Automatic production line for assembling block composted in splinter shaped

An automated production line, a technology for synthesizing blocks, applied in chemical instruments and methods, chemical/physical processes, methods of chemically changing substances by atmospheric pressure, etc., can solve the problems of unstable quality, low production efficiency, and undiscovered, etc., Achieve stable quality, improve production efficiency, save manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

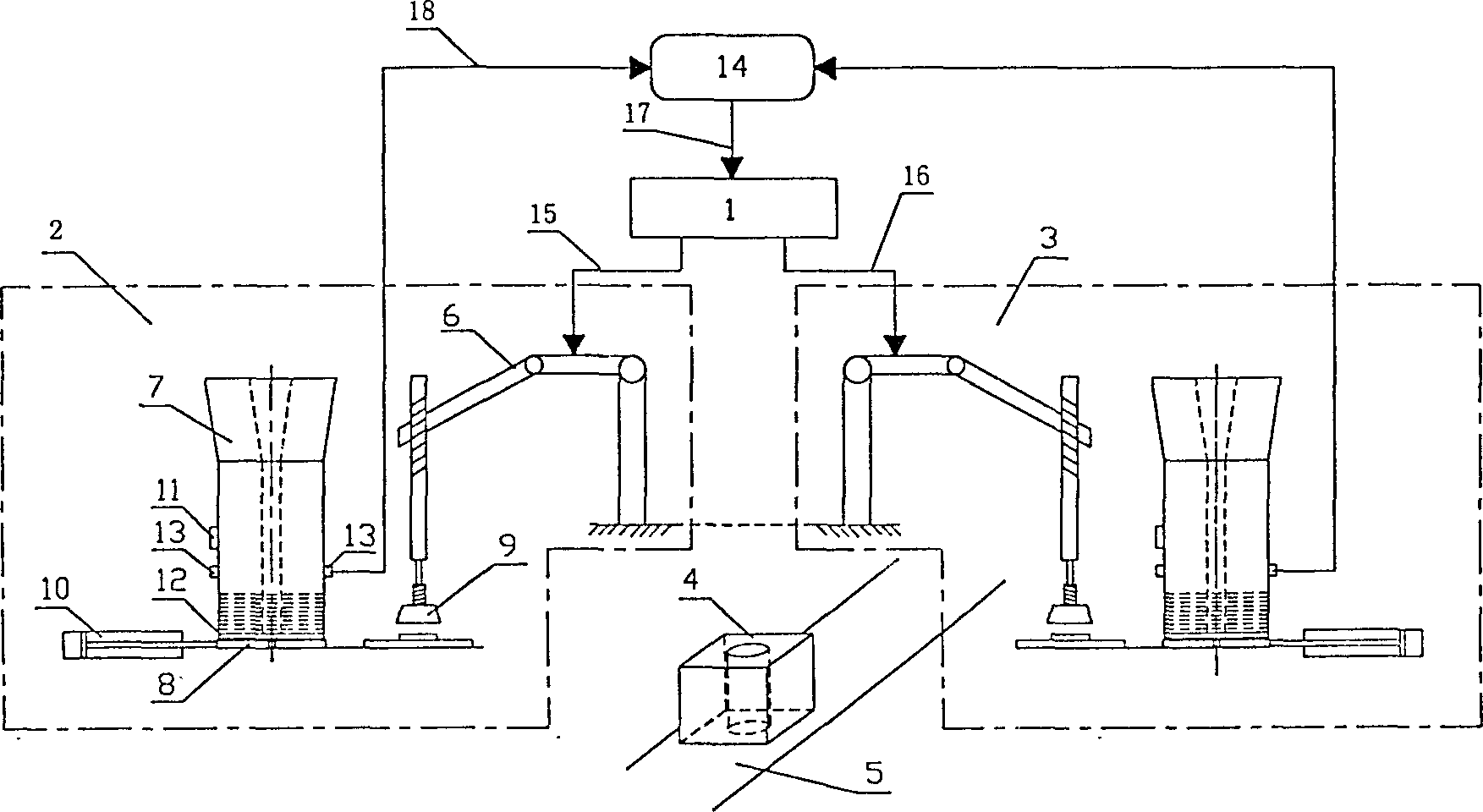

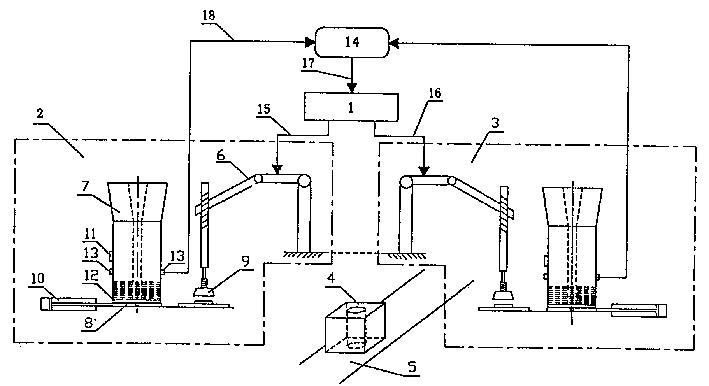

[0010] Such as figure 1 As shown, the present invention mainly includes: manipulator controller 1, graphite sheet assembly mechanism 2, catalyst sheet assembly mechanism 3, assembly block 4 and conveyor belt 5, and its connection mode is: graphite sheet assembly mechanism 2, catalyst sheet assembly mechanism 3 are located on the conveyor belt On the left and right sides of 5, the assembly block 4 is arranged on the conveyor belt 5, the manipulator controller 1 is connected with the graphite sheet assembly mechanism 2 through the communication cable 15, and connected with the catalyst sheet assembly mechanism 3 through the communication cable 16.

[0011] Graphite sheet assembly mechanism 2 and catalyst sheet assembly mechanism 3 have the same structure, mainly including: manipulator 6, vertical hopper 7, tray 8, vacuum suction cup 9, cylinder 10, the connection method is: manipulator 6 is fixed on the ground, and the end is passed through wire The bar is connected with the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com