TIG automatic welding technique for titanium alloy thick plate narrow interstice

An automatic welding and welding process technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of large welding residual stress, wide welding heat affected zone, low welding efficiency, etc., to achieve stable welding process and solve the key problems. Effects of technical issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

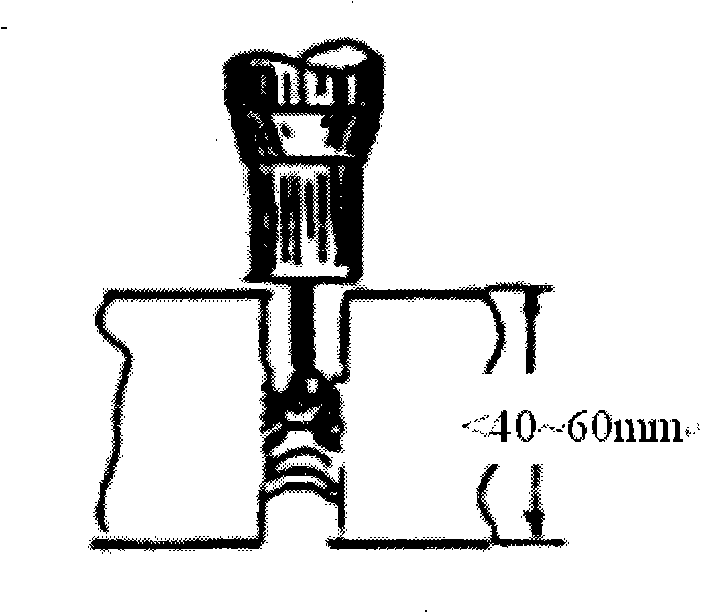

[0039] Example 1: Butt welding a pair of TA2 plates with a thickness of 20mm, a length of 300mm and a width of 150mm is carried out, the groove form is shown in Figure 5 , the grade of welding wire used is TA2, and the diameter of welding wire is 1.2mm.

[0040] Due to the small thickness of the test plate, only ordinary welding guns are used in the welding process; the thickness of the plate is considered to be small in the design of the groove, and the groove angle is not reserved to ensure that the width of the weld surface is 6-12mm, and the welding process realizes single-layer single-layer Road welding.

[0041] The welding parameters used in the welding process are as follows:

[0042] Position Peak current Pulse time Base current Pulse time Peak voltage Wire feed speed Welding speed

[0043] Primer 160~200 0.1~0.4 30~60 0.1~0.4 10~13 No wire feeding 140~160

[0044] Transition layer 180~240 0.1~0.4 30~60 0.1~0.4 10~13 300~600 70~120

[0045] Middle layer 240~280 0...

