High-strength thick-wall bottle and can die

A high-strength, bottle-can technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of insufficient compressive strength of the bottom of the bottle and can, thick wall of the can, easy to break the can, and wrinkling of the can. Achieve the effect of increasing stable quality, improving axial bearing force and reducing wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

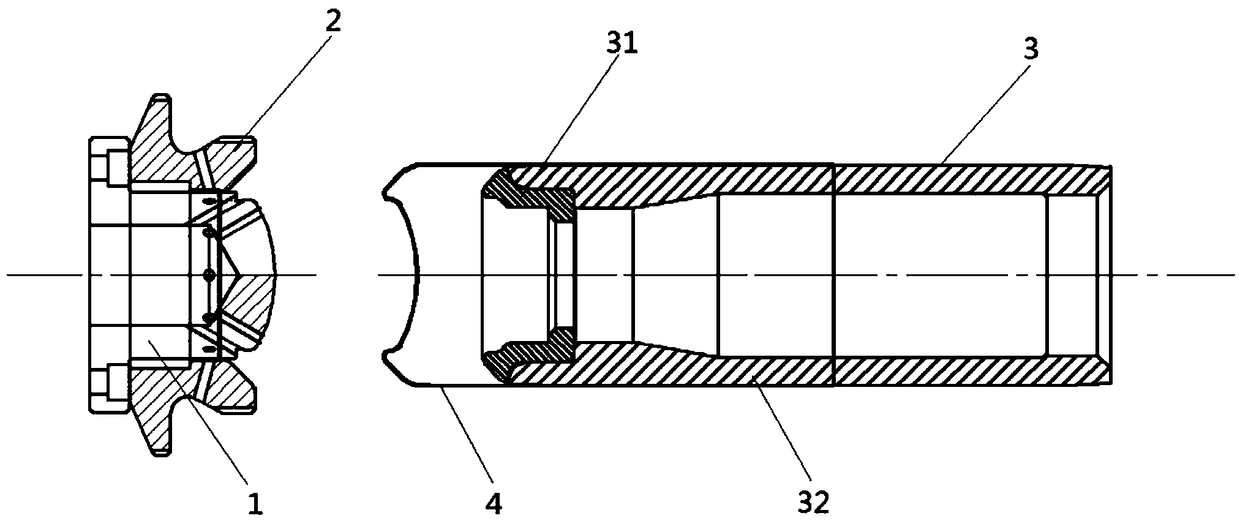

[0030] Such as figure 1 As shown in -7, the present invention provides a kind of high-strength thick-walled bottle mold suitable for stretching machine, including inner bottom mold 1, outer bottom mold 2 and punch 3, wherein punch 3 includes the The nose 31 and the punch body 32 are detachable.

