Patents

Literature

57results about How to "Qualified performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

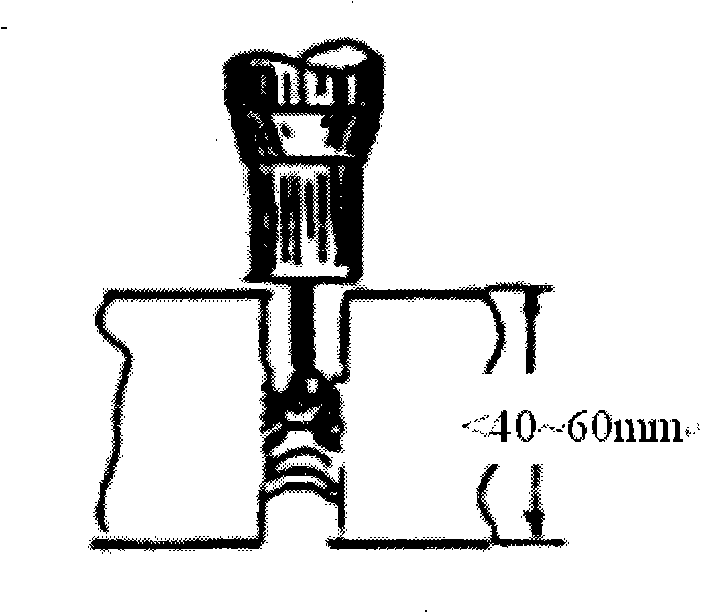

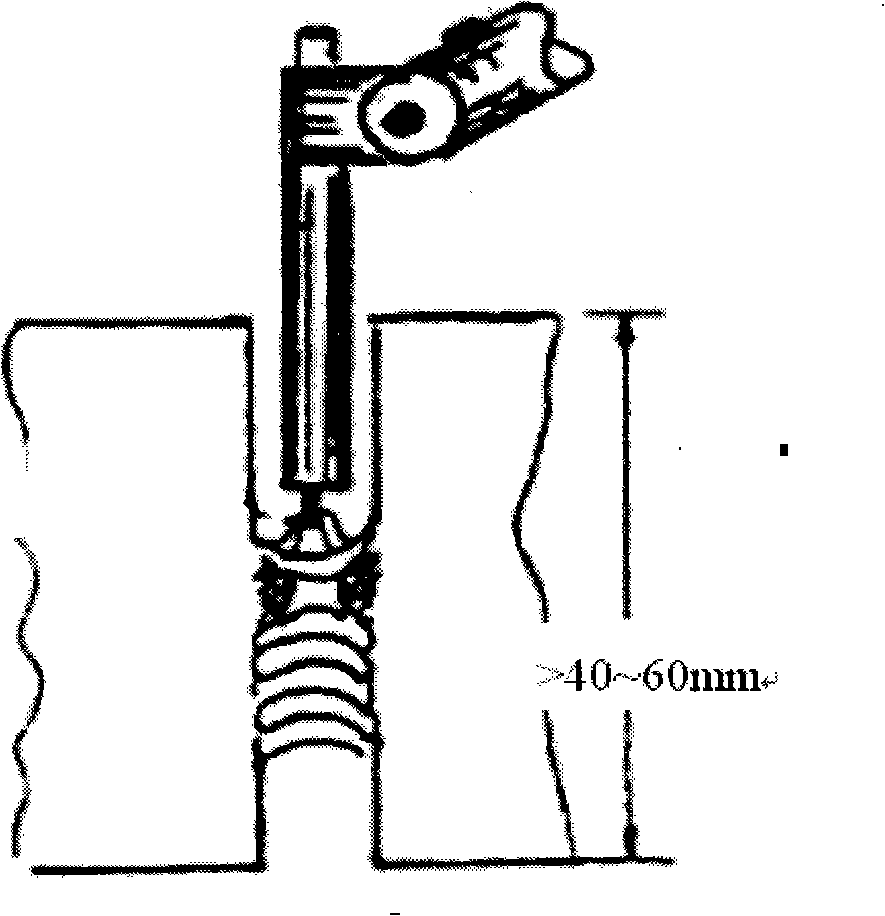

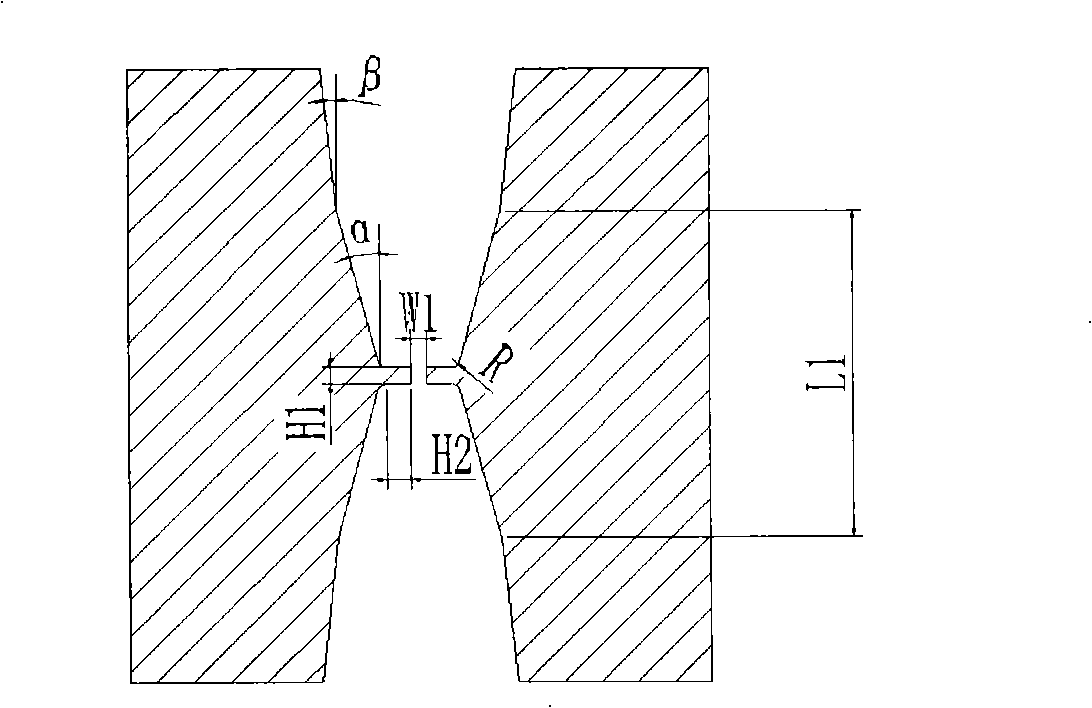

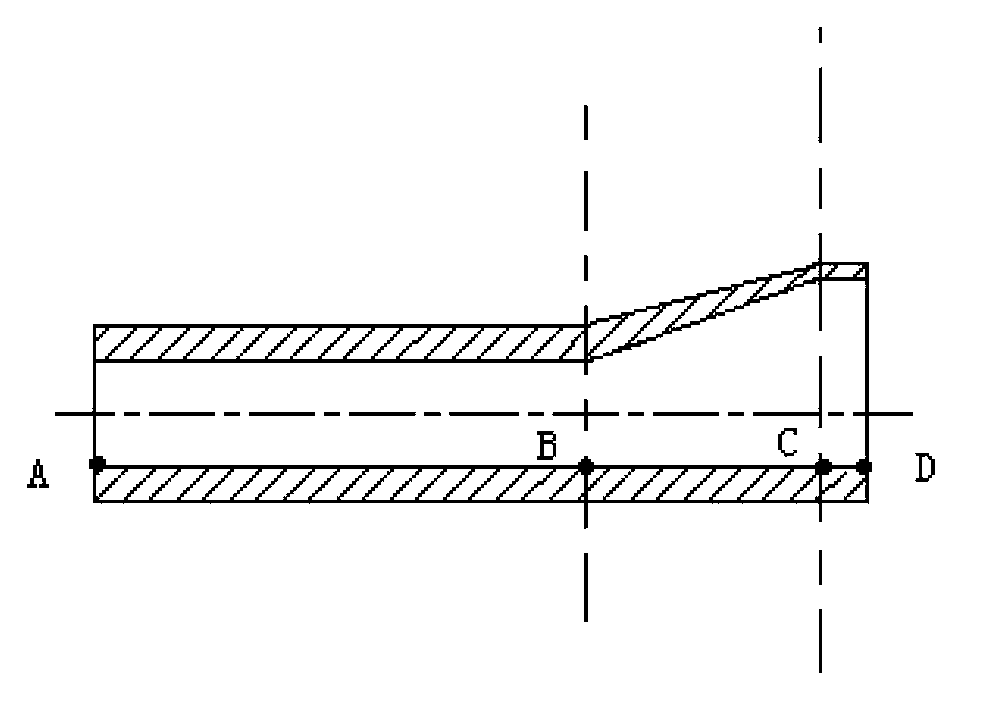

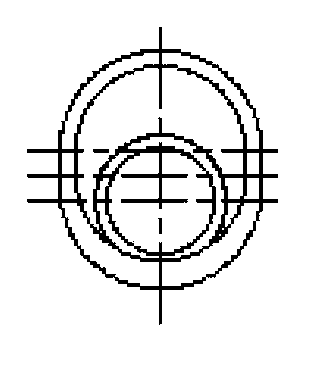

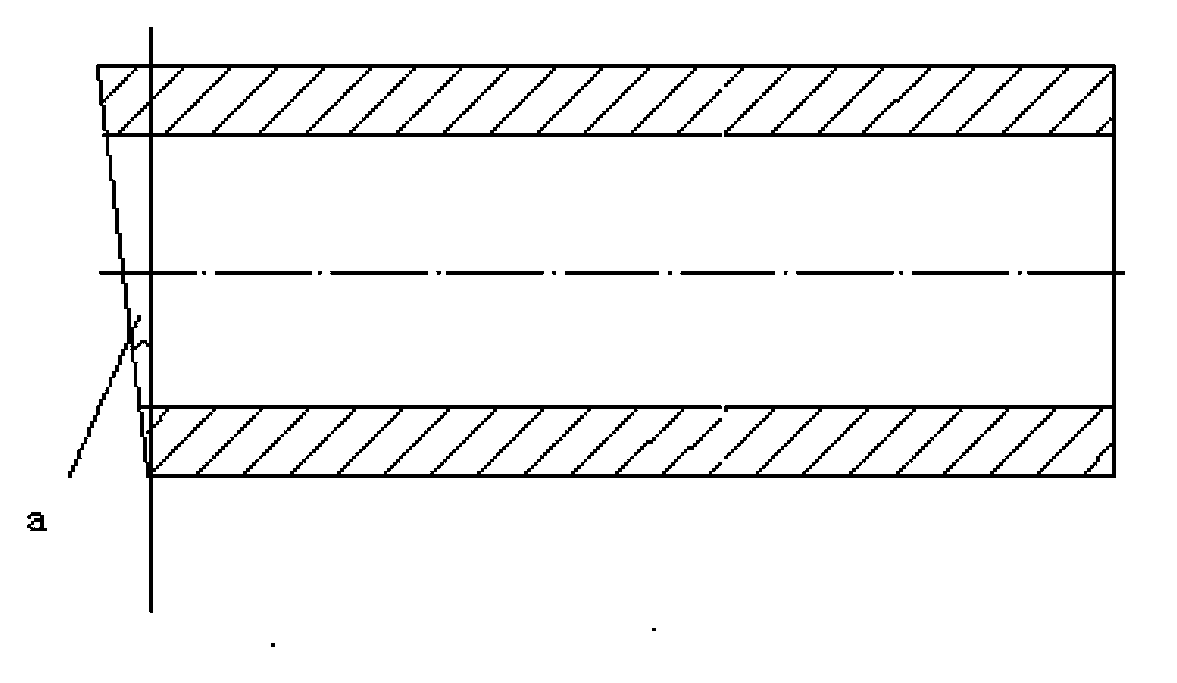

TIG automatic welding technique for titanium alloy thick plate narrow interstice

InactiveCN101293303AEnables narrow gap weldingWeld firmlyElectrode supporting devicesWorkpiece edge portionsEngineeringTitanium alloy

The invention discloses a narrow clearance TIC automatic welding technique for a thick plate of titanium alloy. The welding technique comprises six items of a welding torch form, a welding line spreading form, a bevel for welding form, selecting the parameters of the welding process, selecting the protection atmosphere of the welding process and eliminating a welding stress adopted by welding process. The welding technique of the invention realizes the narrow clearance welding for the large thick plate of the titanium alloy, has stable welding process, can obtain the welding lines which have no defects, qualified properties and 10mm to 16mm of widths of the welding lines on a cover surface layer, thus solving the key technical problems of the narrow clearance TIC automatic welding for the large thick plate of the titanium alloy, realizing the narrow clearance TIC automatic welding for the thick plate of the titanium alloy and having the advantages of high manufacture efficiency, low manufacture cost, small residual stress and residual deformation of joints, relatively thin and small welding line tissues and good mechanical property of the joints.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

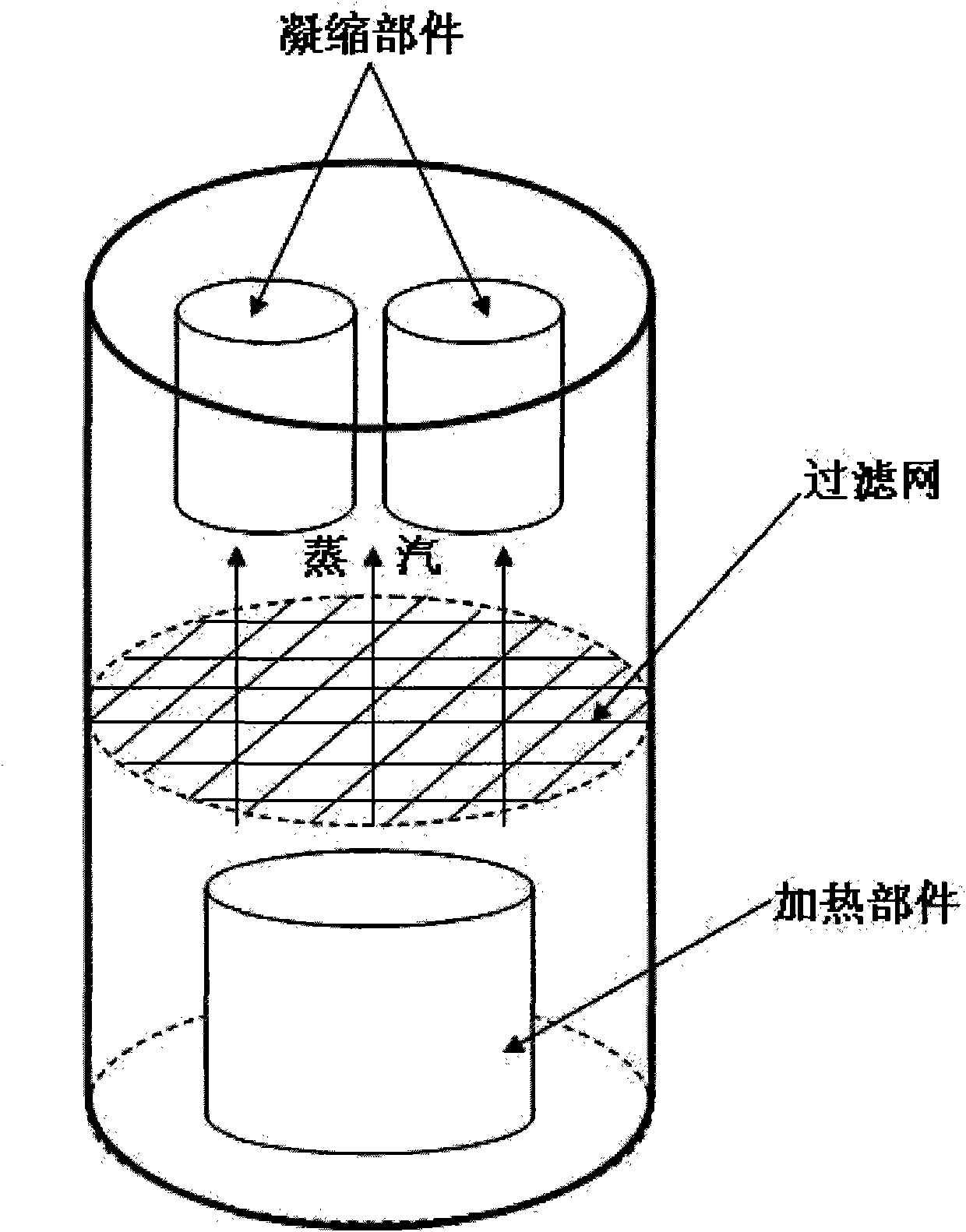

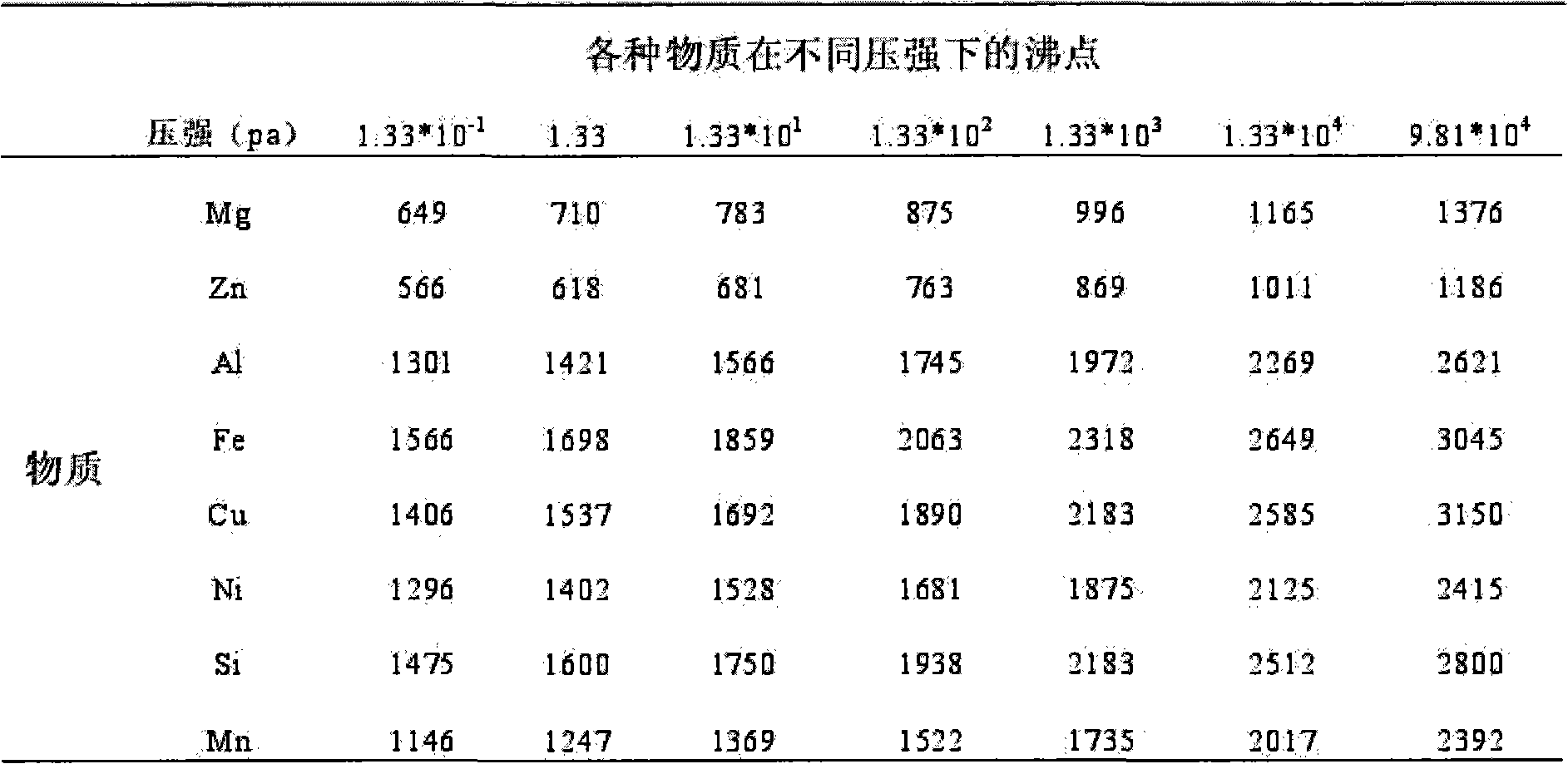

Vacuum distillation method for magnesium alloy

InactiveCN101948957AHigh recovery rateEasy to produceProcess efficiency improvementEnergy consumptionMaterials science

The invention discloses a vacuum distillation method for magnesium alloy. Waste scraps of the magnesium alloy are distilled under the vacuum degree of 0.8Pa so as to recycle high-risk waste magnesium, wherein the distillation temperature is 580 DEG C, the condensing temperature is 330 DEG C and the distillation time is 6 hours. The vacuum distillation method has the advantages of simple production process, high recovery rate of magnesium alloy, economy, feasibility, relatively low energy consumption, completely green metallurgy and great conservation of social wealth and resources and is environment-friendly, and a product has qualified performance. Therefore, the vacuum distillation method has wide application prospect and high application value.

