Pipe-shell type heat converter pipe plate and hemispherical closing head single-side welding narrow gap welding technology

A heat exchanger and welding process technology, applied in heat exchange equipment, welding equipment, manufacturing tools, etc., can solve the problems of increasing the labor intensity of welding operators, an alarming amount of welding materials, and low product production efficiency, and shorten the production cycle. , The assembly is simple and easy, and the effect of improving the quality of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

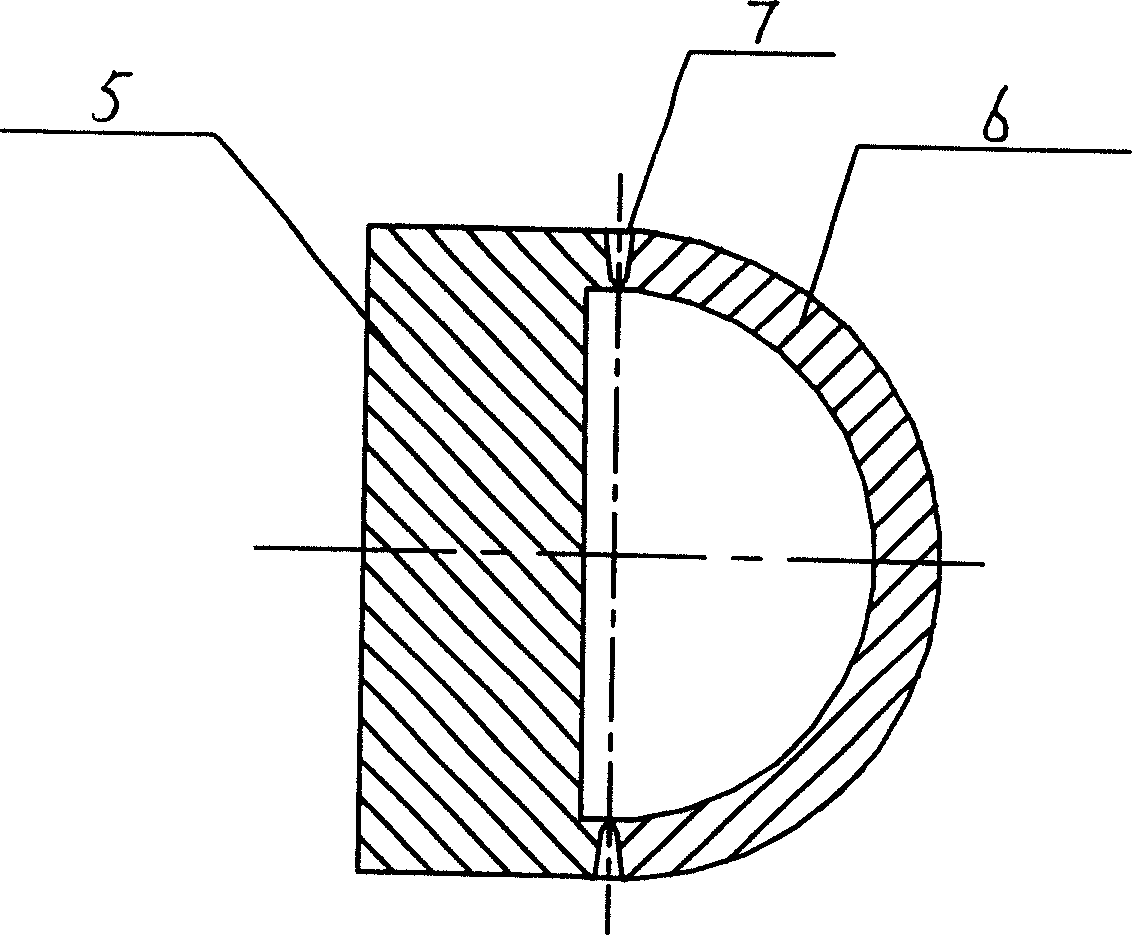

[0027] Such as image 3 As shown, it is a schematic diagram of welding the tube sheet of the shell-and-tube heat exchanger and the hemispherical head, and the main weld 7 of the tube sheet 5 of the shell-and-tube heat exchanger and the hemispherical head 6 is welded.

