An evaluation method of fat coal quality

An evaluation method and fat coal technology are applied in the fields of coal chemistry and metallurgical coking, which can solve the problems of fat coal quality defects, inability to meet the production needs of coal blending and coking, and achieve the effect of benefiting coke quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail through specific embodiments below.

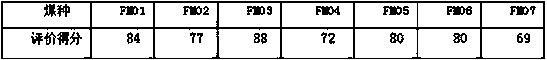

[0030] Take 7 coking fat coal types currently used by a certain company as an example, and evaluate by the method of the present invention.

[0031] A kind of evaluation method of fat coal coal quality, comprises the following steps:

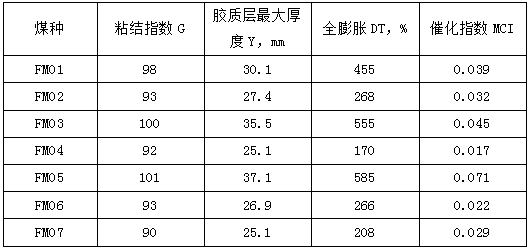

[0032]1) Detect the key indicators of coal quality of fat coal, take coal samples for testing, including industrial analysis, ash composition analysis, cohesion index G, maximum thickness of colloidal layer Y and full expansion DT, calculate MCI through industrial analysis and ash composition, The obtained data are shown in Table 1;

[0033] 2) Set P as the fat coal quality evaluation index, and determine it according to formula 1:

[0034] P=k 1 ×G+k 2 ×Y+k 3 ×DT + k 4 ×MCI + m Formula 1

[0035] In Formula 1, G, Y, DT, and MCI are the cohesive index, the maximum thickness of the colloidal layer, the total expansion degree, and the cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com