Rail flaw detection vehicle for subway

A technology for rail flaw detection vehicles and subways, which is applied to railway inspection vehicles, railway car body parts, railway vehicle shape measuring devices, etc. It can solve the problems of slow flaw detection speed, low efficiency, and low degree of automation, and achieve small maintenance workload, The effect of stable structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

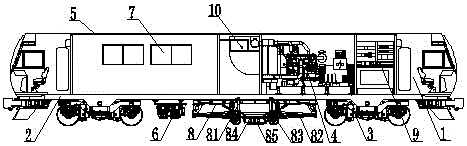

[0013] Such as figure 1 It is a structural schematic diagram of the present invention, a rail flaw detection car for subway, including a driver's cab 1, a frame 2, a bogie 3, a diesel engine unit 4, a carriage 5, an air source system 6, a flaw detection studio 7, a flaw detection device 8 and The electrical cabinet 9, driver's cab 1, diesel engine unit 4, flaw detection studio 7 and electrical cabinet 9 are installed in the compartment 5, the compartment 5 is connected to the top of the frame 2, the bogie 3, the air source system 6 and the flaw detection device 8 are connected At the bottom of the vehicle frame 2 , an AC / DC electric transmission device 10 is arranged in the compartment 5 , and a lifting rod 81 , a stabilizing rod 82 , a flaw detection wheel 83 , a flaw detection rod 84 and a flaw detector 85 are arranged on the flaw detection device 8 . The flaw detector 85 is a sliding shoe structure. The flaw detection wheel 83 is connected to the bottom of the flaw detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com