Owner:NINGBO XIANGBO MACHINE

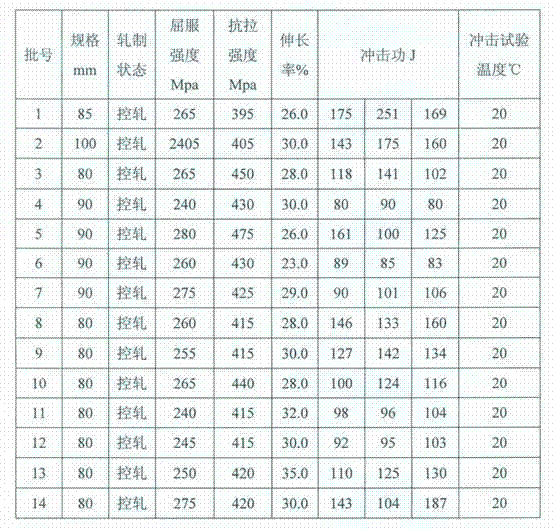

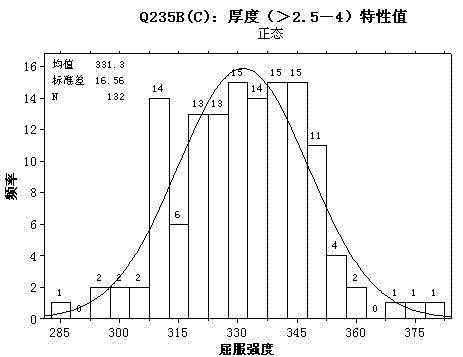

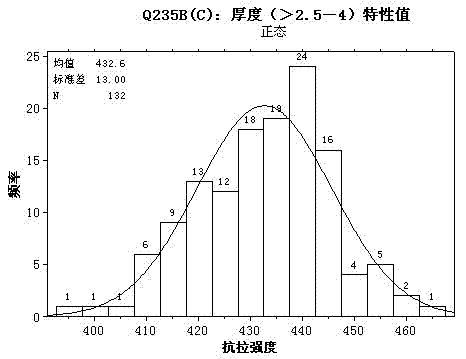

Method for producing flaw detection and performance guaranteed Q235B steel plate with 80-100mm in argon station

InactiveCN102345050AGuarantee the quality of flaw detectionGuaranteed performanceChemical compositionIngot

The invention discloses a method for producing a flaw detection and performance guaranteed Q235B steel plate with 80-100mm employing argon station steel. The produced steel plate of the specification comprises chemical components of 0.10-0.19% of C, 0.15-0.30% of Si, 0.50-0.80% of Mn, P no more than 0.023%, S no more than 0.015%, Als no more than 0.020% and N no more than 0.005%. The invention employs a 250mm continuous casting billet; and a production process flow comprises steps of: molten iron desulphurization, treatment in 120t top-bottom combined blown converter, continuous casting, casting blank insulation and slow cooling, rolled steel plate stack cooling, finishing, examination and warehouse entering. Compared with a prior art, the invention employs argon station steel to produce flaw detection guaranteed steel plate, cancels a routine LF refining production, shortens a production flow and reduces costs per ton of steel; meanwhile, a 250mm thickness section is adopted in the production to increase production rhythm and substantially reduce production costs, compared with a routine section thicker than 250mm or mold ingot.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

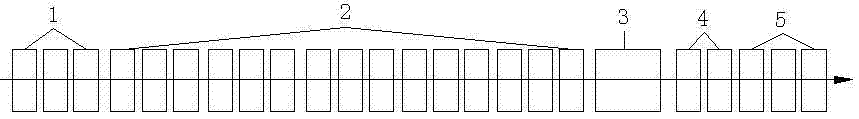

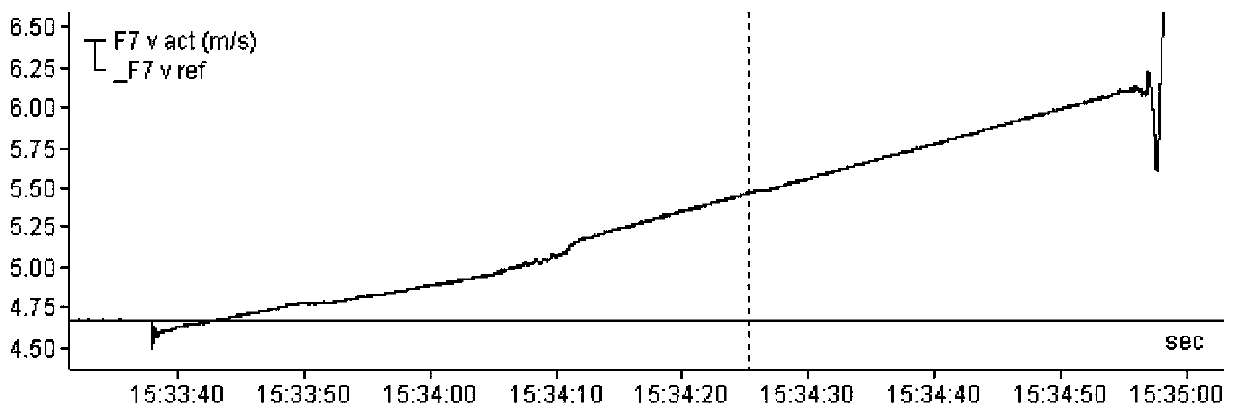

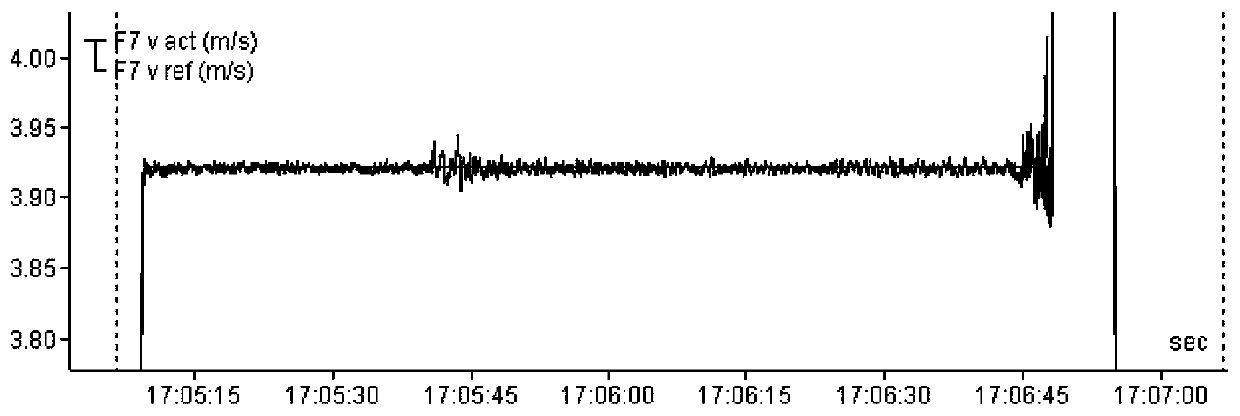

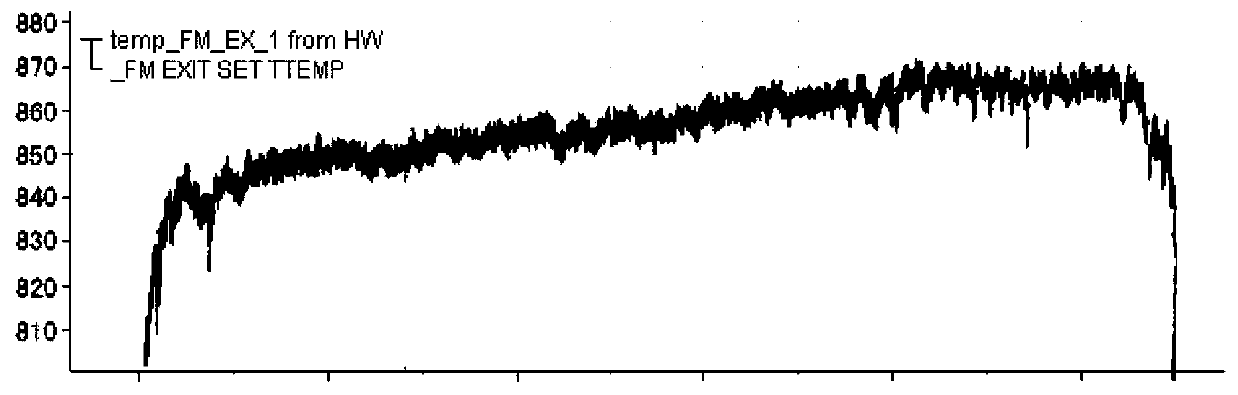

Hot-rolled board strip production line laminar cooling method

ActiveCN103286147ASteady improvement in qualityReduce smelting and rolling production costsWork treatment devicesMetal rolling arrangementsProduction lineLaminar cooling

The invention discloses a hot-rolled board strip production line laminar cooling method. A laminar cooling area between a finishing mill set and a coiling machine is divided into a rapid cooling section I, a coarse adjusting section, an air cooling section, a rapid cooling section II and a fine adjusting section. A board strip with the thickness of 2.5-12mm and the temperature of 850-900 DEG C is made to pass through the laminar cooling area with the speed of 8-10m / s. Water spraying pressure of a nozzle above the laminar cooling area is 0.068Mpa to 0.0735MPa, water spraying pressure of a nozzle below the laminar cooling area is 0.068MPa to 0.0735MPa, water spraying pressure of nozzles at the two sides of the laminar cooling area is 0.95Mpa to 1.05MPa, and air jetting pressure of an air jetting nozzle is 1MPa. When strip steel is conveyed on the laminar cooling area, the strip steel is cooled through the nozzles arranged above, below and at the two sides of the laminar cooling area. Cooling performance is good, a controlling effect is better, qualified performance of steel coil products is ensured, comprehensive quality of steel coils is stably improved, and refining and rolling production cost of the steel coil products is greatly reduced.

