Wire stripping and wrapping machine

A stand-alone, wire-stripping technology, applied in the direction of line/collector parts, cable installation devices, electrical components, etc., can solve the problems of manual mechanical devices such as high labor intensity, difficult quality assurance, and low work efficiency, so as to save manpower and material resources , quality and stability, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

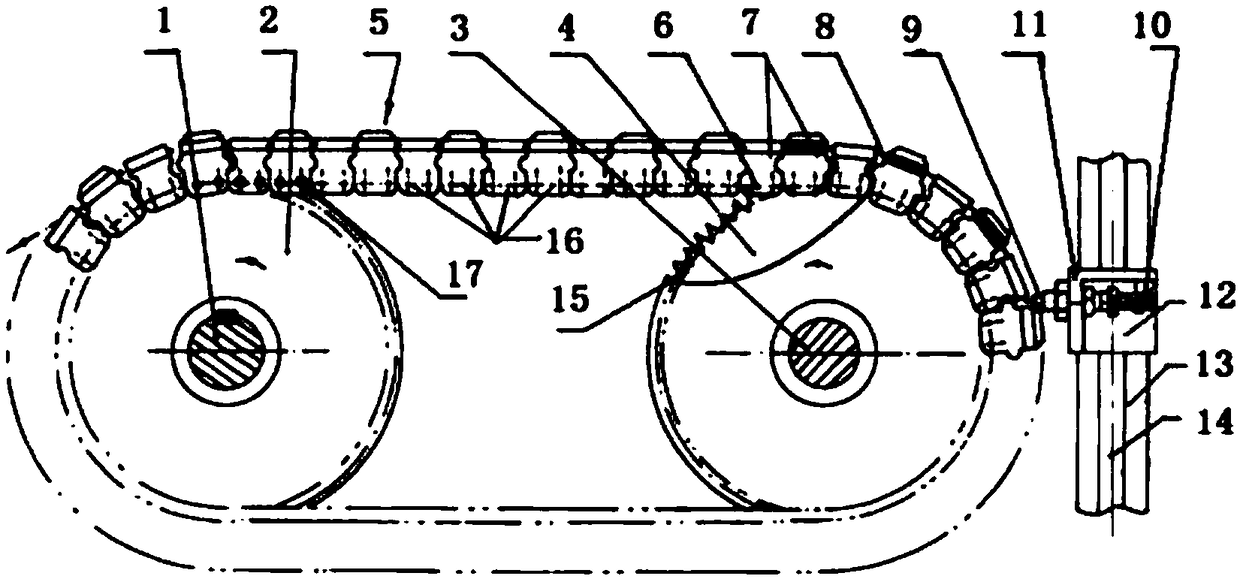

[0011] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0012] This embodiment provides a wire stripping punching machine, characterized in that: the wire stripping punching machine includes a driving shaft 1, a driving wheel 2, a driven shaft 3, a driven wheel 4, a conveyor belt 5, a chain 6, and a wire fixing block 7. Lead wire 8, wire inlet tube 9, lead wire guide wheel 10, bracket 11, slider 12, support 13, slideway 14, locking teeth 15, wire stripping 16, punching sheet 17; among them: there is a fixed wire on the conveyor belt 5 Block 7, fixed wire block 7 is used for clamping wire 8, and driving wheel 2 is installed on the driving shaft (1), and driven wheel 4 is installed on the driven shaft 3, and driving wheel 2 and driven wheel 4 are the sprockets that are shaped on teeth 15 , The junction of the conveyor belt 5 and the sprocket is a chain 6 .

[0013] The driving wheel 2 and the driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com