Production of 40cr steel plate for 200mm thick straightening machine bearing seat by rolling instead of forging and its production process

A production process and straightening machine technology, applied in the field of 40Cr steel plate and production process, can solve the problems of high content of steel inclusions and unstable flaw detection quality, and achieve the effect of ensuring internal quality, reducing core defects and tight organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

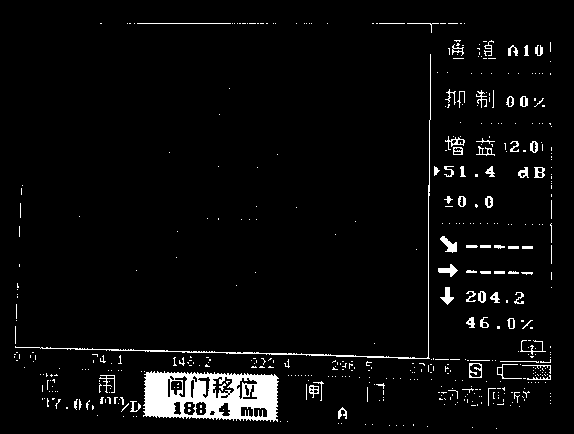

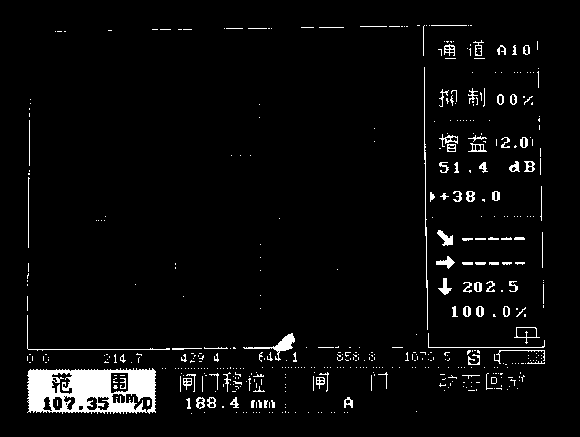

Image

Examples

Embodiment 1

[0035] The production process of 40Cr steel plate for 200mm thick straightening machine bearing housing by rolling instead of forging:

[0036] The content of trace elements in molten iron is as follows: Sn 0.02%, As 0.004%, Sb 0.02%, Zn 0.02%.

[0037] Molten iron pretreatment: through KR molten iron pretreatment, slag removal to ensure that the thickness of the slag layer is controlled below 10mm, after desulphurization, ensure that the S content is ≤0.010%; ≤0.100%, the total amount of molten iron and steel is controlled at an ingot weight of 8t;

[0038] Top-bottom combined blowing converter: The converter reasonably controls the position of the gun, adopts single slag operation to ensure that the tapping carbon is ≥ 0.12%, and the tapping P is ≤ 0.015%; If the slag stop cone fails to be placed, the furnace will be lifted in advance to avoid slag during the tapping process; the deoxidizer silicon aluminum calcium barium will be deoxidized at 1.3kg / t during the tapping pro...

Embodiment 2

[0047] The production process of producing 40Cr steel plates for 200mm thick straightening machine bearing seats by rolling instead of forging includes the following steps:

[0048] The content of trace elements in molten iron is as follows: Sn 0.05%, As 0.006%, Sb 0.04%, Zn 0.03%.

[0049] Molten iron pretreatment: through KR molten iron pretreatment, slag removal to ensure that the thickness of the slag layer is controlled below 10mm, after desulphurization, ensure that the S content is ≤0.010%; ≤0.100%, the total amount of molten iron and steel is controlled at an ingot weight of 8.5t;

[0050] Top-bottom combined blowing converter: The converter reasonably controls the position of the gun, adopts single slag operation to ensure that the tapping carbon is ≥ 0.12%, and the tapping P is ≤ 0.015%; If the slag stop cone fails to be placed, the furnace will be lifted in advance to avoid slag during the tapping process; the deoxidizer silicon aluminum calcium barium will be deox...

Embodiment 3

[0059] The production process of producing 40Cr steel plates for 200mm thick straightening machine bearing seats by rolling instead of forging includes the following steps:

[0060] The content of trace elements in molten iron is as follows: Sn 0.04%, As 0.01%, Sb 0.03%, Zn 0.02%.

[0061] Molten iron pretreatment: through KR molten iron pretreatment, slag removal to ensure that the thickness of the slag layer is controlled below 10mm, after desulphurization, ensure that the S content is ≤0.010%; ≤0.100%, the total amount of molten iron and steel is controlled at an ingot weight of 9.5t;

[0062] Top-bottom combined blowing converter: The converter reasonably controls the position of the gun, adopts single slag operation to ensure that the tapping carbon is ≥ 0.12%, and the tapping P is ≤ 0.015%; If the slag stop cone fails to be placed, the furnace will be lifted in advance to avoid slag during the tapping process; the deoxidizer silicon aluminum calcium barium will be deoxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com