Evaluation method of fat coal quality

An evaluation method and fat coal technology, applied in the petroleum industry, instruments, data processing applications, etc., can solve the problems of coal quality evaluation and difficult to fully control, and achieve the effect of reducing the fluctuation range of thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail through specific embodiments below.

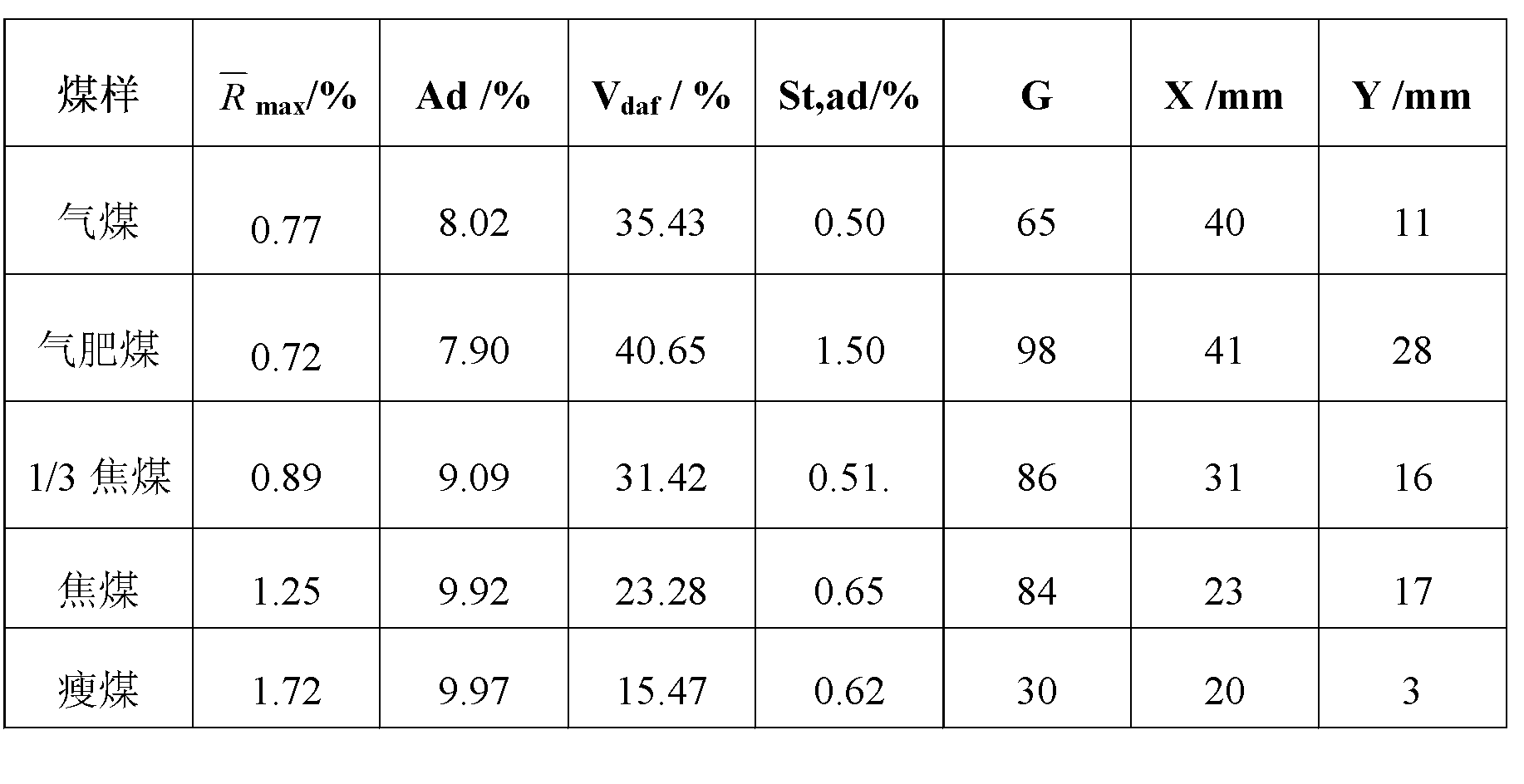

[0018] The proportion of fat coal in an enterprise is 20%, the dry basis ash content of the fat coal is ≤9.00%, and the sulfur content is ≤0.6%. The specific coal blending plan is:

[0019] Coking coal: 40%; fat coal: 20%; 1 / 3 coking coal: 25%; lean coal: 15%.