Owner:CHONGQING IRON & STEEL CO LTD

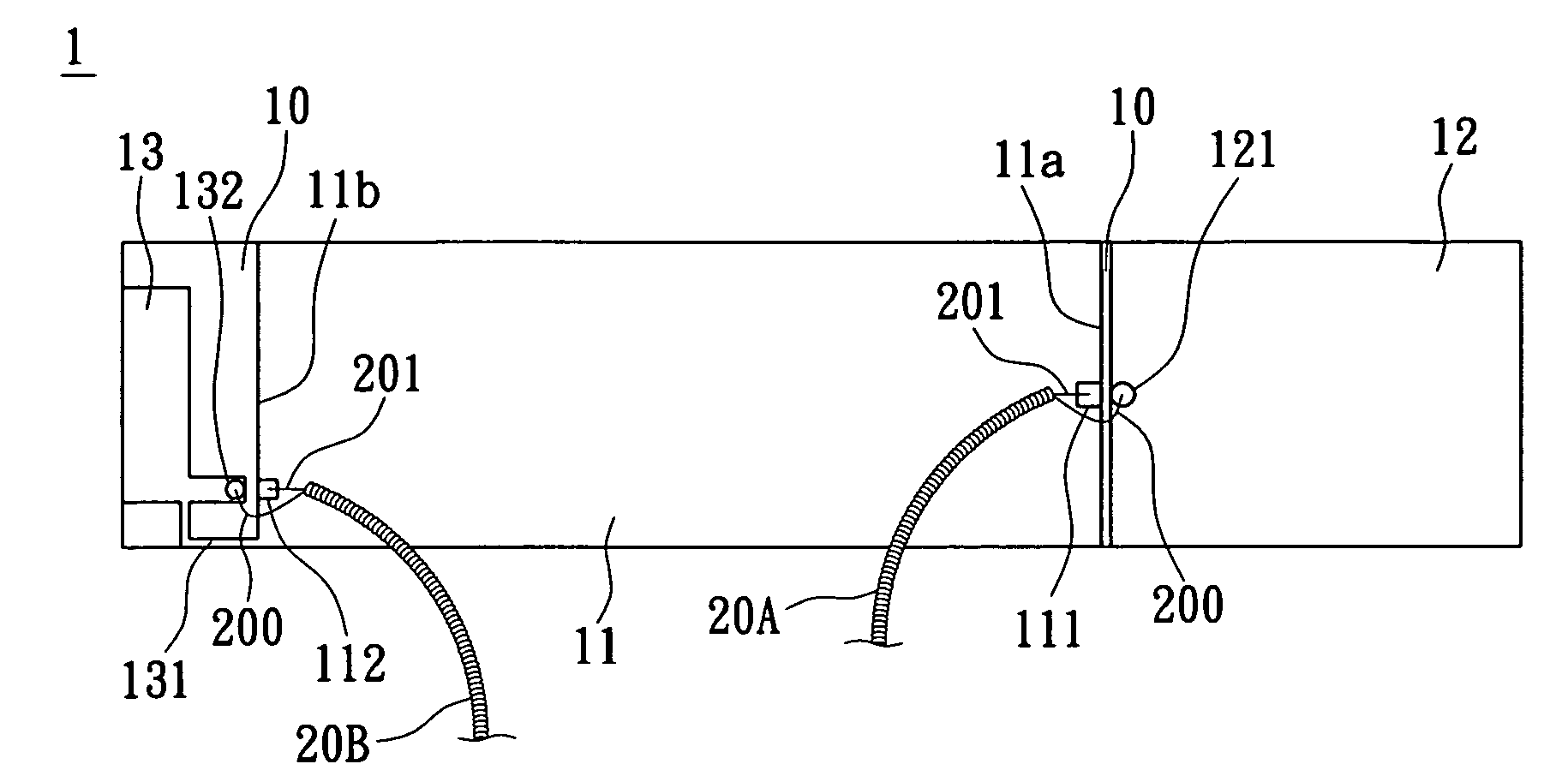

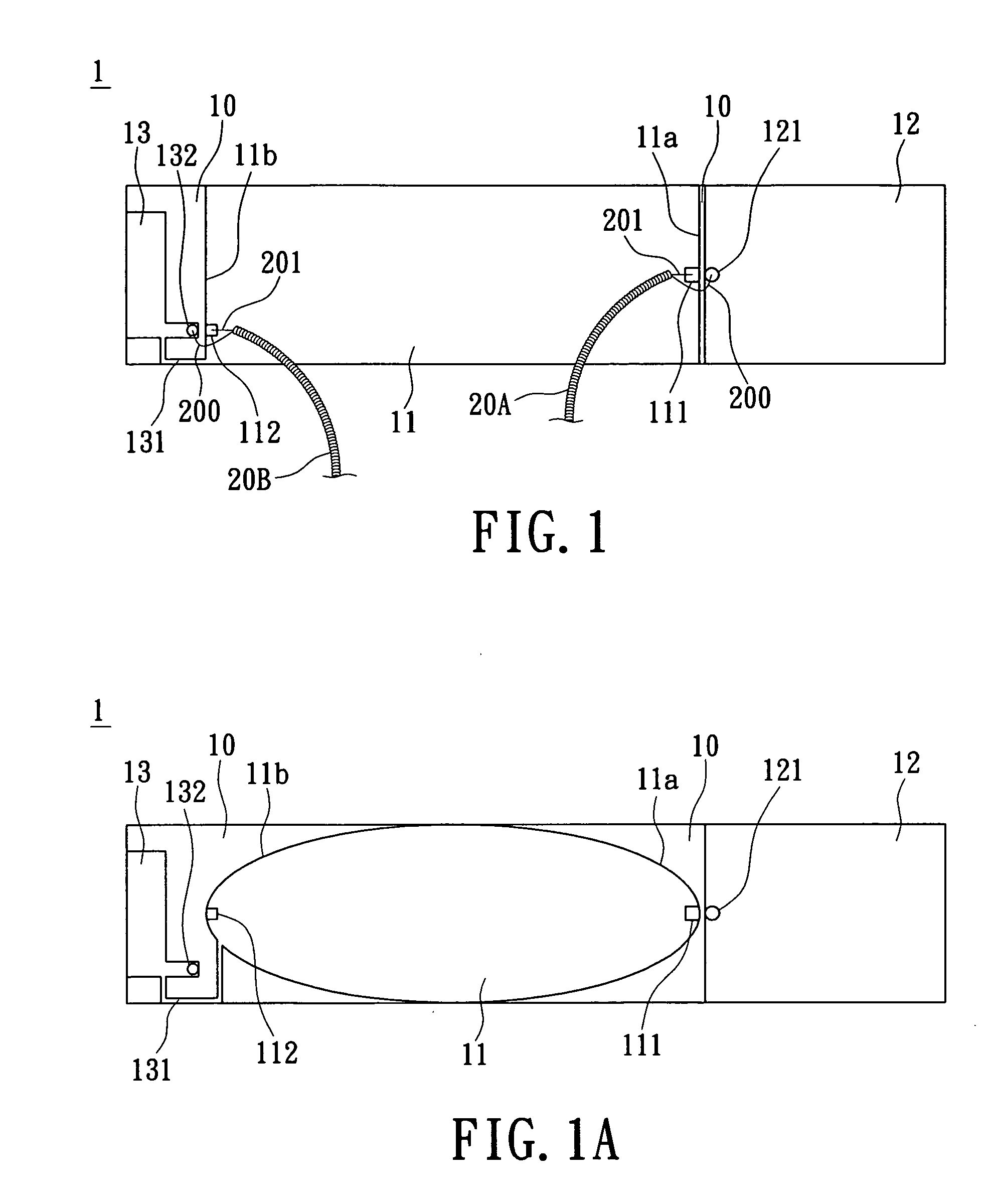

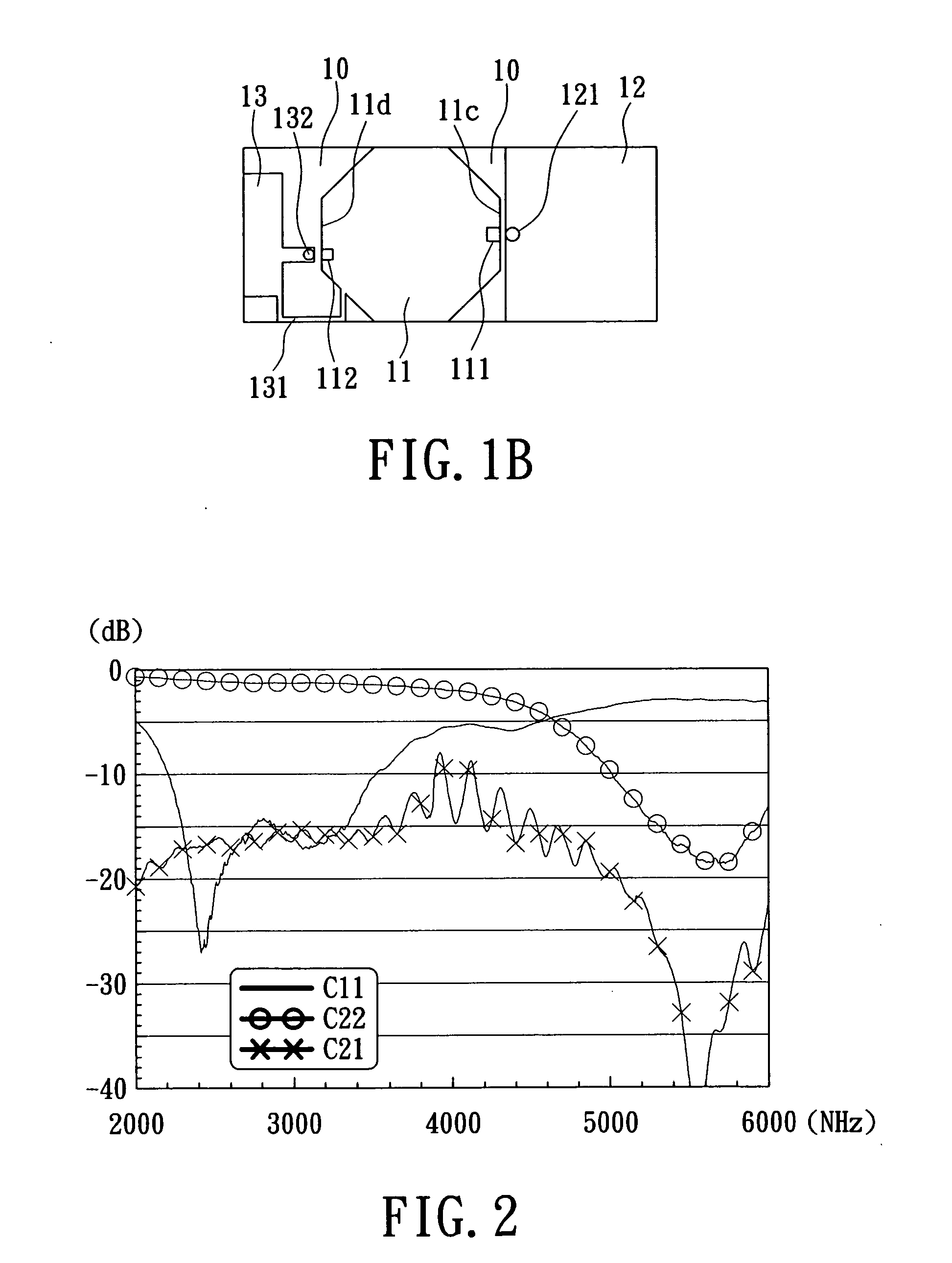

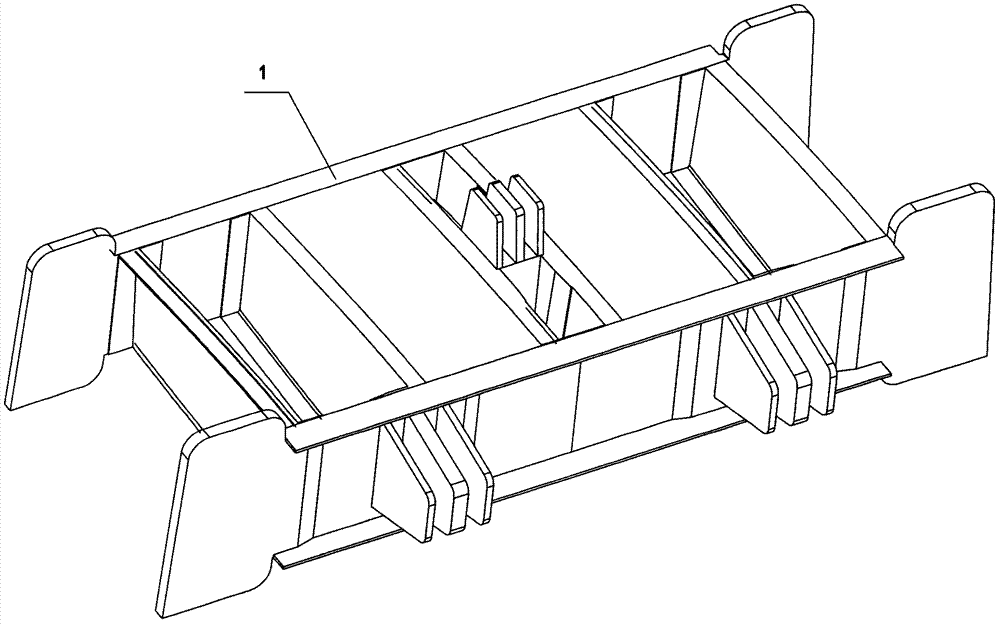

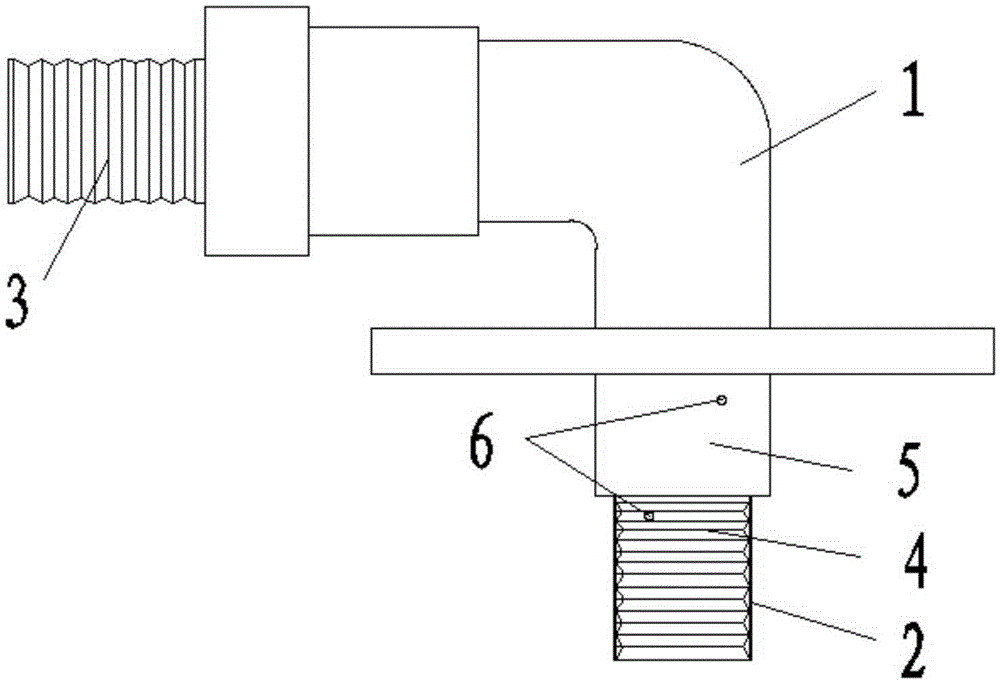

Dual-feed and dual-band antenna

ActiveUS20090251381A1Small sizeQualified performanceAntenna arraysSimultaneous aerial operationsCoaxial cableEngineering

A dual-feed and dual-band antenna includes a substrate, a grounding unit disposed on the substrate and having two opposite sides, a first radiating unit disposed on the substrate near the first side of the grounding unit, and a second radiating unit disposed on the substrate near the second side. The second radiating unit has a short-circuit strip electrically connected to the grounding unit. The antenna further includes a first coaxial cable electrically connected to the first radiating unit and the grounding unit, and a second coaxial cable electrically connected to the second radiating unit and the grounding unit.

Owner:LITE ON TECH CORP +1

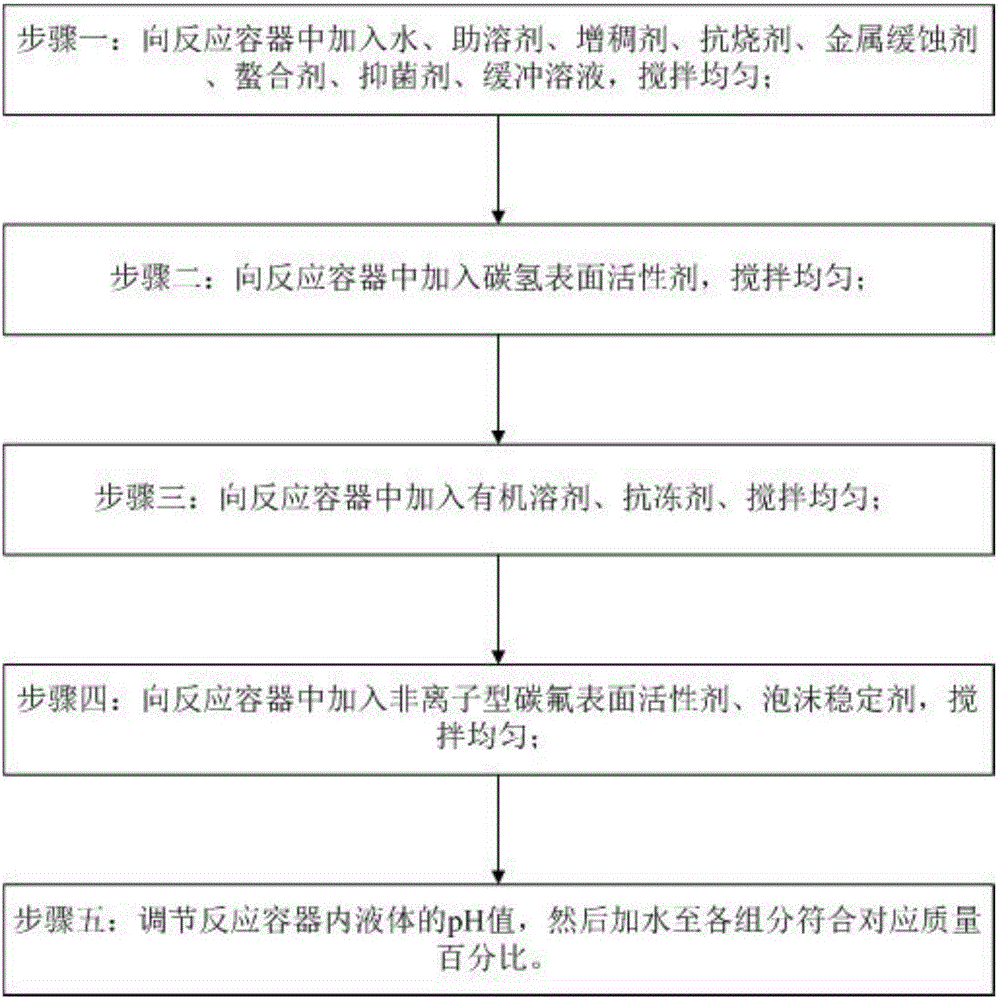

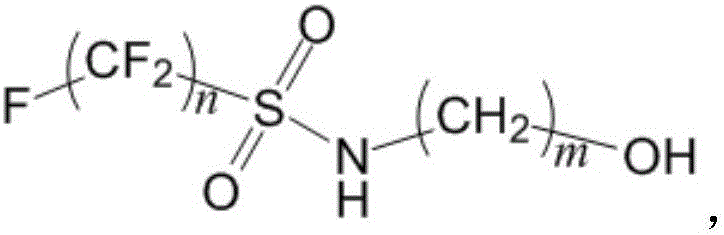

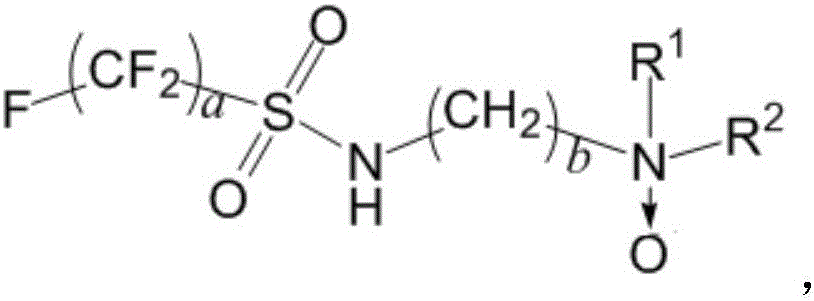

Fire extinguishing agent and preparation method thereof

The invention discloses a fire extinguishing agent. The fire extinguishing agent is characterized by consisting of the following components in percentage by mass: 1.5-3% of a non-ionic fluorocarbon surfactant, 0.1-1% of a foam stabilizer, 2-4% of a hydrocarbon surfactant, 0.1-0.5% of a thickening agent, 0.1-0.5% of an anti-burning agent, 2-5% of a cosolvent, 1-5% of an organic solvent, 0.2-2% of a buffer solution, 0.1-0.5% of a metal corrosion inhibitor, 4-10% of an anti-freezing agent, 0.2-0.5% of a bacteriostatic agent, 0.5-2.5% of a chelating agent and the balance water. The fire extinguishing agent disclosed by the invention is rich and stable in forma, spreads quickly on an oil surface, is self-inspected according to the PRC National Standards GB 15308-2006 ( Foam Fire Extinguishing Agent), is qualified in performance and is excellent in fire extinguishing performance. Besides, the components of the fire extinguishing agent do not rely on imports, so that the product is relatively low in price, can be diluted with fresh water or seawater for use, is wide in scope of application, and has a very great market prospect.

