A Push-Back Rotary Steerable Drilling System

A technology of rotary steerable drilling and rotating shaft, which is applied in the automatic control system of drilling, directional drilling, drilling equipment, etc., can solve the problems of complex structure of non-rotating outer cylinder, increased size of drilling system, complex downhole environment, etc. The effect of smoothness and reliability, downsizing, and simplification of internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

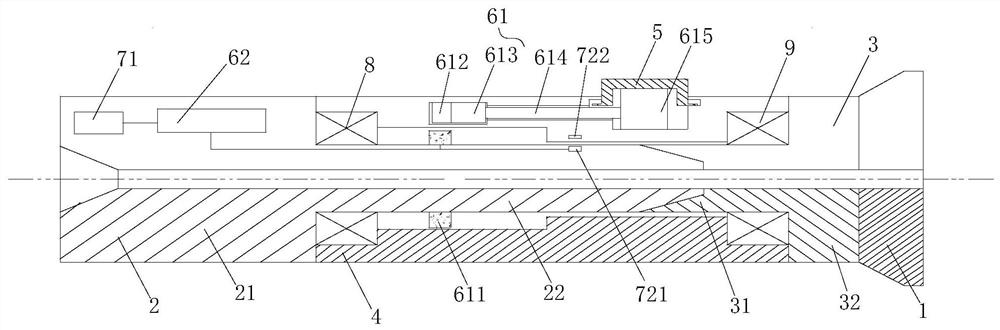

[0072] Embodiment 1: The first motion converting member 613 is a cam mechanism, the cam mechanism includes a rotating shaft and a cam sleeved on the rotating shaft, the rotating shaft is driven to rotate by the driven electromagnetic gear 612, and the connecting member One end of 614 is in contact with the cam surface of the cam. When the driven electromagnetic gear 612 drives the cam to rotate, the cam surface pushes the connecting member 614 to move linearly along the axis of the steering part 4 . Using the cam mechanism, only need to design the appropriate cam surface profile, the connecting piece can get any expected movement and stroke, and the structure is simple, compact and convenient to design.

Embodiment 2

[0073] Embodiment 2: the first motion conversion part 613 is a ball screw, the ball screw includes a screw and a nut sleeved on the screw, the screw is driven by the driven electromagnetic gear 612 to rotate, Therefore, the nut is driven to move, and the connecting member 614 is connected to the nut. The rotation of the driven electromagnetic gear 612 drives the screw to rotate, and the screw drives the nut to move linearly, so as to drive the connecting member 614 to move linearly along the axis of the steering part 4 . The ball screw is adopted, which has small friction loss and high transmission efficiency, and can realize high-speed feed and micro-feed.

[0074] At the same time, the structure of the second motion converting member 615 is not specifically limited in this embodiment, as long as the linear motion of the connecting member 614 can be converted into the movement of the pushing member 5 along the diameter of the turning portion 4 . Direct linear motion, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com