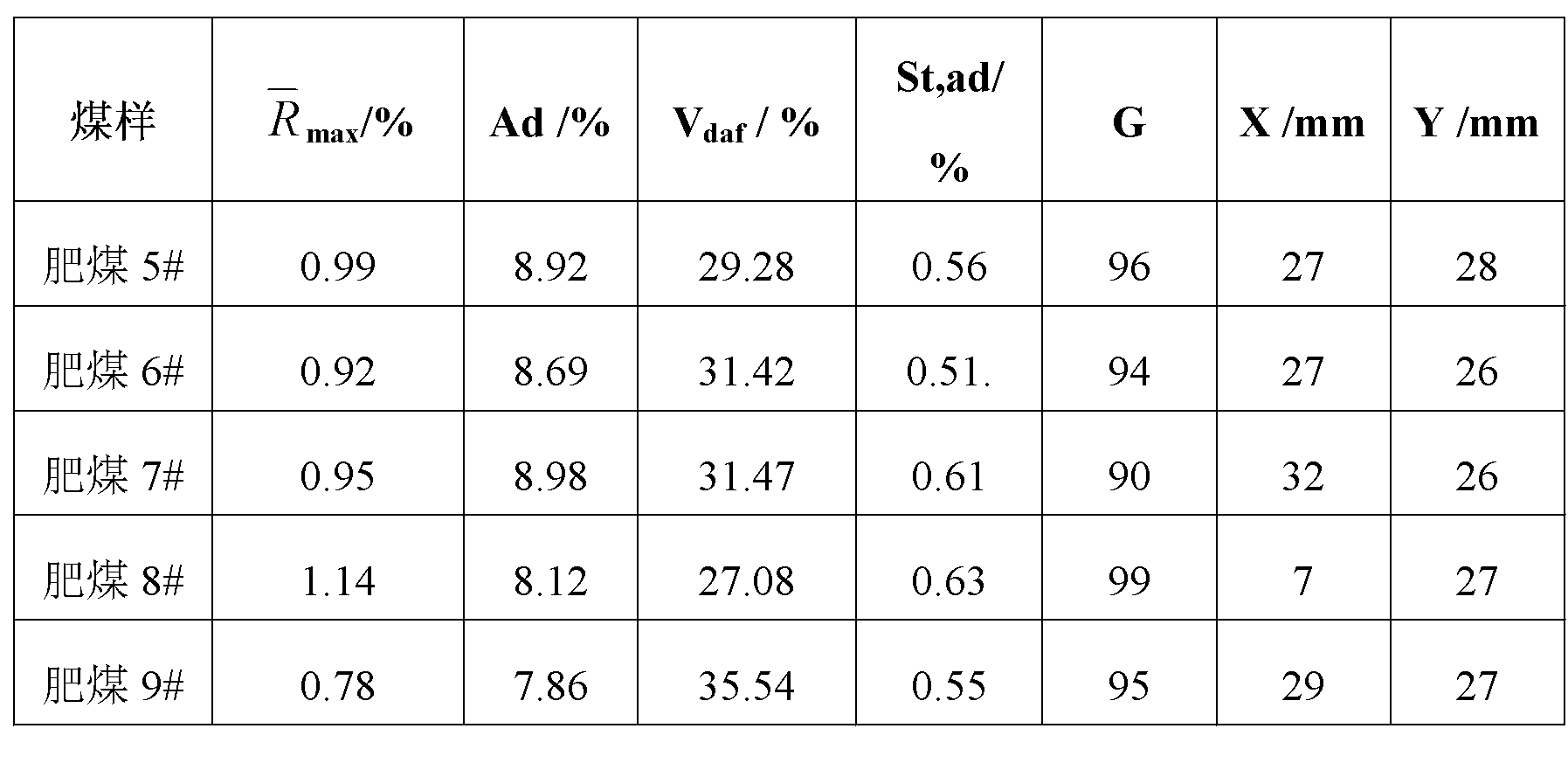

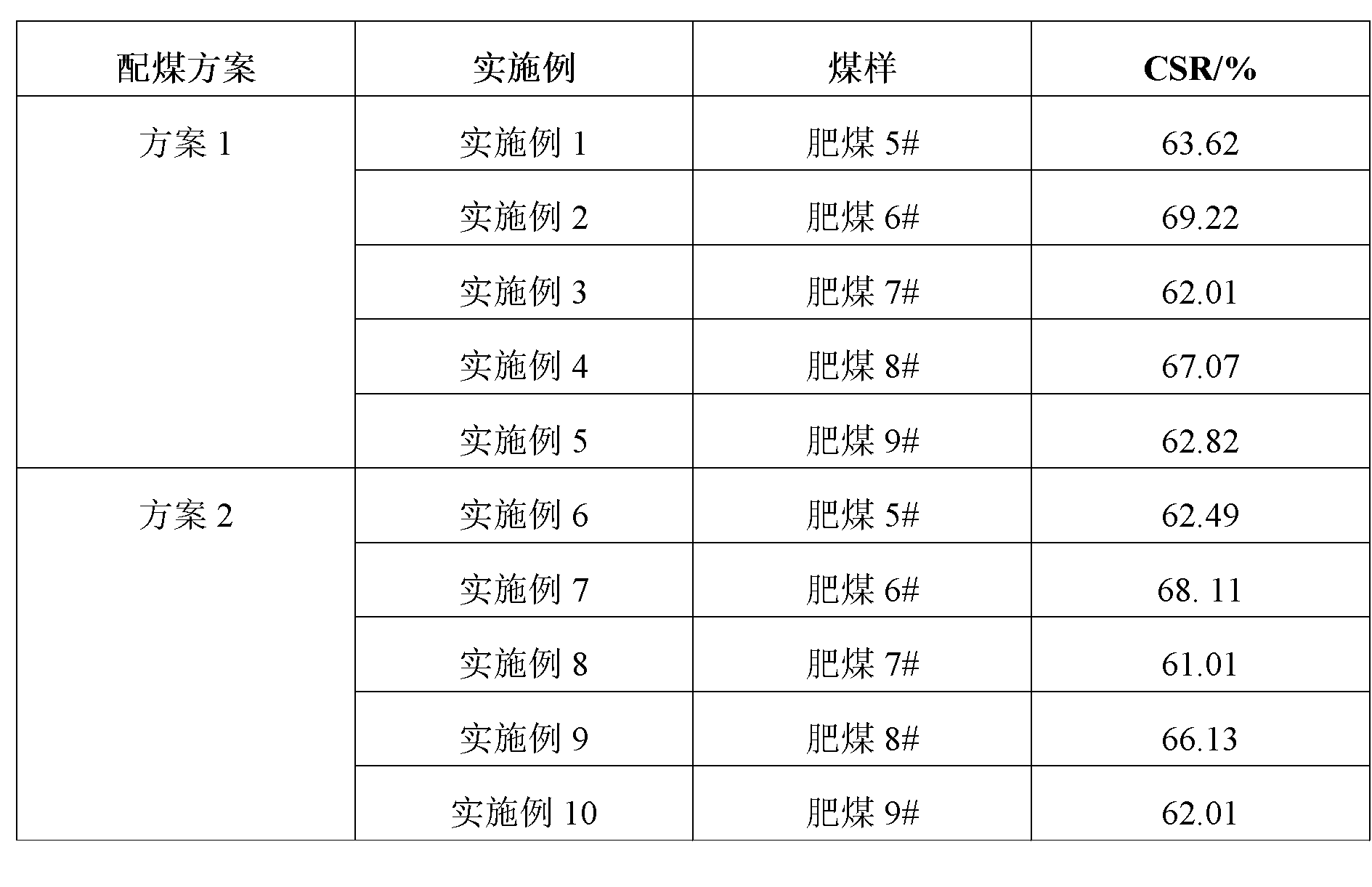

[0020] Coking coal, 1 / 3 coking coal, and lean coal remain unchanged, and four groups of different fat coals are taken, and coal blending is carried out according to the above-mentioned ratios for coking, and the coke strength after thermal reaction (CSR) is obtained. The relevant data are shown in Table 1.

[0021] Table 1 The strength of coke after thermal reaction after coal blending with different fat coals

[0022] coal sample

X / %

MF / ddpm

b / %

CSR / %

Fat coal 1#

40

60000

150

65.65

Fat coal 2#

40

5976

100

63.01

Fat coal 3#

60

4000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com