Owner:浙江睦田消防科技开发有限公司

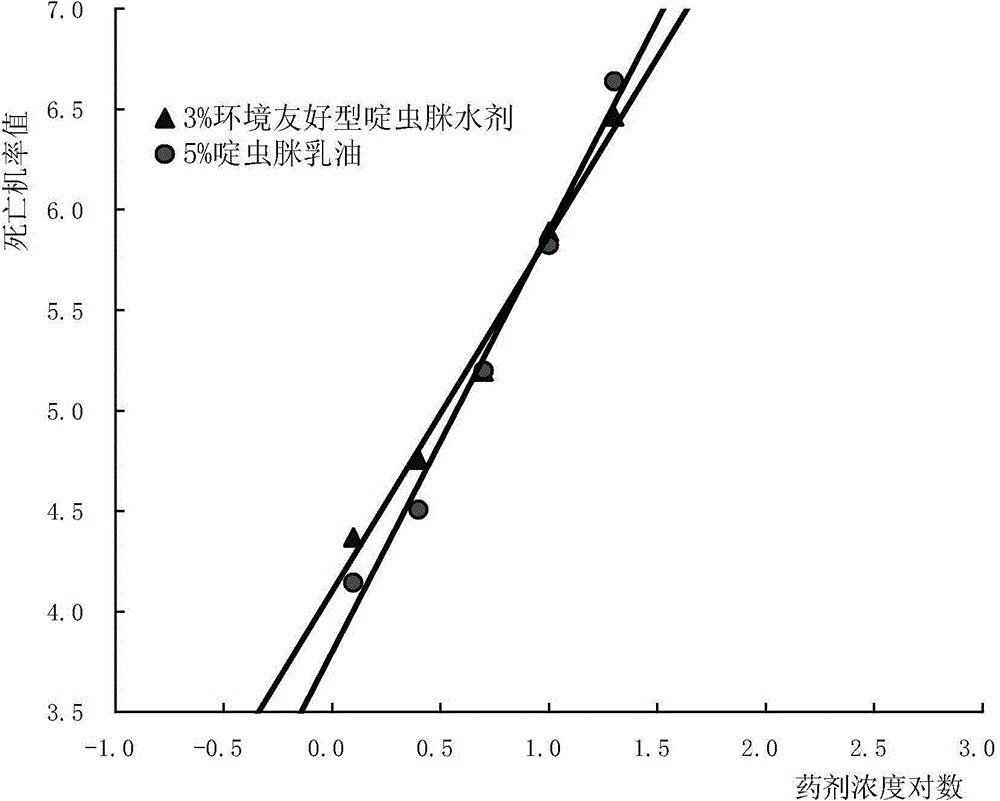

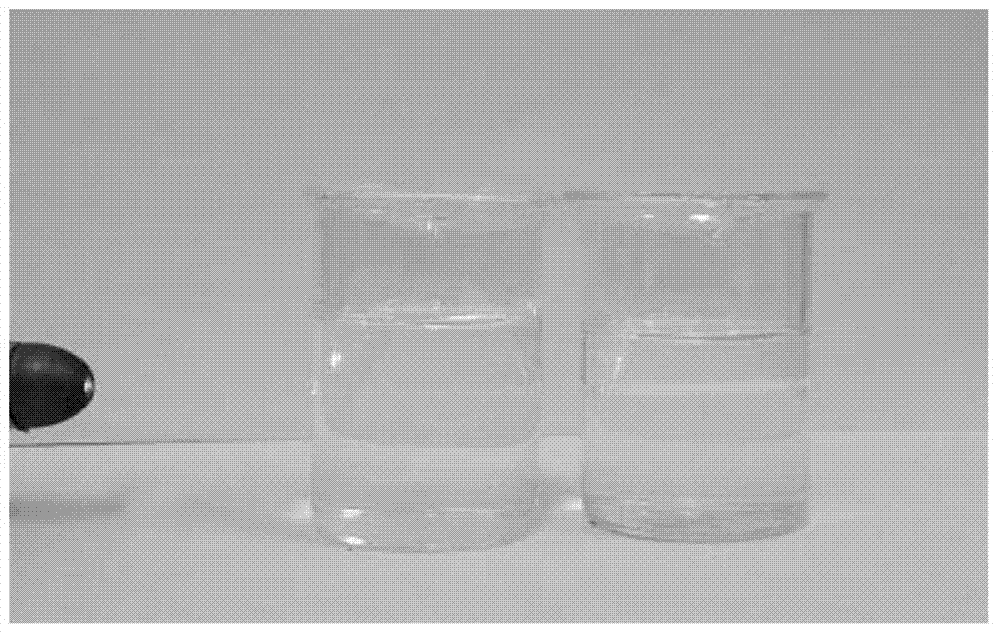

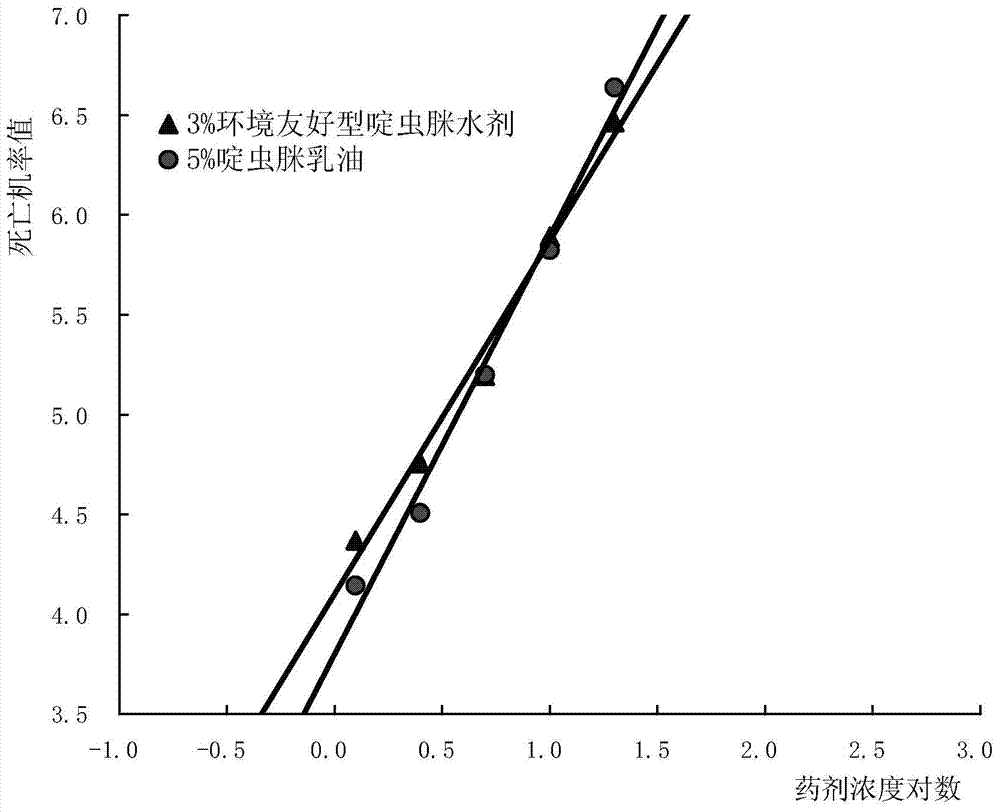

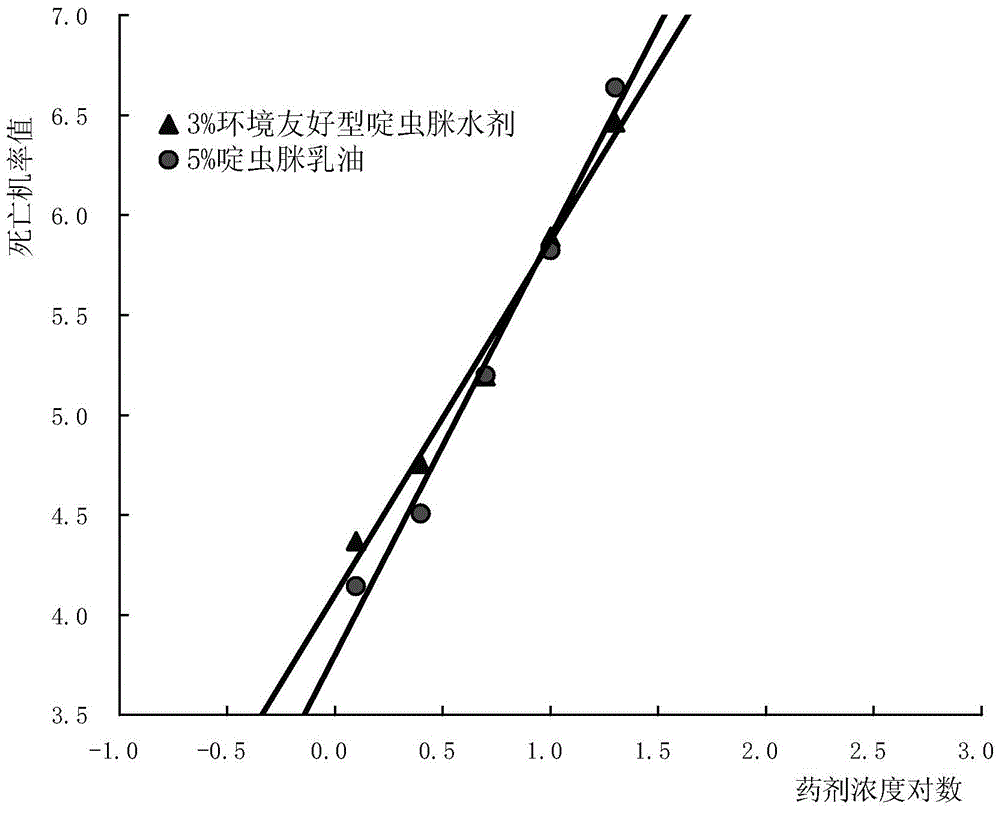

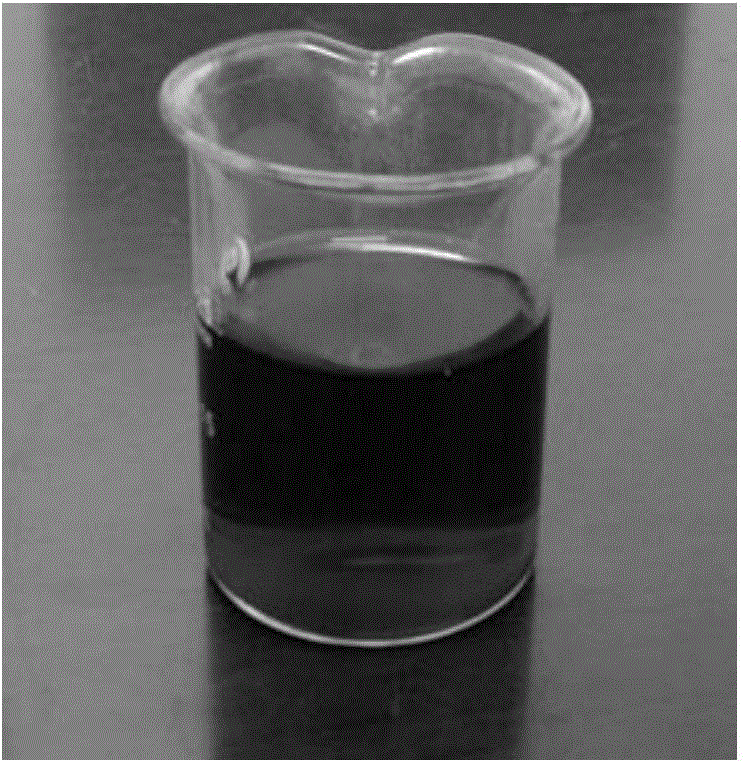

Multifunctional environment-friendly acetamiprid aqua and preparation method thereof

ActiveCN103907643AHard water resistance qualifiedQualified performanceBiocideAnimal repellantsWater basedOrganic solvent

The invention provides a multifunctional environment-friendly acetamiprid aqua, comprising, by weight, 1 to 5% of acetamiprid, 1 to 10% of an agent A and 1 to 5% of a functional agent. The agent A is one or more selected from the group consisting of an anionic surfactant containing a sulfonic acid group, an anionic surfactant containing a sulfuric acid group and an anionic surfactant containing a carboxylic group. Preferably, the aqua may further comprise an agent B accounting for 1 to 5% of the total weight of the aqua. The invention also provides a preparation method for the multifunctional environment-friendly acetamiprid aqua. The multifunctional environment-friendly acetamiprid aqua does not contain any organic solvent and / or corrosive solvent, is a uniform and clear solution and has indoor insecticidal activity similar to that of acetamiprid missible oil. Thus, the aqua provided by the invention is obviously better than missible oil and other water-based dosage forms.

Owner:南京善思生态科技有限公司

Continuous annealing production method for thin cold-rolled lace-rolled hard steel plate

ActiveCN105779752AStable productionEliminate lossFurnace typesHeat treatment furnacesSheet steelStrip steel

The invention relates to a continuous annealing production method for a thin cold-rolled lace-rolled hard steel plate. By the adoption of the continuous annealing production method for the thin cold-rolled lace-rolled hard steel plate, the technical problem that due to the fact that the lace plate shape defect of existing 0.17-0.20 mm thick cold-rolled lace-rolled hard steel plate exists, stable production is difficult when annealing is conducted through a continuous annealing unit is solved. According to the technical scheme, a cold-rolled lace-rolled hard steel plate roll which is 0.17-0.20 mm thick is uncoiled, cleaned, annealed, flattened and coiled through a vertical continuous annealing furnace unit, and tin electroplating substrates are obtained; the unit tension of strip steel of a cleaning section is 28.05-38.89 N / mm<2>; the speed of the strip steel of a central section of the unit is decreased to 350-500 mpm and the temperature of the strip steel of a heating section and a uniform heating section in the annealing furnace is decreased to 585-605 DEG C 5-10 minutes before the cold-rolled lace-rolled hard steel plate roll enters the vertical continuous annealing furnace unit; the annealing time is 54-79 S; and the unit tension of the strip steel in the uniform heating section is 11.4-15.0 N / mm<2>.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

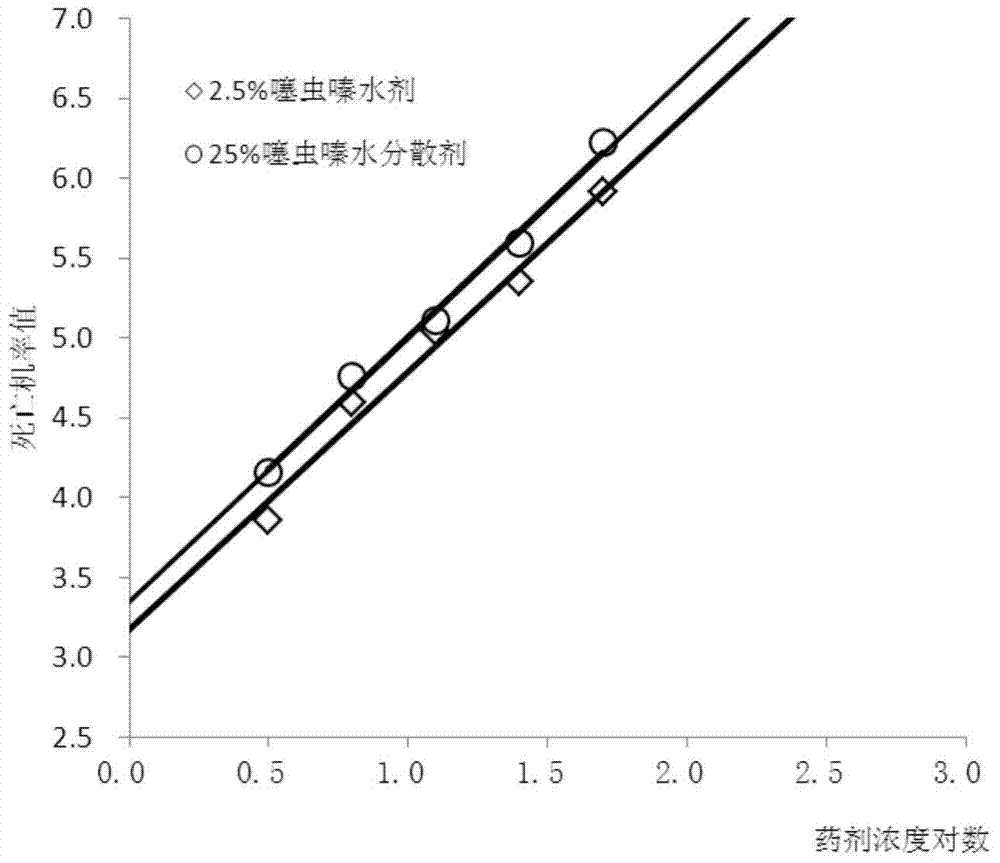

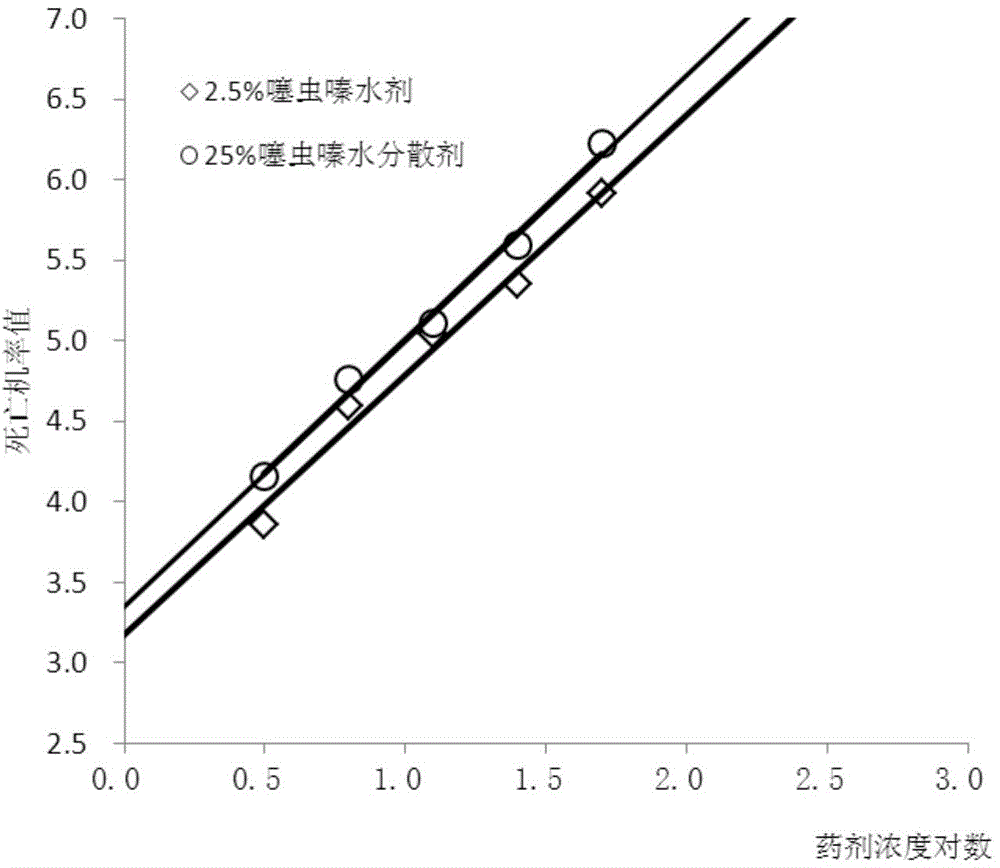

Multifunctional environmental-friendly thiamethoxam aqua and preparation method thereof

ActiveCN103858922AStable storageAccelerated dilutionBiocideAnimal repellantsWater basedOrganic solvent

The invention provides a multifunctional environmental-friendly thiamethoxam aqua. The multifunctional environmental-friendly thiamethoxam aqua contains the following ingredients in percentage by weight: 1-5% of thiamethoxam, 1-10% of action agent A and 1-5% of functional agent, wherein the action agent A is one or more selected from sulfonic acid group containing anionic surfactant, sulfuric acid group containing anionic surfactant and carboxylic acid group containing anionic surfactant; preferably, the multifunctional environmental-friendly thiamethoxam aqua can also contain an action agent B which is 1-6% the total weight of the multifunctional environmental-friendly thiamethoxam aqua. The invention further also provides a method for preparing the multifunctional environmental-friendly thiamethoxam aqua. Proved by experiments, the indoor insecticidal activity of the multifunctional environmental-friendly thiamethoxam aqua provided by the invention is equivalent to that of a thiamethoxam aqueous dispersion with concentration which is the same as that of the multifunctional environmental-friendly thiamethoxam aqua. The thiamethoxam aqua provided by the invention does not contain any organic solvent, is of a uniform clarified solution in appearance and is stable in long-term placement, so that the thiamethoxam aqua is obviously better than emulsified oil preparations and other water-based preparation forms.

Owner:南京善思生态科技有限公司

Multipurpose outdoor sports shoes

The invention discloses multipurpose outdoor sports shoes. The sports shoe comprises a composite sole, a composite insole, and a composite vamp cloth. The composite sole is formed by combining an EVA injection molding midsole, a rubber outsole, and an injection molding arch supporting frame in sequence. The composite insole is formed by combining a modified EVA foaming insole and an insole cloth. The composite vamp cloth is formed by a shoe fabric and a shoe lining which are overlaid in sequence. The insole cloth is a blended fabric of bastose and chemical fibers. The shoe fabric is a blended fabric obtained by fibers through blending. The sports shoes have relatively good damping function, and relatively good half sole bending resistance performance and midsole torque resistance function. Through tests, the shoe can bend for 100 thousand times in normal temperature, and has no broken surface and no glue failure. The shoe can bend for 40 thousand times in low temperature of -20 DEG C, and has no broken surface and no glue failure. The sports shoes have relatively good no-skid property, and the sports shoes have relatively good ageing-resistant performance and wash resistance performance.

