Automatic copper ball feeder

An automatic adding and adding machine technology, applied in the direction of electrolytic process, electrolytic components, etc., can solve the problems of product qualification rate decline, human resources waste, and affect the production efficiency of electroplating equipment, so as to improve production efficiency, save production cost, and avoid impact The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

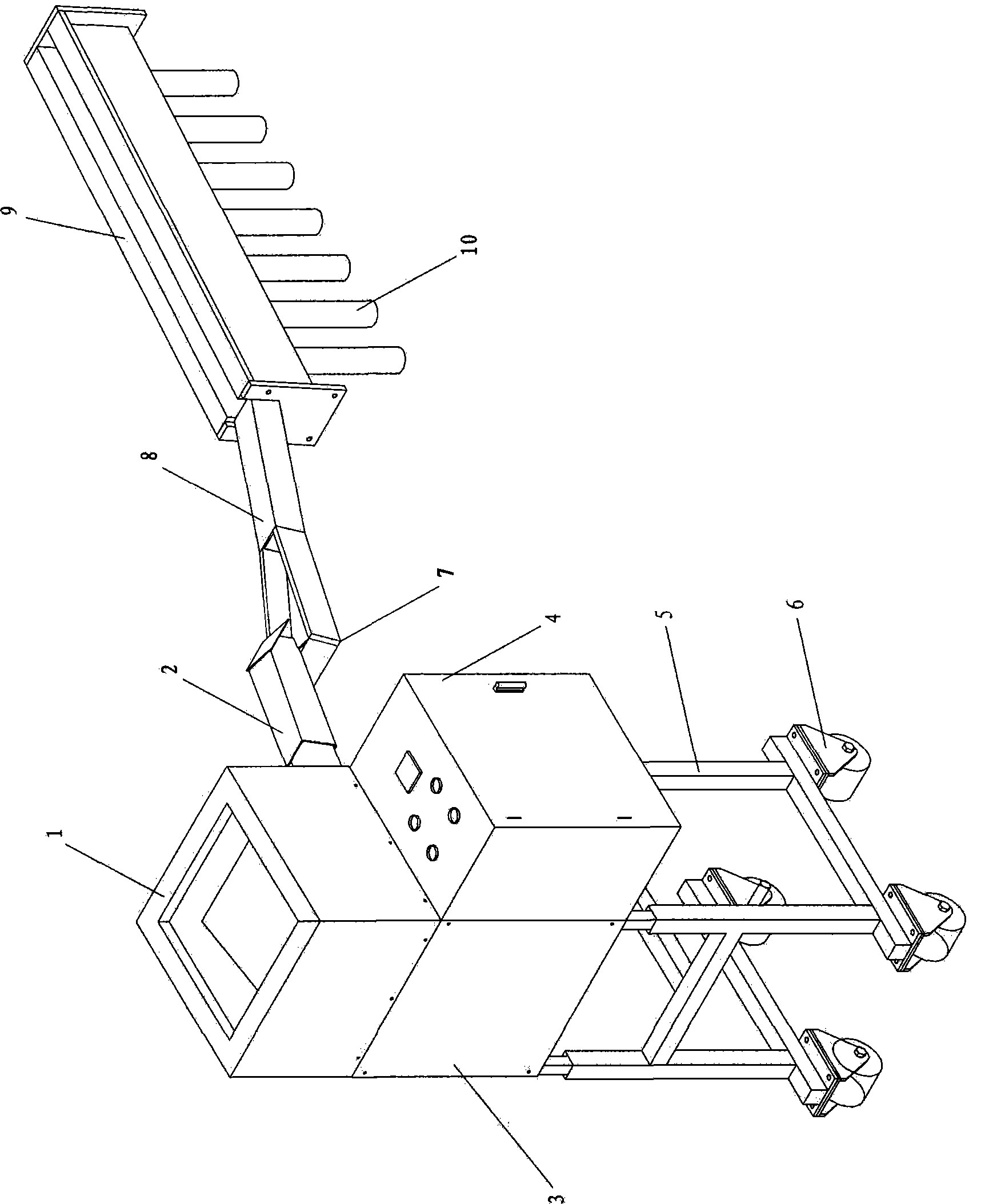

