Image detection-based on-line detection and correction method of reflection angle of heliostat

A correction method and image detection technology, which are applied in the direction of measuring angles, measuring devices, measuring instruments, etc., can solve the problems of increasing system construction and operation and maintenance costs, high cost of optical measuring devices, and delaying the debugging time of CSP stations, and achieve improvement. Concentrating effect and operating efficiency, reducing the workload of debugging and maintenance, and direct and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

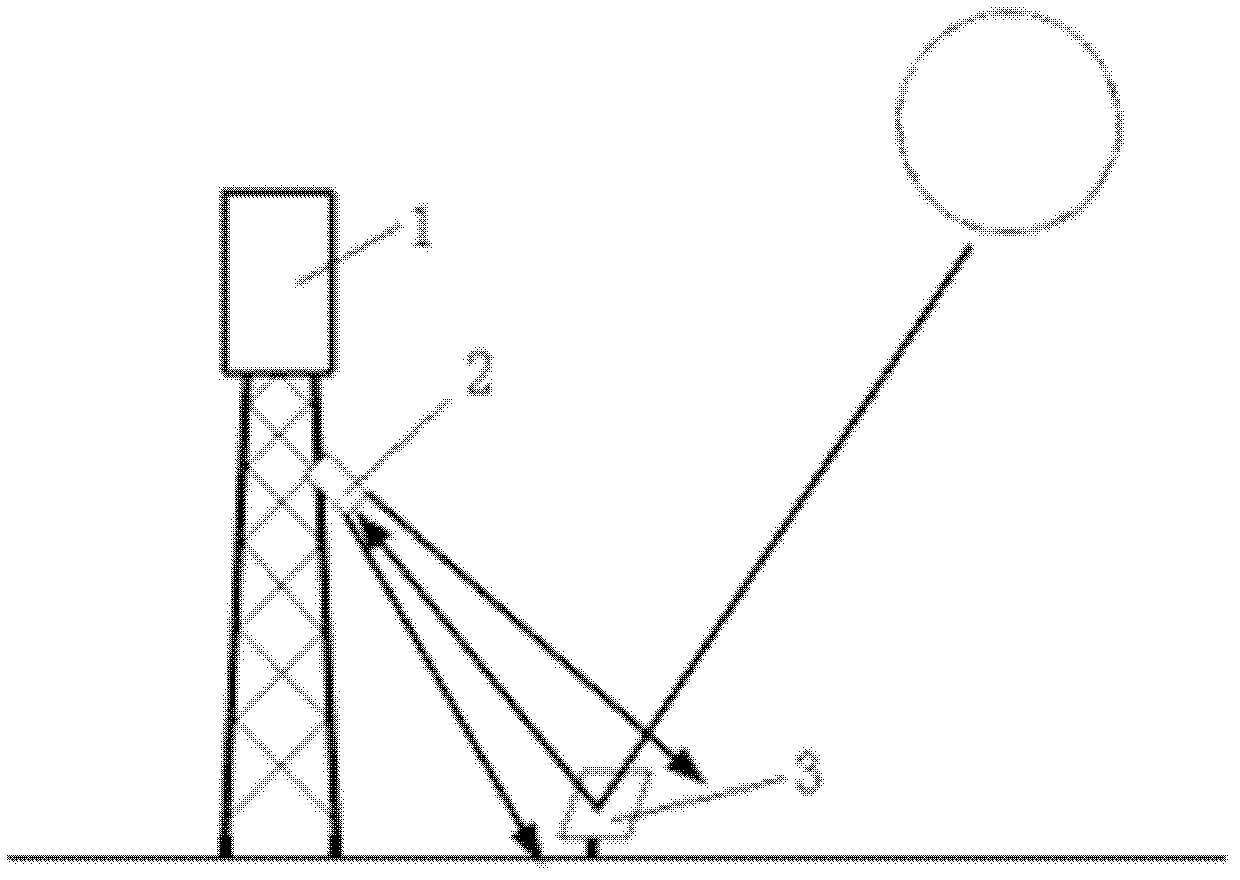

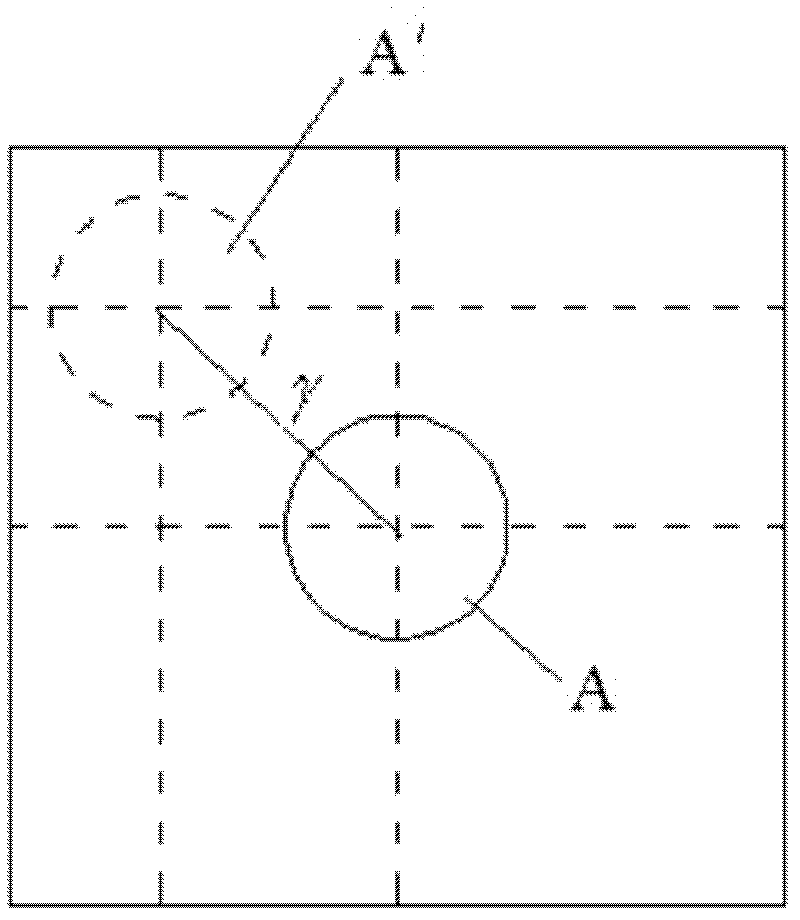

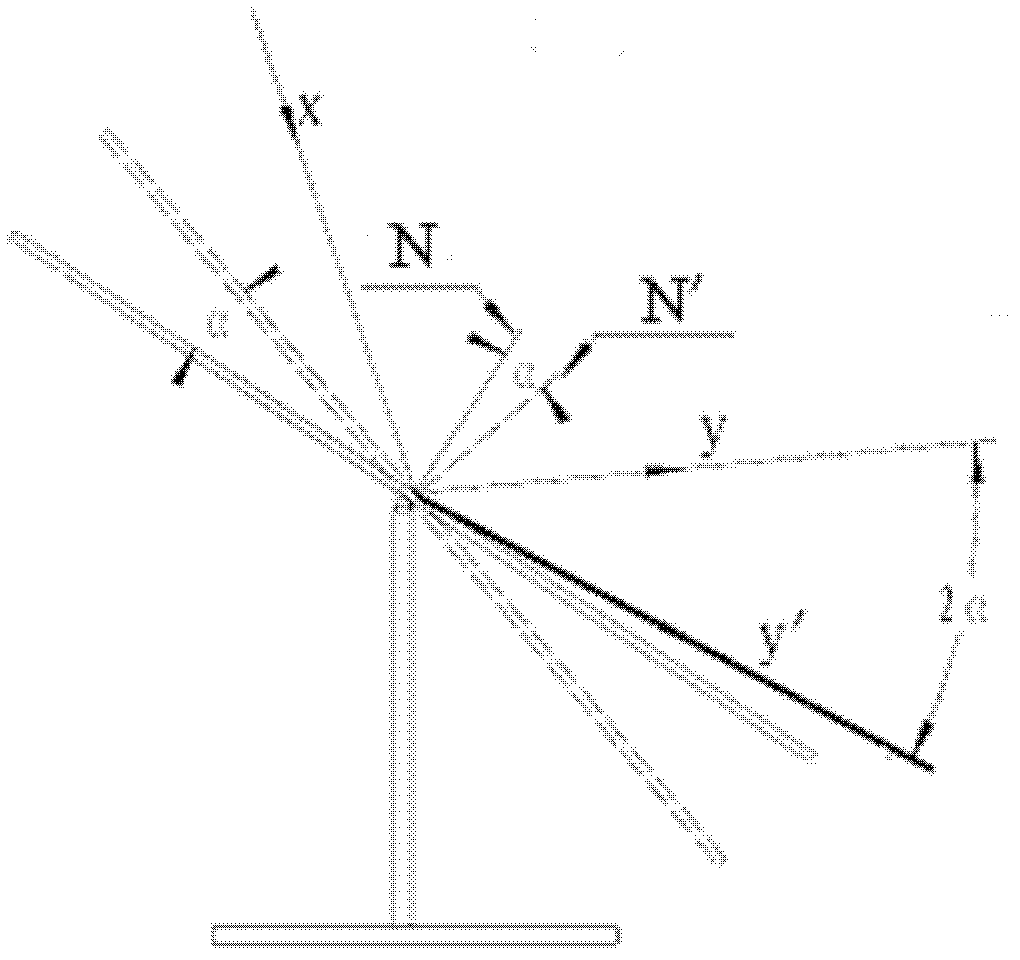

[0029] The present invention is a method for online detection and correction of the reflection angle of a heliostat based on image detection, and the specific steps are as follows: figure 1 As shown, first, the heliostat 3 to be corrected and the sun spot image in the heliostat 3 are captured by the camera 2, and the obtained image is processed to obtain the relative position of the sun spot image in the heliostat 3, and judge Whether the sun spot image is located at the center of the heliostat 3, if the sun spot image is located at the center of the heliostat, it is judged that the camera is aligned with the heliostat 3 to be corrected; otherwise, the sun spot image is aligned with the center of the heliostat The offset of the position, calculate the angle deviation between the sun reflected light and the reflection axis, and define it as the reflection angle deviation θ of the heliostat, control the normal direction of the heliostat to rotate θ / 2 in the direction of eliminati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com