Owner:LI NING CHINA SPORTS GOODS +2

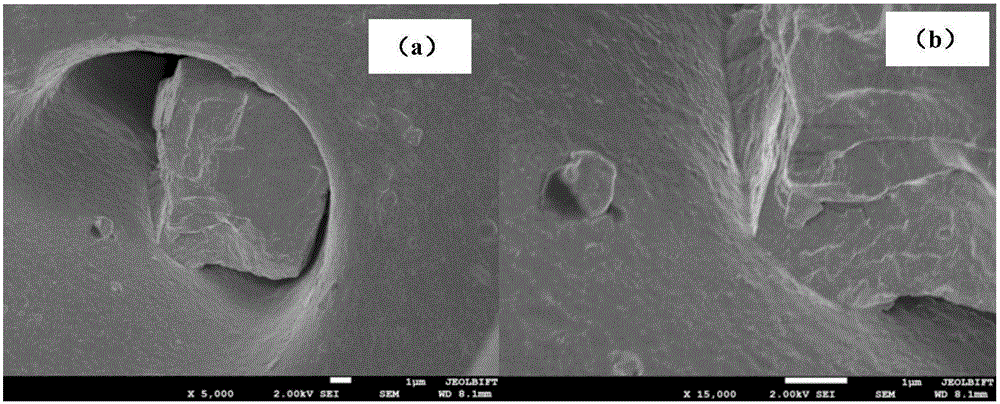

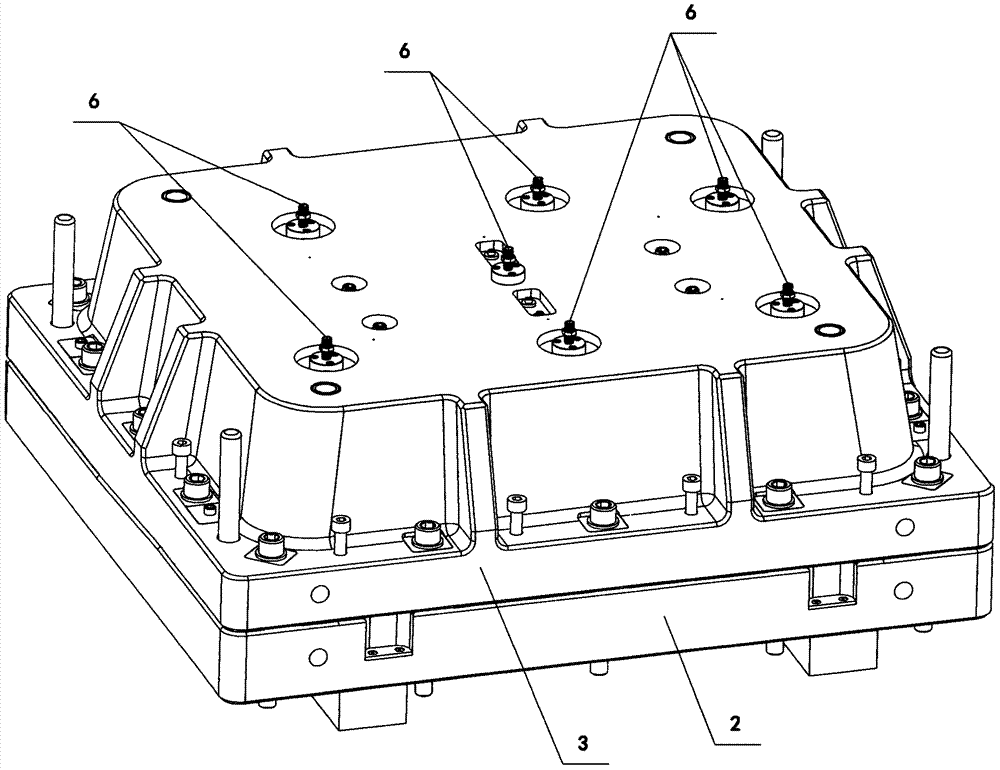

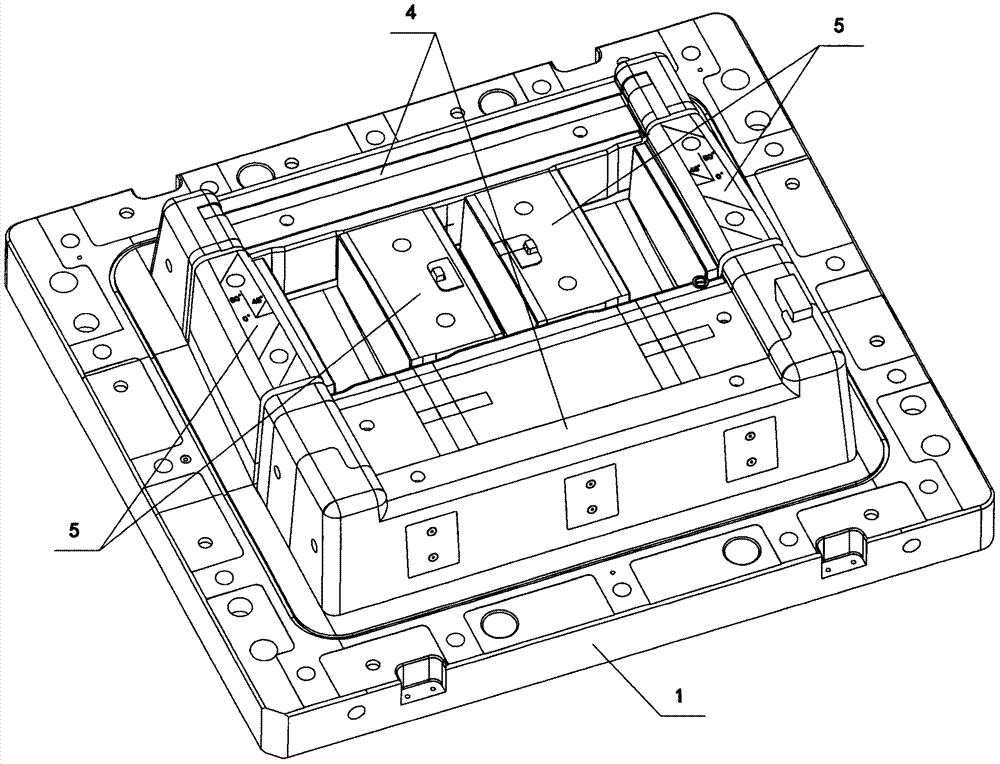

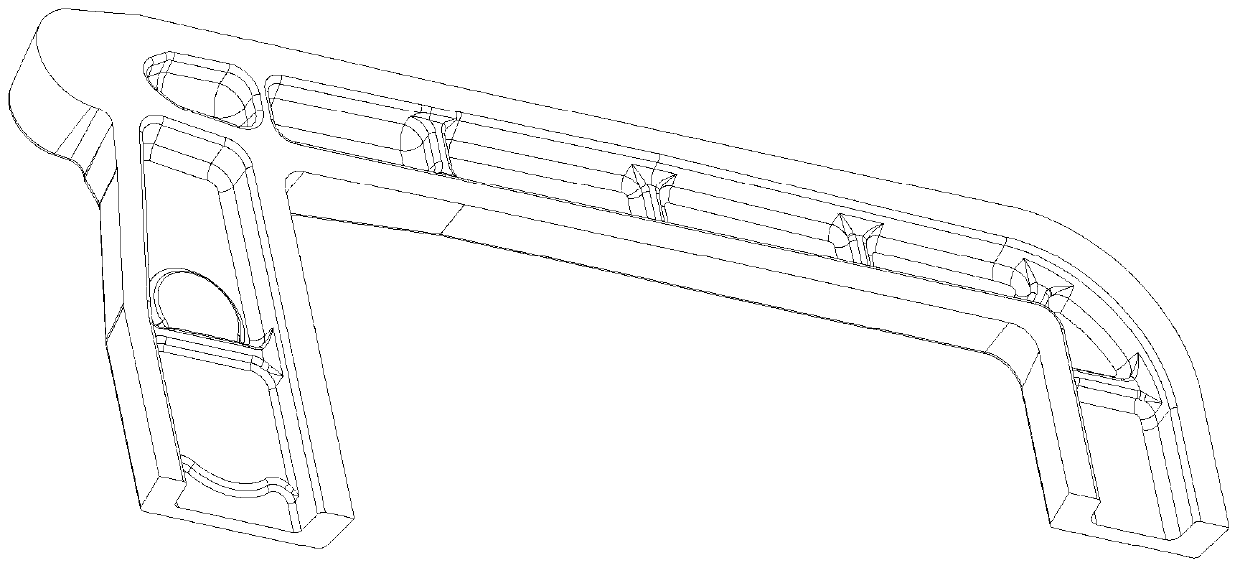

Forming method for shell of airplane cover

InactiveCN107187079AGuaranteed positional stabilityQualified performanceDomestic articlesFiberVolumetric Mass Density

The invention discloses a forming method for a shell of an airplane cover. The forming method comprises the steps that (1) a special forming mould is manufactured; (2) carbon fiber cloths are laid; (3) mould compounding and glue injecting are conducted; (4) vacuumizing operation is conducted while glue is injected; (5) solidification and pressure maintaining are conducted; and (6) a product is demoulded and taken out. By adopting the method, the stability of the positions of the carbon fiber cloths is guaranteed, the density uniformity of the product is guaranteed accordingly, and it is guaranteed that performance of the finished product is qualified.

Owner:NINGBO CITY EPL MOLD & PLASTIC

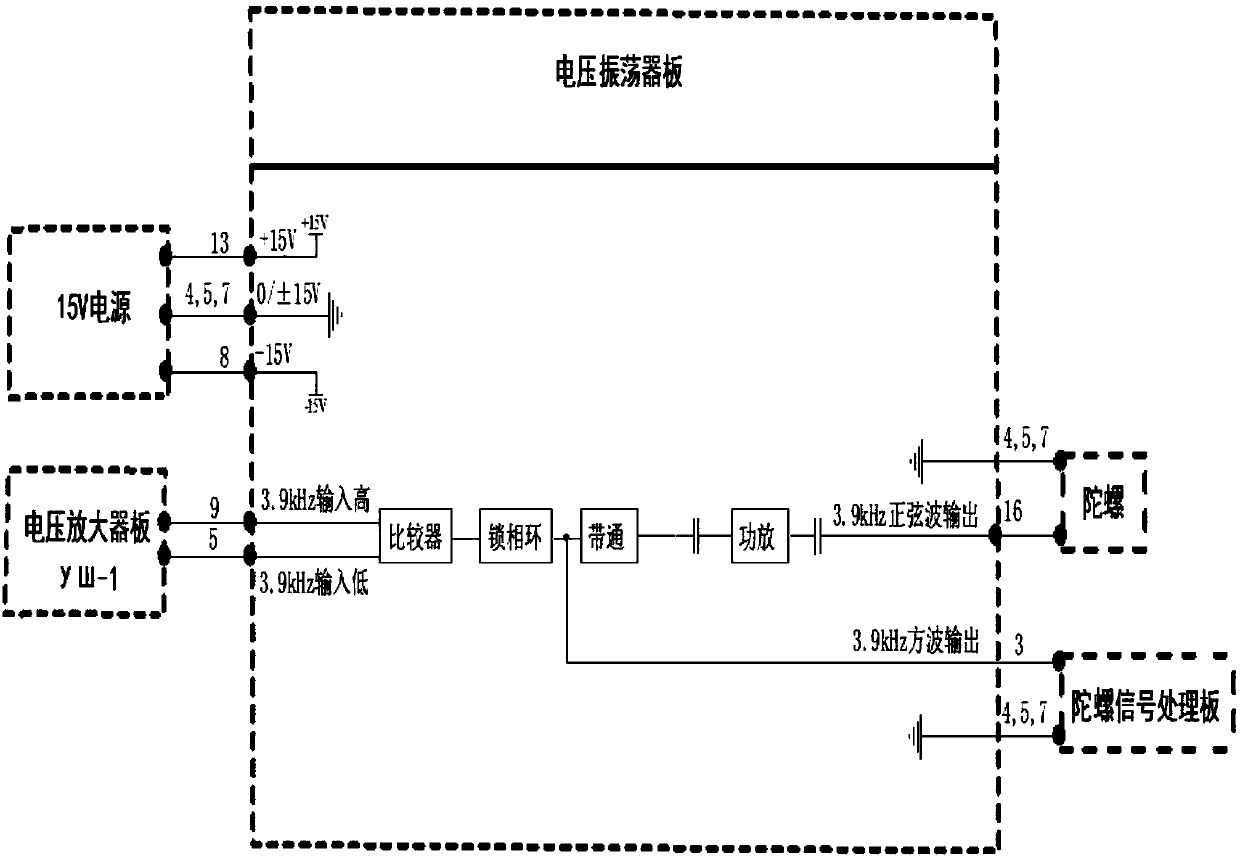

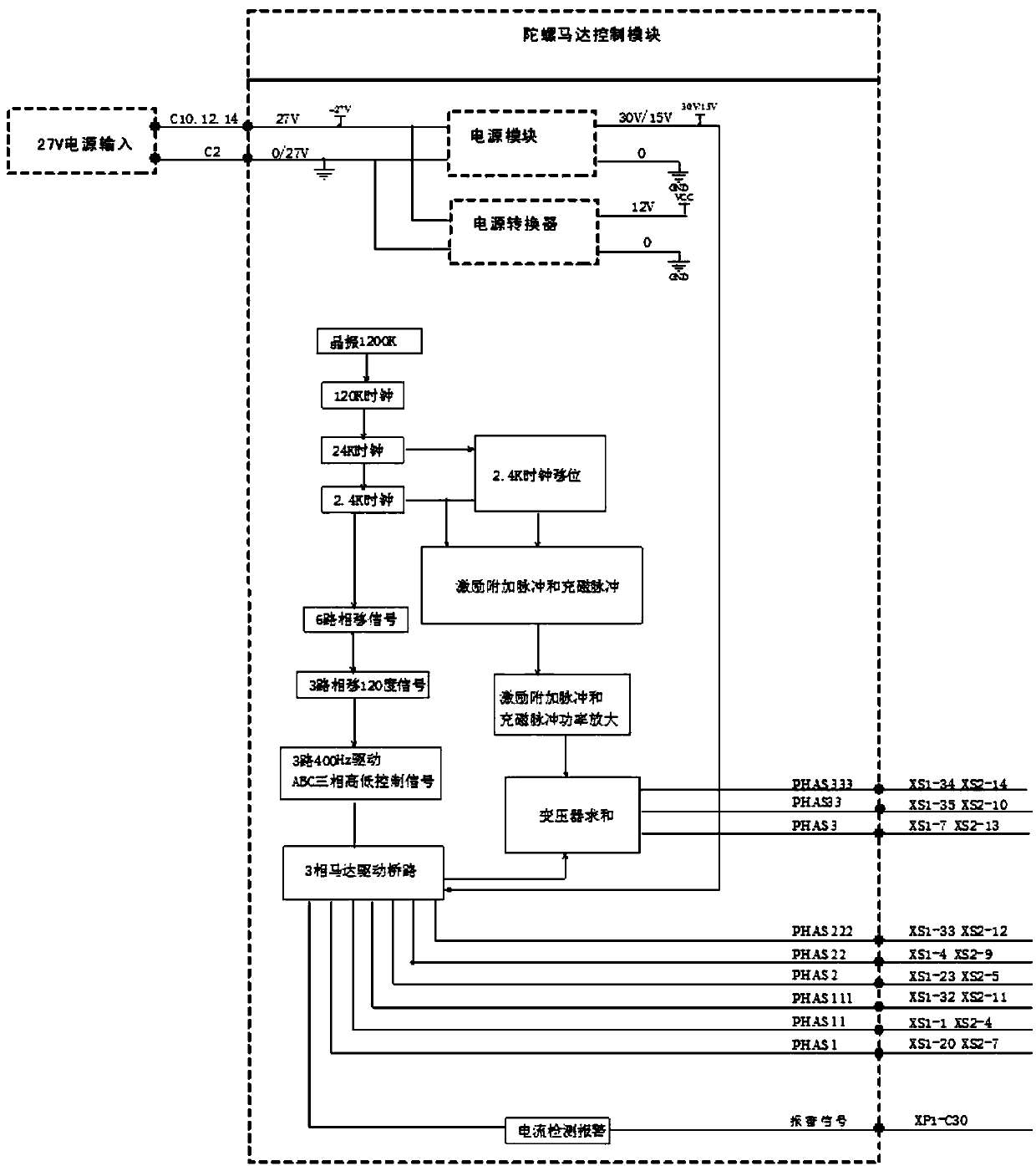

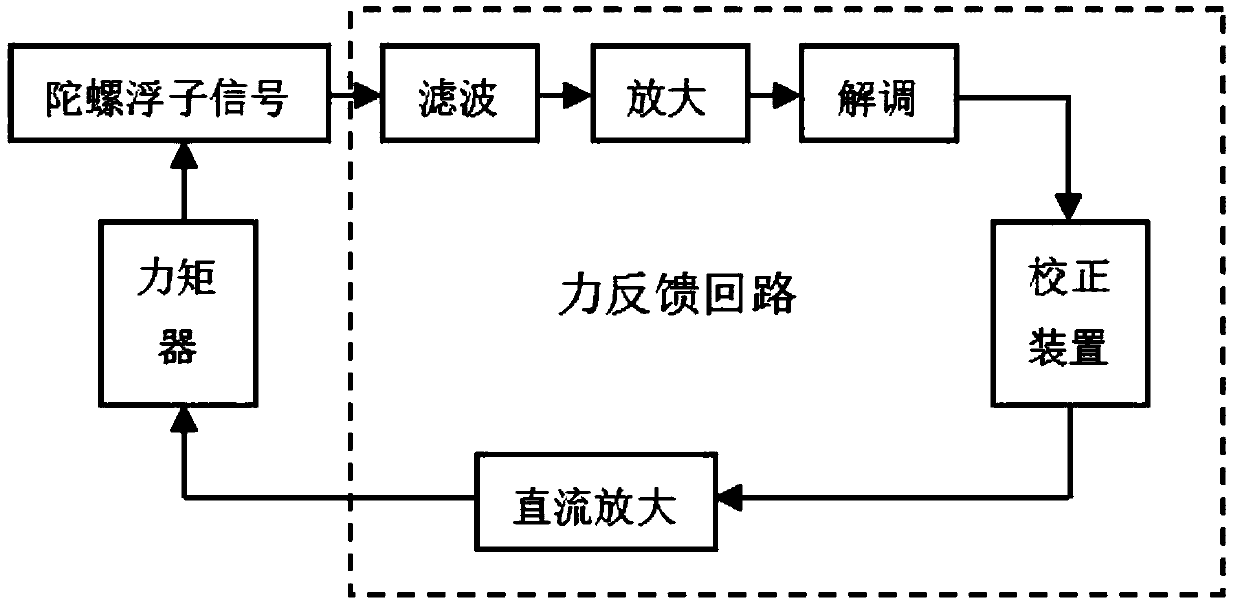

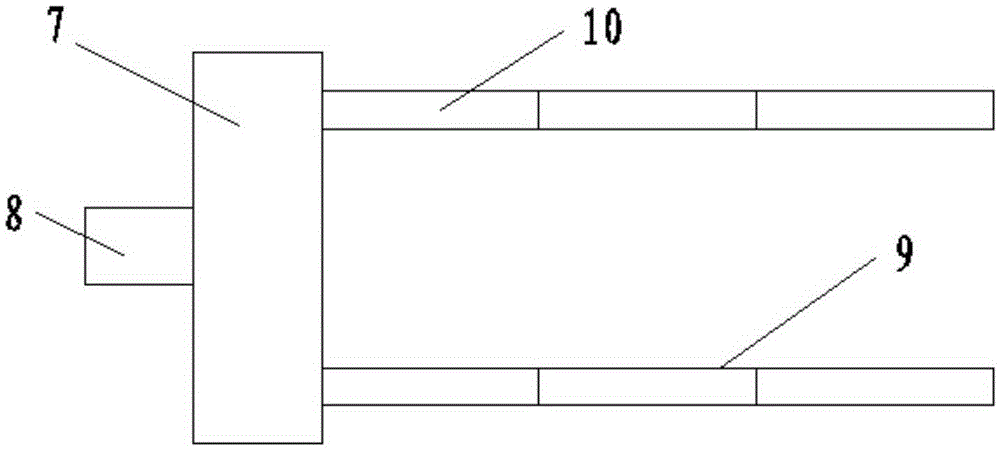

Testing method for gyroscope with unknown parameters

ActiveCN107702731ARealize precise test functionGuaranteed uptimeMeasurement devicesGyroscopeMotor drive

The invention relates to a testing method for a gyroscope with unknown parameters. The method has the technical characteristics of: separating a gyroscope output signal from an inertial navigation system and separating a sensor excitation signal, and constructing a gyroscope excitation signal circuit; separating a gyroscope motor signal from the inertial navigation system, and constructing a gyroscope motor drive signal circuit; using the sensor excitation signal and the motor signal as the drive signal of the gyroscope, and constructing a parameter matched force feedback loop; connecting thegyroscope excitation signal circuit, the gyroscope motor drive signal circuit and the force feedback loop together to compose a gyroscope testing system to test the gyroscope with unknown parameters.Through analysis of gyroscope signal in the inertial navigation system and design of the excitation signal circuit, the motor drive signal circuit and the force feedback loop meeting the testing requirements, the method provided by the invention realizes the accurate testing function on the liquid floated gyroscope with unknown parameters, finally provides the inertial navigation gyroscope with qualified performance, and guarantees the normal operation of a vessel inertial navigation system.

