Method for evaluating coal quality of coking coal having largest Gieseler fluidity of 2000ddpm or less

A technology of Gibson's fluidity and coking coal, which is applied in the direction of material inspection products, fuel oil testing, etc., can solve the problems of large differences in coking coal quality evaluation, inability to accurately match, and inability to scientifically and rationally select cost-effective coking coal, so as to reduce thermal performance The effect of volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail through specific embodiments below.

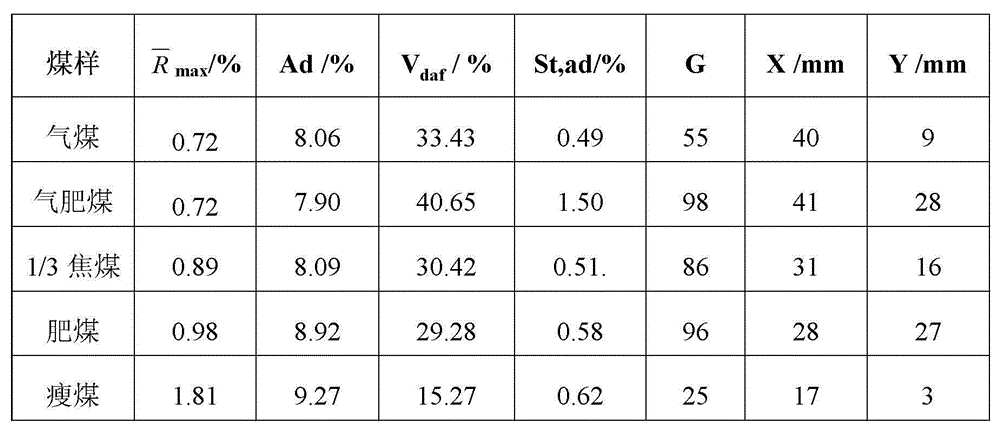

[0017] The coking coal blending ratio of an enterprise is 40%, the dry basis ash content of the coking coal is ≤9.00%, and the sulfur content is ≤0.6%. The specific coal blending plan is:

[0018] Coking coal: 40%; fat coal: 15%; 1 / 3 coking coal: 26%; gas fat coal: 5%; lean coal: 14%.

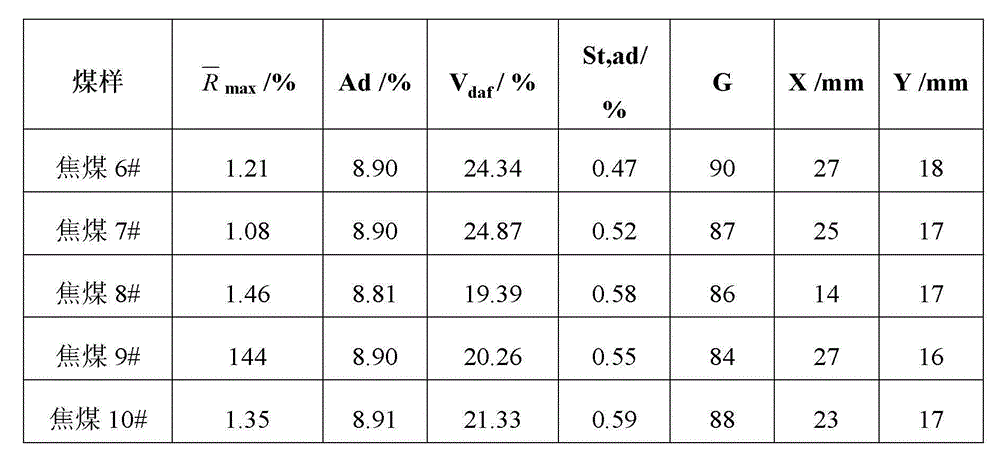

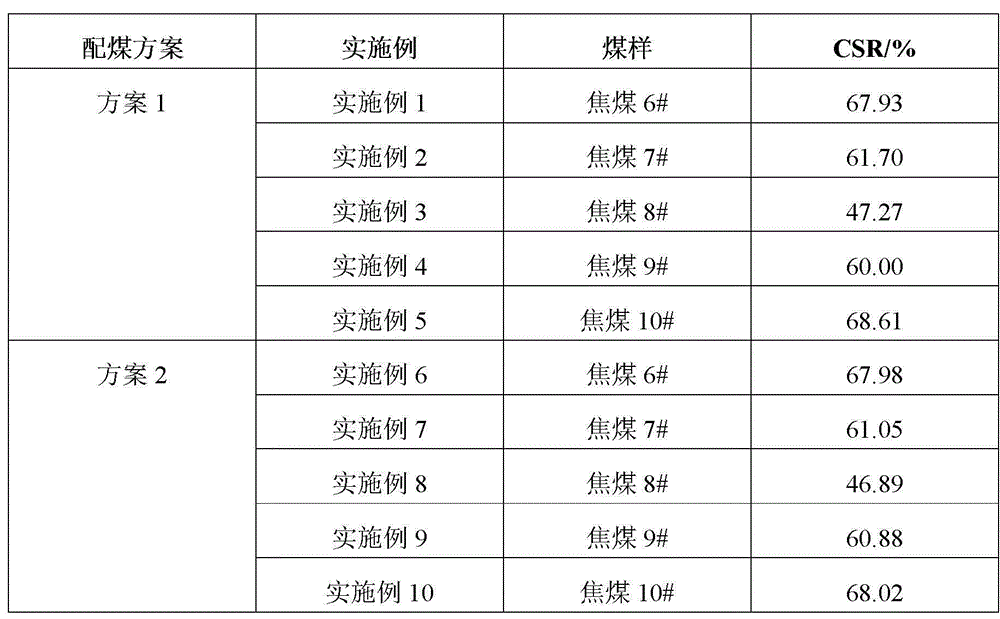

[0019] Fat coal, 1 / 3 coking coal, gas fat coal and lean coal remain unchanged, and five groups of different coking coals are taken, and coal blending is carried out according to the above proportions, and the coke strength after thermal reaction (CSR) is obtained. The relevant data are shown in Table 1 .

[0020] Table 1 The strength of coke after thermal reaction of different coking coals after coal blending

[0021] coal sample

X 1 / %

X 2 / %

MF / ddpm

b / %

CSR / %

Coking coal 1#

62

0

1278

36

65.24

Coking coal 2#

71

2

88...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cohesion index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com