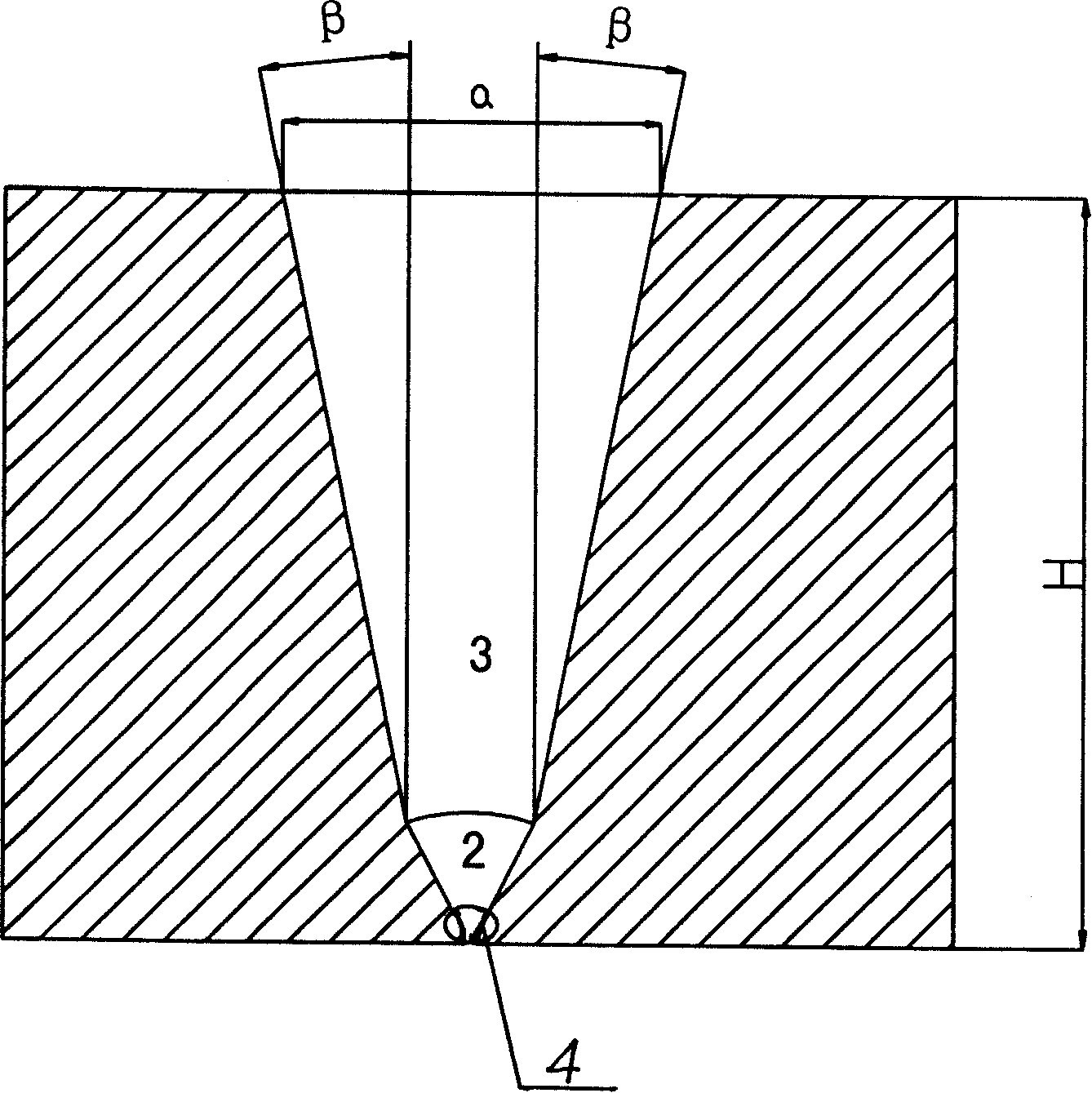

[0028] Such as Figure 4 As shown, it is a schematic diagram of the narrow gap welding process of the tube sheet and the hemispherical head of the shell-and-tube heat exchanger. The method is:

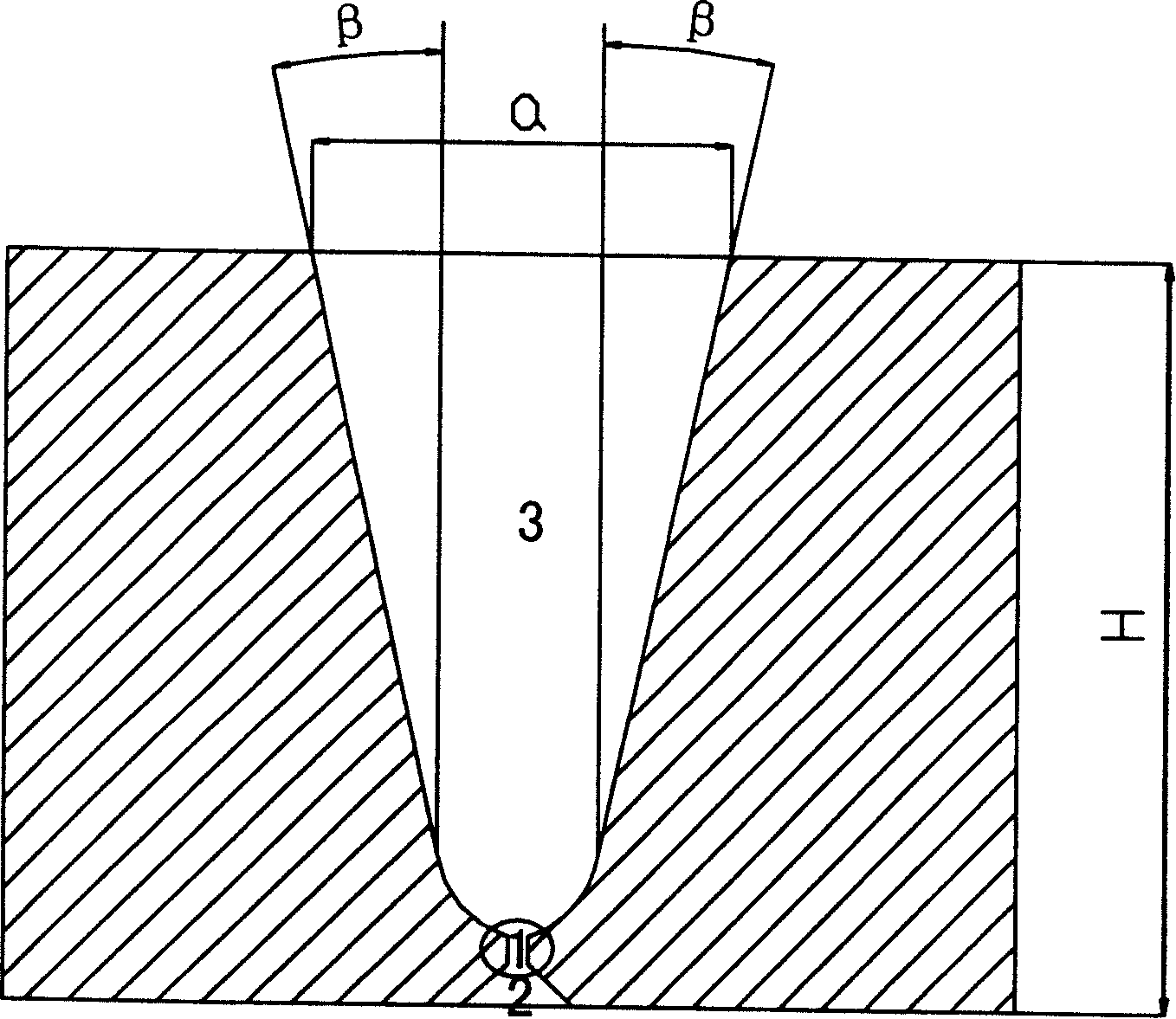

[0029] Step 1: Determine the main weld groove width

[0030] The main weld groove angle β decreases with the increase of the thickness, the thickness H is in the range of 170mm, and the angle changes at 1°, ensuring that the width of the main weld groove a is 32mm;

[0031] Step 2: The bottom layer is welded with a model NSA4-300 manual argon arc welding machine with a pen-type manual argon arc welding torch. The welding material is a mushroom-shaped melting lining ring. The thickness of the bottom layer is 3mm. Flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com