Prefabricated module board body and outer wall system of curtain wall type building as well as construction method of outer wall system

A curtain wall and construction technology, applied in the field of prefabricated exterior walls, can solve the problems of high manufacturing cost of exterior wall systems, unsuitability for residential buildings, complex construction, etc., to ensure durability and weather resistance, prevent joint cracking, and low construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

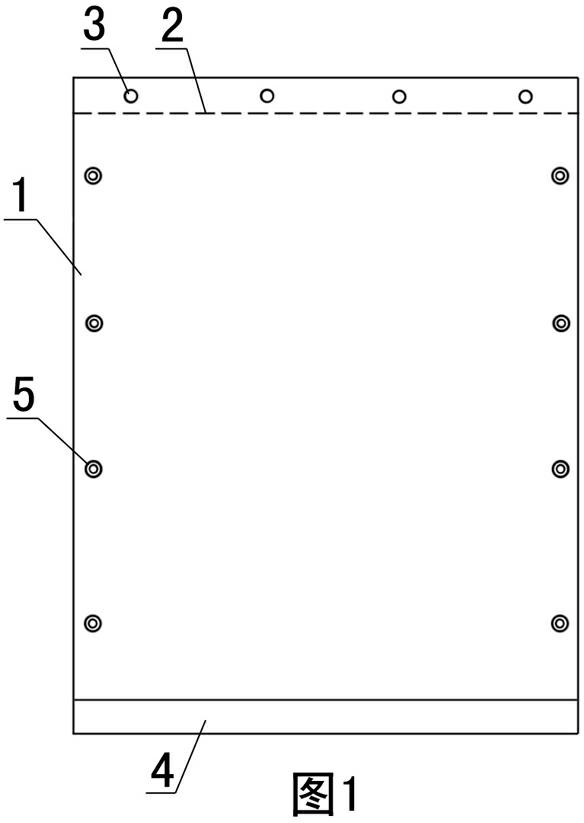

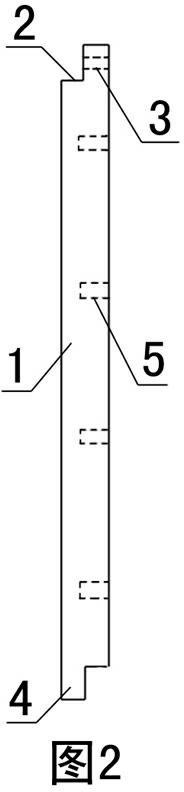

[0042] see figure 1 , figure 2 As shown, the first embodiment of the prefabricated modular panel of this curtain wall type building, its panel body is a reinforced mesh concrete structure, and the upper edge of the panel body of the prefabricated modular panel 1 is provided with a transverse L-shaped slot 2, and the horizontal L-shaped clamp On the side wall of the groove 2, there are prefabricated module board straight-through connection holes 3 distributed at intervals in the transverse direction. The horizontal L-shaped protruding head 4 corresponding to the horizontal L-shaped slot on the adjacent prefabricated module board has longitudinal internal thread sleeves 5 pre-embedded at vertical intervals on the left and right side edges of the inner surface of the board.

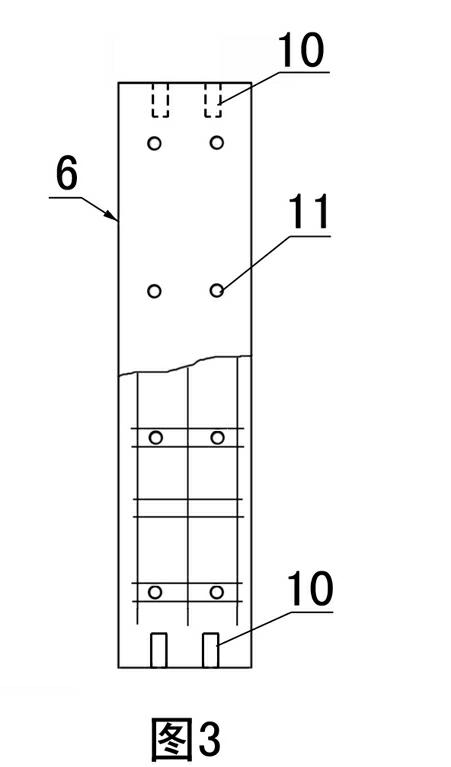

[0043] see Figure 6 , Figure 7 The second embodiment of the prefabricated modular panel of the curtain wall type building is different from the first embodiment in that the prefabricated modular panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com