Hot-rolled board strip production line laminar cooling method

A laminar cooling, production line technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of poor cooling, poor targeting, long cycle, etc., to achieve good cooling, good control effect, The effect of stable improvement of comprehensive quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

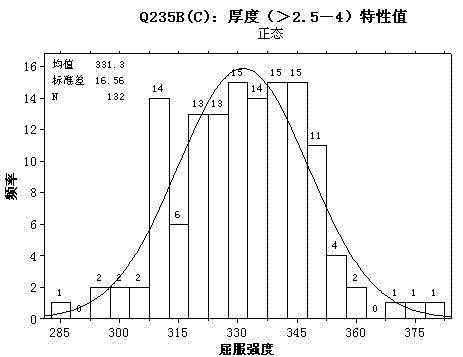

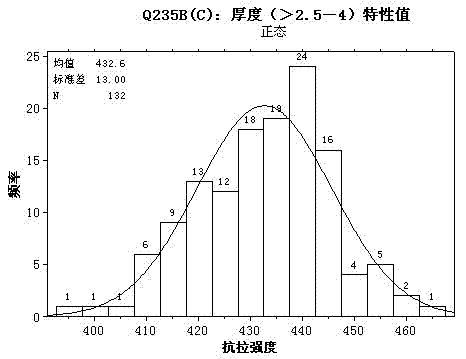

[0035] A batch of strips (steel type: Q235B(c)) with a thickness of 2.5-4mm and a temperature of 875-890°C passed through the laminar cooling zone at a speed of 8m / s. The spray pressure of the nozzle above the laminar cooling area is 0.068MPa, and the total flow of spray water above is 5415m 3 / h; the water spray pressure of the nozzle below the laminar cooling area is 0.068MPa, and the total flow of water spray below is 6507.5m 3 / h. The spray pressure of the nozzles on both sides of the laminar cooling area is 0.95MPa, and the total flow rate of the side spray is 364.8m 3 / h. The jet pressure of the jet nozzle is 1MPa, and the total jet flow is 0.4nm 3 / h.

[0036] After cooling, the temperature sent to the coiler is 625-650°C, and its mechanical properties are as follows: Figure 2-5 As shown, from the histogram Figure 2-5 From the above, it conforms to the normal distribution, the difference between the sample value and the average value is small, the single value dia...

Embodiment 2

[0038] Roll a batch of strips (steel type: Q235B(c)) with a thickness of 4-6 mm and a temperature of 850-870 °C in the finishing rolling mill at a speed of 9 m / s through the laminar cooling zone; The water spray pressure of the nozzle is 0.07MPa, and the total flow of water sprayed above is 5700m 3 / h; the water spray pressure of the nozzle below the laminar cooling area is 0.07MPa, and the total flow of water spray below is 6850m 3 / h; the spray pressure of the nozzles on both sides of the laminar cooling area is 1MPa, and the total flow of side spray is 384m 3 / h; the jet pressure of the jet nozzle is 1MPa, and the total jet flow rate is 0.4nm 3 / h.

[0039] After cooling, the temperature sent to the coiler is 645-662°C, and its mechanical properties are as follows: Figure 6-9 As shown, from the histogram Figure 6-9 From the above, it conforms to the normal distribution, the difference between the sample value and the average value is small, the single value diagram of...

Embodiment 3

[0041] Roll a batch of strips (steel type: Q235B(c)) with a thickness of 6-8mm and a temperature of 870-890°C in the finishing rolling mill through the laminar cooling zone at a speed of 10m / s; The water spray pressure of the nozzle is 0.0735MPa, and the total flow of water sprayed above is 5985m 3 / h; the water spray pressure of the nozzle below the laminar cooling area is 0.0735MPa, and the total flow of water spray below is 7192.5m 3 / h; the water spray pressure of the nozzles on both sides of the laminar cooling area is 1.05MPa, and the total flow rate of the side spray is 403.2m 3 / h; the jet pressure of the jet nozzle is 1MPa, and the total jet flow rate is 0.4nm 3 / h.

[0042] After cooling, the temperature sent to the coiler is 655-680 °C, and its mechanical properties are as follows: Figure 10-13 As shown, from the histogram Figure 10-13 From the above, it conforms to the normal distribution, the difference between the sample value and the average value is small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com