Method for producing flaw detection and performance guaranteed Q235B steel plate with 80-100mm in argon station

A performance-guaranteed and performance-guaranteed steel plate technology, which is applied in the production of Q235B 80-100mm steel plates with guaranteed flaw detection and performance in the argon station, can solve the problems of long cycle, long process, and reduced production costs, so as to improve the production rhythm and reduce the production cost. cost, and the effect of shortening the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

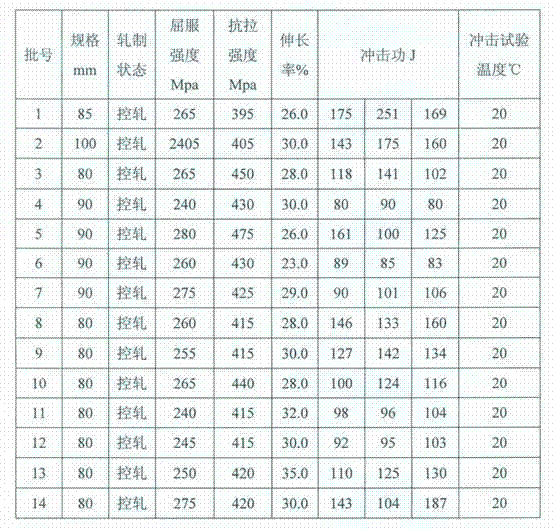

[0009] According to the method of the present invention for producing steel plates with Q235B 80-100mm specification guaranteed flaw detection and performance at an argon station, the chemical composition of the Q235B 80-100mm specification guaranteed flaw detection steel plate is: C: 0.10-0.19%, Si: 0.15-0.30 %, Mn: 0.50~0.80%, P≤0.023%, S≤0.015%, Als≤0.020%, N≤0.005%; the rest is Fe and unavoidable impurities; its production method is to take desulfurized molten iron from converter molten iron, molten iron S content ≤ 0.003%; Converter adopts top-bottom re-production smelting, steel tapping C ≥ 0.08%; Argon station uses ladle refining slag to make slag, and prolongs argon blowing time ≥ 12min; Continuous casting slabs are poured at a low casting speed of 0.70m / min , the superheat of the molten steel in the tundish is controlled at 15±5°C; after the slab is cut, the heat preservation cover is used for heat preservation and slow cooling for > 48 hours; after the steel plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com