Narrow-gap GMAW (gas metal arc welding) method for band electrode

A strip-shaped electrode and narrow gap technology, which is applied in the direction of arc welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of poor fusion of side walls, achieve good heating and melting, low cost, and good fusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

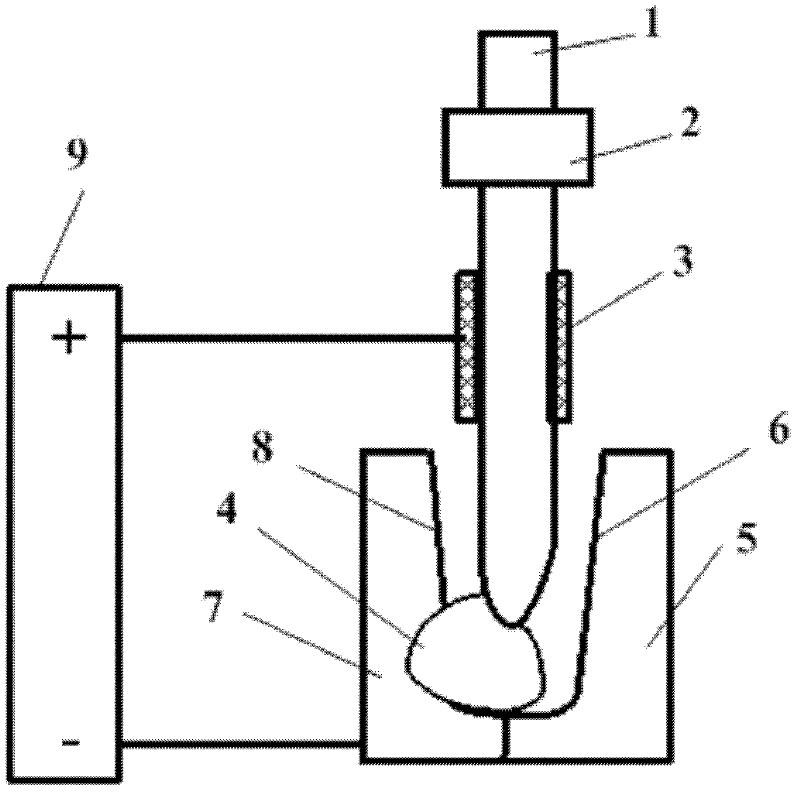

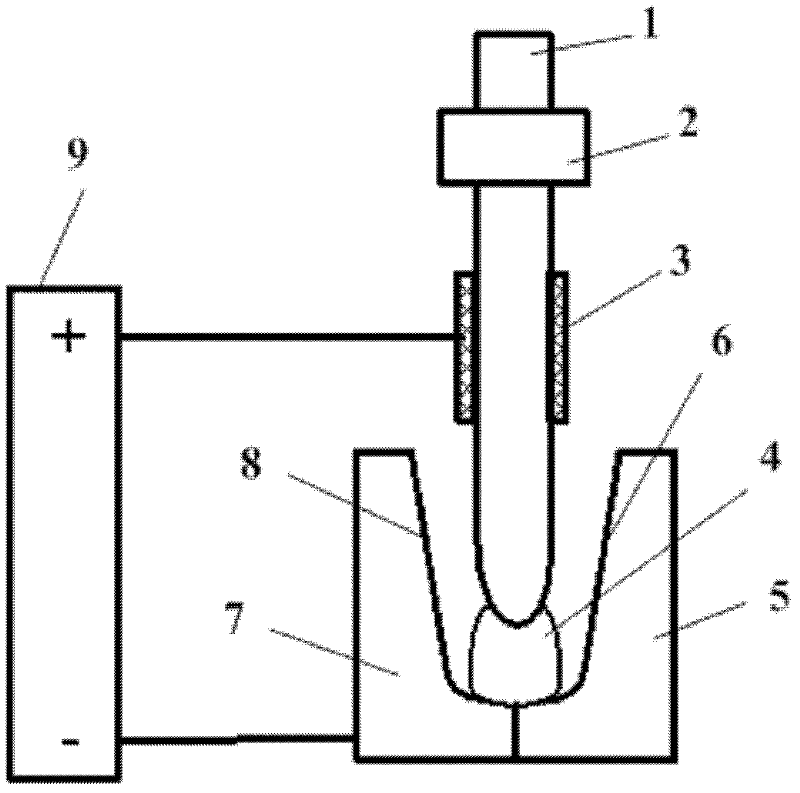

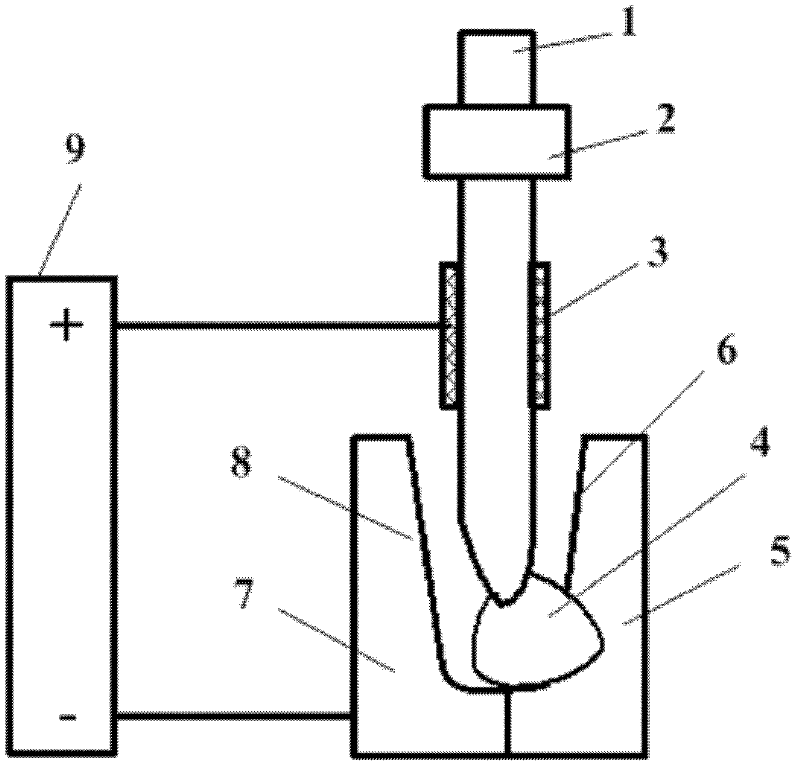

[0012] Specific Embodiment 1: The strip-shaped electrode narrow-gap GMAW method in this embodiment is carried out according to the following steps: 1. Use a strip-shaped electrode with a rectangular cross-section as the melting electrode. The width of the strip-shaped electrode cross-section is 6-8mm, and the thickness is 0.2- 0.4mm, the belt feeding mechanism guides the strip electrode into the electrode holder in the welding torch, and then puts the welding torch into the gap of the workpiece to be welded. The gap size is 8-10mm, so that the width direction of the strip electrode is perpendicular to the welding direction. The protruding length of the strip electrode is 10-20mm; 2. Introduce the protective gas, adjust the voltage to 20-30V, start the welding power supply, feed the tape at a speed of 7-18m / min, ignite the arc, and carry out welding, which is completed Strip electrode narrow gap GMAW.

[0013] The material and thickness of the workpiece to be welded that are su...

specific Embodiment approach 2

[0014] Embodiment 2: This embodiment differs from Embodiment 1 in that: the flow rate of the protective gas introduced in step 2 is 15-30 L / min. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the welding speed in step 2 is 20-30 cm / min. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com