Ultrasonic flaw detection method for computer-assisted examination

A computer-aided, ultrasonic technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as poor quality and difficult identification, and achieve the effects of improving efficiency, ensuring the quality of flaw detection, intuitive and convenient and quick adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

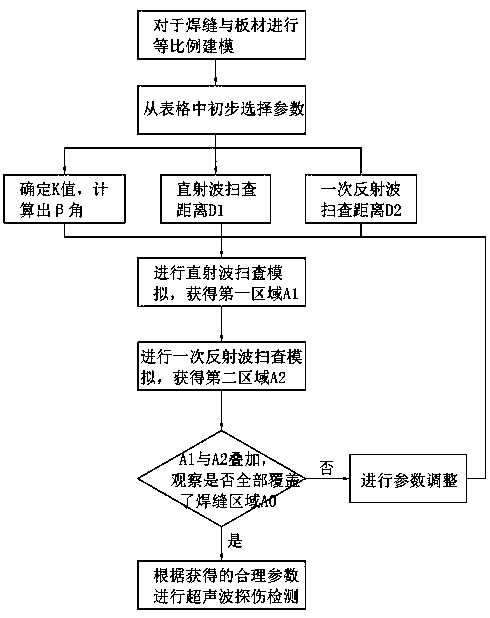

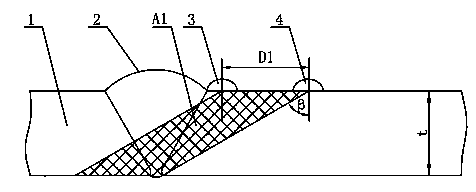

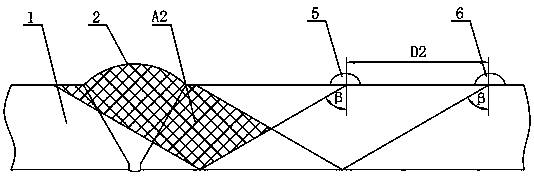

[0018] Such as figure 1 As shown, the ultrasonic flaw detection method of the computer aided checking of the present invention is divided into following steps:

[0019] The first step: computer modeling. Use drawing software on the computer, such as AutoCAD, according to the plate thickness t of the butt welded plate 1 to be detected, the type of welded joint 2 (including groove angle, blunt edge, butt gap, etc.), weld width, weld margin Advanced actual size, draw the cross-section figure of the welded joint in proportion to the actual object, and establish a two-dimensional model.

[0020] Step 2: Preliminary selection of scanning parameters from the table. Select the K value probe from "Table 18" of the "JB / T4730.3-2005" standard according to the plate thickness t; determine the direct wave according to the method of "5.1.4.1" of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com