Owner:TIANJIN NAVIGATION INSTR RES INST

Environmental-friendly acetamiprid aqua and preparation method thereof

ActiveCN103858860AStrong production operabilityImprove solubilityBiocideAnimal repellantsWater basedOrganic solvent

The invention provides an environmental-friendly acetamiprid aqua. The environmental-friendly acetamiprid aqua contains the following ingredients in percentage by weight: 1-5% of acetamiprid and 1-10% of action agent A, wherein the action agent A is one or more selected from sulfonic acid group containing anionic surfactant, sulfuric acid group containing anionic surfactant and carboxyl group containing anionic surfactant; preferably, the acetamiprid aqua provided by the invention can also contain an action agent B which is 1-5% the total weight of the environmental-friendly acetamiprid aqua; the action agent B is selected from non-ionic surfactant and / or natural macromolecular surfactant. The invention further provides a method for preparing the preparation. The environmental-friendly acetamiprid aqua provided by the invention does not contain any organic or corrosive solvent, is of a uniform clarified solution in appearance and is stable in long-term placement, and the indoor insecticidal activity of the environmental-friendly acetamiprid aqua is equivalent to that of an emulsified oil preparation with concentration which is the same as that of the environmental-friendly acetamiprid aqua, so that the environmental-friendly acetamiprid aqua provided by the invention is obviously better than emulsified oil preparations and other water-based preparation forms.

Owner:南京善思生态科技有限公司

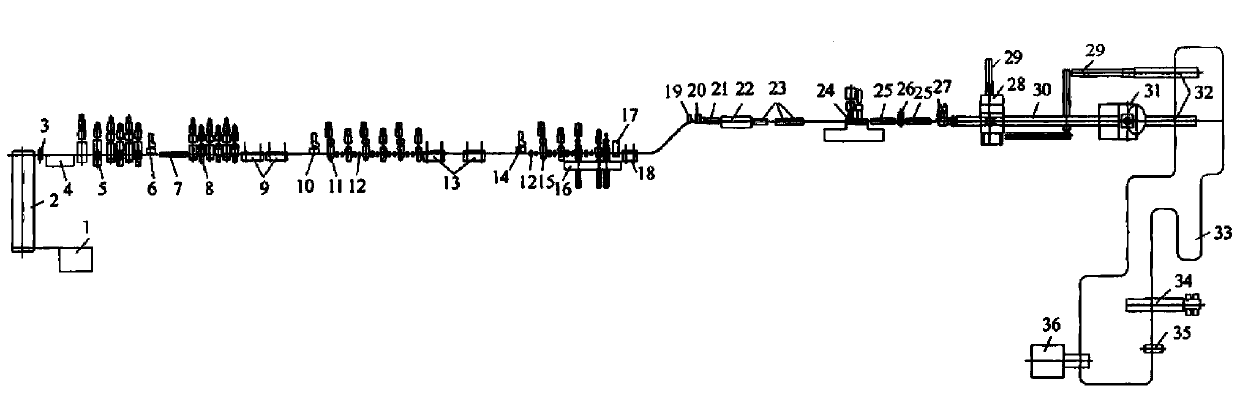

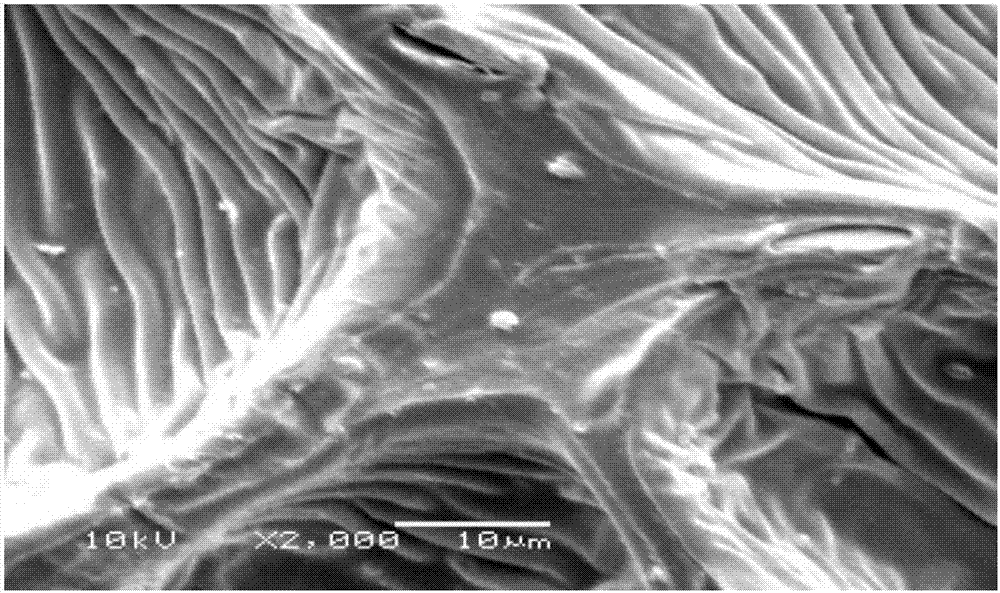

Method for producing titanium and titanium alloy wires through hot continuous rolling

ActiveCN104174649AMeet the small batchMeet the characteristicsTemperature control deviceMetal rolling arrangementsStructure propertyTitanium

The invention relates to a method for producing titanium and titanium alloy wires through hot continuous rolling, belongs to the technical field of metal plastic working, and aims to solve the technical problems and provide a method for producing titanium and titanium alloy wires on a traditional steel hot continuous rolling unit. According to the method for producing the titanium and titanium alloy wires through hot continuous rolling, a heating system, blooming temperature, rolling speed and hole pattern are controlled, processes including shearing, cooling and spinning to form coils are performed, and titanium and titanium alloy square billets are discharged from a furnace through single heating and rolled into wires with the diameter ranging from phi 5.5 mm to phi 20 mm. According to the method for producing the titanium and titanium alloy wires through hot continuous rolling, titanium and titanium alloy wire products with large single wire coil weight, good surface quality and roundness and uniform structure property can be produced quickly and efficiently on the hot continuous rolling unit.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

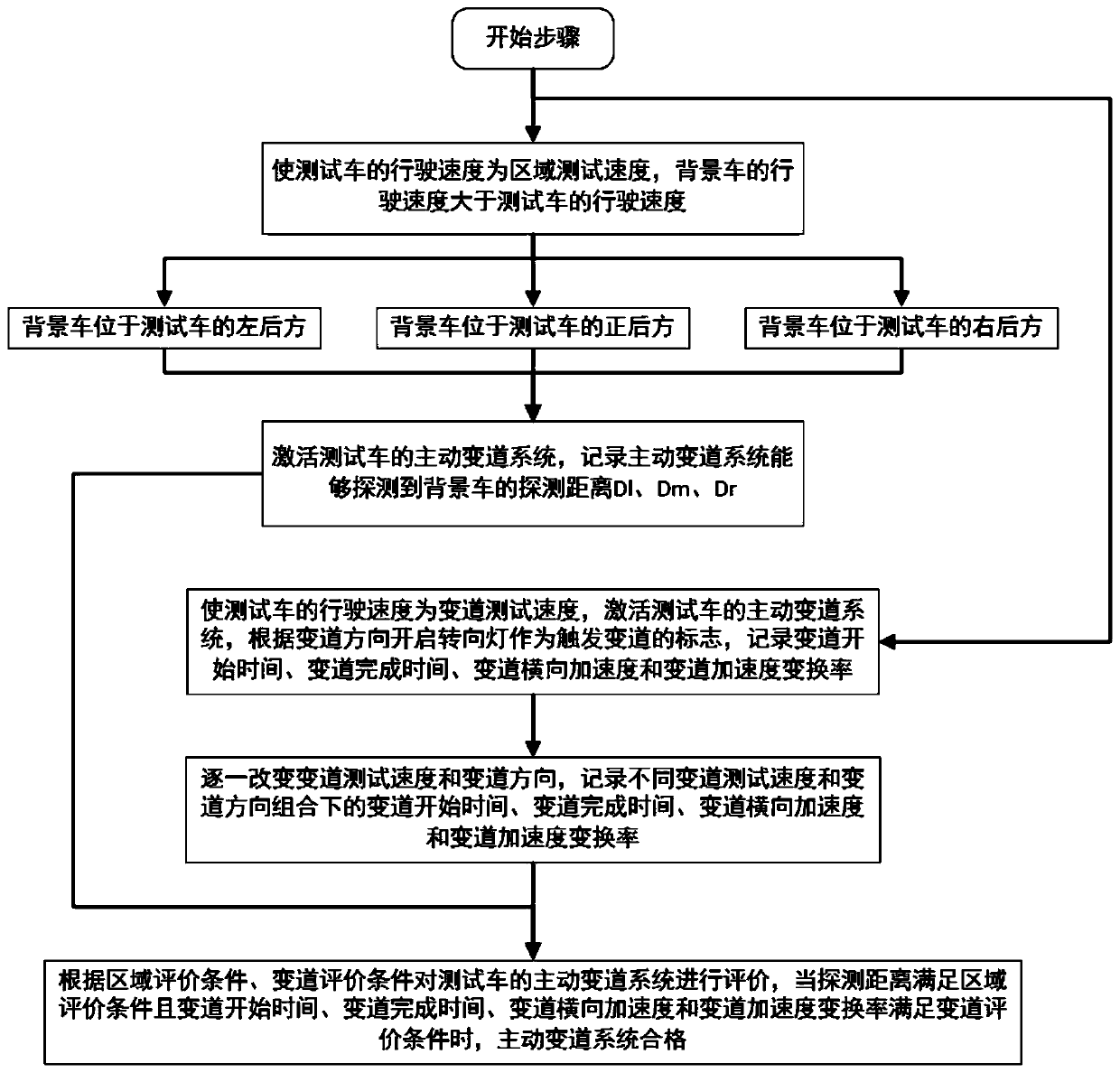

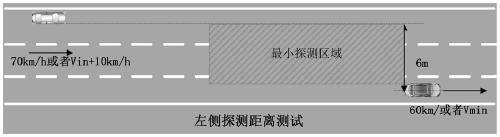

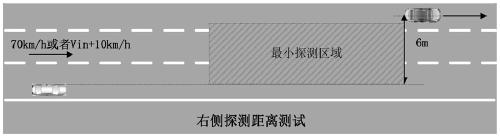

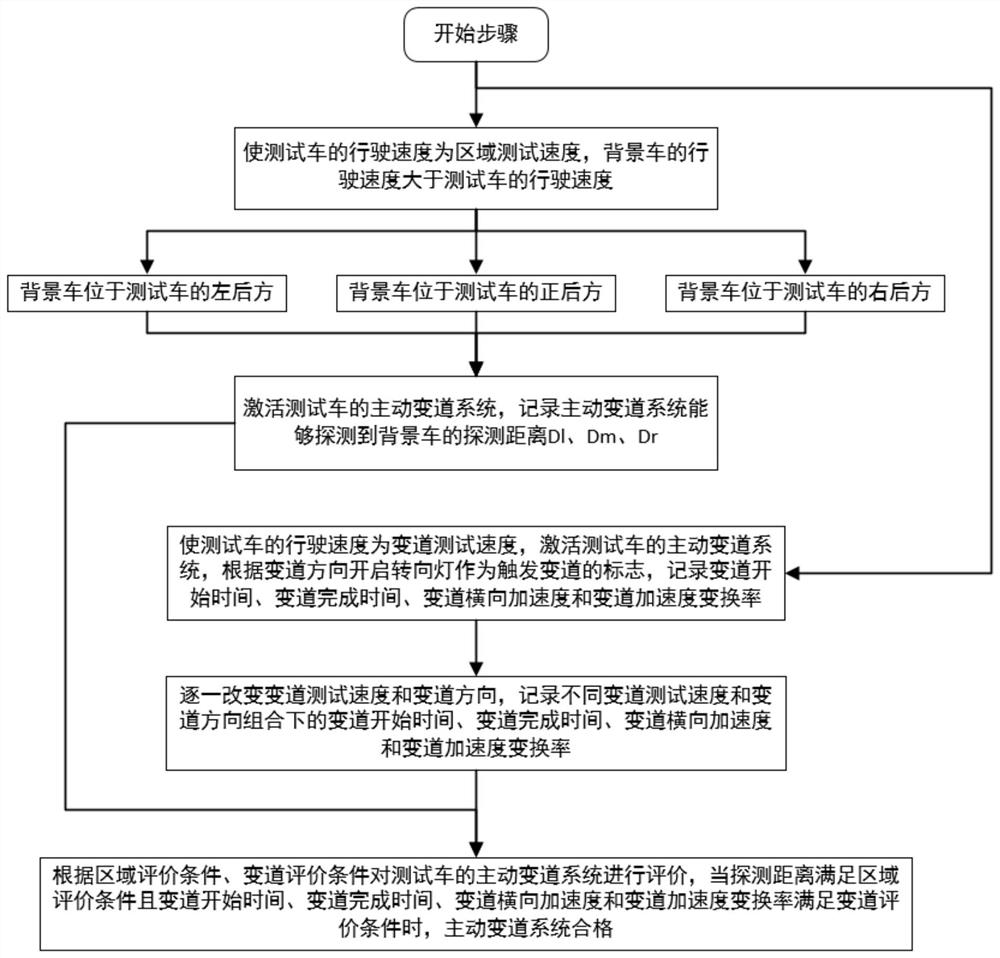

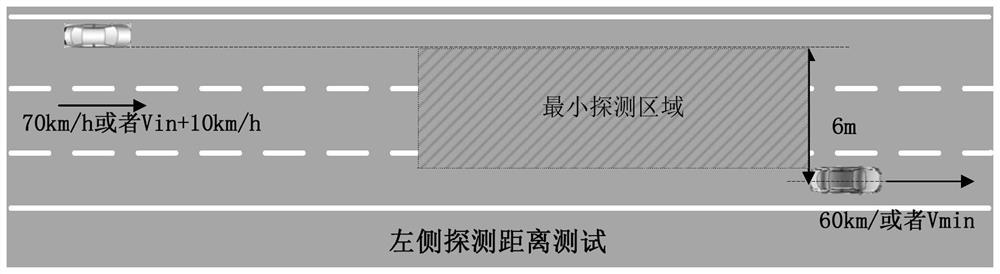

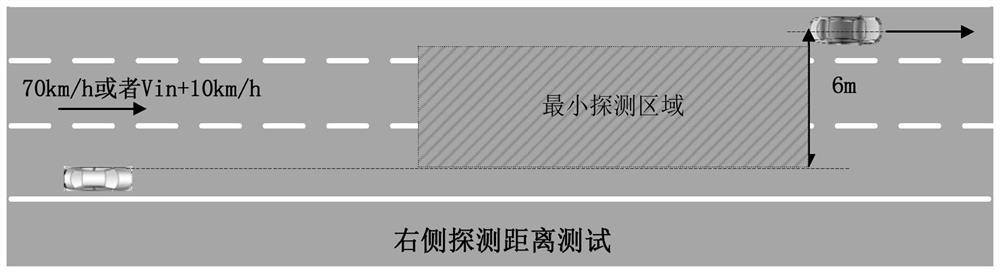

Vehicle active lane changing system test evaluation method

The invention relates to the technical field of vehicle active lane changing performance test, and particularly relates to a vehicle active lane changing system test evaluation method. The method comprises a detection area test step and a lane changing test step. In the detection area test step, through the test, when a background vehicle and a test vehicle are located at different positions, detection distances D1, Dr and Dm of the background vehicle which can be detected by the test vehicle are obtained. In the lane changing test step, through the test, under different lane changing test speeds Vb and lane changing directions, lane changing start time, lane changing completion time, lane changing transverse acceleration and lane changing acceleration change rate can be obtained. By the adoption of the scheme, the active lane changing system is completely, scientifically and effectively tested, so that the active lane changing system is accurately evaluated, major traffic accidents caused when the system is used are avoided, or the situation that a driver does not trust the system, and therefore the system is abandoned is avoided.

