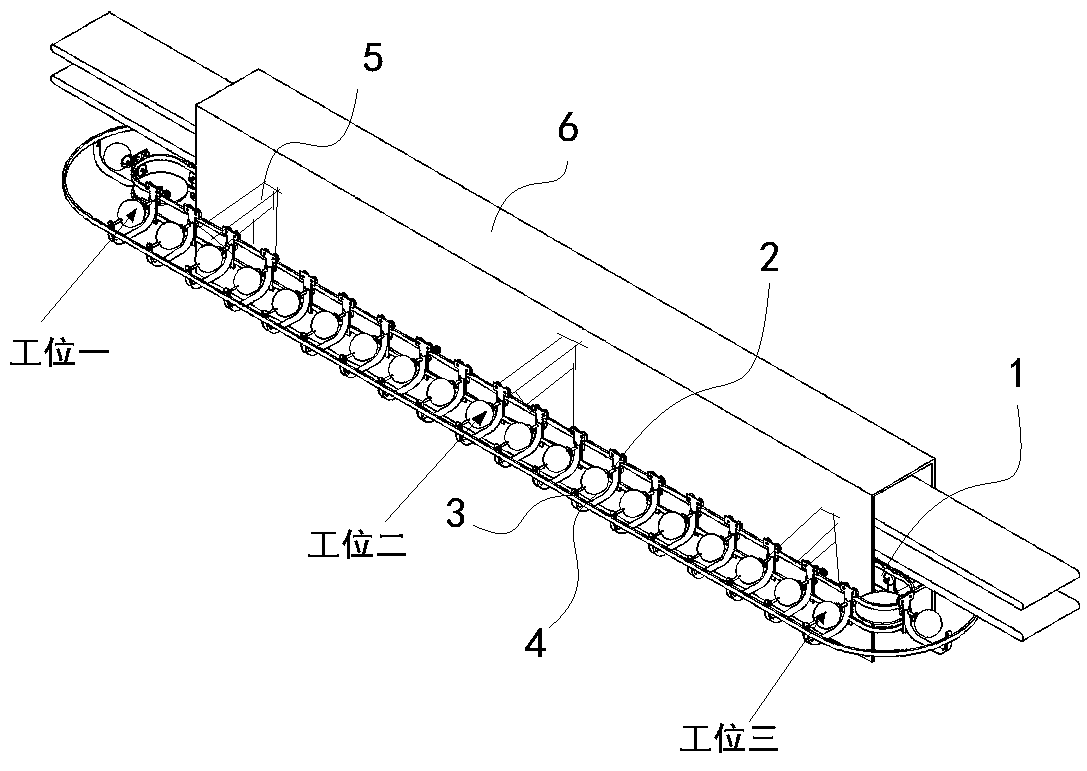

[0024] Step 1: Start the glue spraying machine. The liner glue spraying machine is equipped with at least three stations, and a conveying mechanism 1 is provided between each station. The conveying mechanism is chain conveying. The conveying mechanism 1 is equipped with a grabbing mechanism 2, fixed The mechanism 3 and the guiding bracket 4 for containing the bladder, the grasping mechanism 2, the fixing mechanism 3 and the guiding bracket 4 for storing the bladder are transmitted along with the conveying mechanism 1, and the conveying mechanism 1 is fixedly provided with a glue spraying mechanism 5 to place the bladder In the section between the gripping mechanism 2 and the fixing mechanism 3, the gripping mechanism 2 hinges to clamp the bladder, and the gripping mechanism 2 supports the bladder at a fixed point. When spraying glue, it can be sprayed on any po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com