Annunciator coating repairing technique

A process method and signal device technology, which is applied to coatings, devices for coating liquid on surfaces, and surface pretreatment, etc., can solve problems such as coating falling off, insulating coating cracks exceeding the standard, and large funds to save costs , qualified performance, and the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with embodiment.

[0033] A method for repairing a signal coating, the specific steps are as follows:

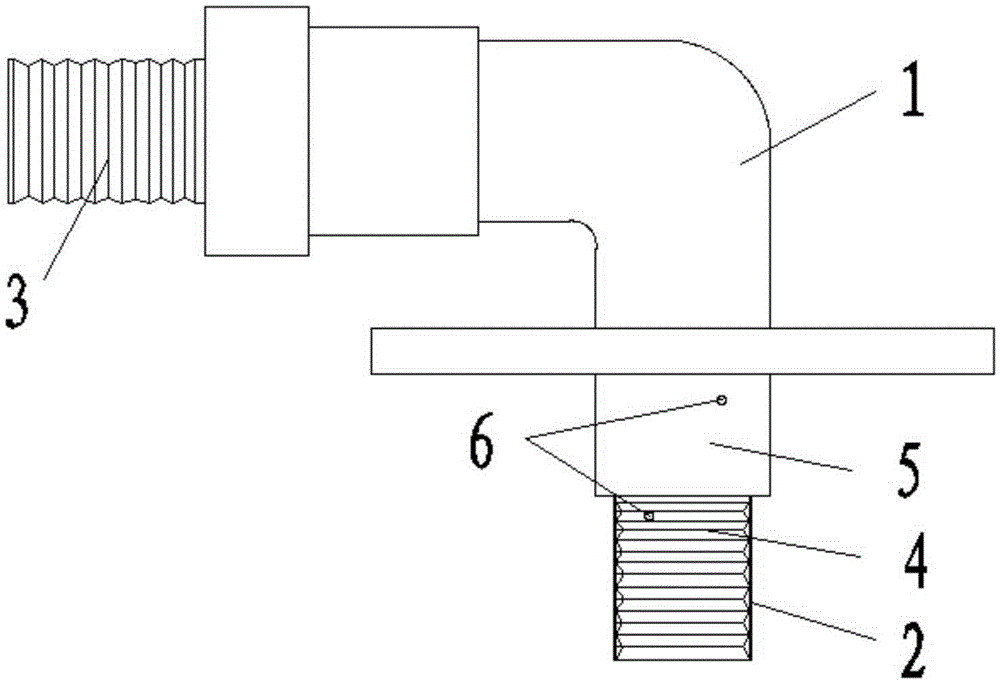

[0034] Step 1. Remove the residual coating on the signal device

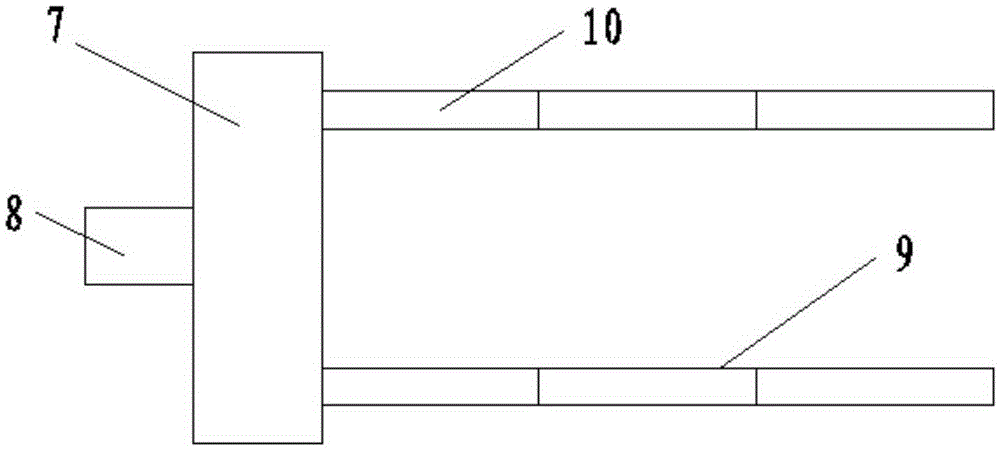

[0035] Such as figure 1 As mentioned above, the signal device 1 has an L-shaped structure, one end is coated with an insulating coating end 2, and the other end is a threaded connection end 3, the threaded surface 4 of the insulating coating end 2 is coated with an insulating coating, and the threaded connection The end is a smooth surface, and there is a small hole 6 with a diameter of 1 mm on the threaded surface 4 to be coated with an insulating coating and the smooth journal 5 connected to the thread, leading to the inside of the signal device 1 housing ;The residual coating attached to the surface of the thread is removed by mechanical turning method to ensure the complete removal of the residual coating and high effic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com