Owner:CHINA AUTOMOTIVE ENG RES INST

Annunciator coating repairing technique

The invention discloses an annunciator coating repairing technique. By the adoption of the annunciator coating repairing technique, an insulating coating with the cracks exceeding the standard or a chipping coating of an annunciator can be repaired, so that the use function of the coating is recovered. The annunciator coating repairing technique comprises the specific steps that firstly, coating residues on the annunciator are removed; secondly, lubricating oil in a shell is removed; thirdly, the annunciator is protected; fourthly, gluing is conducted; and fifthly, finishing and inspection are conducted. The repairing method has been used for repairing test samples and taken part in a test run examination of a factory; after the test run, it is shown through appearance inspection that the coating is free of cracks and chipping faults, the performance of the coating is qualified, the state of the coating is good, and the use requirement of an engine can be met; by the adoption of the repairing method, the cost can be greatly reduced for the factory; the repairing method can also be popularized to be used for repairing other engines; machine parts rotates at a constant speed, and formation of the coating can be effectively guaranteed before solidification. A fixing rod on a clamp is designed to be of a multi-section type, so that repairing of multiple accessories can be achieved at a time, and the production efficiency is multiplied.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Lead-free free-cutting high-strength high-plasticity high-conductivity tellurium-silver-chromium bronze material

The invention discloses a lead-free free-cutting high-strength high-plasticity high-conductivity tellurium-silver-chromium bronze material. The material is characterized by being composed of, by weight, 0.02%-0.2% of Ag, 0.08%-0. 5% of Te, 0.1%-1.5% of Cr, 0.002%-0.015% of P, less than 0.01% of Pb, and the balance copper and unavoidable impurities. The most appropriate added content of copper, tellurium, chromium and copper-phosphorus alloy in the alloy material are adjusted to obtain an accumulation effect so that the alloy material can have excellent cutting performance and high conductivity; and compared with existing chromium-zirconium copper, tellurium copper and red copper, the tellurium-silver-chromium bronze material has higher strength, higher plasticity, higher conductivity, andhigher machining efficiency, and meanwhile, the material has high oxidation resistance and softening resistance at high temperature.

Owner:NINGBO XINGAODA ADVANCED METALLIC MATERIALS

Preparation process of polyethylene coated paper

InactiveCN105421148AHigh barrierGood heat sealing performanceNon-fibrous pulp additionPaper coatingMasterbatchPolymer science

The invention discloses a preparation process of polyethylene coated paper and relates to the technical field of paper making. The preparation process comprises the process steps of raw material mixing, body paper uncoiling, corona, high temperature extrusion, film spraying, hydraulic pressure, cooling for formalization and the like. According to the preparation process method, environment-friendly type polyethylene is selected as the master batch, the characteristics of paper such as the barrier property, the thermal sealing property and the toughness are greatly improved, soluble starch is adopted as the stabilizing agent in the preparation process of the raw materials, stearic acid is selected as the lubricant, glycerin is selected as the plasticizer, water-based polyolefin is further added, the raw materials are saved, cost is lowered, stability of the polyethylene coated paper is improved, all performance of the obtained polyethylene coated paper can be qualified and even exceed the standard requirements by optimizing matching of the raw materials in the preparation process, and the preparation process is simple and easy to grasp.

Owner:ANQING SHENGHUA PAPER PACKAGING

A kind of multipurpose outdoor sports shoes

The invention discloses multipurpose outdoor sports shoes. The sports shoe comprises a composite sole, a composite insole, and a composite vamp cloth. The composite sole is formed by combining an EVA injection molding midsole, a rubber outsole, and an injection molding arch supporting frame in sequence. The composite insole is formed by combining a modified EVA foaming insole and an insole cloth. The composite vamp cloth is formed by a shoe fabric and a shoe lining which are overlaid in sequence. The insole cloth is a blended fabric of bastose and chemical fibers. The shoe fabric is a blended fabric obtained by fibers through blending. The sports shoes have relatively good damping function, and relatively good half sole bending resistance performance and midsole torque resistance function. Through tests, the shoe can bend for 100 thousand times in normal temperature, and has no broken surface and no glue failure. The shoe can bend for 40 thousand times in low temperature of -20 DEG C, and has no broken surface and no glue failure. The sports shoes have relatively good no-skid property, and the sports shoes have relatively good ageing-resistant performance and wash resistance performance.

Owner:LI NING CHINA SPORTS GOODS +2

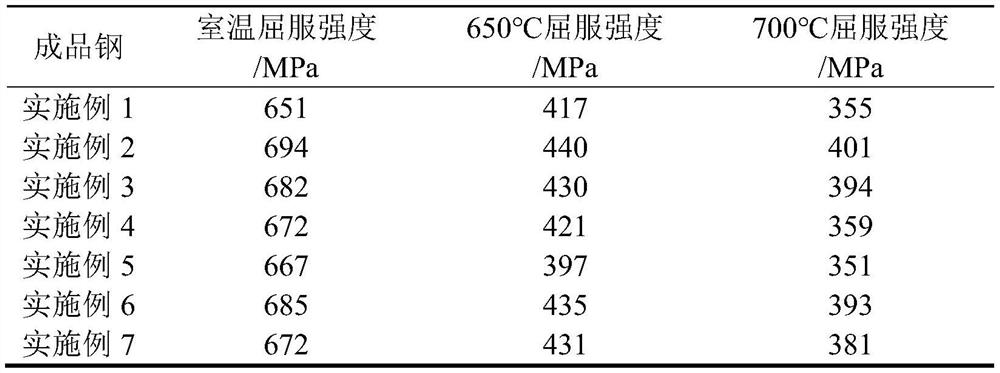

Automobile dual-phase steel and machining method thereof

PendingCN110004377AQualified performanceOrganization QualifiedTemperature control deviceMetal rolling arrangementsInlet temperatureControl parameters

The invention provides automobile dual-phase steel and a machining method thereof. The automobile dual-phase steel comprises the chemical components including, by weight percent, not greater than 0.08% of C, 1.25-1.35% of Mn, 0.01-0.025% of Ti, 0.02-0.03% of Nb, 0.15-0.25% of Cr, 0.02-0.05% of Als and the balance Fe and inevitable impurities. The machining method comprises the process including the steps of smelting; casting; heating; rolling; cooling; and coiling. By controlling parameters including the rough rolling inlet temperature, the precision rolling speed, the finish rolling temperature, the layered cooling boiled water valve group number, the coiling temperature and the like, step cooling of the dual-phase steel is achieved on the basis of a traditional steel strip hot rolling line, accordingly, a satisfactory metallographic structure of the dual-phase steel is obtained, and stable production of the dual-phase steel is finally achieved.

Owner:RIZHAO STEEL HLDG GROUP

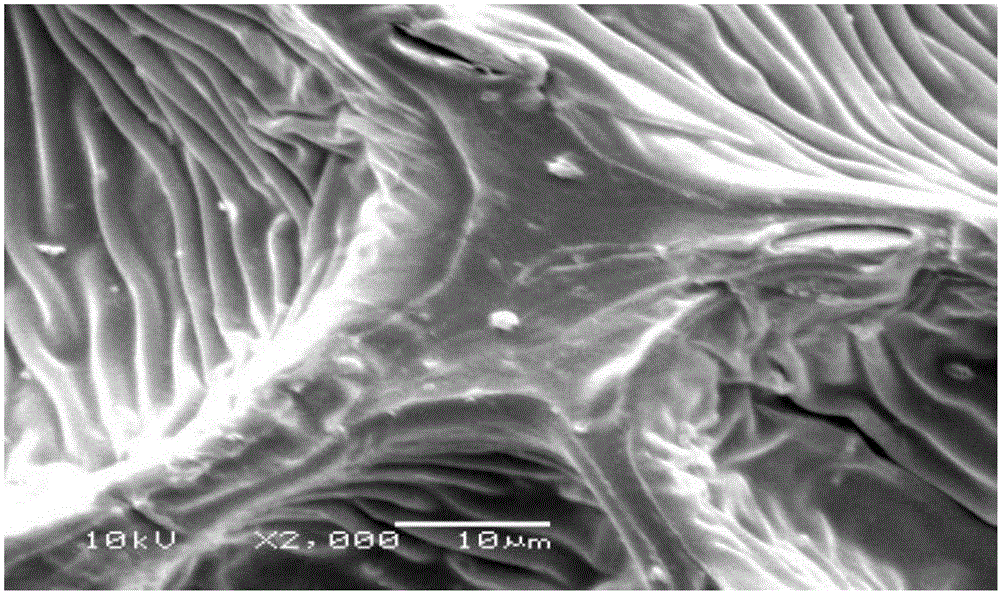

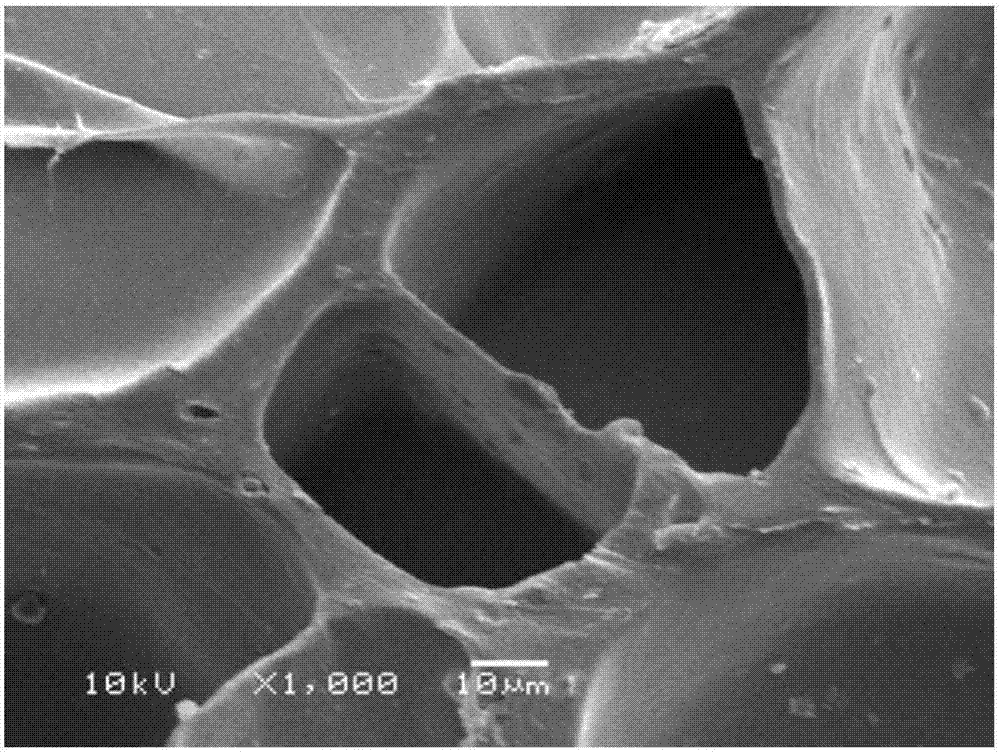

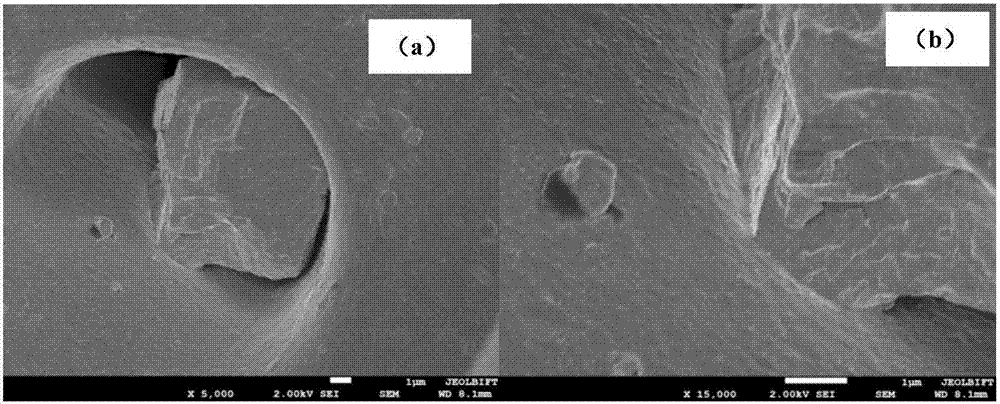

High-strength austenitic stainless steel and preparation method thereof

ActiveCN113231648AHave a strengthening effectEnhanced effect achievedAdditive manufacturing apparatusIncreasing energy efficiencyAl powderSS - Stainless steel

The invention discloses high-strength austenitic stainless steel and a preparation method thereof. The high-strength austenitic stainless steel comprises an austenitic stainless steel matrix as well as micron nitride, submicron oxide and nano oxide which are dispersed and distributed in the austenitic stainless steel matrix, wherein the micron nitride is TiN, the submicron oxide is Al2O3, and the nano oxide is Y-Al-O. During preparation, mixed powder A is subjected to laser melting forming; and then the structure property is controlled. The mixed powder A is obtained by ball-milling and mixing micron nitride and powder B; the powder B is obtained by ball-milling the submicron oxide and the powder C; the powder C is obtained by ball-milling nano oxide and austenite steel powder; and the nano oxide is obtained by carrying out ball milling and solid solution on nano Y2O3 and nano Al powder. The austenitic stainless steel is strengthened by introducing various particles with different sizes into the steel by utilizing an oxide metallurgy technology and a dispersion strengthening theory, the process and product reproducibility is good, the cleanliness is the same, and the structure and the performance are easy to control.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

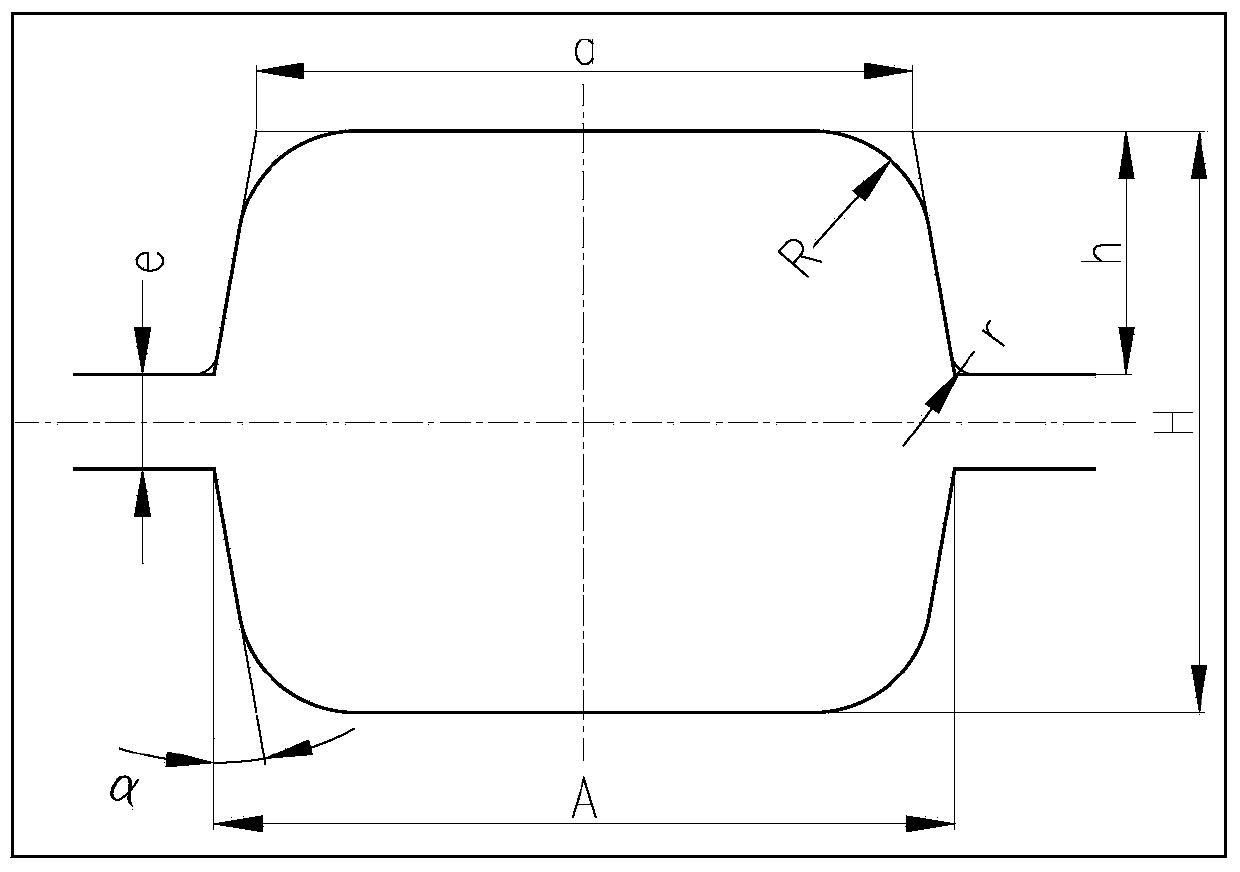

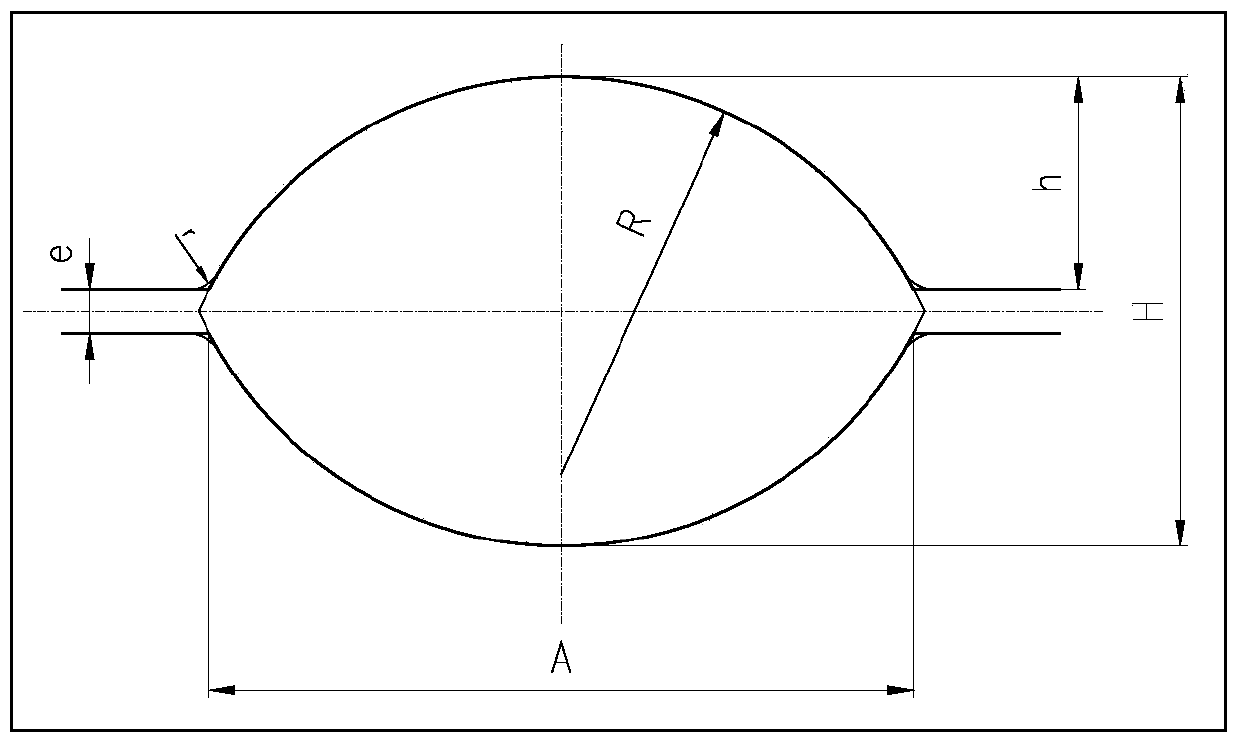

Eccentric check reducer forging method

InactiveCN103801644AAvoid deformationPrevent oxidative decarburizationMetal-working apparatusEngine componentsSlope angleEngineering

The invention belongs to the field of the metal forging technology, and particularly relates to an eccentric check reducer forging method. The method includes the following steps that (Step 1) a slope is turned on the front end of a pipe billet, and the slope angle Alpha is 5 to 13 degrees; (Step 2) glass lubricant is applied in the bore of the pipe billet, and the spraying range includes the shaped part and is extended backward for 15mm to 30mm; (Step 3) the coated pipe billet is heated, and the heating range includes the shaped part and is extended backward for 5mm to 10mm; (Step 4) a die with a guiding mechanism is used for forging on a horizontal forging machine, including: preforging: a semi-conical surface, of which the slope is smaller than 26 degrees, is first forged on the shaped orifice of the pipe billet; final forging: the shaped orifice of the pipe billet is then forged into an eccentric check reducer; (Step 5) the finally forged eccentric check reducer is put into an insulating box and slowly cooled.