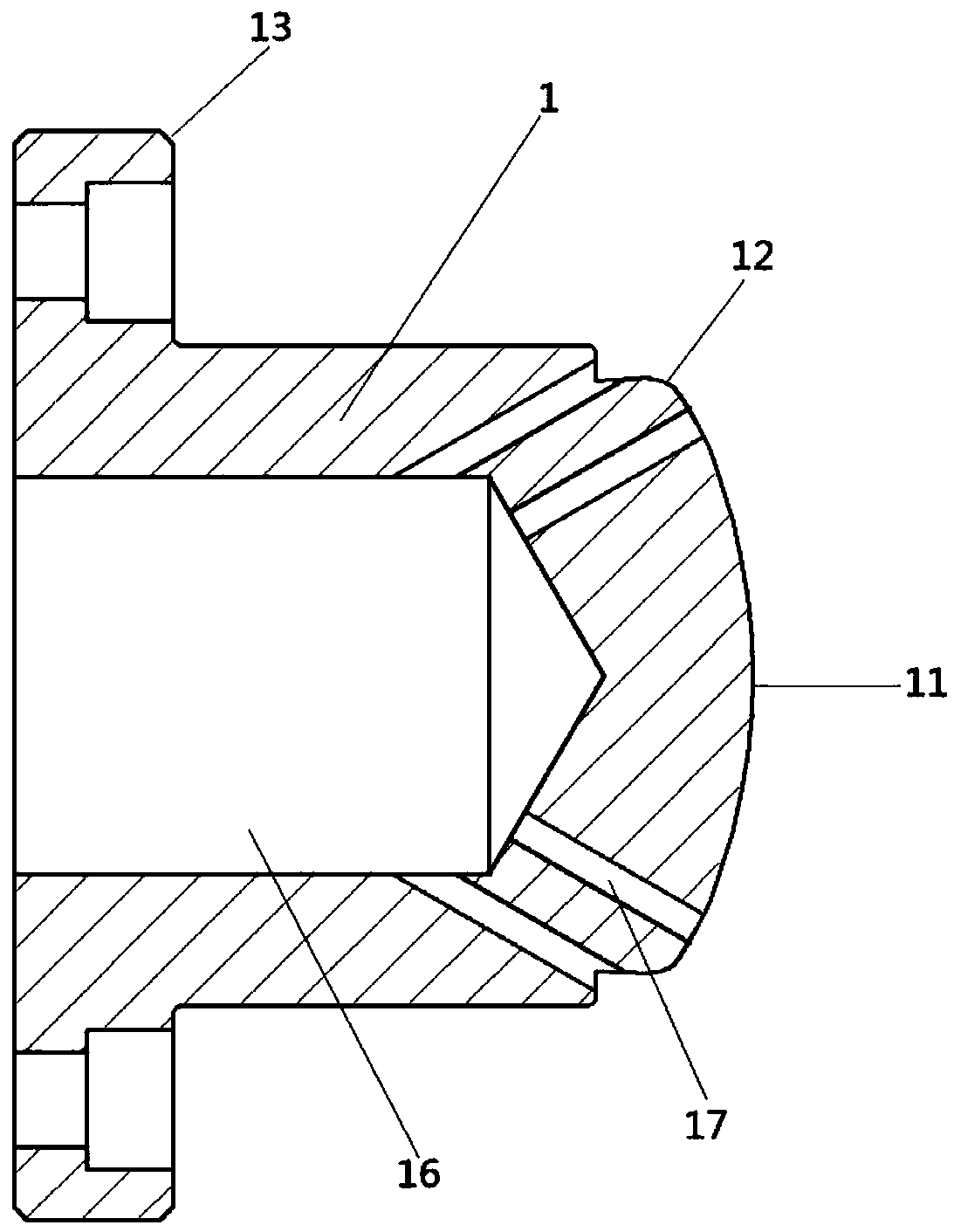

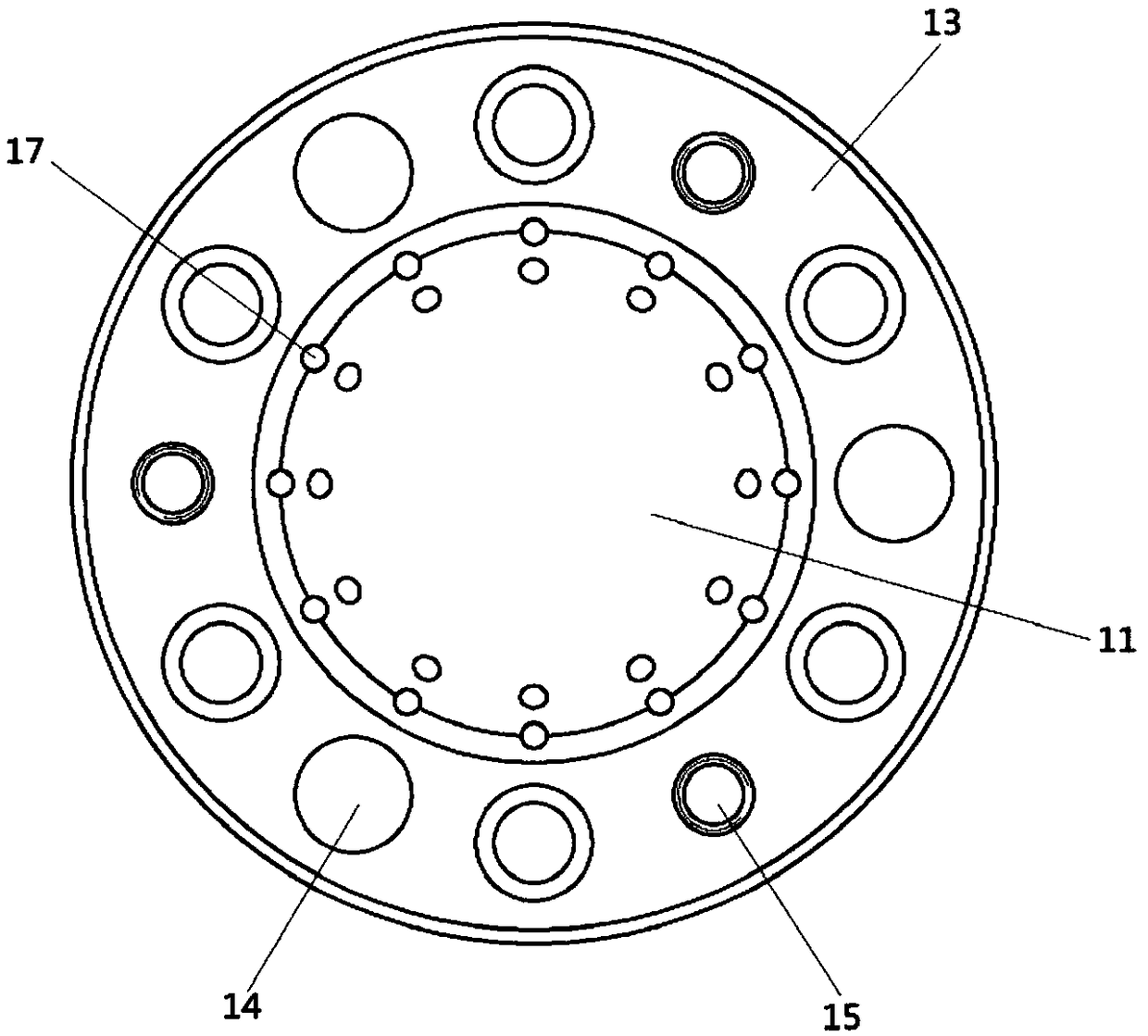

[0031] Such as figure 2 As shown in -3, the end of the inner bottom mold 1 facing the punch is provided with an arc-shaped convex surface 11, and the R angle of the arc-shaped convex surface 11 is between 45-46mm. Preferably, the R angle of the arc-shaped convex surface 11 is set to 45.62mm . The edge of the arc-shaped convex surface 11 and the outer wall of the inner bottom mold 1 are smoothly transitioned by an arc segment 12, and the R angle of the arc segment 12 is between 24.5-25.5mm. Preferably, the R angle of the arc segment 12 is set to 25.00mm . Such setting makes the bottom of the bottle 4 after stamping have a larger radian, and the bottom edge also transitions smoothl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com