Direct-drive composite type permanent magnet motor

A permanent magnet motor, composite technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of large installation space of motors and mechanical speed change devices, reducing system reliability and efficiency, and difficult to achieve high-precision control, etc. Achieve the effect of reducing maintenance workload and cost, compact structure and high power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

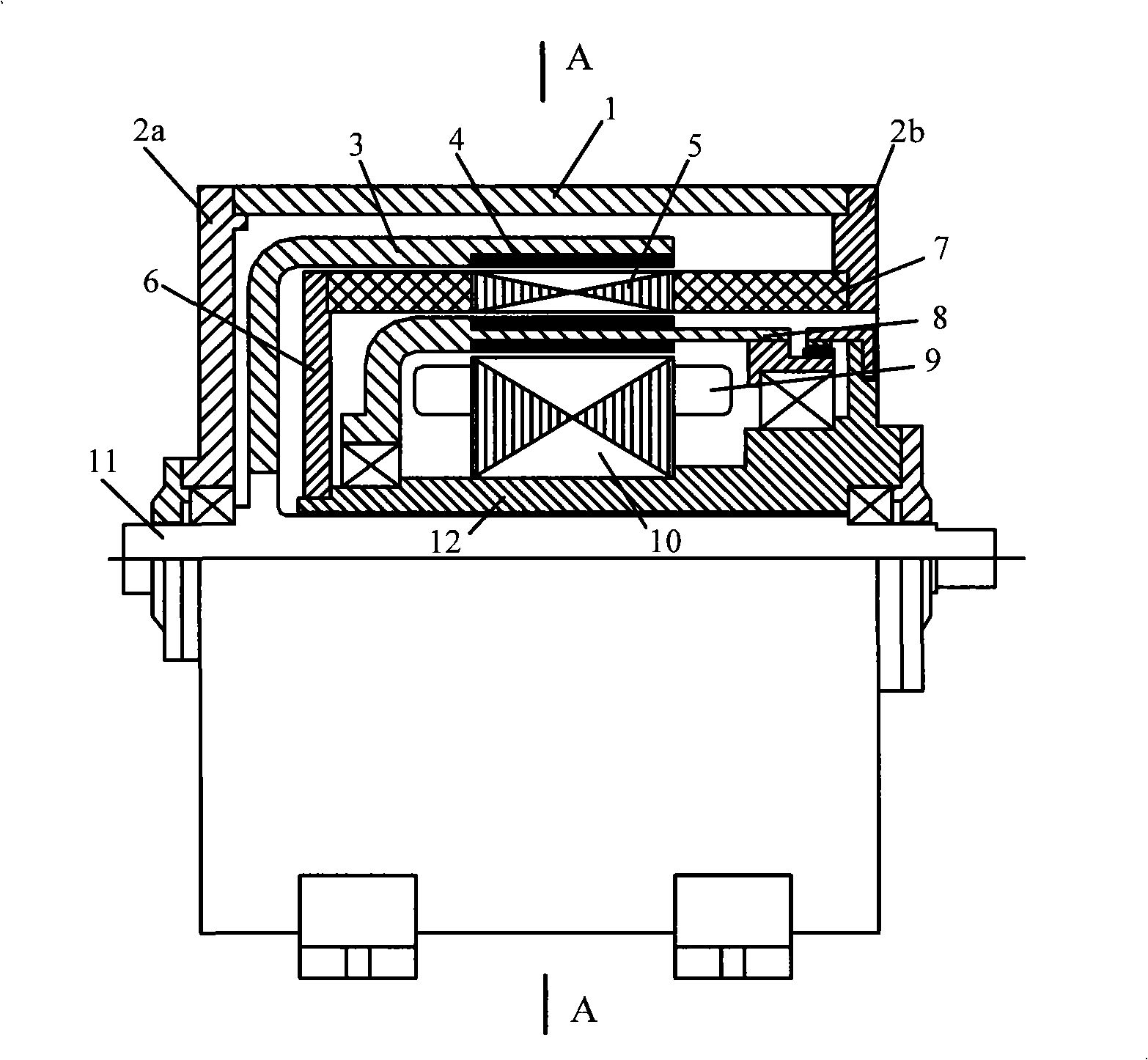

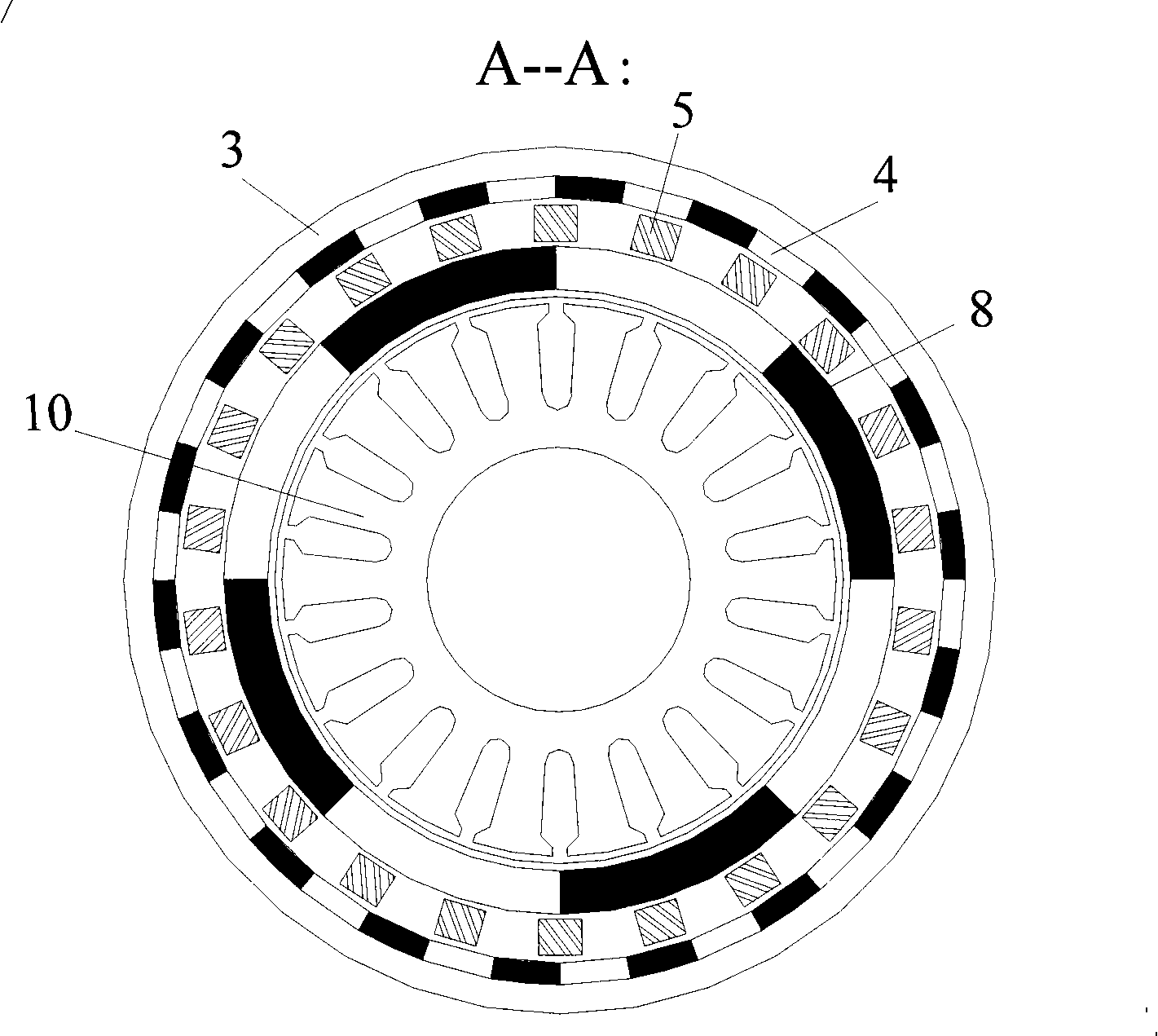

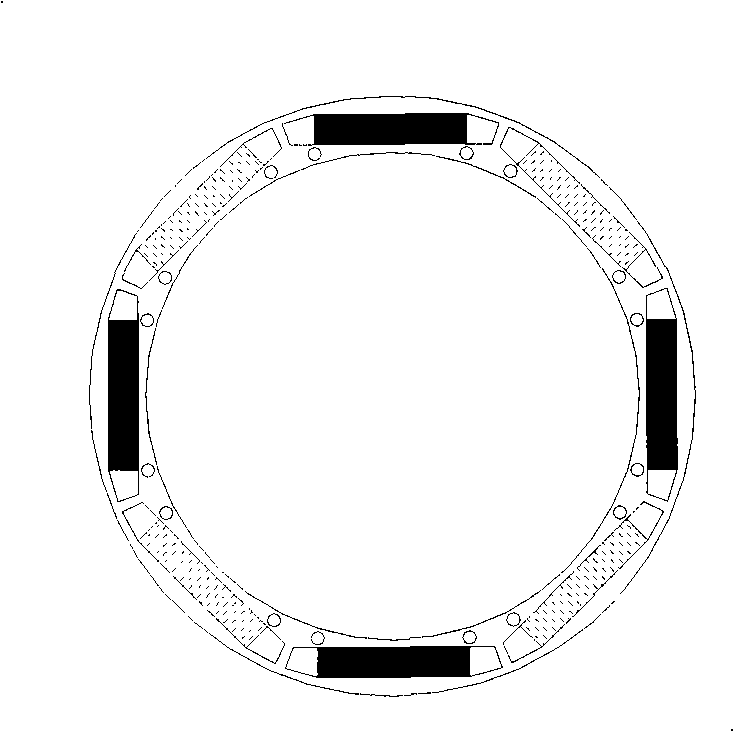

[0023] Embodiment one: see figure 1 and figure 2 , the direct drive compound permanent magnet motor includes a self-controlled permanent magnet motor and a concentric magnetic gear, the self-controlled permanent magnet motor and the concentric magnetic gear are combined into a double rotor structure, that is, the outer rotor 3 of the magnetic gear and the outer stator 7 and the inner rotor 8 and inner stator 12 of the permanent magnet motor adopt a sleeve-like structure to form a concentric structure.

[0024] The outer rotor 3 is a cup-shaped rotor, and its cup-shaped bottom is fixedly connected to the central rotating shaft 11; the outer stator 7 is a cylindrical body, one end of which is directly fixedly connected to an end cover 2b of the machine base 1, and the other end is fixed through a diameter The disc 6 is fixedly connected to the inner end of the inner stator 12; the inner rotor 8 is also a cup-shaped rotor, and its two ends are supported on the inner and outer e...

Embodiment 2

[0028] Embodiment two: see Figure 5 , direct drive This composite permanent magnet motor is made in axial series, which is equivalent to a self-controlled permanent magnet motor coaxially connected with a magnetic gear. The self-controlled permanent magnet motor is in the form of an inner rotor, that is, the inner rotor 8 in the above example is divided into two rotors: the self-controlled permanent magnet motor rotor 8a and the magnetic gear inner rotor 8b. The self-controlled permanent magnet motor rotor 8a has a large space. The form is more flexible, and it is easy to make a wide-speed adjustable permanent magnet motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com