Embodiment 2

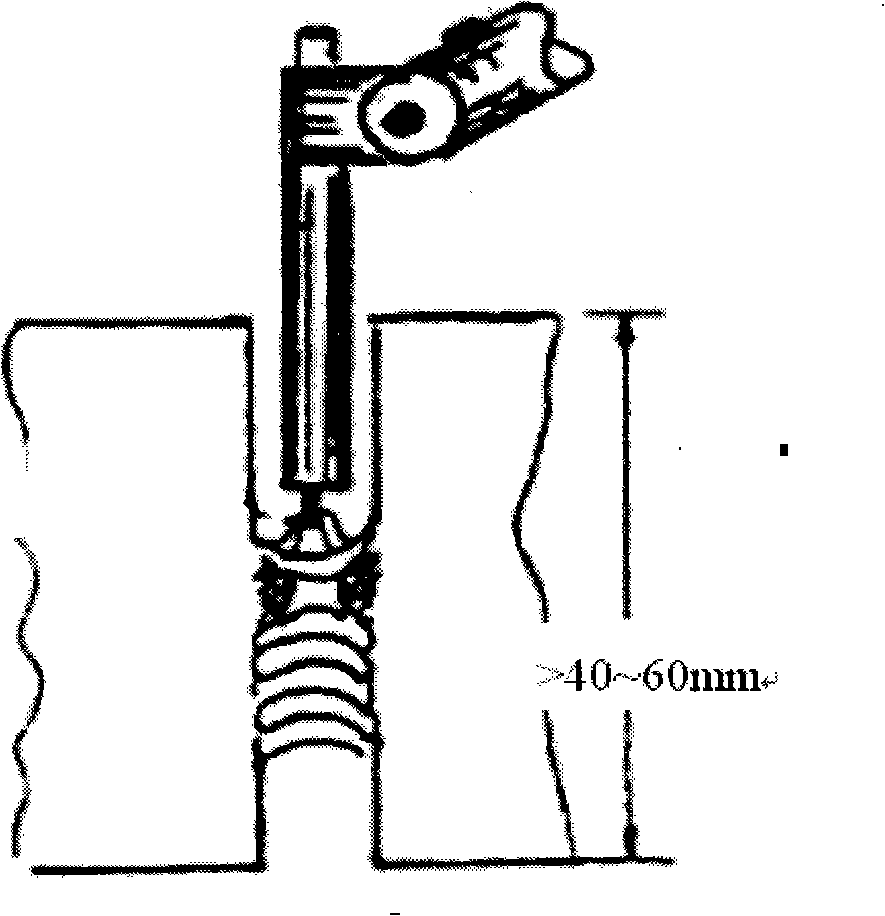

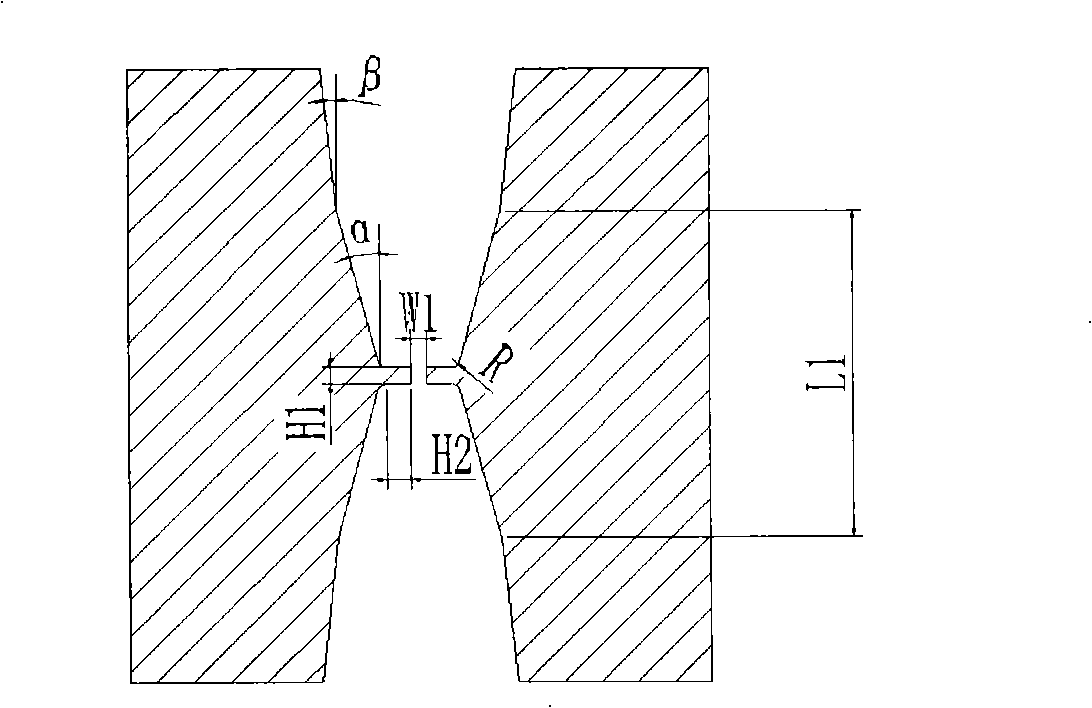

[0051] Example 2: Carry out butt welding of a pair of Ti75 test plates of 300mm×150mm×100mm, see the groove form Image 6 . The grade of the welding wire used is Ti70, and the diameter of the welding wire is 1.0mm~1.2mm. During the welding process, according to the change of the groove parameters, certain rigid fixing measures are appropriately added to make the welding groove width always meet the requirements of single-layer single-pass welding. It is required that the width of the finally obtained weld surface is less than 12mm.

[0052]Due to the large thickness of the test plate, the groove angle selected in the welding process is small, and the upper and lower groove angles are used. According to the different shrinkage and deformation conditions in different stages of the welding process, the adjustment of the groove angle offsets the shrinkage of the welding process, ensuring The surface width of the weld seam is 6mm to 12mm, realizing single-layer single-pass welding...

Embodiment 3

[0065] Example 3: Carry out butt welding of (φ2289mm~φ2093mm)×400mm two Ti75 alloy rings, the thickness of the weld seam is 98mm, and the form of the welding groove is shown in Figure 7 , The grade of welding wire used is Ti70, and the diameter of welding wire is 1.0mm~1.2mm.

[0066] Due to the double-sided welding groove, the depth of the groove is less than 50mm, and the thickness is small, and only ordinary welding torches are used in the welding process; the groove design takes into account the symmetrical shrinkage of both sides during the welding process, the shrinkage is small, and the welding is performed at different stages. The shrinkage is different, so a small groove angle is reserved, and the upper and lower groove angles are used at the same time to ensure that the weld surface width is 6-12mm, and the welding process realizes single-layer single-pass welding.

[0067] The welding parameters used in the welding process are as follows:

[0068] Position Peak cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com