Owner:CHINA HANGFA SOUTH IND CO LTD

A test and evaluation method for vehicle active lane change system

ActiveCN111289266BQualified performanceSuccessful activationVehicle testingDriver/operatorTraffic crash

The invention relates to the technical field of vehicle active lane change performance testing, in particular to a vehicle active lane change system test and evaluation method, the detection area test steps and the lane change test steps, the detection area test steps: the background vehicle and the test vehicle are obtained by testing in different positions. Under the position, the test car can detect the detection distance Dl, Dr, Dm of the background car; the lane change test step: obtain the lane change start time of the test car during the lane change process under different lane change test speeds Vb and lane change direction through the test , lane change completion time, lane change lateral acceleration and lane change acceleration rate. Using this program to conduct a complete scientific and effective test on the active lane change system, so as to accurately evaluate the active lane change system, and then avoid major traffic accidents when using the system, or the driver's distrust of the system, thereby Abandonment of the system occurs.

Owner:CHINA AUTOMOTIVE ENG RES INST

A kind of continuous annealing production method of thin-gauge cold-rolled lace-rolled hard steel plate

ActiveCN105779752BStable productionEliminate lossFurnace typesHeat treatment furnacesSheet steelTin plating

The present invention relates to a continuous annealing production method of thin-gauge cold-rolled lace-rolled hard steel plate, which solves the problem that the existing 0.17-0.20mm thick cold-rolled lace-rolled hard steel plate is difficult to stably produce when it is annealed by a continuous annealing unit due to lace plate shape defects question. The technical solution of the present invention is to use a vertical continuous annealing furnace unit to uncoil, clean, anneal, smooth, and coil a cold-rolled lace-rolled hard steel sheet with a plate thickness of 0.17-0.20 mm to obtain an electro-tinned substrate; the strip in the cleaning section The steel unit tension is 28.05~38.89N / mm2; 5~10 minutes before the cold-rolled lace-rolled hard steel plate coil enters the vertical continuous annealing furnace unit, the strip speed in the central section of the unit is reduced to 350~500mpm, and the heating section in the annealing furnace and The temperature of the strip steel in the soaking section drops to 585~605°C; the annealing time is 54~79S; the unit tension of the strip steel in the soaking section is 11.4~15.0N / mm2.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

A kind of environment-friendly acetamiprid aqueous agent and preparation method thereof

ActiveCN103858860BImprove solubilityImprove performanceBiocideAnimal repellantsWater basedOrganic solvent

Owner:南京善思生态科技有限公司

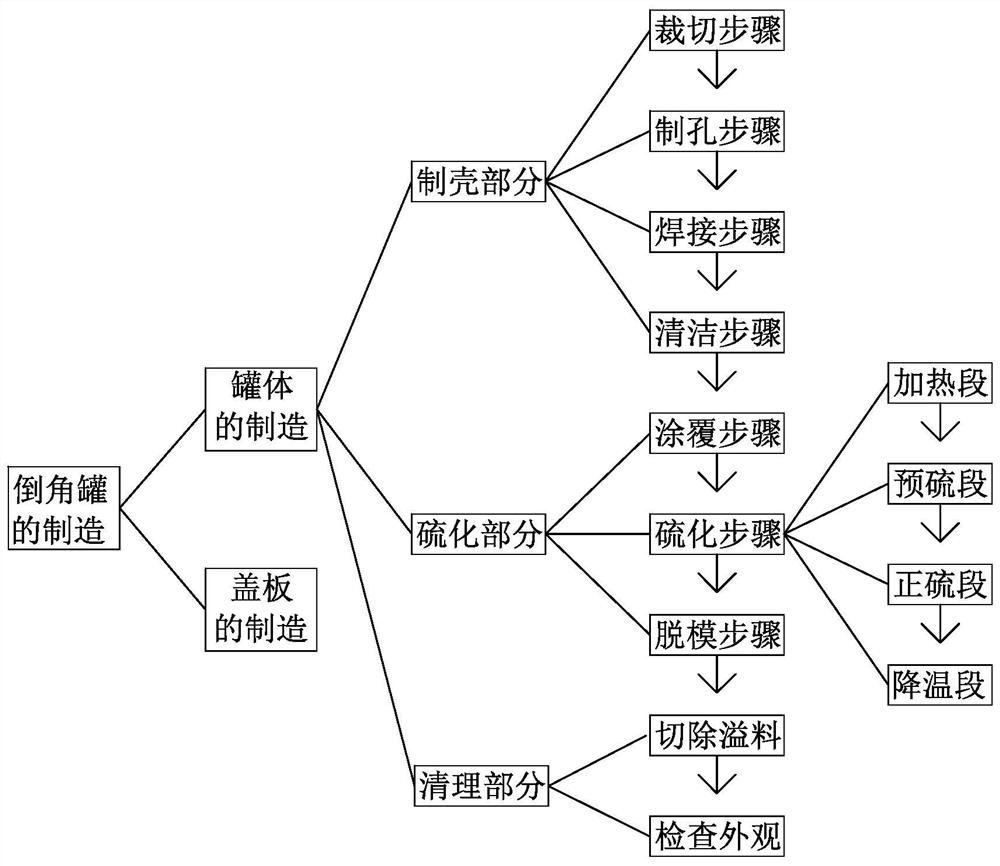

A kind of manufacturing method of chamfered can

The invention discloses a manufacturing method of a chamfered tank, comprising: a shell-making part of the tank body: manufacturing a metal shell of the tank body, and the surface of the metal shell is clean; the vulcanization part of the tank body: filling the metal shell with glue Vulcanization, including a coating step, a vulcanization step, and a mold release step, wherein the coating step coats the inner surface of the metal shell with an adhesive, the vulcanization step uses a vulcanizer and a vulcanization mold, and the vulcanization step The metal shell is filled with rubber and vulcanized. The vulcanization step includes a preheating section, a pre-vulcanizing section, a positive sulfur section, a cooling section and a demoulding section; the cleaning part of the tank body: remove the vulcanization flash to obtain the tank body. The manufacturing method of the chamfered can of the present invention can reduce or even prevent the occurrence of pits in the rubber layer of the can body, avoid poor chamfering, and save the cost of picking and rework.

Owner:广东昊达智能装备科技有限公司

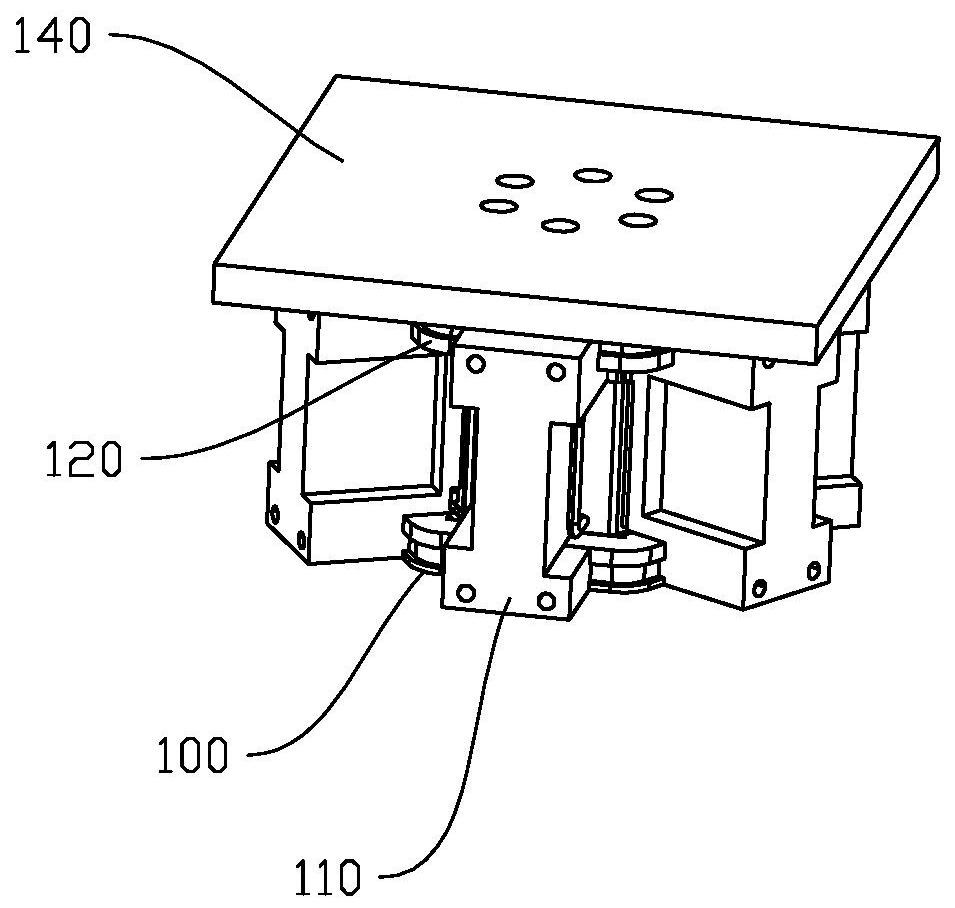

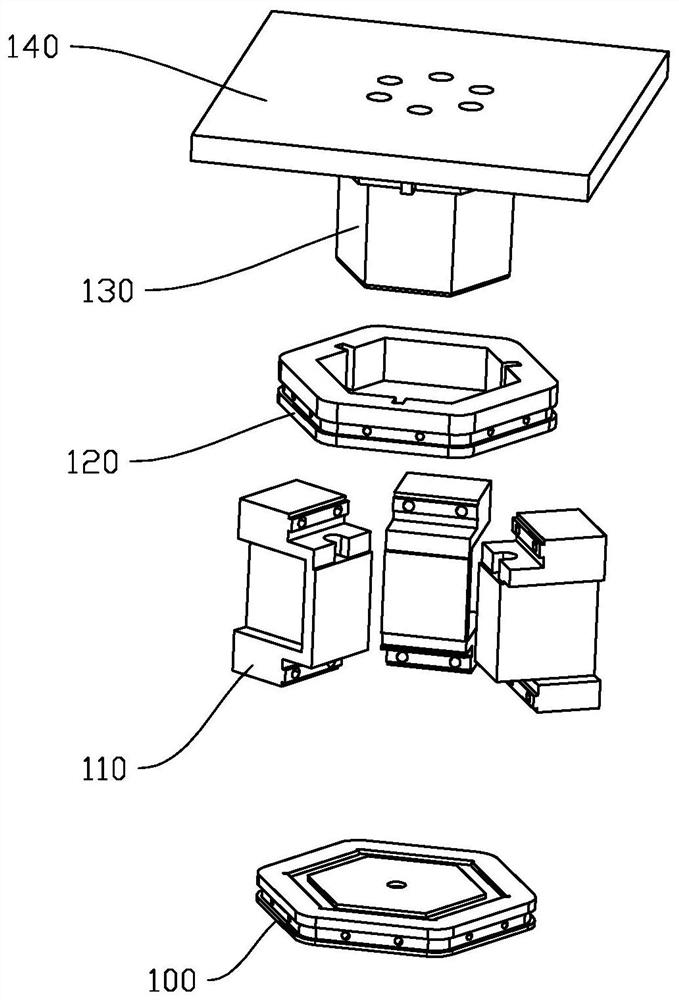

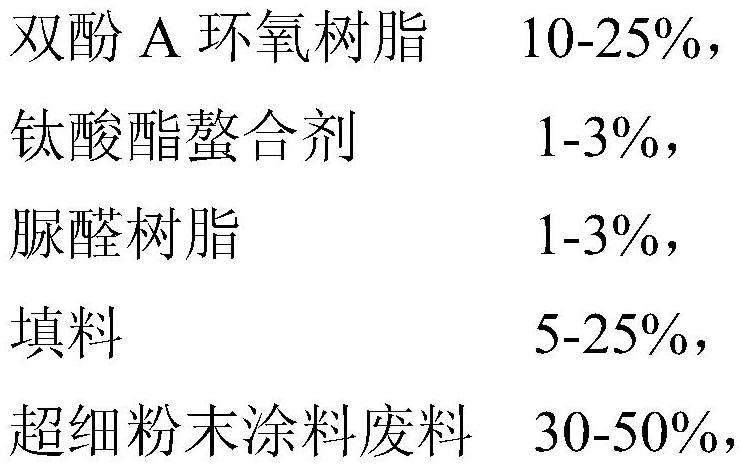

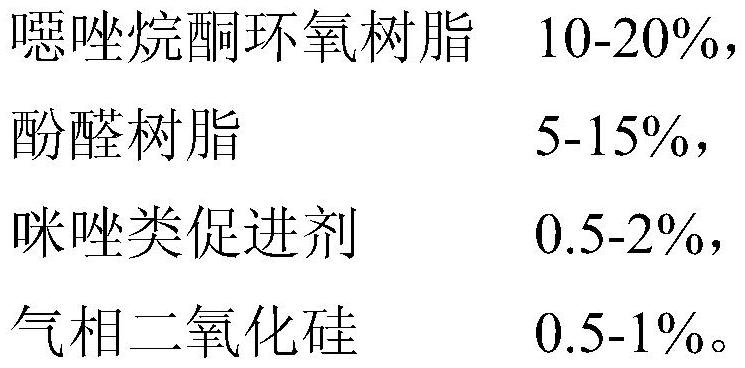

A kind of powder coating composition prepared by utilizing ultra-fine drill pipe and oil pipe inner coating epoxy powder waste

ActiveCN112852256BEasy to wrapQualified performancePowdery paintsEpoxy resin coatingsBis epoxideBisphenol

Owner:海隆石油产品技术服务(上海)有限公司

A kind of multifunctional environment-friendly thiamethoxam aqueous agent and preparation method thereof

ActiveCN103858922BStable storageAccelerated dilutionBiocideAnimal repellantsWater basedOrganic solvent

Owner:南京善思生态科技有限公司

A method for preparing high-strength and high-toughness aluminum alloy die forgings for aircraft wings

ActiveCN109108196BImprove performanceQualified performanceMetal-working apparatusIngotAircraft safety

Owner:NORTHEAST LIGHT ALLOY CO LTD +1

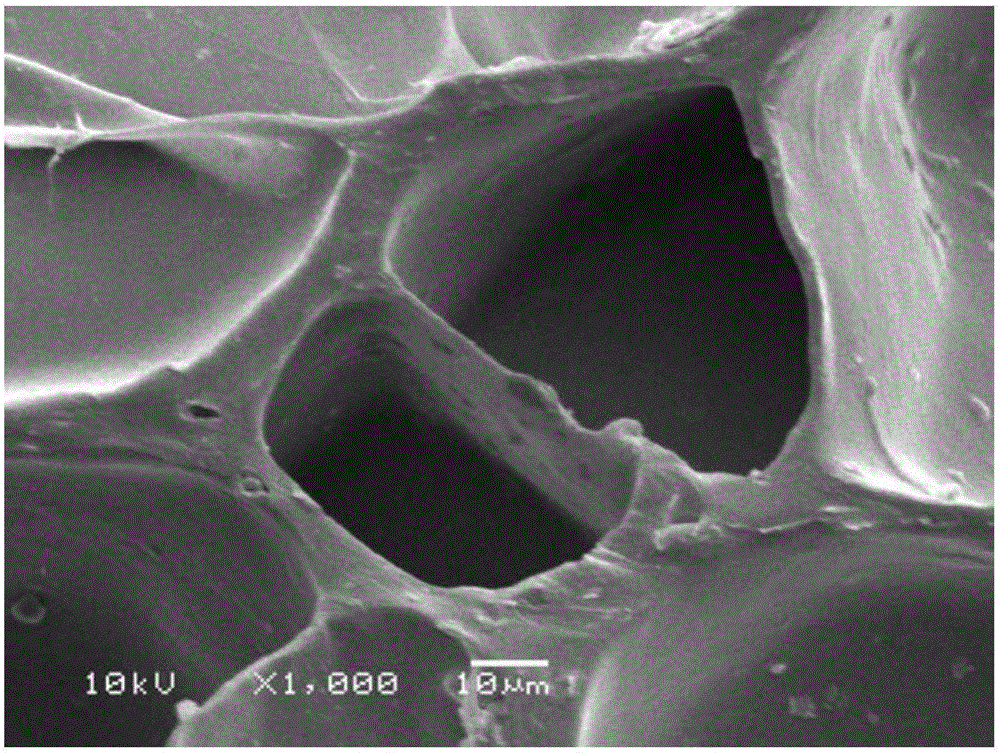

Nano-reinforcing agent for foamed concrete and preparation method of nano-reinforcing agent

The invention discloses a nano-reinforcing agent for foamed concrete and a preparation method of the nano-reinforcing agent. The nano-reinforcing agent is prepared from raw materials in percentage byweight as follows: 10%-30% of polyether, 8%-20% of acrylic acid, 8%-20% of an initiator, 1%-10% of a surfactant, 6%-15% of a thickening time control agent, 2%-10% of a catalyst and 60%-70% of deionized water. The preparation method comprises steps as follows: a, the raw materials are weighed in percentage by weight; b, the deionized water is added to a reactor, polyether is added, acrylic acid andthe initiator are dropwise added to the reactor when the temperature is increased to 55-65 DEG C, the temperature in the reactor is reduced to 35-45 DEG C, and then acrylic acid, the initiator, polyether and the deionized water are stirred for 10-20 min to be uniformly mixed. The prepared nano-reinforcing agent is high in stability, has qualified performance and multiple functions of saving comprehensive cost of concrete, improving concrete workability and concrete strength and the like, meets the harmful substance standards, reduces cement consumption, and is simple to use and low in mixingamount and investment.

Owner:佛山市海烨精密塑料制管有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com