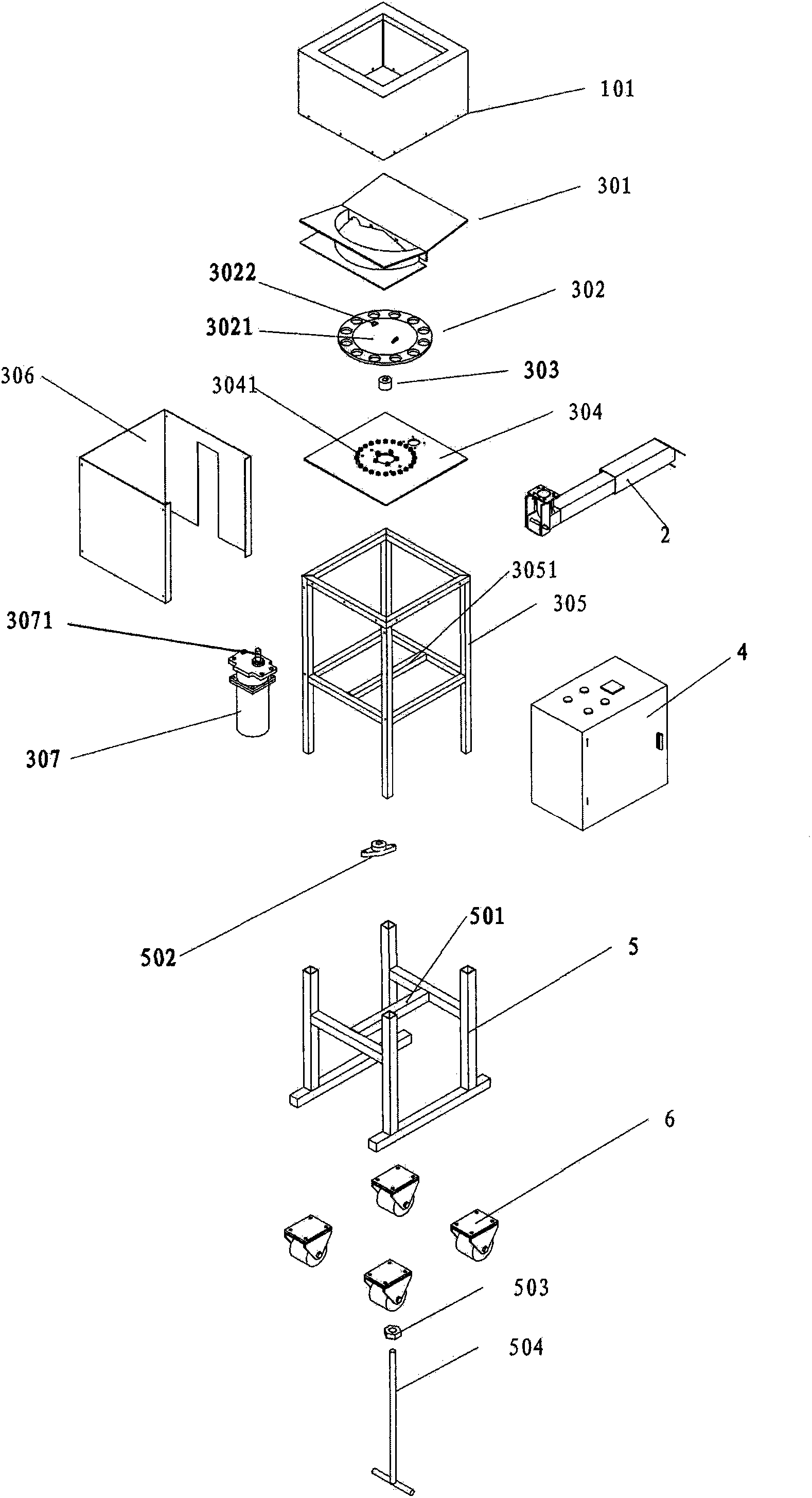

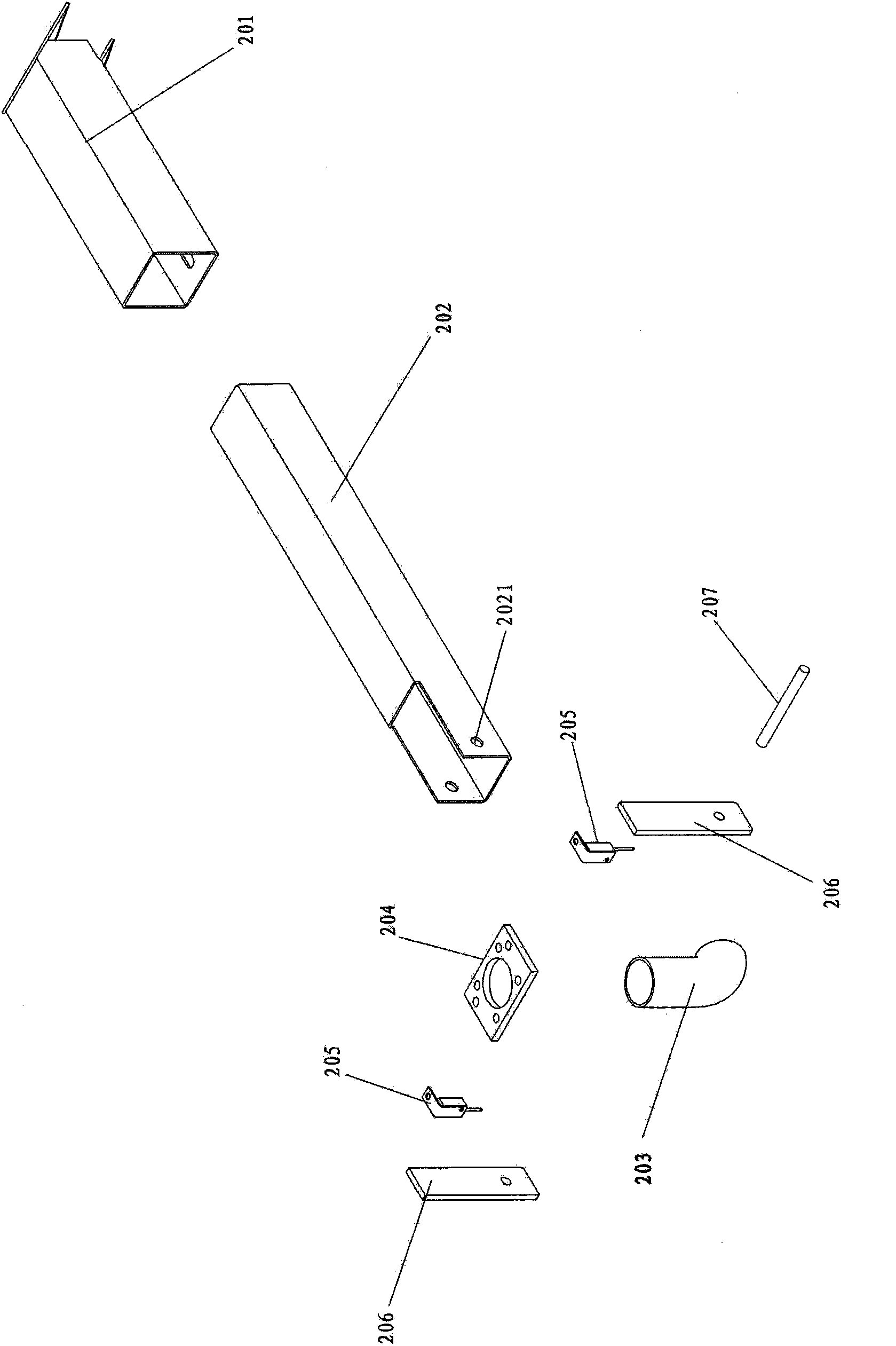

[0092] Such as Figure 1-Figure 20 Shown, a kind of automatic adding machine of copper ball comprises the ball box 1 that is mutually connected and fixed by mechanical means, adding machine 3, electric control box 4 and the tripod 5 that at least four castors 6 are fastened and connected with the bottom, as figure 1 ;

[0093] The ball box 1 is composed of a hollow ball box body 101, which is located on the upper part of the adding machine 3 as a whole. The overall shape of the ball box body 101 can be a cube or a cuboid, hollow, and can be directly made of a steel plate. type, the upper part of the ball box 101 is provided with an entrance (the shape of the entrance can be rectangular or circular), and the copper ball can enter the inside of the box from this opening, and the lower part is directly fixed on the adding machine 3; the ball b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com